Profile modification method for thread profiles of pin rollers of planetary pin roller screw pairs

A planetary roller and thread technology, which is applied in the field of roller thread modification in planetary roller screw pairs, can solve the problems of uneven load bearing and short service life of thread teeth, and reduce adhesive wear and contact fatigue Abrasion and life-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

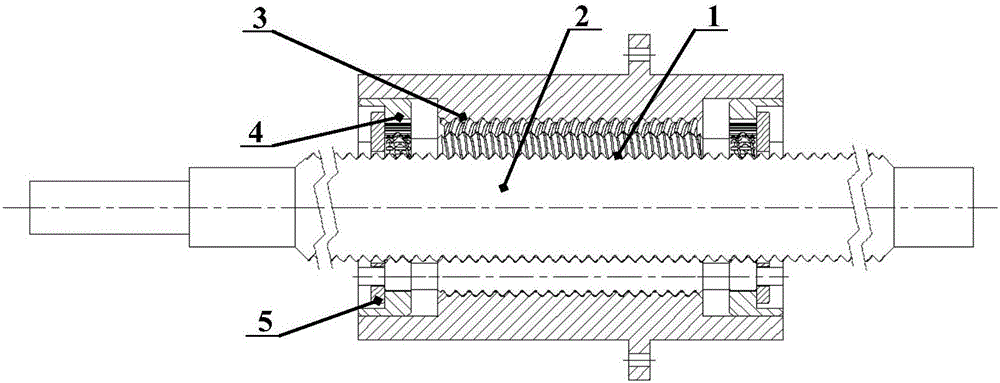

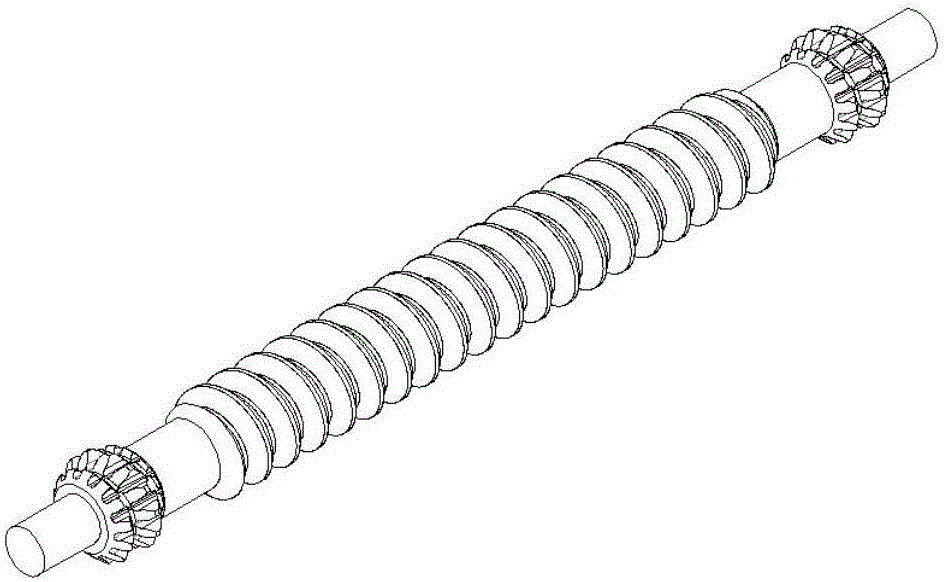

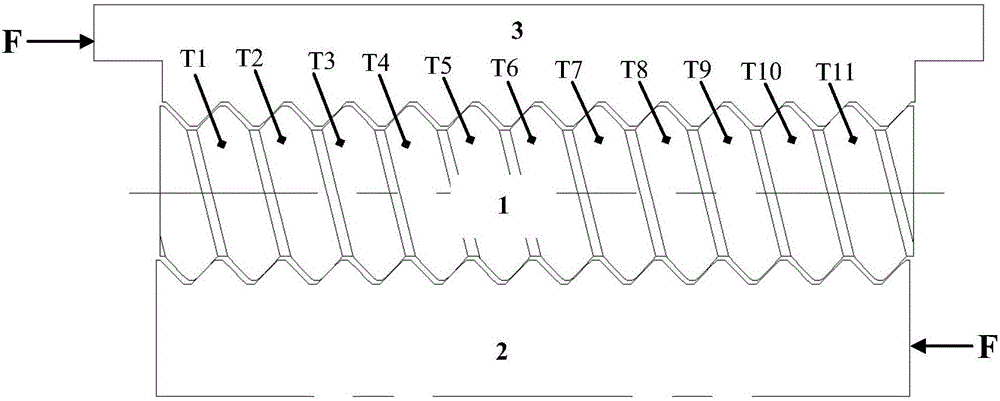

[0041] refer to Figure 4-6 . The specific steps of the method for modifying the shape of the roller thread teeth in the planetary roller screw pair of the present invention are as follows:

[0042] Step 1. Analysis of the contact characteristics of the threads of the planetary roller screw pair.

[0043] Using the finite element analysis method to analyze the thread contact of the planetary roller screw pair, the load distribution of each thread tooth at the contact point between the roller 1 and the screw 2 and the nut 3, the stress distribution of each contact point and the axial direction of the contact point displacement. The results show that the load and contact stress on each thread tooth increase or decrease sharply with the increase of the thread tooth number, and the maximum modification amount of the thread tooth of roller 1 can be obtained according to the axial displacement of the thread tooth contact point. Magnitude.

[0044] Step 2, the specific process of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com