Patents

Literature

104 results about "Adhesive wear" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

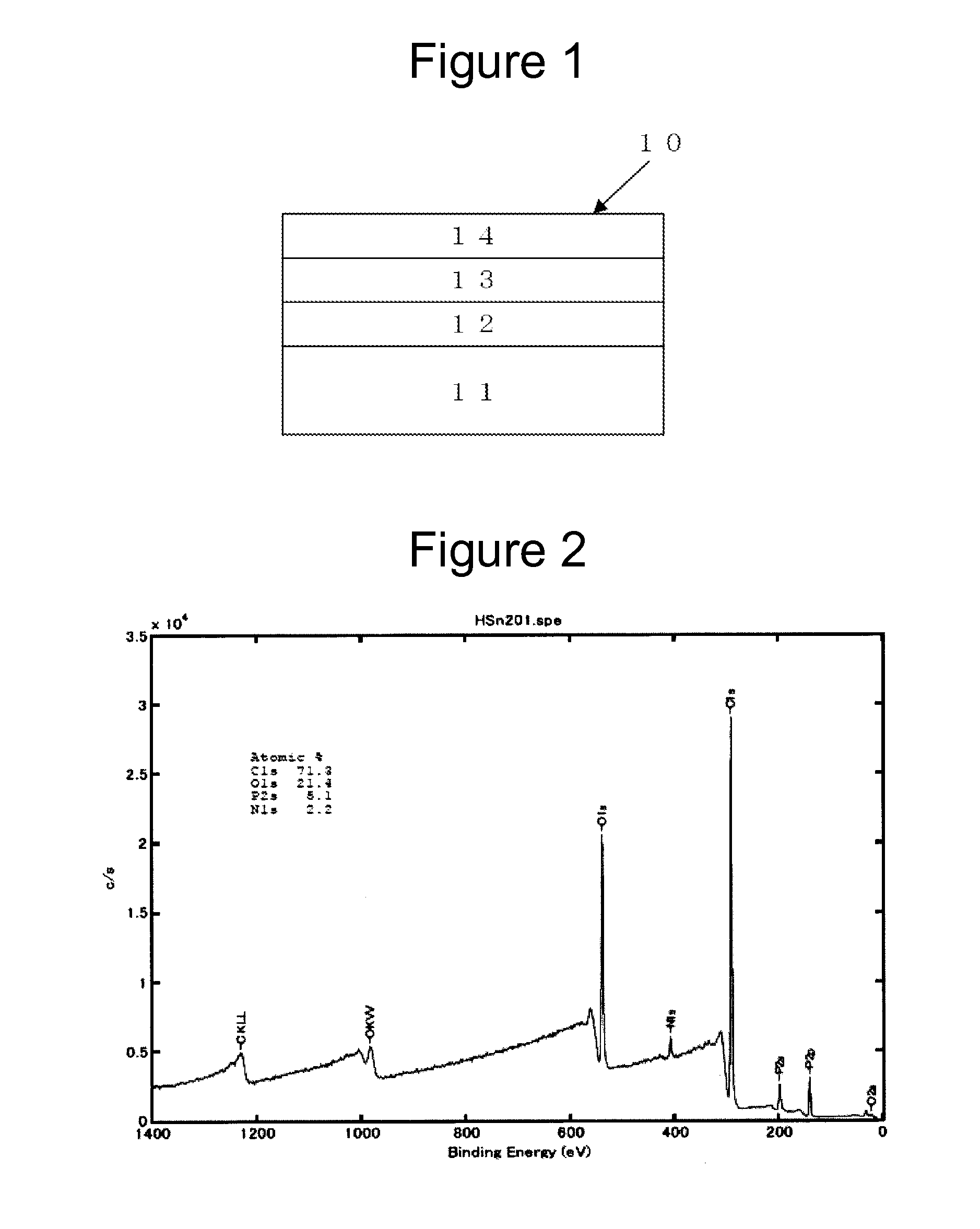

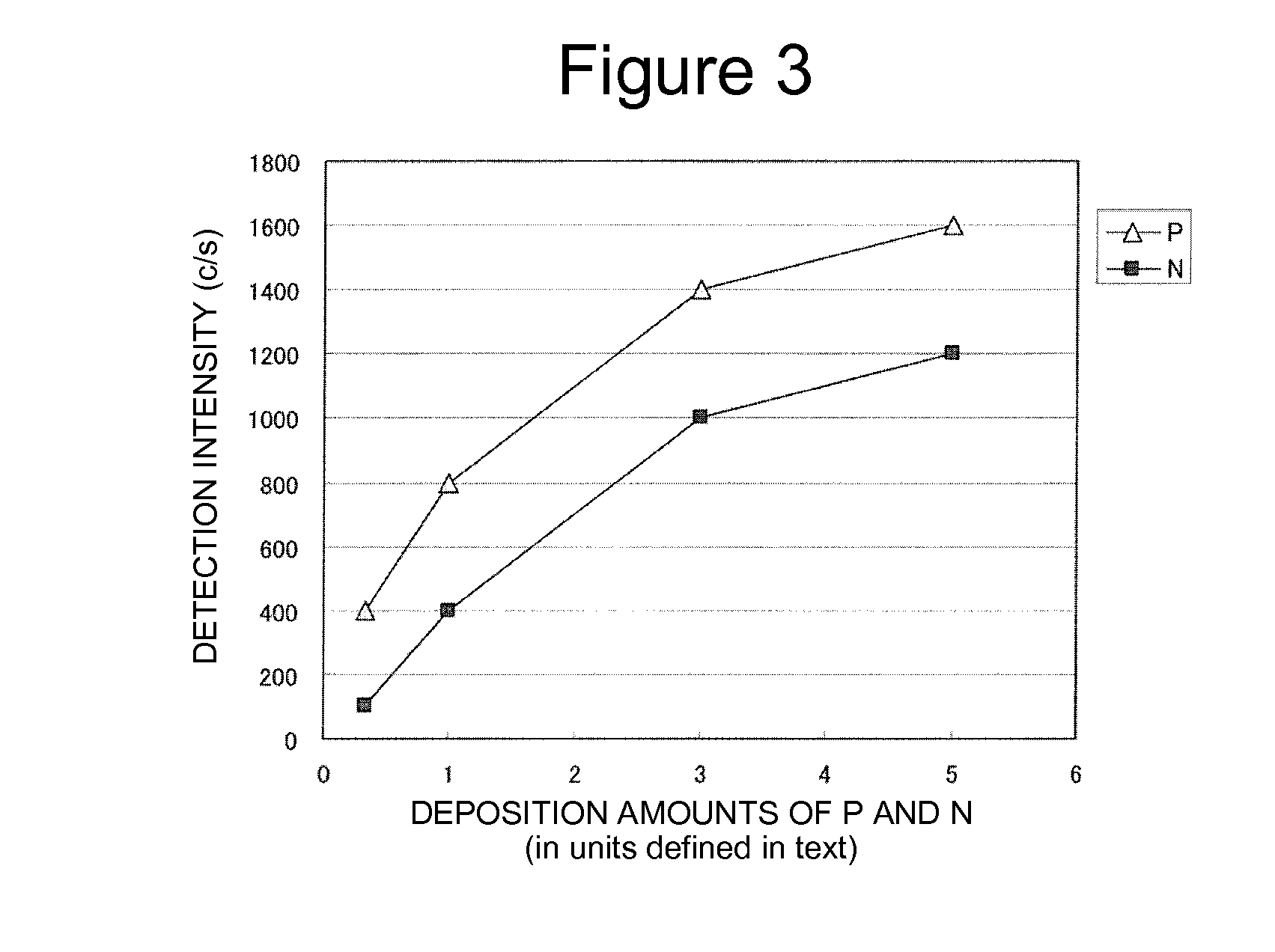

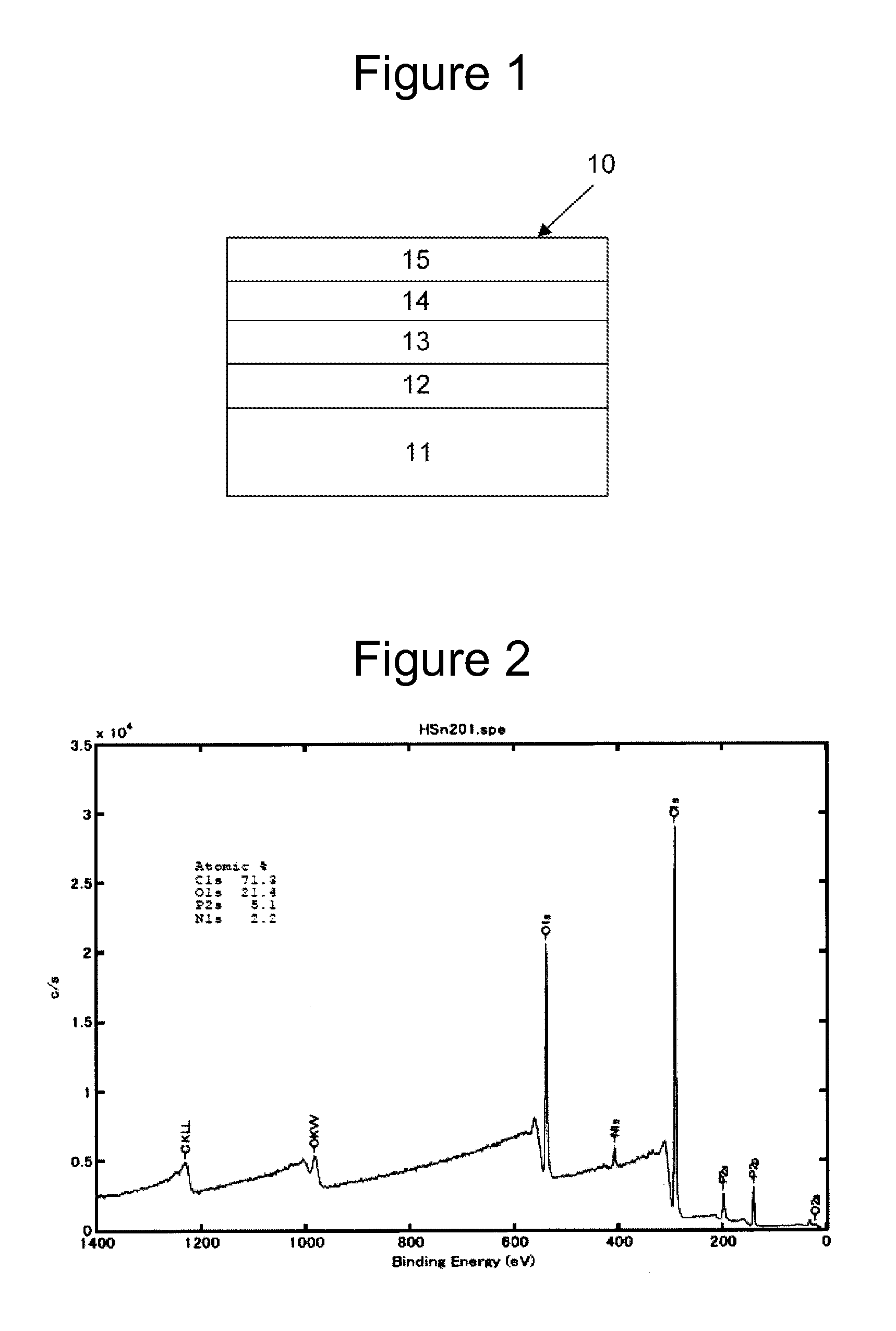

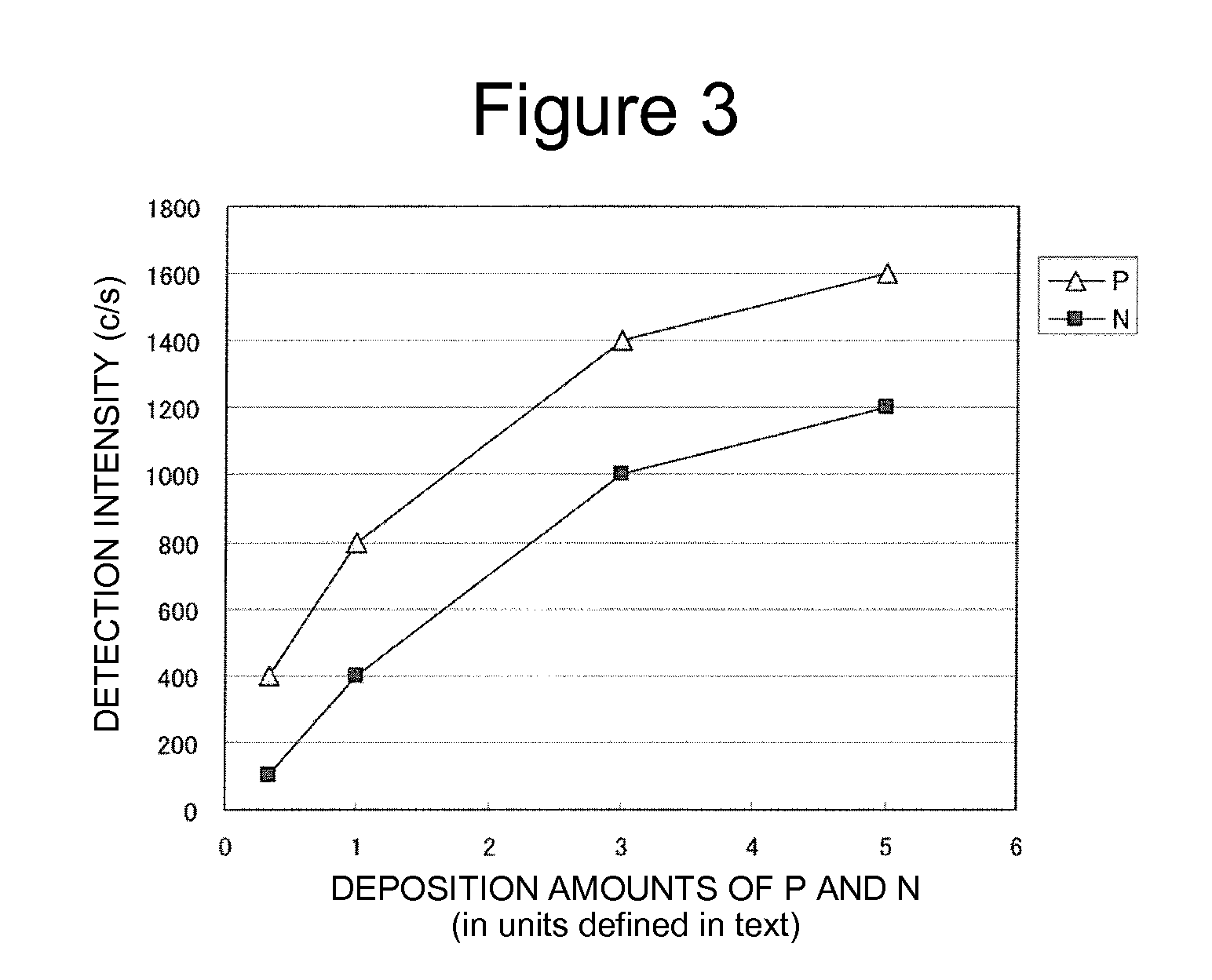

Nitrogen alloyed stainless steel and process

InactiveUS20120082586A1Improved kineticsIncrease resistanceSolid state diffusion coatingMetal layered productsMartensitic stainless steelSS - Stainless steel

