Patents

Literature

53results about How to "Uniform wear resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

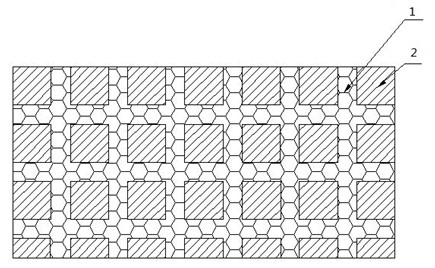

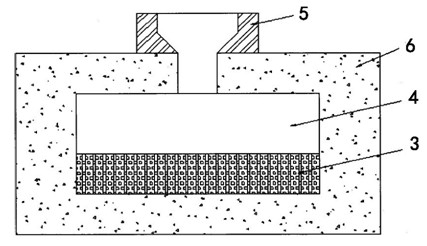

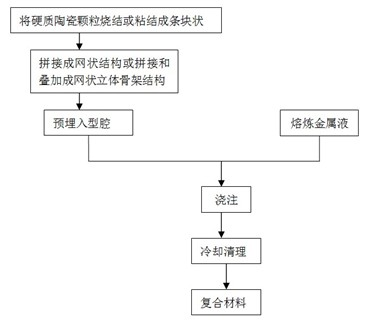

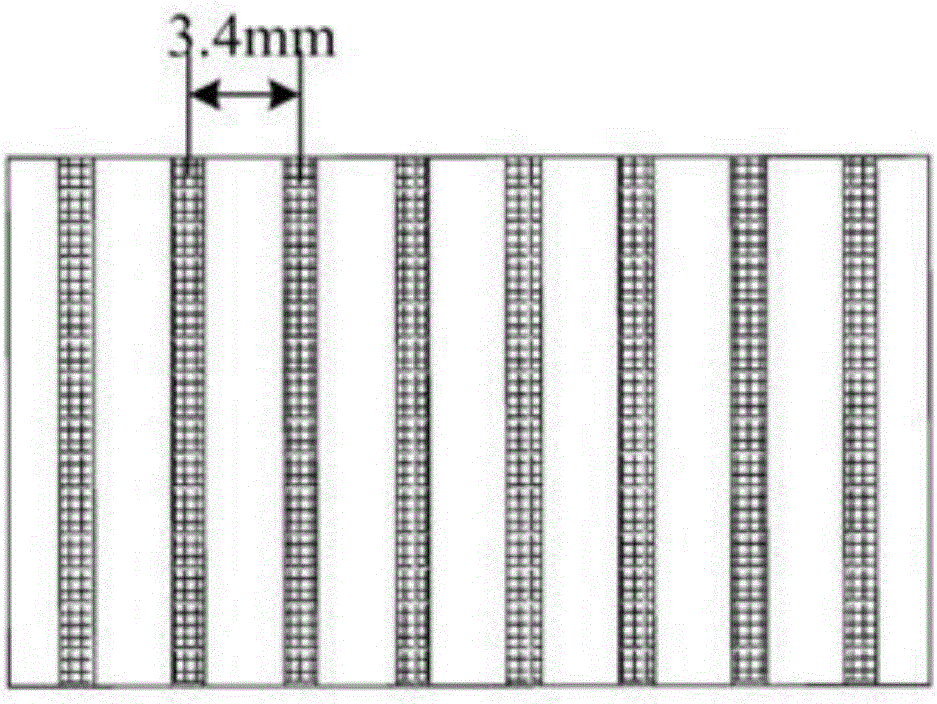

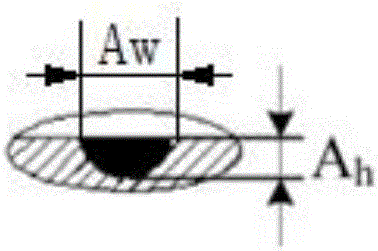

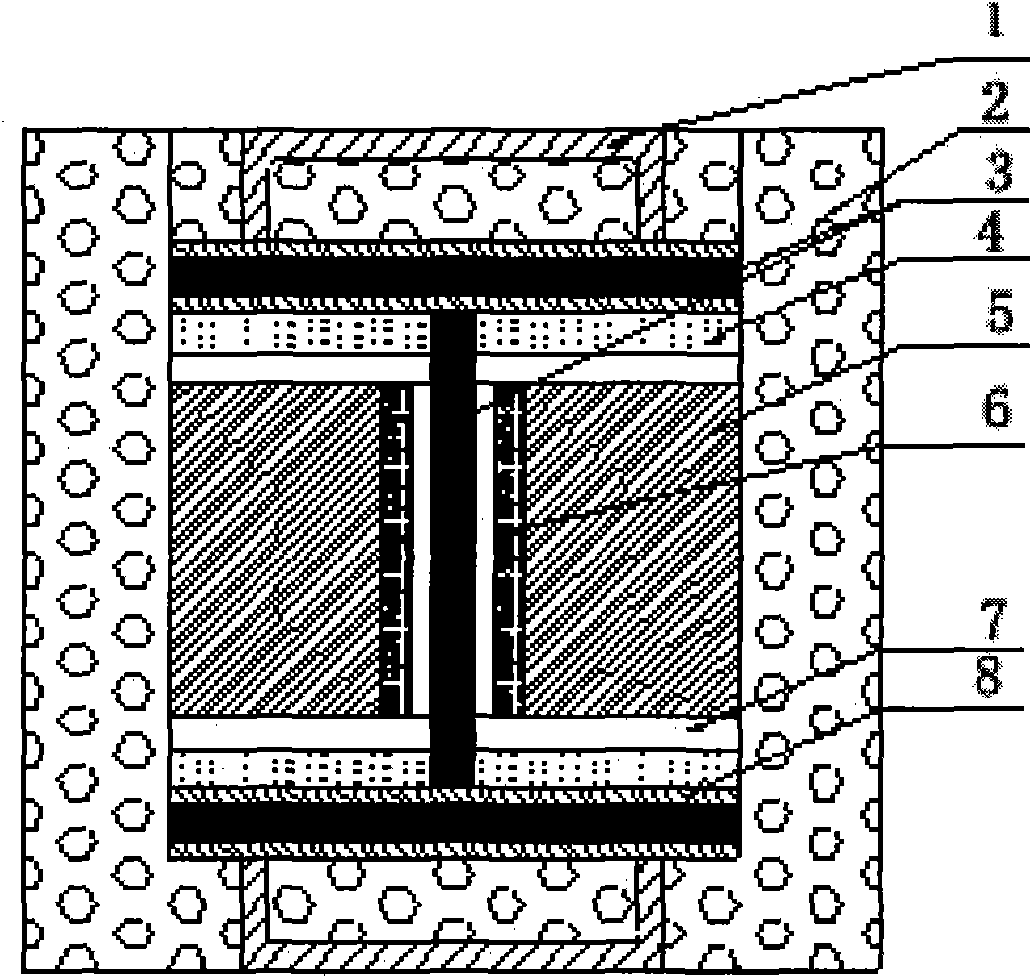

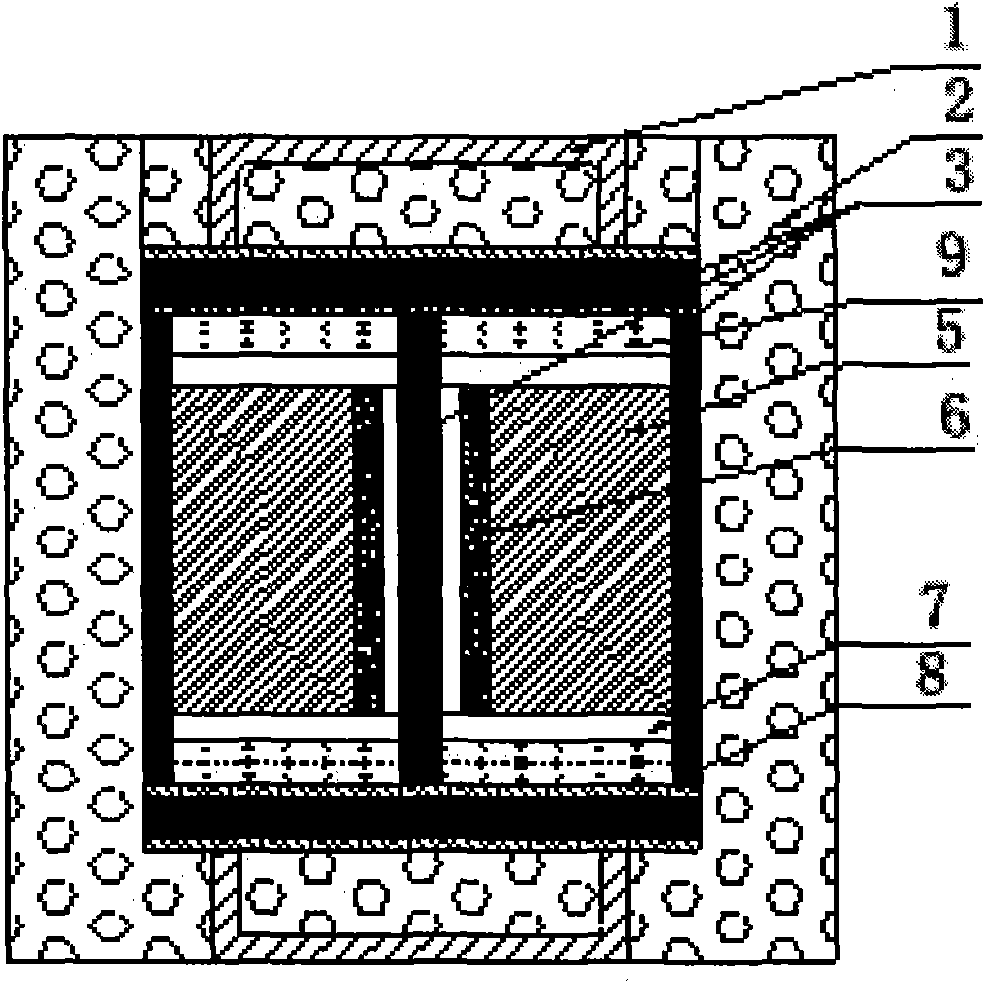

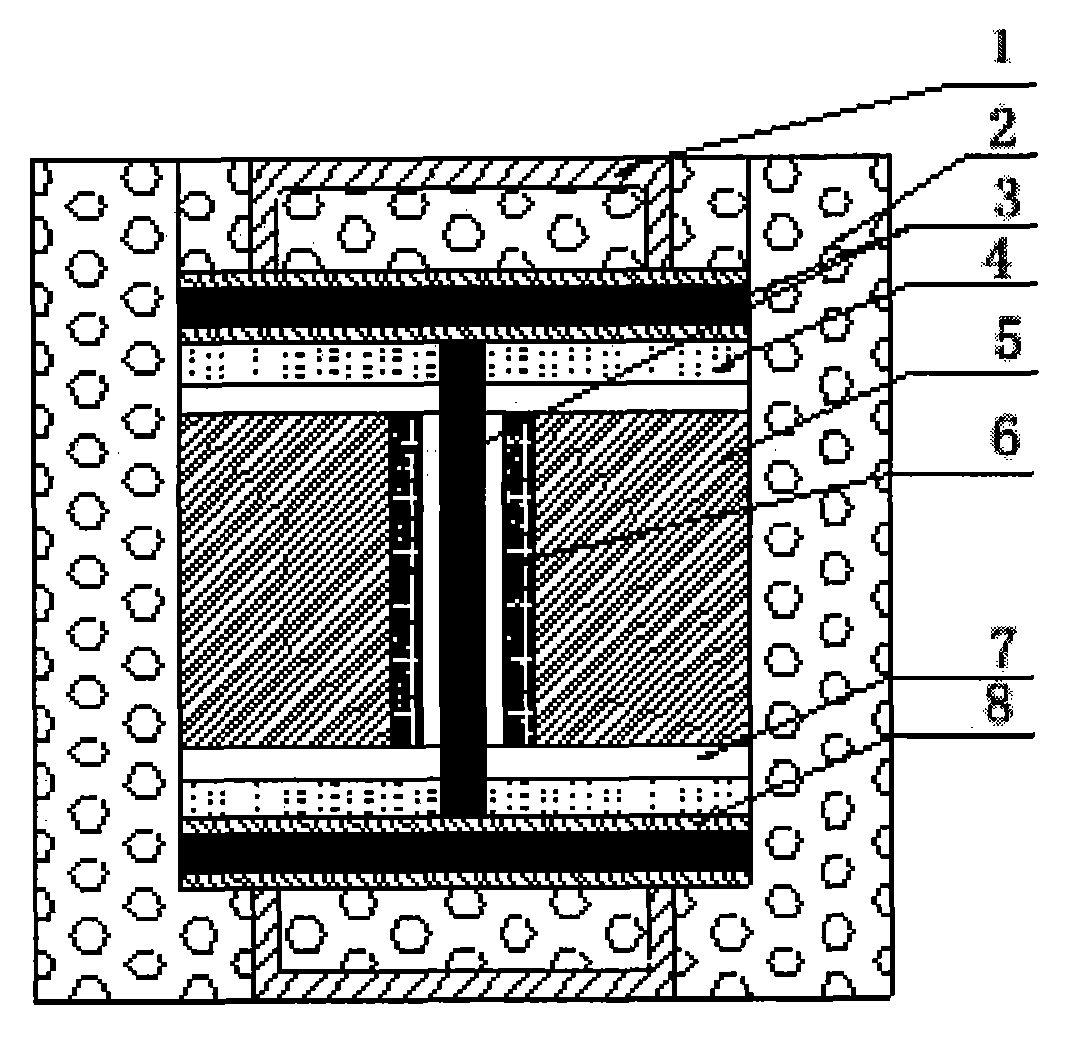

Method for preparing ceramic particle reinforced steel-based mesh material

The invention provides a method for preparing a ceramic particle reinforced steel-based mesh material, which comprises: forming a mixture of hard ceramic particles and alloy powder into strip blocks by powder sintering or by using and adhesive; joining the strip blocks into a corresponding mesh structure or joining and overlapping the strip blocks into mesh three-dimensional framework structure; and performing normal sand casting or lost foam casting, namely melting a substrate metal material, pouring the molten substrate metal material in a molding cavity, allowing the molten substrate metal material to cool and condense at room temperature, removing sand and obtaining the ceramic particle reinforced steel-based mesh material. The obtained ceramic particle reinforced steel-based mesh material gives full play to the high wear resistance of the ceramic particle hard phase and the toughness of the steel base; and the method with convenience for regulation and reliable process solves the problem of incomplete reaction of the composite material, nonuniform reinforcing phase particle distribution, pollution weakening on a reinforcing phase interface and the like and is used in wear resistance fields of mines, power, metallurgy, coal, building materials and the like.

Owner:KUNMING UNIV OF SCI & TECH

Vacuum production method for SiOx coating on organic precoating metal sheet

InactiveCN101153380AUniform wear resistanceUniform scratch resistanceVacuum evaporation coatingSputtering coatingSurface cleaningPlasma generator

