Patents

Literature

58results about How to "Reduce Adhesive Wear" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Screw thread adhesion abrasion resisting self-lubricating coating and preparation method thereof

InactiveCN101125995APrevent Adhesive WearReduce coefficient of frictionPolyurea/polyurethane coatingsEpoxy resin coatingsWear resistantSolvent

The invention relates to a self-greasing paint which can prevent screw thread from sticking and wearing and a preparation method thereof. The self-greasing paint which can prevent screw thread from sticking and wearing is a two-component self-greasing paint that consists of a component A and a component B. Component A consists of raw materials with weight proportion of 40-90 percent of film-forming material, 5-60 percent of solid greasing material, 0-10 percent of additive, 0-50 percent of solvent, 0-10 percent of color paint and 0-10 percent of filling while component B consists of raw materials with weight proportion of 50-100 percent of curing agent and 0-50 percent of solvent. The weight ratio of component A and component B is 1 to 0.1-5. The friction coefficient of the coat formed by the paint is low and the paint has self greasing function, anti-sticking and wearing resistant performances; the invention reduces and even avoids the use of grease and solves pollution problem caused by grease. The self-greasing paint is applicable to various mechanical parts such as bolt, screw, etc., in particular to screw threads of oil pipe, cashing and drill rod, etc. that are special for oil industry.

Owner:王新虎

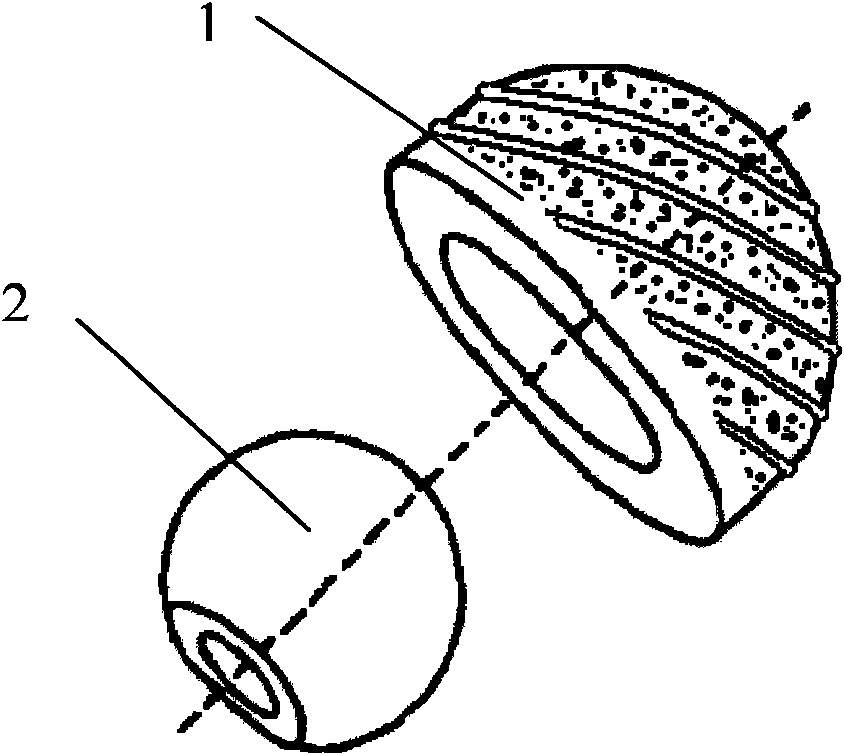

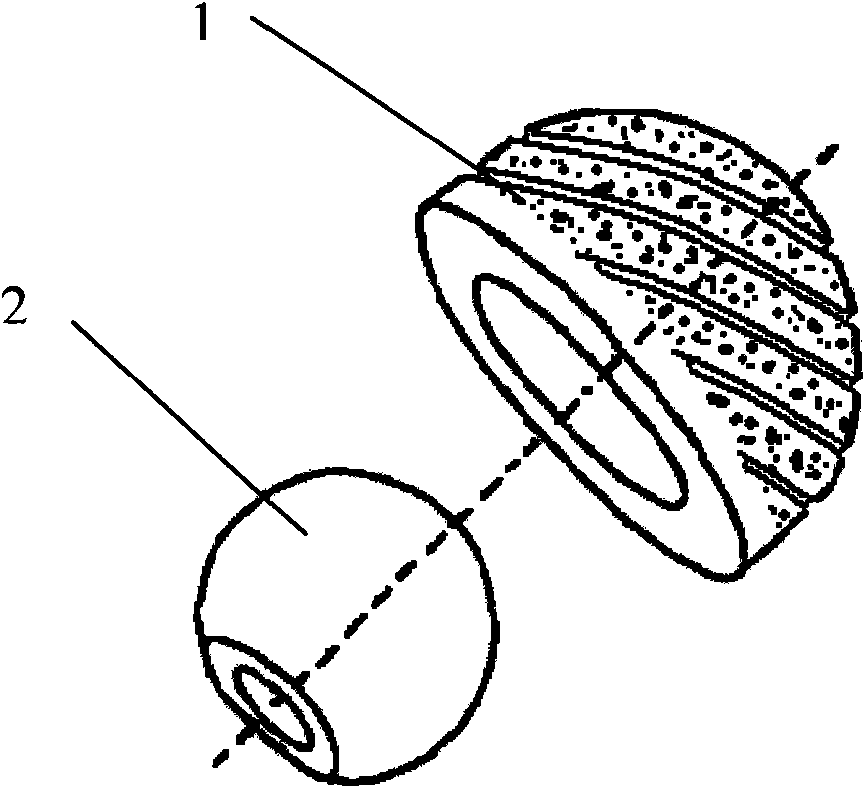

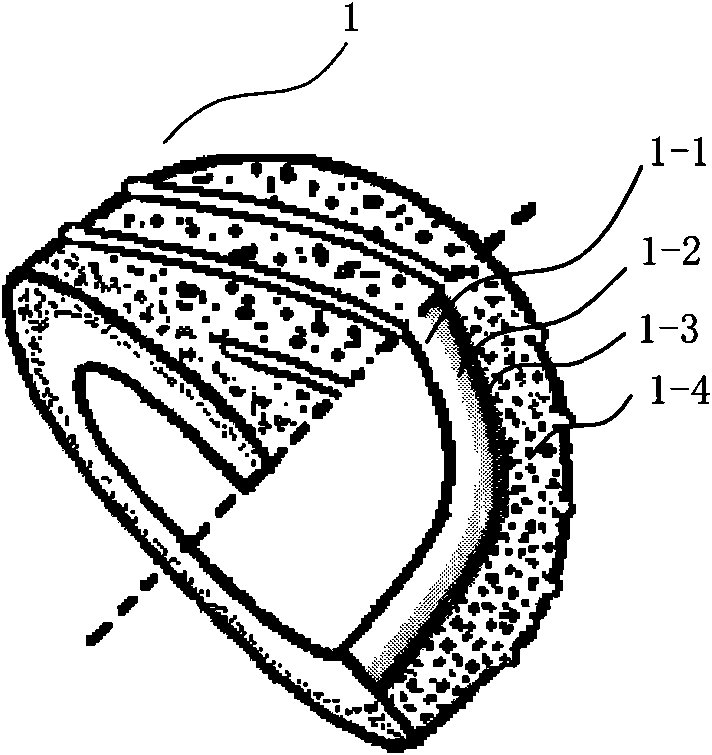

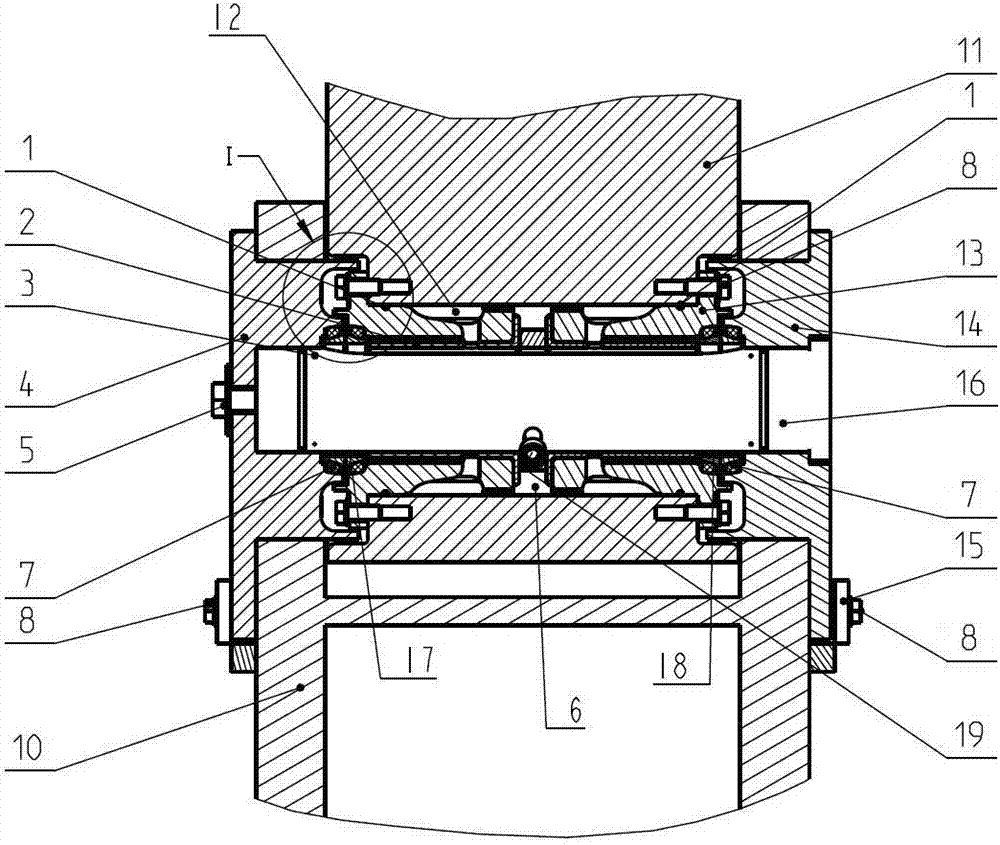

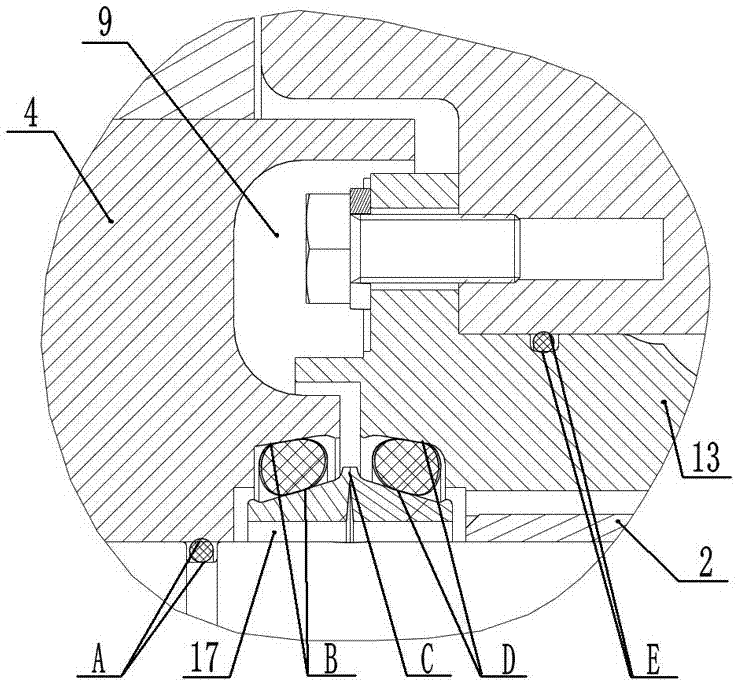

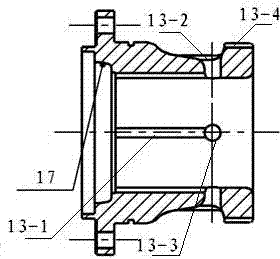

Artificial hip joint consisting of multilayer shell core composite structural components

The invention discloses an artificial hip joint consisting of multilayer shell core composite structural components. The artificial hip joint comprises an artificial acetabulum and an artificial thigh bone. The artificial hip joint is characterized in that: the artificial acetabulum has a multilayer shell core composite structure and consists of a ceramic acetabulum lining, a transition layer, a porous metal, a porous alloy or a porous toughened ceramic acetabulum shell; the artificial thigh bone has a multilayer shell core composite structure and consists of a ceramic spherical shell layer, a transition layer and a toughened ceramic inner core. The ceramic acetabulum lining and the spherical shell layer of the artificial thigh bone have high hardness, corrosion resistance and abrasion resistance; the artificial acetabulum shell layer and the inner core of the thigh bone have high toughness and impact resistance; and the transition layers are made of gradient composite materials between the materials for the shell layer and the inner core layer, and have the functions of increasing the bonding strength between the shell layer and the inner core layer, reducing the interface stressbetween the shell layer and the inner core layer and the like. The artificial hip joint has the characteristics of long service life, high reliability, high performance and the like.

Owner:SUZHOU DINGAN ELECTRONICS TECH

Iron-based abrasion resisting and reducing surfacing flux-cored wire

InactiveCN102744532AImprove wear resistanceGood crack sensitivityWelding/cutting media/materialsSoldering mediaManganeseTitanium

The invention relates to an iron-based abrasion resisting and reducing surfacing flux-cored wire. The current abrasion resistant surfacing welding wires and alloys have many types; some abrasion resistant surfacing welding wires and alloys have high abrasion resistance and can protect the surfaced tools or parts, but have poor abrasion reduction performance and cannot effectively prevent other contacted parts or components from being abraded; some surfacing alloys have the abrasion reduction performance but lose the abrasion resistance. The iron-based abrasion resisting and reducing surfacing flux-cored wire comprises a low-carbon steel sheathing, and flux-cored powder; and the wire includes the following alloy elements in percentage by weight: 0.2 to 0.8% of carbon, 5 to 20.0% of chromium, 1.0 to 7.0% of titanium, 0.3 to 5.0% of boron, 0.1 to 1.5% of silicon, 0.2 to 2.0% of manganese, and the balance of iron. According to the iron-based abrasion resisting and reducing surfacing flux-cored wire, the abrasion resisting surfacing alloy has high hardness, and good toughness and matching performance, and is hard to crack, and has both the abrasion resistance and the abrasion reduction performance, and achieves high abrasion resistance along with high abrasion reduction performance.