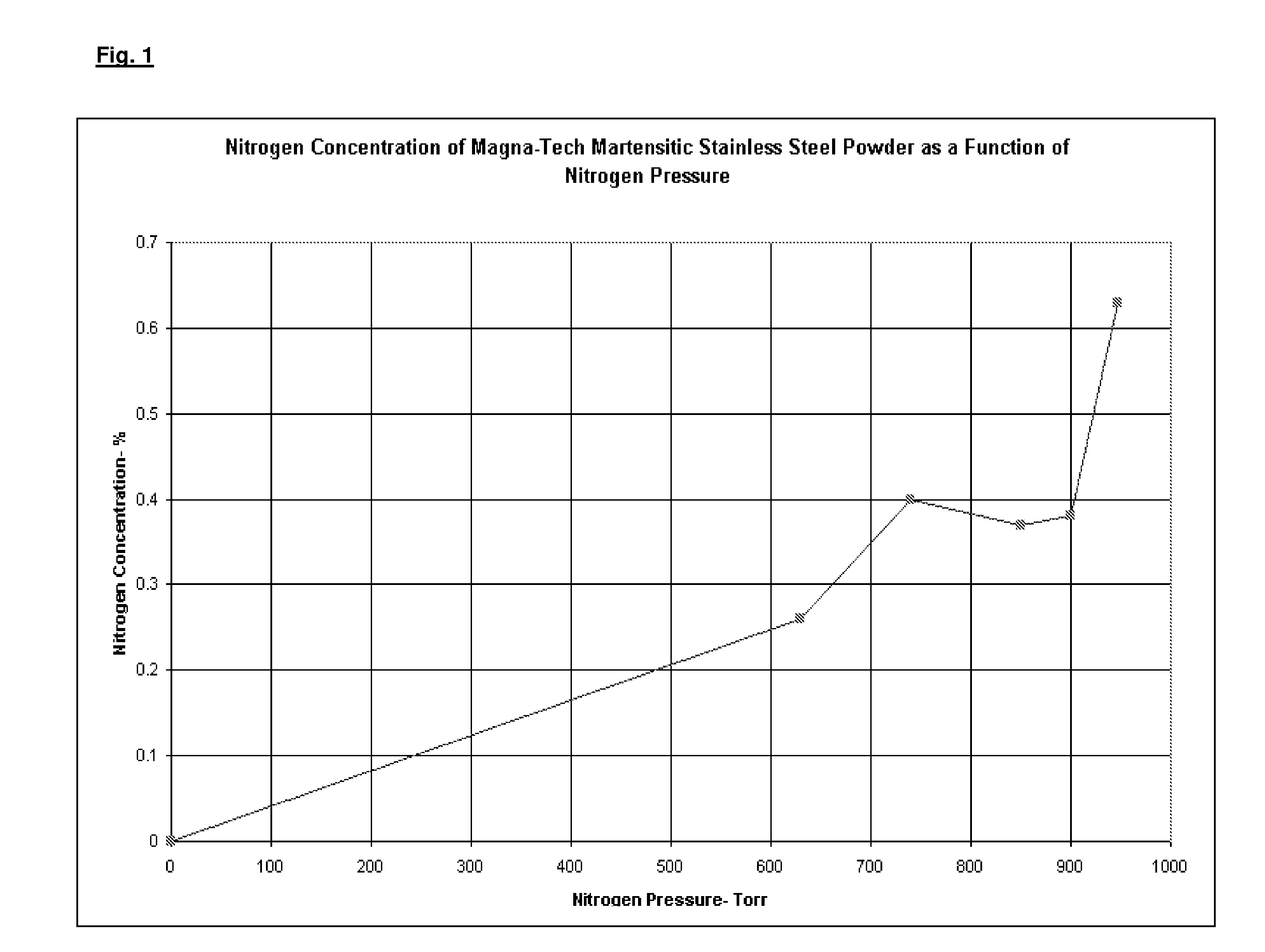

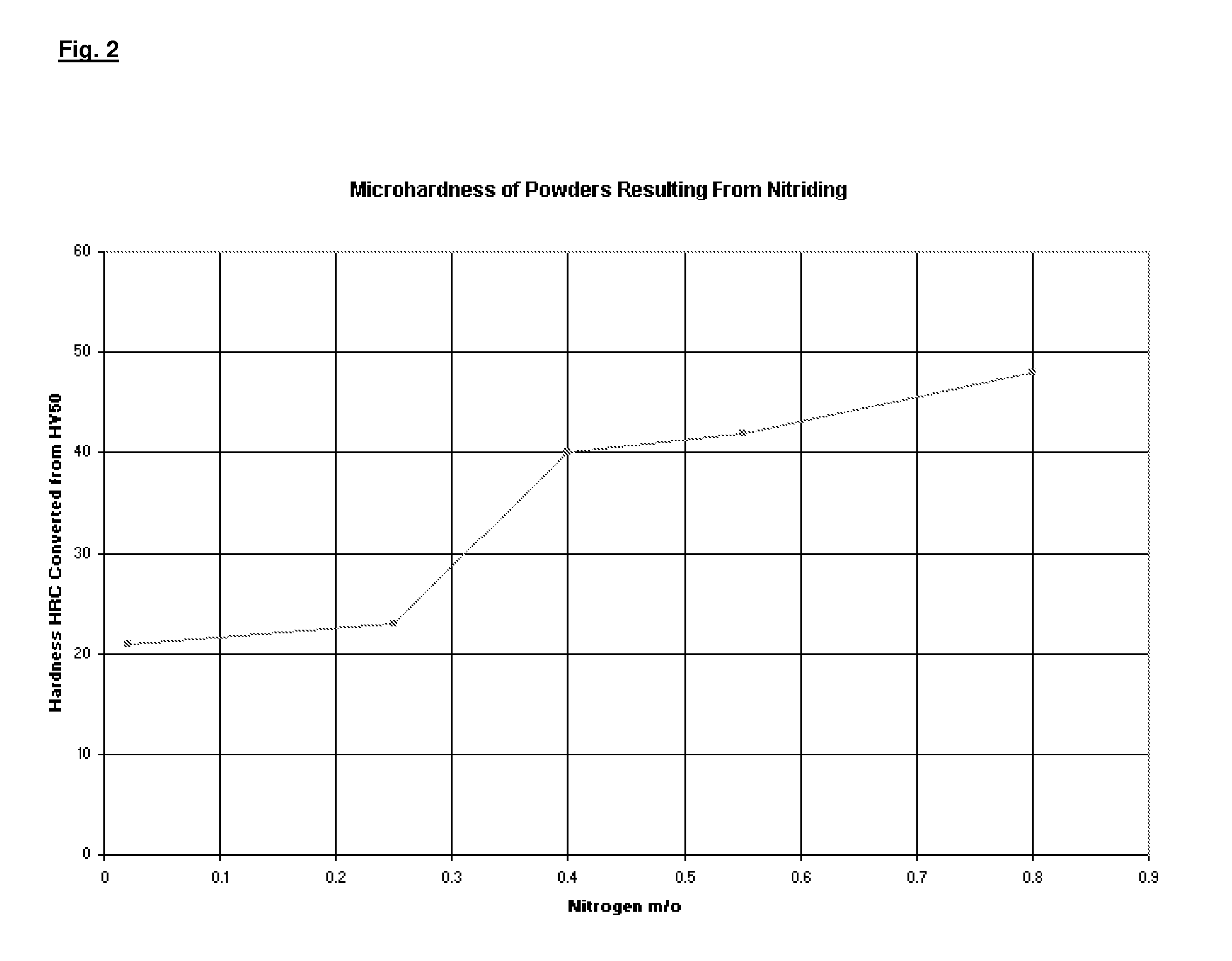

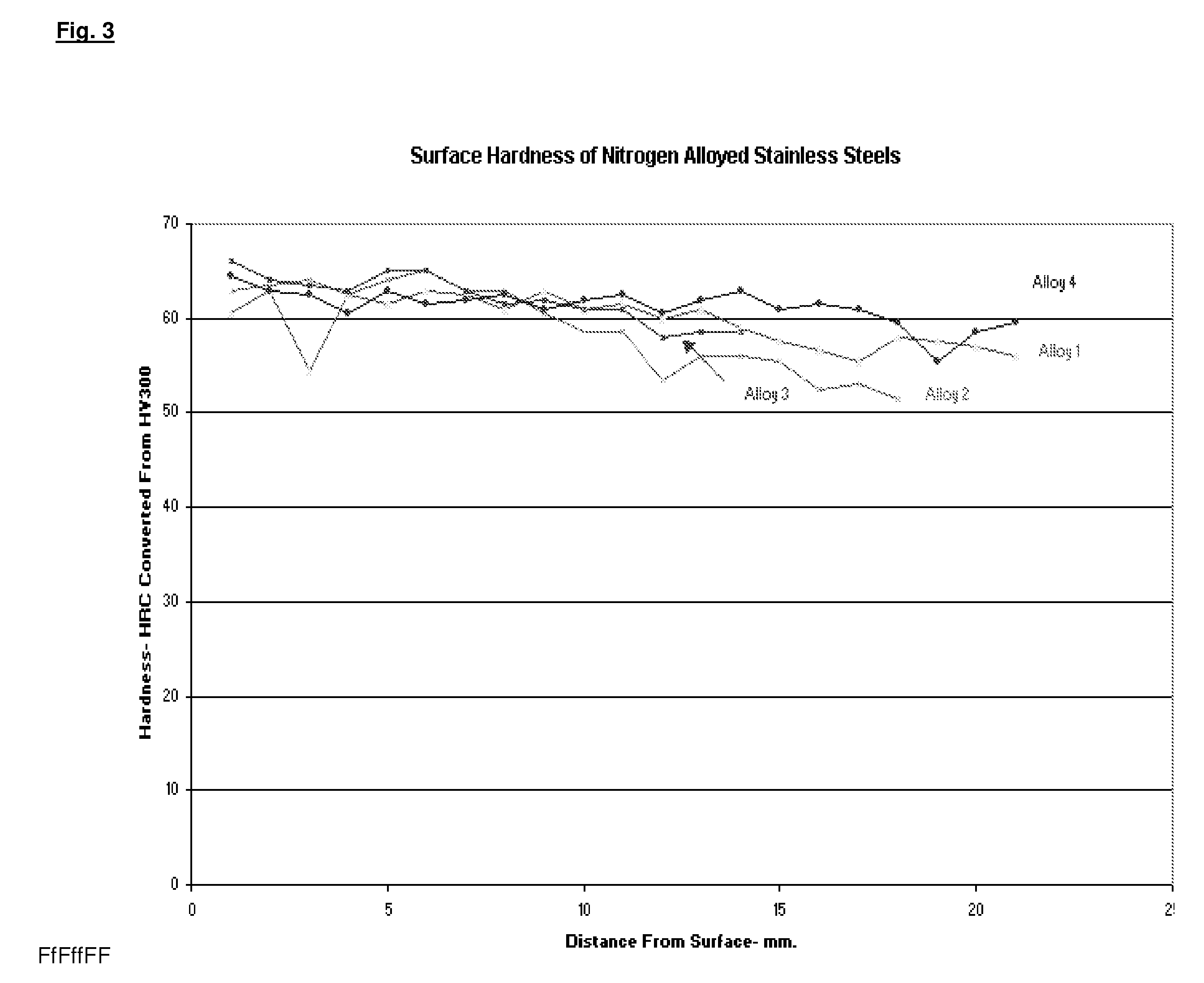

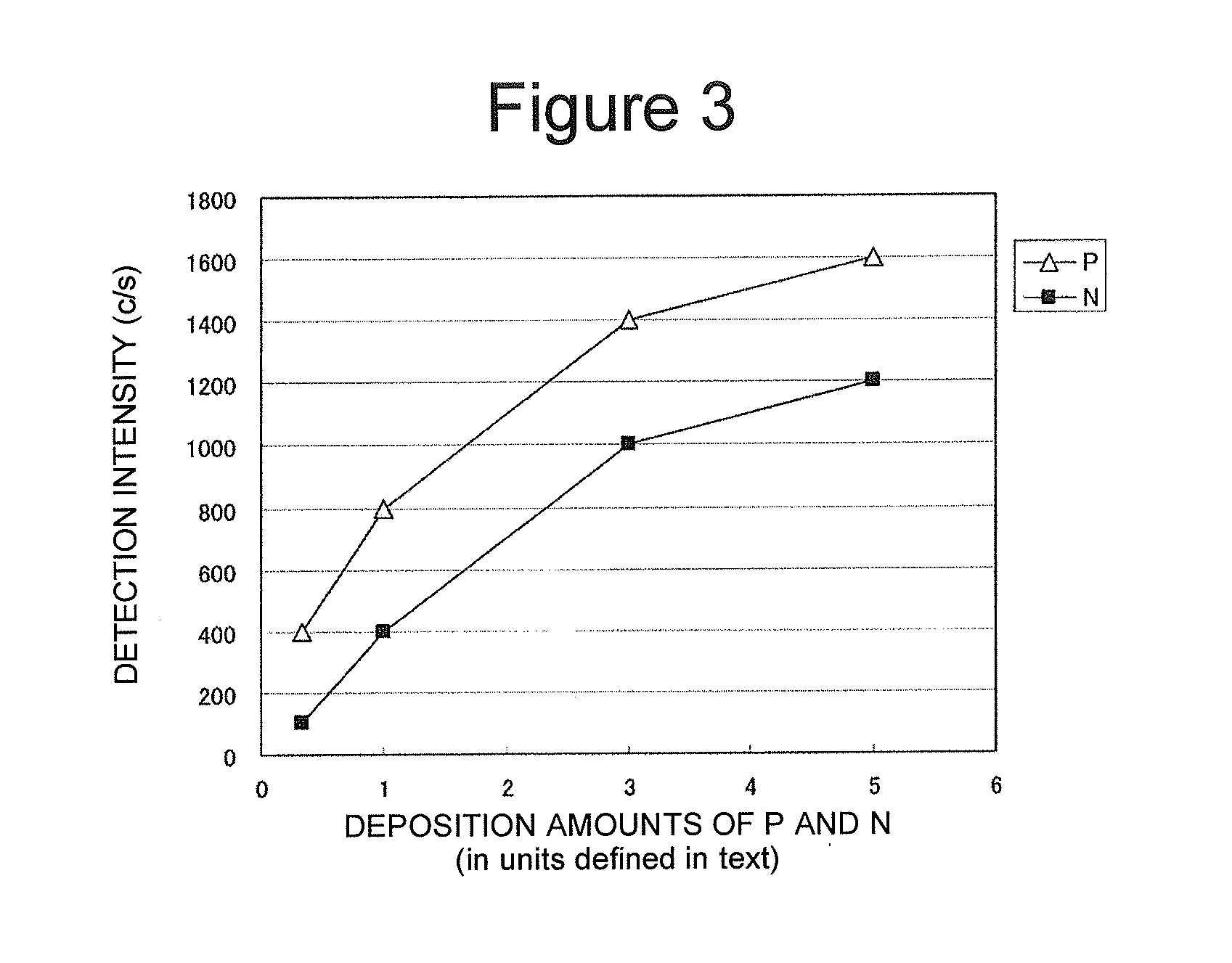

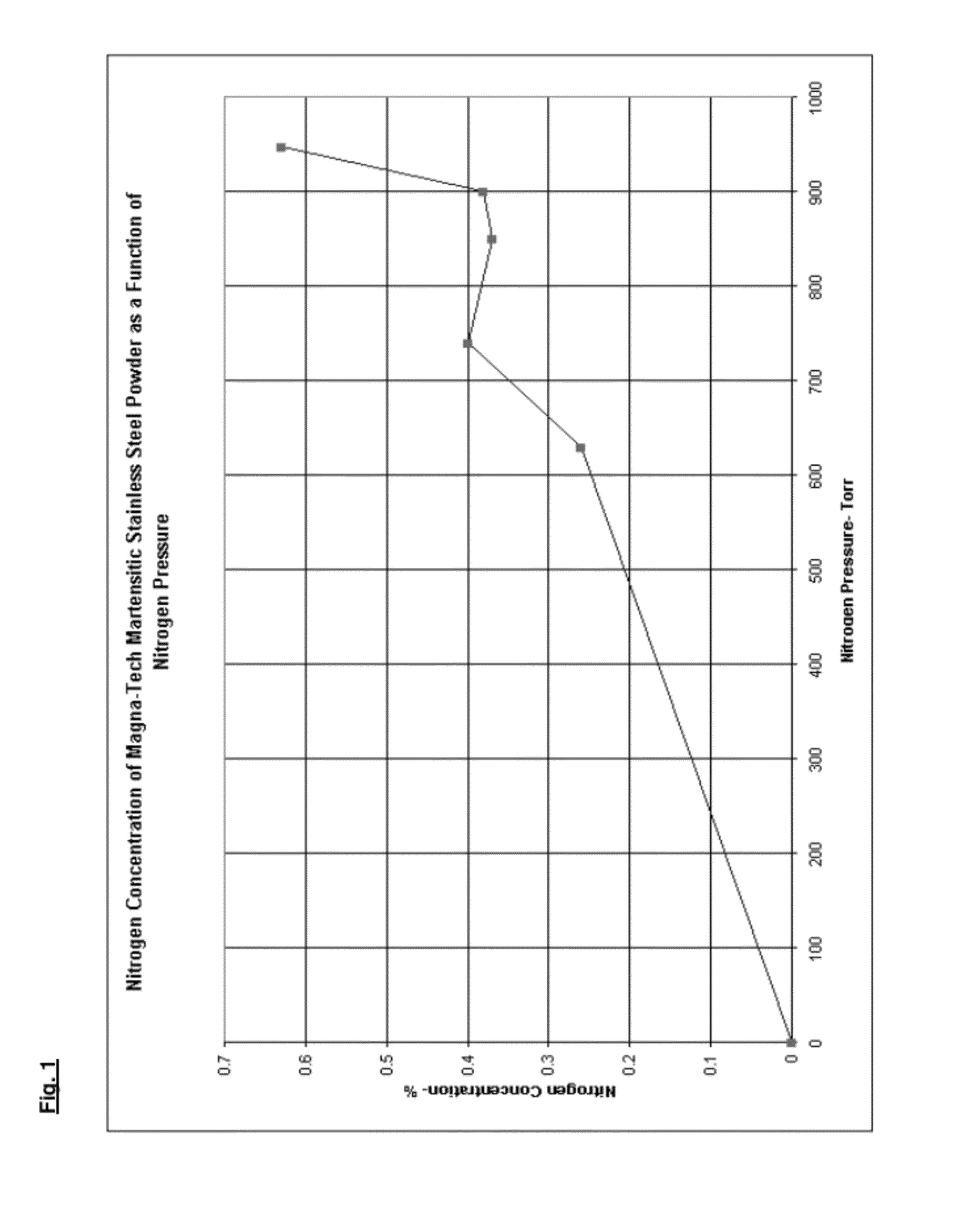

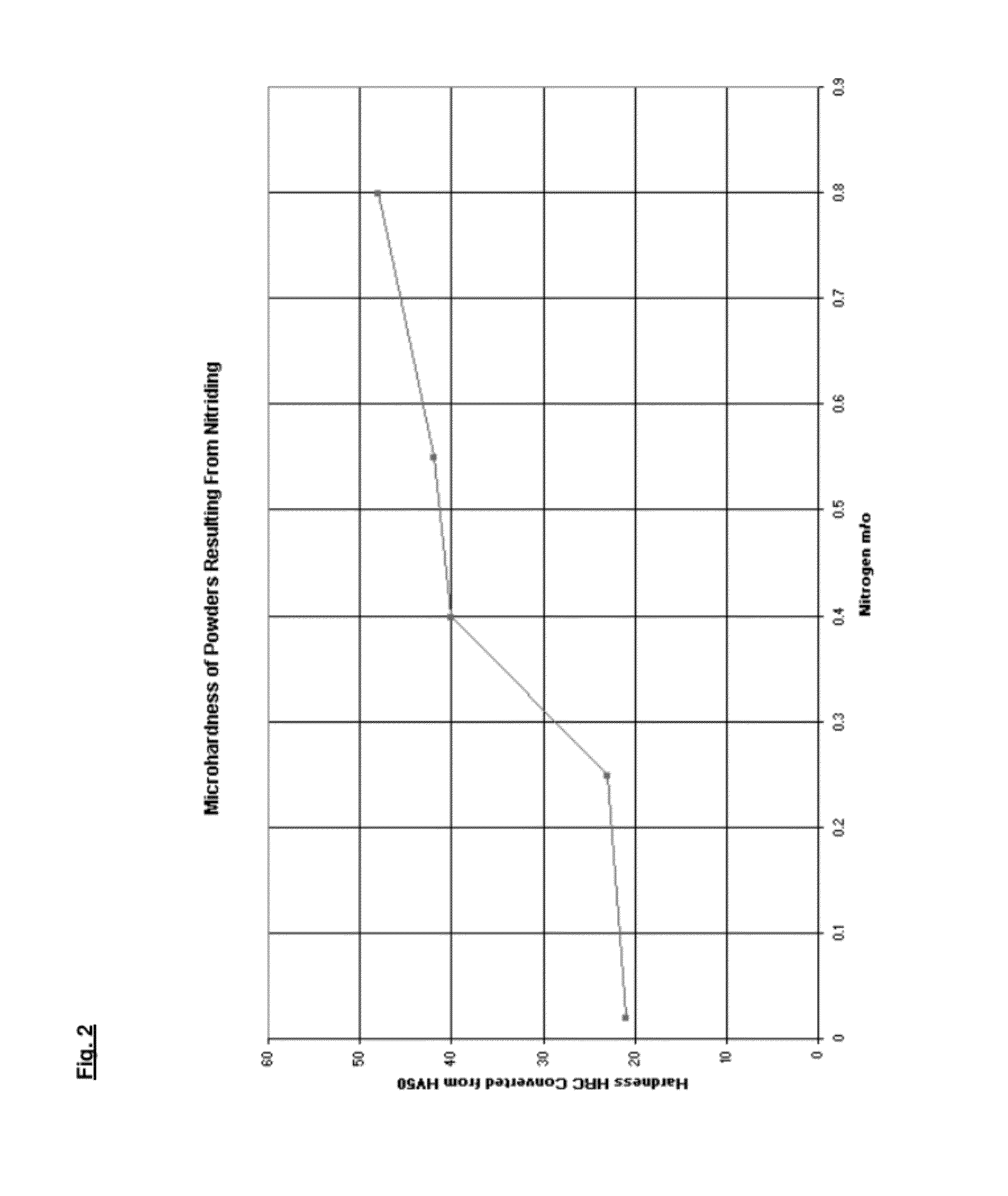

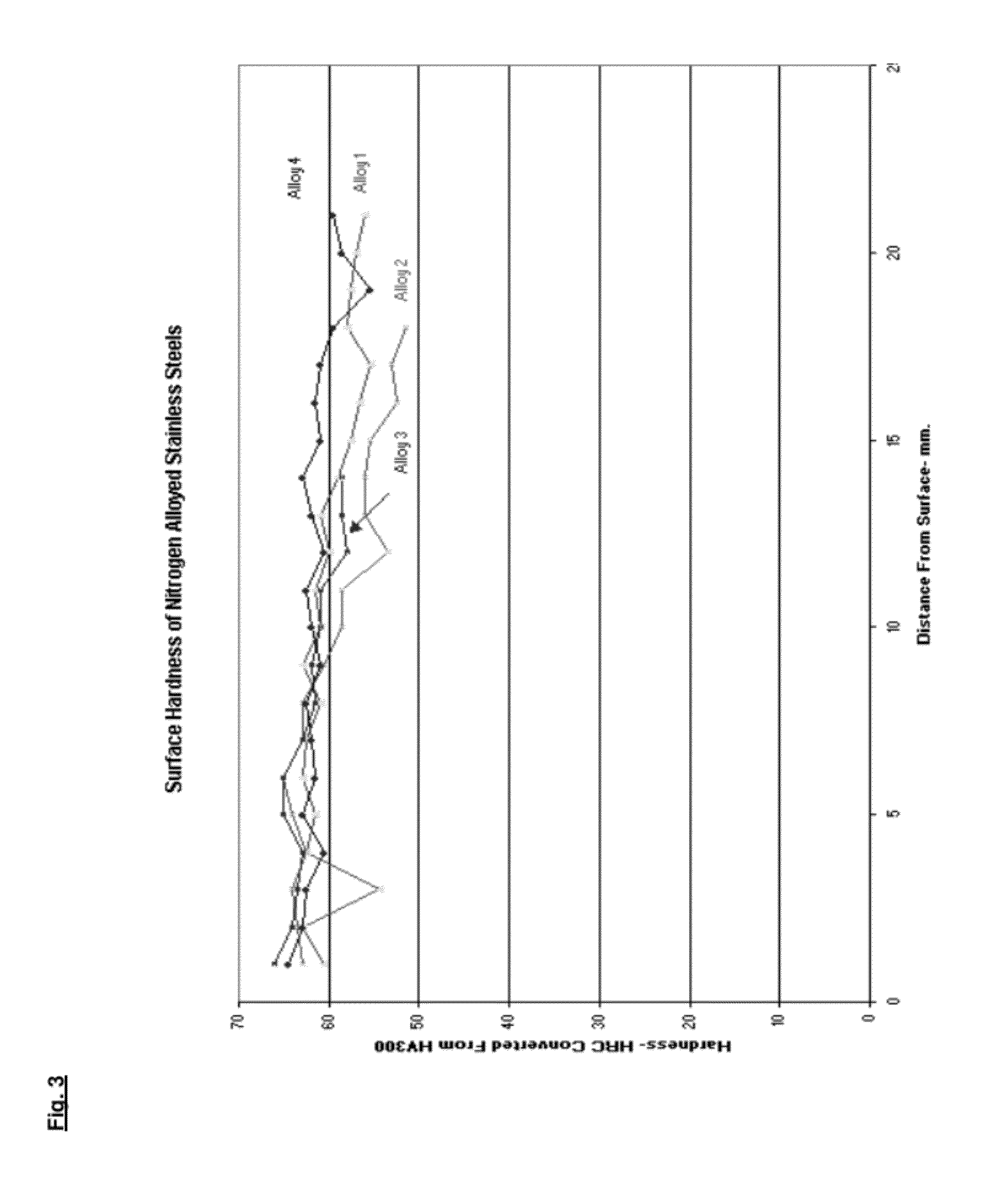

The present invention comprises the nitridization of stainless steel with a gaseous nitrogen compound such as nitrogen gas (N2), or ammonia (NH3) at high temperature wherein the reaction pressure is lowered. A base powder with properties similar to those of a martensitic stainless steel is prepared from a molten metal with the subsequent incorporation of selective additives such as cobalt, chromium, boron, copper, vanadium, niobium and mixtures thereof to improve high temperature resistance to scuffing and adhesive wear. The molten mixture is then atomized by water- or air-atomization to yield a base powder which is mixed with nitrogen or ammonia gas at various pressures in a static or fluidized bed to provide a nitrogen alloyed particulate, i.e., a nitrided particulate alloy. The powder is heated in a hot isostatic press under vacuum with argon gas at reduced pressure and later cooled to ambient (room) temperature. A second embodiment of the invention also comprises the use of a wrought iron-based stainless steel or casting as the starting material to be nitrided.

Owner:MAGNA TECH PM LABS

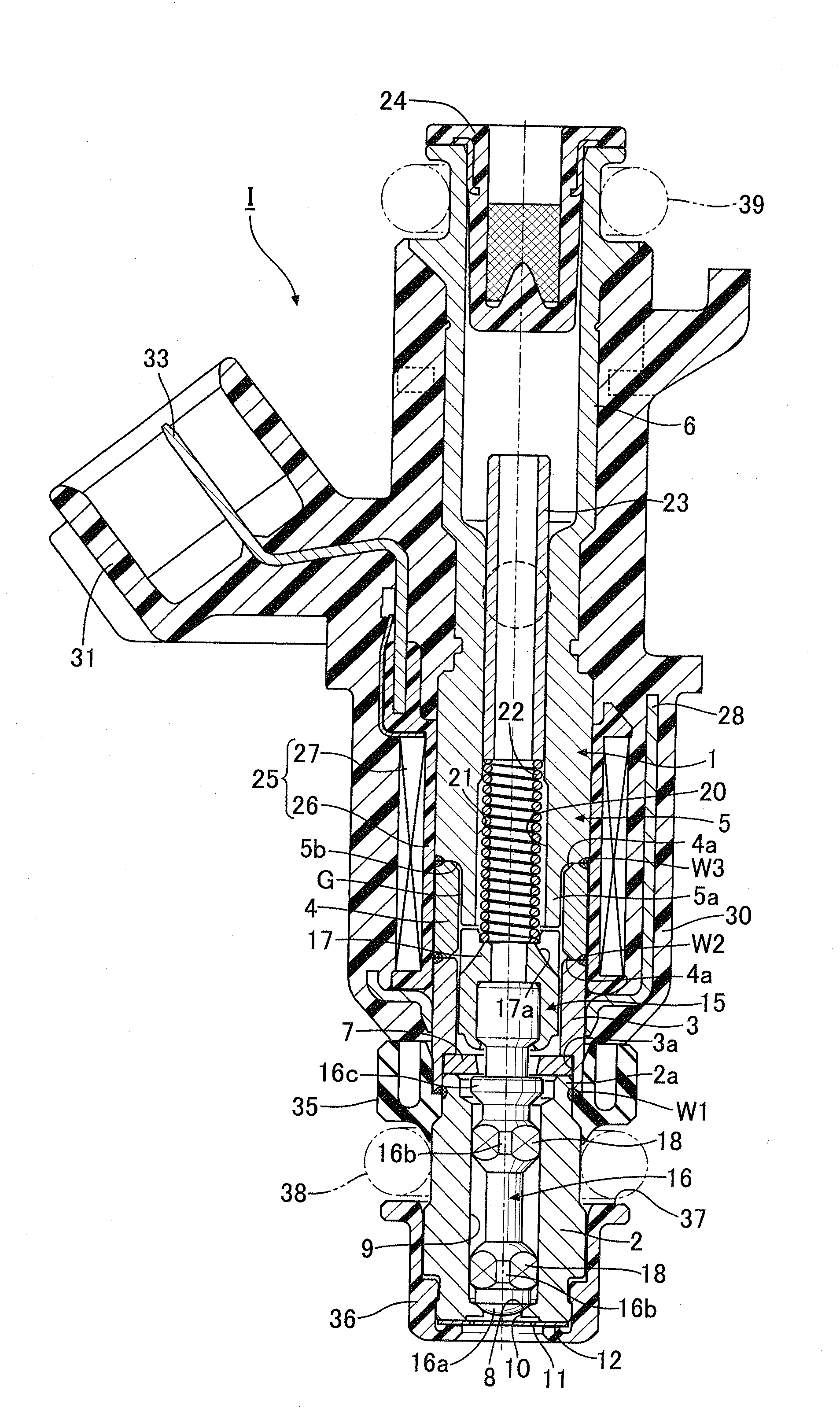

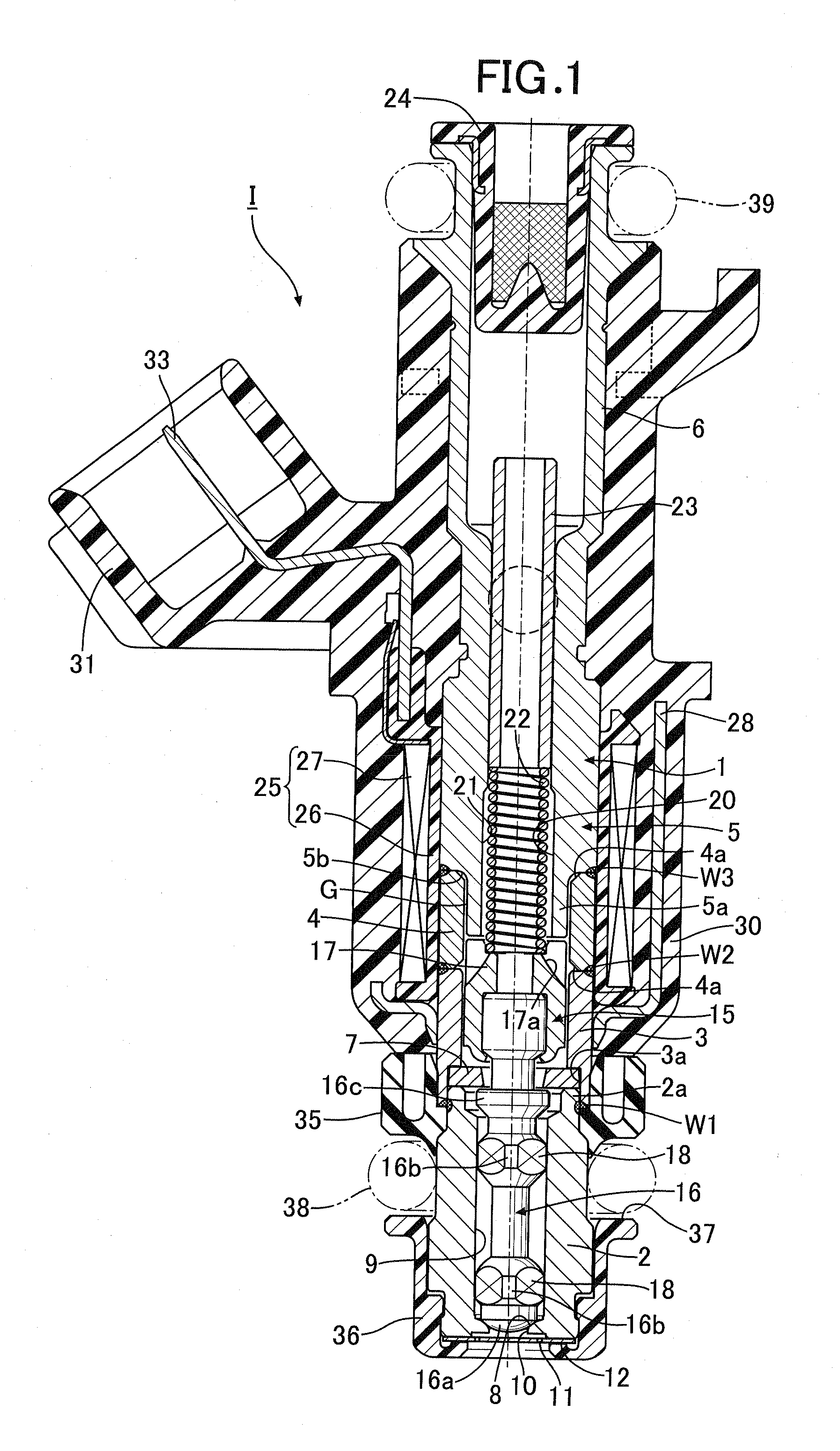

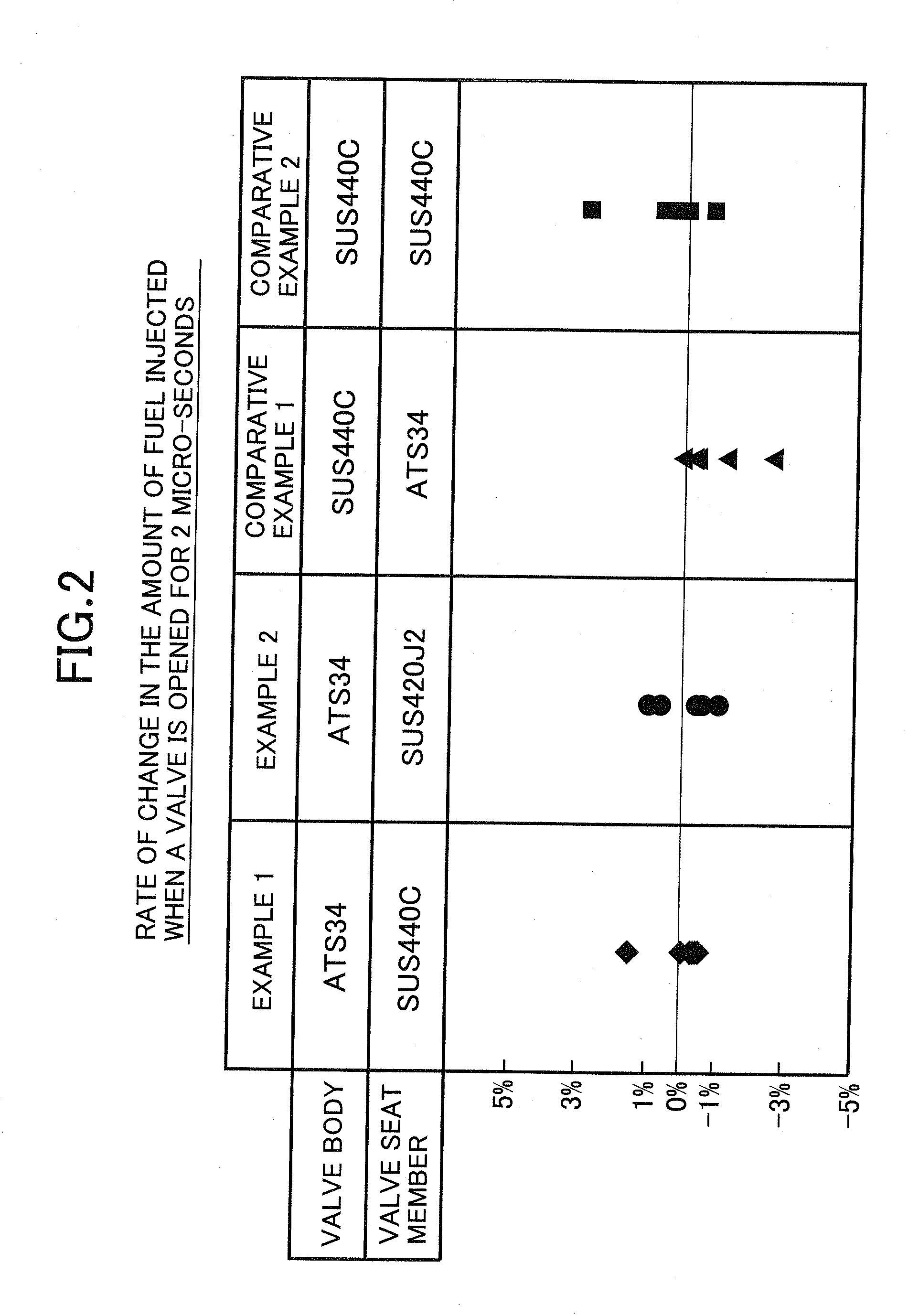

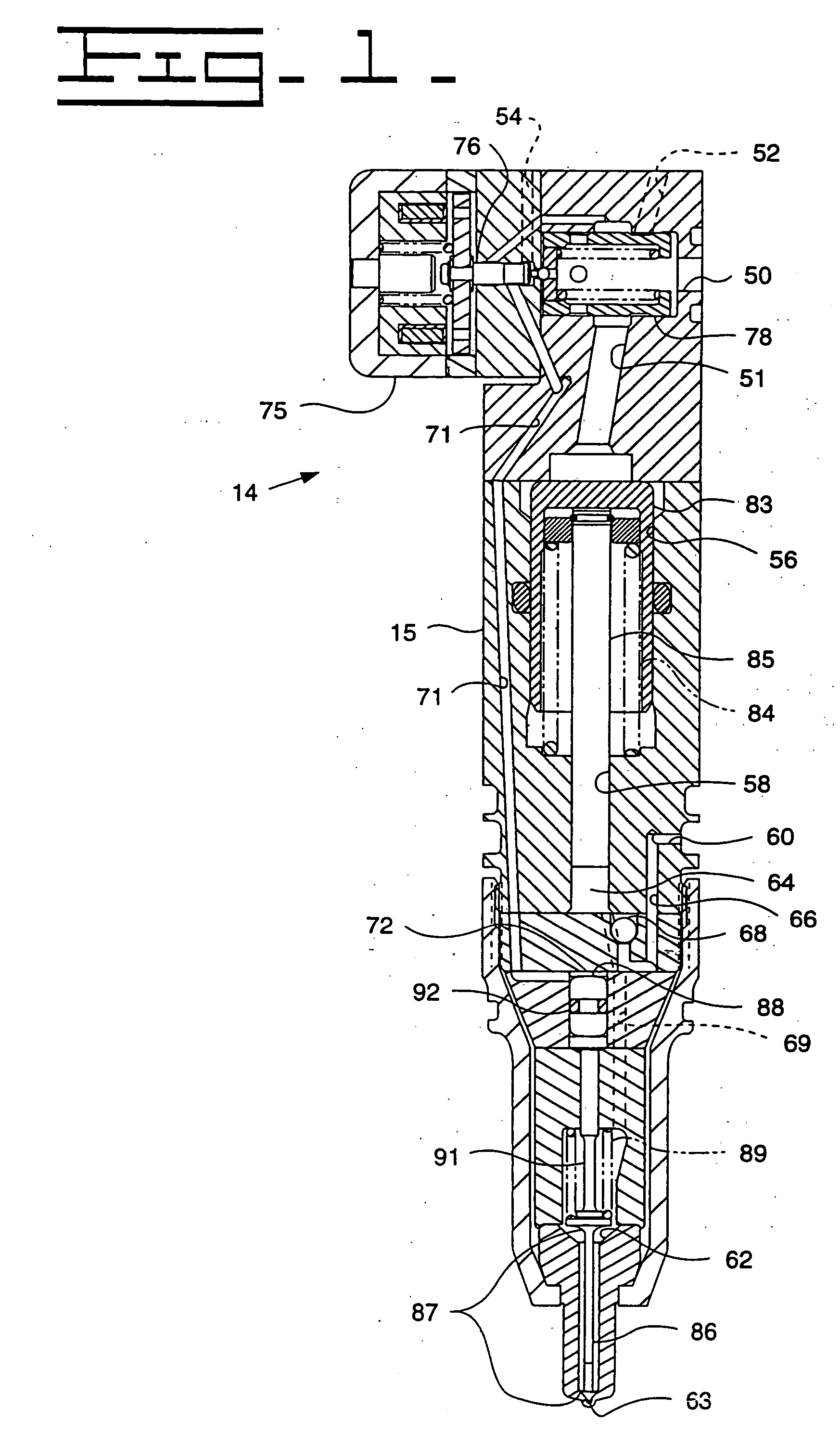

Electromagnetic fuel injection valve

ActiveUS20100001215A1Prevent Adhesive WearReduce Adhesive WearOperating means/releasing devices for valvesMachines/enginesAlcohol fuelMartensitic stainless steel

In an electromagnetic fuel injection valve, a valve housing includes: a cylinder-shaped valve seat member having a valve seat in its front end portion; a magnetic cylindrical body coaxially connected to a rear end portion of the valve seat member; a nonmagnetic cylindrical body coaxially and liquid-tightly welded to a rear end of the magnetic cylindrical body; and a hollow cylindrical stationary core coaxially and liquid-tightly welded to a rear end of the nonmagnetic cylindrical body. A valve assembly is housed in the valve housing and includes: a valve body capable of being seated on the valve seat; and a movable core connected to a rear end of the valve body and opposed to a front end of the stationary core. The valve body and the valve seat member are respectively made of different martensitic stainless steels so that a hardness of the valve body is higher than that of the valve seat member. Accordingly, it is possible to provide an electromagnetic fuel injection valve for alcohol fuel which is capable of preventing the adhesive wear from occurring in the seat portion while a valve body and a valve seat member made of martensitic stainless steel are used.

