Cutter wear mechanism analysis method

A tool wear and mechanism analysis technology, which is applied in the direction of manufacturing tools, metal processing machinery parts, measuring/indicating equipment, etc., can solve the problems of long time consumption and high cost, and achieve the effect of low cost and wide application

Inactive Publication Date: 2013-03-20

ZHEJIANG OCEAN UNIV

View PDF5 Cites 10 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] The problem to be solved by the present invention is that it takes a long time and high cost to analyze the mechanism of tool wear with existing instruments.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0023] Cutting simulation conditions:

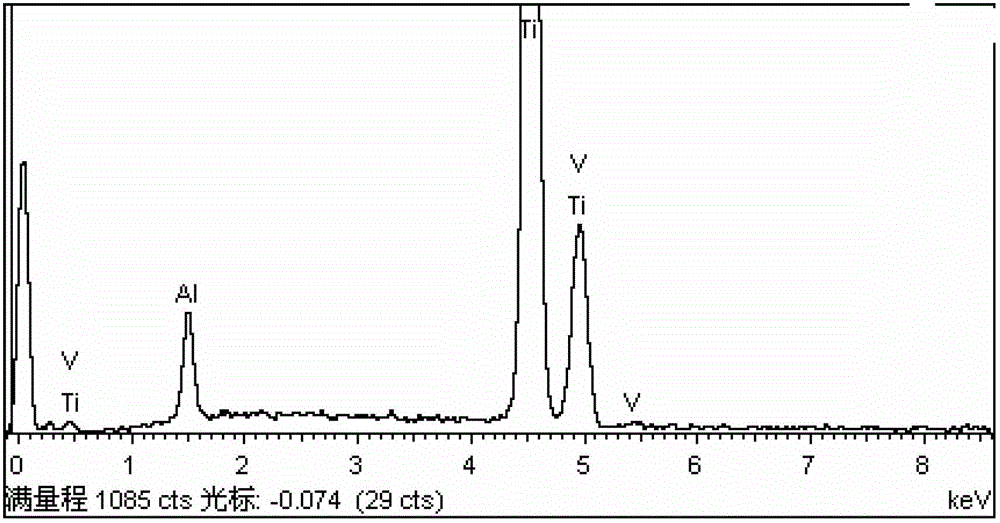

[0024] Workpiece material: titanium alloy TC4, solution aging in heat treatment state;