The invention relates to a vacuum preparation method for SiOx plating coat of organic precoat metal plate, including the following steps: firstly, surface cleaning and surface activation are completed under plasma condition; secondly, SiOx filming is completed on an organic coating inside a vacuum filming unit through a vacuum seal device. Based on the two steps, the following steps can also be adopted: thirdly, oxygen plasma is generated by a plasma generator inside a post treatment unit and the outermost surface layer of the film generated by the above steps is converted to SiO2 and tends to a steady state; fourthly, product with steady SiOx surface is formed under nitrogen or inert gas condition. The preparation method improves the anti-wear and anti-scratching performance of organic coating and adopts nonpolluting process; meanwhile, flexible and accurate adjustment of related parameters of the film can be realized.

Owner:BAOSHAN IRON & STEEL CO LTD

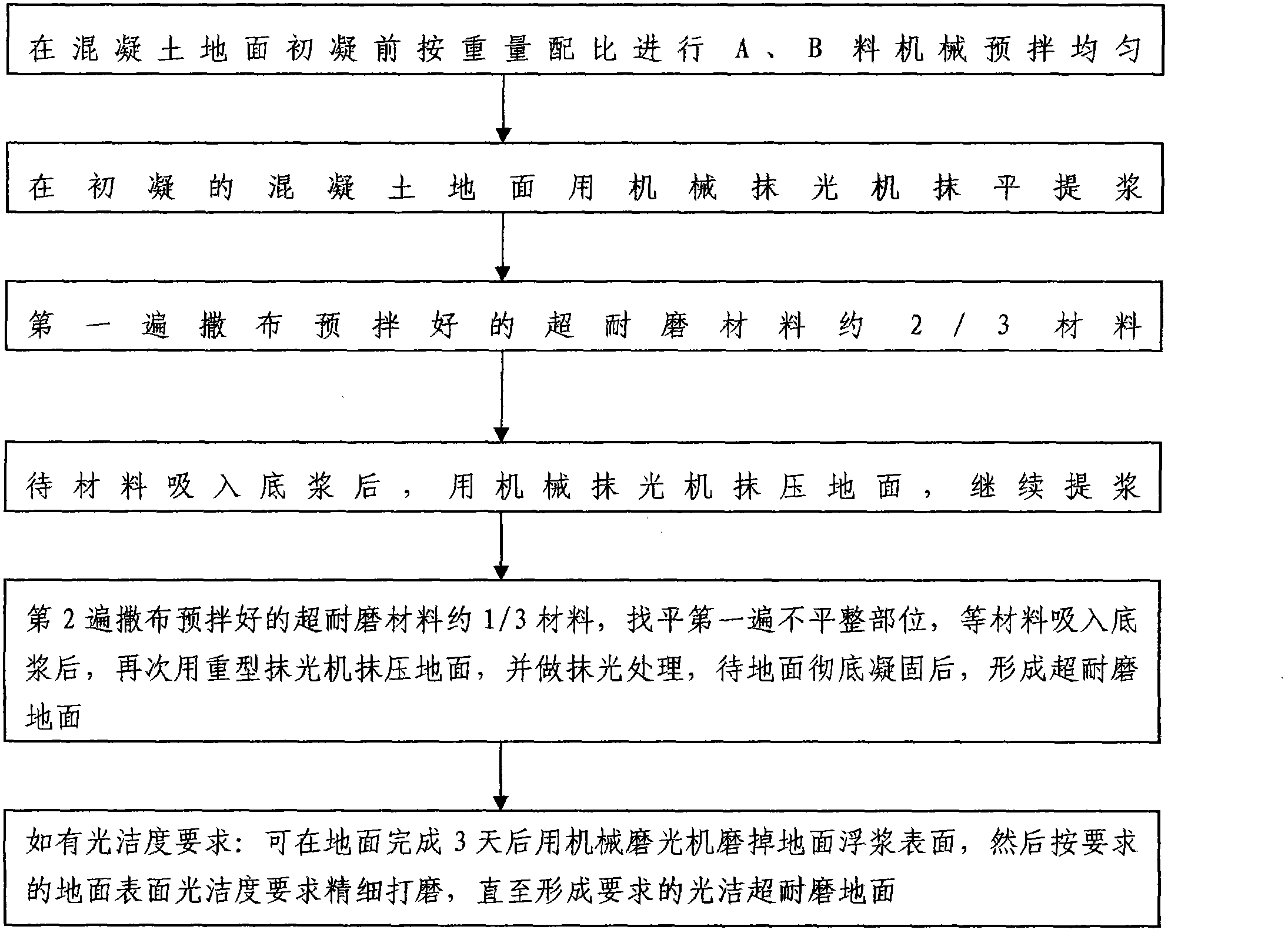

Production formula and construction technology of ultra-wear-resistant ground

The invention discloses a production formula and construction technology of an ultra-wear-resistant ground. The ultra-wear-resistant ground is prepared by the following steps: premixing a dry powder material A and a liquid material B according to a weight ratio of 5:1 to 10:1 on the construction site so as to obtain semi-dry mortar, evenly spraying the semi-dry mortar on the surface of concrete, which starts to cure, for 2 to 3 times so as to make the surface flat and smooth, levelling and polishing the surface by using a mechanical trowelling machine, and controlling the flatness according to the related national standards during the construction process. The mixing of the dry powder material A and the liquid material B can greatly improve the wear resistance and strength of the wear-resistant ground. The dry powder material is subjected to dry-wet premixing before spraying, so the requirement on base slurry is low, the dry powder material can more easily penetrate into and combine with the basic layer, and the finished ground has uniform strength and wear resistance. Moreover, material spraying after the wet-dry premixing will not generate dusts, so the environment pollution is avoided, and the health of workers is protected. The materials that are subjected to wet-dry mixing are more easily combined, and the phenomenon of peeling, delaminating, and insufficient curing is avoided.