Owner:HITACHI ASTEMO LTD

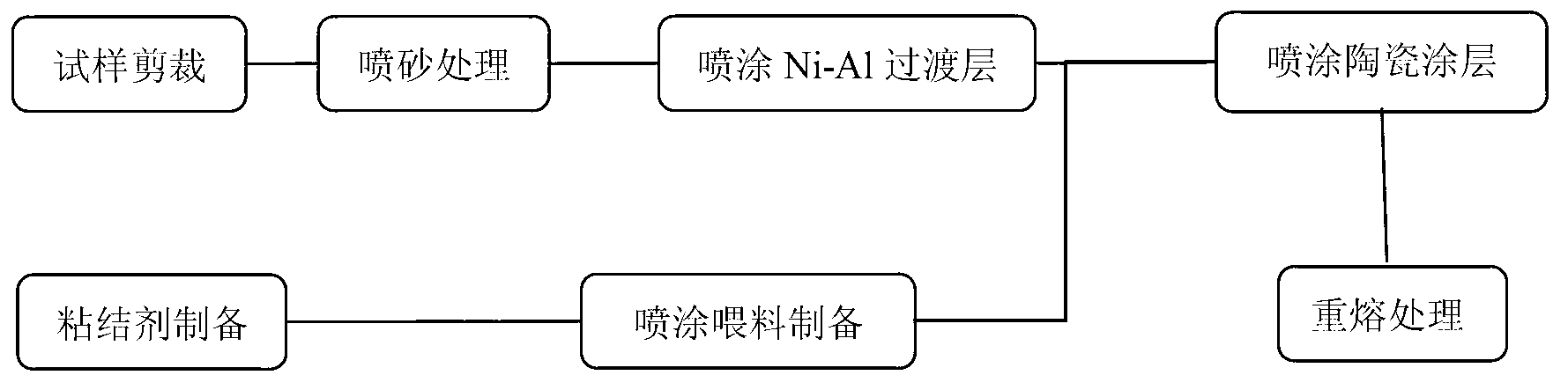

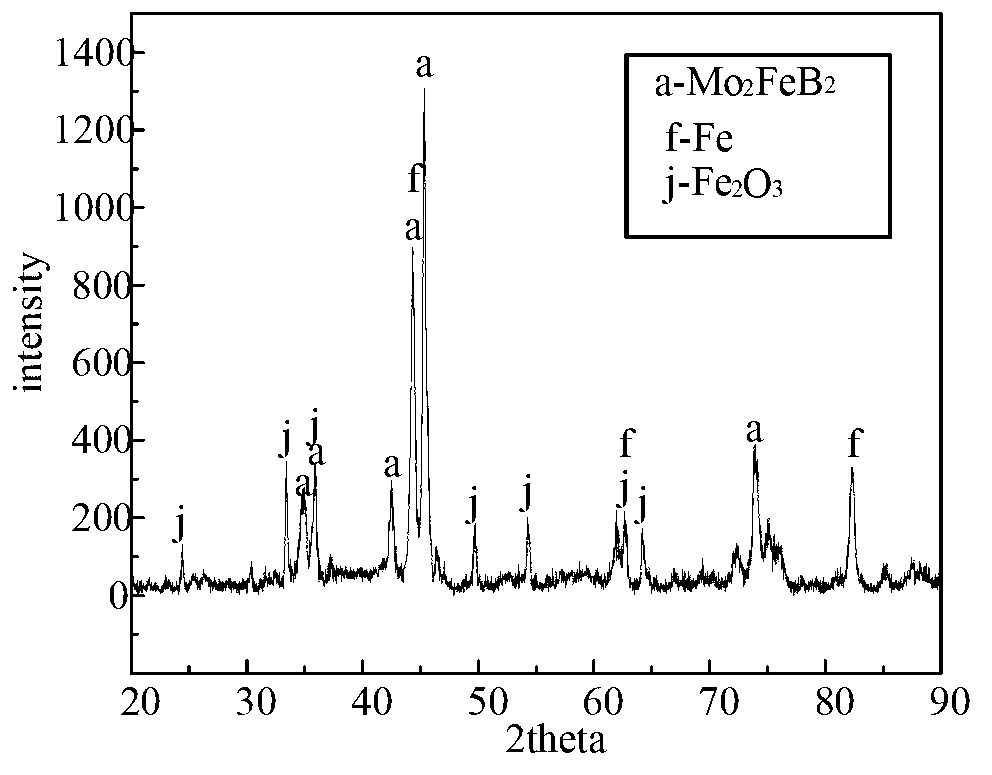

Ternary boride ceramic coating with cerium oxide and preparation method thereof

The invention discloses a ternary boride ceramic coating with cerium oxide and a preparation method thereof, belonging to the technical field of coating preparation. The preparation method comprises the following steps of: adopting a thermal spraying technology, taking Mo powder, Fe powder and FeB powder as raw materials, and preparing the Mo2FeB2 ternary boride ceramic coating on a Q235 steel matrix; and adding CeO2 powder with a friction reducing effect on the ternary boride ceramic coating, and preparing the Mo2FeB2 ternary boride ceramic coating with CeO2 components by using the same technology. In comparison with the Q235 matrix, the abrasive wear resistance of the ternary boride ceramic coating disclosed by the invention is improved by 50%, and the adhesive wear resistance of the ternary boride ceramic coating is improved by 59%, so that the ternary boride ceramic coating has an excellent abrasion resistance and a higher friction coefficient ranging from 0.31 to 0.52.

Owner:LIAONING TECHNICAL UNIVERSITY

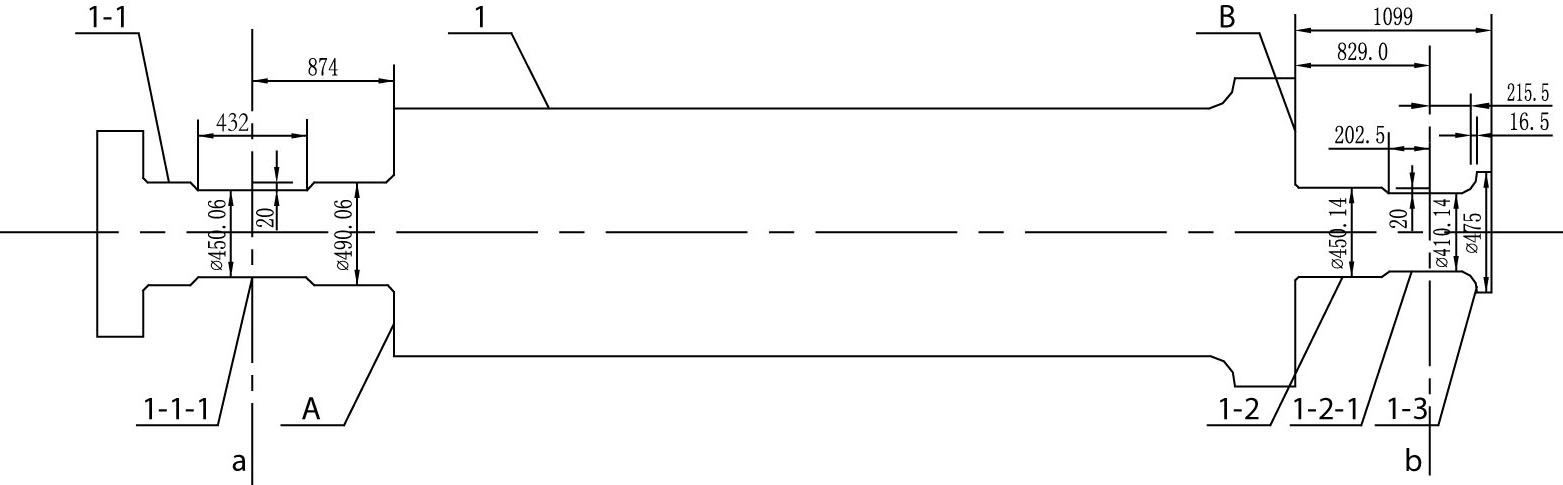

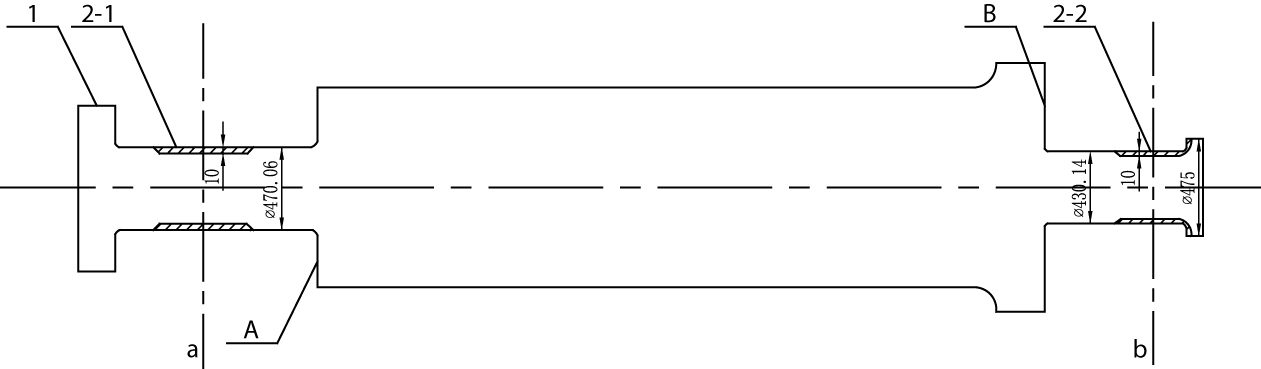

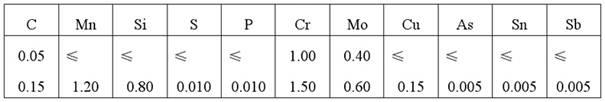

Surfacing method of 12-percent Cr steel high and middle pressure rotor journal of ultra supercritical steam turbine

ActiveCN101837501AAvoid stickingPrevent sintering failure phenomenonArc welding apparatusEngineeringAdhesive wear

The invention relates to a surfacing method, in particular to a surfacing method of a 12-percent Cr steel high and middle pressure rotor journal of an ultra supercritical steam turbine, solving the problem of mechanical adhesive wear of the surfaces of the 12-percent Cr steel high and middle pressure rotor journal and a bearing. The surfacing method comprises the following steps of: firstly, respectively turning a first journal and a second journal of a blank rotor in a groove mode; secondly, carrying out dye inspection on a turning surface; thirdly, assembling the blank rotor to a special surfacing device; fourthly, preheating a surface to be surfaced of the rotor journal; fifthly, surfacing the surface to be surfaced; sixthly, distressing and heating a rotor; seventhly, turning and finishing the surfaced rotor; and eighthly, carrying out nondestructive inspection detection on the finished rotor. The surfacing method is used for surfacing the 12-percent Cr steel high and middle pressure rotor of the ultra supercritical steam turbine.

Owner:HARBIN TURBINE +1

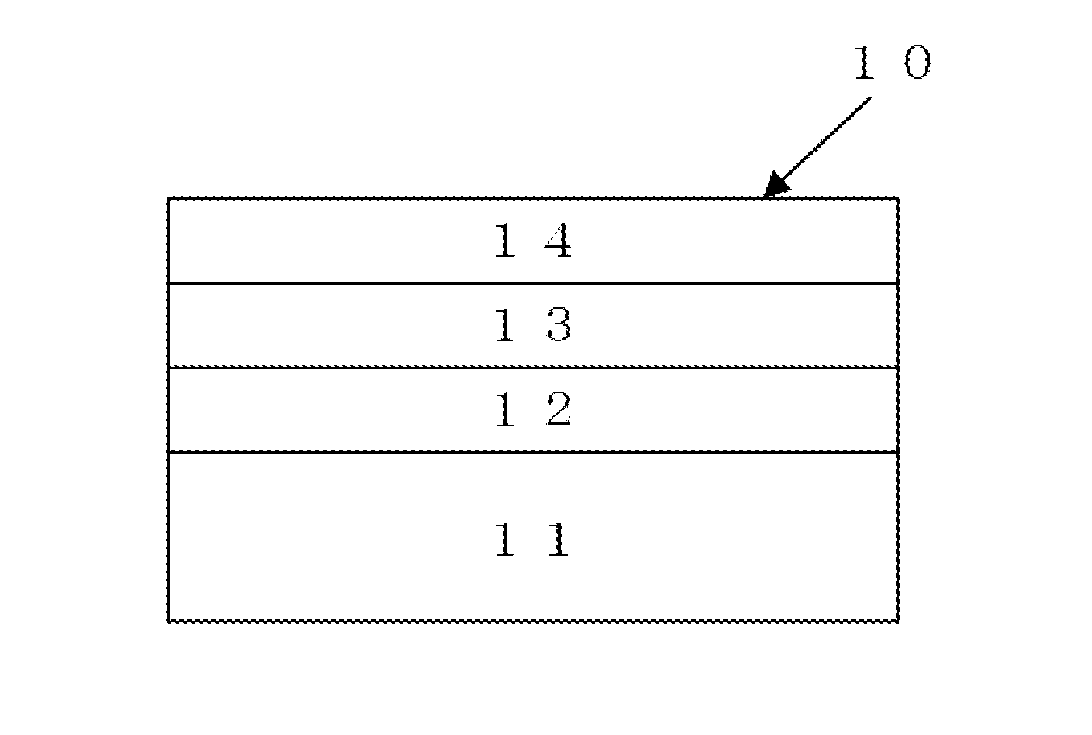

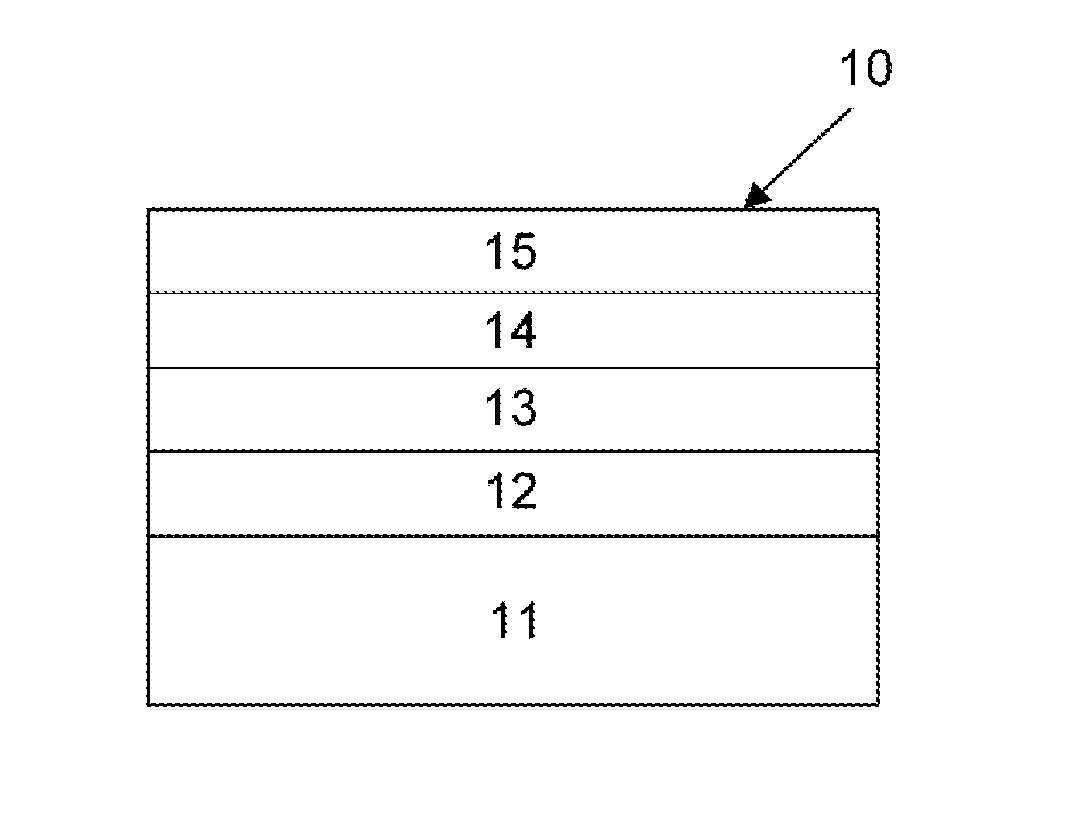

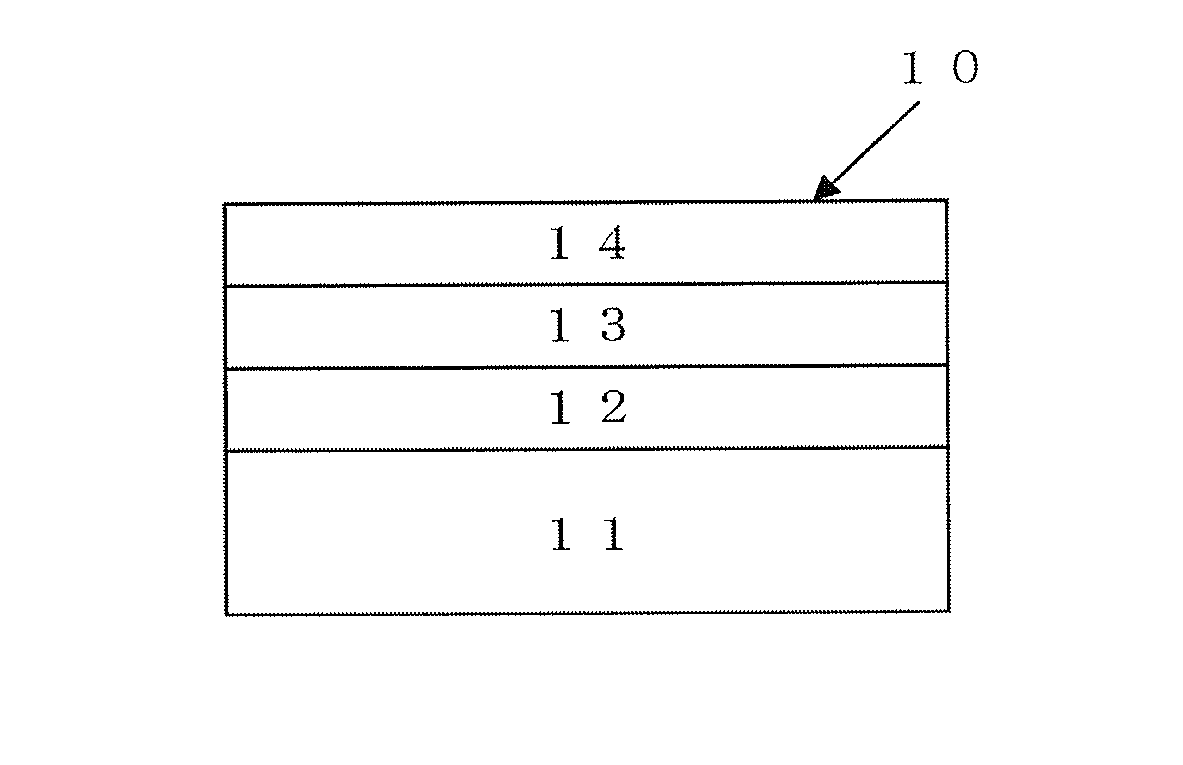

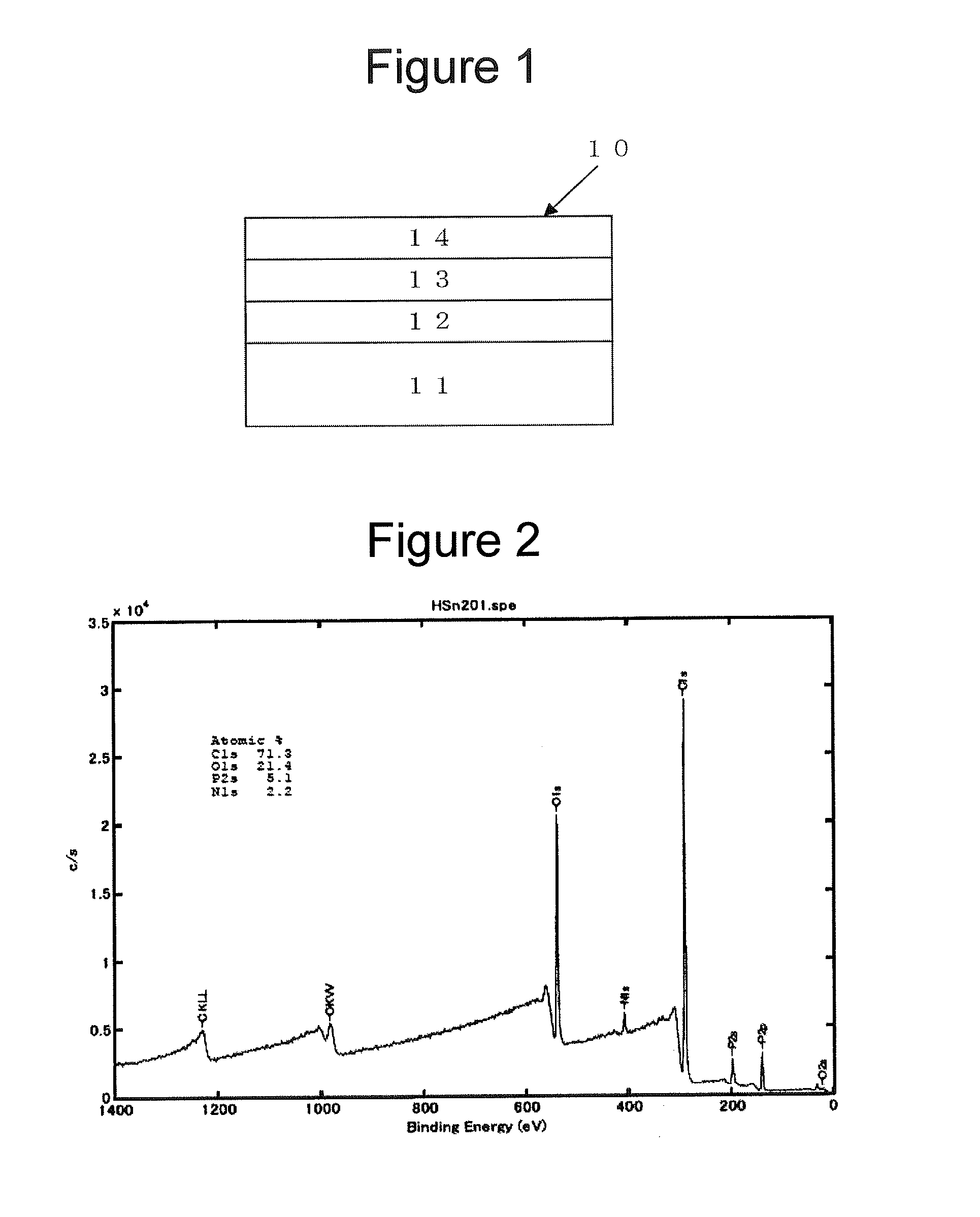

Metallic Material For Electronic Components And Method For Producing Same, And Connector Terminals, Connectors And Electronic Components Using Same

ActiveUS20150194746A1Low degreeIncreased durabilitySingle bars/rods/wires/strips conductorsPhosphatisationMetallic materialsOptoelectronics

The present invention provides metallic materials for electronic components, having low degree of whisker formation, low adhesive wear property and high durability, and connector terminals, connectors and electronic components using such metallic materials. The metallic material for electronic components includes: a base material; a lower layer formed on the base material, the lower layer being constituted with one or two or more selected from a constituent element group A, namely, the group consisting of Ni, Cr, Mn, Fe, Co and Cu; an intermediate layer formed on the lower layer, the intermediate layer being constituted with one or two or more selected from a constituent element group B, namely, the group consisting of Ag, Au, Pt, Pd, Ru, Rh, Os and Ir; and an upper layer formed on the intermediate layer, the upper layer being constituted with an alloy composed of one or two or more selected from the constituent element group B, namely, the group consisting of Ag, Au, Pt, Pd, Ru, Rh, Os and Ir and one or two selected from a constituent element group C, namely, the group consisting of Sn and In; wherein the thickness of the lower layer is 0.05 μm or more and less than 5.00 μm; the thickness of the intermediate layer is 0.01 μm or more and less than 0.50 μm; and the thickness of the upper layer is 0.02 μm or more and less than 0.80 μm.

Owner:JX NIPPON MINING& METALS CORP

Novel process for making piston ring

InactiveCN1632297AHigh surface hardnessReduce coefficient of frictionPiston ringsMachines/enginesPiston ringHigh energy laser beam

The new processing technology of piston ring involves the processing technology of piston ring. It includes the following process steps: casting→grinding→heat treatment→grinding→gold processing→laser strengthening treatment→heat setting→gold processing. Since the surface layer of the piston ring is processed by laser alloying or laser cladding, and is rapidly melted by a high-energy laser beam, the matrix at a certain depth on the outer surface of the piston ring is rapidly melted and then solidified to form a specific ceramic particle reinforced composite coating. The coating and the piston ring body are metallurgical structures, which will not fall off or peel off under the action of external force. The invention is easy for industrial production, has excellent anti-adhesive wear and anti-abrasive wear capabilities, and has good product technical stability.

Owner:江苏仪征威龙活塞环有限公司 +1

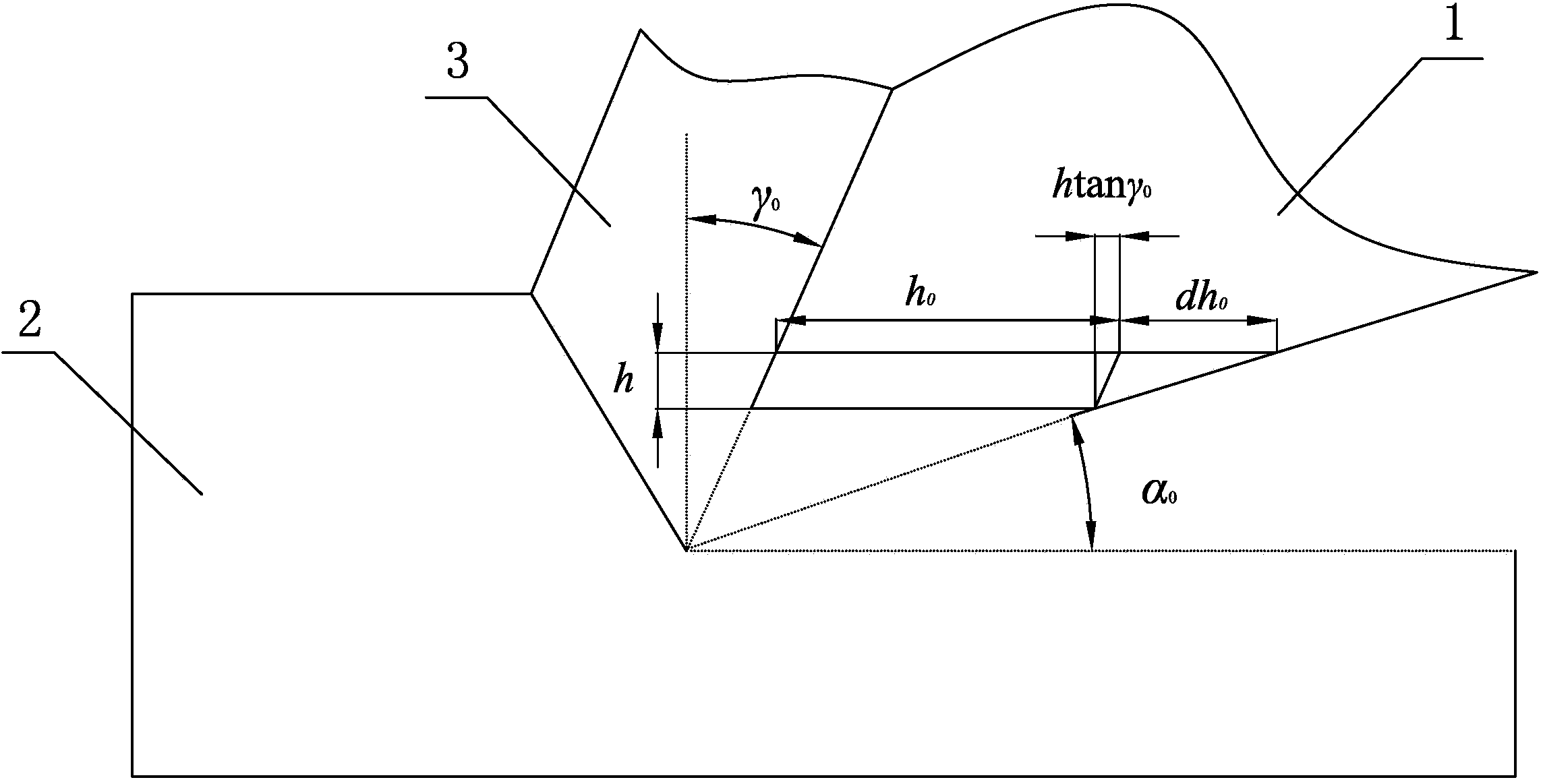

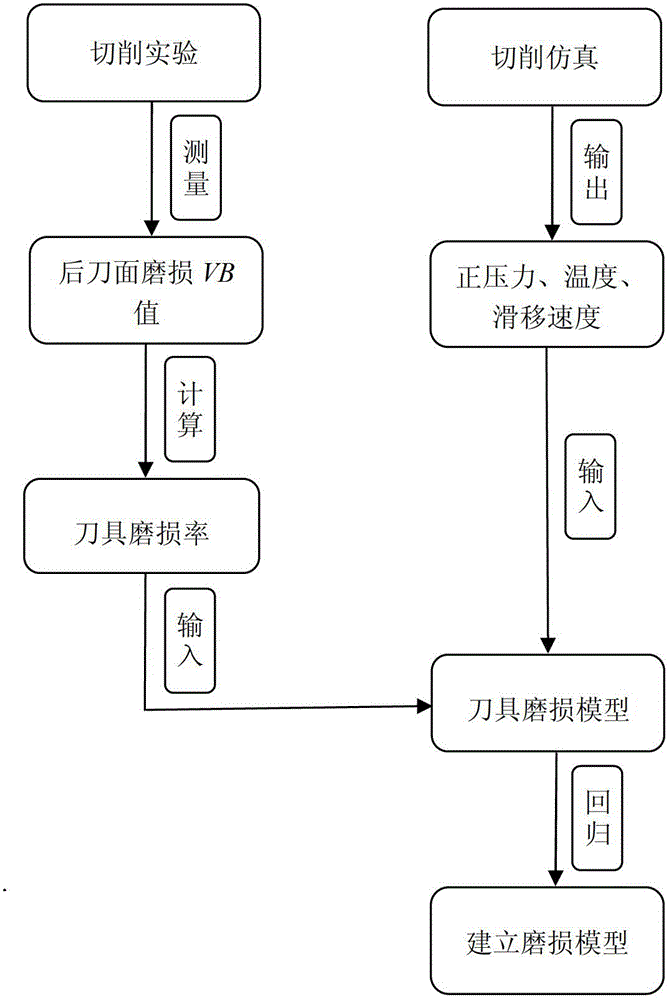

Cutting parameter determining method for combined machining of cutting tool and high-temperature alloy

Provided is a cutting parameter determining method for combined machining of a cutting tool and high-temperature alloy. The cutting parameter determining method is used for solving the problems that in the high-temperature alloy cutting process, due to the fact that reasonable cutting parameters cannot be easily selected, a tool is seriously worn, and efficiency of cutting machining is low. The cutting parameter determining method is based on an Archard model in an adhesive wear theory tool model built by F.T.Bowden and D.Tabor, the cutting temperature adopted when the adhesive wear between a workpiece material and a wear surface of the cutting tool is minimum in the cutting process of the high-temperature alloy is determined by building a wear model of a rear tool face in the combined machining process of the cutting tool and the high-temperature alloy and according to cutting test data, the correspondence between different cutting speeds and different cutting feed rates is built according to the cutting temperature obtained through the wear model, and the cutting speed and the cutting feed rate are determined; the purpose of improving cutting machining efficiency and the purpose of reducing tool wear are achieved.

