Method for manufacturing handwork flower folding knife

A manufacturing method and flower knife technology, applied in the field of decorative knives, can solve the problems of inability to reproduce, lost craftsmanship, etc., and achieve the effects of easy mastery, simple craftsmanship and less capital

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

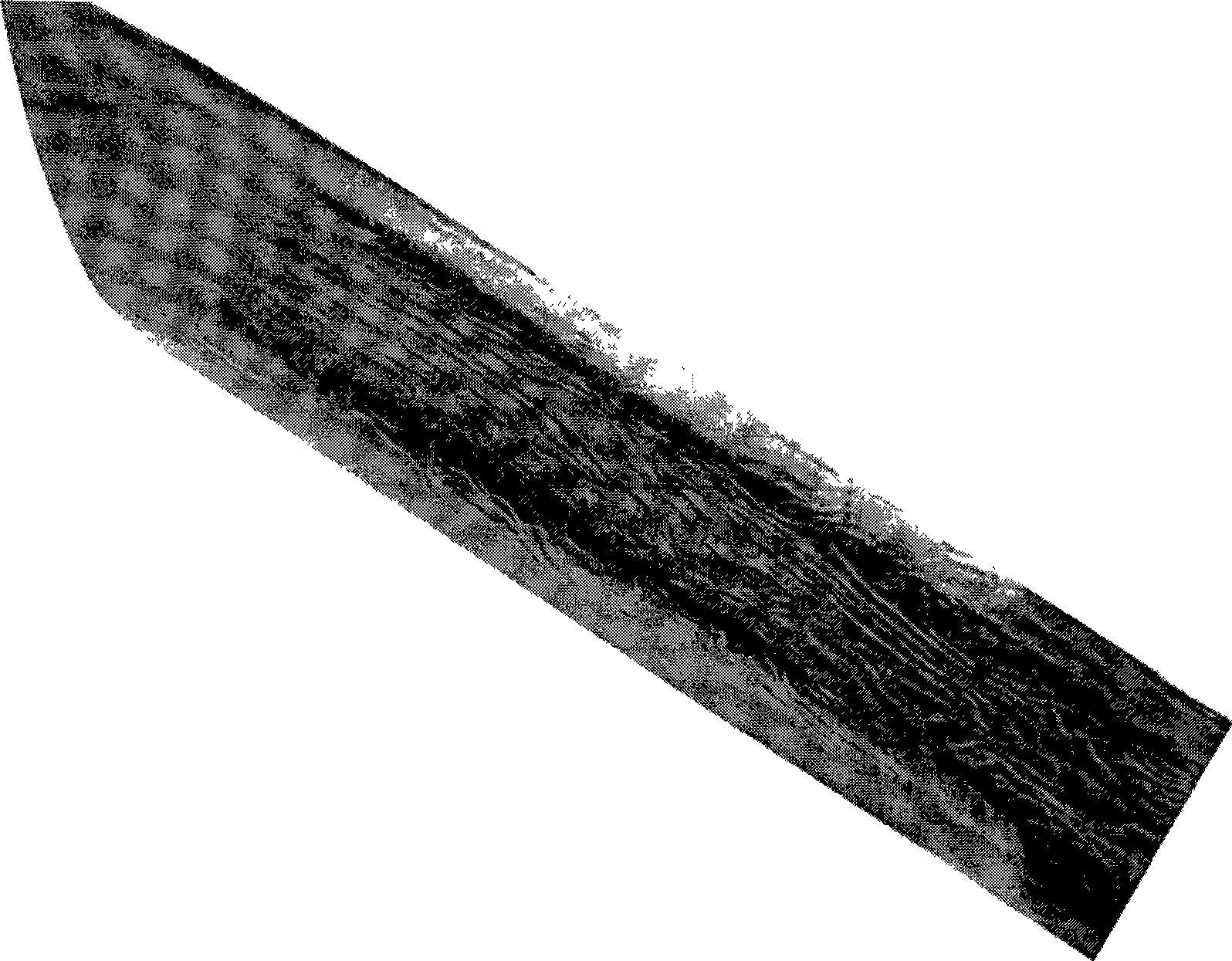

Image

Examples

Embodiment 1

[0057] 1. Iron and steel laminated with fire

[0058] (5) Hammer steel and wrought iron into thin slices with a thickness of 1mm,

[0059] (6) Lay multiple steel sheets and wrought iron sheets alternately to form a processed part. The first and last two layers are of the same material, up to 7 layers in total.

[0060] (7) The processed parts are put into the furnace for smelting, the temperature of smelting is 1400°C, and it is maintained for five minutes.

[0061] (8) Take out the workpiece from the furnace, beat it until the thickness of the workpiece is halved,

[0062] 2. Fold in half

[0063] (5) Send the workpiece processed in the previous step into the furnace for fire refining,

[0064] (6) Take the workpiece out of the furnace, fold the workpiece in half,

[0065] (7) Send the folded workpiece into the furnace for fire refining,

[0066] (8) Take out the heat-smelted workpiece from the furnace, beat until the thickness of the workpiece is halved,

[0067] 3. tw...

Embodiment 2

[0100] 1. Iron and steel laminated with fire

[0101] (9) Hammer the steel and wrought iron into thin slices with a thickness of 4mm,

[0102] (10) Lay multiple steel sheets and wrought iron sheets alternately to form a processed part. The first and last two layers are of the same material, up to 15 layers in total.

[0103] (11) The workpiece is put into the furnace for smelting, and the temperature of smelting is 1500°C, and it is maintained for five minutes.

[0104] (12) Take out the workpiece from the furnace, beat it until the thickness of the workpiece is halved,

[0105] 2. Fold in half

[0106] (9) Send the processed parts of the previous step into the furnace for fire refining,

[0107] (10) Take the workpiece out of the furnace, fold the workpiece in half,

[0108] (11) Send the folded workpiece into the furnace for fire refining,

[0109] (12) Take out the heat-smelted processed piece from the furnace, beat it until the thickness of the processed piece is halv...

Embodiment 3

[0142] 1. Iron and steel laminated with fire

[0143] (13) Steel and wrought iron are hammered into thin slices with a thickness of 2mm.

[0144] (14) Lay multiple steel sheets and wrought iron sheets alternately to form a processed part. The first and last two layers are of the same material, up to 13 layers in total.

[0145] (15) The processed parts are put into the furnace for smelting, the temperature of smelting is 1450°C, and it is maintained for five minutes.

[0146] (16) Take out the workpiece from the furnace, beat it until the thickness of the workpiece is halved,

[0147] 2. Fold in half

[0148] (13) Send the processed parts of the previous step into the furnace for fire refining,

[0149] (14) Take the workpiece out of the furnace, fold the workpiece in half,

[0150] (15) Send the folded workpiece into the furnace for fire refining,

[0151] (16) Take out the processed piece of fire smelting from the furnace, beat, beat until the thickness of the processed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com