Owner:BEIJING JD RAINROW BUILDING DECORATION

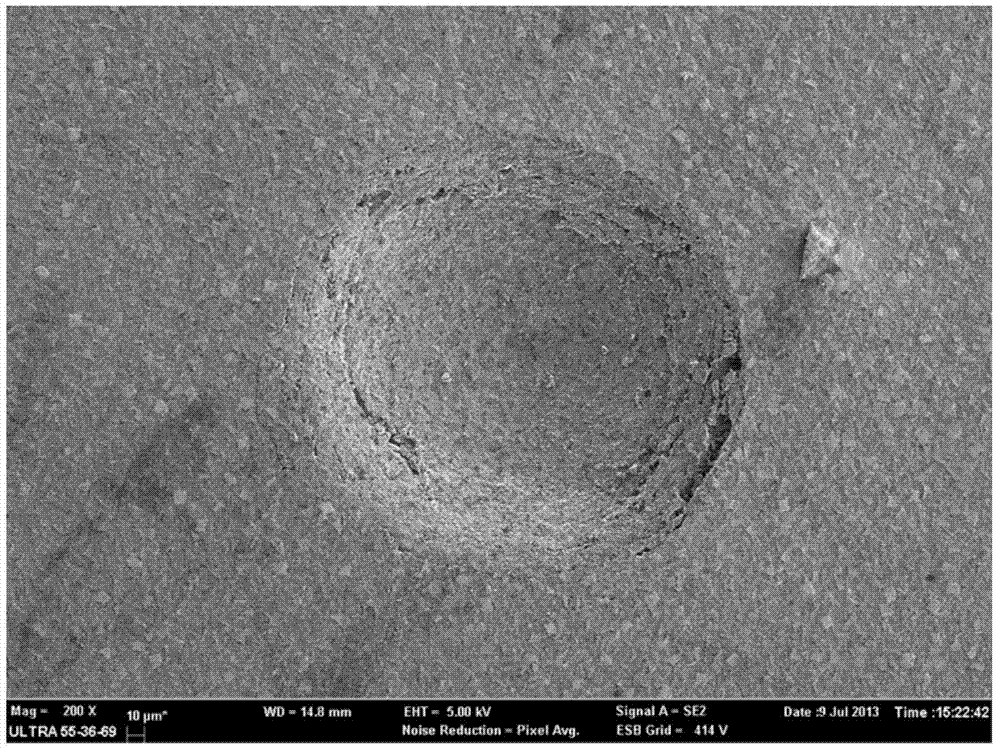

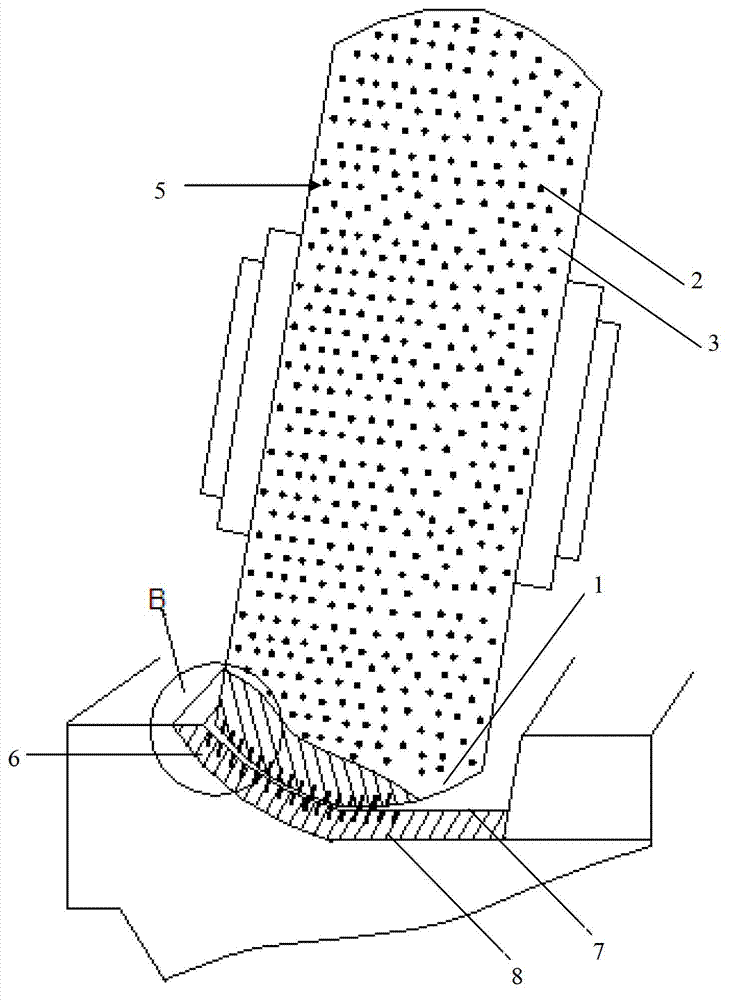

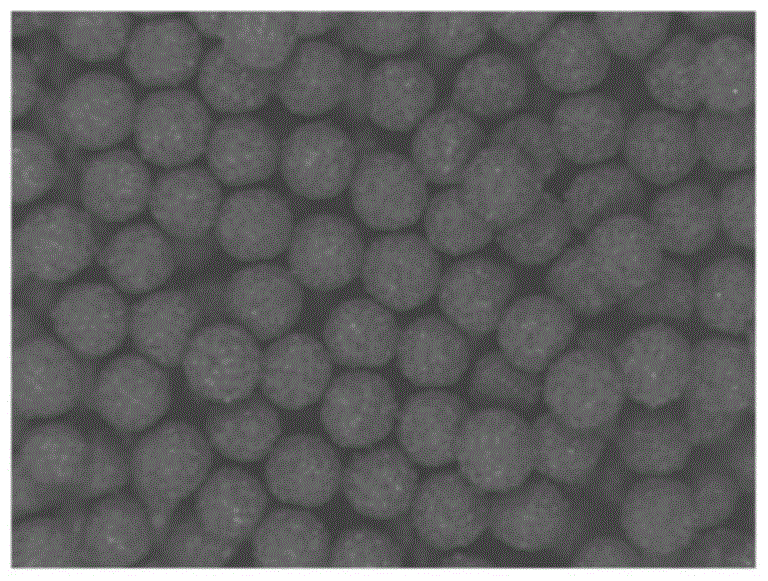

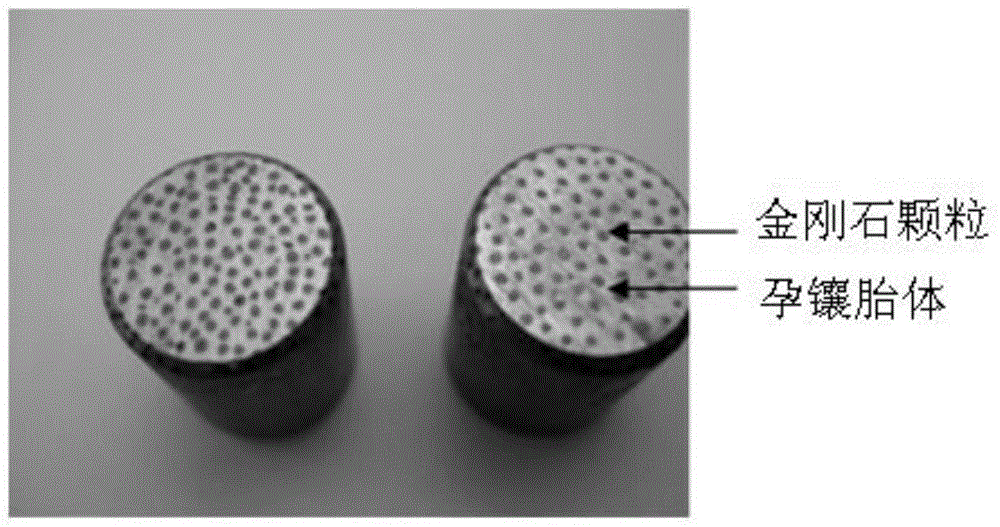

Impregnated tooth applicable to high-abrasiveness hard formation and preparation method thereof

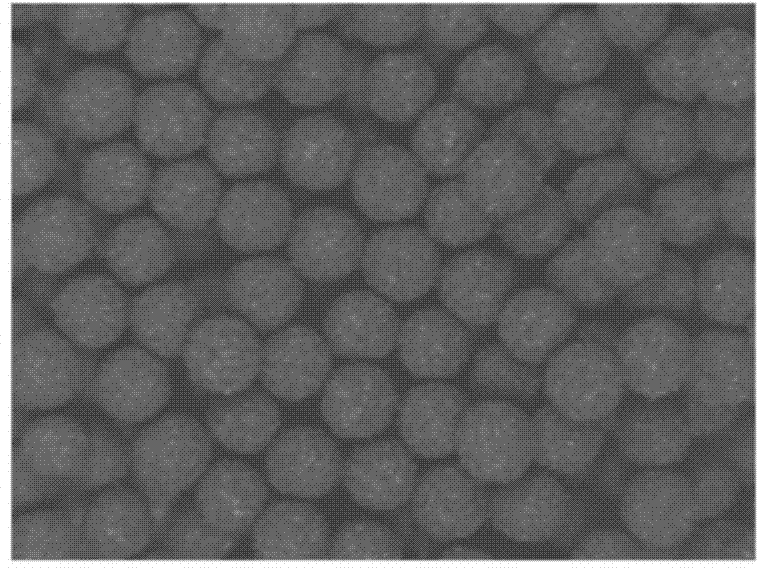

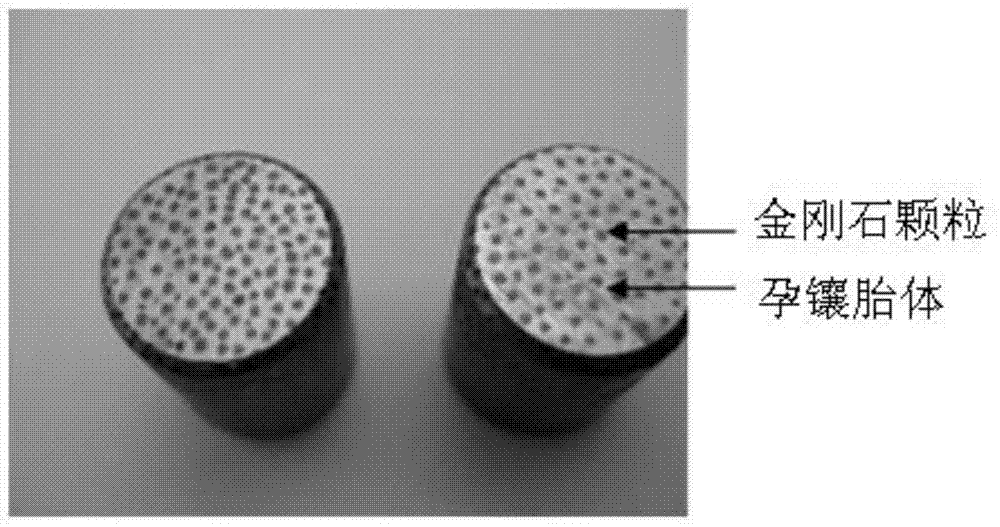

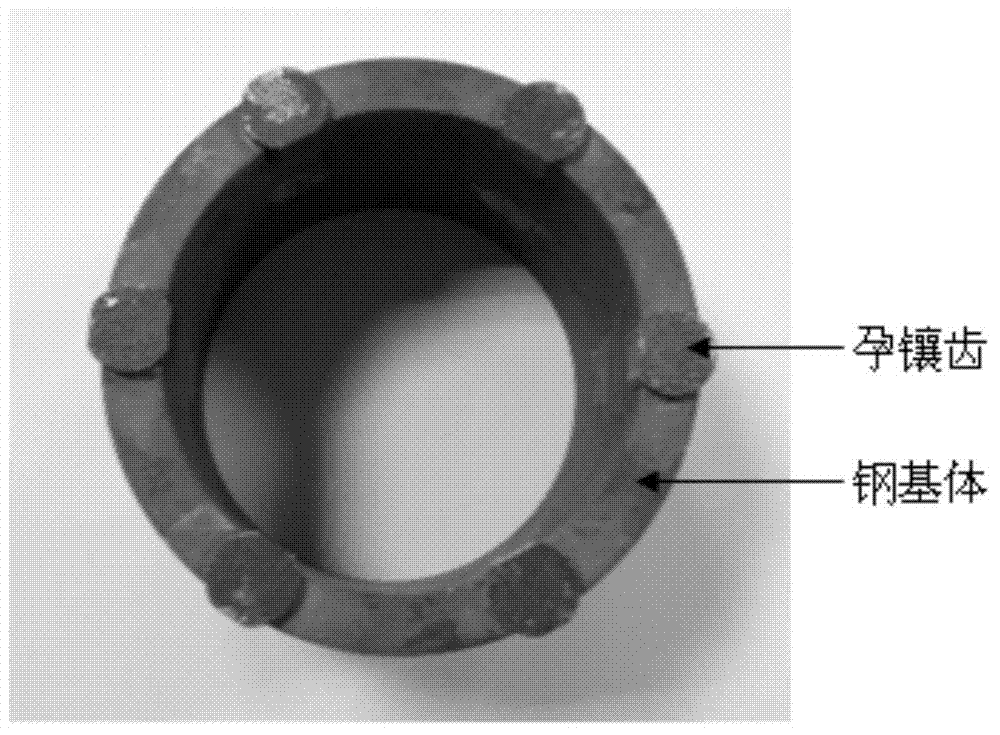

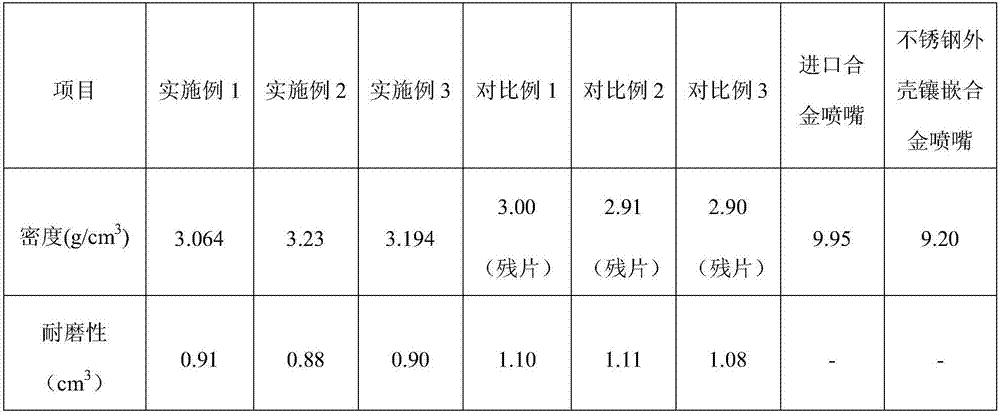

The invention relates so an impregnated tooth applicable to a high-abrasiveness hard formation and a preparation method of the impregnated tooth. The impregnated tooth comprises an impregnated matrix and a diamond which is arranged in the impregnated matrix in an impregnated mode. The impregnated matrix comprises, by weight, 60% to 70% of tungsten carbide, 10% to 25% of cobalt powder, 5% to 10% of copper powder, 2.5% to 5% of nickel powder and 2.5% to 5% of manganese powder. The preparation method comprises the steps that the components for preparation of the impregnated matrix are evenly mixed, and then granulation is carried out on the mixture and diamond particles which are wetted by a glycerol alcoholic solution so that balls can be formed, wherein the concentration of the diamond ranges from 110% to 150%; the prepared balls are placed into a mold to be processed through sintering forming so that the impregnated teeth applicable to the high-abrasiveness hard formation can be obtained, wherein the sintering temperature ranges from 1080 DEG C to 1100 DEG C, the sintering pressure ranges from 40 MPa to 50 MPa, and the temperature holding time ranges from 5 min to 10 min. The impregnated tooth is high in strength, abrasive resistance and drilling efficiency, and long in service life.