Owner:HEILONGJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

Metallic Material For Electronic Components And Method For Producing Same, And Connector Terminals, Connectors And Electronic Components Using Same

ActiveUS20150171537A1Low degreeIncreased durabilitySingle bars/rods/wires/strips conductorsPhosphatisationMetallic materialsWhiskers

The present invention provides metallic materials for electronic components, having low degree of whisker formation, low adhesive wear property and high durability, and connector terminals, connectors and electronic components using such metallic materials. The metallic material for electronic components includes: a base material; a lower layer formed on the base material, the lower layer being constituted with one or two or more selected from a constituent element group A, namely, the group consisting of Ni, Cr, Mn, Fe, Co and Cu; an intermediate layer formed on the lower layer, the intermediate layer being constituted with one or two or more selected from a constituent element group B, namely, the group consisting of Ag, Au, Pt, Pd, Ru, Rh, Os and Ir; an upper layer formed on the intermediate layer, the upper layer being constituted with an alloy composed of one or two or more selected from the constituent element group B, namely, the group consisting of Ag, Au, Pt, Pd, Ru, Rh, Os and Ir and one or two selected from a constituent element group C, namely, the group consisting of Sn and In; an outermost layer formed on the upper layer, the upper layer being constituted with one or two selected from the constituent element group C, namely, the group consisting of Sn and In, wherein the thickness of the lower layer is 0.05 μm or more and less than 5.00 μm; the thickness of the intermediate layer is 0.01 μm or more and less than 0.50 μm; the thickness of the upper layer is less than 0.50 μm; and the thickness of the outermost layer is 0.005 μm or more and less than 0.30 μm.

Owner:JX NIPPON MINING & METALS CO LTD

Wear prediction method for shield tunneling hob

InactiveCN111005733APredicted service lifeData processing applicationsMining devicesEngineeringShield tunneling

The invention discloses a wear prediction method for a shield tunneling hob. The wear prediction method for the shield tunneling hob comprises the following steps that a unit displacement wear loss caused by a plastic removal mechanism, a unit displacement wear loss caused by a brittle fracture mechanism, a unit displacement wear loss caused by adhesive wear, a unit displacement wear loss caused by fatigue wear, a rock breaking arc length generated when a point on the front side of the hob rotates by one circle, a spatial rock breaking arc length generated when a point on the side face of thehob rotates by one circle, a normal cutting force of the hob, and a horizontal force borne by the hob are acquired; the radial wear and wear size of the front side of a hob ring caused when the hob rotates by one circle are worked out; the wear loss and wear size of the side face of the hob ring caused when the hob rotates by one circle are worked out; the four wear losses are multiplied by corresponding fitting coefficients, and the products are added to obtain the wear size of the front side and the wear size of the hob ring; and a wear prediction model is generated, and the wear is predicted. By the adoption of the wear prediction method, the service life of the shield tunneling hob can be predicted, the prediction precision can be improved, and the problems of severe wear of the hob and frequency opening of a bin are solved.

Owner:SOUTHWEST PETROLEUM UNIV

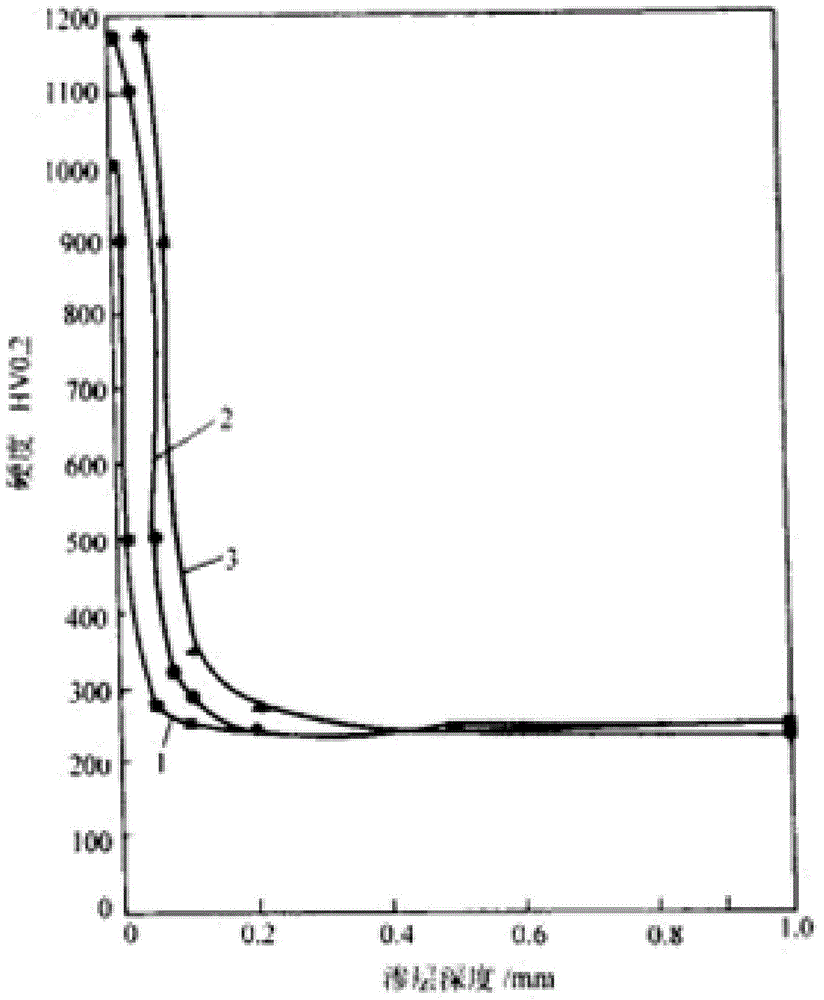

Low-temperature nitriding method for forming corrosion-resistant hardened layer on surface of stainless steel

ActiveCN103215536AImprove wear resistanceReduce coefficient of frictionSolid state diffusion coatingSS - Stainless steelThermal treatment

The invention relates to a low-temperature nitriding method for forming a corrosion-resistant hardened layer on the surface of stainless steel. The low-temperature nitriding method is characterized in that the low-temperature nitriding method comprises the following steps: 1, preparing a soldering flux melt, and putting a stainless steel product in the soldering flux melt for removing a passive film; 2, immersing the stainless steel product in a chloride solution to maintain the surface activity condition of the stainless steel product; and 3, carrying out nitriding heating treatment of the activated stainless steel product to form the corrosion-resistant hardened layer on the surface of the stainless steel product. The surface hardness of the product processed through the nitriding method reaches 900-1300HV0.1, and the wear resistance of the product is greatly improved. Additionally, the method can substantially reduce the frication coefficient of the surface of the product, and is in favor of improving the interlocking and adhesion wearing resistances of stainless steel components working at a high temperature. The method is suitable for the batch production of miniature precise components.

Owner:SHANGHAI SINOTEC +1

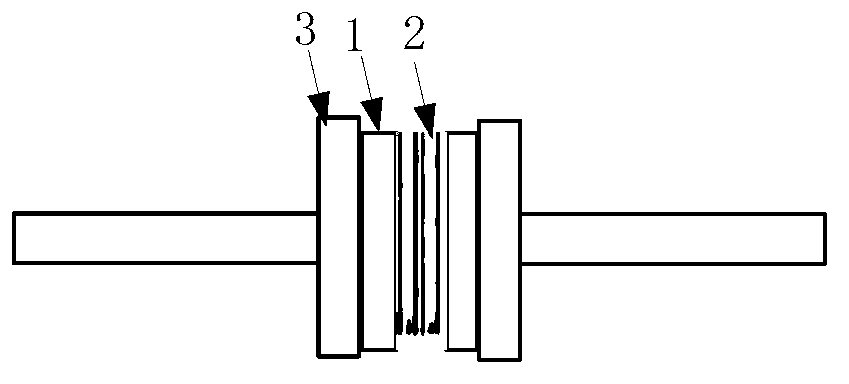

Anti-attrition spacer capable of reducing frictional abnormal sound and application of anti-attrition spacer

InactiveCN105782215AReduce friction noiseSqueak and rattle mitigationWashersSolid state diffusion coatingUniversal jointFrictional coefficient

The invention discloses an anti-attrition spacer capable of reducing frictional abnormal sound and an application of the anti-attrition spacer and belongs to the field of mechanical parts. The anti-attrition spacer takes a low-carbon alloy cold-rolled sheet as a base body, and carbonitriding thermal treatment and surface coating treatment of a polyfluorocomplex and / or a nylon 11 coating are successively performed on the low-carbon alloy cold-rolled sheet. The adhesive force between the coating and the base body in the anti-attrition spacer provided by the invention is large, and the coating has excellent anti-attrition effect and wear-resistant effect. The anti-attrition spacer is used between contact surfaces which rub with each other. With prolonging of frictional time, the coating on the anti-attrition spacer does not fall off, so that the durability of the anti-attrition spacer is ensured, the frictional coefficient between the anti-attrition spacer and the contact surfaces is effectively reduced, and the adhesive wear is reduced, and therefore, the frictional abnormal sound is further reduced. In particular, the anti-attrition spacer used in the field of automobiles can effectively relieve the frictional abnormal sound generated between the end face of a universal joint at the fixed end of a driving shaft and a contact surface of a hub bearing of an automobile.

Owner:CHERY AUTOMOBILE CO LTD

Supersonic spray process for shaped roll pass made of semisteel

ActiveCN103173713AImprove performanceImprove heat resistanceMolten spray coatingCoated surfaceHeat resistance

The invention discloses a supersonic spray process for a shaped roll pass made of semisteel, which comprises the following steps: 1) carrying out pretreatment on the working surface of the roll pass; 2) carrying out shot blasting on the working surface of the roll pass; 3) carrying out supersonic spray on the working surface of the roll pass; and 4) carrying out hole sealing treatment on a coating. The supersonic spray process disclosed by the invention has the advantages that 1, by using a JP5000-type supersound flame spraying system, the flying speed of melting powder is greater than 720 m / s, the property of the coating is excellent, and the surface of the coating is dense, so that the surface quality of products is greatly improved; 2, the tungsten carbide metal composite powder coating is good in wear resistance and heat resistance, so that for insufficiently cooled shaped lower rolls, the steel bonding caused by frictional wear and the roll marks caused by adhesive wear are avoided, thereby reducing the accident loss due to poor quality; and 3, the wear resistance of the roll pass is increased, the steel passing quantity of the roll pass is increased, the roll loss is reduced, and the service life of a semi-steel shaped roll is prolonged.

Owner:ANHUI HENGYI HARD FACE ENG CO LTD

Wear resistant surfacing alloy containing ceramic phase with molybdenum and chromium elements and production technology thereof

InactiveCN103769765AIncrease production costLow costPlasma welding apparatusWelding/cutting media/materialsWear resistantAlloy

The invention discloses a wear resistant surfacing alloy containing ceramic phase with molybdenum and chromium elements and a production technology thereof. The wear resistant surfacing alloy containing the ceramic phase with the molybdenum and chromium elements is characterized in that alloy composition comprises 15 to 30 % of chromium, 3 to 12 % of molybdenum, 0.5 to 1 % of nickel, 6 to 10 % of carbon and the remaining is ferrum and unavoidable impurities. The production technology of the wear resistant surfacing alloy containing the ceramic phase with the molybdenum and chromium elements comprises mechanically mixing ferrochrome powder, molybdenum powder, nickel powder, graphite and reduced iron powder; uniformly mixing through a dry type ball mill of a ball grinder; coating the powder on a carbon steel plate after the powder is cooled; uniformly mixing into a coating layer with the thickness of 4 mm through water glass; standing under room temperature; drying in a drying oven; enabling the temperature to be cooled to the room temperature in the drying oven; performing ion surfacing. The production technology of the wear resistant surfacing alloy containing the ceramic phase with the molybdenum and chromium elements has the advantages of being simple in technological process, less in added alloy variety and low in cost and enabling hard phase of obtained alloy surfacing layer to be good in bonding performance with base materials, not easy to fall off, high in rigidity and wear resistance, obvious in adhesive wear resistant effect compared with other iron-based surfacing wear resistant alloy.

Owner:SHENYANG POLYTECHNIC UNIV

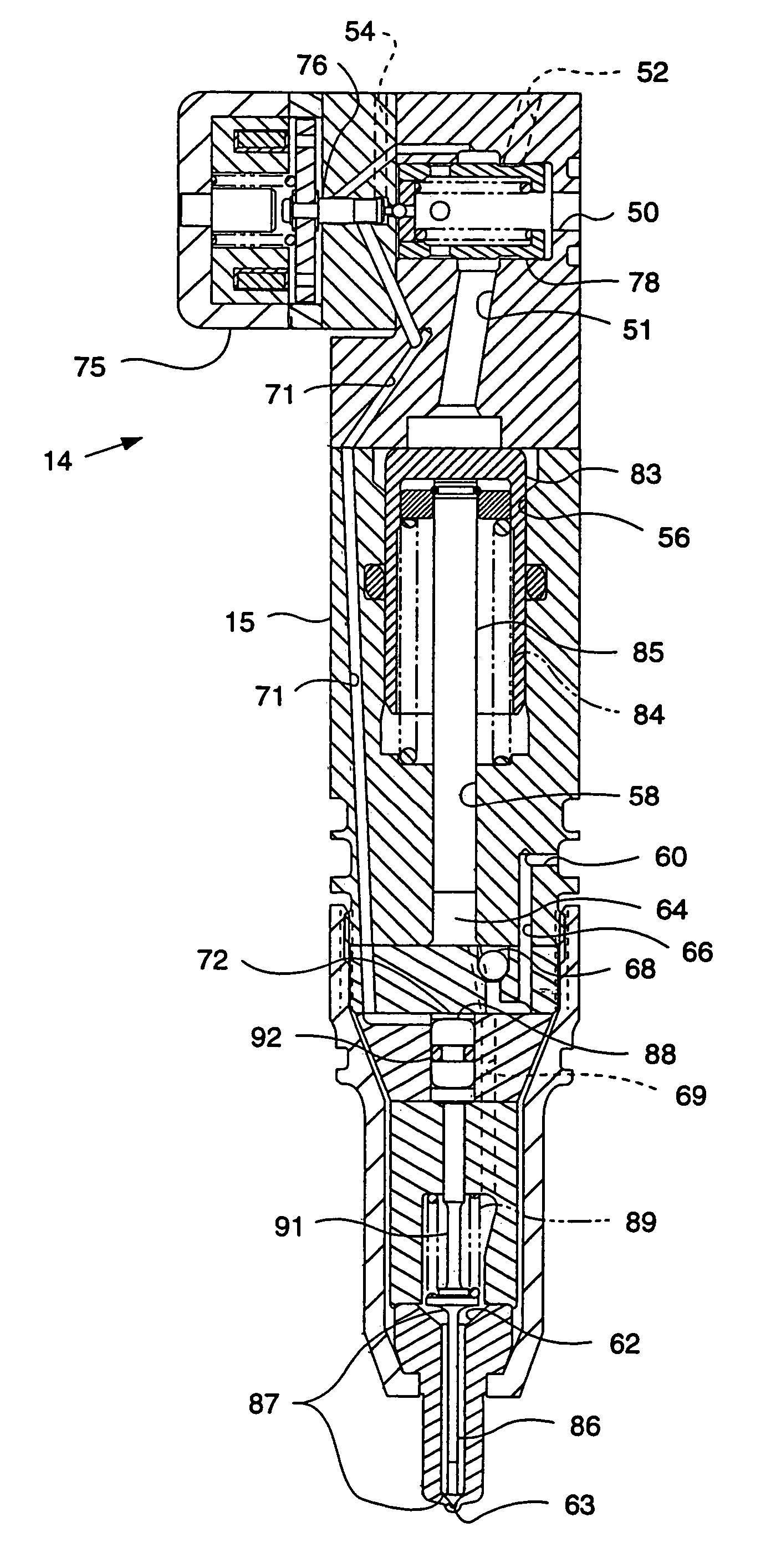

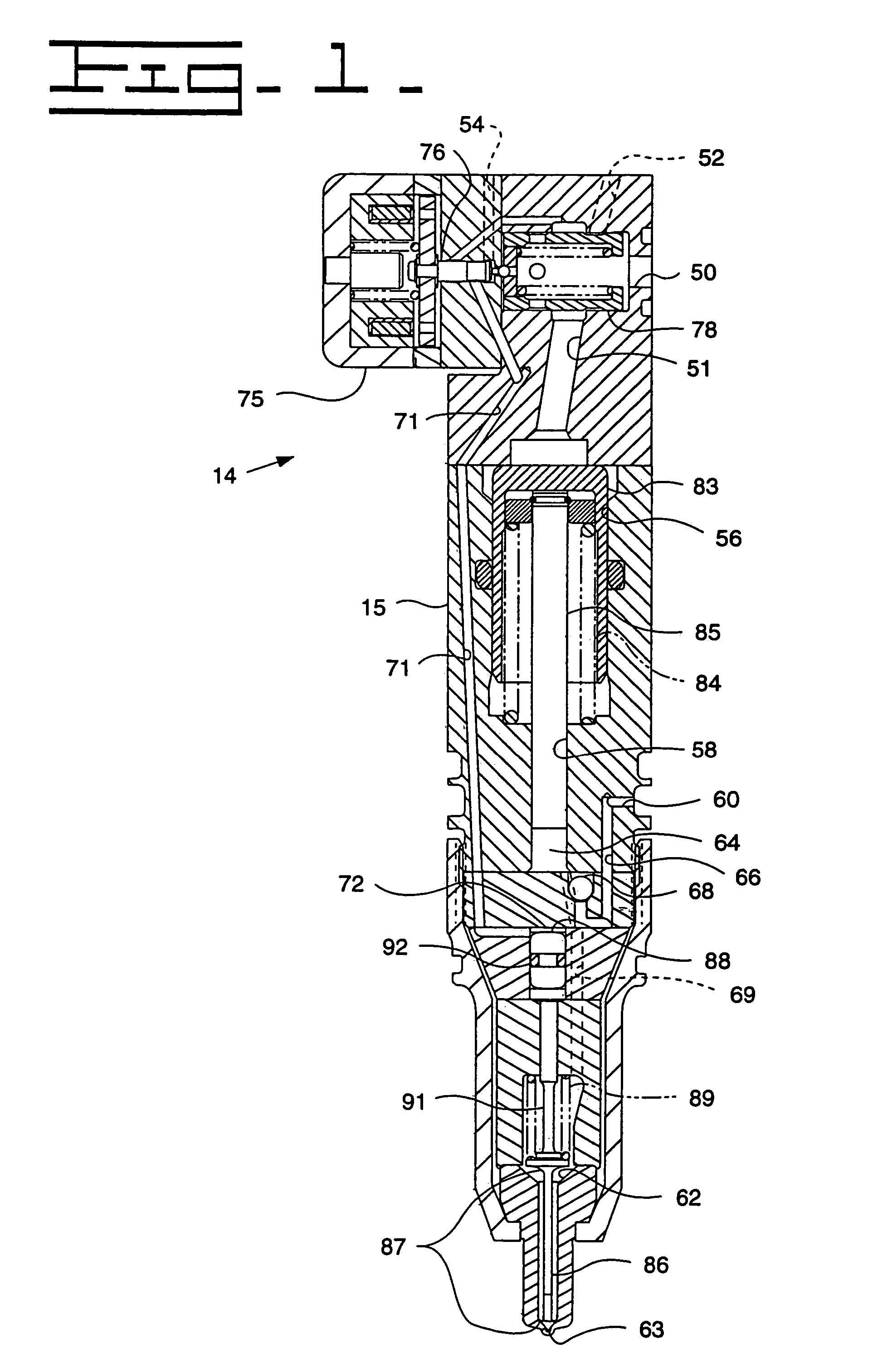

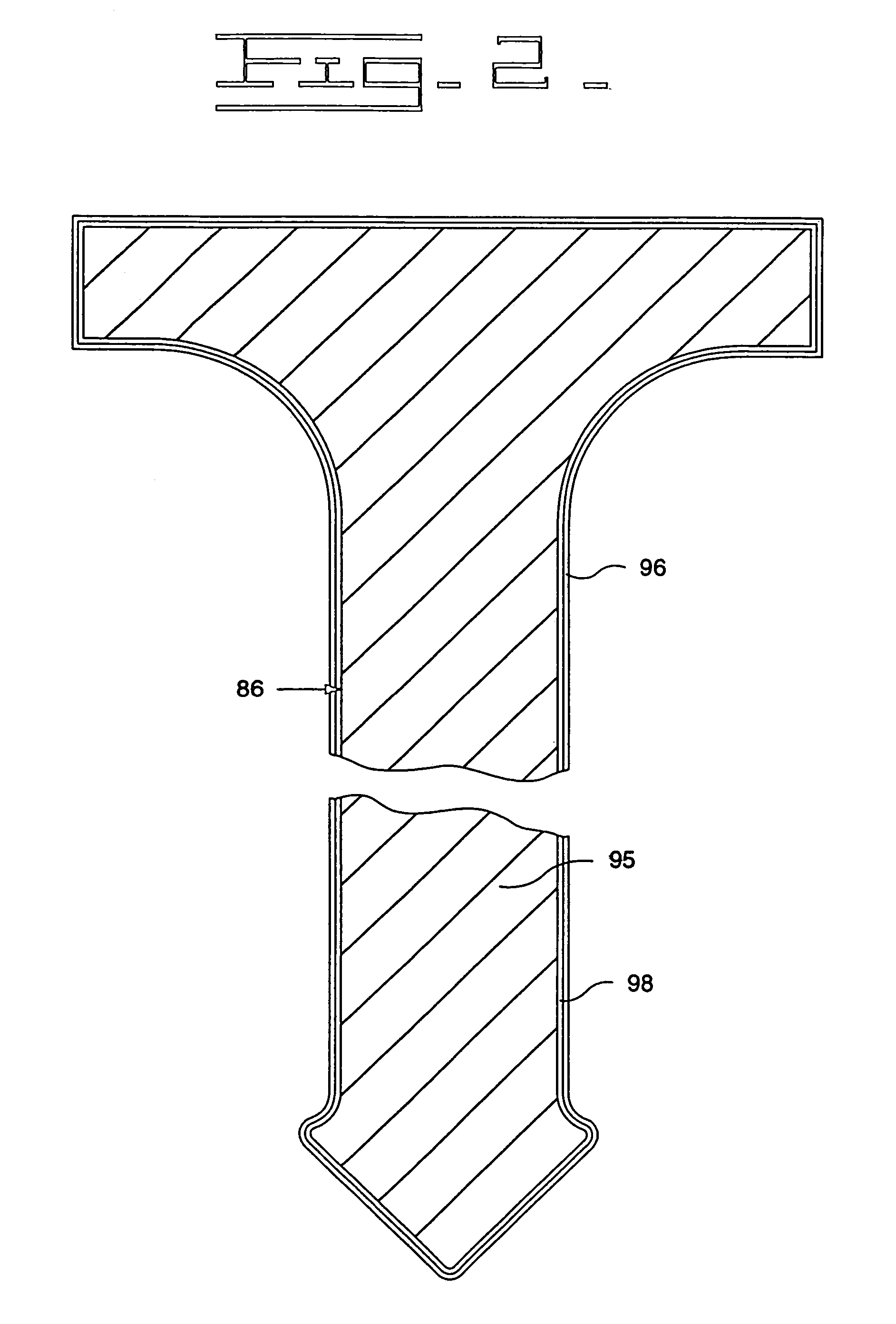

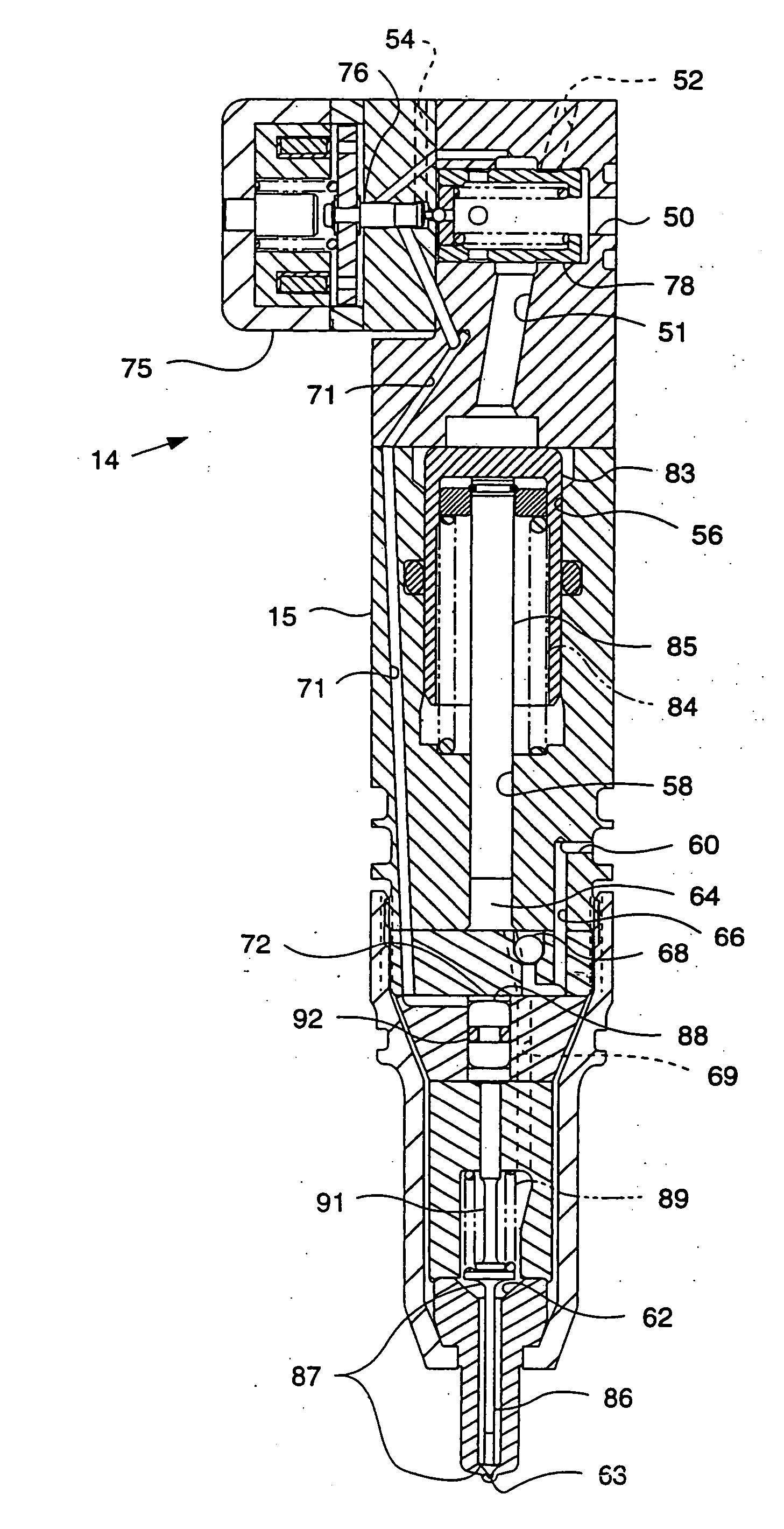

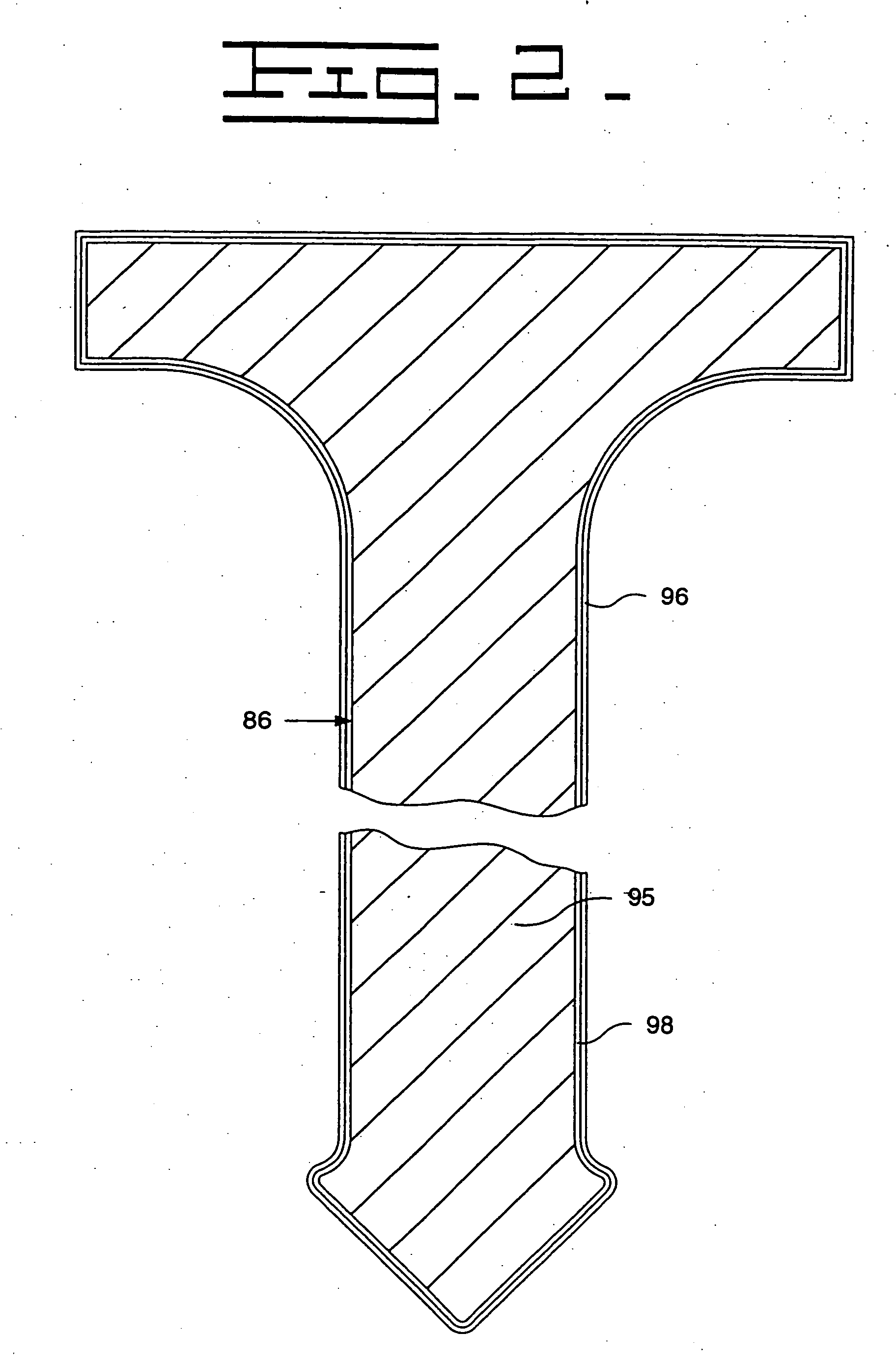

Thin film coatings for fuel injector components

A thin film coating for a low allow steel or tool steel components in a fuel injector (14), such as a fuel injector needle valve (86) is disclosed. A thin film coating (96) consists of a metal carbon material layer less than 2.0 microns thick applied to a low alloy steel substrate (95) or tool steel substrate (95) used in fuel injector components, such as the fuel injector needle valve (86) or a portion thereof. Optionally, a thin bond layer (98) of chromium is deposited between the steel substrate (95) and the primary metal carbon material coating (96). The thin film coating (96) minimizes abrasive and adhesive wear associated with the needle valve (86) and cooperating nozzle surfaces (62,63) of the fuel injector (14).

