Multi-structure different-interval bionic surface combined cast-iron guide rail and regeneration method thereof

A multi-structure, guide rail technology, which is applied in the direction of large fixed members, metal processing machinery parts, metal processing equipment, etc., can solve the problems of guide rail size difficult to meet the use standard, guide rail regeneration difficulty, waste of raw materials, etc., to maintain wear resistance performance , Anti-wear performance is uniform, and the effect of improving wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

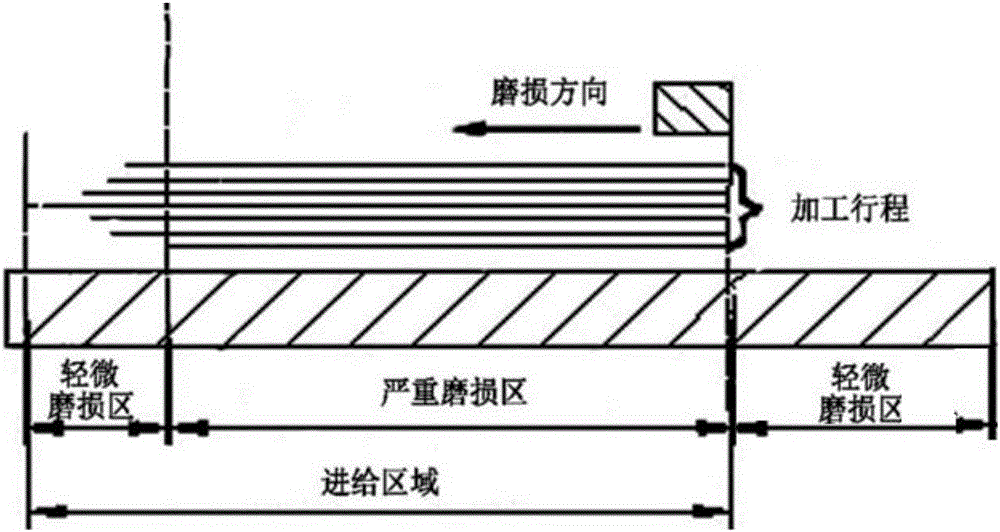

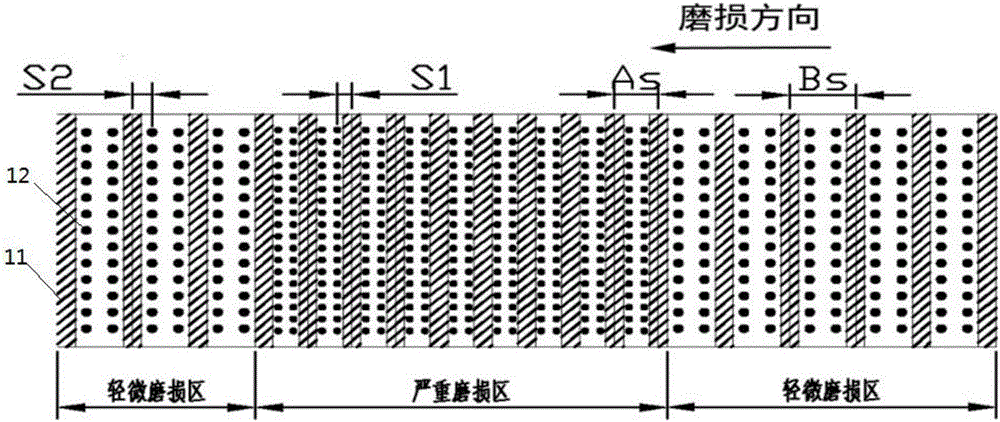

[0035] like figure 2 As shown, the first bionic coupling element and the second bionic coupling element are made on the working surface of the guide rail, the first bionic coupling element is a strip-shaped bionic coupling element 11, and the second bionic coupling element is a pit-shaped coupling element 12; The angle between the strip-shaped bionic coupling element 11 and the load feeding direction is 90°, and the pit-shaped coupling elements 12 are arranged around the strip-shaped bionic coupling element 11 .

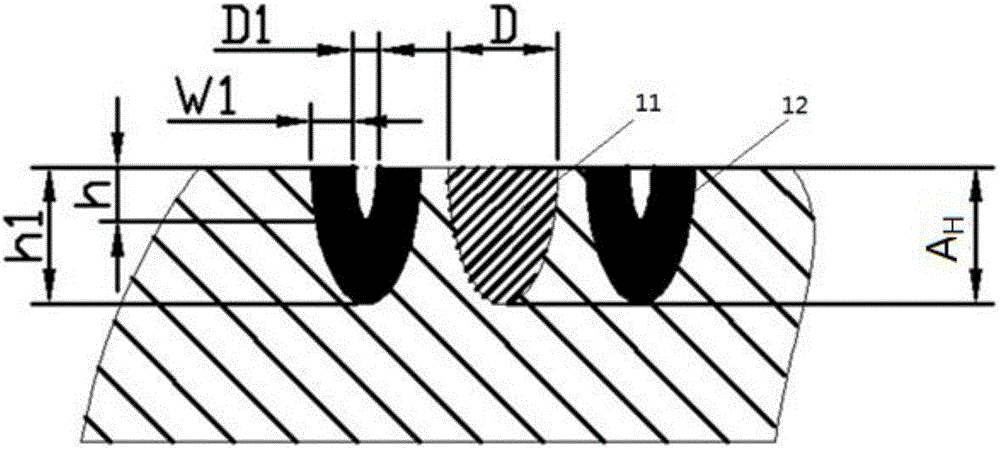

[0036] like image 3 As shown, the strip-shaped bionic coupling element 11 has a "U"-shaped cross section and forms a "soft and hard" columnar structure with the parent body. Its structure is composed of high-hardness carbide and martensite, and its surface width D is 0.6mm. ~2mm, depth A H 0.3mm~0.5mm; the pit-shaped coupling element 12 is a pit-shaped coupling element with a "U"-shaped ring-shaped cross-section after being processed by a high-energy laser beam, ...

Embodiment 2

[0041] like Figure 4 As shown, the first bionic coupling element and the second bionic coupling element are made on the working surface of the guide rail, the first bionic coupling element is a mesh bionic coupling element 21, and the second bionic coupling element is a pit-like coupling element 22; The angle between the strengthening part in the vertical direction of the mesh bionic coupling element 21 and the load feeding direction is 90°, and the pit-shaped coupling elements 12 are arranged in the grid of the mesh bionic coupling element 21 . The spacing and depth of the mesh-like bionic coupling elements 21, the cross-sectional shape and depth of the pit-like coupling elements 22, and the distance between the pit-like coupling elements 22 and adjacent mesh-like bionic coupling elements 21 are the same as those in Embodiment 1.

[0042]The surface of the guide rail along the working direction of the tool is processed to form a combination of multi-structure and different-d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com