Owner:王新虎

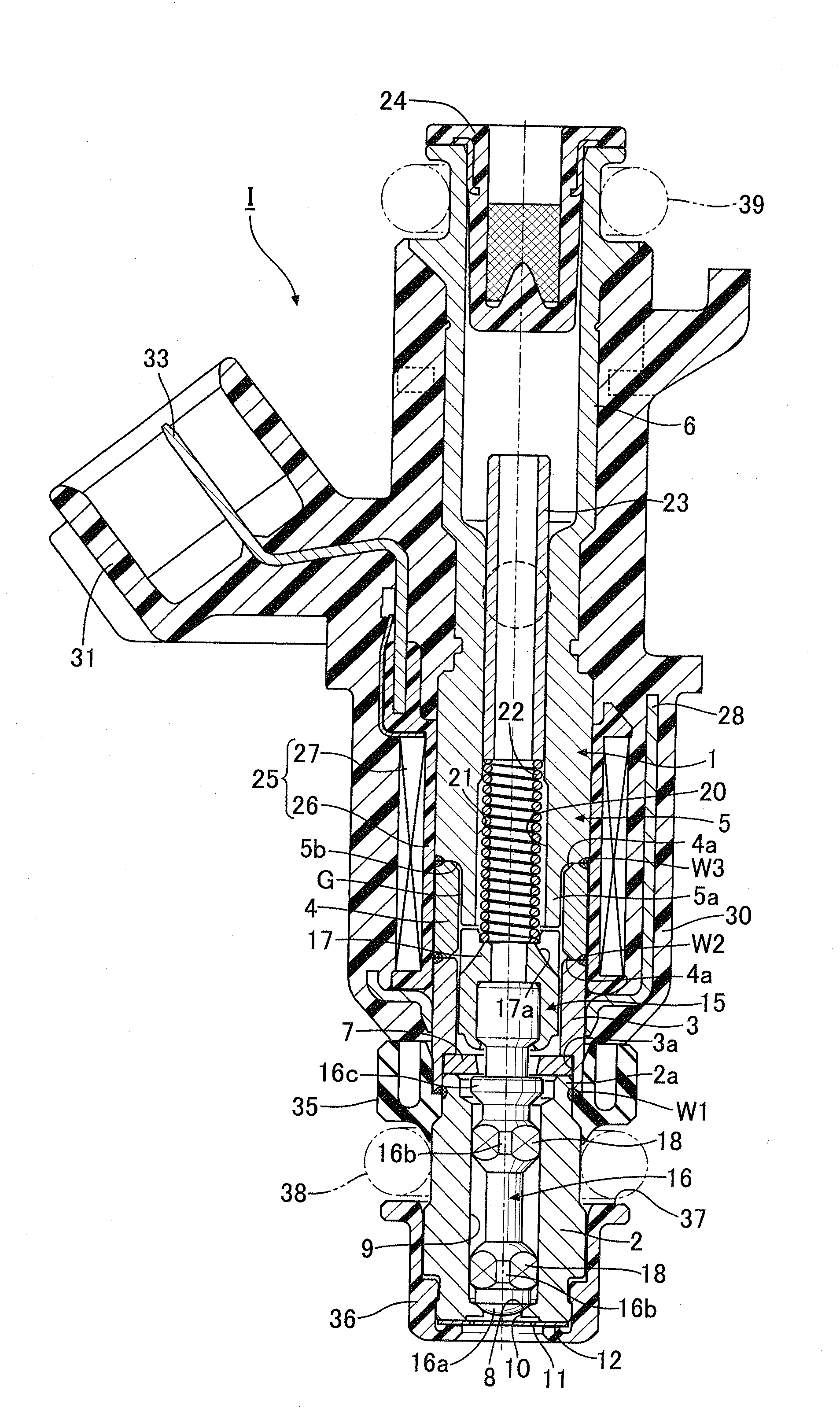

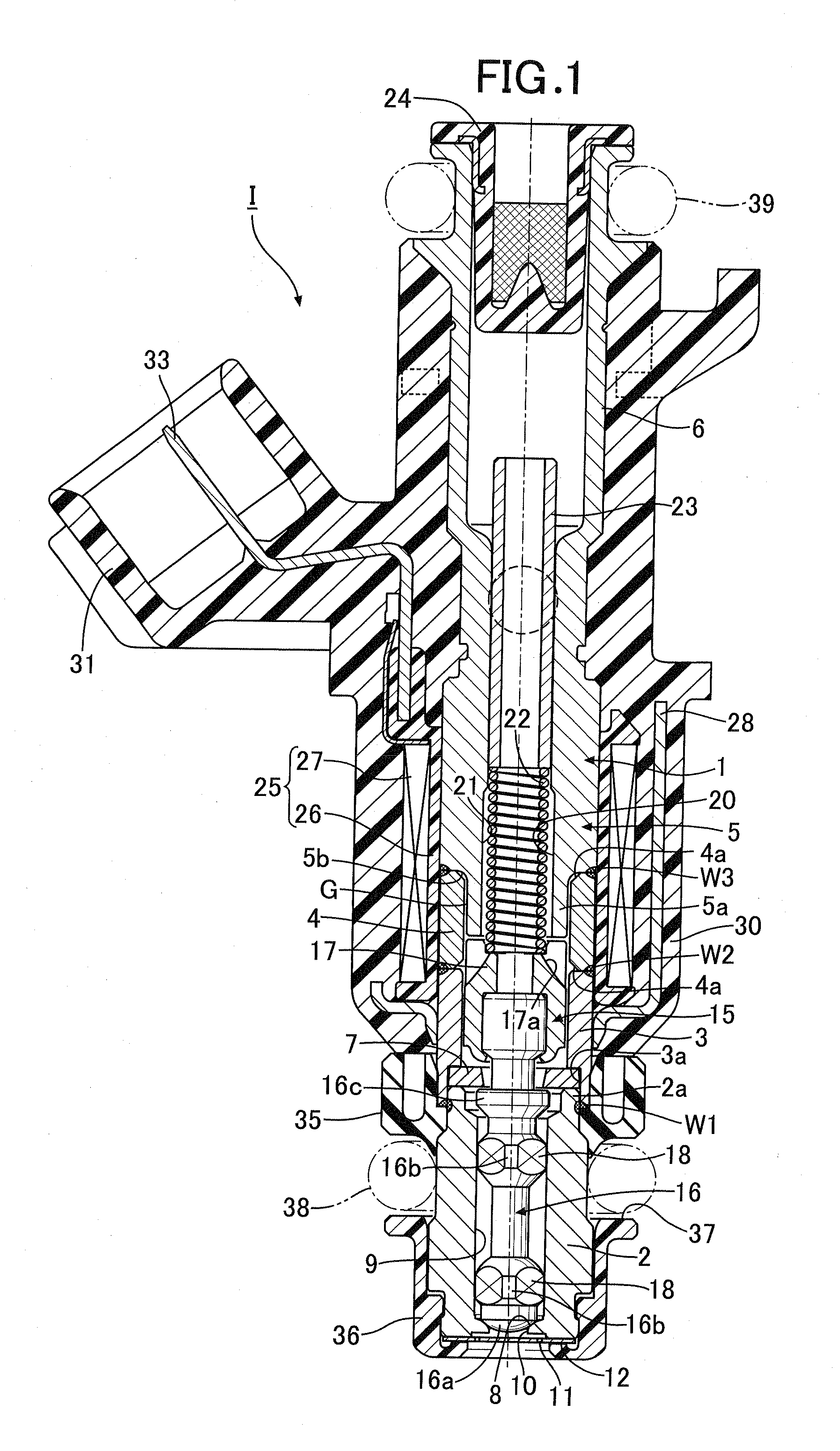

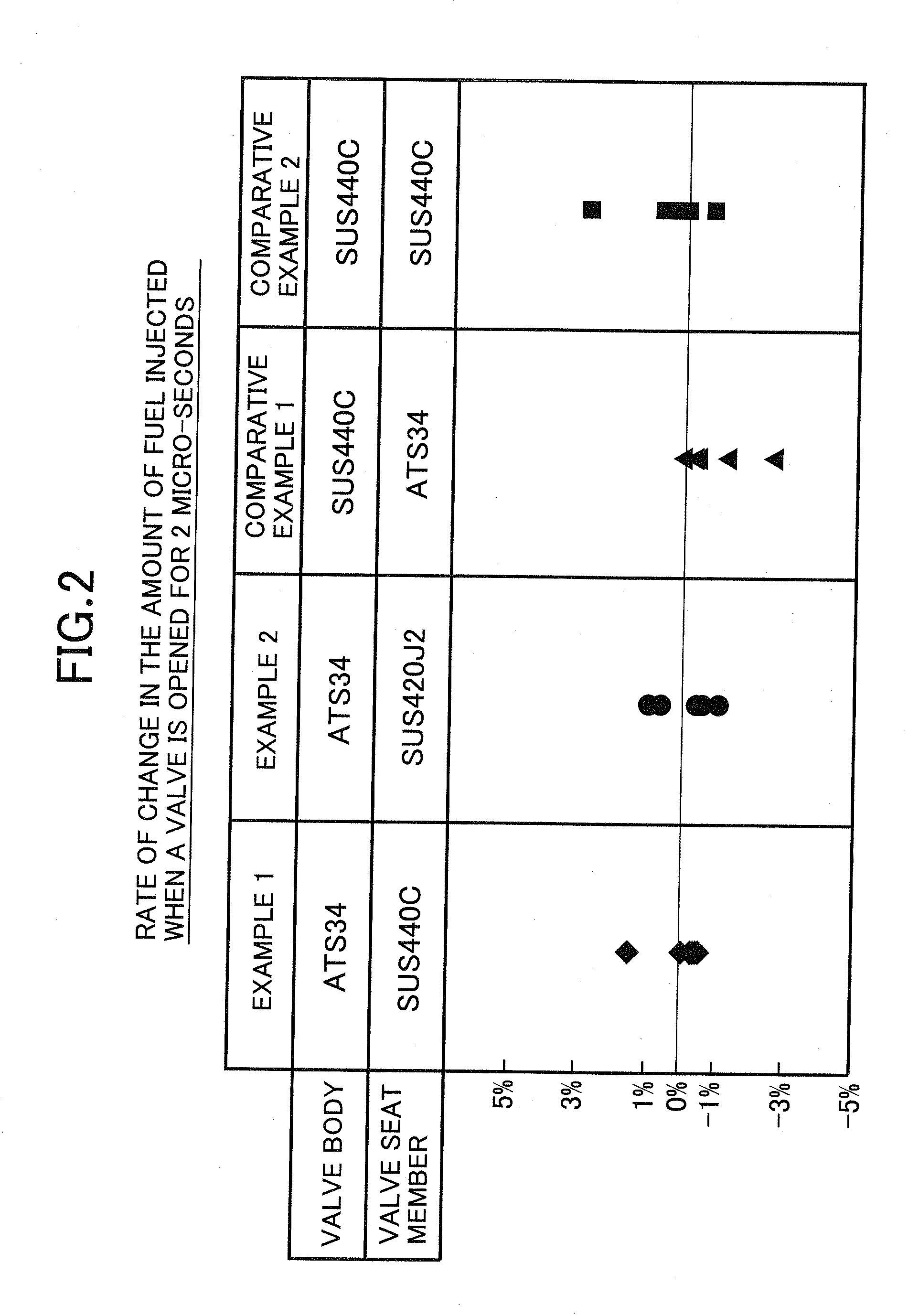

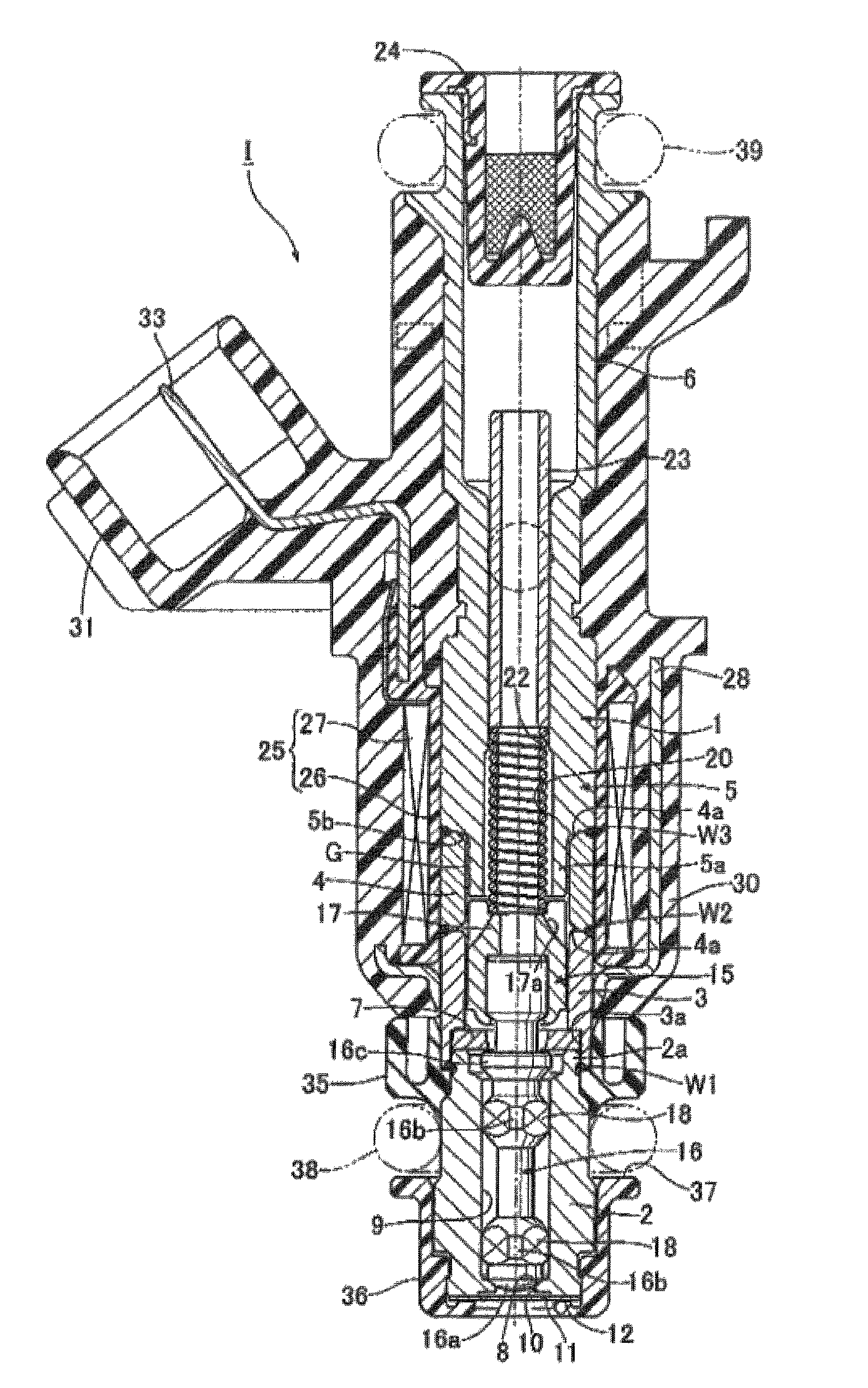

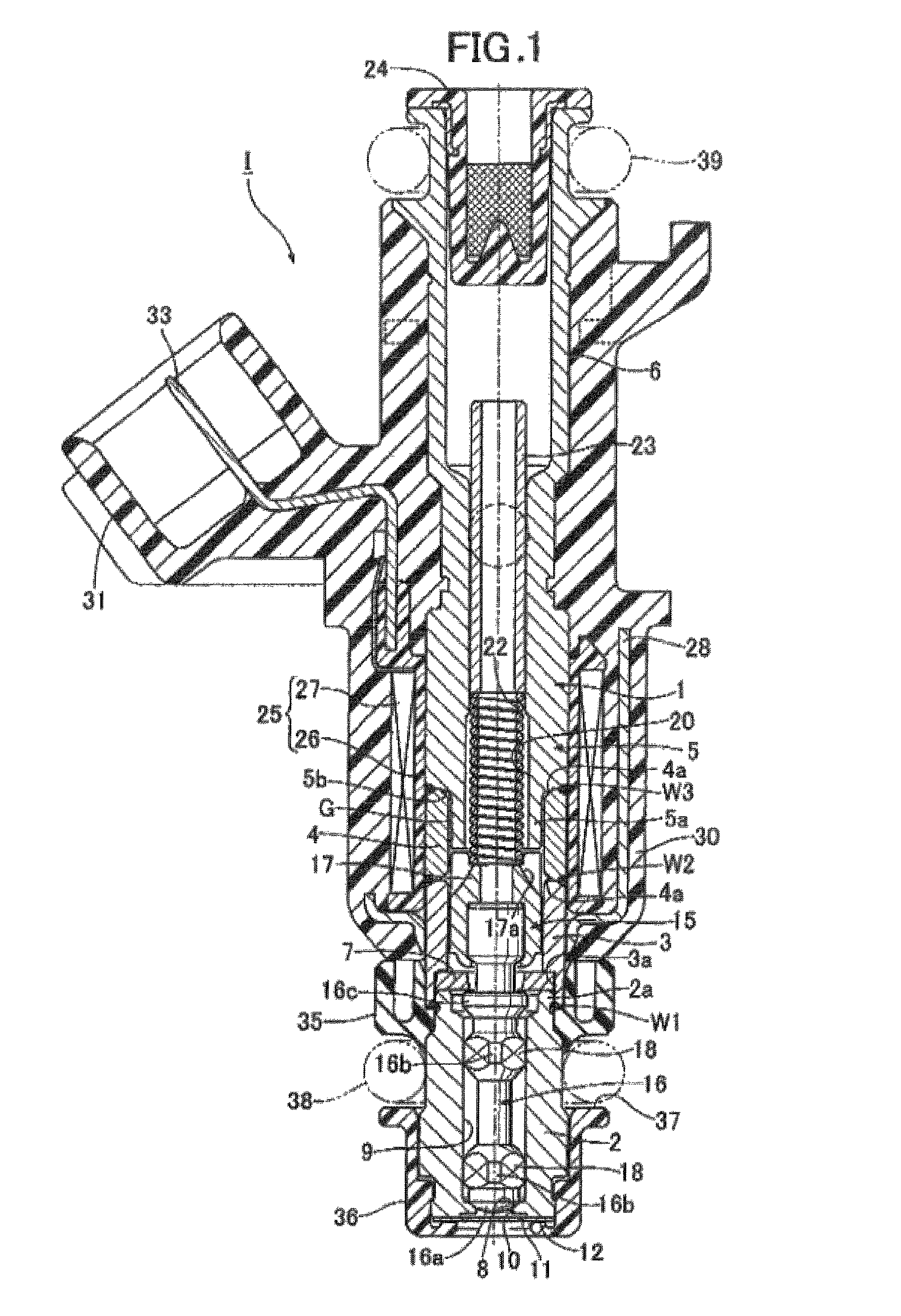

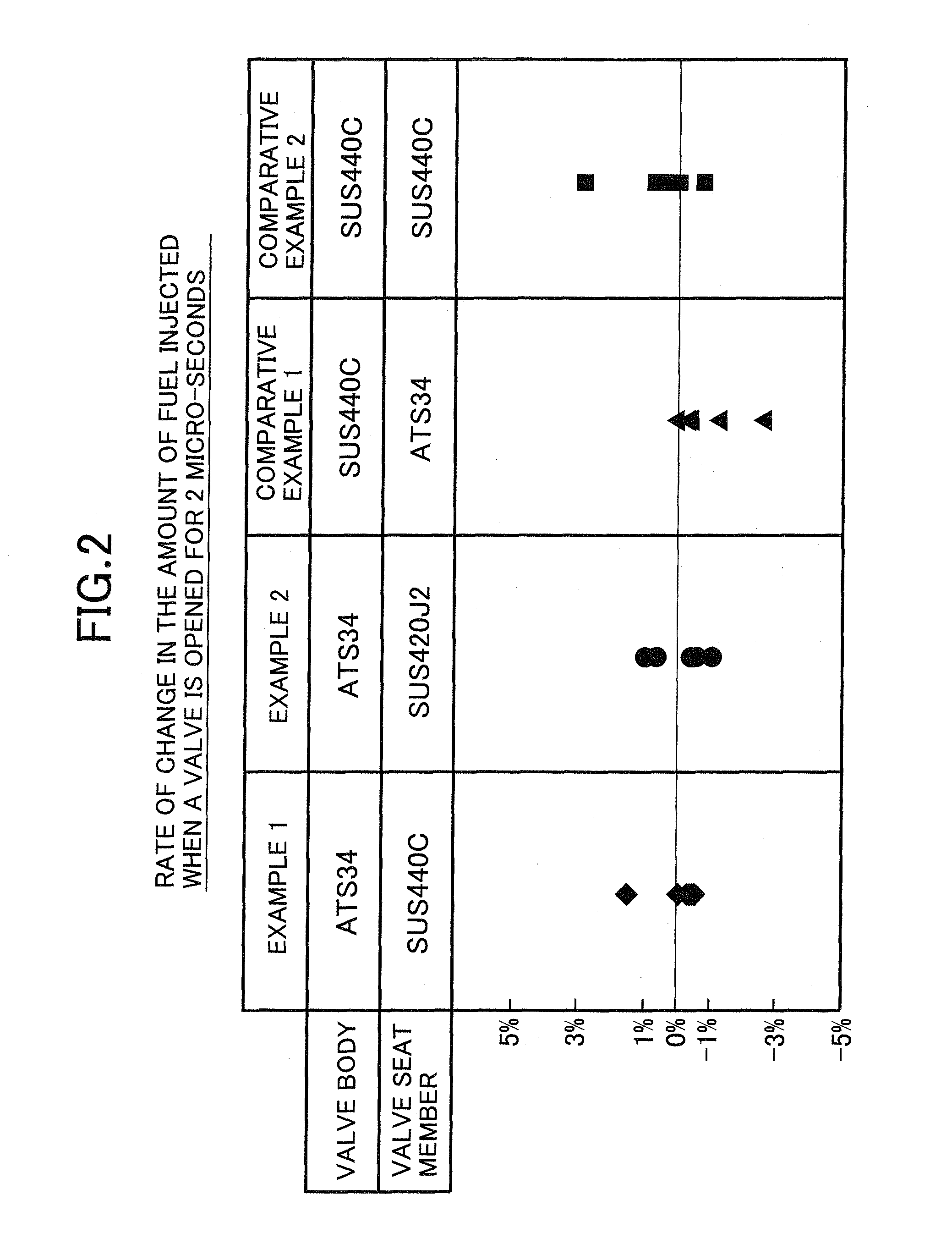

Electromagnetic fuel injection valve

ActiveUS20100001215A1Prevent Adhesive WearReduce Adhesive WearOperating means/releasing devices for valvesMachines/enginesAlcohol fuelMartensitic stainless steel

In an electromagnetic fuel injection valve, a valve housing includes: a cylinder-shaped valve seat member having a valve seat in its front end portion; a magnetic cylindrical body coaxially connected to a rear end portion of the valve seat member; a nonmagnetic cylindrical body coaxially and liquid-tightly welded to a rear end of the magnetic cylindrical body; and a hollow cylindrical stationary core coaxially and liquid-tightly welded to a rear end of the nonmagnetic cylindrical body. A valve assembly is housed in the valve housing and includes: a valve body capable of being seated on the valve seat; and a movable core connected to a rear end of the valve body and opposed to a front end of the stationary core. The valve body and the valve seat member are respectively made of different martensitic stainless steels so that a hardness of the valve body is higher than that of the valve seat member. Accordingly, it is possible to provide an electromagnetic fuel injection valve for alcohol fuel which is capable of preventing the adhesive wear from occurring in the seat portion while a valve body and a valve seat member made of martensitic stainless steel are used.

Owner:HITACHI ASTEMO LTD

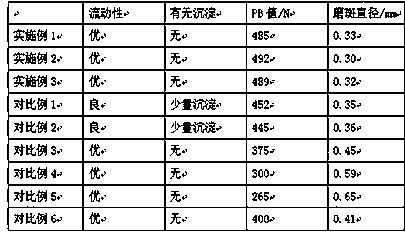

Self-lubricating composite material as well as preparation method and application thereof

The invention relates to the technical field of composite materials, in particular to a self-lubricating composite material and a preparation method and application thereof. The self-lubricating composite material is prepared from the following raw materials: a two-dimensional layered nano material, epoxy resin and a curing agent, wherein each sheet layer of the two-dimensional layered nano material consists of a plurality of layers of MXene units; the mass ratio of the two-dimensional layered nano material to the epoxy resin is (0.1-40):(60-99.9); and the mass of the curing agent is 10-15% ofthe mass of the epoxy resin. The two-dimensional layered nano material with a graphene-like structure is added into the epoxy resin matrix, so that the self-lubricating composite material with excellent tribological properties under boundary and mixed lubrication conditions is obtained.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

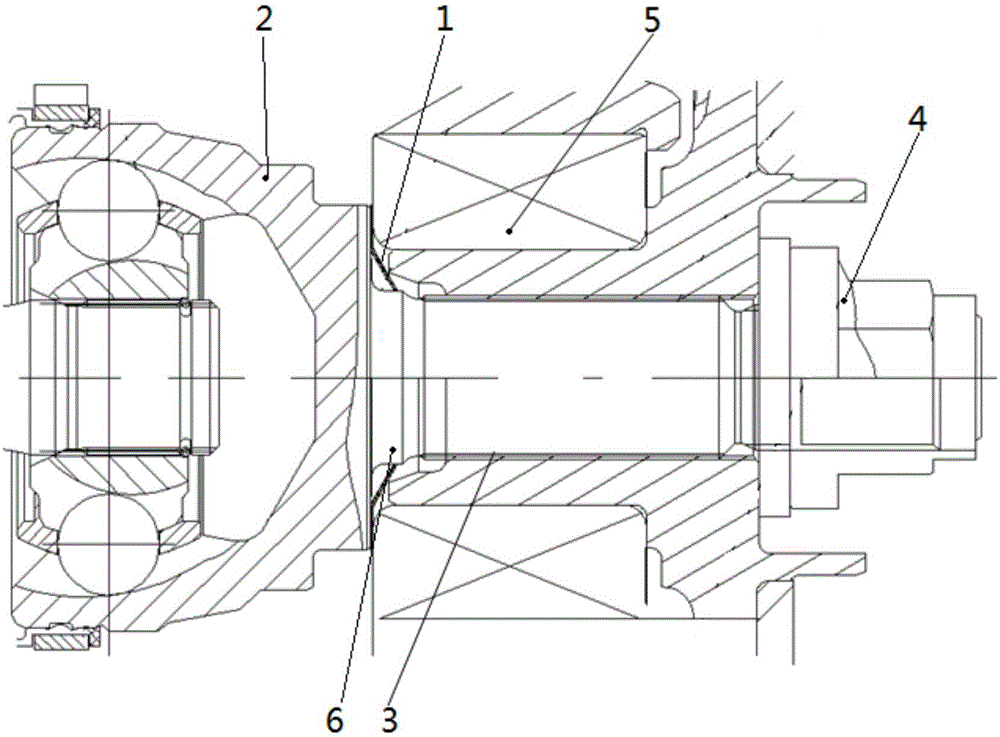

Anti-attrition spacer capable of reducing frictional abnormal sound and application of anti-attrition spacer

InactiveCN105782215AReduce friction noiseSqueak and rattle mitigationWashersSolid state diffusion coatingUniversal jointFrictional coefficient

The invention discloses an anti-attrition spacer capable of reducing frictional abnormal sound and an application of the anti-attrition spacer and belongs to the field of mechanical parts. The anti-attrition spacer takes a low-carbon alloy cold-rolled sheet as a base body, and carbonitriding thermal treatment and surface coating treatment of a polyfluorocomplex and / or a nylon 11 coating are successively performed on the low-carbon alloy cold-rolled sheet. The adhesive force between the coating and the base body in the anti-attrition spacer provided by the invention is large, and the coating has excellent anti-attrition effect and wear-resistant effect. The anti-attrition spacer is used between contact surfaces which rub with each other. With prolonging of frictional time, the coating on the anti-attrition spacer does not fall off, so that the durability of the anti-attrition spacer is ensured, the frictional coefficient between the anti-attrition spacer and the contact surfaces is effectively reduced, and the adhesive wear is reduced, and therefore, the frictional abnormal sound is further reduced. In particular, the anti-attrition spacer used in the field of automobiles can effectively relieve the frictional abnormal sound generated between the end face of a universal joint at the fixed end of a driving shaft and a contact surface of a hub bearing of an automobile.