Owner:KINGDREAM PLC CO +1

High-performance SiC/W metal ceramic composite nozzle and preparation method thereof

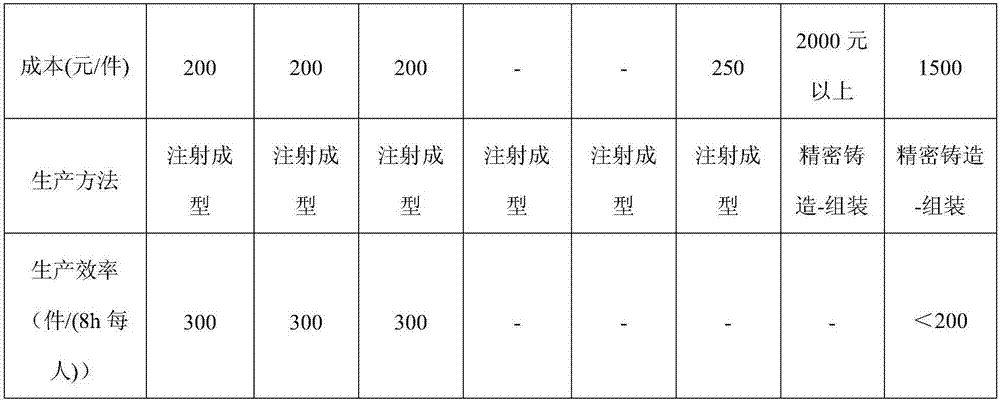

The invention relates to a high-performance SiC / W metal ceramic composite nozzle which is prepared by adopting silicon carbide feeding particles, performing injection molding and sintering. The silicon carbide feeding particles are composed of, by mass, 60-80% of silicon carbide micropowder, 1-5% of boron carbide, 1-5% of titanium diboride, 0.5-5% of tungsten, 1-5% of carbon black, 1-5% of graphite, 5-15% of paraffin, 2-6% of high-density polyethylene, 2-6% of ethylene-vinyl acetate copolymer and 1-3% of stearic acid. The composite nozzle is obtained by introducing enhancing particles into silicon carbide feeding and combining with the method, free silicon content is reduced, wear resistance and mechanical performance of metal ceramic are improved, and service life of the nozzle is prolonged greatly; the composite nozzle is high in production efficiency, low in cost and supportive of continuous production.

Owner:山东宝纳新材料有限公司

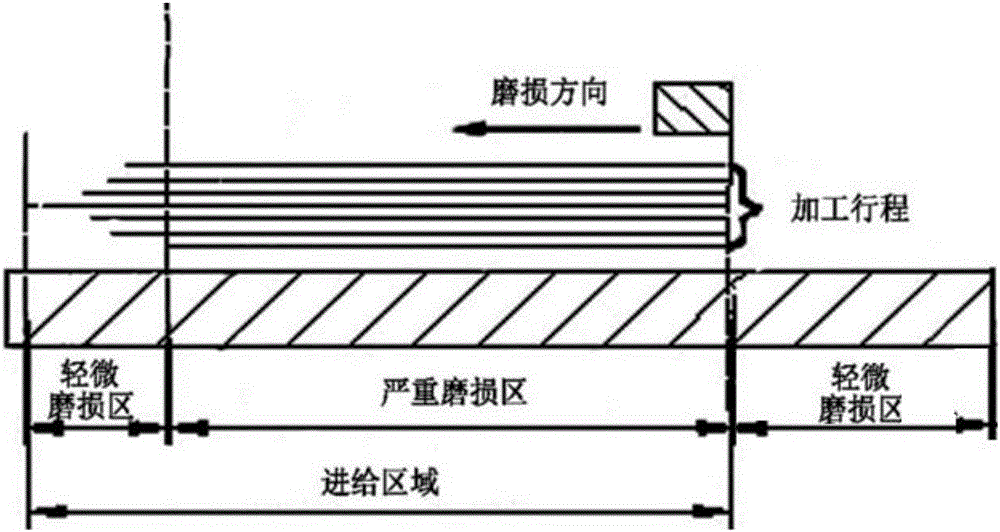

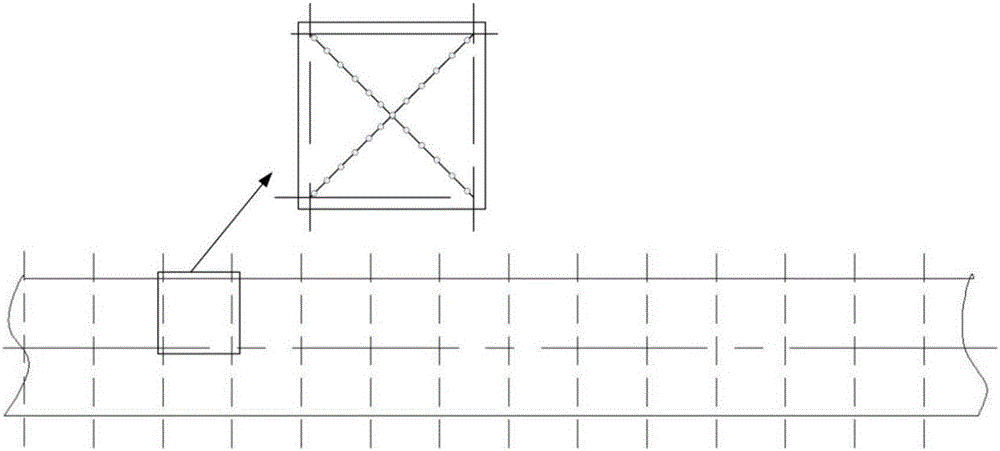

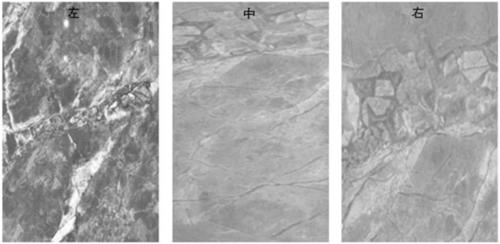

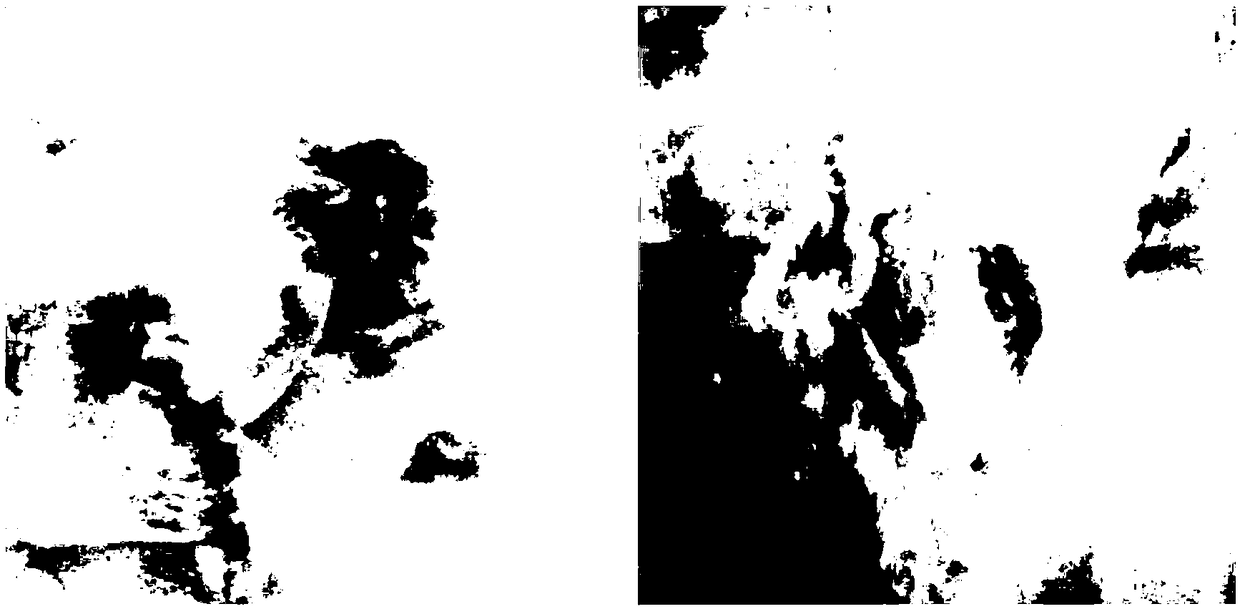

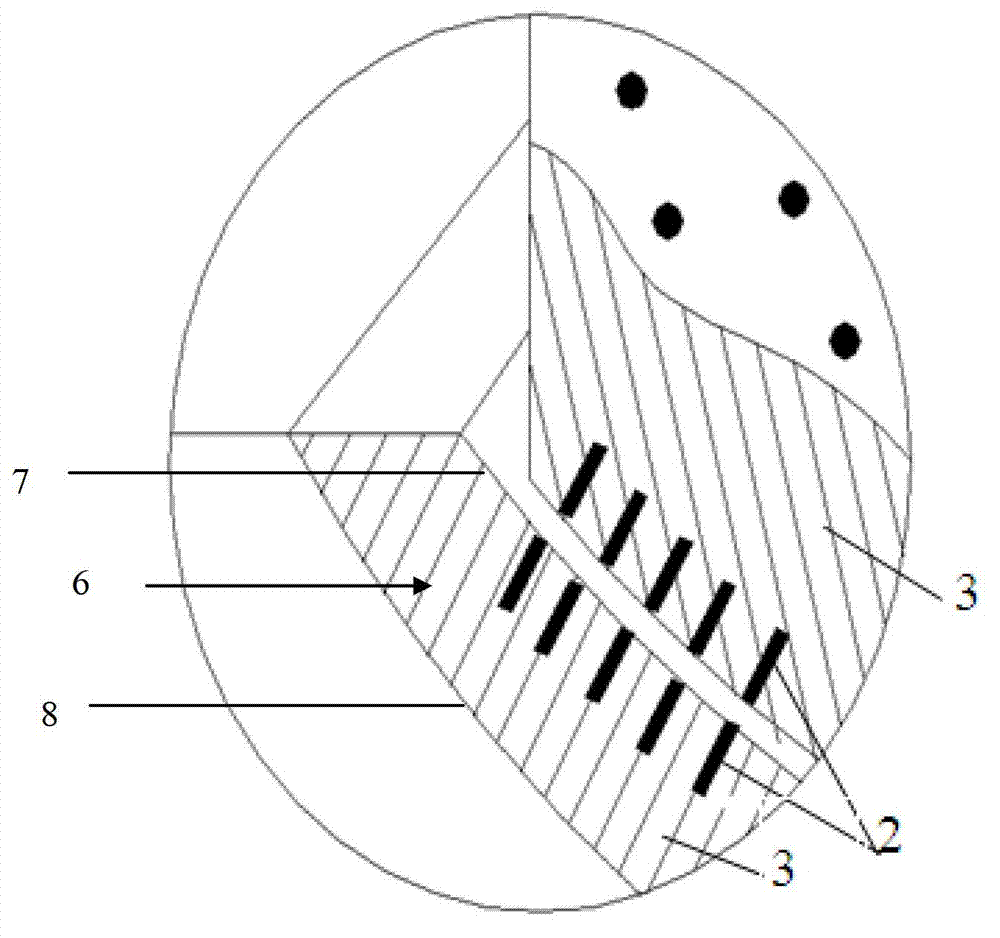

Multi-structure different-interval bionic surface combined cast-iron guide rail and regeneration method thereof

InactiveCN105108503AOvercoming Difficult-to-Regenerate ProblemsImprove wear resistanceLarge fixed membersStress distributionCoupling

The invention relates to a multi-structure different-interval bionic surface combined cast-iron guide rail and a regeneration method thereof. First bionic coupling elements and second bionic coupling elements are made on mild wear areas and a severe wear area of the guide rail working face; the first bionic coupling elements are strip-shaped or net-shaped bionic coupling elements, and intervals of the first bionic coupling elements in the mild wear areas are larger than those of the first bionic coupling elements in the severe wear area; the second bionic coupling elements are pit-shaped coupling elements and are distributed among the first bionic coupling elements. According to the multi-structure different-interval bionic surface combined cast-iron guide rail and the regeneration method thereof, according to the rigidity or stress distribution situations of the areas with different wear degrees, two double-coupling-element bionic surfaces with changeable intervals are set, a multi-structure different-interval bionic surface combination with different anti-wear performances is formed, and the surface of which the rigidity or the stress is distributed evenly is obtained, so that the effect that the overall anti-wear performance of the surface is uniform and stable for a long time is achieved. In addition, by means of the interaction between the two coupling elements and a machine body, the wear resistance of the sliding guide rail is further improved.

Owner:JILIN UNIV

Preparation method for WC-Co cemented carbide nozzle for oil field

The invention provides a preparation method for a WC-Co cemented carbide nozzle for an oil field. Co powder, WC powder, TaC and NbC are mixed and then subjected to wet grinding, drying, plasticizer adding, pressing forming, plasticizer removal and sintering, so that WC-Co cemented carbide is obtained; during mixing, based on the total weight 100% of the mixed materials, Co powder accounts for 8.5-13wt%, TaC / NbC accounts for 0.35-0.55wt%, and the rest is WC. The synergism of the materials and proportioning in the mixing process is favorable for inhibiting growth of grains and improving the alloy structure after sintering, thereby improving the toughness, high-temperature strength and hardness of the alloy, improving the heat impact resistance and heat fatigue resistance of the alloy, purifying the grain boundary, and increasing the interface binding force. Distribution of the Co phase is more uniform, and the toughness and abrasion resistance of the alloy are greatly unified.

