A kind of attapulgite-titanium dioxide modified ultra-high molecular weight polyethylene composite material and its preparation method and application

A technology of ultra-high molecular weight and attapulgite, which is applied in the field of attapulgite-titanium dioxide modified ultra-high molecular weight polyethylene composite material and its preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] In the present invention, the attapulgite-titanium dioxide (ATP-TiO 2 ) The preparation method preferably comprises the following steps:

[0031] 1) Pretreating the attapulgite to obtain purified attapulgite;

[0032] 2) mixing butyl titanate, ethanol and acid to obtain a butyl titanate precursor solution;

[0033] 3) Mix the purified attapulgite with the butyl titanate precursor solution, and after suction filtration, add ethanol to the obtained solid product, and alternately perform stirring and ultrasonic dispersion until the obtained dispersion is viscous and does not settle. state, to obtain the attapulgite-butyl titanate precursor dispersion;

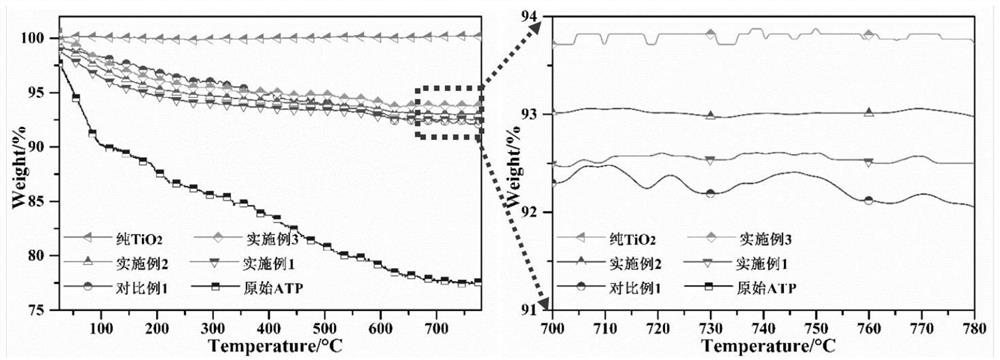

[0034] 4) The attapulgite-butyl titanate precursor dispersion liquid is subjected to steam hydrolysis under the conditions of magnetic stirring and constant temperature water bath, and the obtained product is sequentially aged, dried and calcined to obtain attapulgite-titanium dioxide composite material ;

[0035] The r...

Embodiment 1

[0077] Mix 10 mL of butyl titanate with 30 mL of ethanol, then add 2 mL of acetic acid, and magnetically stir the resulting solution for 30 min (rotating at 480 rpm) to obtain a butyl titanate precursor solution;

[0078] Add 2 g of purified attapulgite to the butyl titanate precursor solution, stir magnetically for 2 h (320 rpm) and then ultrasonically disperse for 1 h. After suction filtration, add 10 mL of ethanol to the resulting product, and alternately stir (30 min, 480rpm) and ultrasonic dispersion (30min) each three times to obtain the attapulgite-butyl titanate precursor dispersion;

[0079] Put the attapulgite-butyl titanate precursor dispersion into a small beaker (100mL), place the small beaker in a large beaker (500mL), add 100mL deionized water to the periphery, and seal the large beaker with plastic wrap , placed in a water bath with magnetic stirring, rotating speed 80rpm, heating at a constant temperature of 60°C, and performing steam hydrolysis. After the rea...

Embodiment 2

[0083] Mix 10 mL of butyl titanate with 40 mL of ethanol, then add 2 mL of acetic acid, and magnetically stir the resulting solution for 20 min (320 rpm) to obtain a butyl titanate precursor solution;

[0084] Add 2 g of purified attapulgite to the butyl titanate precursor solution, stir magnetically for 2 h (320 rpm) and then ultrasonically disperse for 1 h. After suction filtration, add 10 mL of ethanol to the resulting product, and alternately stir (30 min, 320rpm) and ultrasonic dispersion (30min) each three times to obtain the attapulgite-butyl titanate precursor dispersion;

[0085] Put the attapulgite-butyl titanate precursor dispersion into a small beaker (100mL), place the small beaker in a large beaker (500mL), add 100mL deionized water to the periphery, and seal the large beaker with plastic wrap , placed in a water bath with magnetic stirring, rotating speed 160rpm, heating at a constant temperature of 40°C, and performing steam hydrolysis. After the reaction, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com