Owner:CHERY AUTOMOBILE CO LTD

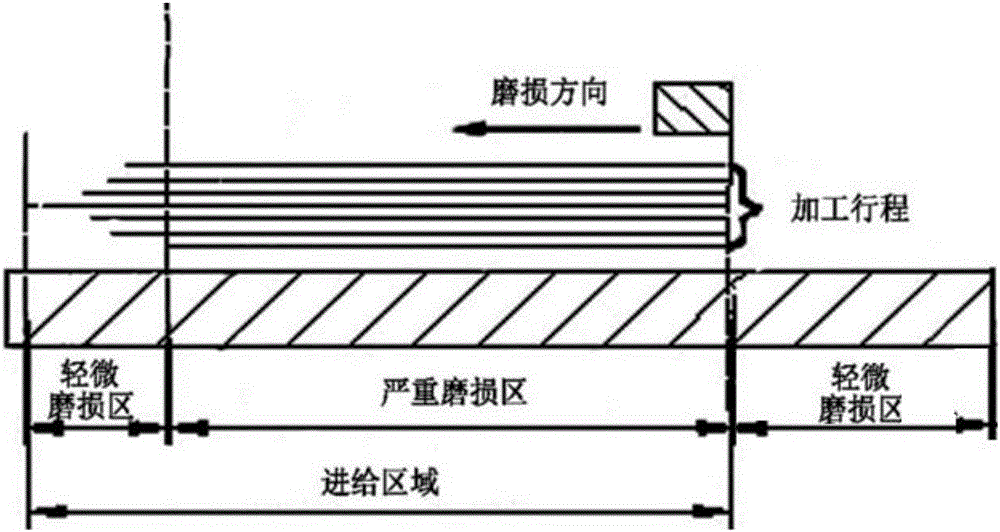

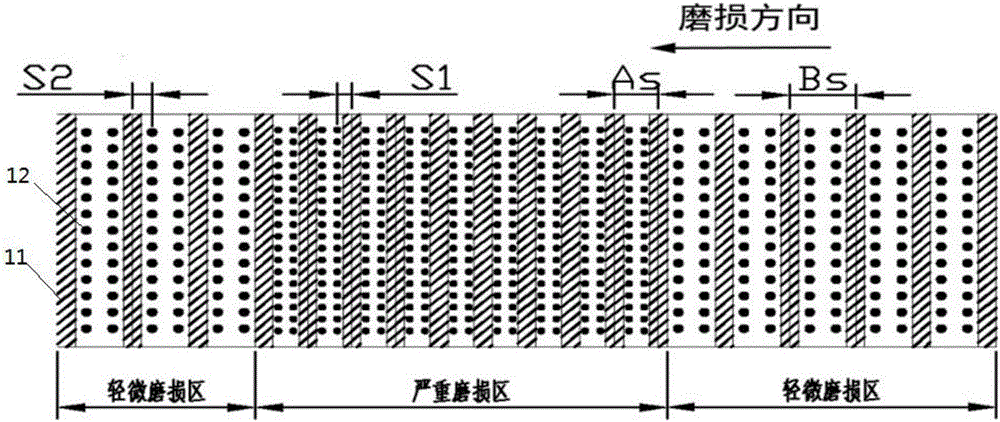

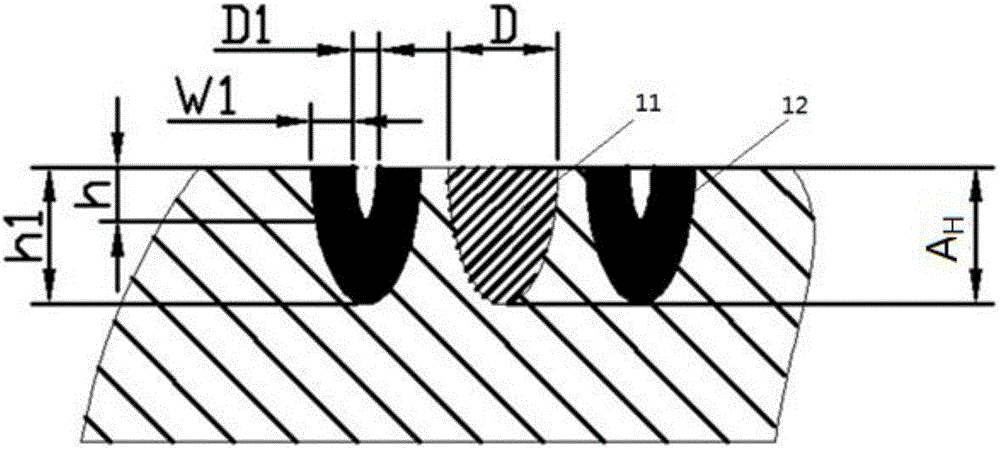

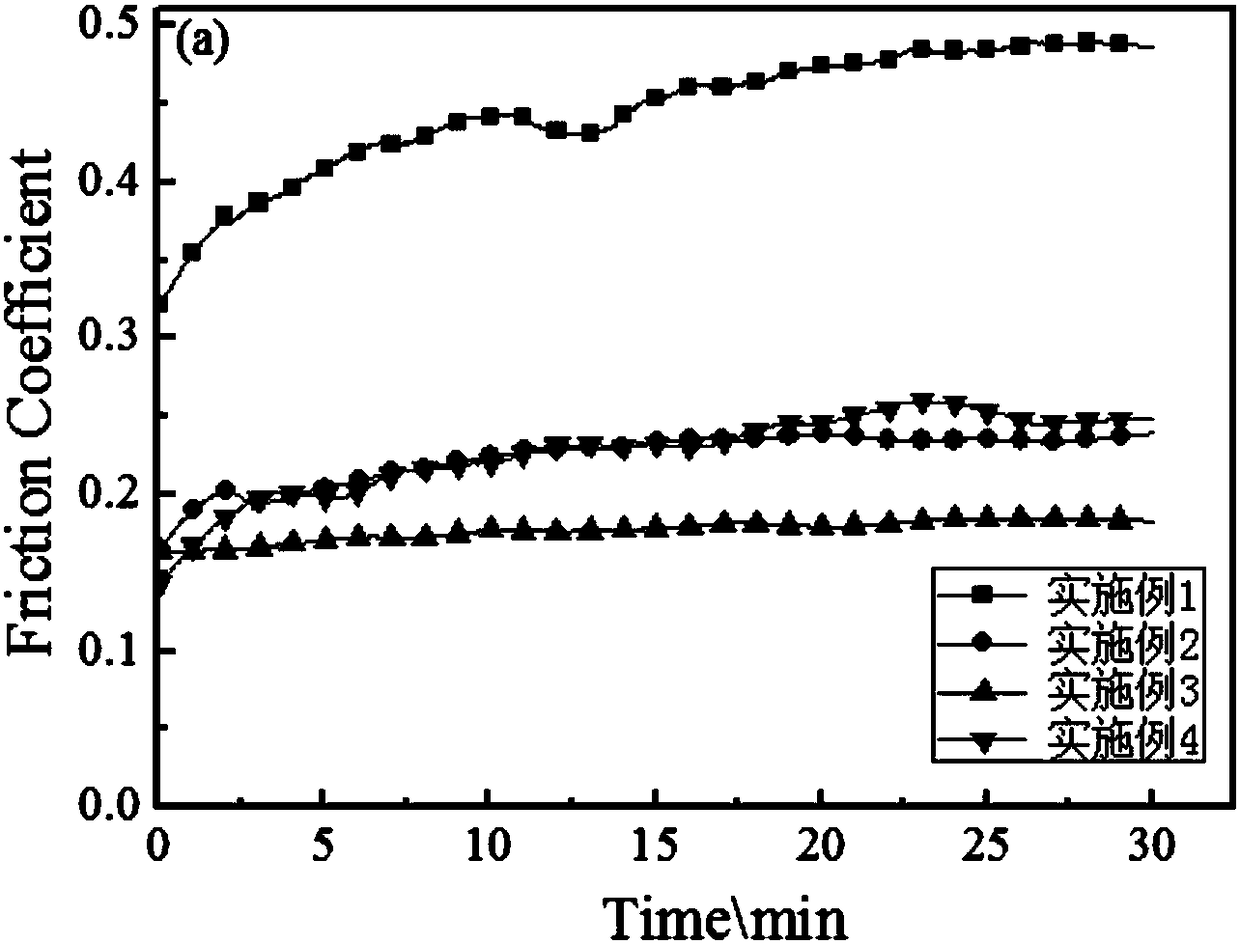

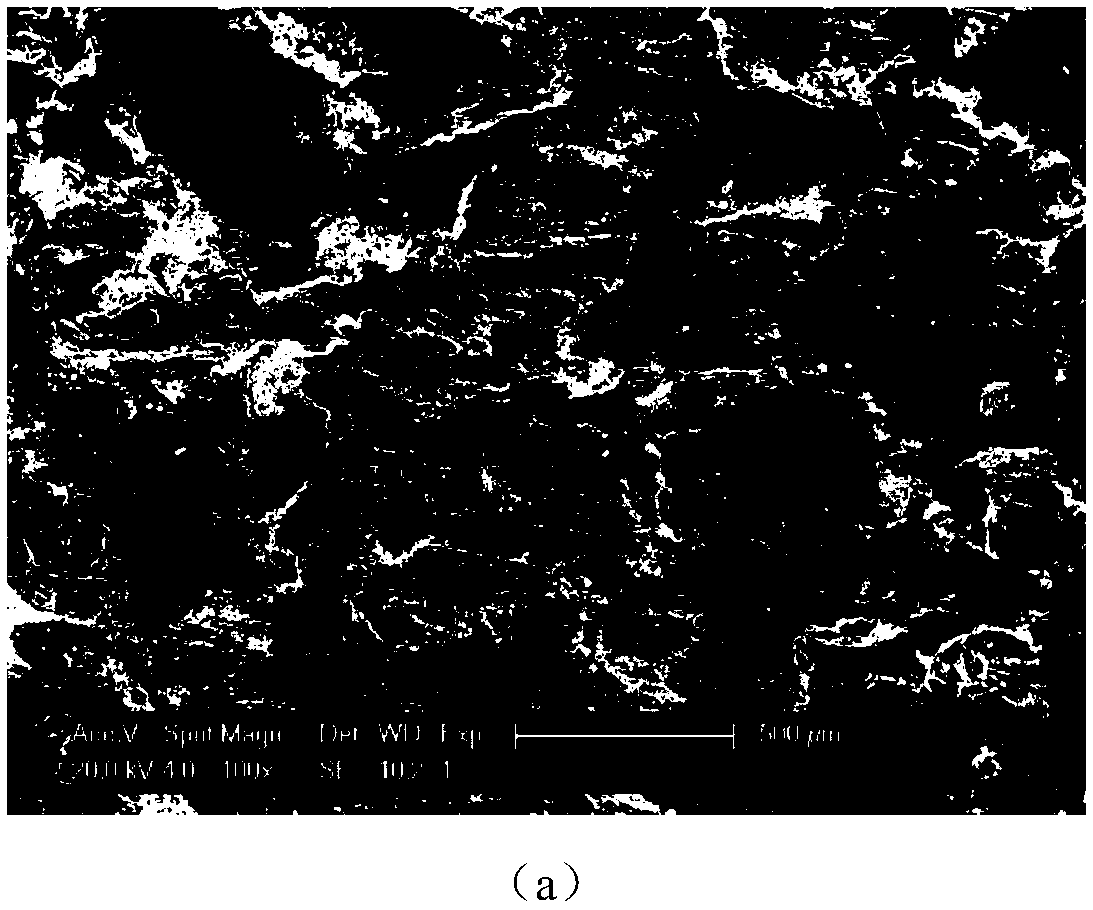

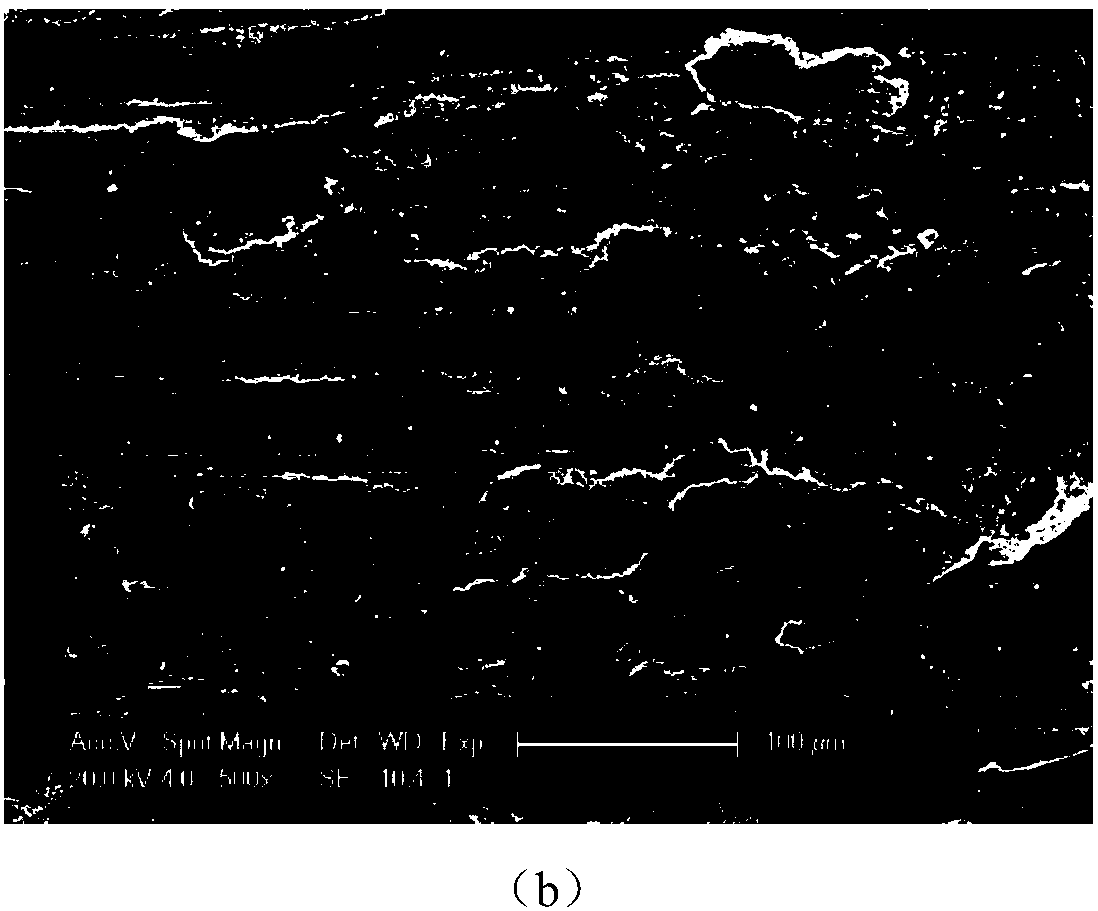

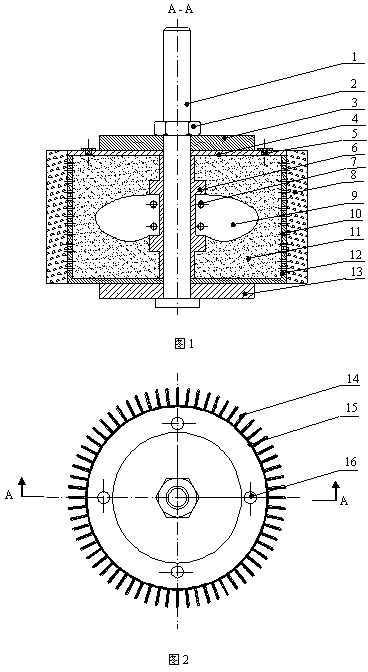

Multi-structure different-interval bionic surface combined cast-iron guide rail and regeneration method thereof

InactiveCN105108503AOvercoming Difficult-to-Regenerate ProblemsImprove wear resistanceLarge fixed membersStress distributionCoupling

The invention relates to a multi-structure different-interval bionic surface combined cast-iron guide rail and a regeneration method thereof. First bionic coupling elements and second bionic coupling elements are made on mild wear areas and a severe wear area of the guide rail working face; the first bionic coupling elements are strip-shaped or net-shaped bionic coupling elements, and intervals of the first bionic coupling elements in the mild wear areas are larger than those of the first bionic coupling elements in the severe wear area; the second bionic coupling elements are pit-shaped coupling elements and are distributed among the first bionic coupling elements. According to the multi-structure different-interval bionic surface combined cast-iron guide rail and the regeneration method thereof, according to the rigidity or stress distribution situations of the areas with different wear degrees, two double-coupling-element bionic surfaces with changeable intervals are set, a multi-structure different-interval bionic surface combination with different anti-wear performances is formed, and the surface of which the rigidity or the stress is distributed evenly is obtained, so that the effect that the overall anti-wear performance of the surface is uniform and stable for a long time is achieved. In addition, by means of the interaction between the two coupling elements and a machine body, the wear resistance of the sliding guide rail is further improved.

Owner:JILIN UNIV

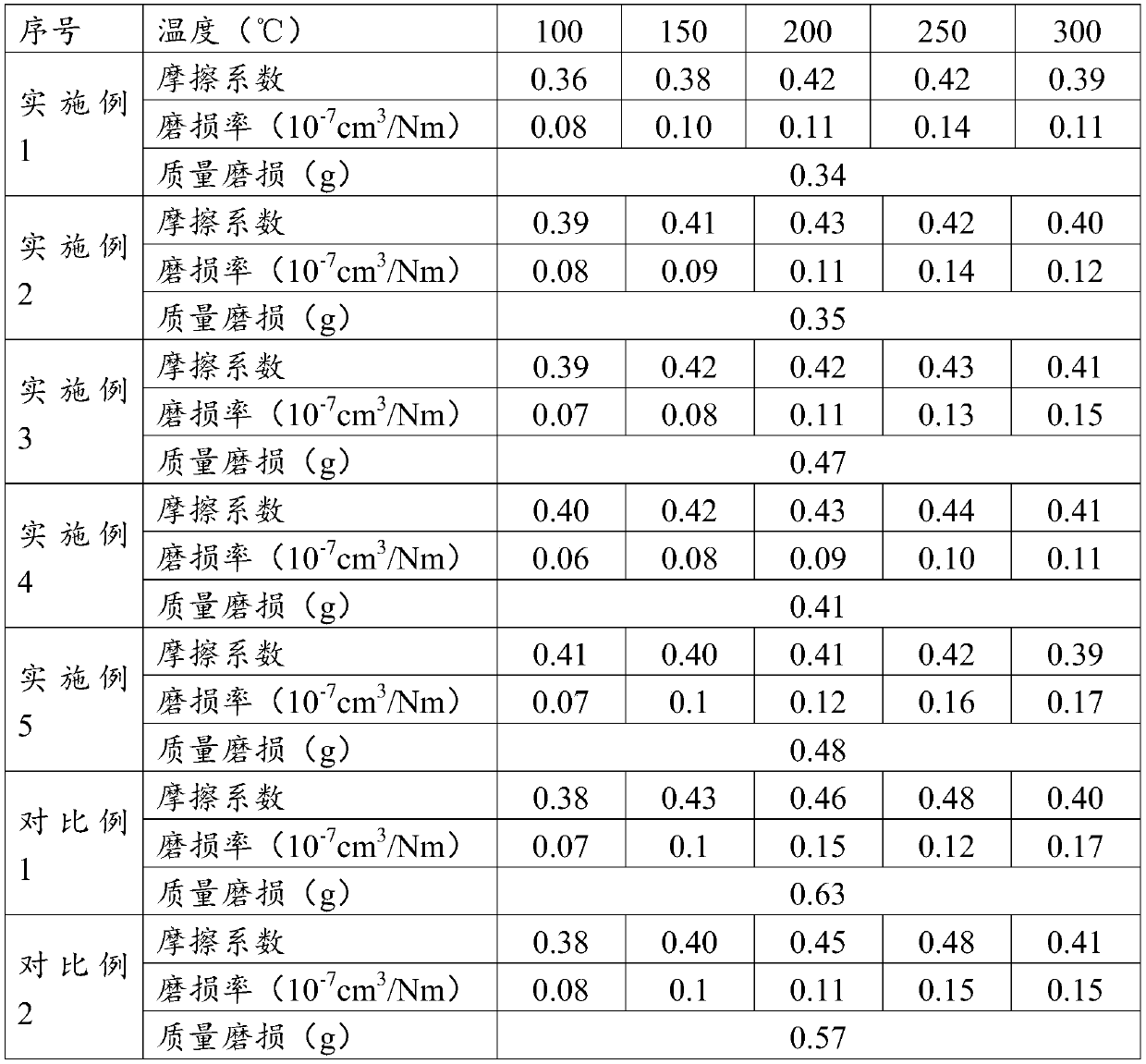

Copper-based powder metallurgy brake pad material as well as preparation method and application thereof

The invention discloses a copper-based powder metallurgy brake pad material as well as a preparation method and application thereof. The copper-based powder metallurgy brake pad material is prepared from the following raw materials in percentage by weight: 54 weight percent to 67 weight percent of copper powder, 13 weight percent of graphite, 4 weight percent to 17 weight percent of iron powder, 8weight percent to 14 weight percent of a ferrochrome alloy, 1 weight percent to 4 weight percent of silicon carbide and 1 weight percent to 4 weight percent of silicon dioxide; the preparation methodof the copper-based powder metallurgy brake pad material comprises the following steps: 1) weighing the raw materials according to the ratio and putting the raw materials into a mixer and uniformly mixing; 2) filling the mixed raw materials into a mold; carrying out hot pressing sintering or spark plasma sintering under the protection of a vacuum atmosphere or nitrogen gas to obtain the brake padmaterial with excellent comprehensive performance. The prepared brake pad material has high density and rigidity, stable friction coefficient, abrasion resistance and excellent comprehensive performance, and can meet the requirements on braking friction plates of high-speed rail trains. The copper-based powder metallurgy brake pad material disclosed by the invention can be used for preparing a brake pad; the preparation method comprises the following steps: taking Q235 as a base material, and compounding and sintering the raw materials for preparing the copper-based powder metallurgy brake pad material and the base material through a hot pressing sintering technology, so as to obtain the brake pad.