Owner:CATERPILLAR INC

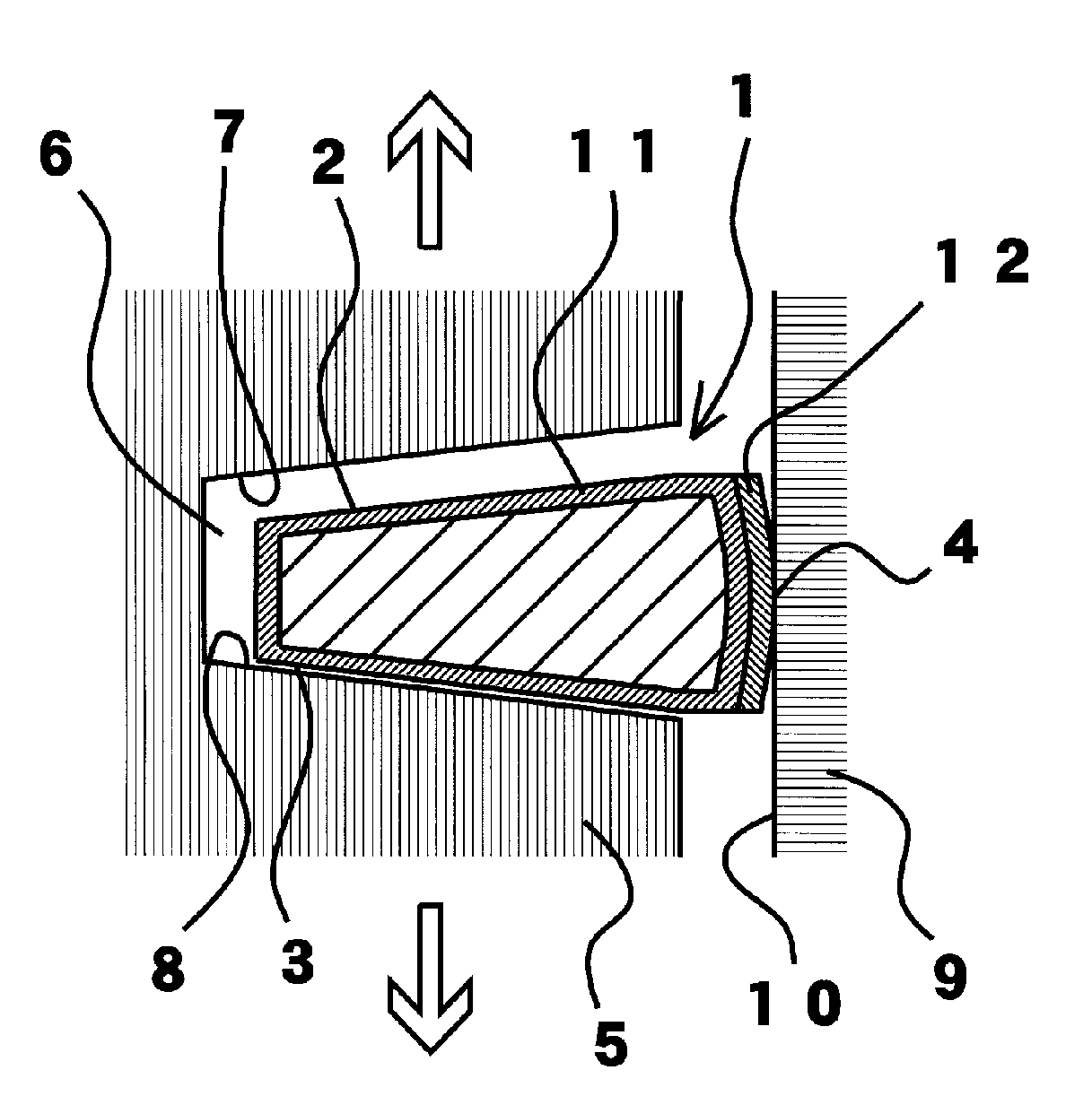

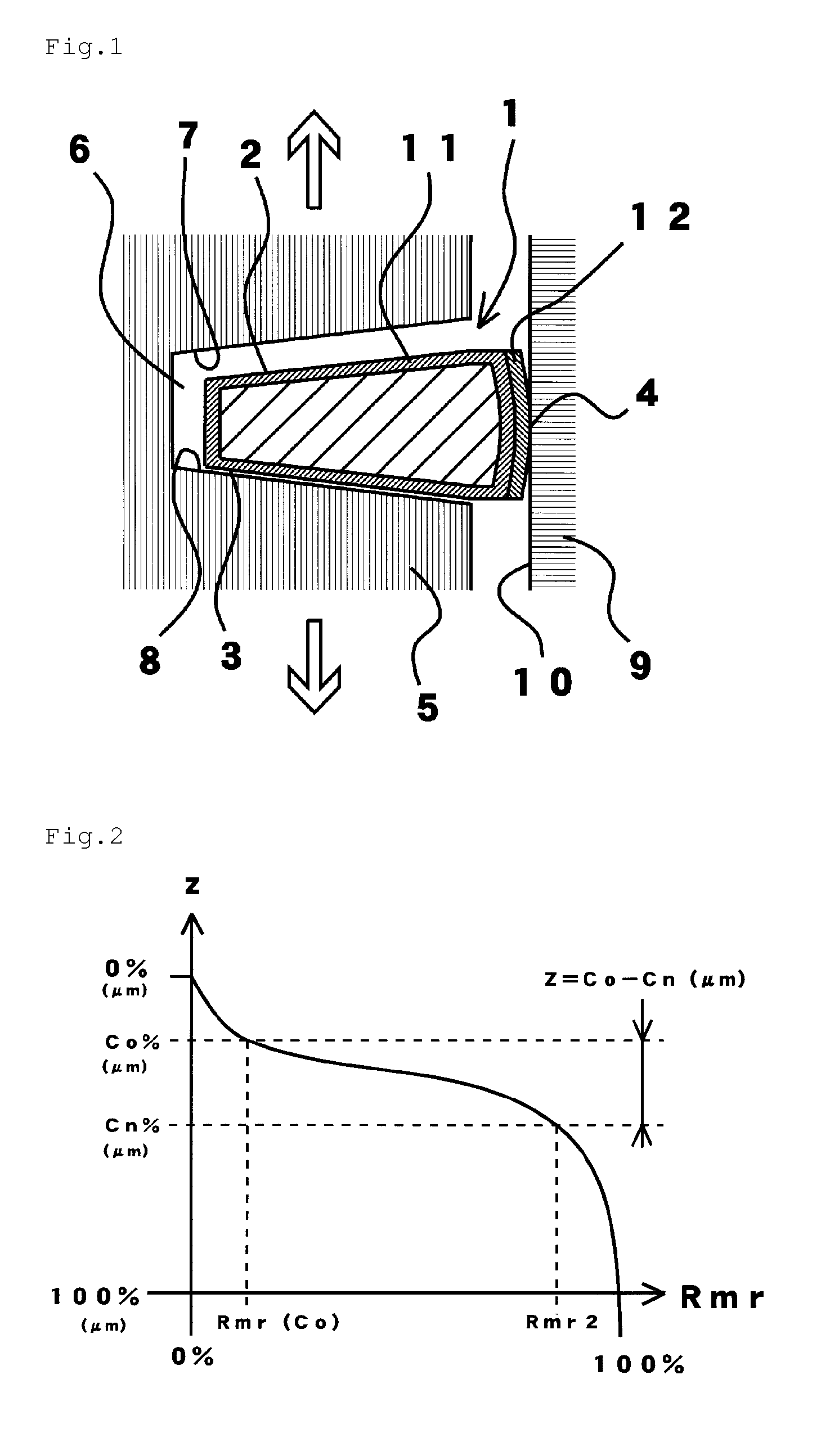

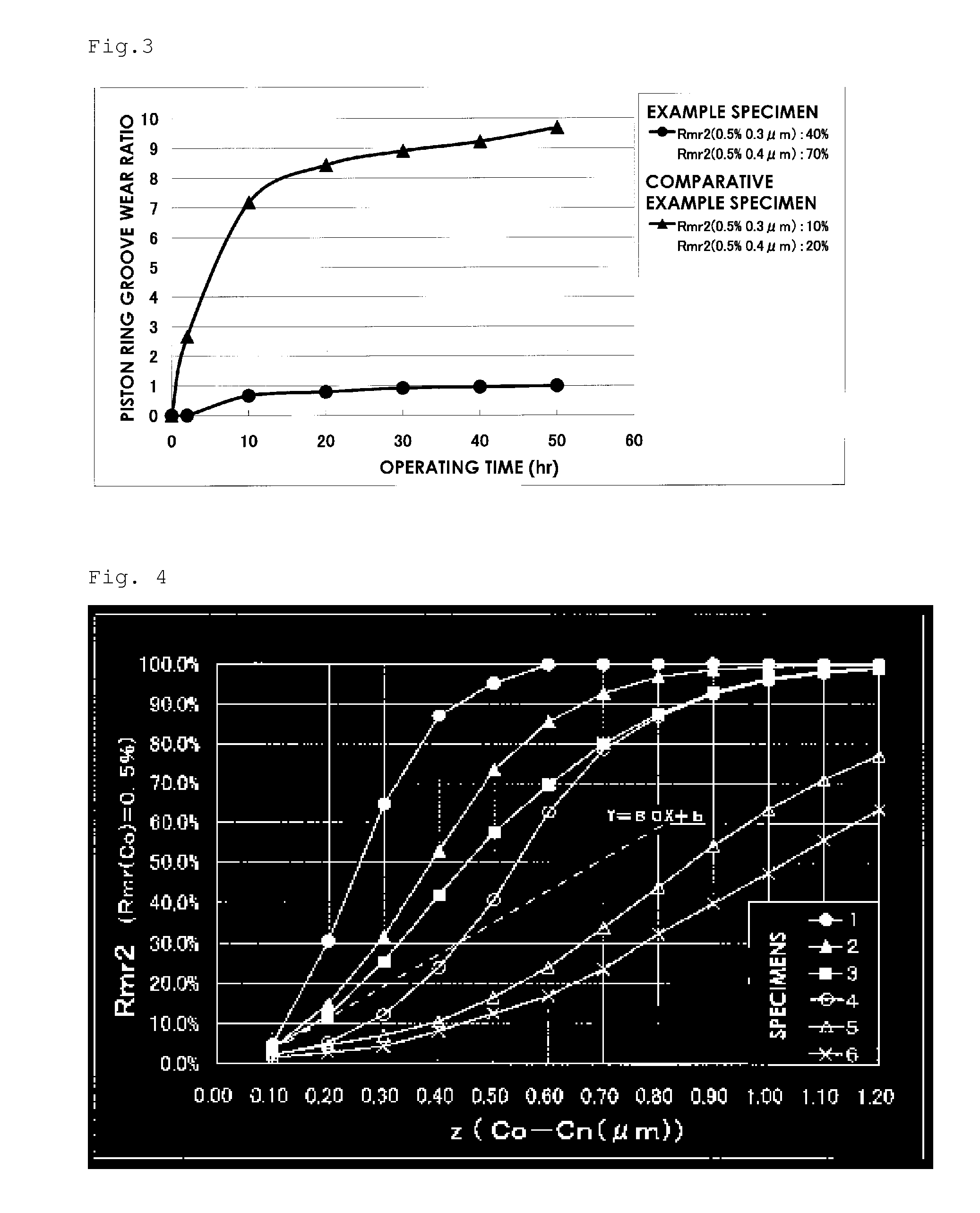

Piston ring

ActiveUS20130043659A1InhibitionReduce the amount requiredPiston ringsBraking action transmissionPiston ringDieseling

Provided is a piston ring such that it is possible to sufficiently inhibit adhesive wear when the piston ring is mounted to a piston for a diesel engine in which at least the piston ring groove in the piston is formed from steel or cast iron. Disclosed is a piston ring mounted to a piston for a diesel engine, wherein the load length ratio (Rmr2) (in accordance with JIS B0601:2001) of the top surface and bottom surface of the piston ring satisfies each of the following conditions: Rmr2 (0.5%, 0.3[mu]m)=20% and Rmr2 (0.5%, 0.4[mu]m)=40%.

Owner:NIPPON PISTONRING CO LTD

Metallic Material For Electronic Components And Method For Producing Same, And Connector Terminals, Connectors And Electronic Components Using Same

ActiveUS20150147924A1Low degreeIncreased durabilityElectrically conductive connectionsSingle bars/rods/wires/strips conductorsMetallic materialsAlloy

The present invention provides metallic materials for electronic components, having low degree of whisker formation, low adhesive wear property and high durability, and connector terminals, connectors and electronic components using such metallic materials. The metallic material for electronic components includes: a base material; a lower layer formed on the base material, the lower layer being constituted with one or two or more selected from a constituent element group A, namely, the group consisting of Ni, Cr, Mn, Fe, Co and Cu; an intermediate layer formed on the lower layer, the intermediate layer including an alloy constituted with one or two or more selected from a constituent element group B, namely, the group consisting of Ag, Au, Pt, Pd, Ru, Rh, Os and Ir, and one or two selected from a constituent element group C, namely, the group consisting of Sn and In; and an upper layer formed on the intermediate layer, the upper layer being constituted with one or two selected from a constituent element group C, namely, the group consisting of Sn and In; wherein the thickness of the lower layer is 0.05 μm or more and less than 5.00 μm; the thickness of the intermediate layer is 0.02 μm or more and less than 0.80 μm; and the thickness of the upper layer is 0.005 μm or more and less than 0.30 μm.