Owner:单麒铭

High-fluidity, scratch-resistant and low-temperature-folding-resistant ABS (acrylonitrile butadiene styrene)/TPU (thermoplastic polyurethane) alloy material and preparation method and application thereof

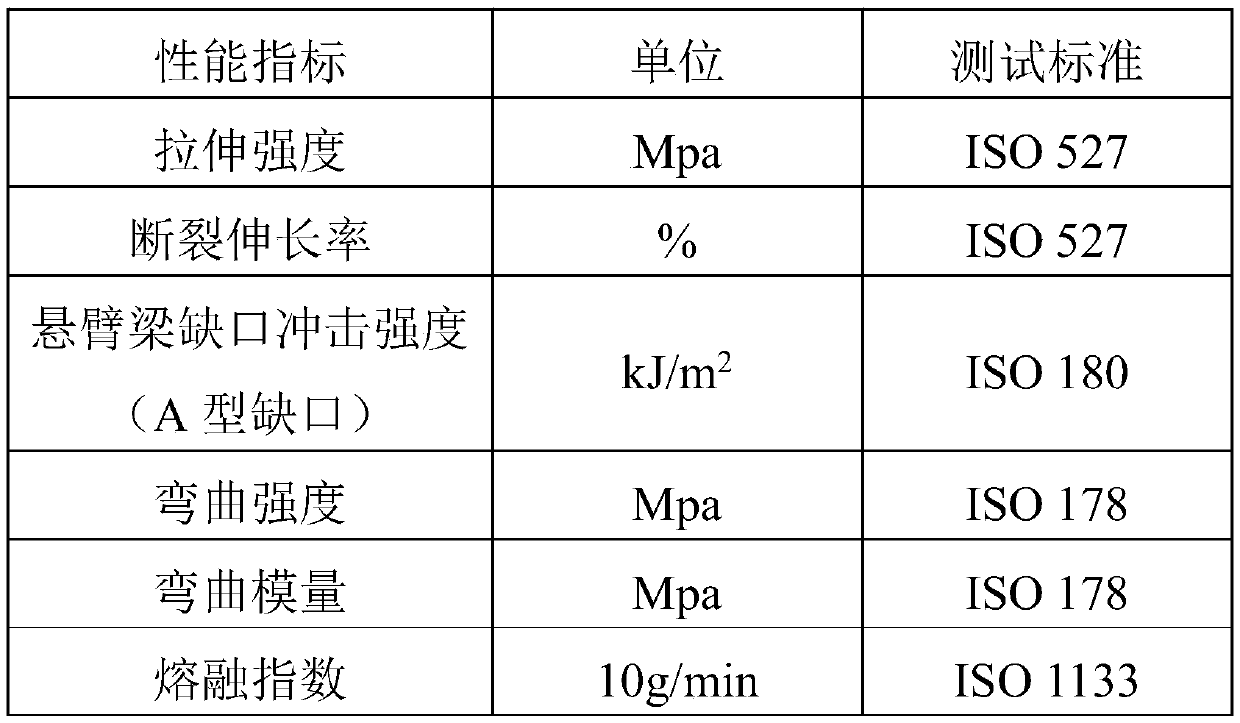

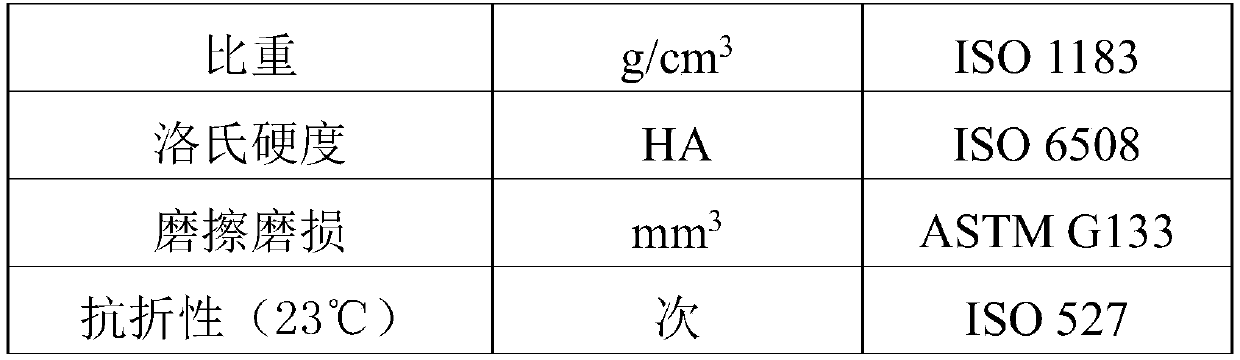

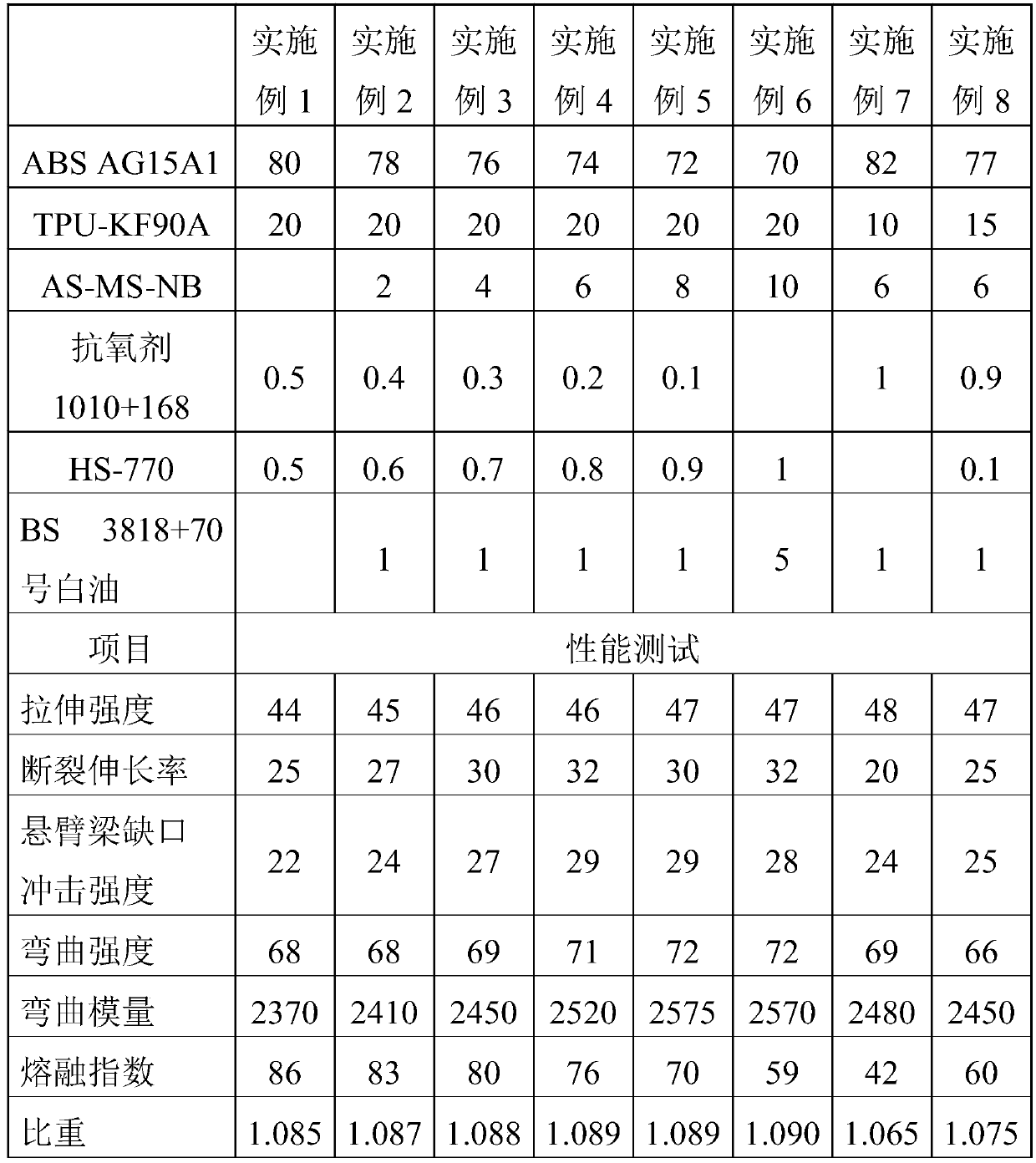

The invention discloses a high-fluidity, scratch-resistant and low-temperature-folding-resistant ABS / TPU alloy material which is prepared from the components by weight percentage of 60 wt%-85 wt% of ABS resin, 10 wt%-30 wt% of TPU and 1 wt%-10 wt% of compatilizer; the preparation method comprises the steps that the ABS resin and the TPU are dried under the condition of 85 DEG C to 100 DEG C for 2-4 hours, then the ABS resin and the TPU are fully mixed with other component raw materials according to the ratio by a high-speed mixer for 2-10 minutes, the mixtures is then transmitted to a double-screw extruder by a precision metering feeding device, and a product is obtained through mixing, extrusion, bracing, cooling and grain cutting; the prepared ABS / TPU alloy material has excellent scratch resistance, low low temperature folding resistance and high fluidity, the preparation method is simple in process, convenient to operate and suitable for industrial production, and the ABS / TPU alloy material can be applied to the fields of small electronic consumer products, electric tools, computer keys, automobile bumpers and the like.

Owner:JIANGSU KINGFA SCI & TECH ADVANCED MATERIALS CO LTD

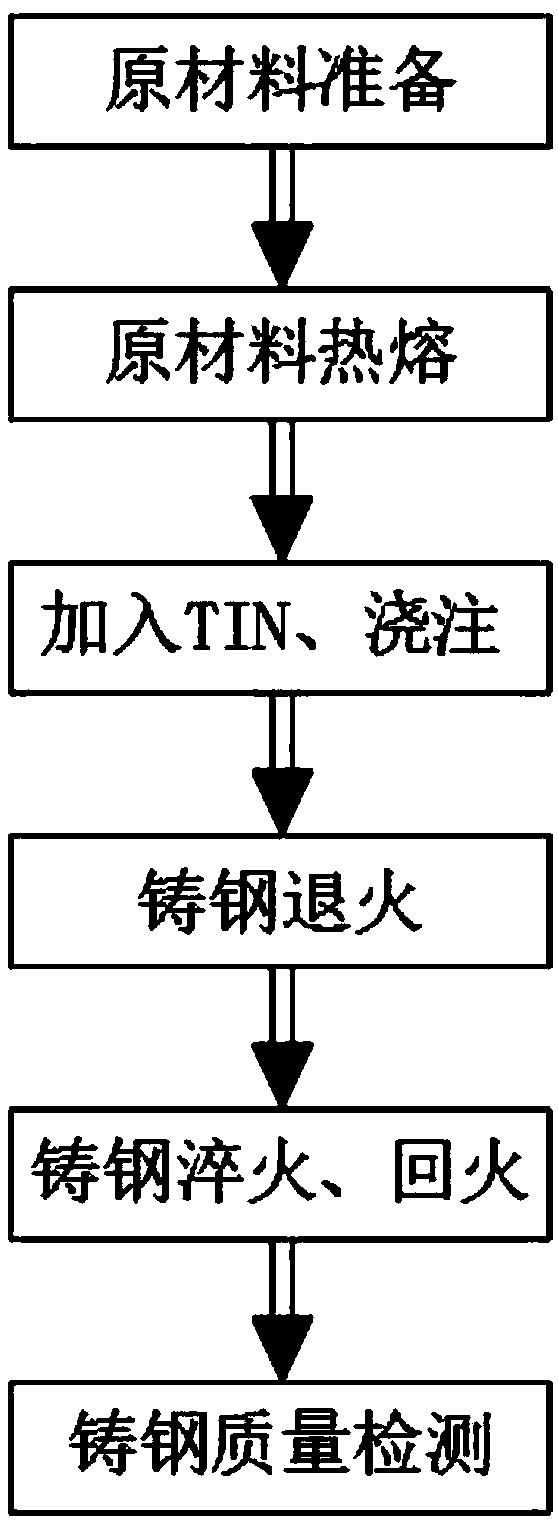

High-strength high-wear-resistant bainite cast steel used for block cast middle groove, and preparation technology thereof

ActiveCN109252098AExtended service lifeHigh strengthFoundry mouldsFoundry coresWear resistantQuenching