Owner:SOUTHEAST UNIV

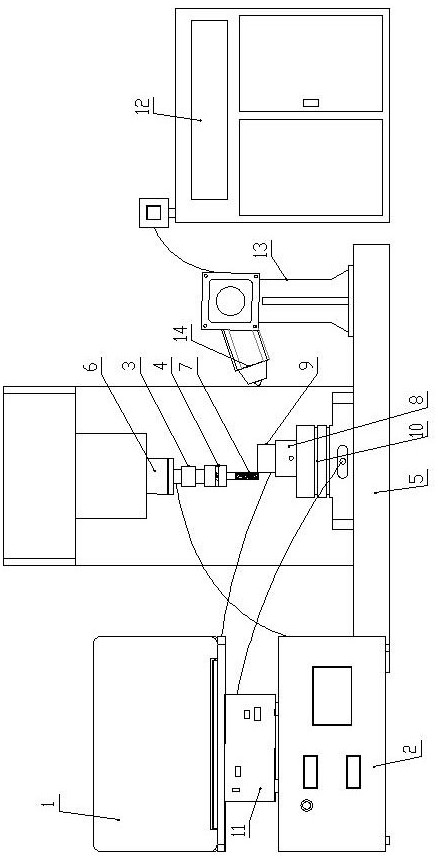

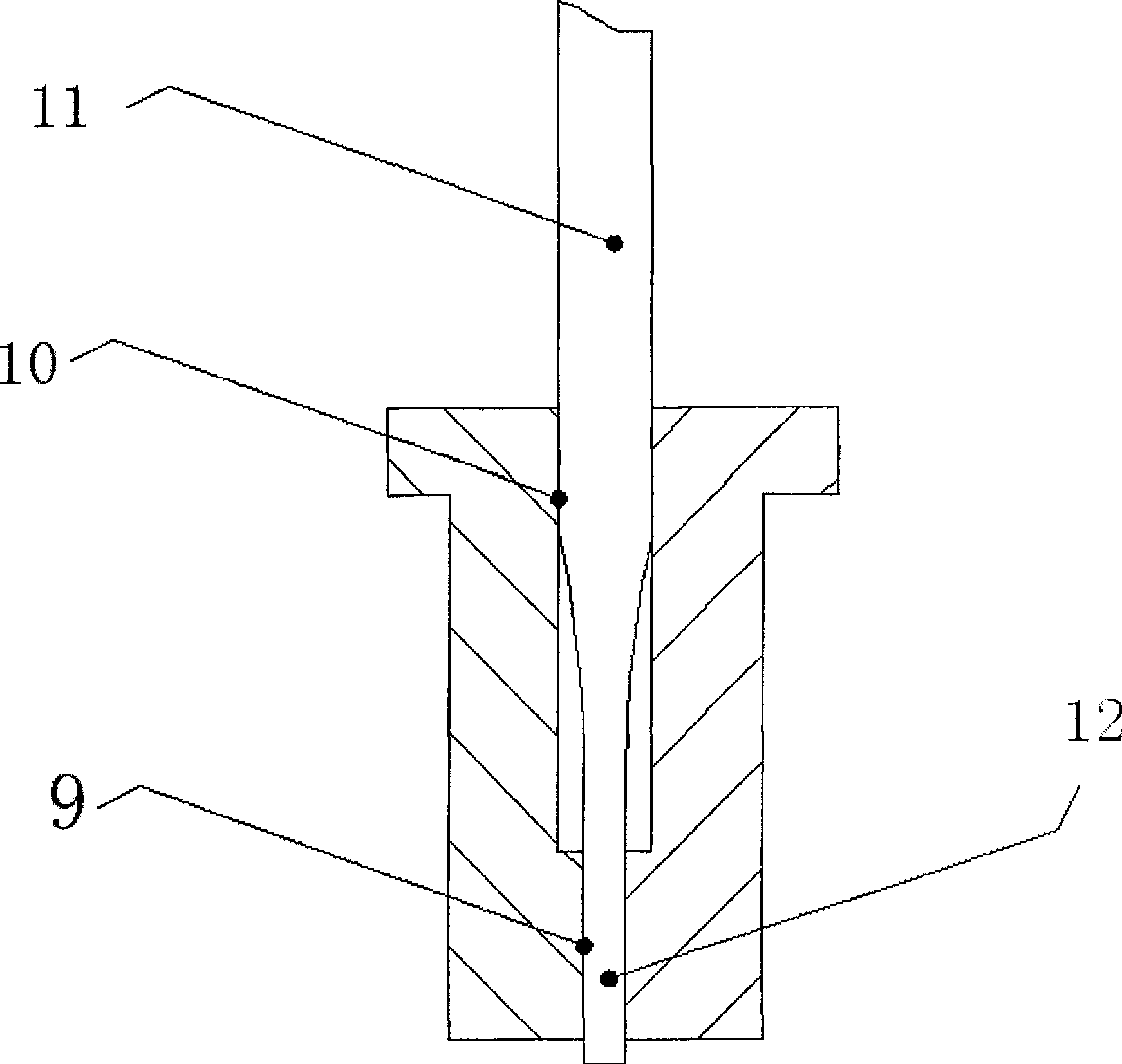

Ultrasonic vibration machining device and method for aluminum-based silicon carbide composite material

ActiveCN112548175AImprove quality and efficiencyImprove processing efficiencyMilling equipment detailsCarbide siliconMachine parts

The invention discloses an ultrasonic vibration machining device and method for an aluminum-based silicon carbide composite material. The ultrasonic vibration machining device comprises a computer, alaser auxiliary heating part, an ultrasonic vibration machining part, a machine tool workbench, a machine tool spindle and a micro-edge milling cutter, wherein the ultrasonic vibration machining partcomprises an ultrasonic generator, a transducer and an amplitude-change pole; the lower end of the machine tool spindle is connected with the transducer, the lower end of the transducer is connected with the amplitude-change pole, the upper end of the micro-edge milling cutter is clamped at the lower end of the amplitude-change pole, and the ultrasonic generator is connected with the transducer through a wire; a clamp holder is arranged on the machine tool workbench, a workpiece made of the aluminum-based silicon carbide composite material is clamped on the clamp holder, and the clamp holder is connected with a three-way dynamometer; and the laser auxiliary heating part is used for heating a to-be-machined part of the workpiece. In the milling operation process, chip removal can be accelerated, flutter of a cutter is eliminated, abrasive abrasion and adhesive abrasion are reduced, milling force and cutting heat are reduced, the machining size precision is guaranteed, the workpiece surface quality and the machining efficiency are improved, and the machining cost is saved.

Owner:HENAN POLYTECHNIC UNIV

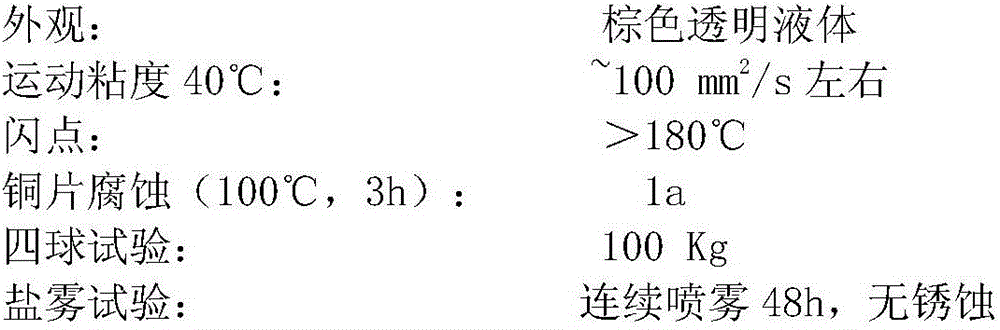

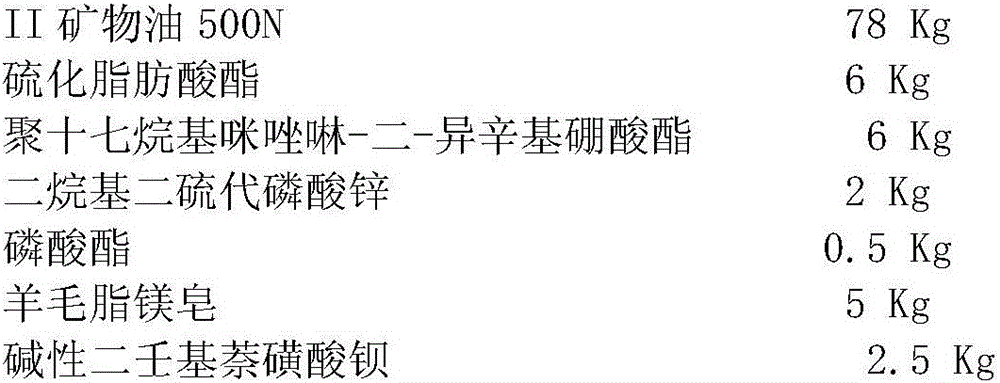

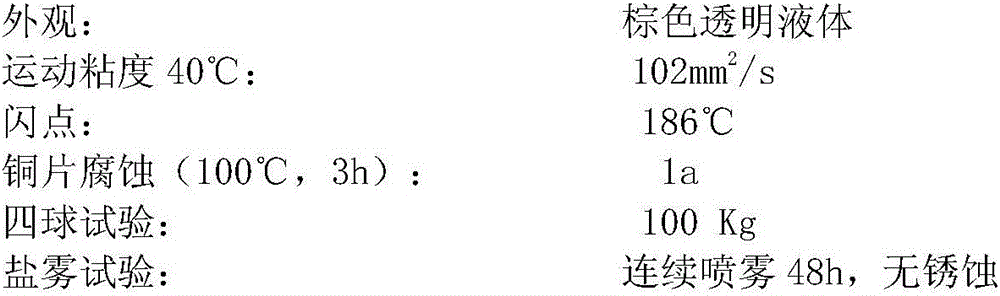

High-performance punching oil used for thick plate

The invention discloses high-performance punching oil used for a thick plate, belongs to the field of metal processing operating fluid, and particularly relates to operating fluid for metal stamping processing. The high-performance punching oil comprises, by mass, 60%-80% of refined mineral oil, 5%-10% of a sulfur-containing extreme pressure agent, 5%-15% of a macromolecule polymerization ester extreme pressure agent, 0.5%-5% of an antiwear agent and 5%-10% of an antirust agent. One of sulfide aliphatic acid ester and over-based sulfosalt or a mixture of the sulfide aliphatic acid ester and the over-based sulfosalt is selected as the sulfur-containing extreme pressure agent. Polyheptadecylimidazoline-di-isooctyl borate is selected as the macromolecule polymerization ester extreme pressure agent. According to the high-performance punching oil, under the synergistic effect of the macromolecule polymerization ester extreme pressure agent and the sulfur-containing extreme pressure agent, excellent lubricating performance and anti-corrosion performance can be given to the punching oil, and the high-performance punching requirements for the thick plate are met. Moreover, the rusting problem of punched products and the ecological environment problem are solved without chlorinated paraffin.

Owner:BOER TECH WUHAN

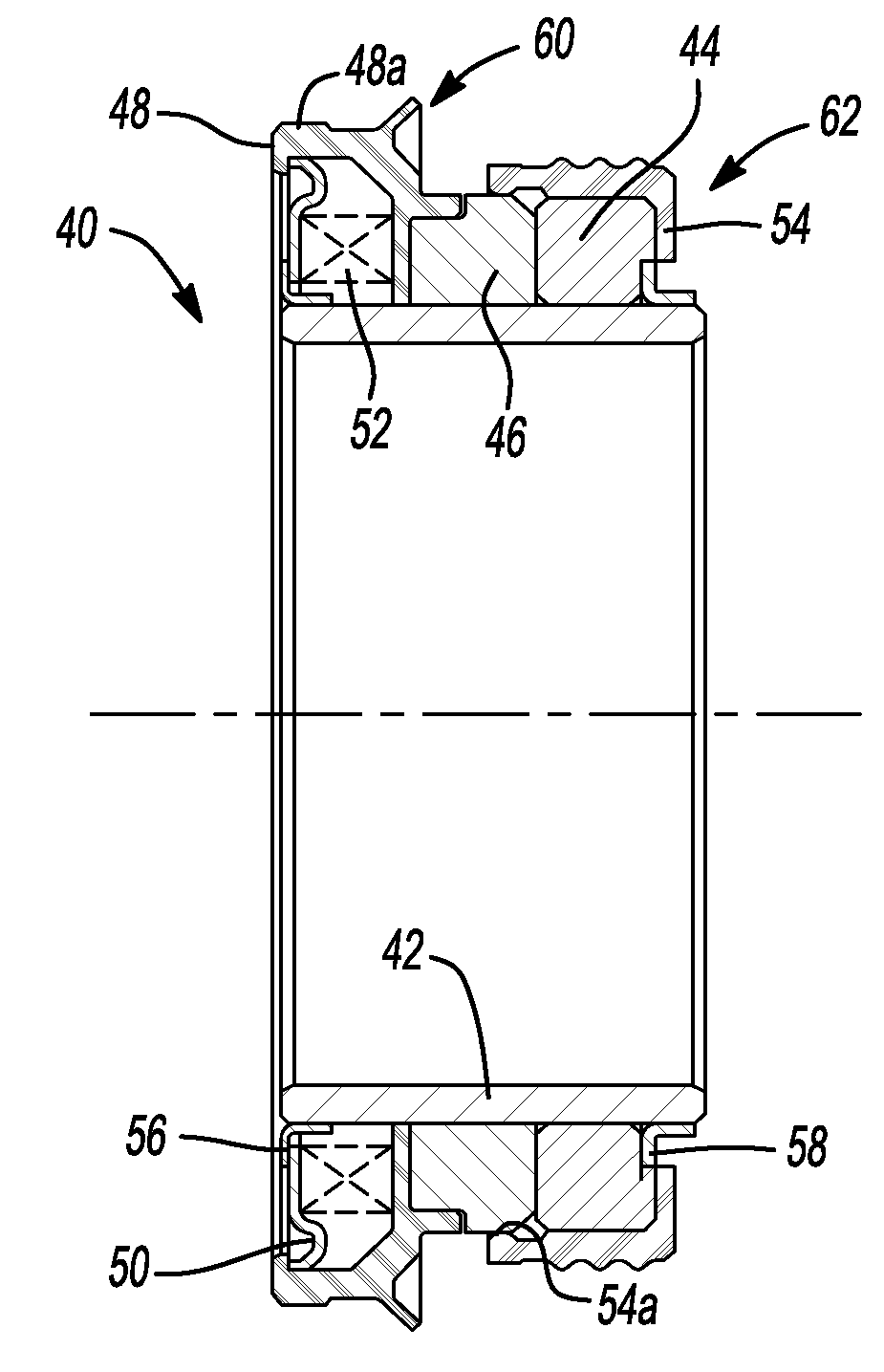

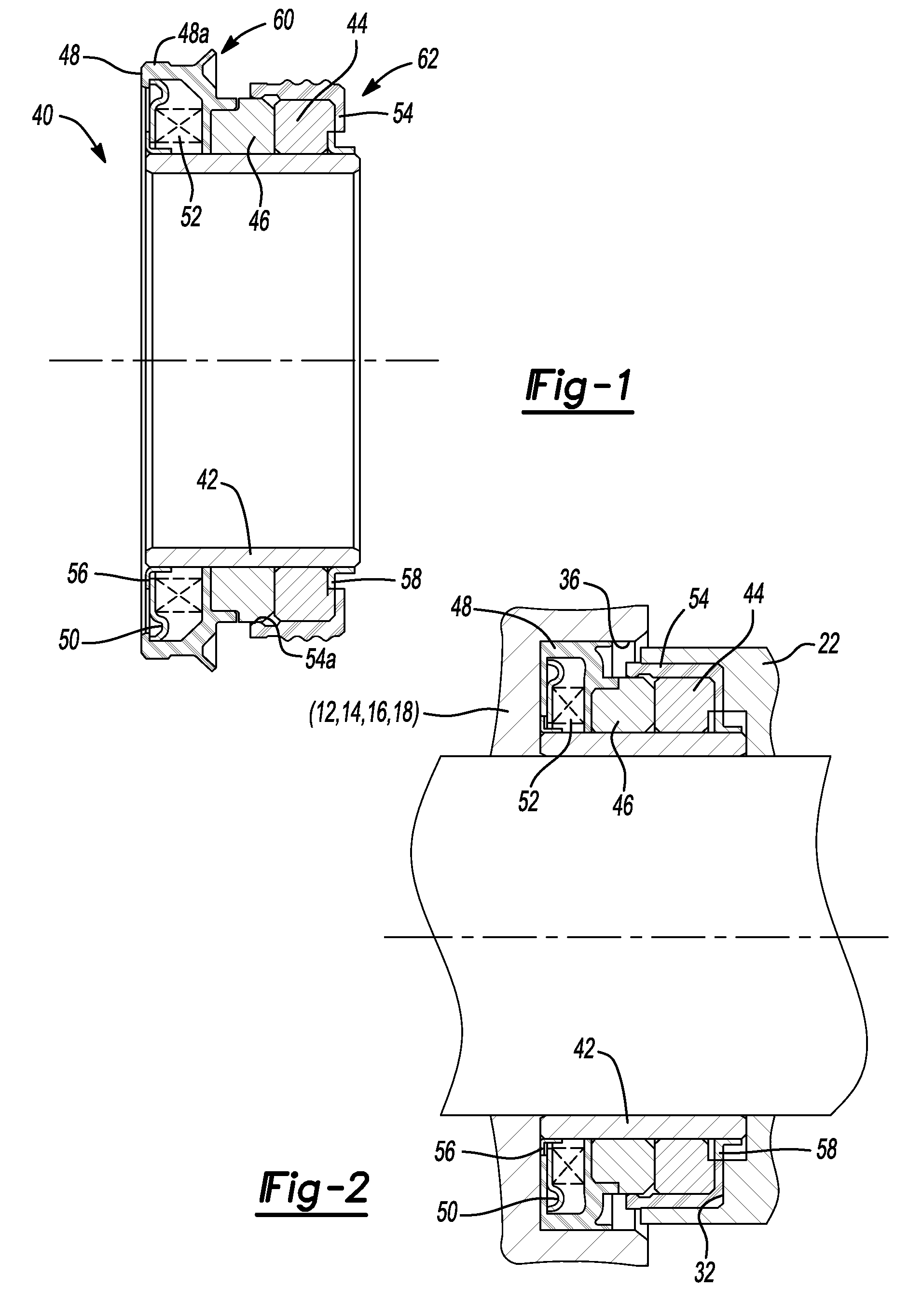

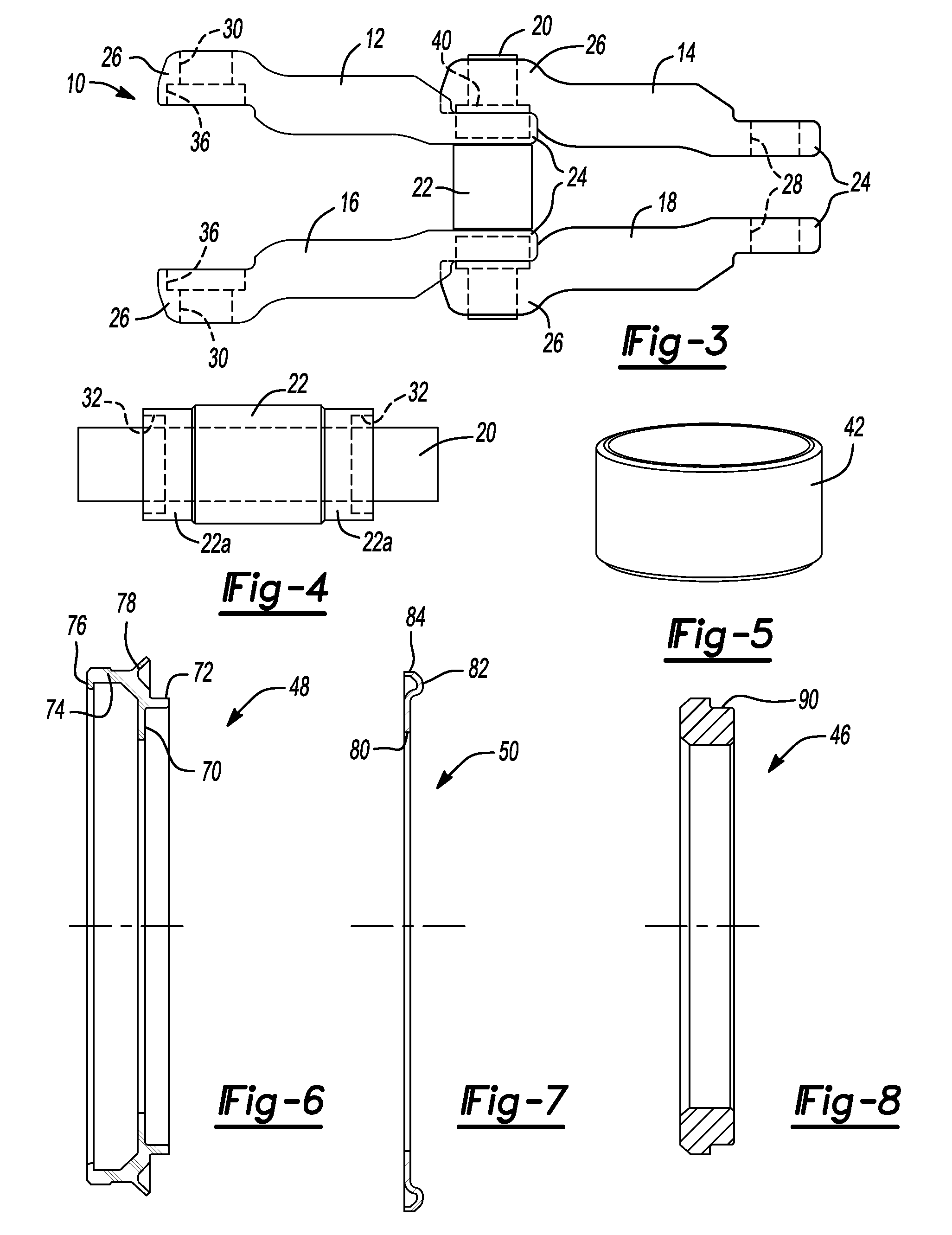

Unitized Seal With Integral Spacer

ActiveUS20090261650A1Solution to short lifeReduce frictionEngine sealsSuperstructure subunitsEngineeringChain link