Owner:JX NIPPON MINING& METALS CORP

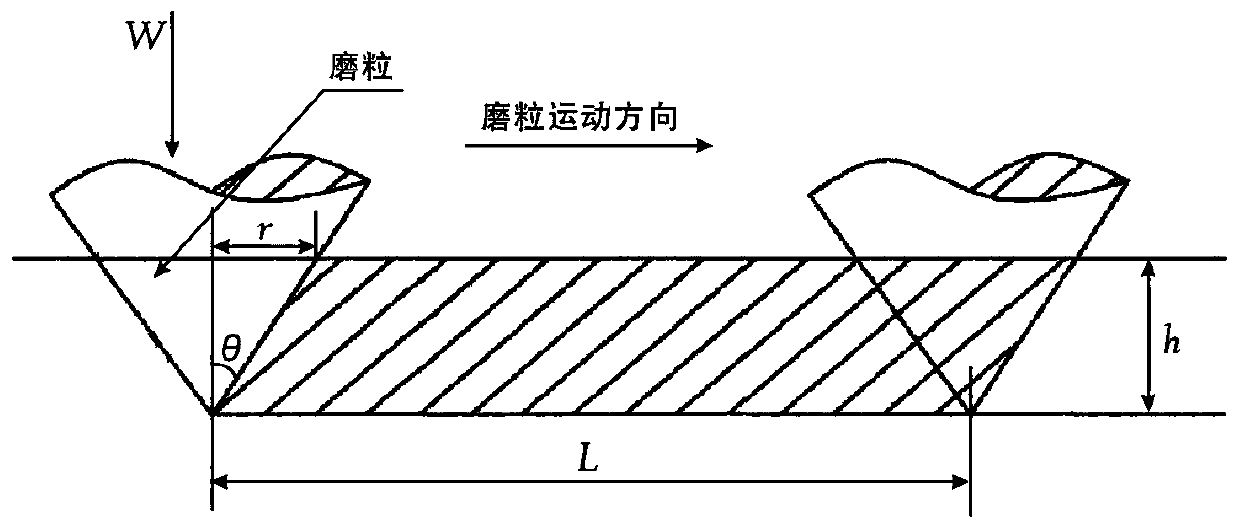

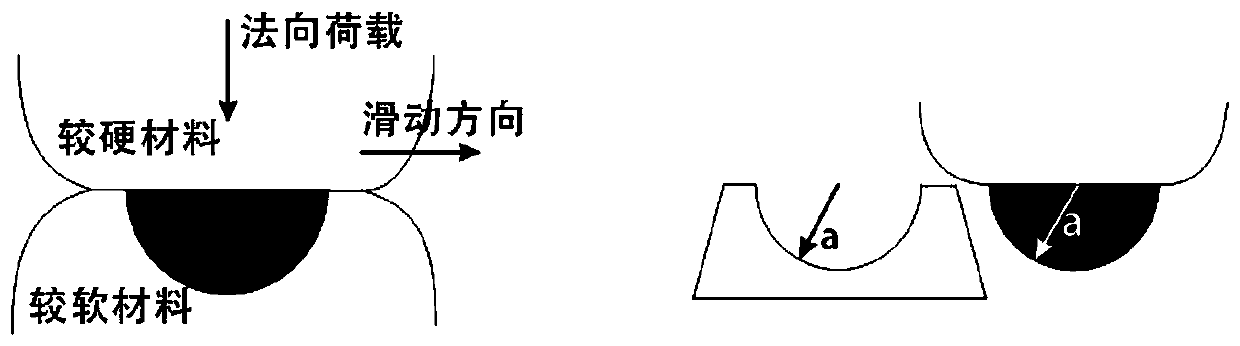

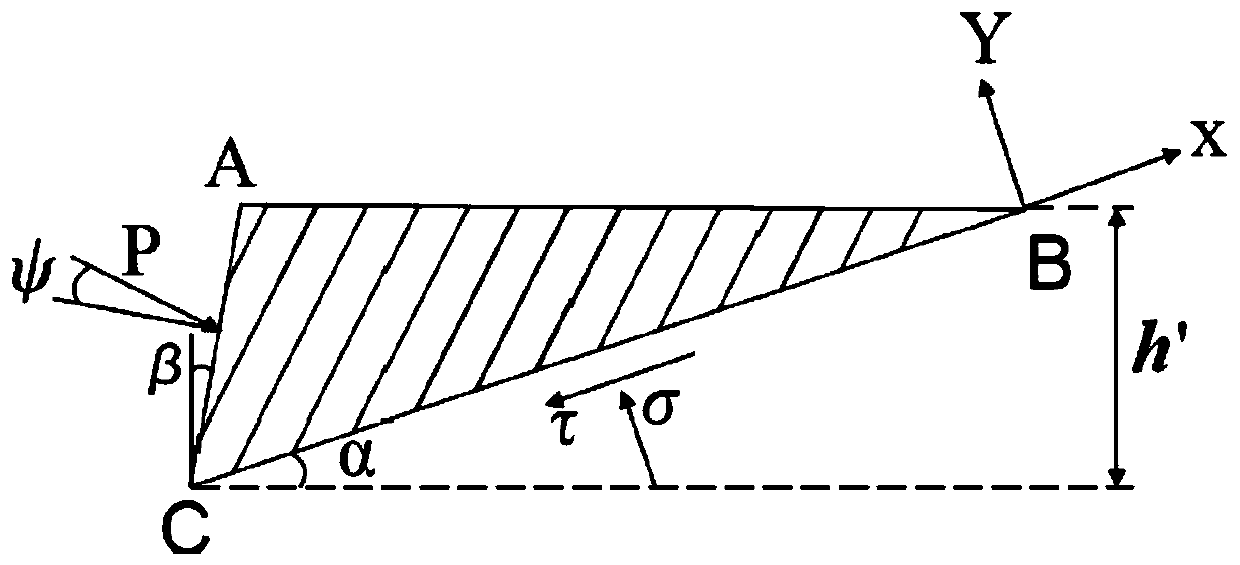

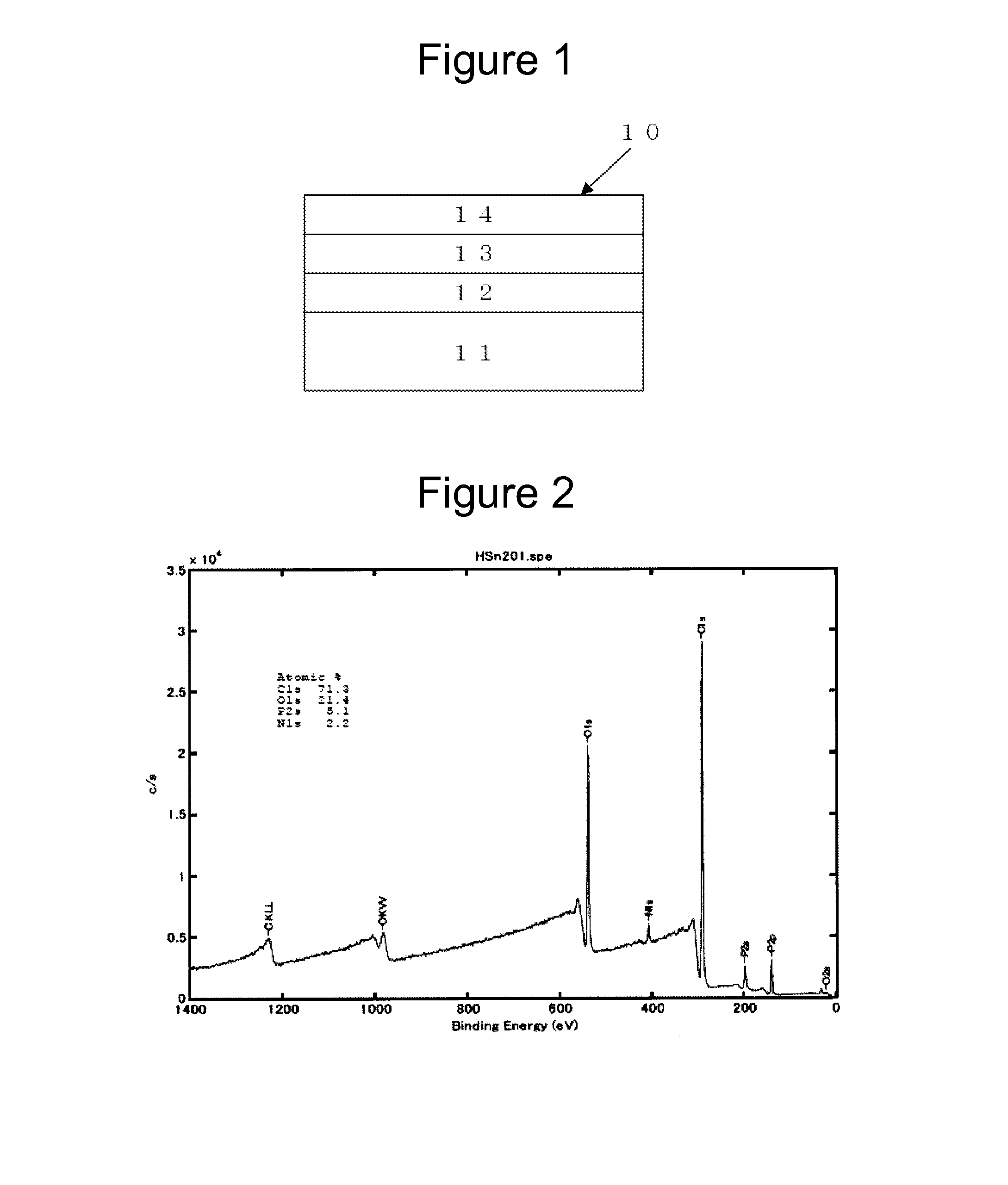

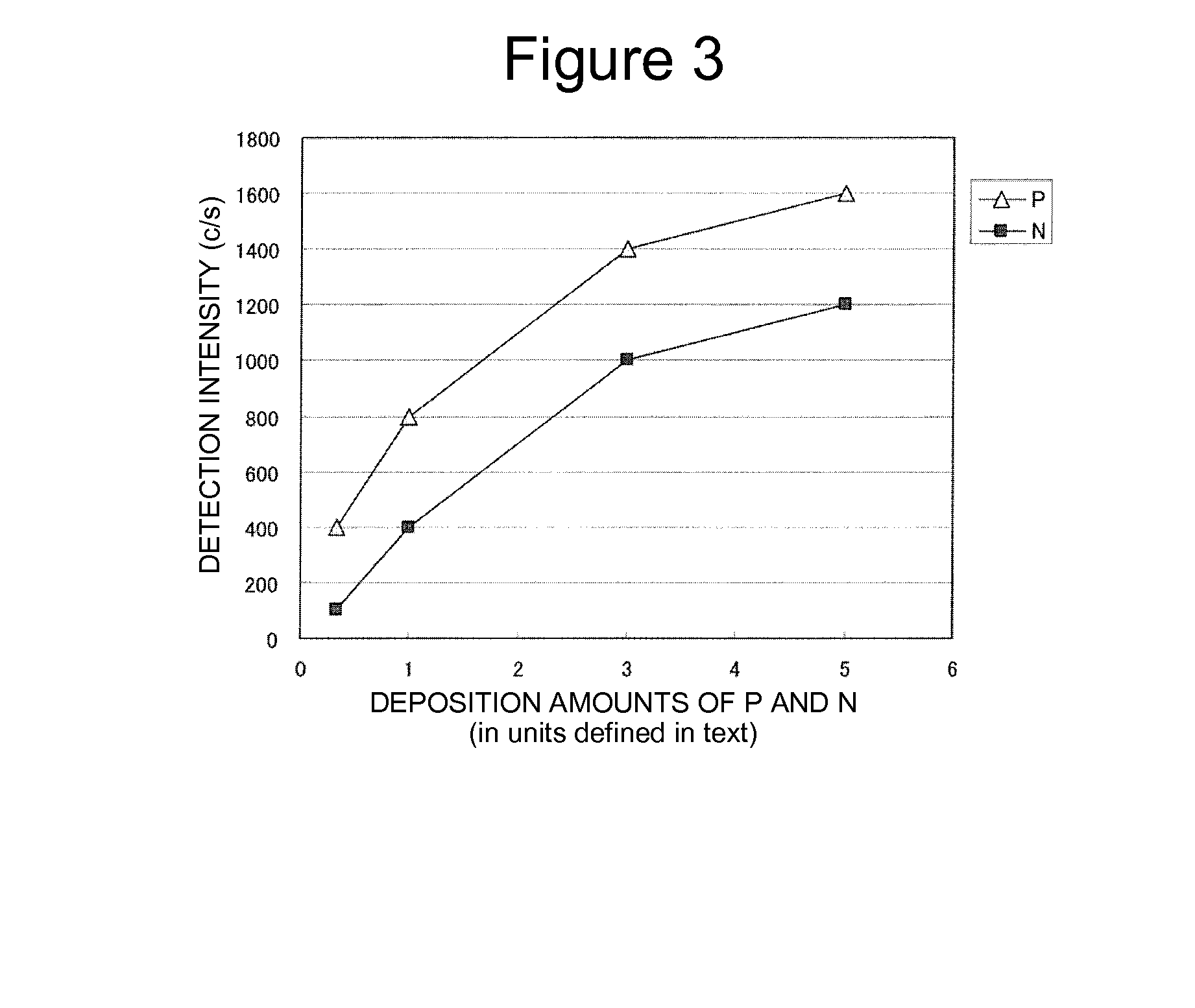

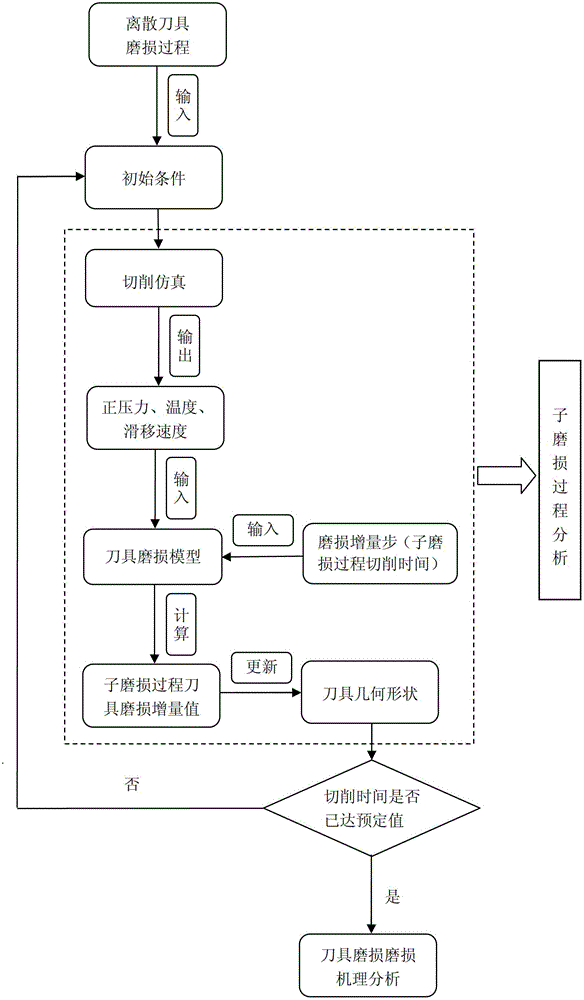

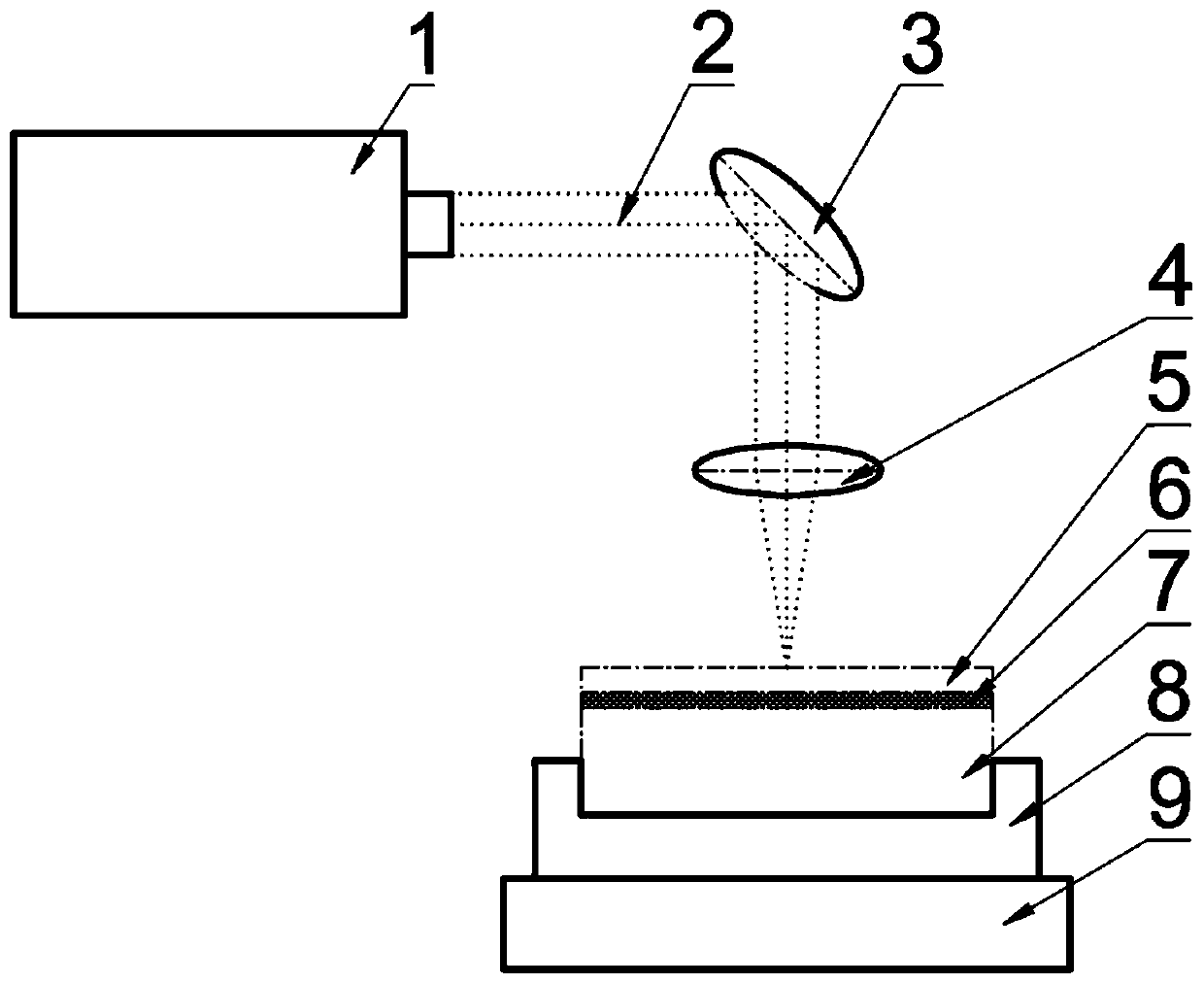

Cutter wear mechanism analysis method

InactiveCN102975083ALow costWide applicabilityMeasurement/indication equipmentsEngineeringAnalysis method

The invention discloses a cutter wear mechanism analysis method, belonging to the technical field of metal cutting machining. The analysis of a cutter wear mechanism is realized by building a novel cutter wear model and by means of a finite element method. The cutter wear model is as shown by an accompanying drawing, wherein the rear cutter surface wear value VB of a cutter can be measured through an experiment, the wear rate of the cutter is further obtained, other variables can be obtained through cutting simulation, and finally the corresponding numerical values of abrasive wear, adhesive wear and diffusive wear can be measured through a multiple regression method. Since the finite element simulation method is used for analyzing the wear mechanism of the cutter, the cutter wear mechanism analysis method has the advantages that the method is simple and feasible and the cost is lower.

Owner:ZHEJIANG OCEAN UNIV

Metallic Material for Electronic Components and Method for Producing Same, and Connector Terminals, Connectors and Electronic Components Using Same

ActiveUS20150213918A1Low degreeIncreased durabilityNon-insulated conductorsInsulating substrate metal adhesion improvementMetallic materialsOptoelectronics

The present invention provides metallic materials for electronic components, having low degree of whisker formation, low adhesive wear property and high durability, and connector terminals, connectors and electronic components using such metallic materials. The metallic material for electronic components includes: a base material; a lower layer formed on the base material, the lower layer being constituted with one or two or more selected from a constituent element group A, namely, the group consisting of Ni, Cr, Mn, Fe, Co and Cu; an intermediate layer formed on the lower layer, the intermediate layer being constituted with one or two or more selected from the constituent element group A and one or two selected from a constituent element group B, namely, the group consisting of Sn and In; and an upper layer formed on the intermediate layer, the upper layer being constituted with one or two selected from the constituent element group B and one or two or more selected from a constituent element group C, namely, the group consisting of Ag, Au, Pt, Pd, Ru, Rh, Os and Ir; wherein the thickness of the lower layer is 0.05 μm or more and less than 5.00 μm; the thickness of the intermediate layer is 0.01 μm or more and less than 0.40 μm; and the thickness of the upper layer is 0.02 μm or more and less than 1.00 μm.

Owner:JX NIPPON MINING& METALS CORP

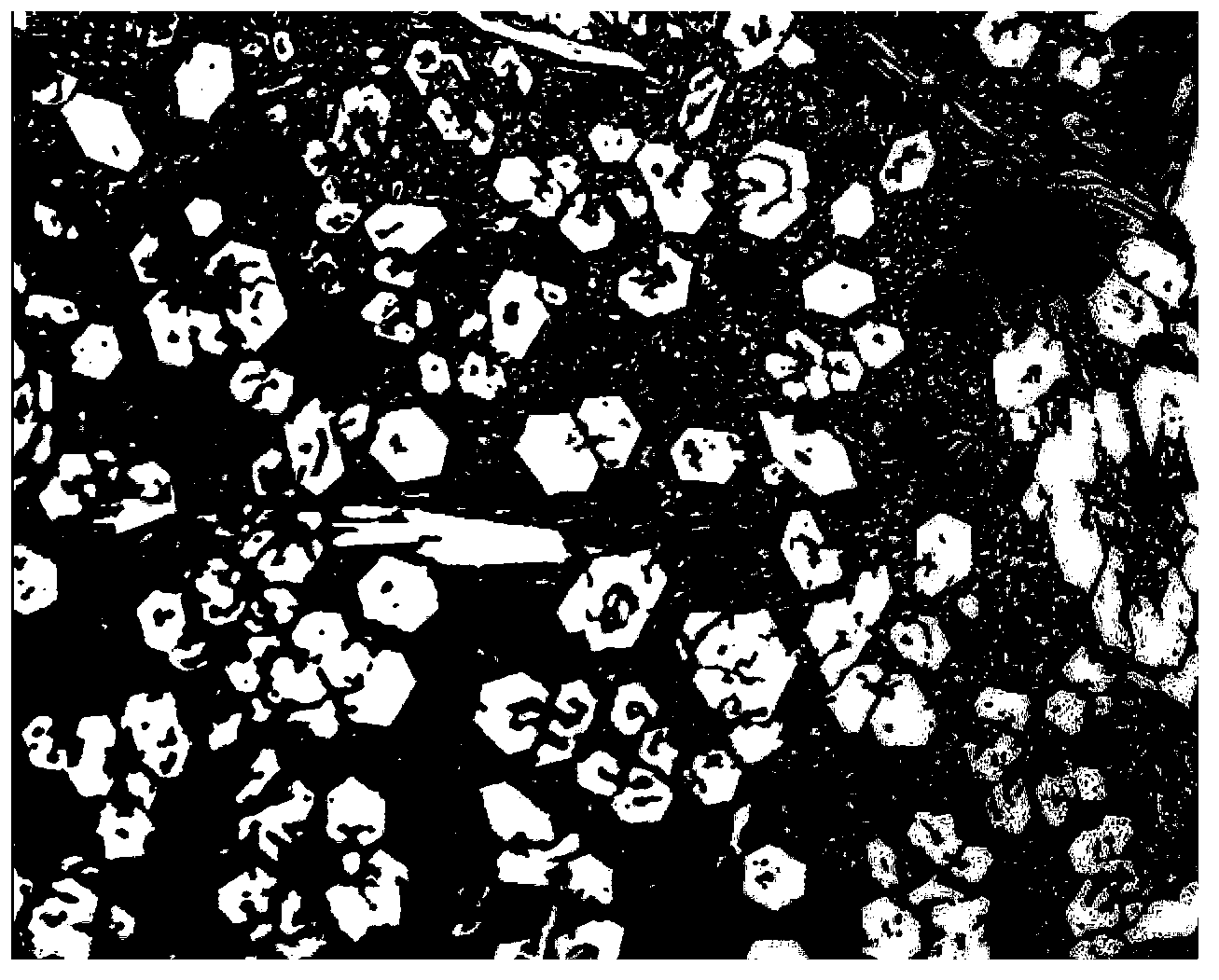

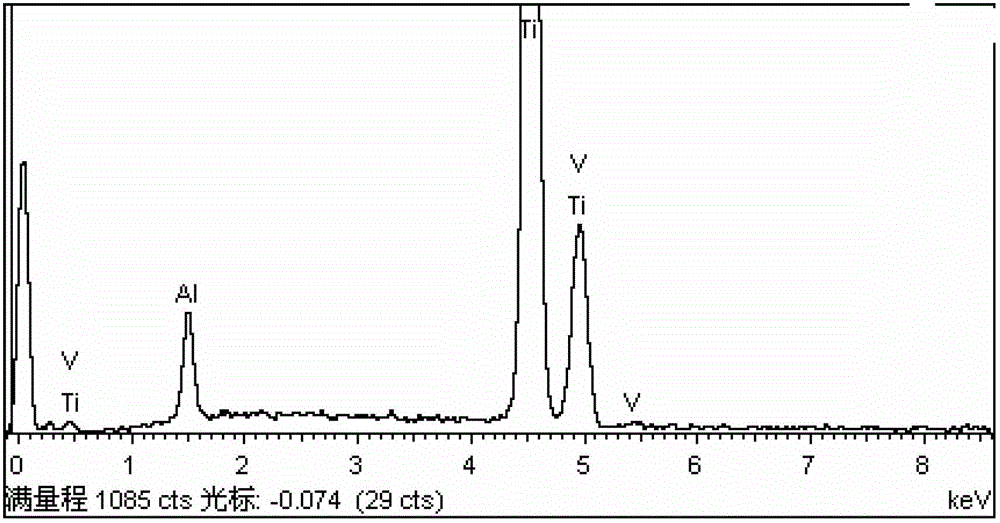

Nitrogen alloyed stainless steel and process

InactiveUS8182617B2Improved kineticsIncrease resistanceSolid state diffusion coatingMetal layered productsParticulatesNiobium

The present invention comprises the nitrogen alloying of stainless steel with a gaseous nitrogen compound such as nitrogen gas (N2), or ammonia (NH3) at high temperature wherein the reaction pressure is lowered. A base powder with properties similar to those of a martensitic stainless steel is prepared from a molten metal with the subsequent incorporation of selective additives such as cobalt, chromium, boron, copper, vanadium, niobium and mixtures thereof to improve high temperature resistance to scuffing and adhesive wear. The molten mixture is then atomized by water- or air-atomization to yield a base powder which is mixed with nitrogen or ammonia gas at various pressures in a static or fluidized bed to provide a nitrogen alloyed particulate, i.e., a nitrided particulate alloy. The powder is heated in a hot isostatic press under vacuum with argon gas at reduced pressure and later cooled to ambient temperature.

Owner:MAGNA TECH PM LABS

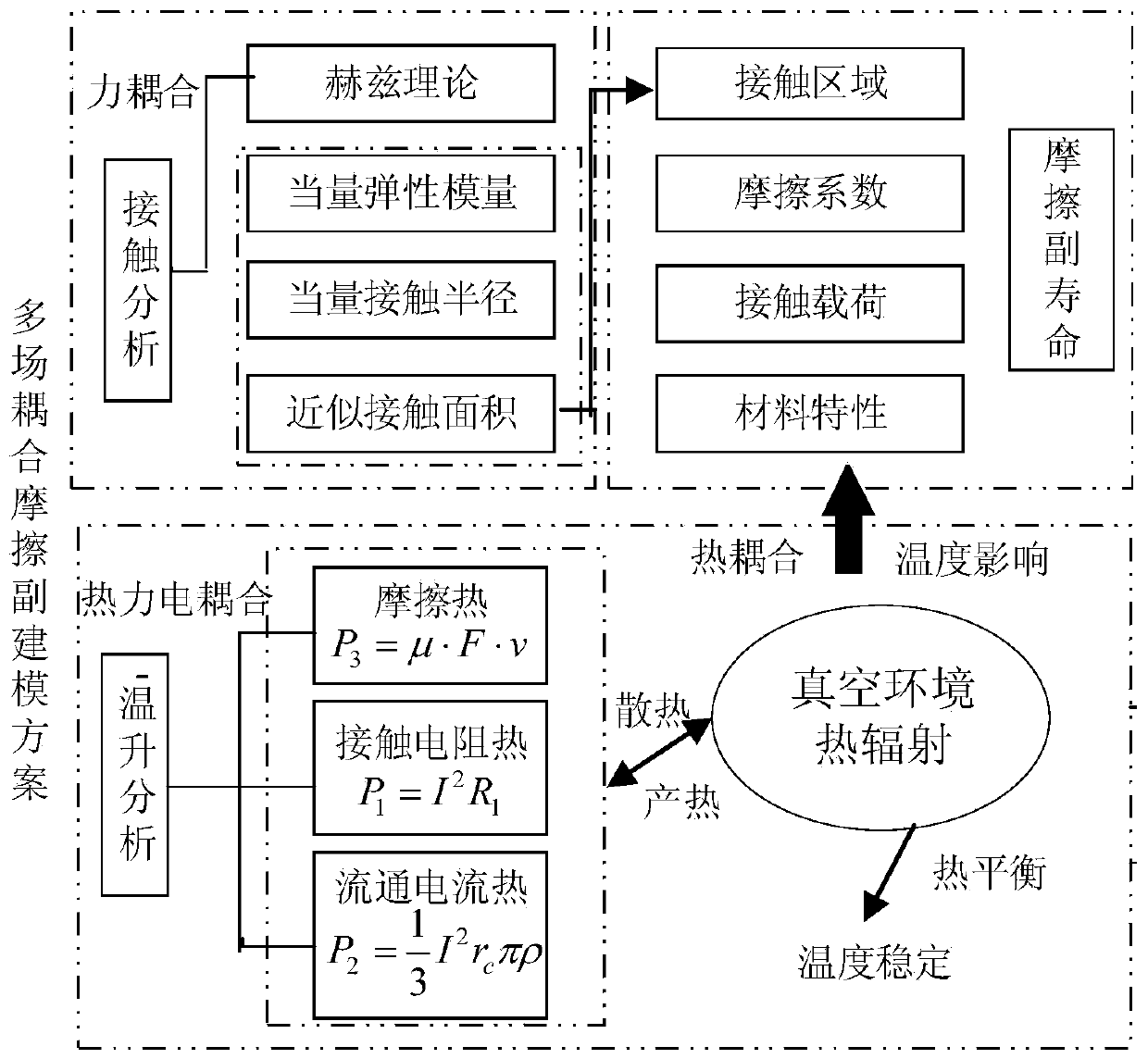

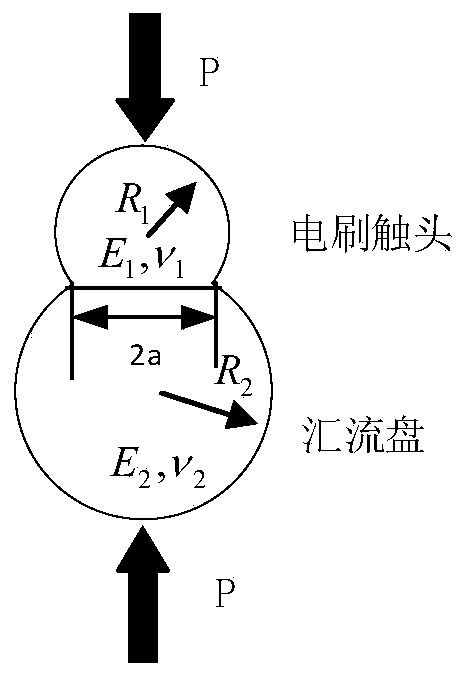

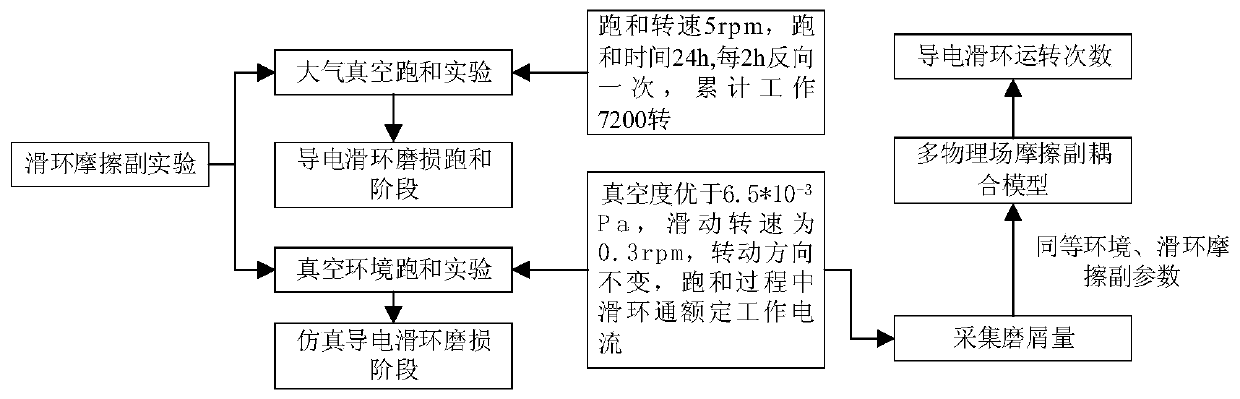

Multi-field coupled spatial conductive slip ring wear modeling and life prediction method

ActiveCN110287515AFor easy referenceAvoid high feesSustainable transportationDesign optimisation/simulationMulti fieldSimulation

The invention provides a modeling analysis and service life prediction method for friction wear of a spatial conductive slip ring, and aims to overcome the problems that the existing current-carrying friction wear is difficult to quantitatively evaluate and the service life is difficult to predict. The frictional wear analysis method comprises the following steps: calculating the abrasive dust amount, the contact area and the temperature change in the running process of a friction pair according to an adhesive wear theoretical calculation method, a Hertz theory and a heat transfer theory, and solving the coupling relationship of the mutual influence among thermoelectricity; carrying out quantitative analysis on the operation failure process of the conductive slip ring, and establishing a corresponding model of the abrasive dust amount and the number of running circles under different environment and condition parameters, so that the running life of the conductive slip ring is predicted, and technical and data support is provided for service life evaluation of the slip ring in the actual machining process.

Owner:SHANGHAI AEROSPACE EQUIP MFG GENERAL FACTORY

Thin film coating for fuel injector components

A thin film coating for a low allow steel or tool steel components in a fuel injector (14), such as a fuel injector needle valve (86) is disclosed. A thin film coating (96) consists of a metal carbon material layer less than 2.0 microns thick applied to a low alloy steel substrate (95) or tool steel substrate (95) used in fuel injector components, such as the fuel injector needle valve (86) or a portion thereof. Optionally, a thin bond layer (98) of chromium is deposited between the steel substrate (95) and the primary metal carbon material coating (96). The thin film coating (96) minimizes abrasive and adhesive wear associated with the needle valve (86) and cooperating nozzle surfaces (62,63) of the fuel injector (14).

