Large-tonnage jack tension construction technology for non-bonded prestressed silo

A construction technology and jack technology, which is applied in the field of unbonded prestressed silo large-tonnage jack tensioning construction technology, can solve problems such as low work efficiency and long construction period, improve construction quality, reduce construction cost, and avoid reinforcement rust effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

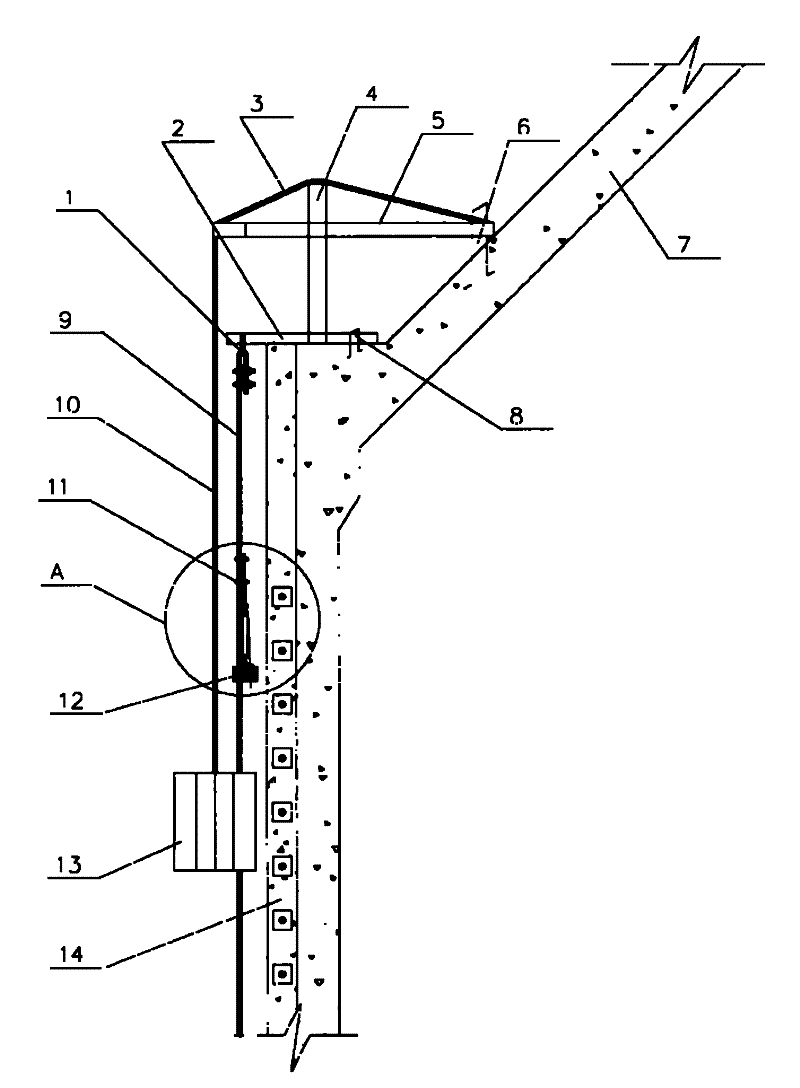

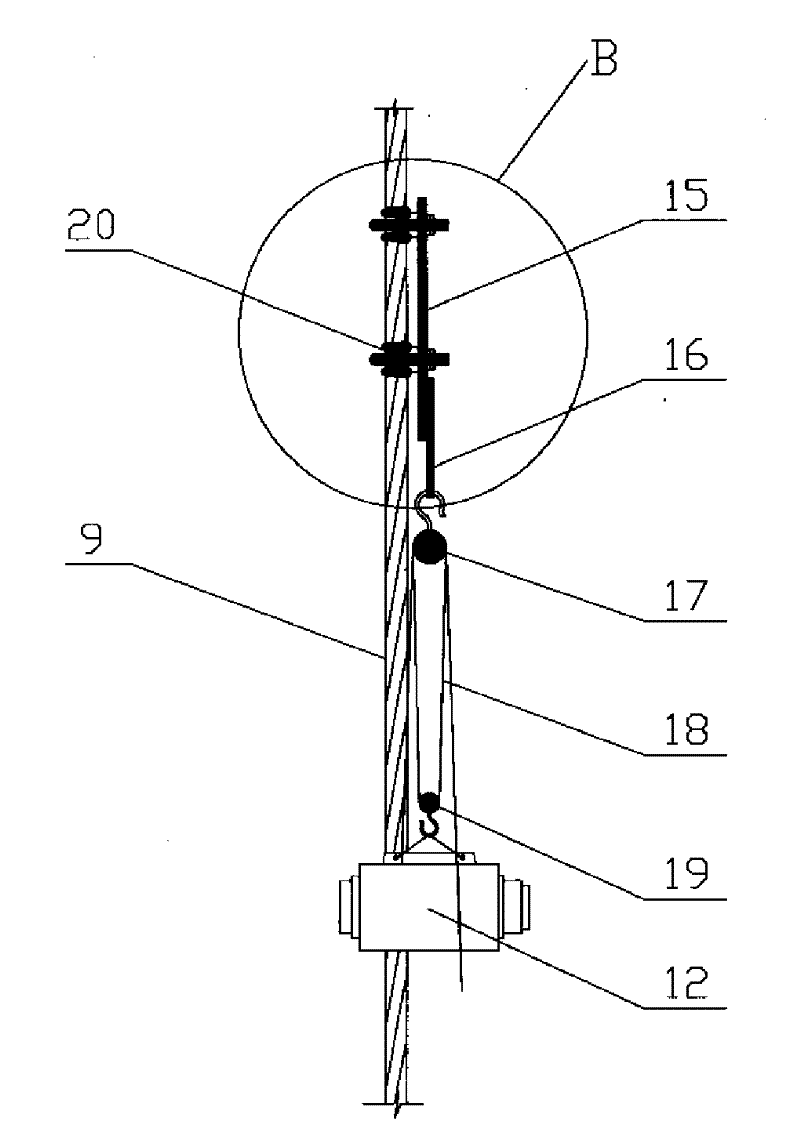

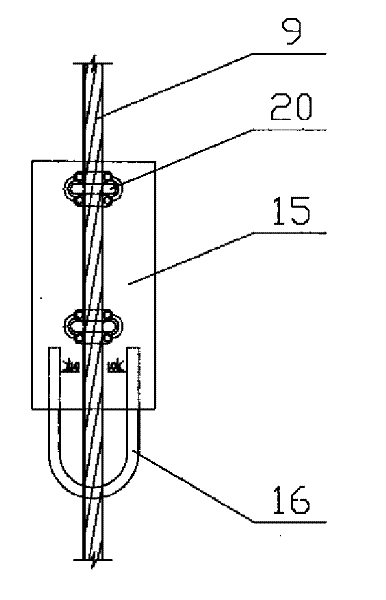

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0022] The construction of the silo generally starts with the binding of ordinary steel bars for the main body of the silo, the laying of unbonded prestressed tendons, and pouring of concrete. After stretching, the treatment of the anchor end is carried out. Except that the structure of the anchor plate, the hanging position of the hanging basket, and the hanging method of the jack are different from the prior art, the tensioning construction technology of the large-tonnage jack for the unbonded prestressed silo of the present invention has other construction technologies, such as the main body of the silo. The binding of ordinary steel bars, the laying of unbonded prestressed tendons, the installation of pouring concrete, anchors and anchor pads, and the treatment of anchor ends are the same as those of the existing technology, strictly in a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com