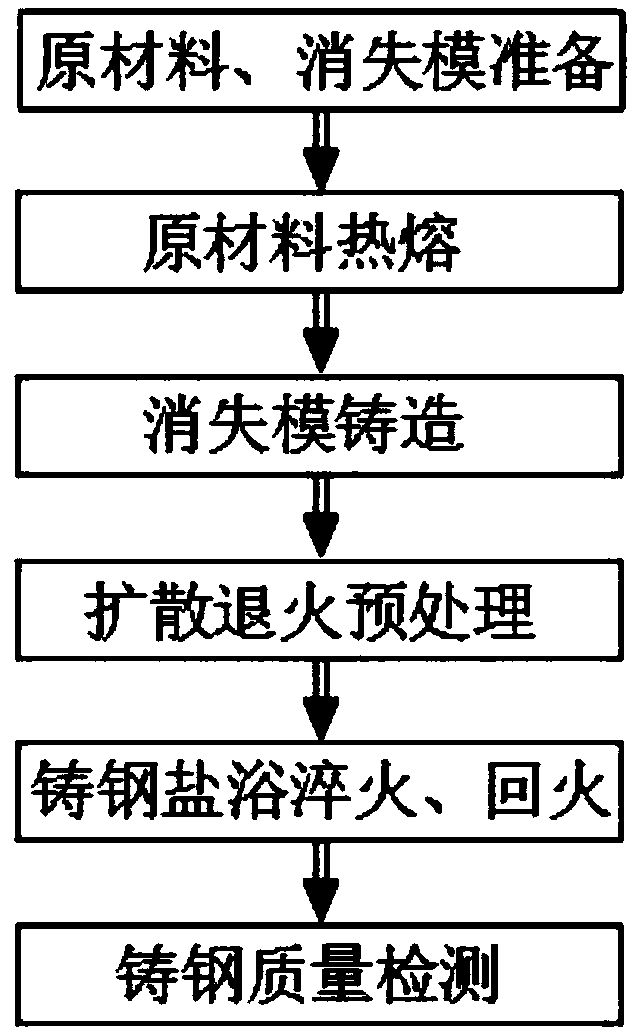

The invention discloses high-strength high-wear-resistant bainite cast steel used for a block cast middle groove, and a preparation technology thereof. The preparation technology comprises the following technical steps: preparing raw materials and evanescent modes, carrying out raw material hot melting, casting the evanescent modes, carrying out diffusion annealing preprocessing, carrying out caststeel salt bath quenching and tempering and detecting cast steel quality. The bainite cast steel used for the middle groove has the characteristics of high strength and high wear-resistant performance, the middle groove is subjected to integral casting forming, and the problem that all positions have inconsistent wear resistance is avoided. When a work surface is turned, maintenance is not required, the current work surface is directly turned to a next work surface, and the coal mining efficiency is improved. Meanwhile, since the materials of different positions are different, so that the effect of new goods are traded for old goods is realized, waste middle groove can be recovered and recast, waste is recycled, and the fully mechanized mining cost of users is greatly lowered, thus realizing an important meaning for the energy and material saving, the circular economy and the sustainable development of coal production.

Owner:JIKAI HEBEI MECHATRONICS TECH CO LTD

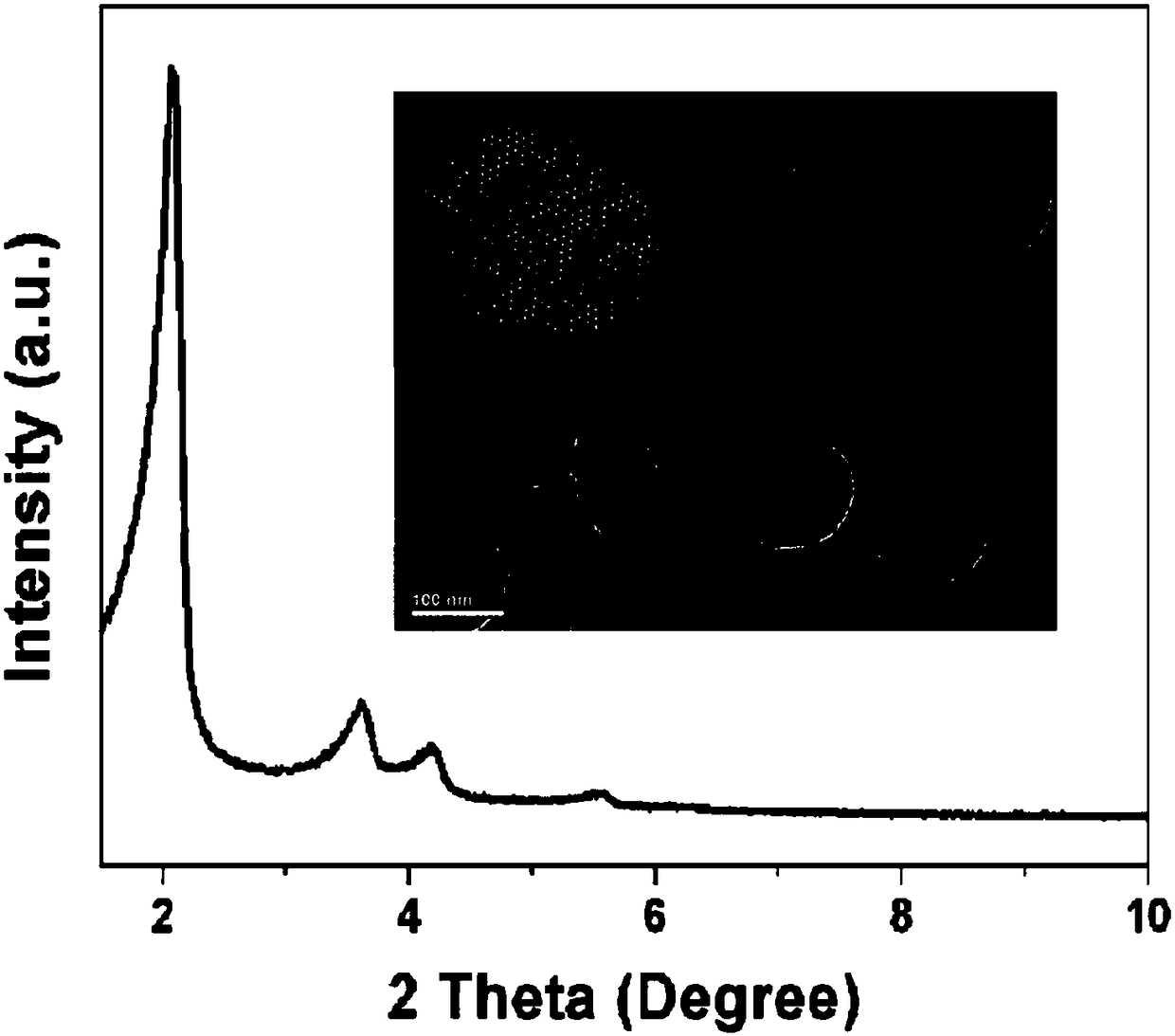

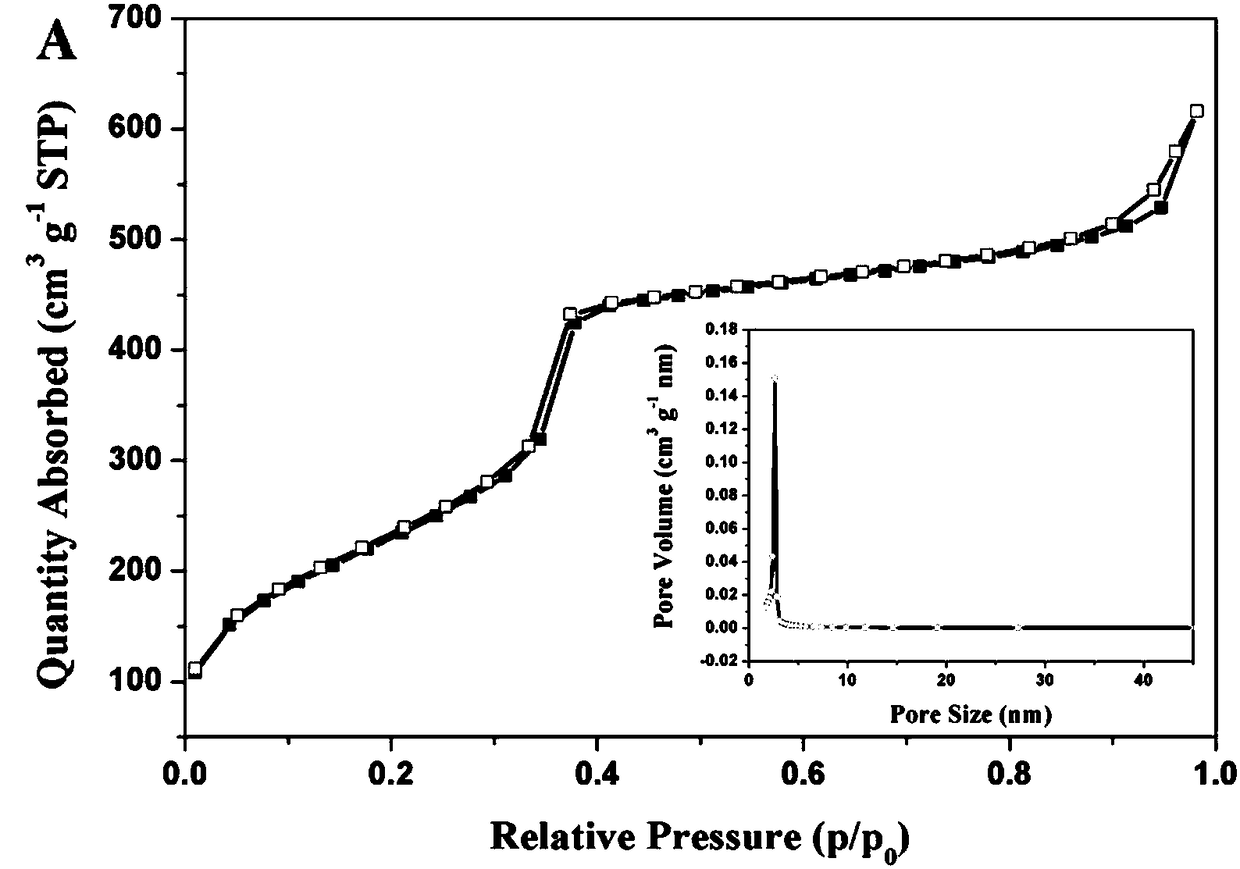

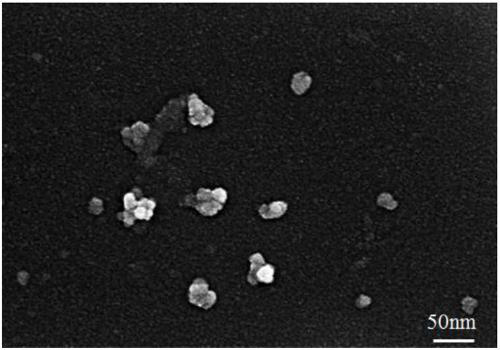

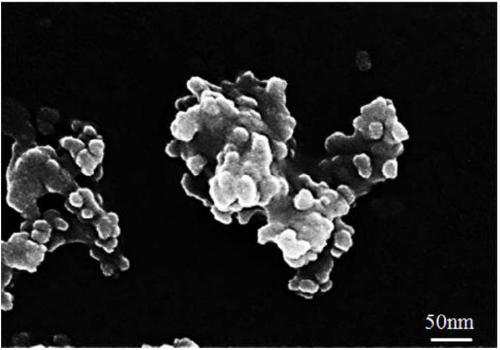

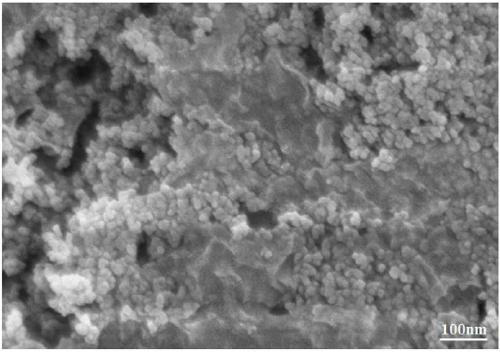

Application of aminated mesoporous silica nanomaterial as lubricating oil antiwear agent

InactiveCN108165341AImprove anti-wear and anti-friction performanceImprove carrying capacityAdditivesWear resistantMesoporous silica

The invention relates to an application of an aminated mesoporous silica nanomaterial as a lubricating oil antiwear agent. The aminated mesoporous silica nanomaterial with an ordered pore passage structure can be used as the lubricating oil antiwear agent, can significantly improve the wear resistant and friction reducing properties and the bearing capacity of the lubricating oil. The interior ofthe mesoporous silica nanomaterial has a highly ordered pore passage structure, and can provide good oil absorption and oil storage functions. In the process of friction, the lubricating oil stored inpores is released to form an oil film, cracks of the friction surface are filled, the wear can be further reduced and excellent lubrication effect is achieved. With application of the aminated mesoporous silica nanomaterial, the lubricating oil has the advantages of no corrosion of friction pair materials, environmental protection, no pollution, good chemical stability and the like. The preparation method of the aminated mesoporous silica nanomaterial has the advantages of high efficiency, rapidness, wide sources of raw materials and low cost. After the mesoporous silica nanomaterial is aminated, the mesoporous silica nanomaterial is dispersed evenly in the lubricating oil, and the antiwear property is more uniform.

