Rudder post for rudders for water vehicles

A rudder stock, marine technology, applied in the direction of steering with rudder, steering gear, boat construction, etc., can solve problems such as difficulty and heavy weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

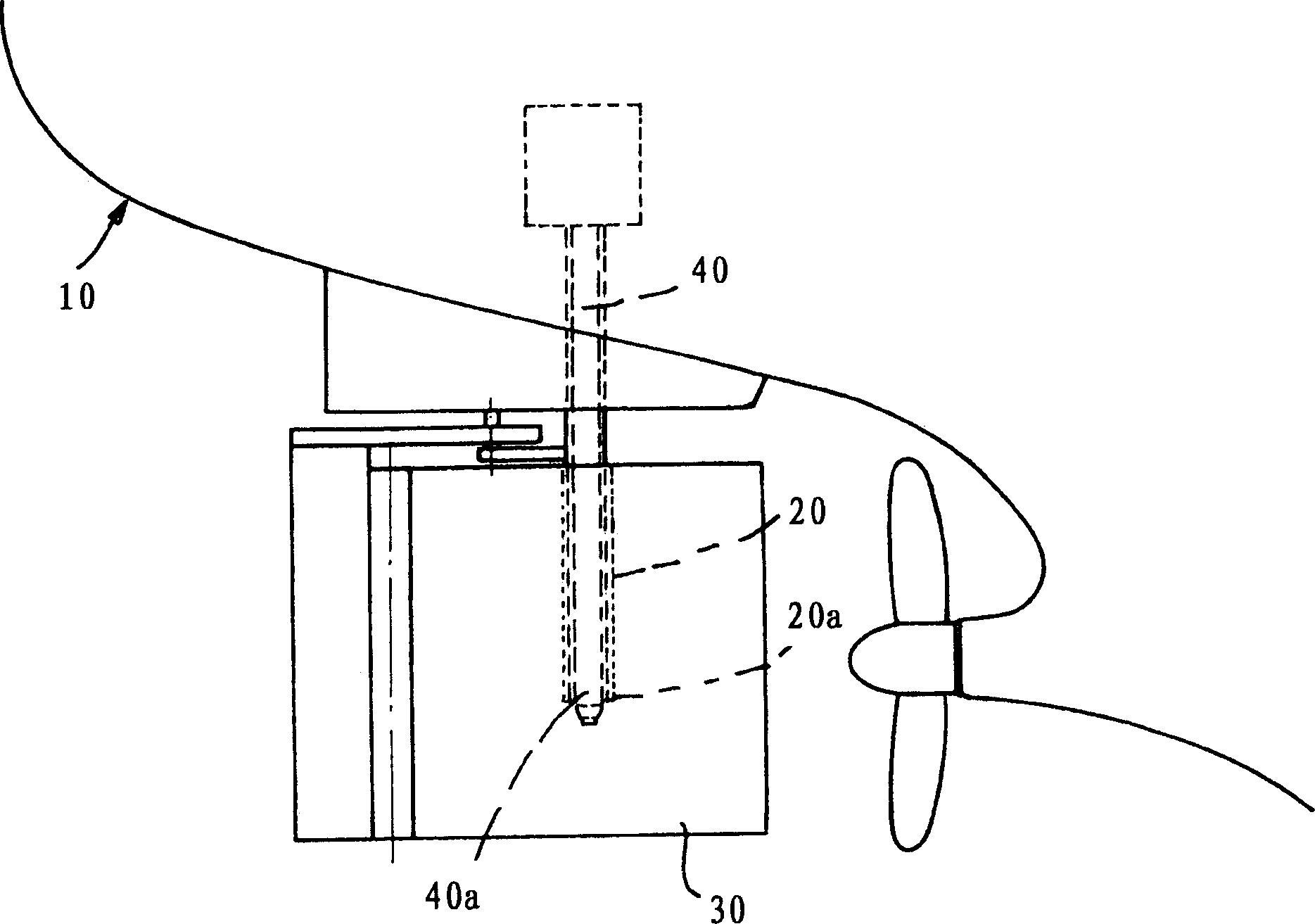

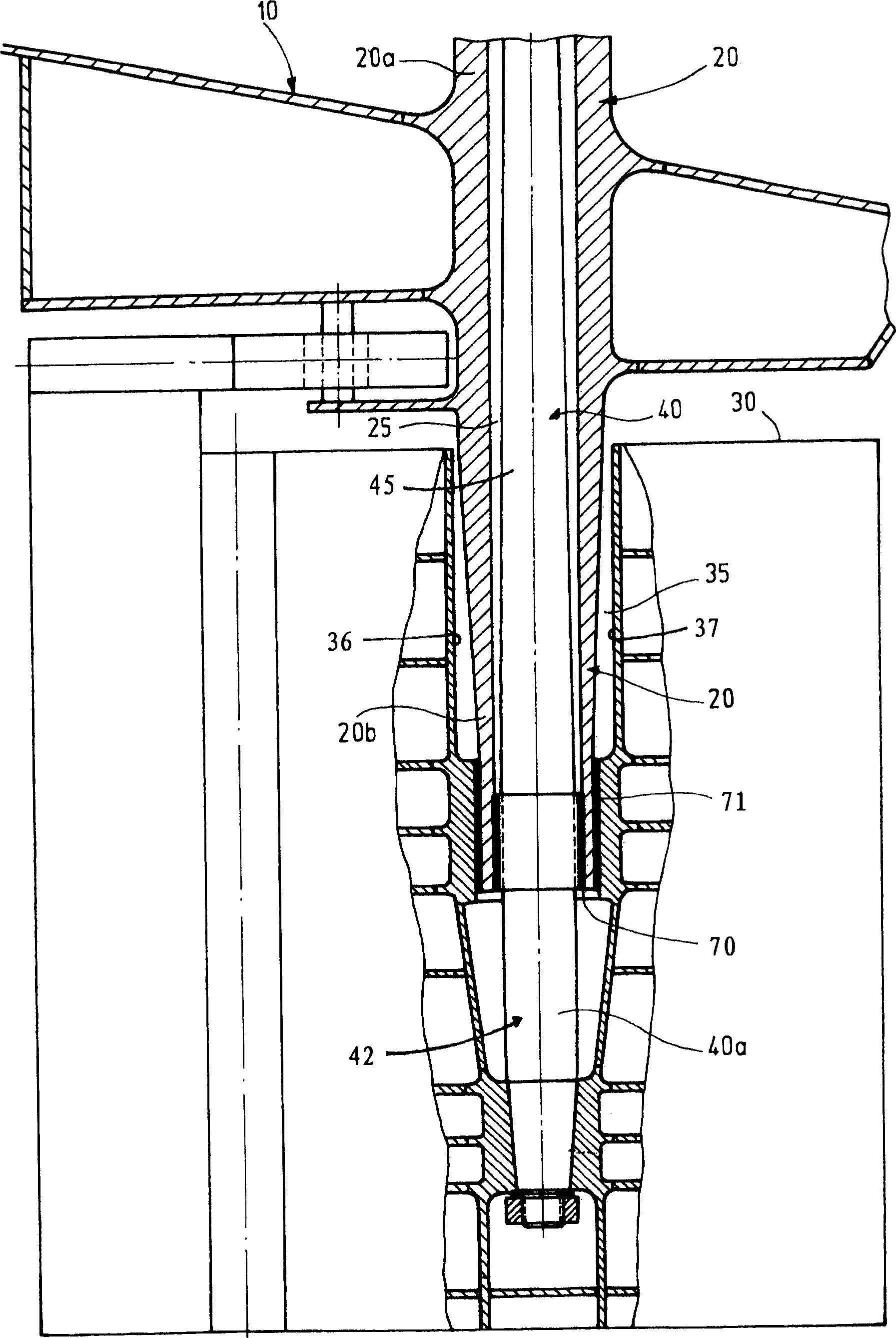

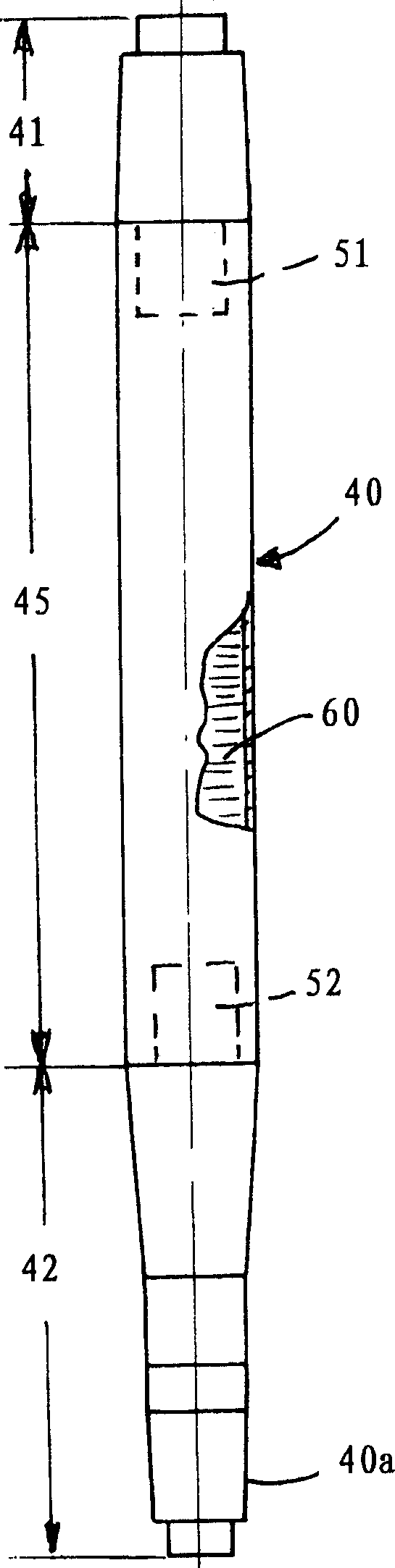

[0015] exist figure 1 and 2 In the illustrated embodiment, reference numeral 10 designates the hull, 20 designates the rudder bearing in the rudder barrel with its ends 20a, 20b, 30 designates the rudder blade and 40 designates the rudder stock.

[0016] The inner rudder bearing 20 of the rudder tube, designed as a cantilever beam, is fixedly connected via its upper end 20 a to the hull 20 and has an inner bore 25 which accommodates a rudder stock 40 . The inner rudder bearing 20 of the rudder barrel penetrates into the rudder blade 30, and its rudder blade 30 is fixedly connected with the free lower end portion 20b of the rudder stock 40 passing through the inner hole 25 of the inner rudder bearing 20 of the rudder barrel. A preferably cylindrical lead-in portion 35 formed in the rudder blade 30 is defined by lateral outer plates 36, 37 for accommodating the free end 20b ( figure 2 ).

[0017] In order to support the rudder stock 40, the rudder bearing 20 in the rudder ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com