Owner:CATERPILLAR INC

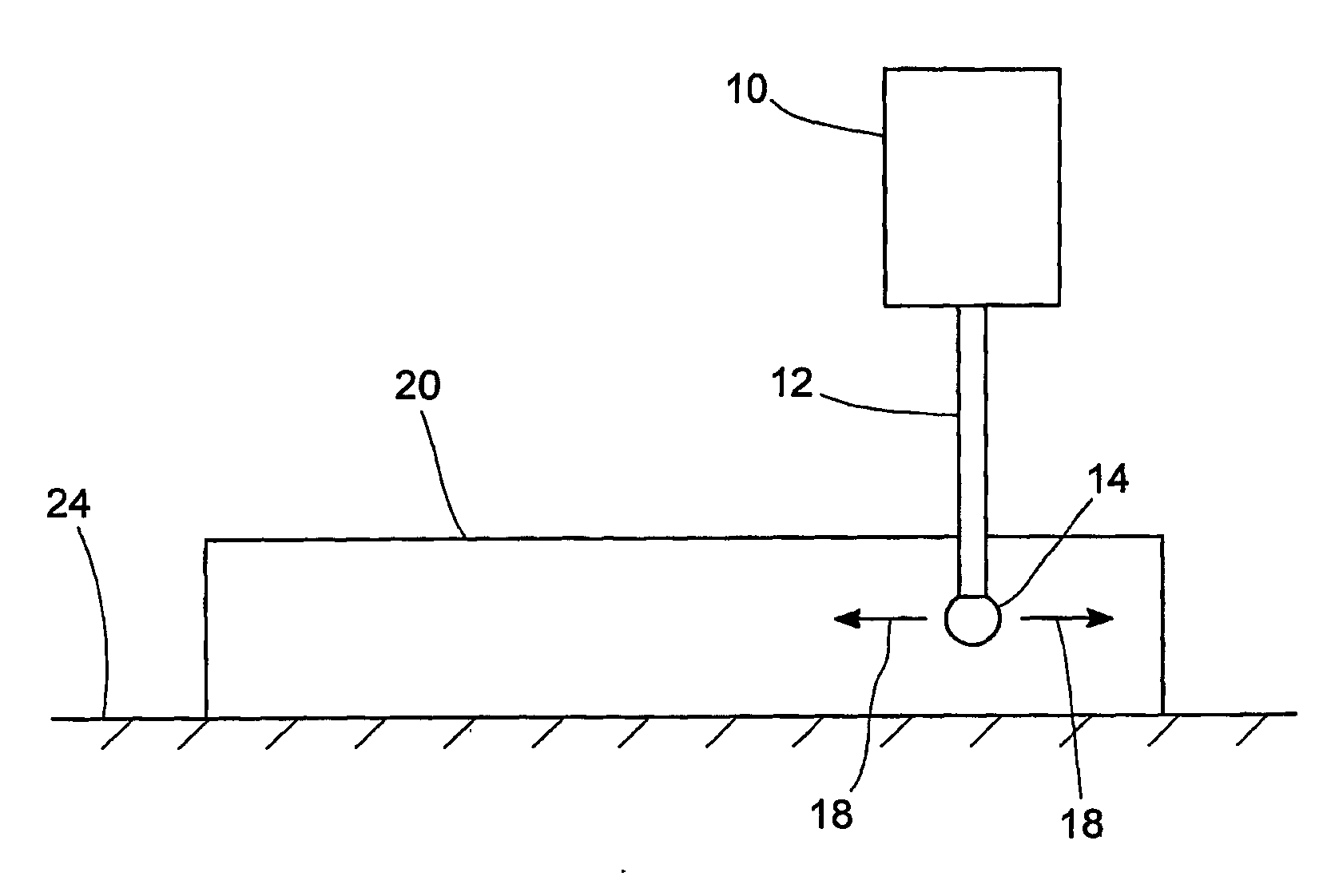

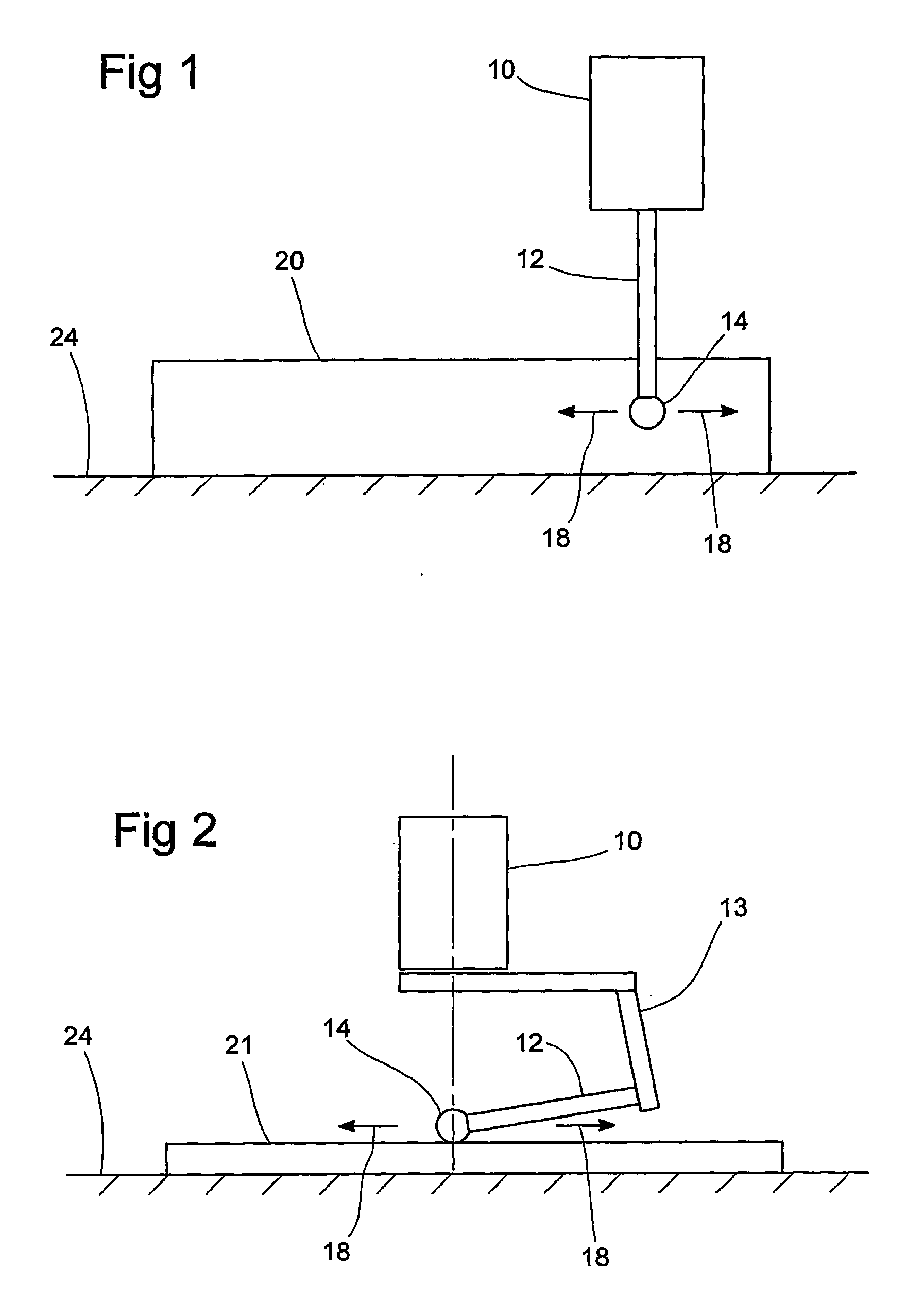

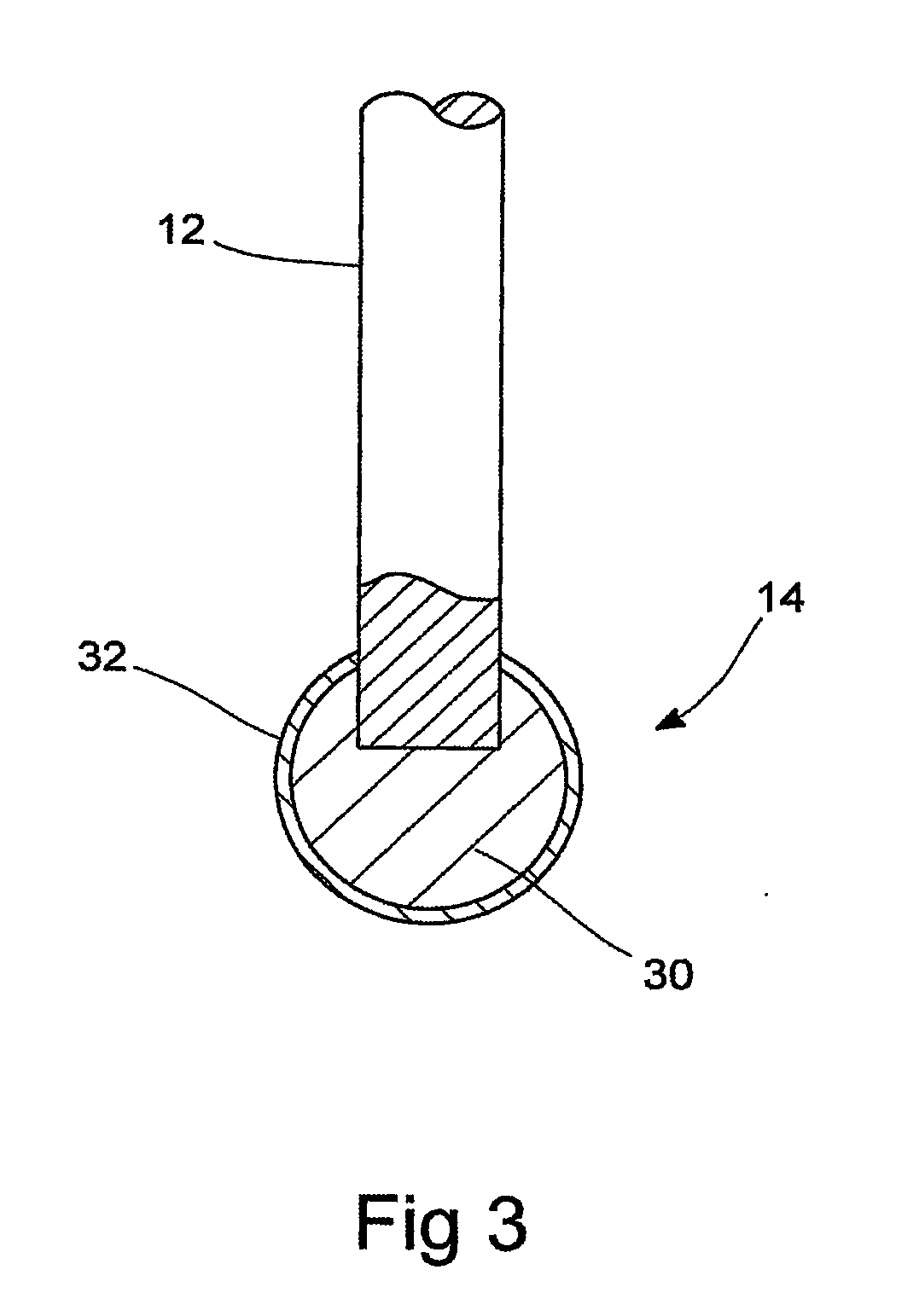

Stylus tip for workpiece contacting probe

InactiveUS20070137057A1Affects accuracy of sphericityMechanical measuring arrangementsPoint coordinate measurementsAdhesive wearMaterials science

A stylus 12 for a workpiece contacting probe has a tip 14 which comprises a self-lubricating or low friction material, in order to inhibit debris generation or adhesive wear (pick up) as the tip scans a workpiece surface. Various materials are described, including composites having a solid state lubricant incorporated into a dimensionally stable microstructure. The tip 14 may be made entirely of such a composite, or may have a substrate 30 with a coating 32 of the self-lubricating or low friction material.

Owner:RENISHAW PLC

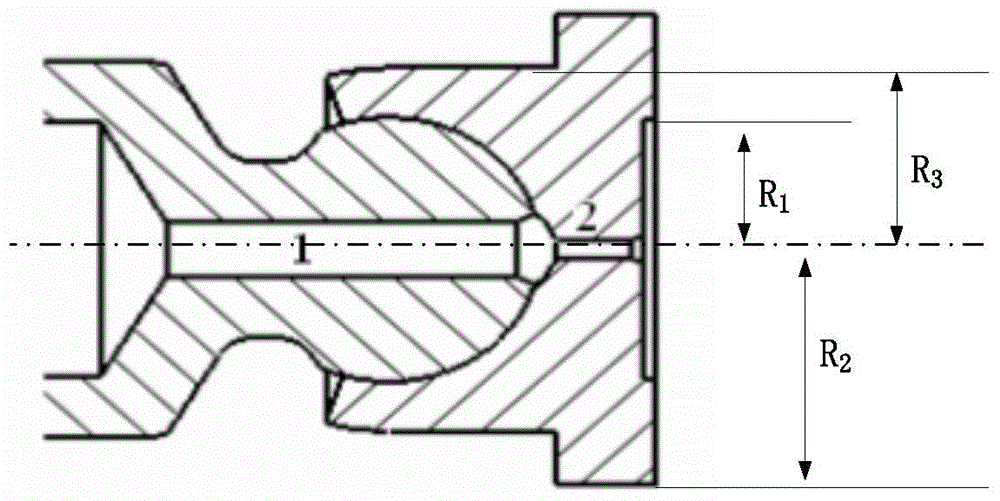

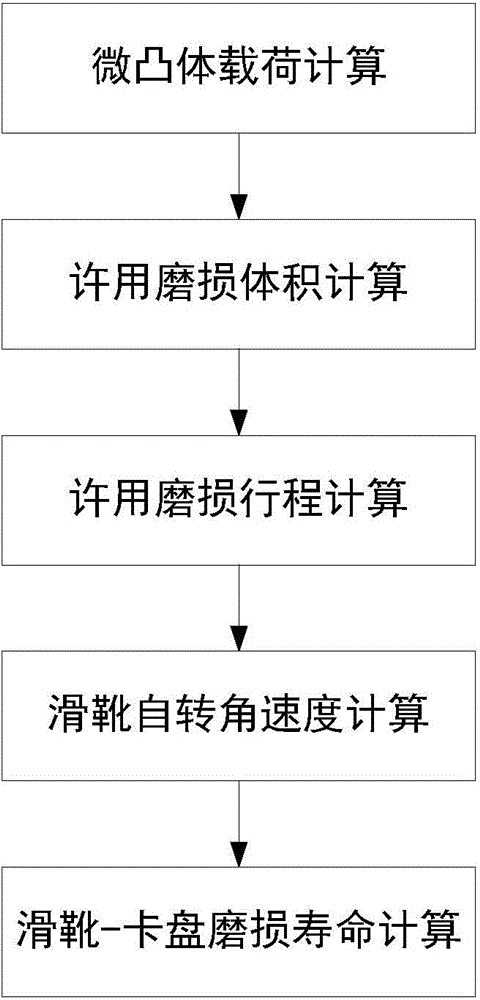

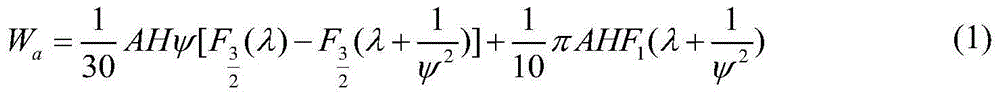

Method for calculating sliding shoe-chuck wear life of plunger pump

ActiveCN104156598AWear life determinationImprove engineering applicabilitySpecial data processing applicationsSpinsEngineering

The invention provides a method for calculating the sliding shoe-chuck wear life of a plunger pump. The method for calculating the sliding shoe-chuck wear life of the plunger pump includes the following steps of firstly, micro-bulge load calculation, secondly, allowable wear volume calculation, thirdly, allowable wear stroke calculation, fourthly, sliding shoe spin velocity calculation and fifthly, sliding shoe-chuck wear life calculation. The method can be directly applied to products, the sliding shoe spin velocity is determined by establishing the relationship between liquid frictional work and kinetic energy generated by rotating a sliding shoe relative to a chuck, the sliding shoe-chuck wear life of the plunger pump is determined in combination with an Archard adhesive wear model and through theoretical calculation, and the method has the advantage of being high in engineering adaptability.

Owner:BEIHANG UNIV

Surface treatment method for alloy steel W18Cr4V mold parts

InactiveCN105525253ASurface technology improvementsSolid state diffusion coatingFurnace temperatureDecomposition

The invention discloses a surface technology improvement for alloy steel W18Cr4V mold parts. The surface technology improvement relates to that gas nitriding treatment performed on surfaces of mold parts includes four steps, namely four processes of drawing up, degassing, heating and cooling. In the degassing process of the surface gas nitriding to alloy steel W18Cr4V mold parts, the proportions of ammonia gas and a gas carrier (RX) are 50%, respectively. In the heating process, a nitriding temperature is within a range of 400-500 DEG C and is kept for 5 hours, and the decomposition of the ammonia gas is 35-40%; a working temperature of a heating furnace is not high and usually not higher than 700 DEG C. However, an extremely high requirement is made to the furnace temperature uniformity of the furnace; after the gas nitriding treatment, a nitriding depth ranges from 0.05 to 0.07mm and the hardness ranges from 900 to 1200HV. After the surface technology for alloy steel W18Cr4V mold parts is improved, the surface hardness, abrasion resistance and anti-scuffing property, and especially the adhesive wear resistance (anti-seizing capability) of the parts can be improved; the thermal stability is improved; the corrosion resistance of non-stainless steel is improved, and the fatigue resistance of the same is improved, resulting in low fatigue notch sensibility.

Owner:WUXI HUAYE IRON & STEEL

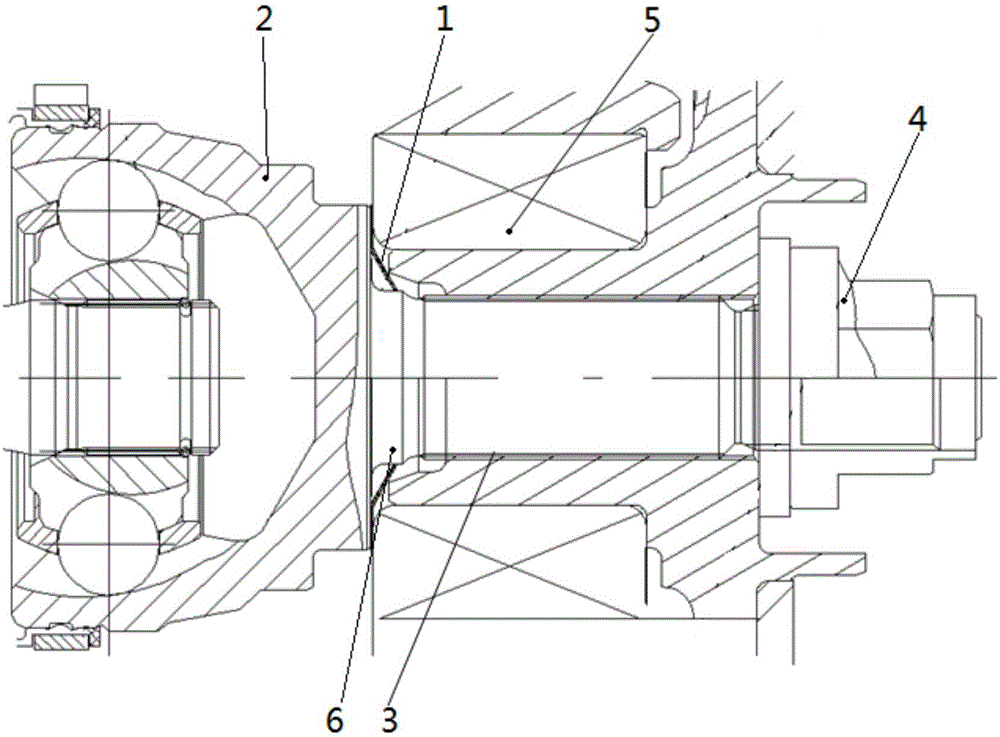

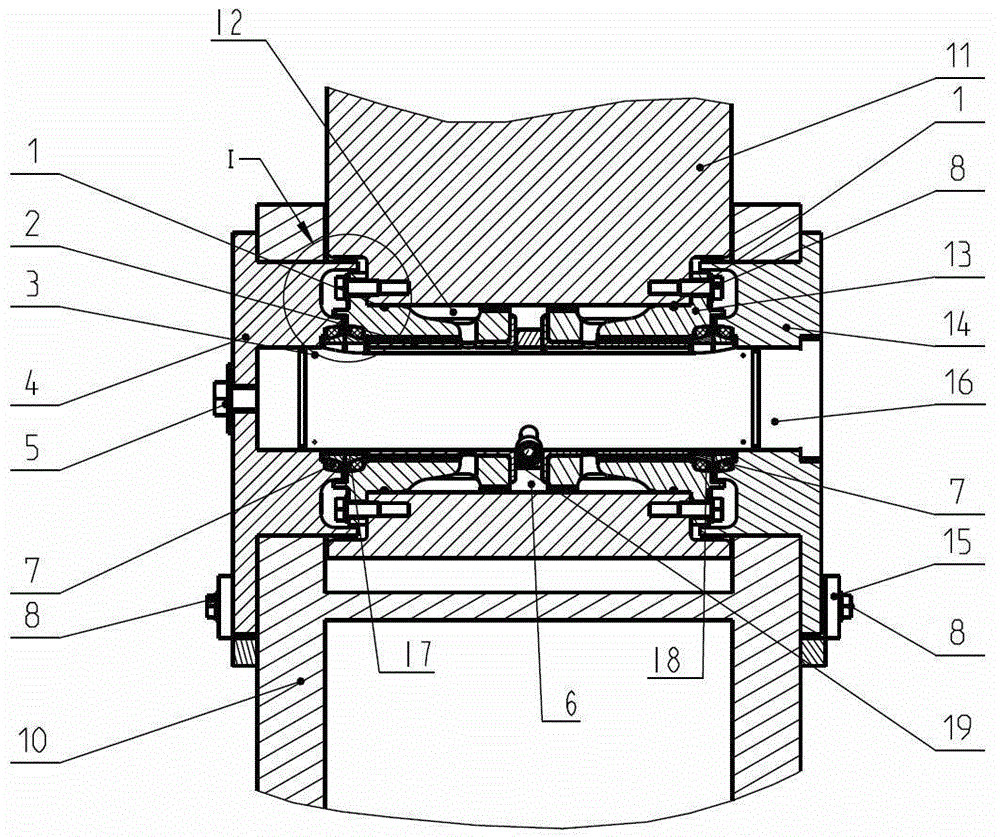

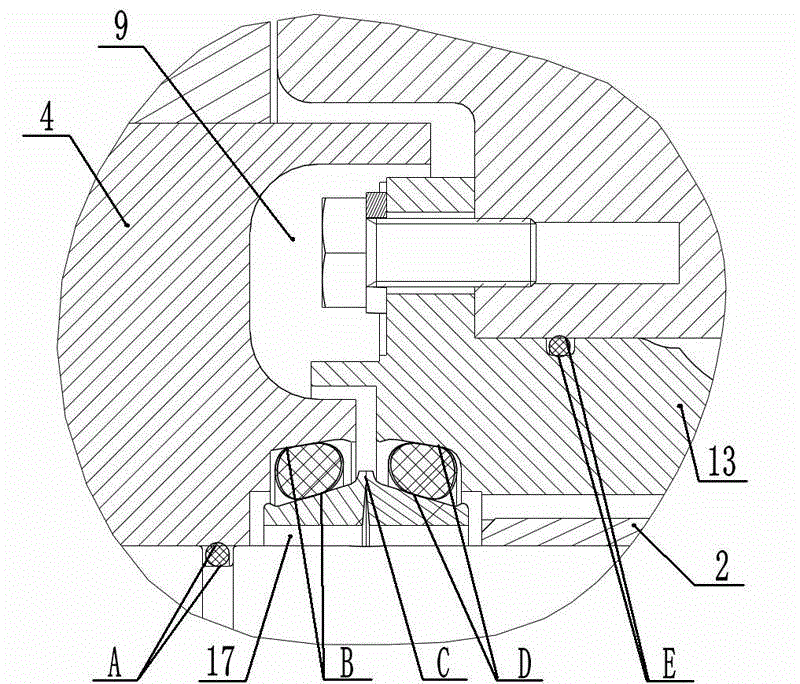

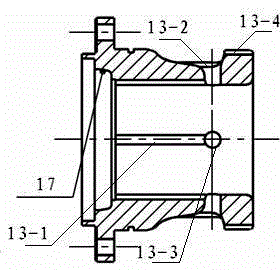

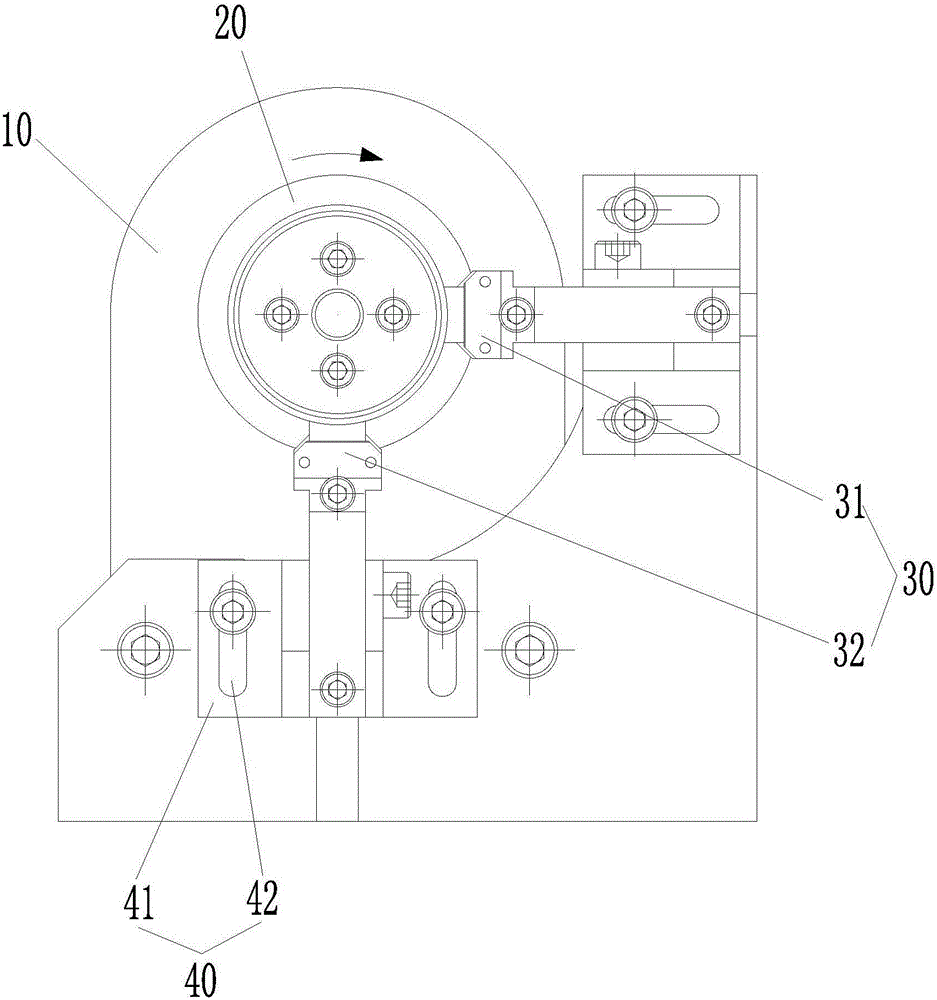

Working device articulating mechanism

ActiveCN104454957AEasy accessReduce Adhesive WearBearing componentsPivotal connectionsParticulatesMechanical engineering

The invention provides a working device articulating mechanism, and relates to the technical field of construction machinery. The articulating mechanism comprises a bearing bush, a shaft arranged in the bearing bush in a penetrating way, and a dustproof ring, wherein a lining sleeves the bearing bush, and the two ends of the shaft respectively sleeve left and right floating seal seats; a first floating oil seal cavity is arranged on a surface, in contact with the left floating seal seat, of the lining, and a second floating oil seal cavity is arranged on a surface, in contact with the right floating seal seat, of the lining; the first and second floating oil seal cavities are communicated with the shaft, and a floating oil seal is arranged in each floating oil seal cavity. Compared with the prior art, the floating oil seals are respectively arranged on the inner end surfaces of the floating seal seats and in the floating oil seal cavities on the lining, so that a static seal is formed; when the floating oil seals contact with each other and rotate, an end surface dynamic seal is formed, and thus small particulate matters can not enter a part between the shaft and a shaft sleeve easily, and the dustproof effect is very good, and therefore, the adhesive wear and the abrasive wear of bearings can be reduced, and the reliability of a sliding bearing mechanism in work is improved.