A unitized seal assembly is provided for installation between linkages of a chain drive designed for tracked vehicles. The seal assembly facilitates field preventative maintenance on the drive chain by utilizing an integral spacer that holds the critical sealing surfaces together at all times, and has a seal head that can be easily removed from the outer link bore of a chain link. Removal of the seal head from the outer link bore causes as-installed clearance passageways between the seal head and seat portions and the spacer to forcefully close and prevent abrasive particles from getting inside the seal and reaching the interior interface junction of the dynamic sealing surfaces during seal maintenance. The seal assembly also includes additional sealing features that provide improved performance.

Owner:FREUDENBERG NOK GEN PARTNERSHIP

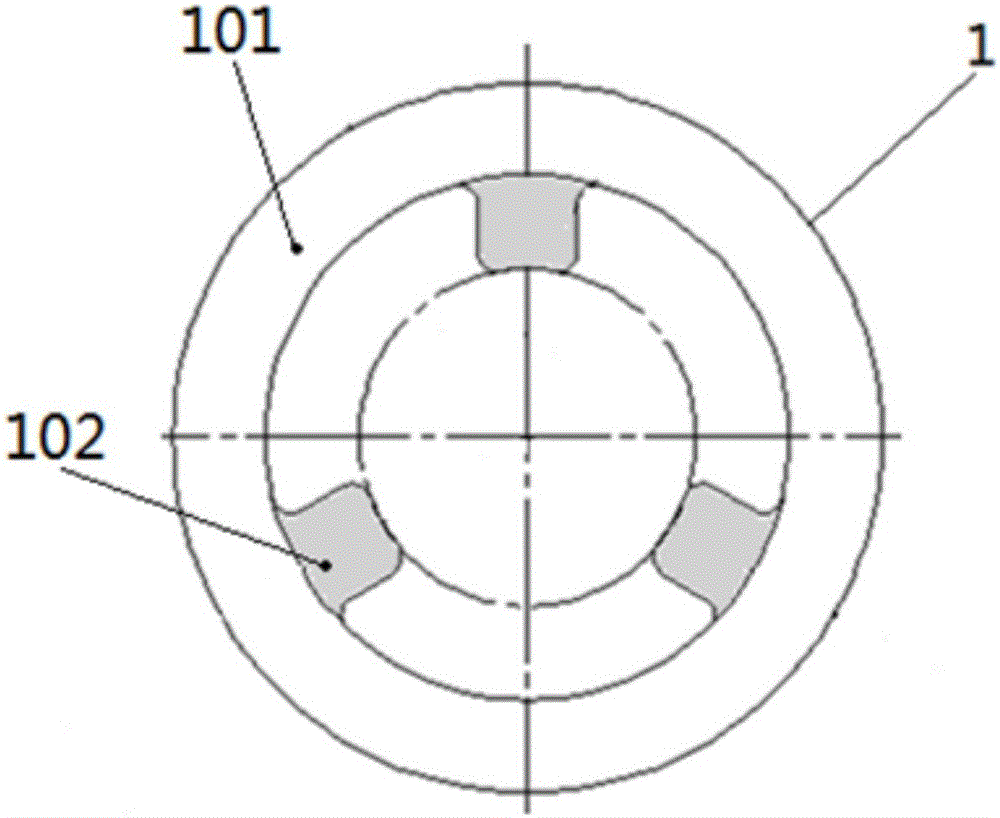

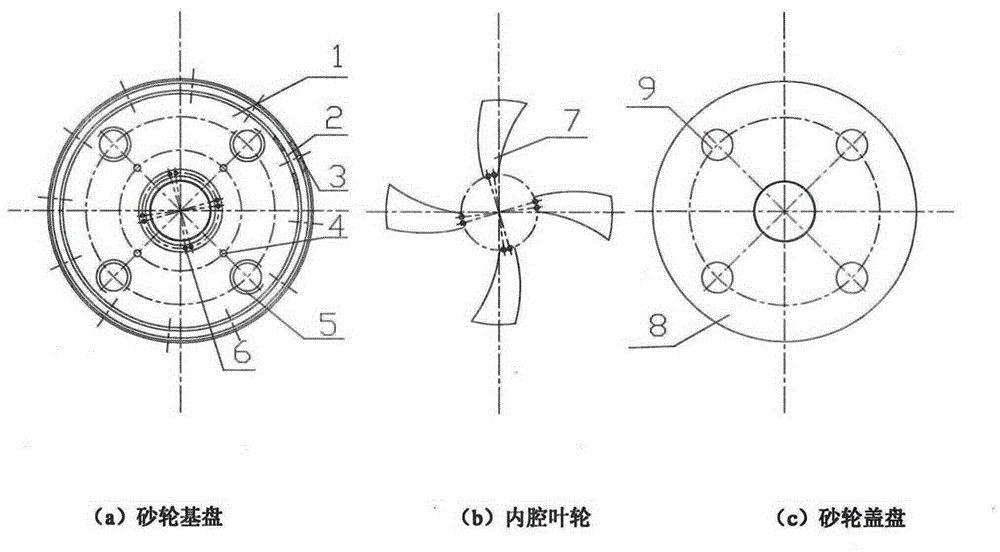

Impeller supercharging solid self-lubricating grinding wheel matrix structure

InactiveCN102794717ASimple self-lubricationReduce Adhesive WearBonded abrasive wheelsInlet valveCentrifugal force

The invention discloses an impeller supercharging solid self-lubricating grinding wheel matrix structure. An impeller centrifugal pump structure is introduced into manufacturing of a grinding wheel; and the matrix structure mainly comprises a grinding wheel base plate and an impeller cover plate. An impeller is arranged on an impeller pedestal designed in the inner cavity of the grinding wheel base plate, the outer edge of the grinding wheel base plate is provided with a ring slot, and a one-way air inlet valve is arranged on the inner wall of the ring slot; during grinding, a main shaft of the grinding wheel drives the impeller in the inner cavity to simultaneously rotate at a high speed, so that high-pressure airflow is generated in the inner cavity; the high-pressure airflow bursts through the one-way air inlet valve, so that a solid lubricating agent filled in the ring slot is continually and properly precipitated on the surface of the grinding wheel under driving coaction of the high-pressure airflow, a centrifugal force, grinding heat and the like through micro pores on the outer wall of the inner cavity of the ring slot. The structure is simple and facilitates to popularize; and through the structure, the solid lubricating agent in the grinding wheel can be conveyed to a grinding arc area reliably with low cost, so that dry grinding can be realized.

Owner:TIANJIN UNIV OF TECH & EDUCATION TEACHER DEV CENT OF CHINA VOCATIONAL TRAINING & GUIDANCE

Abrasion-resistant clutch friction plate for automobile

InactiveCN106090056AReduce wearExtended service lifeOther chemical processesFriction clutchesAdhesiveAgricultural engineering

The invention discloses an abrasion-resistant clutch friction plate for an automobile. The abrasion-resistant clutch friction plate comprises, by mass, 0.4-1.2 parts of compounding agents, 6-8 parts of sulphur, 8-12 parts of starch, 18-25 parts of adhesives, and 64-87 parts of filling agents. According to the technical scheme provided by the embodiment of the invention, certain materials are added into the friction plate, abrasive material abrasion caused by tight combination between a friction plate and a flywheel as well as between the friction plate and a compression plate in the using process of a clutch can be effectively reduced, adhesion abrasion caused by high temperature due to vehicle overloading can also be effectively reduced, the abrasion of the friction plate and a mating plate is reduced, and the service life of the clutch is prolonged.

Owner:NANTONG WANDA FRICTION MATERIAL

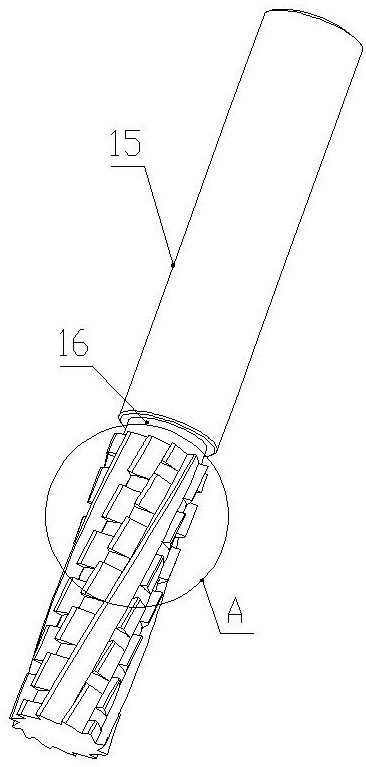

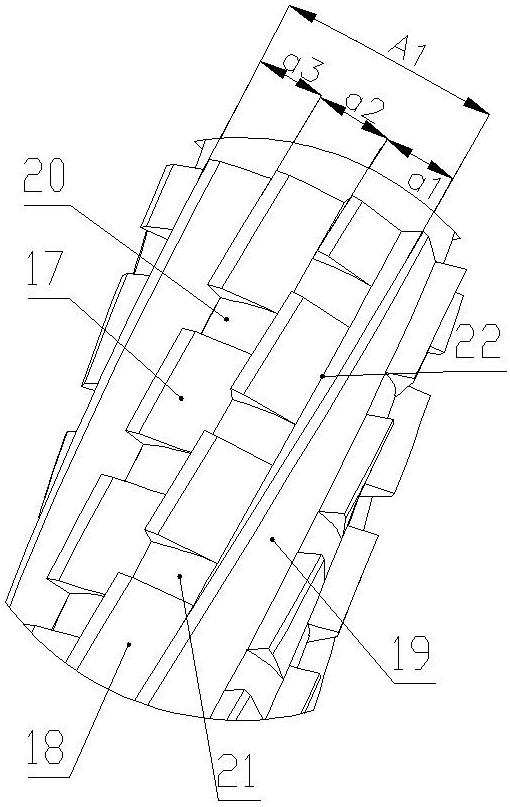

Spraying, grinding and throwing abrasive belt flap wheel in gas phase and solid phase

InactiveCN103894941ASimple structureReduce Adhesive WearFlexible-parts wheelsSolid phasesEngineering

The invention relates to a spraying abrasive belt flap wheel in gas phase and solid phase for drying type polishing and throwing, wherein the spraying abrasive belt flap wheel is mainly oriented to machining of high-strength and high-tenacity materials difficult to machine. Fan blades and an inner cavity structure for differential rotation of a chassis of the abrasive belt flap wheel are introduced into manufacturing of the abrasive belt flap wheel. The abrasive belt flap wheel is mainly composed of an abrasive belt flap wheel mounting handle, the chassis, a cover disk, the differential fan blades, abrasive belt blades and other parts. In the grinding and throwing process, a main shaft of a machine tool drives the abrasive belt flap wheel mounting handle, a base, a cover plate and the like to rotate together at high speed, the differential blades of the inner cavity of the base are connected with a fan blade mounting sleeve, the rotating speed of the differential blades of the inner cavity of the base is not consistent with that of the abrasive belt flap wheel mounting handle so that driving force can be exerted on lubricating mediums filled in the inner cavity of the base, and the lubricating mediums are precipitated to the surface of the abrasive belt blades continuously and quantitatively under the joint action of the driving force and eccentric force. The abrasive belt flap wheel is simple in structure and easy to popularize, the lubricating mediums in the abrasive belt flap wheel can be reliably conveyed to the grinding and throwing arc area with low cost through the structure, and therefore the drying type polishing and throwing of the high-strength and high-tenacity materials difficult to machine can be achieved.