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

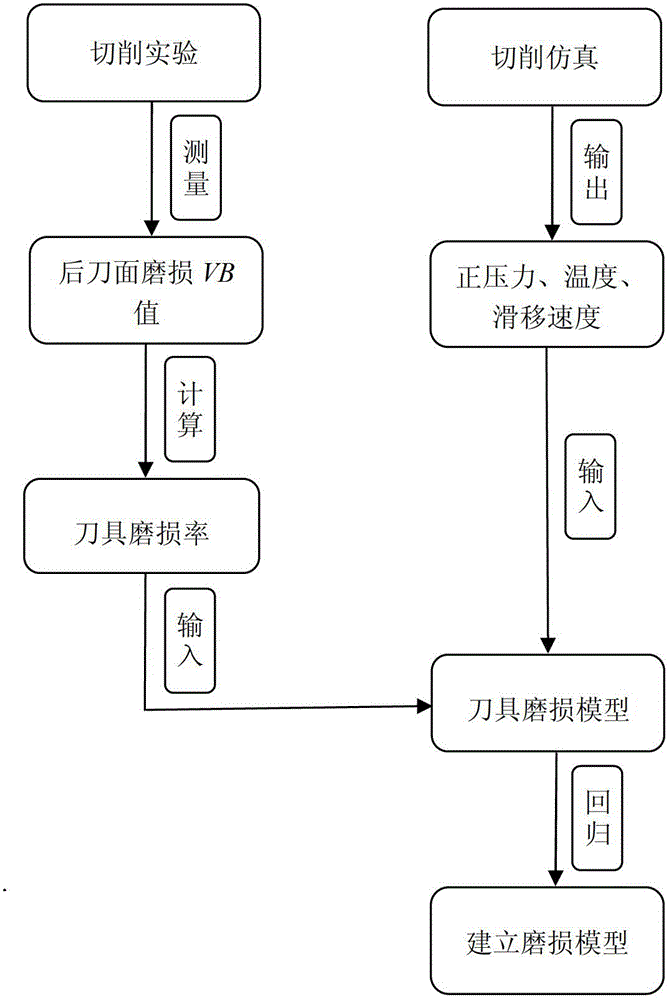

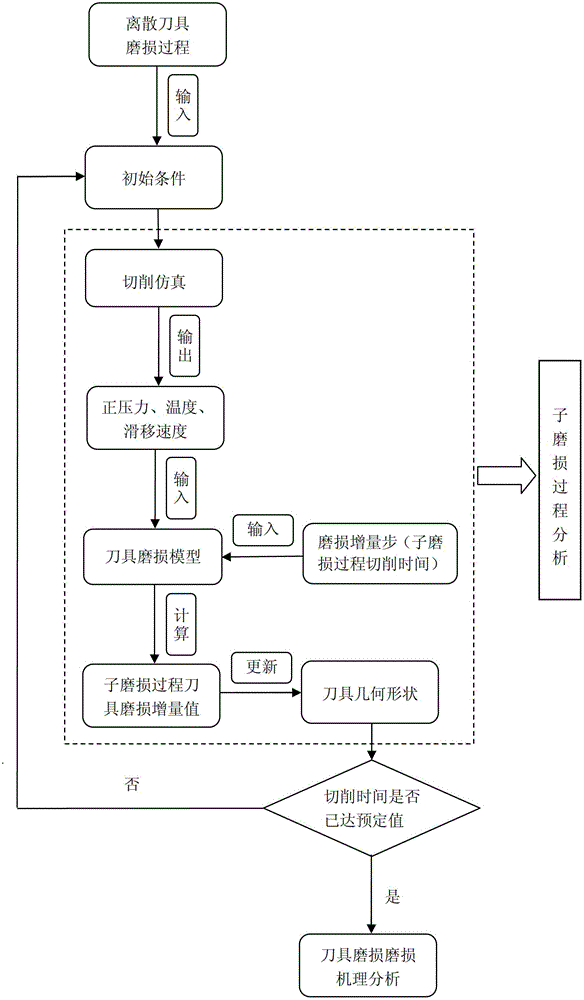

The invention discloses a cutter wear mechanism analysis method, belonging to the technical field of metal cutting machining. The analysis of a cutter wear mechanism is realized by building a novel cutter wear model and by means of a finite element method. The cutter wear model is as shown by an accompanying drawing, wherein the rear cutter surface wear value VB of a cutter can be measured through an experiment, the wear rate of the cutter is further obtained, other variables can be obtained through cutting simulation, and finally the corresponding numerical values of abrasive wear, adhesive wear and diffusive wear can be measured through a multiple regression method. Since the finite element simulation method is used for analyzing the wear mechanism of the cutter, the cutter wear mechanism analysis method has the advantages that the method is simple and feasible and the cost is lower.

Description

technical field [0001] The invention relates to a tool wear mechanism analysis method, which belongs to the technical field of metal cutting. Background technique [0002] Tool wear has an important impact on the metal cutting process. In order to control and optimize the metal cutting process and obtain the best cutting speed under certain cutting conditions, it is necessary to master the tool wear mechanism. Tool wear in metal cutting is a cumulative and irreversible process, which is quite complicated. Common causes of wear include abrasive wear, adhesive wear, and diffusion wear. At present, there is no good method to analyze the mechanism of tool wear. It can only be analyzed by means of scanning electron microscope and energy spectrum analysis. It is not only time-consuming and costly, but also easy to cause oxidation of the specimen and affect the analysis results. Therefore, it is an urgent problem to be solved. . Contents of the invention [0003] The purpose o...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B23Q17/09

Inventor 袁跃峰

Owner ZHEJIANG OCEAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com