Owner:LIUGONG CHANGZHOU MACHINERY +2

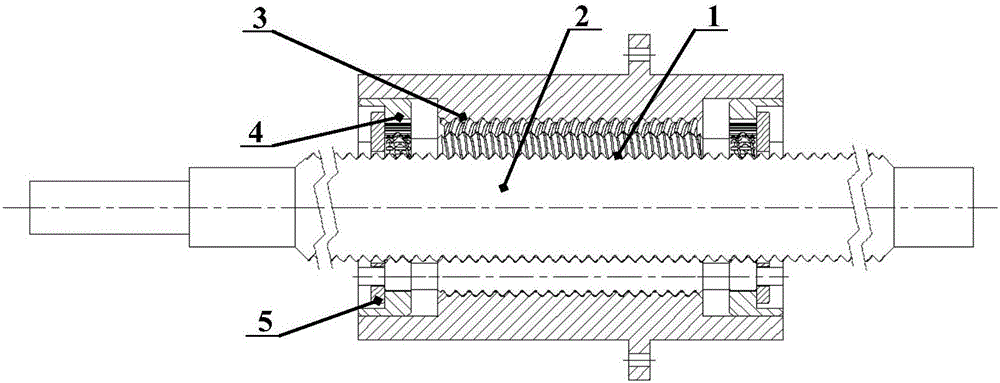

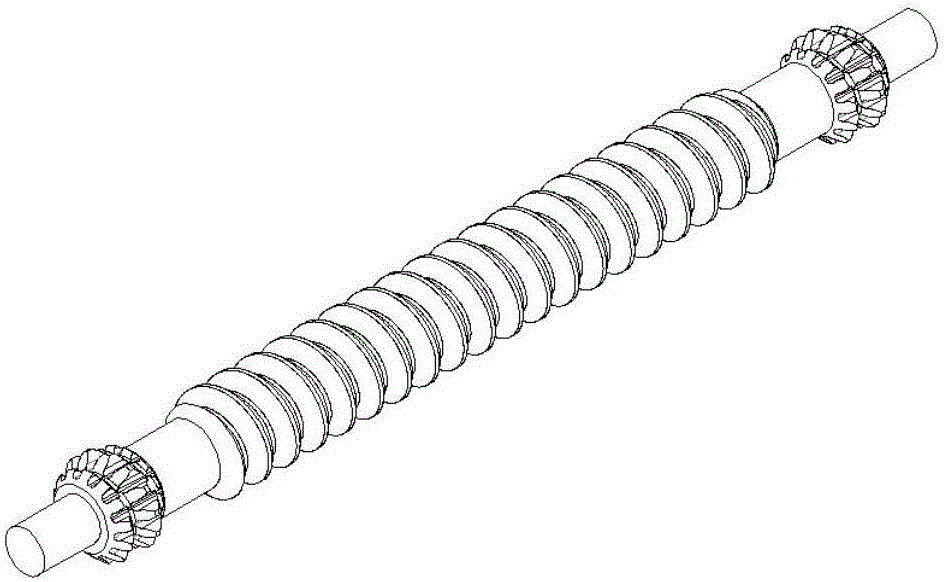

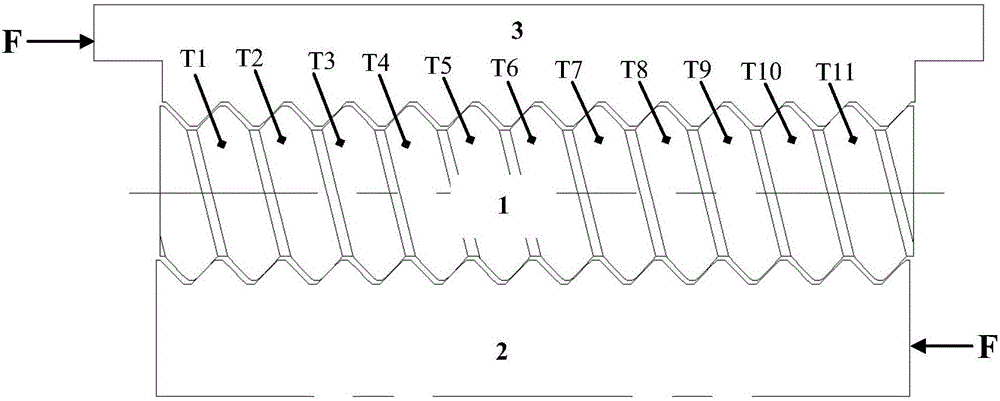

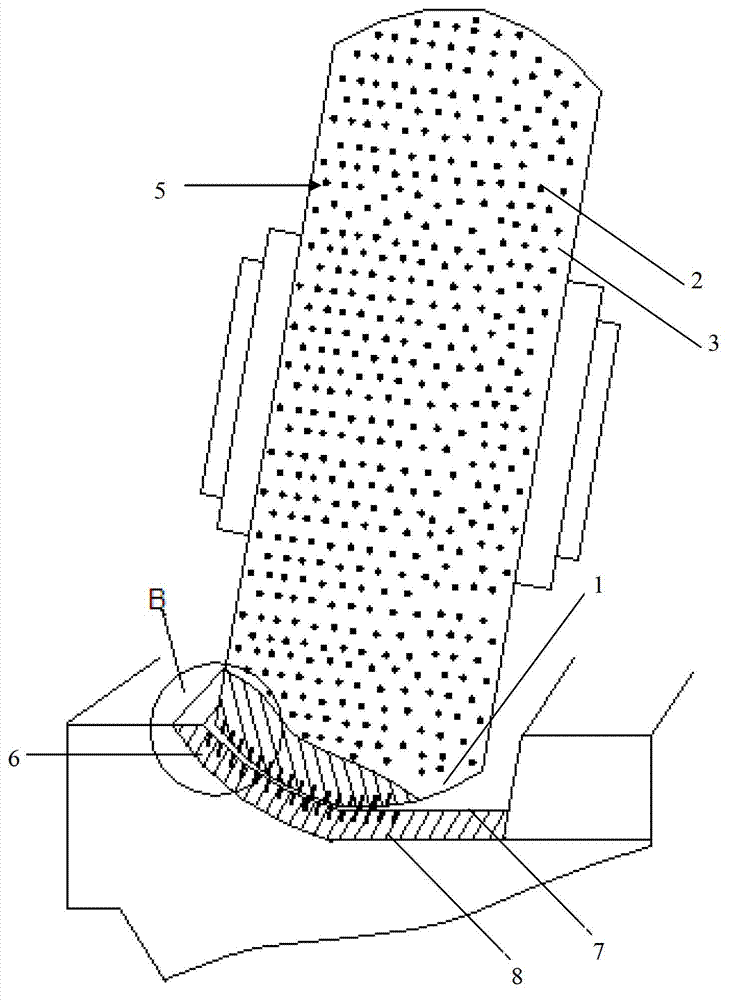

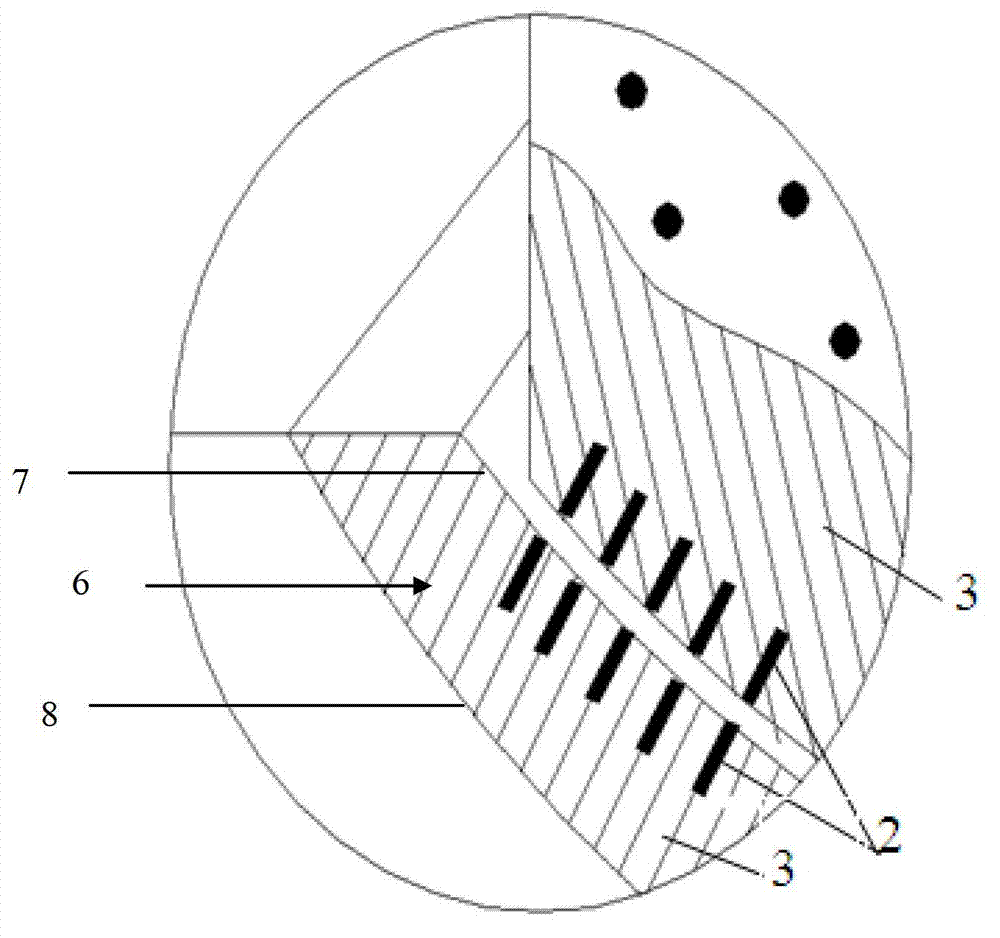

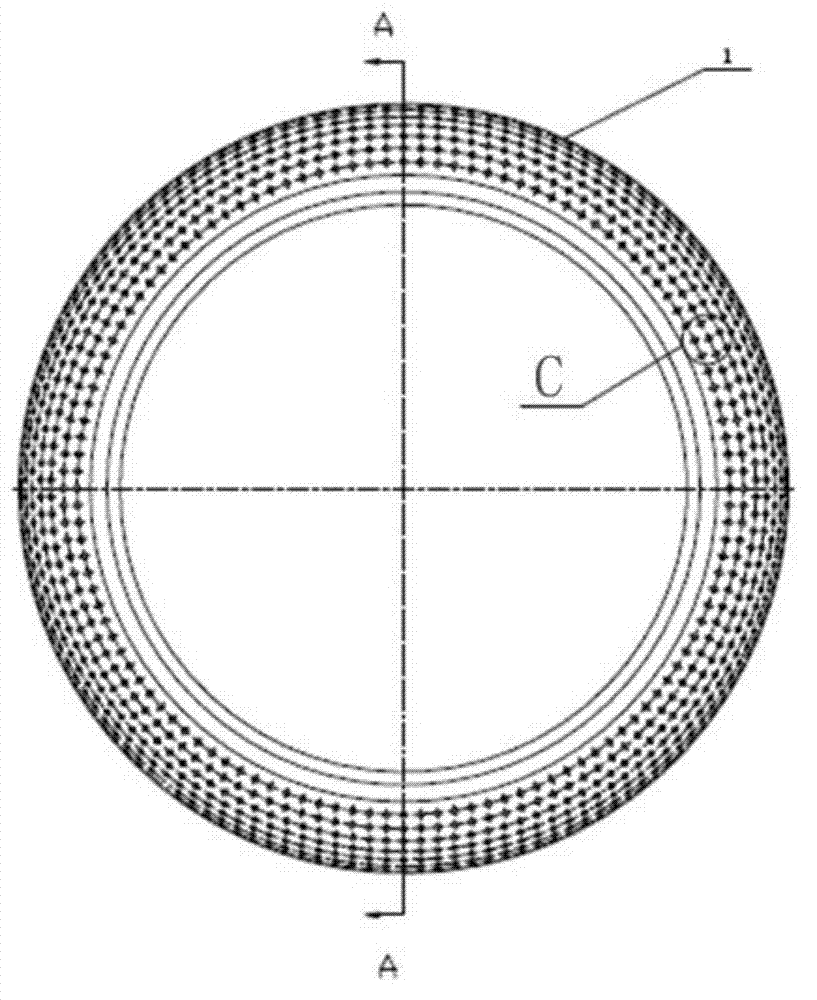

Profile modification method for thread profiles of pin rollers of planetary pin roller screw pairs

The invention discloses a profile modification method for thread profiles of pin rollers of planetary pin roller screw pairs. The profile modification method is used for solving the technical problem that the thread profiles of the existing planetary pin roller screw pairs are short in service life because of non-uniform bearing. According to the technical scheme, contact analysis is carried out on the planetary pin roller screw pairs through software of finite element analysis on the condition of a given load, the maximum profile modification amount of the thread profiles of the pin rollers is obtained through analysis results, and the pin rollers with the profiles modified are designed according to the maximum profile modification amount. Contact analysis of finite elements is carried out on pin roller screws with the profiles modified and nuts, then loads on the thread profiles on bearing sides of the pin rollers, the screws and the nuts are effectively lowered through the pin rollers with the profiles modified on the condition that the total load is fixed, and therefore adhesive wear and contact fatigue wear of the thread profiles caused by overloads can be reduced, and the service life of the planetary pin roller screw pairs can be prolonged.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

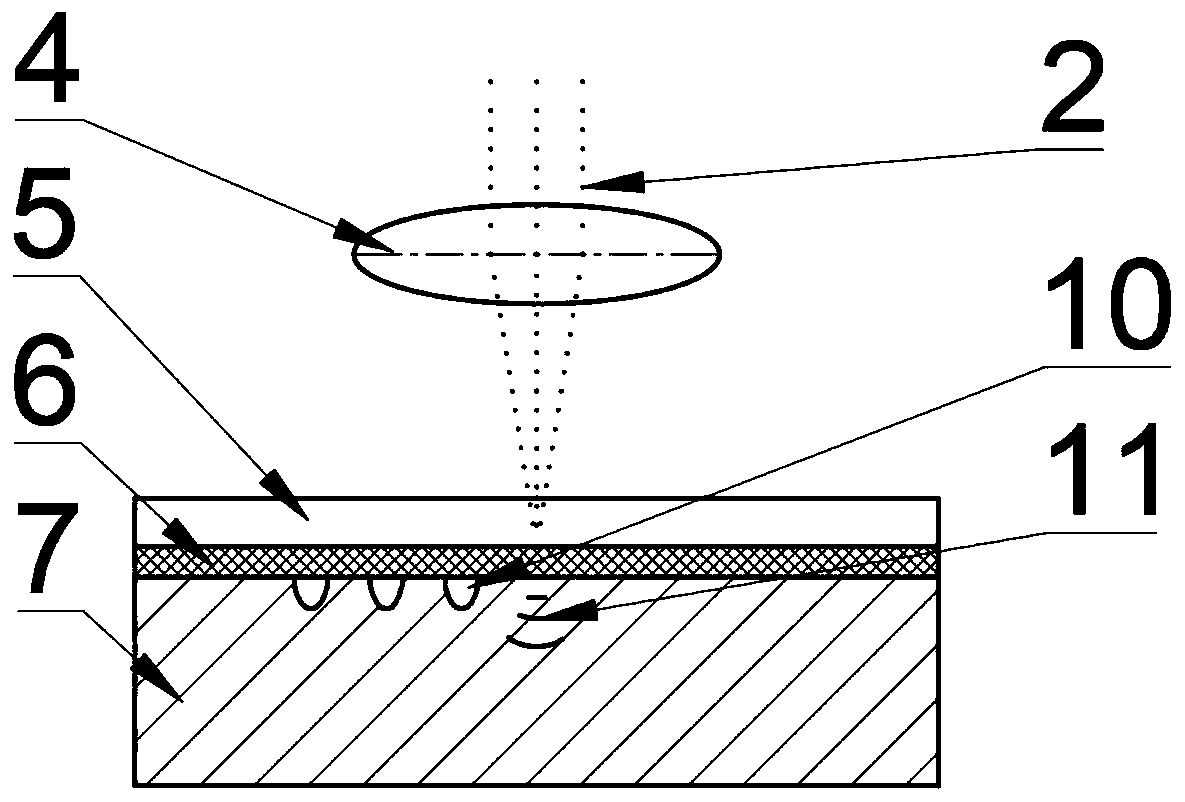

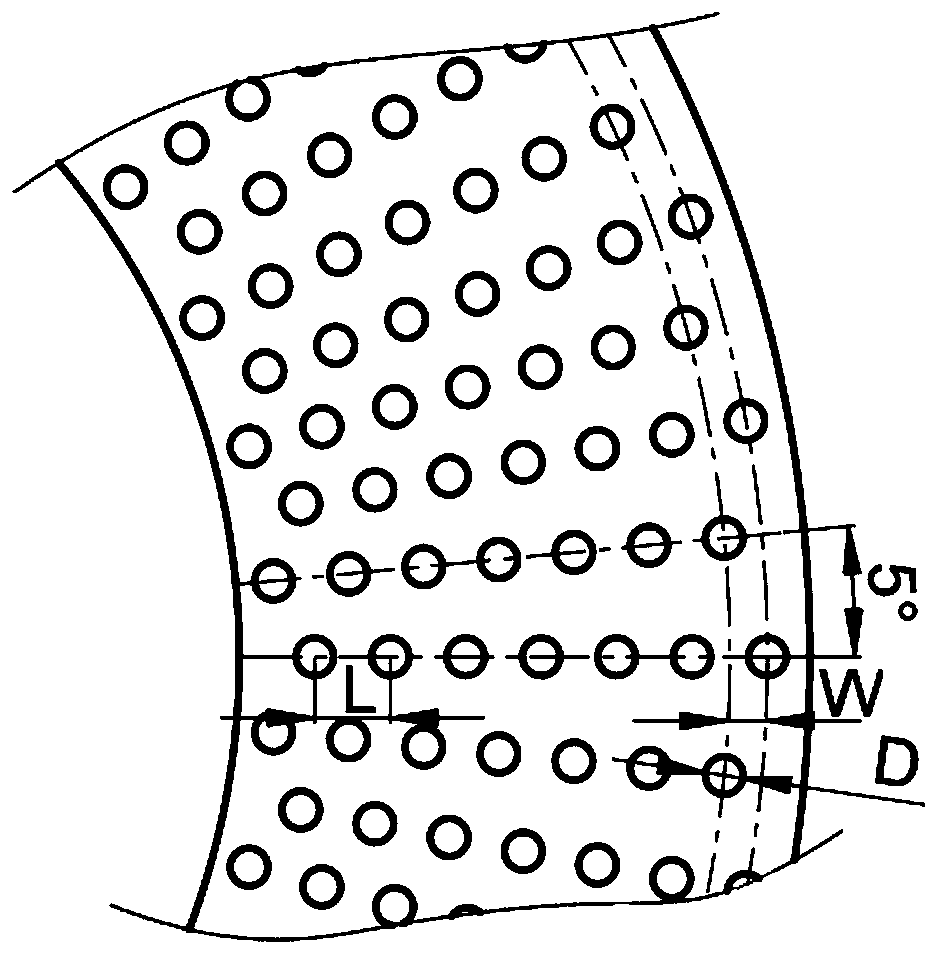

Laser shock gray cast iron component surface micro-texturing method

InactiveCN110592365AImprove wear resistanceReduce wearLaser beam welding apparatusShock waveEnergy absorption

The invention provides a laser shock gray cast iron component surface micro-texturing method. The method is characterized in that a pulse laser is utilized to emit a laser beam, the laser beam is converted into a longitudinal light path through a reflecting mirror, and the longitudinal light path passes through a focusing lens, penetrates through constraint layer water, acts on an energy absorption layer aluminum foil and absorbs laser energy to rapidly generates plasma gasification to form a plasma cluster; and the plasma cluster is exploded to generate shock waves under the action of a constraint layer, the shock waves are transmitted to the interior of a gray cast iron material, pressure of the shock waves is far greater than dynamic yield strength of the gray cast iron, flake graphiteis dispersed and evolves into a spherical group shape, ferrite grains are refined and cut into smaller sub-grains, the surface of the gray cast iron generates plastic deformation and dislocation slipto form pits to relieve abrasive wear and adhesive wear, the wear surface is mainly Fe3O4, Fe2O3 and more cementite at high temperature, a discontinuous oxide film with a larger area is formed, directcontact of a friction pair is avoided, and wear resistance of the material is improved.

Owner:JIANGSU UNIV OF SCI & TECH

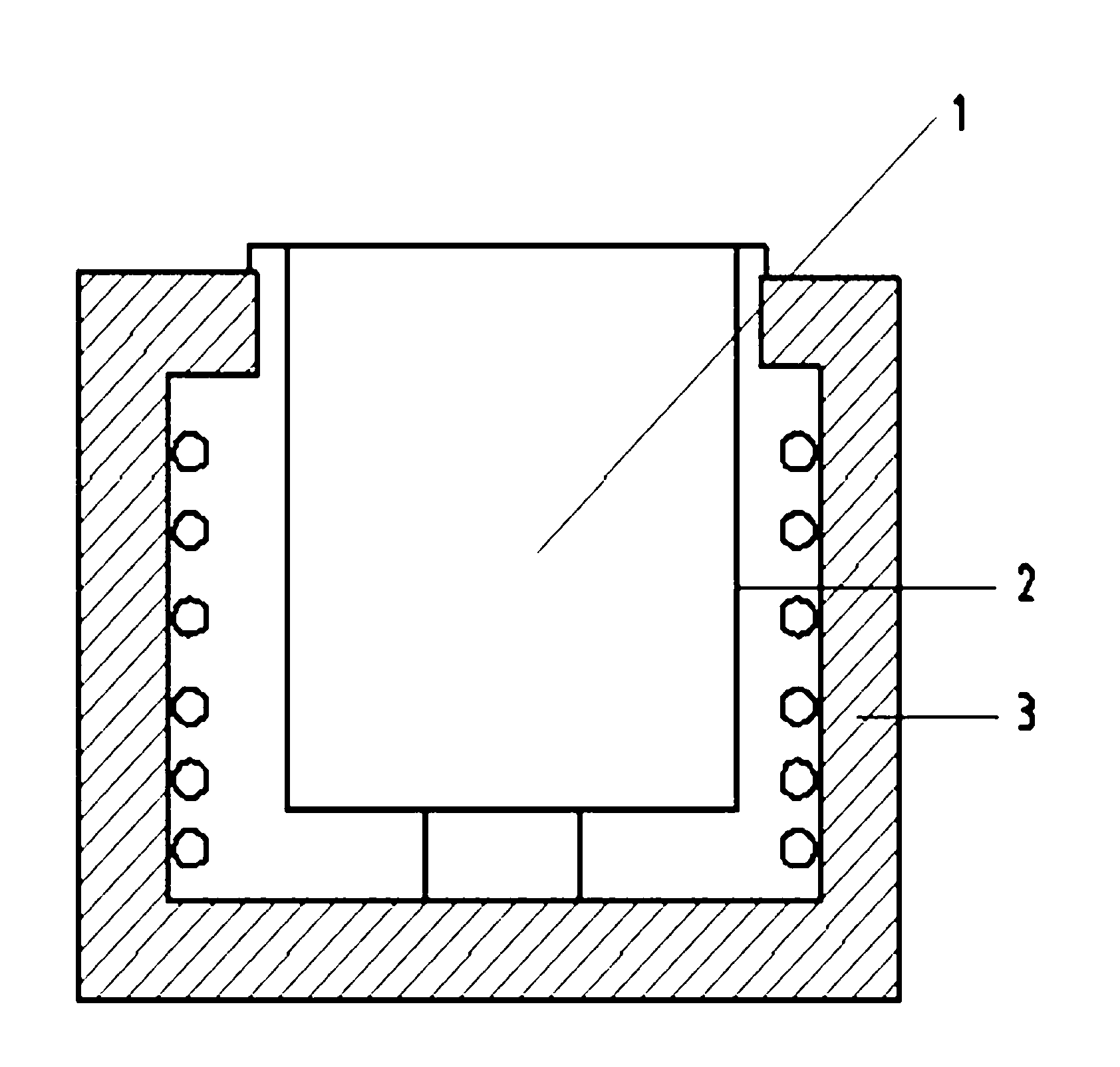

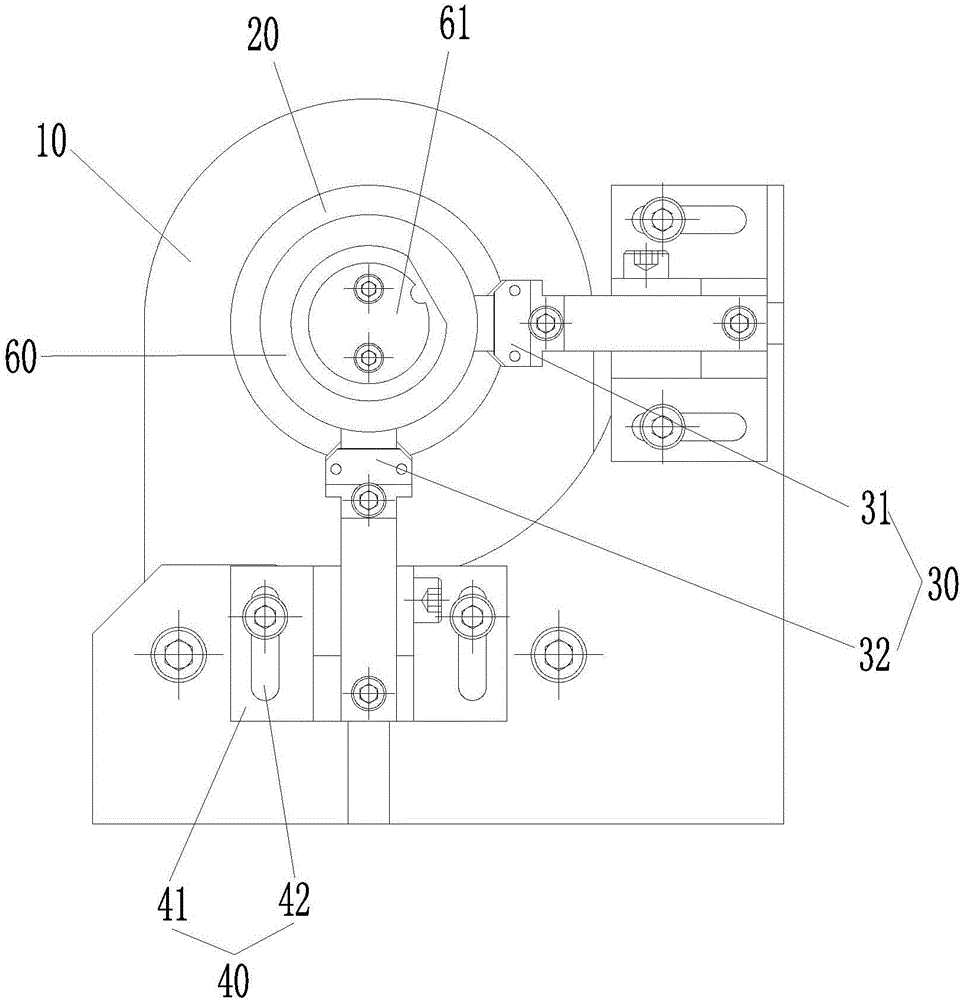

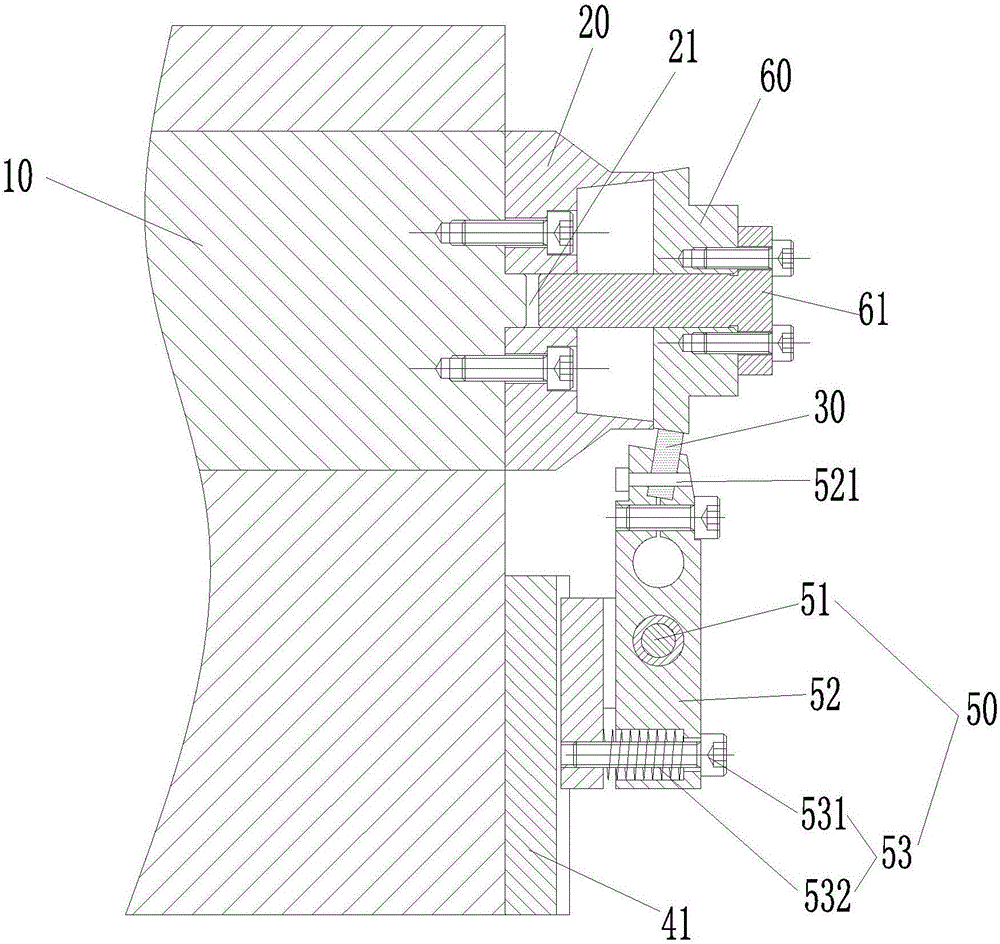

Electromagnetic centerless fixture for conical ring machining and positioning and adjusting tool technique thereof

InactiveCN106112631AReduce non-conformitiesGuaranteed stabilityPositioning apparatusMetal-working holdersCircular coneMachining

The invention discloses a shoe-type centerless fixture for processing a cone ring and its positioning adjustment tooling technology. The support block is movable and set in a machine clamp mode, so that the support surface of the support block can be adjusted radially relative to the workpiece installation area, so that the The crawler type centerless fixture for cone ring processing can process workpieces of various specifications and sizes, and the angle adjustment of the supporting surface of the supporting block can be adjusted clockwise or counterclockwise. Through the adjustment of the angle, the supporting surface can be fully aligned with the outer conical surface of the workpiece. fit, so as to reduce the adhesive wear of the outer cone surface between the support surface and the workpiece and cause the unqualified phenomenon of the workpiece. Further, before processing the workpiece, the positioning body is used to pre-adjust the centerless clamp for cone ring processing. The eccentric direction and eccentric distance between the workpiece of the specified size and the workpiece spindle on the fixture ensure the stability of the workpiece during the grinding process.

Owner:WUHAN KYOWA SYNCHRONIZER RING

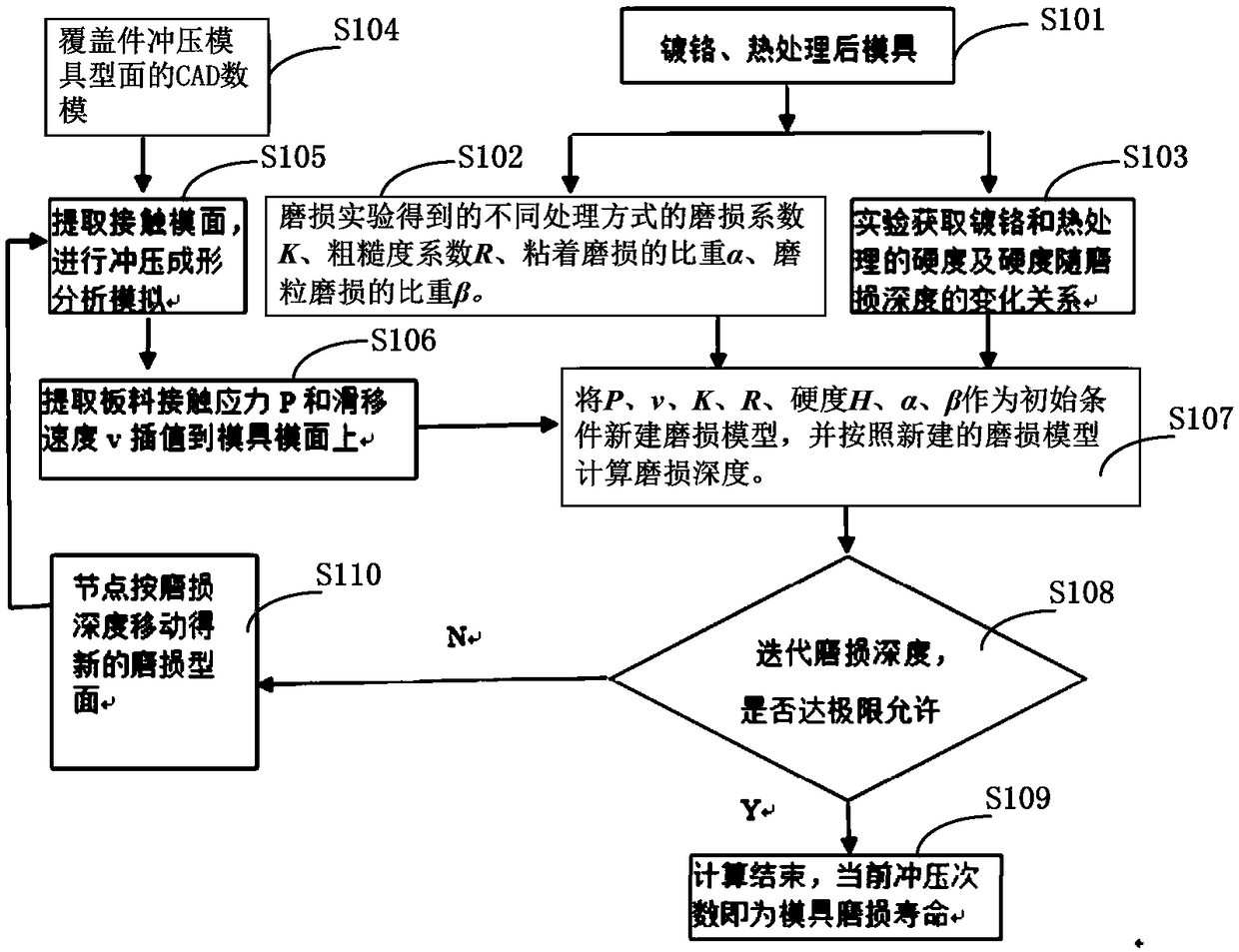

Method for predicting the wear life of stamping dies with full-time wear accumulation

PendingCN109033673AAvoid discontinuationAvoid occupyingGeometric CADDesign optimisation/simulationWear testingHardness

The invention relates to a full-time wear accumulative wear life prediction method of a stamping die, which adopts a wear testing machine to separately measure wear coefficient K, roughness coefficient R, specific gravity alpha of adhesive wear and specific gravity beta of abrasive wear of a plurality of die materials with different treatment modes; through the finite element simulation experiment, the hardness H of the die material and the relationship between the hardness and the wear depth gradient were obtained. According to the die surface CAD digital model of the stamping die, the contact die surface of the stamping die and the stamped sheet metal is extracted, and the contact stress P of the contact die surface and the slip speed v of the stamped sheet metal is extracted relative tothe die through numerical simulation of stamping forming; a new wear model is established and the wear depth is calculated by using the above parameters as boundary conditions. When the wear depth ofthe stamping wear model obtained by iteration reaches the limit allowable value, it is confirmed that the current stamping times is the die wear life. The invention solves the technical problem thatthe prediction accuracy of the traditional Archard model is not high.

Owner:GUANGXI AISHENG CHUANGZHI SCI & TECH CO LTD

Grinding roller and grinding disc tile

InactiveCN103111347AGood compatibilityRealize the compound matching of advantagesGrain treatmentsHardnessAdhesive wear

The invention discloses a grinding roller and a grinding disc tile. The grinding roller and the grinding disc tile comprise basal bodies and multiple ceramic rods, wherein the ceramic rods are casted in the basal bodies along the abrasive surfaces of the grinding roller and the grinding disc tile. The grinding roller and the grinding disc tile provided by the invention guarantee that the working layers of the grinding roller and the grinding disc tile have higher hardness, the adhesive wear and the cutting abrasion are reduced on one hand when the wearable ceramic rods are casted in the basal bodies, and the grinding roller and the grinding disc tile are guaranteed to have good tenacity on the other hand to resist exotical impact. The grinding roller and the grinding disc tile provided by the invention adopt routine antifriction material to support and protect a ceramic material, the super stiff and wearable ceramic material is utilized to grind the processed mineral, and the advantage composite matching of the material is realized.

Owner:北京理研社技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com