Owner:TIANJIN UNIV OF TECH & EDUCATION TEACHER DEV CENT OF CHINA VOCATIONAL TRAINING & GUIDANCE

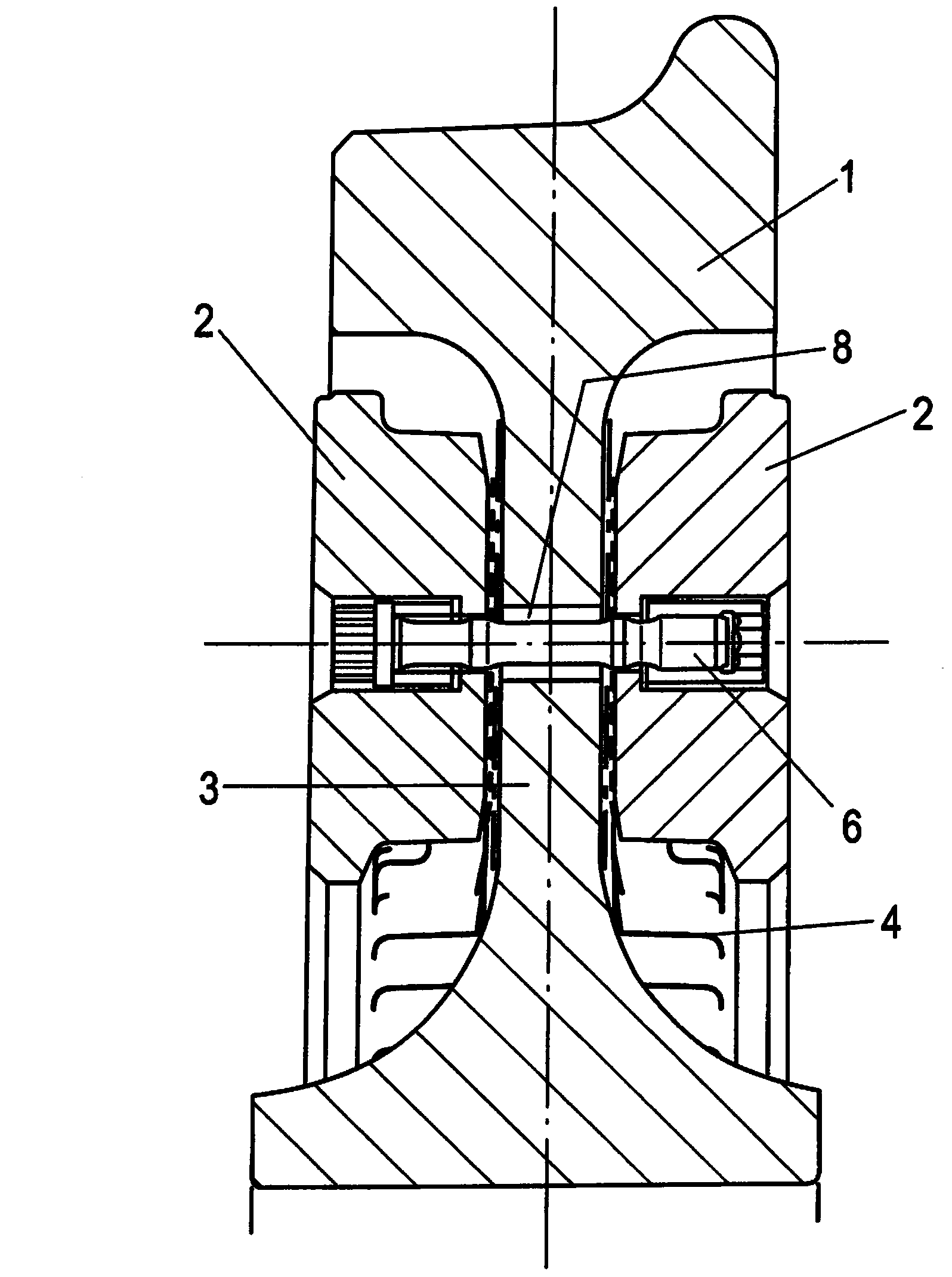

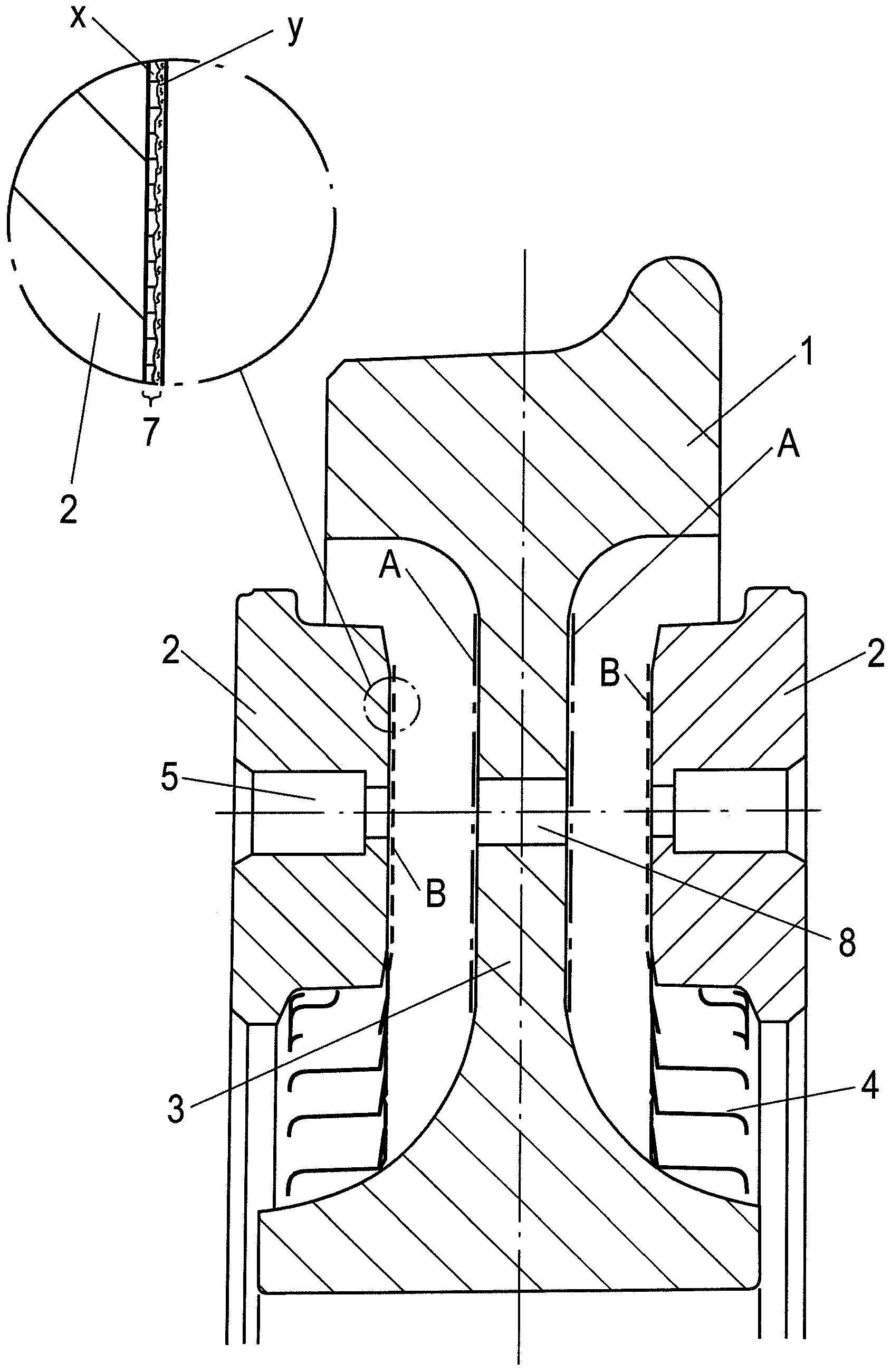

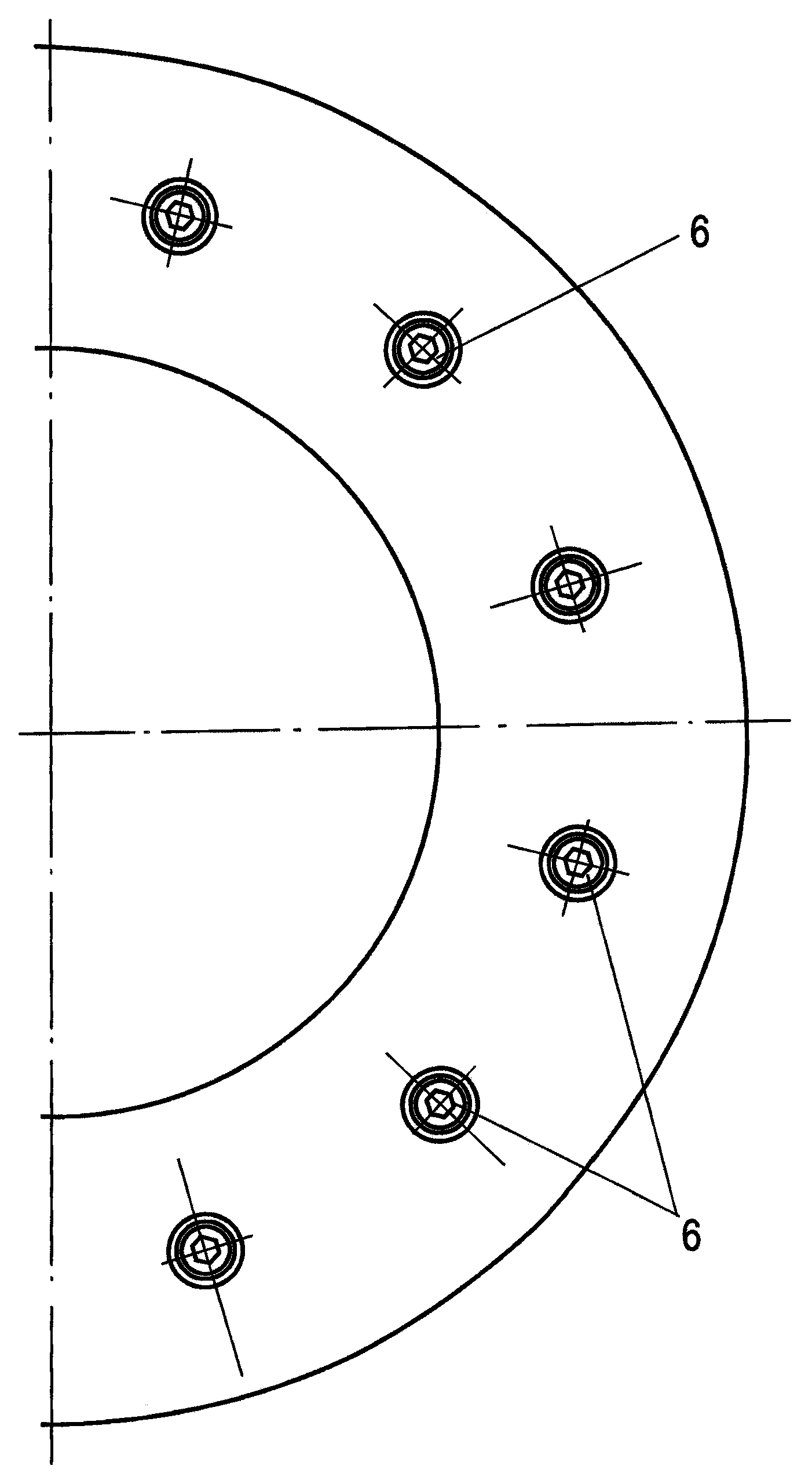

Rail wheel and method for producing a rail wheel

ActiveCN103517811AImprove stabilityHigh hardnessRail-engaging wheelsPhosphatisationMechanical engineeringCoating

A rail wheel with a wheel body (1) and friction discs (2) connected thereto on both sides by fastening elements, wherein a multi-layer coating (7) is arranged at least between the respective contact surfaces (B) of the friction discs (2) and the contact surfaces (A) of the wheel body (1), with a coating (7) which can be subjected to mechanically and thermally high loading, and a method for producing a rail wheel.

Owner:KNORR BREMSE SYST FUR SCHIENENFAHRZEUGE GMBH

Water-based nano tungsten disulfide lubricating agent capable of protecting surface of aluminum profile and used for isothermal die forging and preparation method of water-based nano tungsten disulfide lubricating agent

InactiveCN105400584AGood suspensionNo agglomeration, turbidity and precipitationAdditivesFriction reductionWater based

The invention discloses a water-based nano tungsten disulfide lubricating agent capable of protecting the surface of an aluminum profile and used for isothermal die forging and a preparation method of the water-based nano tungsten disulfide lubricating agent. The water-based nano tungsten disulfide lubricating agent is prepared from raw materials in parts by weight as follows: 7.4-7.6 parts by weight of PAO6 (poly-alpha-olefin), 0.2-0.25 parts of a silane coupling agent kh 560, 8.2-8.4 parts of nano tungsten disulfide, 0.8-1 part of nano carbon balls, 0.8-1 part of nano bentonite, 1-1.2 parts of Span-80, 0.4-0.5 parts of butyl acrylate, 0.6-0.8 parts of methyl acrylate, 0.1-0.2 parts of ammonium persulfate, 0.8-0.9 parts of barium fluoride, 0.3-0.4 parts of nano TiO2, 0.5-0.6 parts of tetraethoxysilane, 0.5-0.6 parts of micron TiO2 and the balance of water. The lubricating agent has an excellent protection function on the surface of the aluminum profile through comprehensive use of barium fluoride, nano TiO2, tetraethoxysilane and micron TiO2 and has better friction reduction and abrasion resistance by comparison with ordinary water-based lubricating agents.

Owner:安徽创奇乐智能游乐设备有限公司

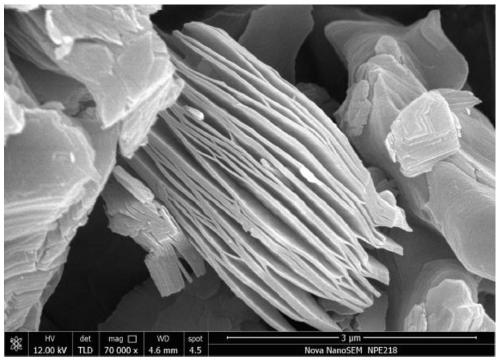

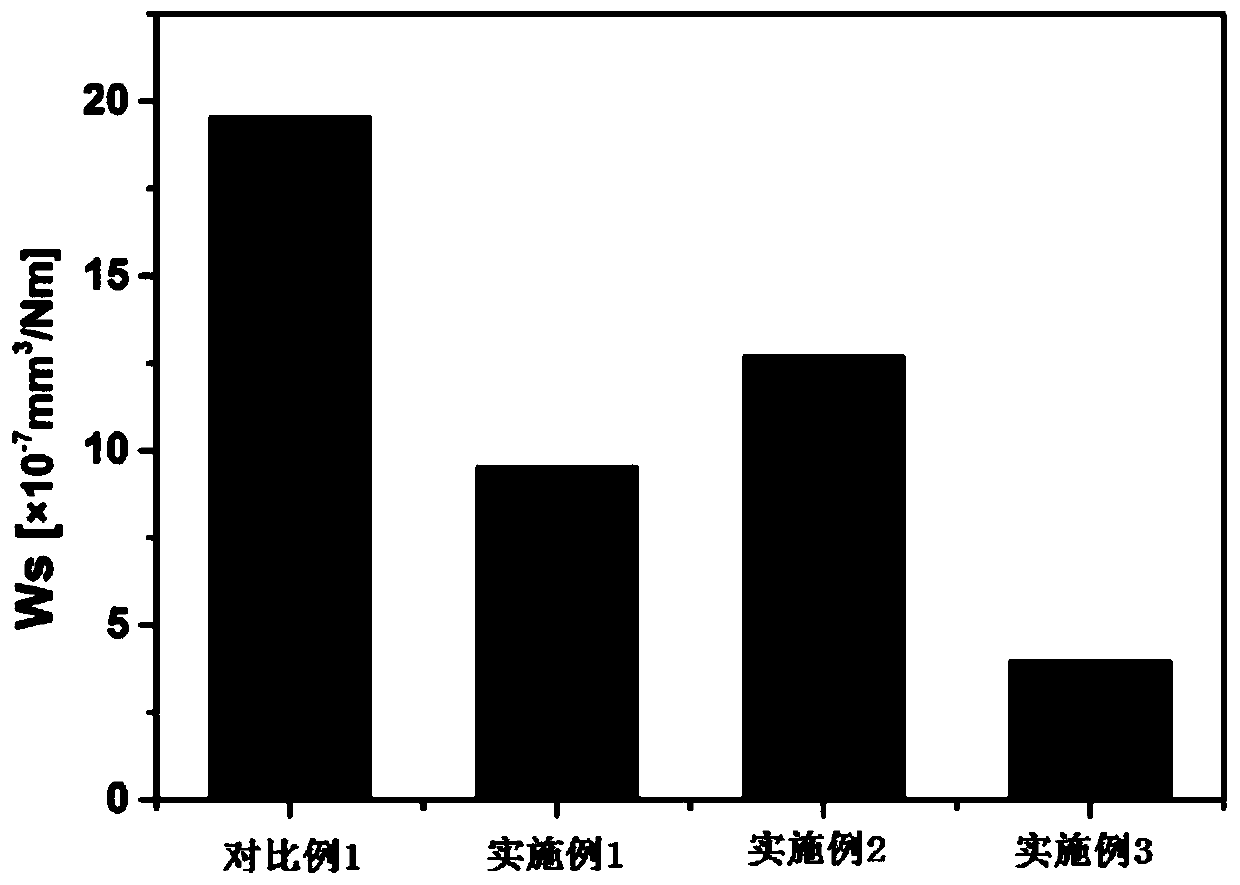

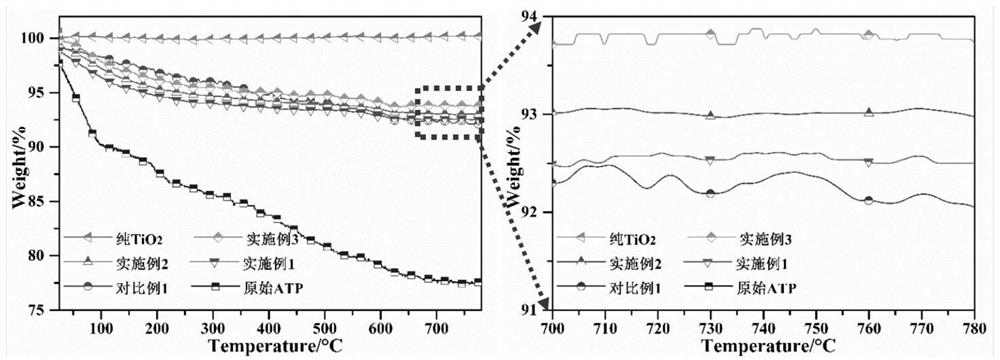

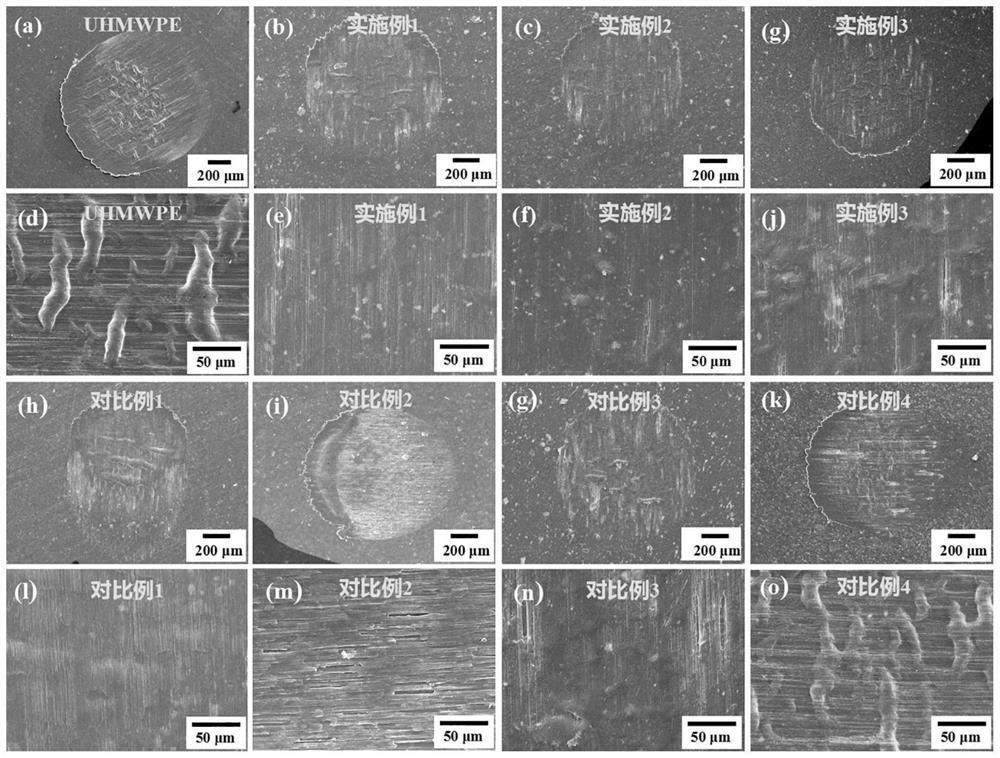

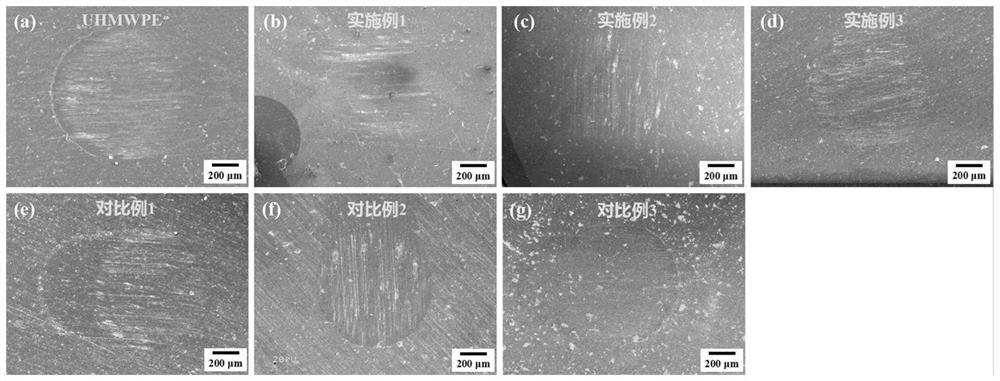

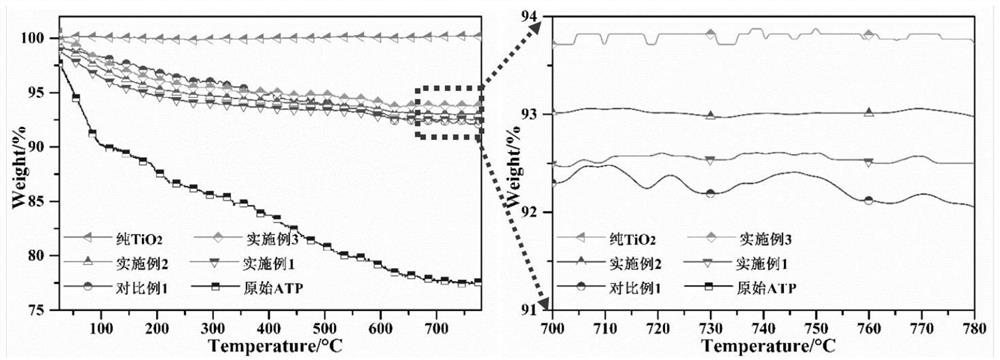

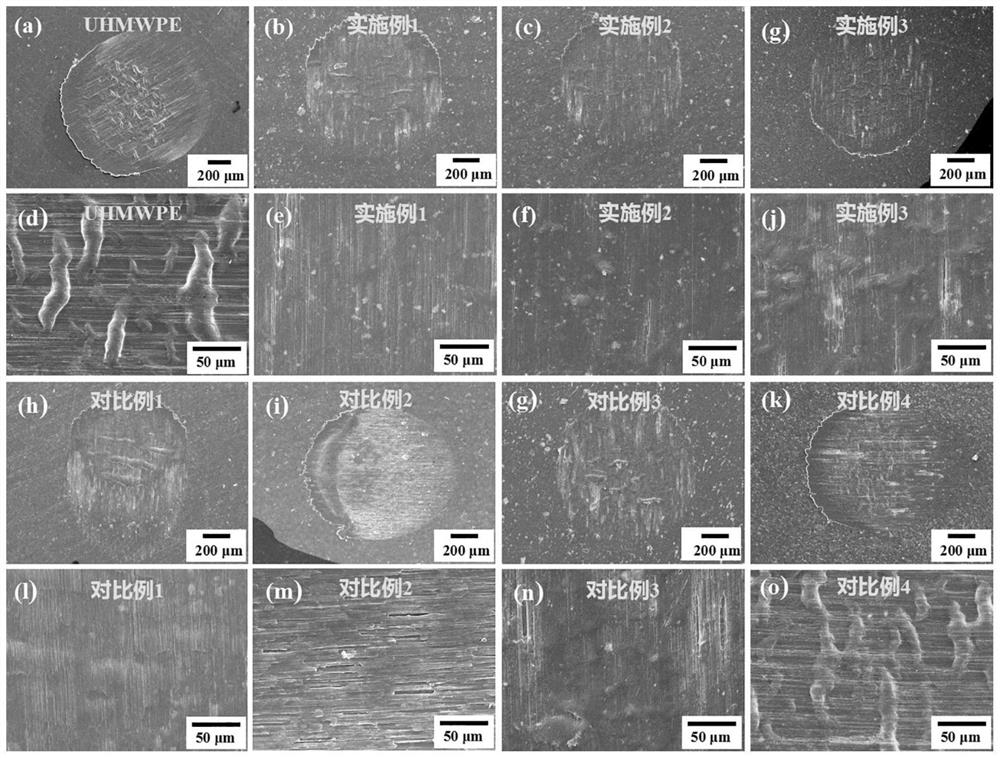

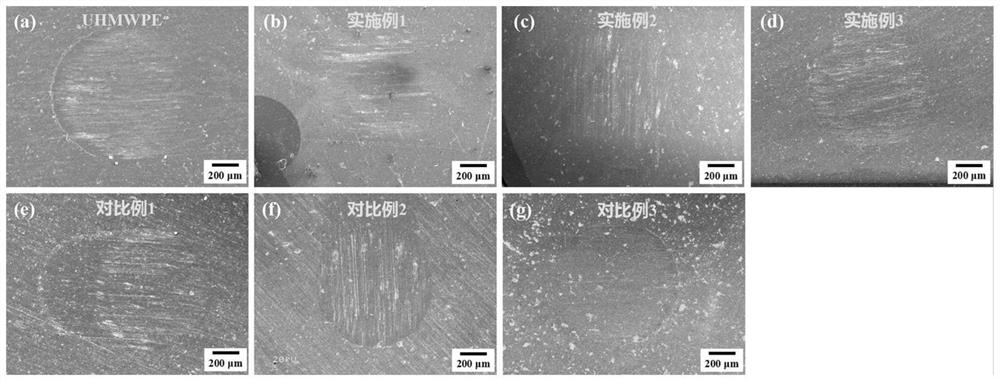

Attapulgite-titanium dioxide modified ultra-high molecular weight polyethylene composite material as well as preparation method and application thereof

ActiveCN112226264AHigh surface energyInhibit wearLubricant compositionPigment physical treatmentHigh surfaceTitanium oxide

The invention provides an attapulgite- titanium dioxide modified ultra-high molecular weight polyethylene composite material as well as a preparation method and application thereof, and belongs to thetechnical field of solid lubricating materials. According to the invention, attapulgite- titanium dioxide is used as a filler in ultrahigh molecular weight polyethylene, titanium dioxide particles have high surface energy, hard high-roughness particles can be formed after the titanium dioxide particles are loaded on attapulgite, and after attapulgite-titanium dioxide serving as filler is combinedwith ultrahigh molecular weight polyethylene, a better bearing effect can be achieved in the friction process, and abrasion of the material can be prevented; and meanwhile, the attapulgite-titanium dioxide is added, so that the heat resistance of an ultrahigh molecular weight polyethylene matrix can be improved, the composite material is not prone to deformation under the condition that frictionheat is concentrated, the deformation degree of the material is reduced to a certain extent, correspondingly, adhesive wear is also reduced to a certain extent, and the anti-friction and wear-resisting properties of the material are further improved.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Material of guide sliding shoe of coal-winning machine and preparation method of material

InactiveCN102191496AHigh strengthHigh hardnessSlitting machinesMetallic material coating processesAlloySolvent

The invention relates to a material of a guide sliding shoe of a coal-winning machine and a preparation method of the material, and belongs to a sliding shoe material and a preparation method thereof. The material consists of a ferrous alloy serving as a base body material and Fe-Cr-Mn-Ti ferrous alloy powder serving as a cladding material. The preparation method of the material comprises the following steps of: pretreating: coarsening a surface: performing blast sanding on a cladded surface so that the cladded surface has certain roughness to facilitate embedding and packing between the powder and the surface of the base material, and purifying the surface: washing by using a trichloroethylene or carbon tetrachloride solvent to remove various impurities and greasy dirt from the cladded surface so as to facilitate humidification and metallurgy combination between the powder and the surface of the base material; and preheating the base body: before cladding, and preheating the pretreated base body, cladding the Fe-Cr-Mn-Ti ferrous alloy powder on the surface of the ferrous alloy by plasmas so as to prepare the plasma cladded material of the sliding shoe of the coal-winning machine,wherein the thickness of a cladding layer is 4 to 5 millimeters. The material has the advantages of high comprehensive mechanical performance, low friction coefficient, high adhesive wear and abrasive wear resistance and the like.

