Knife manufacturing method

A production method and technology of knives, applied in knives, household appliances, kitchen utensils, etc., can solve the problems of easy dullness and laborious cutting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

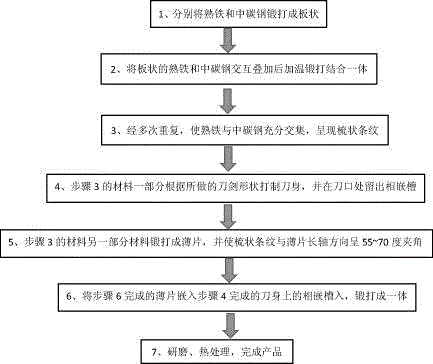

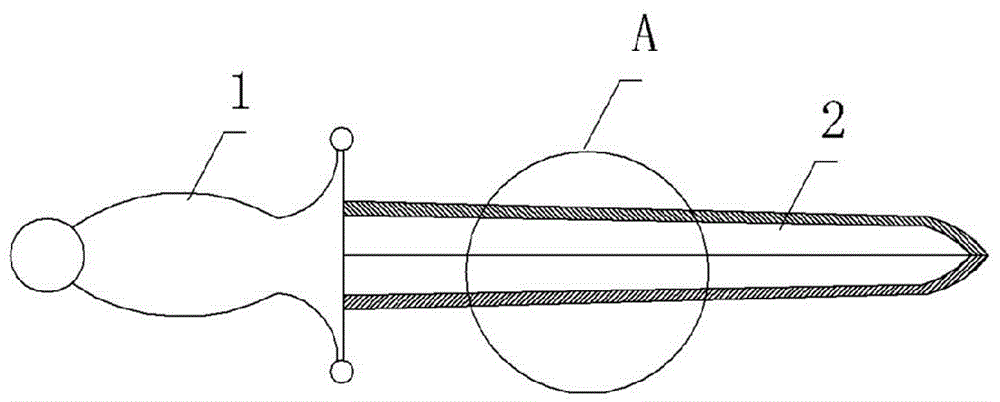

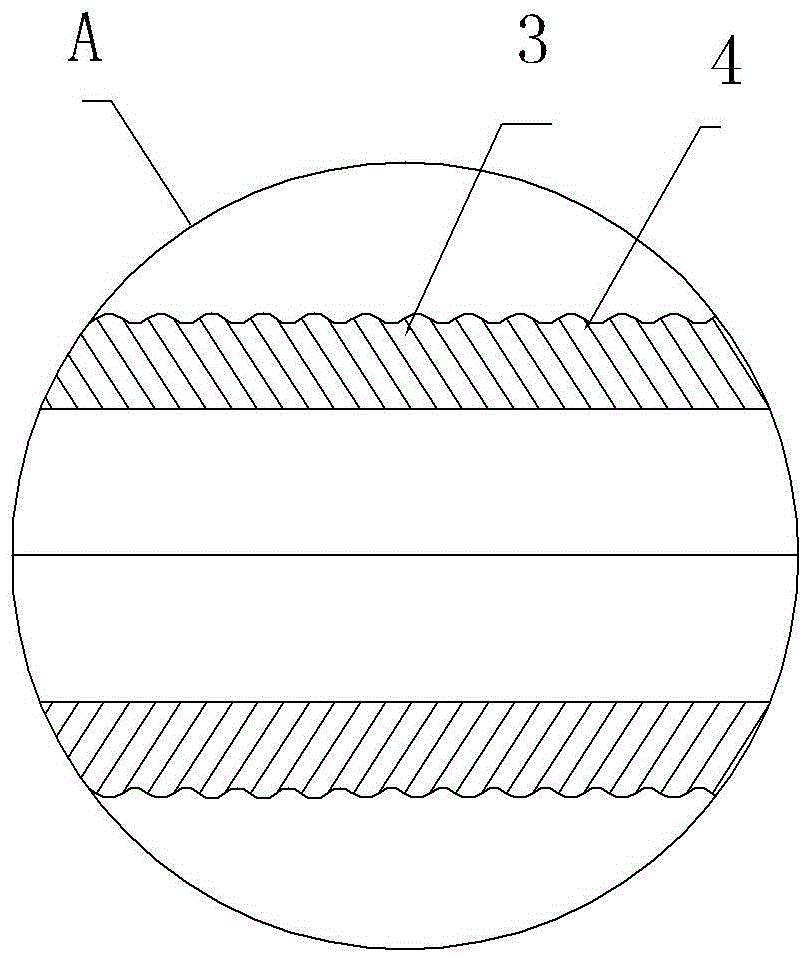

[0012] Embodiment 1: Referring to Figure 1, the method for making a knife proposed by the present invention is used in the production of traditional swords. and wrought iron (about 0.2% carbon content) materials, place the hard steel inside the furnace, heat it at 800-1000 ℃ for about five to seven minutes to soften the hard steel, and use an air hammer to hammer and forge the hard steel into flat. In addition, the wrought iron is placed inside the furnace, heated at 800 - 1000 ℃ for about five to seven minutes to soften the wrought iron, and the wrought iron is hammered and forged into a plate shape with an air hammer.

[0013] The hard steel and wrought iron are heated to about 1200 ℃ to achieve a fused state, and the hard steel and wrought iron are combined into a 1:1 ratio by hammering with an air hammer, and the combined hard steel and wrought iron are integrated. The iron is heated, folded (folded in half), twisted, and forged to form a multi-layered fold; this step can...

Embodiment 2

[0016] Embodiment 2: the manufacturing method of a kind of cutting tool proposed by the present invention, when used for the production of traditional kitchen knives, the steps are as follows: first prepare hard steel (carbon content 0.5% ~ 0.8% up and down) and wrought iron (carbon content Place the hard steel inside the furnace, heat it at 800-1000 ℃ for about five to seven minutes to soften the hard steel, and use an air hammer to hammer and forge the hard steel into a flat shape. In addition, the wrought iron is placed inside the furnace, heated at 800 - 1000 ℃ for about five to seven minutes to soften the wrought iron, and the wrought iron is hammered and forged into a plate shape with an air hammer.

[0017] The hard steel and wrought iron are heated to about 1280 ℃ to achieve a fused state, and the hard steel and wrought iron are combined into a 1:1 ratio by hammering with an air hammer, and the combined hard steel and wrought iron are integrated. The iron is heated, fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com