Owner:北京天元陆兵汽车科技有限公司

Preparation method of biaxially oriented polyester film for electronics tapes

InactiveCN106142794AGood dispersionUniform wear resistanceLamination ancillary operationsSynthetic resin layered productsPolyesterPolymer science

The invention belongs to the technical field of polymer films for electronics tapes and particularly relates to a preparation method of biaxially oriented polyester film for electronics tapes and biaxially oriented polyester film; the method includes the steps of pretreating materials, melt-extruding, stretching and drawing; an extruder used in the melt-extruding step has filtration precision of a head strainer being 5-10 Mum; the stretching step includes sequential steps of longitudinal stretching, transverse stretching and film shaping, wherein the film shaping step includes sequential steps of thermal shaping and quick cooling, a platinum catalyst and a discharge device are mounted in an area of film thermal shaping, and part of oligomers around the film are decomposed with decomposed products discharged; undecomposed oligomers of the film and oligomer dust are separated from the film by a suction device; the film prepared herein has very small thickness and further improved insulating property and heat resistance, and each part of the film is more uniform in performance.

Owner:ANHUI GUOFENG PLASTIC

Preparation method of white carbon black/graphene oxide nano-hybrid filler, nano-hybrid filler and application of nano-hybrid filler

ActiveCN109810323AAchieve decentralizationAchieve nanodispersionEvaporation by sprayingHigh-speed grindingNano hybrid

The invention relates to a preparation method of white carbon black / graphene oxide nano-hybrid filler, the nano-hybrid filler and application of the nano-hybrid filler. The preparation method comprises the following steps: carrying out high-speed grinding and dispersion to prepare stable white carbon black slurry modified by a silane coupling agent; then uniformly stirring and grinding and dispersing the modified white carbon black slurry with a graphene oxide / water suspension solution subjected to high-speed grinding and dispersion and / or ultrasonic treatment; connecting white black carbon and graphene oxide through a bridge effect of the silane coupling agent; and then spraying and drying to prepare the white carbon black / graphene oxide nano-hybrid filler. The nano-hybrid filler is filled into any rubber variety through a traditional melting and blending technology to prepare high-performance tire tread. The preparation method and an application technology of the nano-hybrid filler are simple; and when the nano-hybrid filler is applied to rubber, nano-dispersion of graphene in a rubber matrix can be realized and the limitation of the rubber variety can be broken through, so thata composite material has excellent mechanical property, wet slipping resistance, cutting resistance, properties of delaying dynamic and static crack growth, and the like.

Owner:BEIJING UNIV OF CHEM TECH

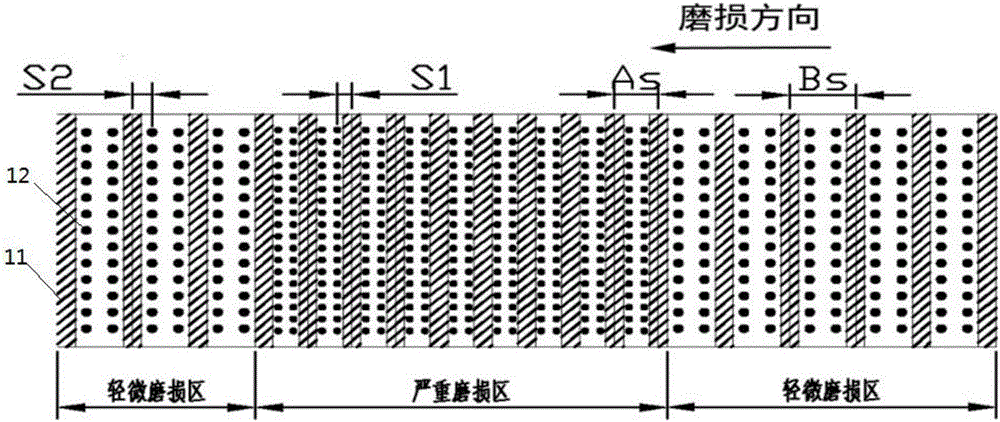

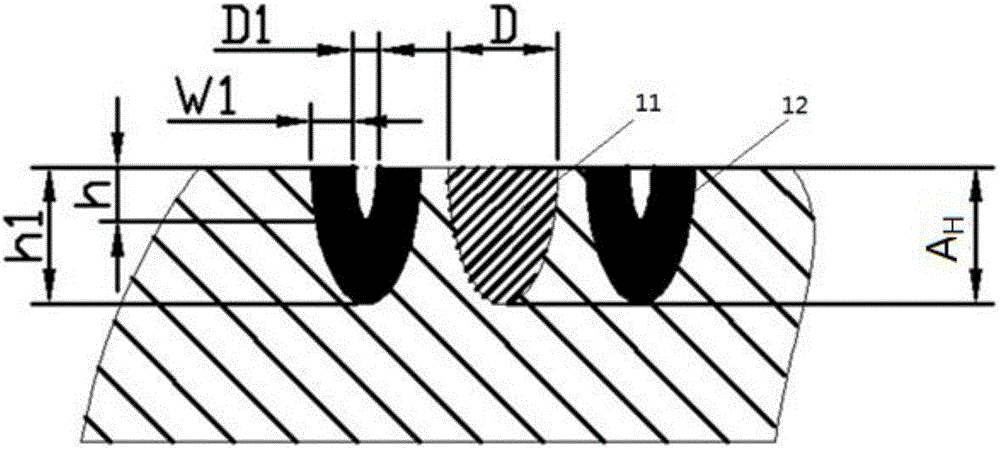

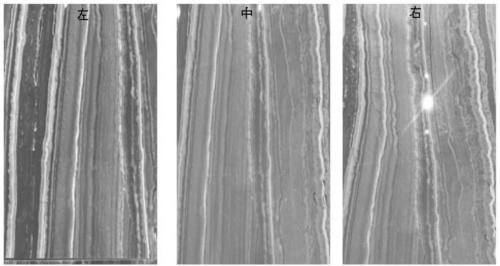

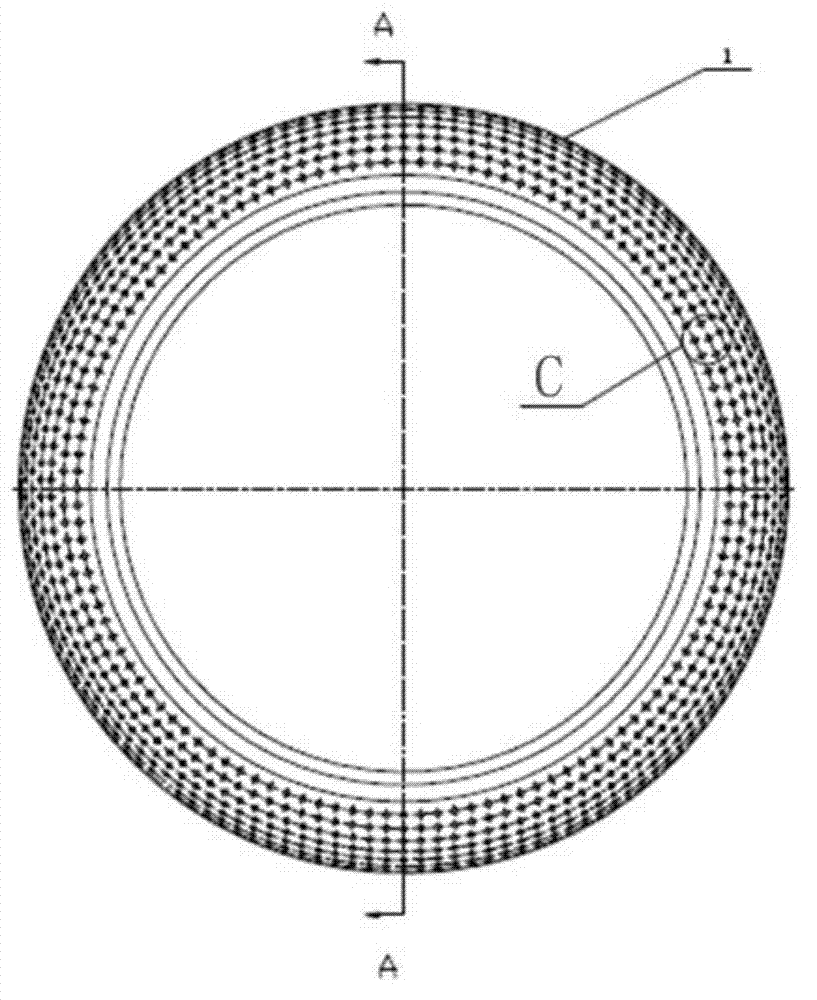

Zone building bionic coupling surface repairing waste machine tool guide rail and method thereof

The invention relates to a zone building bionic coupling surface repairing waste machine tool guide rail. The surface of the guide rail is divided into three zones including a zone A, a zone B and a zone C from big to small according to the hardness obtained before repairing; strip bionic coupling elements, dot and strip combined bionic coupling elements and net bionic coupling elements are machined on the surface of the zone A, the surface of the zone B and the surface of the zone C correspondingly; and each zone is divided into a plurality of fine adjustment zones according to the hardness obtained before repairing, the fine adjustment zones are changed from big to small along with changes of the hardness obtained before repairing, and the distances of the coupling elements on the zones are changed from small to big. According to the zone building bionic coupling surface repairing waste machine tool guide rail, corresponding bionic coupling models are matched with the surfaces of the different hardness zones of the guide rail, the problem about uniformity during non-uniform repairing is solved, and the working years of a repaired machine tool can reach even exceed the working years of a new machine tool; and the service life of the repaired guide rail can reach 8 years to 12 years, the using years of the guide rail and the machine tool are greatly prolonged, scraping of the overall machine tool is avoided, resources wasted for manufacturing the new machine tool are saved, and a large number of resources are saved.

Owner:JILIN UNIV

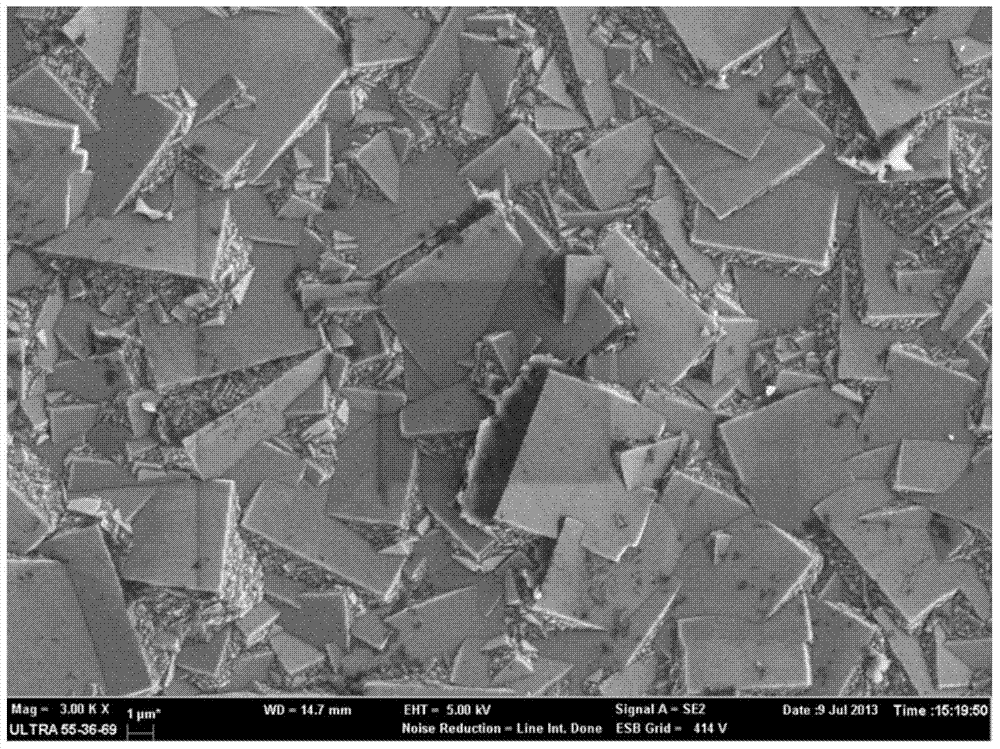

Diamond composite sheet and preparation method thereof

InactiveCN102039413AImprove radial temperature field distributionUniform wear resistanceChemical vapor deposition coatingHeat stabilityImpact toughness

The invention discloses a diamond composite sheet. A diamond layer is compounded on hard alloy, and a glomerocryst diamond layer is compounded on diamond. The invention greatly improves the radial temperature-field distribution of the composite sheet and ensures that cobalt in the hard alloy uniformly spreads cross the diamond layer. The composite sheet prepared with the method has the advantages that the abrasive resistance of the diamond layer is uniform, the diamond layer is firmly combined with the hard alloy layer, and the impact toughness and the heat stability are enhanced.