Owner:CHINA UNIV OF MINING & TECH

Magnetic field assisted ultra-precise machining device and method

InactiveCN111037344AImprove thermal conductivityImprove surface qualityPositioning apparatusMetal-working holdersMachined surfaceEngineering

The invention belongs to the field of ultra-precision machining, and discloses a magnetic field assisted ultra-precise machining device and method. The device comprises a machine tool main body and anexcitation module, the machine tool body comprises an ultra-precision machine tool spindle and a tool rest, and the excitation module comprises a magnet, a fixing frame, an adjusting plate and magnetclamps. The adjusting plate is fixed to the machine tool body through the fixing frame. The two magnet clamps are movably arranged on the adjusting plate, two magnets with the N-S poles arranged opposite to each other are arranged on the two magnet clamps respectively, and a magnetic field of 0-0.3 T is formed between the two magnet clamps; when a spindle of the ultra-precise machine tool clampsa workpiece, the two magnet clamps are located at the two sides of the workpiece so that the machining process of the workpiece can be conducted in the magnetic field. Ultra-precise cutting is assisted by the magnetic field, so that the problems encountered in machining of difficult-to-machine materials are solved, the quality and precision of the machined surface are improved, and tool abrasion is reduced.

Owner:HUAZHONG UNIV OF SCI & TECH

Heat-resisting dust collecting bag

InactiveCN107789919AHigh temperature resistance hasExtended service lifeDispersed particle filtrationCarbon fibersSilanes

The invention discloses a heat-resisting dust collecting bag. The heat-resisting dust collecting bag comprises a bag body and a bag basket inside the bag body, wherein the bag basket is in a hollow-out column structure provided with support bars; the mouth of the bag body is arranged at the top of the bag basket in a hooping mode; the inner diameter of the bag body is smaller than the diameter ofthe cross section of the bag basket. According to the heat-resisting dust collecting bag, potassium titanate whisker and nano titanium dioxide particles achieve synergistic effects to fill and modifypolytetrafluoroethylene resin and further to effectively reduce adhesive abrasion and to prolong the service life; besides, matched application of samarium oxide and gamma-methacryloxy propyl trimethoxyl silane can enhance the interface bonding force among glass fiber, carbon fiber and the polytetrafluoroethylene resin, to improve the modification effects of the glass fiber and the carbon fiber onthe polytetrafluoroethylene resin, to improve breathability, heat resistance and mechanical strength, and to endow the heat-resisting dust collecting bag with the advantages of being age-resistant, heat-resistant, high in mechanical strength and good in dust removing effects.

Owner:广西金邦泰科技有限公司

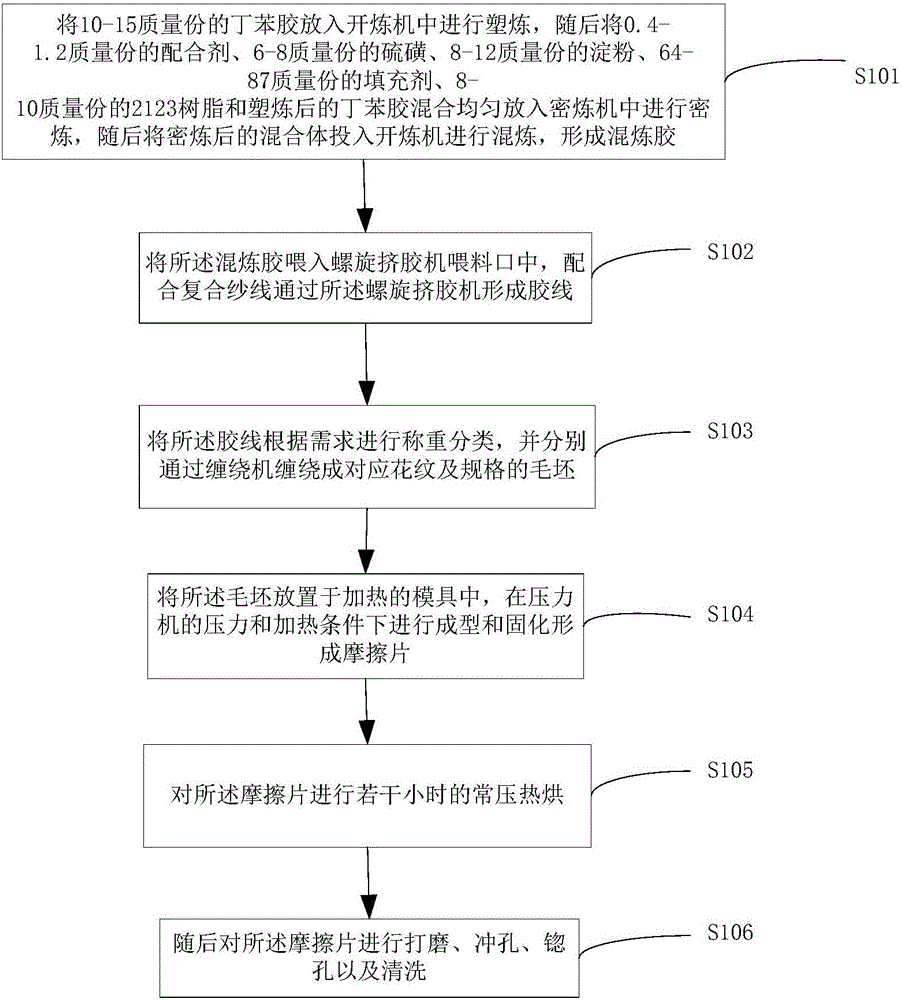

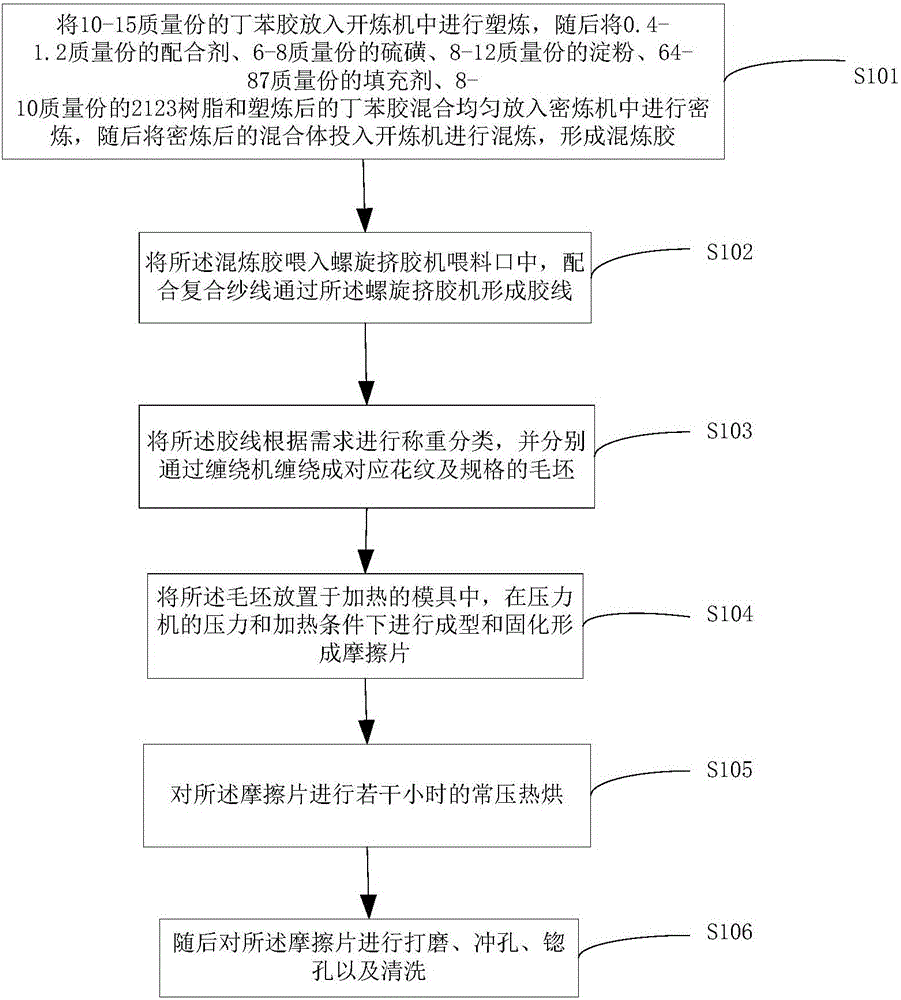

Production method of abrasion-resistant clutch friction plate for automobile

The invention discloses a production method of an abrasion-resistant clutch friction plate for an automobile. The production method comprises the steps that 10-15 parts of butadiene-styrene rubber is put into an open mill to be subjected to plastication; 0.4-1.2 parts of compounding agents, 6-8 parts of sulphur, 8-12 parts of starch, 64-87 parts of filling agents, 8-10 parts of resin and the plastified butadiene-styrene rubber are subjected to banburying, and then mixing is conducted so that a rubber compound can be formed; the rubber compound is fed into a feeding port, and tree scraps are formed in cooperation with composite yarn; the tree scraps are weighed, classified and wound into blanks; the blanks are molded and cured into the friction plate; hot drying is conducted under ordinary pressure; and polishing, punching, spot facing and cleaning are conducted. According to the technical scheme, certain materials are added into the friction plate, abrasive material abrasion caused by tight combination between a friction plate and a flywheel as well as between the friction plate and a compression plate in the using process of a clutch can be effectively reduced, adhesion abrasion caused by high temperature due to vehicle overloading can also be effectively reduced, the abrasion of the friction plate and a mating plate is reduced, and the service life of the clutch is prolonged.

Owner:NANTONG WANDA FRICTION MATERIAL

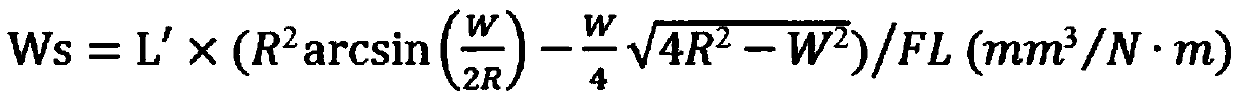

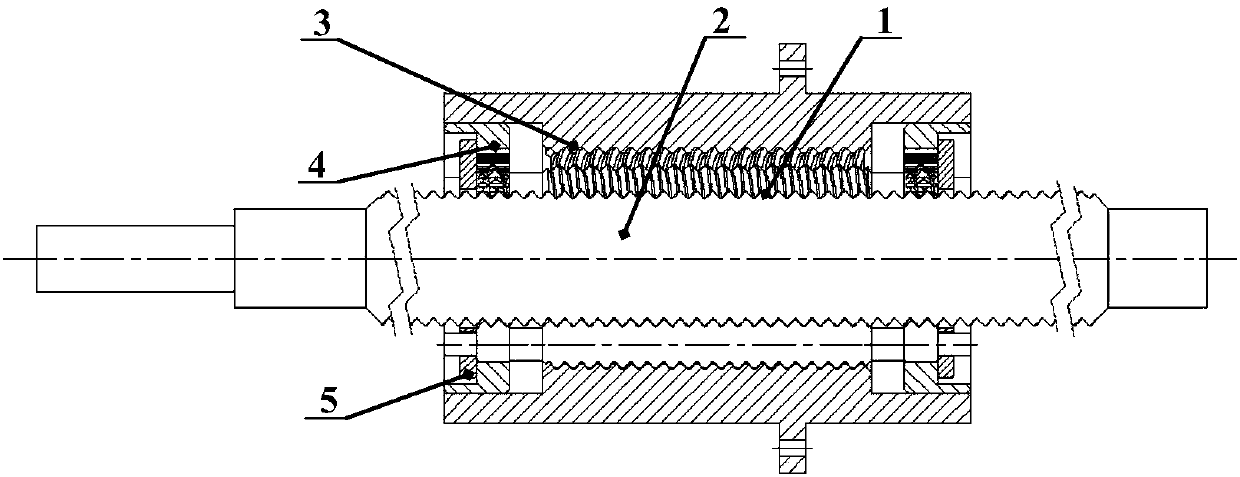

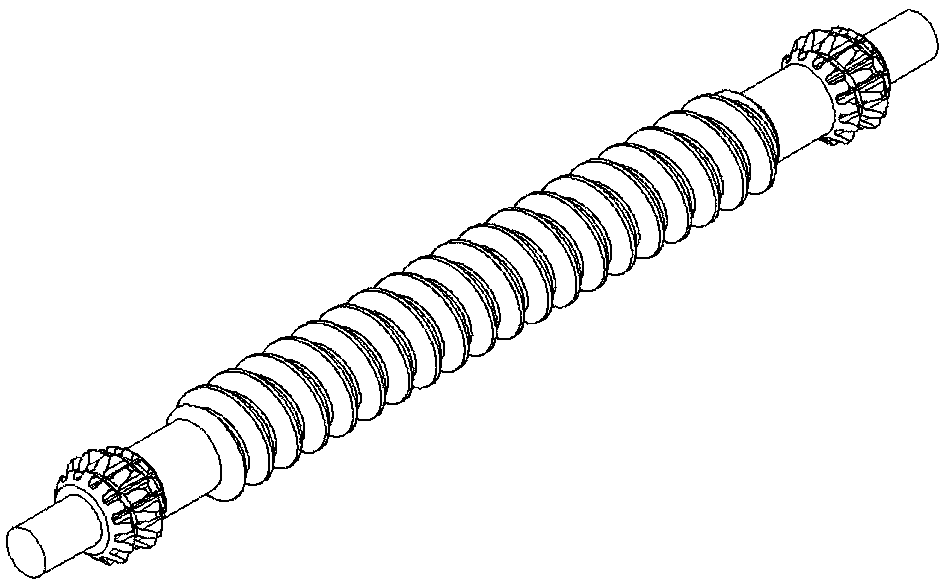

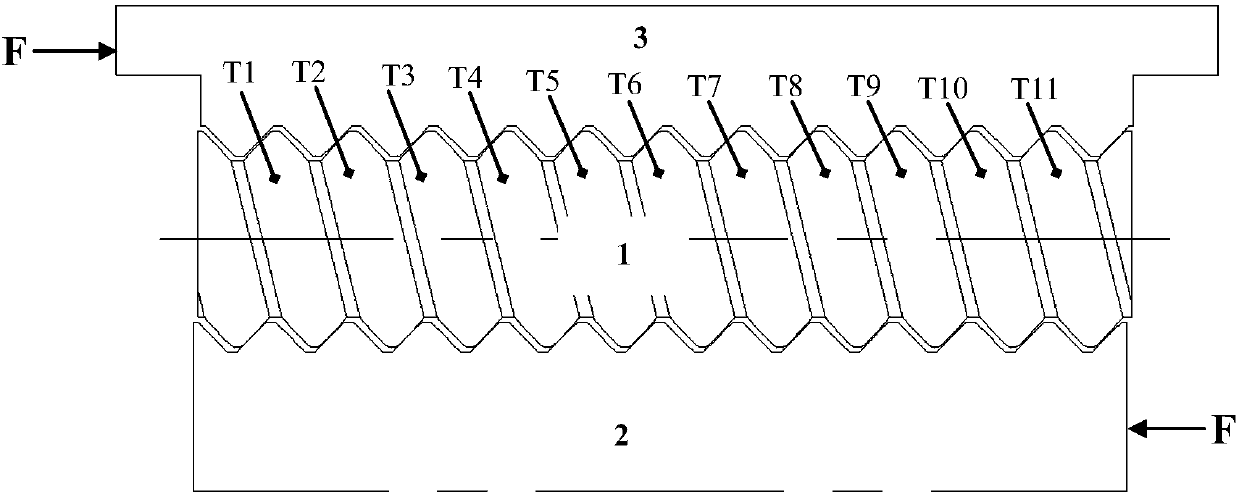

Modification Method of Roller Thread in Planetary Roller Screw Pair

InactiveCN106552971BExtended service lifeReduce loadGearingElement analysisFinite element analysis software

The invention discloses a profile modification method for thread profiles of pin rollers of planetary pin roller screw pairs. The profile modification method is used for solving the technical problem that the thread profiles of the existing planetary pin roller screw pairs are short in service life because of non-uniform bearing. According to the technical scheme, contact analysis is carried out on the planetary pin roller screw pairs through software of finite element analysis on the condition of a given load, the maximum profile modification amount of the thread profiles of the pin rollers is obtained through analysis results, and the pin rollers with the profiles modified are designed according to the maximum profile modification amount. Contact analysis of finite elements is carried out on pin roller screws with the profiles modified and nuts, then loads on the thread profiles on bearing sides of the pin rollers, the screws and the nuts are effectively lowered through the pin rollers with the profiles modified on the condition that the total load is fixed, and therefore adhesive wear and contact fatigue wear of the thread profiles caused by overloads can be reduced, and the service life of the planetary pin roller screw pairs can be prolonged.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

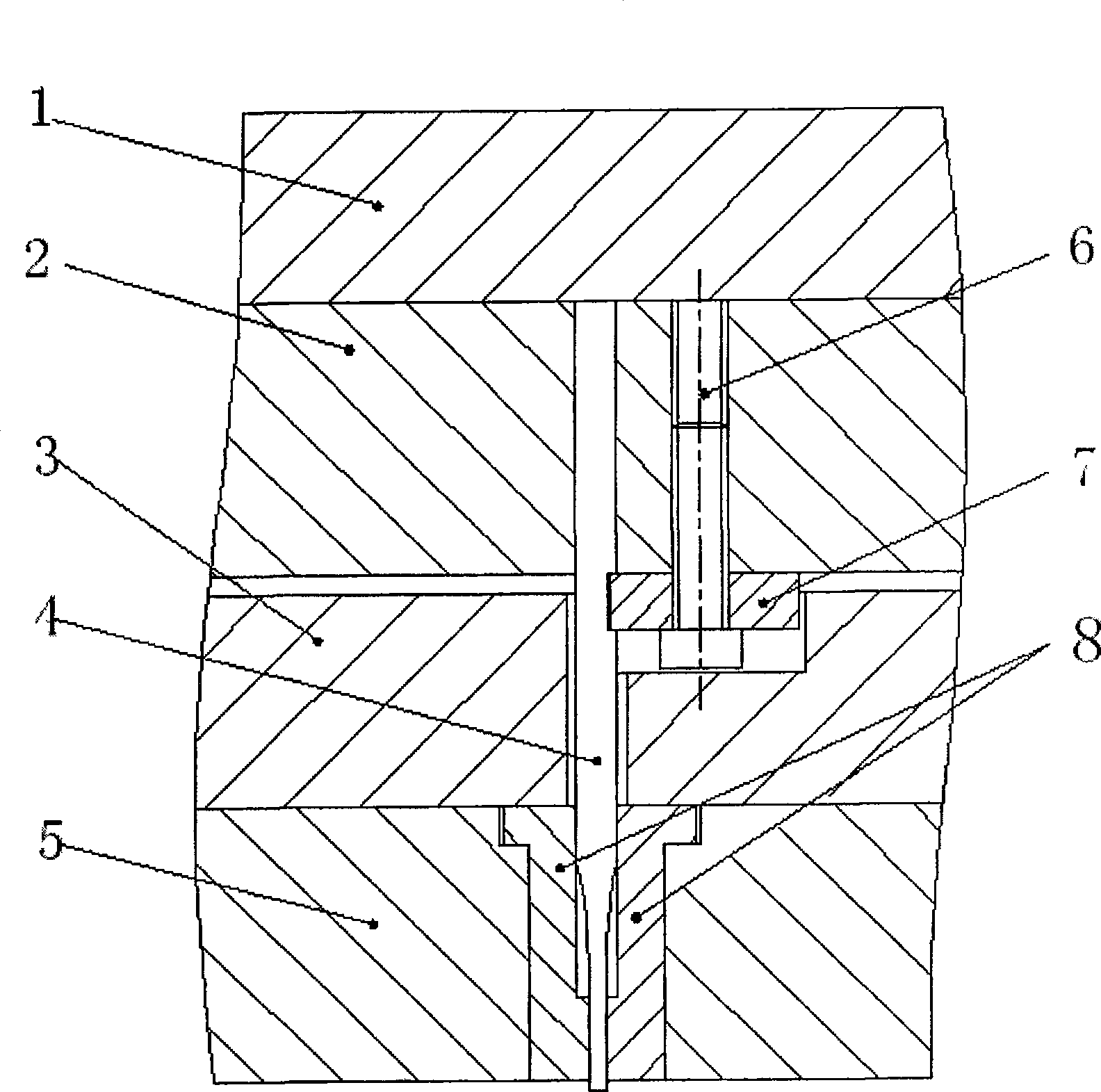

Working device hinging mechanism

InactiveCN106884862ADifficult to enterReduce Adhesive WearBearing componentsPivotal connectionsMechanical engineeringAdhesive wear

The invention provides a working device hinging mechanism, and relates to the technical field of engineering machinery. The working device hinging mechanism comprises a bearing bush, a shaft and an anti-dust ring, wherein a bushing is arranged out of the bearing bush in a sleeving manner; the shaft is arranged in the bearing bush in a penetrating manner; a left floating sealing seat and a right floating sealing seat are respectively connected with the two ends of the shaft in a sleeving manner; a first floating oil sealing cavity is formed in a contact surface between the bushing and the left floating sealing seat; a second floating oil sealing cavity is formed in a contact surface between the bushing and the right left floating sealing seat; the first floating oil sealing cavity and the second floating oil sealing cavity are communicated with the shaft; a floating oil seal is arranged in each floating oil sealing cavity; a concave pit is formed in the inner end surface of each of the left floating sealing seat and the right floating sealing seat; end heads of the bushing are embedded into the concave pits; each embedding gap is a zigzag gap channel; compared with the prior art, the floating oil seals of the working device hinging mechanism form static seal; when the floating oil seals are in contact with each other and are rotated, dynamic end surface seal is formed; small particles do not enter the space between the shaft and a shaft sleeve easily, and an anti-dust effect is good; the adhesive wear and the abrasive wear of a bearing can be reduced; the work reliability of a sliding bearing mechanism can be improved.

Owner:LIUZHOU LIUGONG EXCAVATORS +2

Preparation method of lubricating oil additive with antiwear and antifriction effect

InactiveCN110724574AImprove the lubrication effectImprove dispersion stabilityAdditivesPolymer scienceMeth-

The invention discloses a preparation method of a lubricating oil additive with an antiwear and antifriction effect. The preparation method comprises the following steps: 1) preparing a polyurethane prepolymer; 2) preparing heat-resistant polyurethane microspheres; 3) preparing polyacrylonitrile / polyurethane copolymer microspheres through graft polymerization; 4) adding the polyacrylonitrile / polyurethane copolymer microspheres into a dimethylformamide solution, and carrying out stirring for dissolving to obtain bowl-shaped polyacrylonitrile / polyurethane copolymer particles; and 5) adding the polyacrylonitrile / polyurethane copolymer particles into a trimethylhydroxysilane solution, and carrying out stirring and drying. The lubricating oil additive is in a bowl-shaped particle structure, hasgood dispersion stability in lubricating oil, can form a layer of film with a pit structure on the surface of a friction pair by self-assembly, and can capture abrasive dust particles generated in anabrasion process, so that serious particle abrasion caused by abrasive dust is reduced, a good antiwear and antifriction effect is achieved, the service life of an engine is prolonged, and noise is reduced.

Owner:MAANSHAN SANCHUAN MACHINERY MFG CO LTD

Powder metallurgy self-lubricating bearing and preparation method thereof

InactiveCN110394444AGood self-lubricating performanceImprove wear resistanceShaftsBearing componentsCompression moldingVolumetric Mass Density

The invention discloses a preparation method of a powder metallurgy self-lubricating bearing. The preparation method comprises the following steps that (1) raw materials are mixed, wherein the raw materials are composed of the following components of, by weight percent, 2%-2.5% of carbon, 1%-2% of copper, 0.5%-1.5% of molybdenum disulfide and the balance iron; (2) compression molding is performed,wherein the density of a molded blank is 6.7g / cm<3>-6.9g / cm<3>; (3) sintering is performed; and (4) oil immersion treatment is performed. According to the preparation method, through the three kindsof components of the carbon, the copper and the molybdenum disulfide and use amount mutual combination and mutual cooperation effects of all the components, the sintered body has a relatively good self-lubricating effect, the wear resistance is good, moreover, the crushing strength is high, and the service life of the product is prolonged.

Owner:LAIWU KELI NEW MATERIAL

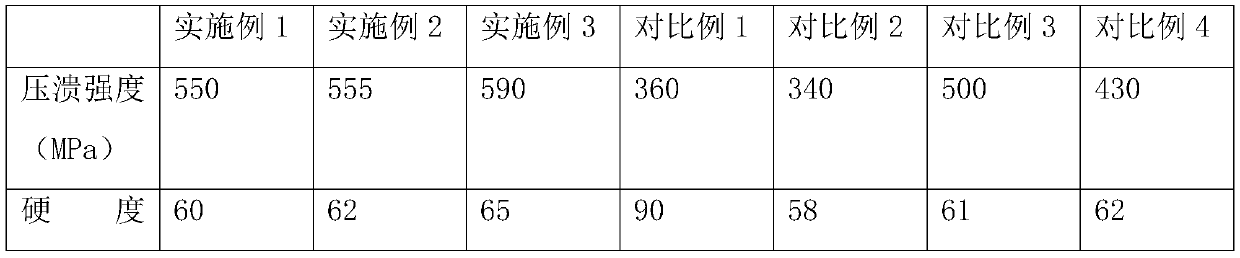

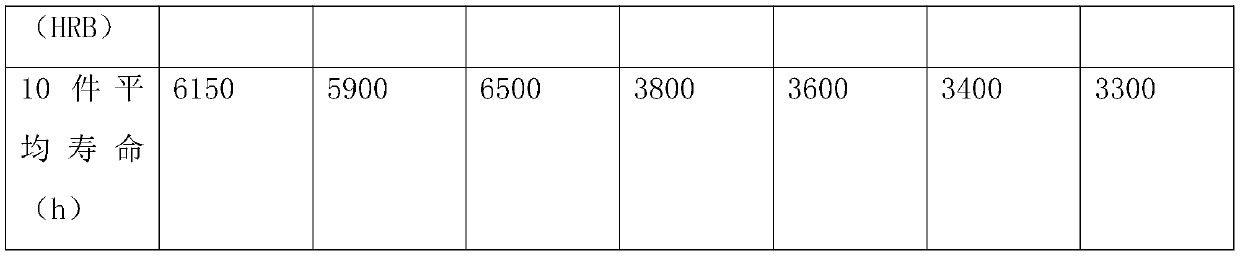

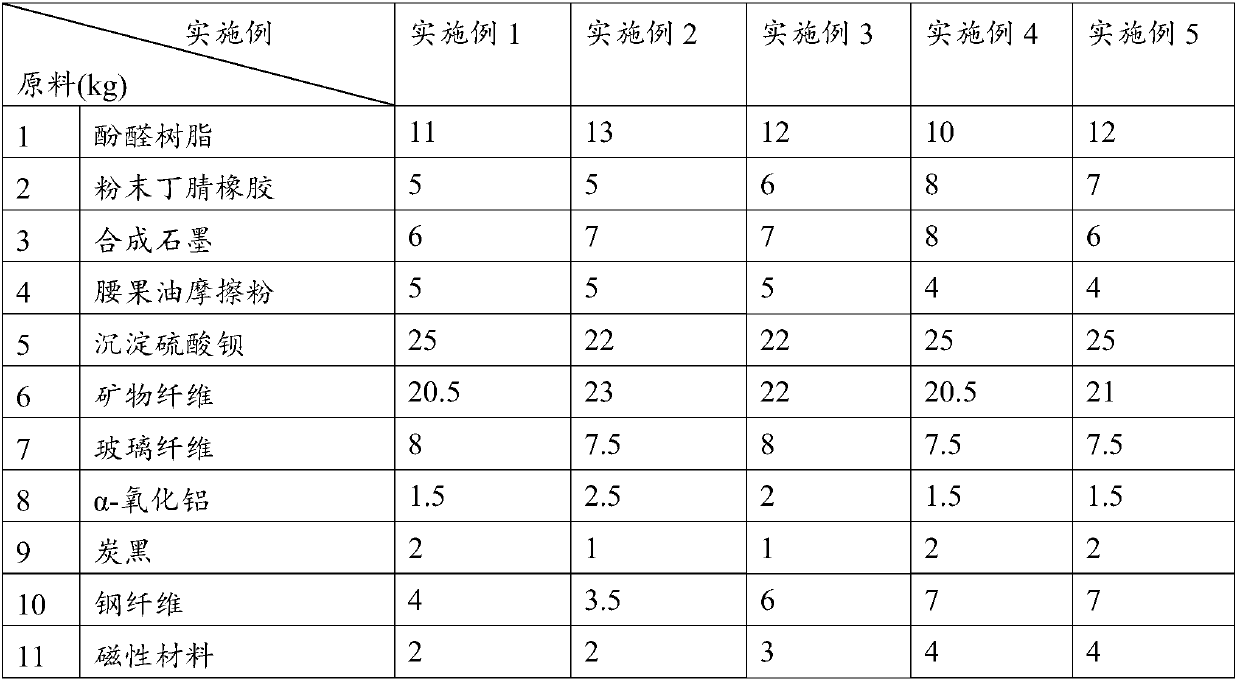

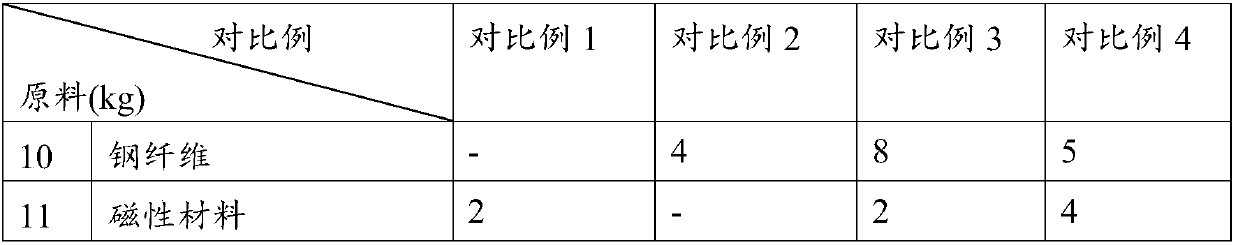

Low abrasion drum-type brake facing and preparation method thereof

The invention relates to low abrasion drum-type brake facing and a preparation method thereof. The brake facing is prepared from the components of raw materials in parts by weight: 10~14 parts of phenolic resin, 3~8 parts of butadiene-acrylonitrile rubber, 6~8 parts of synthesized graphite, 3~5 parts of frication powder, 15~30 parts of pre-cipitated barium sulfate, 20~30 parts of mineral fiber, 6~10 parts of glass fiber, 0.5~2 parts of alpha-aluminium oxide, 1~2 parts of carbon black, 3~7 parts of crystalline flake graphite, 3~8 parts of steel fiber, and 2~4 parts of magnetic materials. According to the low abrasion drum-type brake facing and the preparation method thereof, by adding magnetized magnetic materials to the raw materials, magnetic adsorption can be effectively conducted on thesteel fiber, adhesive wear, cutting wear and abrasive wear caused by a friction function in a braking process can be reduced, thus a degree of wear of the brake facing is lowered, and quality stability of the brake facing is increased.

Owner:HUBEI FEILONG FRICTION & SEALING MATERIALS

A reinforced method of guiding surfaces in guiding protection equipment of long thin embossing dies

InactiveCN100464892CHigh guiding precisionProtection fitShaping toolsPerforating toolsChemical compoundSupersonic waves

A precision long male die guide protective device comprises the top cushion plate, male die retaining plate, thin long male die, stripper plate, screw, clamp, dual directional guide sleeve, protective sleeve sub guide surface, protective sleeve main guide surface, male die installation section and male die working phase, the said reinforcement method for the guiding surface composed of supersonic wave oil removal processing, derusting for the supersonic wave, chemical compound plating and heat treatment. It can be low anticorrosion, low hardness, low price, easy for processing, with the produced dual guiding protective sleeve enjoying high antiwearing feature, high level hardness, self lubricating, increased protective feature, reduced sticking wearing and improved durability.

Owner:SOUTH CHINA UNIV OF TECH

Electromagnetic fuel injection valve

ActiveUS8662472B2Prevent Adhesive WearReduce Adhesive WearOperating means/releasing devices for valvesSpray nozzlesAlcohol fuelMartensitic stainless steel

In an electromagnetic fuel injection valve, a valve housing includes: a cylinder-shaped valve seat member having a valve seat in its front end portion; a magnetic cylindrical body coaxially connected to a rear end portion of the valve seat member; a nonmagnetic cylindrical body coaxially and liquid-tightly welded to a rear end of the magnetic cylindrical body; and a hollow cylindrical stationary core coaxially and liquid-tightly welded to a rear end of the nonmagnetic cylindrical body. A valve assembly is housed in the valve housing and includes: a valve body capable of being seated on the valve seat; and a movable core connected to a rear end of the valve body and opposed to a front end of the stationary core. The valve body and the valve seat member are respectively made of different martensitic stainless steels so that a hardness of the valve body is higher than that of the valve seat member. Accordingly, it is possible to provide an electromagnetic fuel injection valve for alcohol fuel which is capable of preventing the adhesive wear from occurring in the seat portion while a valve body and a valve seat member made of martensitic stainless steel are used.

Owner:HITACHI ASTEMO LTD

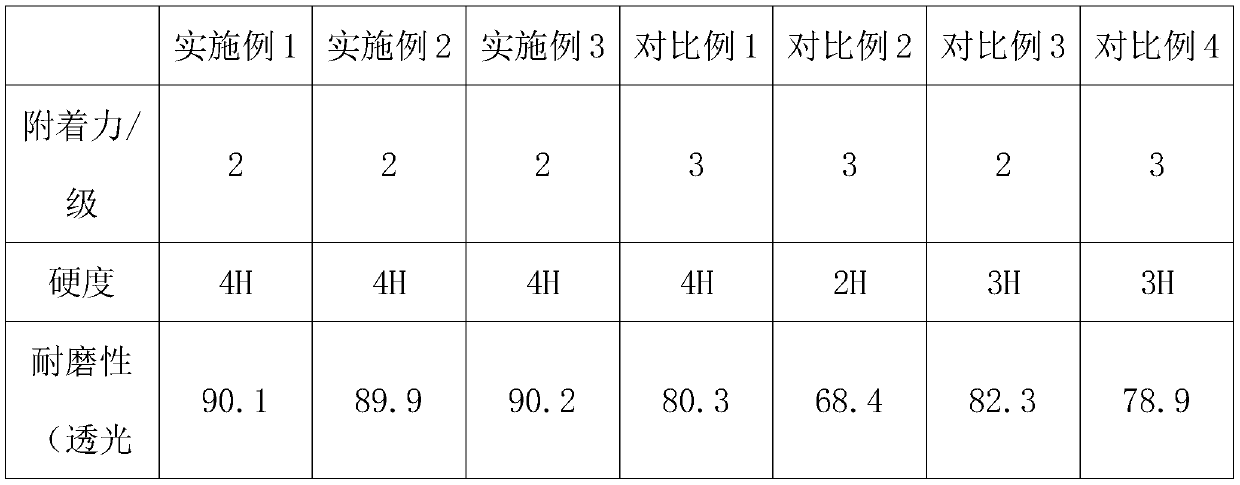

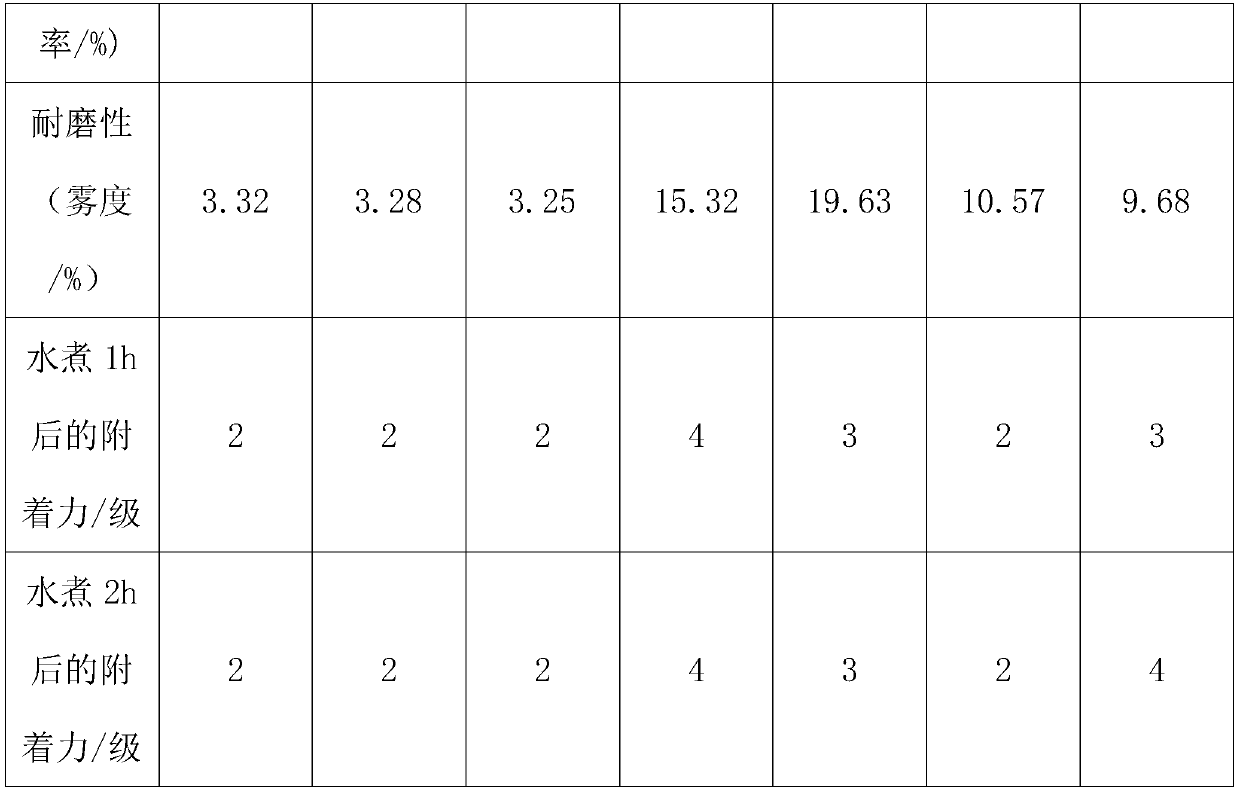

Vehicle environment-friendly wear-resistant paint, and preparation method thereof

The invention discloses a vehicle environment-friendly wear-resistant paint. The vehicle environment-friendly wear-resistant paint is prepared from, by weight, 50 to 60 parts of modified polyester resin, 2.5 to 3 parts of a wear-resistant filler, 1 to 1.5 parts of a lubricating filler, 1 to 1.6 parts of a curing agent, 0.2 to 0.3 part of an antifoaming agent, 0.3 to 0.4 part of an anti-settling agent, 0.2 to 0.3 part of a leveling agent, 0.1 to 0.2 part of an UV absorber, 5 to 8 parts of styrene, and 40 to 50 parts of N,N-dimethyl formamide. The invention also discloses a preparation method ofthe paint. According to the preparation method, modified polyester resin with excellent water resistance, wear resistance, and impact resistance is taken as a paint film forming matrix; the wear-resistant filler is added, so that the wear-resistant filler is preferably dispersed in the resin matrix for bearing and load dispersing effect, and is capable of improving paint wear resistance through forming of more compact inorganic / organic coating layers with the resin; the obtained paint possesses excellent wear resistance and water resistance, and is capable of satisfying vehicle production line spraying technology requirements.

Owner:广东省漆色彩新型材料有限公司

A kind of attapulgite-titanium dioxide modified ultra-high molecular weight polyethylene composite material and its preparation method and application

ActiveCN112226264BHigh surface energyInhibit wearLubricant compositionPigment physical treatmentPolymer scienceHigh surface

The invention provides an attapulgite-titanium dioxide modified ultra-high molecular weight polyethylene composite material and a preparation method and application thereof, which belong to the technical field of solid lubricating materials. The present invention uses attapulgite-titanium dioxide as a filler in ultra-high molecular weight polyethylene, wherein the titanium dioxide particles have high surface energy, and after being loaded on attapulgite-titanium dioxide, hard particles with high roughness can be formed, and attapulgite-titania As a filler combined with ultra-high molecular weight polyethylene, it can play a better load-bearing role in the friction process and prevent material wear; at the same time, the addition of attapulgite-titanium dioxide can improve the heat resistance of the ultra-high molecular weight polyethylene matrix , so that the composite material is less likely to deform under the condition of concentrated frictional heat, the degree of deformation of the material is reduced, and the corresponding adhesive wear is also reduced, thereby further improving the anti-friction and wear resistance of the material.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com