Owner:HENAN FAMOUS DIAMOND IND CO LTD

Method for producing WC-Co hard alloy oilfield spray nozzles

InactiveCN106623912AImprove performanceImprove stabilityTransportation and packagingMetal-working apparatusSpray nozzleAlloy

The invention provides a method for producing WC-Co hard alloy oilfield spray nozzles. The method includes compounding, by weight, 8.5-13% of Co powder, 0.35-0.55% of Tac, 0.35-0.55% of Nbc and the balance WC powder, and conducting wet grinding, spray drying, pressing forming and sintering so as to obtain WC-Co hard alloy, wherein a sintering process includes holding at 300-500 DEG C, heating to 400-500 DEG C at a hydrogen flow speed of 55-65 L / min prior to holding, heating to 550-650 DEG C at a hydrogen flow speed of 35-45 L / min prior to holding, conducting carbon correction in a mixed atmosphere with a ratio of CH4 to H2 being (1-2) to (98-99) at a mixed atmosphere flow speed of 35-45 L / min and at 600-1,000 DEG C, holding in a mixed atmosphere with a ratio of CH4 to H2 being (1-4) to (96-99) at 1,000-1,200 DEG C for precise carbon correction. The method is beneficial to improvement in comprehensive performance and production stability of the WC-Co hard alloy oilfield spray nozzles.

Owner:HUNAN CENTURY SPECIAL ALLOY

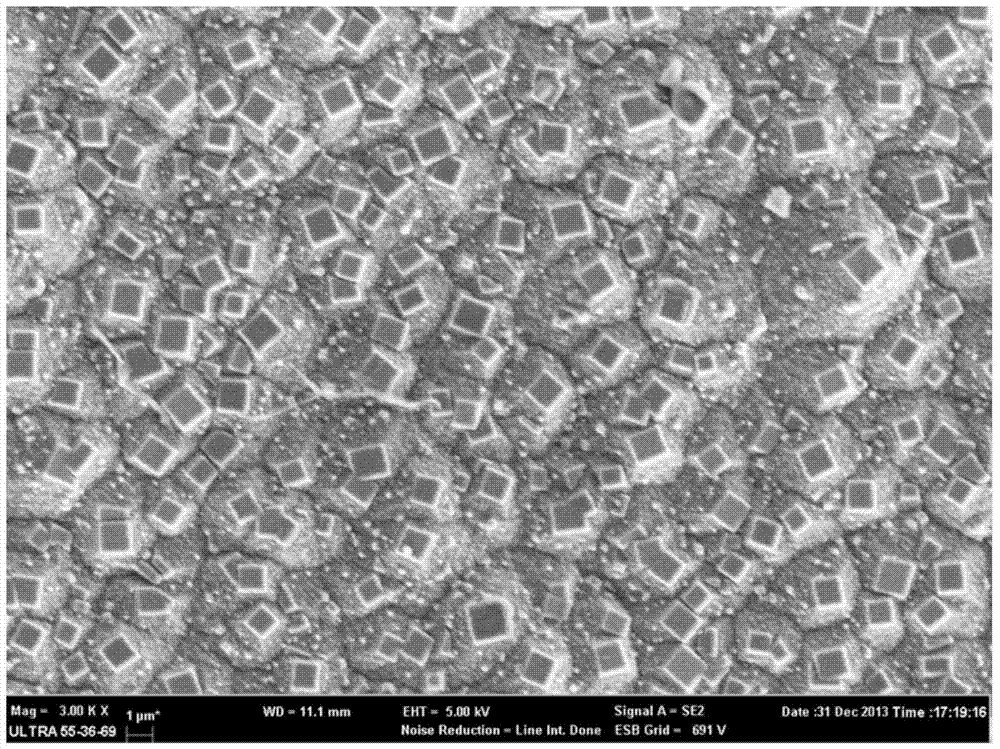

Preparation method of boron-nitrogen co-doped nano-based oriented diamond film

ActiveCN103938182ASimple preparation processUniform wear resistanceChemical vapor deposition coatingPolymer scienceHydrogen

The invention discloses a preparation method of a boron-nitrogen co-doped nano-based an oriented diamond film. The preparation method comprises the following steps: by taking a heater CVD (Chemical Vapor Deposition) device as deposition equipment, adding boron-nitrogen-containing compounds into a conventional hydrogen and acetone reaction system to form a co-doped system; adjusting the reaction technical parameters; preparing the film where diamond particle particles and oriented diamond particles co-exist. The method is simple in process flow. The obtained film has the characteristics that the film has the surface which is leveler than a randomly oriented micron order diamond film, high and uniform wear resistance, easiness in polishing, low internal stress, high adhesive force of the film base and the like.

Owner:SHANGHAI JIAO TONG UNIV +2

3D infiltrated crystallization glaze and application thereof

The invention discloses a 3D infiltrated crystallization glaze and application thereof. The glaze comprises a ground glaze and a cover glaze, wherein the cover glaze comprises the following raw materials: potassium feldspar, soda feldspar, quartz, kaolin, calained talc and a dyeing assistant agent. The glaze formula can really achieve a 3D in-glaze decoration effect and realize the unification ofthe surface decoration effect, the abrasive resistance and the hardness; in addition, the glaze is low in raw material cost, stable in performance, high in transparency, strong in transparent feeling,bright in color, and clear in pattern texture, is favorably compared with raw gemstone basically, and completely subverts the decoration effect of existing infiltrated glaze. By adopting the 3D infiltrated crystallization glaze provided by the invention, the consumption of infiltrated ink can be reduced by 35% relative to that of common infiltrated glaze, meanwhile, the consumption of the dyeingassistant agent can be reduced by 30% relative to that of the common infiltrated glaze, so that the production cost is reduced, the market popularization is benefited, the competitiveness is improved,and the reduction of the consumption of the dyeing assistant agent can reduce the tendency of crazing of ink jet infiltrated product glaze, so that the defects of finished products are reduced, and the rate of finished products is improved by 1%-3%.

Owner:广东道氏陶瓷材料有限公司

Grinding roller and grinding disc tile

InactiveCN103111347AGood compatibilityRealize the compound matching of advantagesGrain treatmentsHardnessAdhesive wear

The invention discloses a grinding roller and a grinding disc tile. The grinding roller and the grinding disc tile comprise basal bodies and multiple ceramic rods, wherein the ceramic rods are casted in the basal bodies along the abrasive surfaces of the grinding roller and the grinding disc tile. The grinding roller and the grinding disc tile provided by the invention guarantee that the working layers of the grinding roller and the grinding disc tile have higher hardness, the adhesive wear and the cutting abrasion are reduced on one hand when the wearable ceramic rods are casted in the basal bodies, and the grinding roller and the grinding disc tile are guaranteed to have good tenacity on the other hand to resist exotical impact. The grinding roller and the grinding disc tile provided by the invention adopt routine antifriction material to support and protect a ceramic material, the super stiff and wearable ceramic material is utilized to grind the processed mineral, and the advantage composite matching of the material is realized.

Owner:北京理研社技术有限公司

High corundum furnace tube

The present invention relates to fireproof materials, in particular to a high corundum furnace tube. The furnace tube is sintered by 90%-95% of white corundum, 2%-7% of kaolin clay and 2%-4% of alumina powder at a high temperature; the white corundum is mixed by particles prepared from a liquid which is smelted by the alumina powder at the high-temperature of 2200 DEG C; and the specification of particles comprises 12 meshes, 24 meshes, 46 meshes, 70 meshes, 120 meshes and 320 meshes. By adopting the technical scheme, by using white corundum particles of different thicknesses to be mixed, the white corundum content is increased, and the internal stress of the furnace tube generated by expansion or contraction of the furnace tube materials in heating or cooling processes is alleviated; and the explosion probability of the furnace tube is reduced, and the service life of the furnace tube is prolonged.

Owner:CHANGXING RONGJUN REFRACTORY EQUIP CO LTD

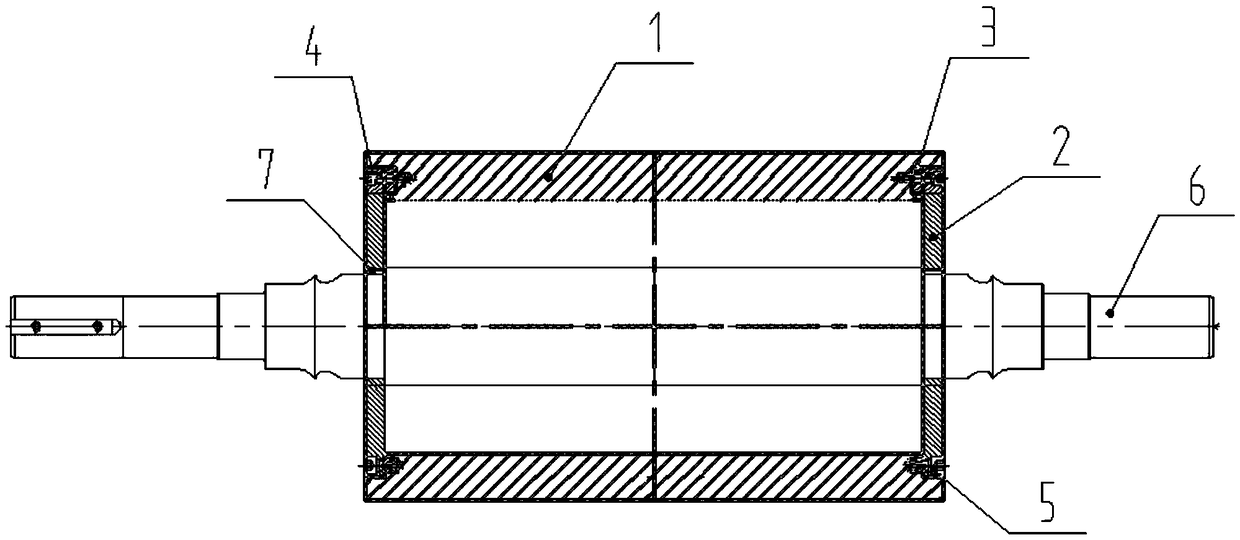

Novel pinch roll

InactiveCN109047341ASmall amount of repairLow costFurnace typesMetal rolling arrangementsEngineeringMechanical engineering

The invention relates to a novel pinch roll. The novel pinch roll comprises an upper pinch roll body and a lower pinch roll body, wherein the upper pinch roll body comprises an upper pinch roll sleeve, an upper pinch roll mandrel is arranged in the upper pinch roll sleeve, the length of the main body of the upper pinch roll mandrel is greater than that of the main body of the upper pinch roll sleeve, end face baffles are arranged at the two ends of an opening of the upper pinch roll sleeve, a connecting key block is arranged on one side of each end face baffle, each connecting key block is provided with a key block fastening bolt used for fixing, baffle fastening bolts used for fixing are arranged on the end face baffles and are opposite to the connecting key blocks, shaft shoulders matched with the inner sides of the end face baffles on the two sides are arranged in the middle of the upper pinch roll mandrel, and mandrel connecting key blocks are arranged at the connecting positions of the end face baffles and the upper pinch roll mandrel; and the lower pinch roll body comprises a lower pinch roll sleeve, and a metallurgical bonding lower pinch roller mandrel is arranged in the lower pinch roll sleeve. The novel pinch roll overcomes shortcomings of existing technology and is reasonable in structure and high in abrasion resistance and toughness, and the comprehensive use performance of the pinch roll is improved.

Owner:山东坤元重工机械有限公司

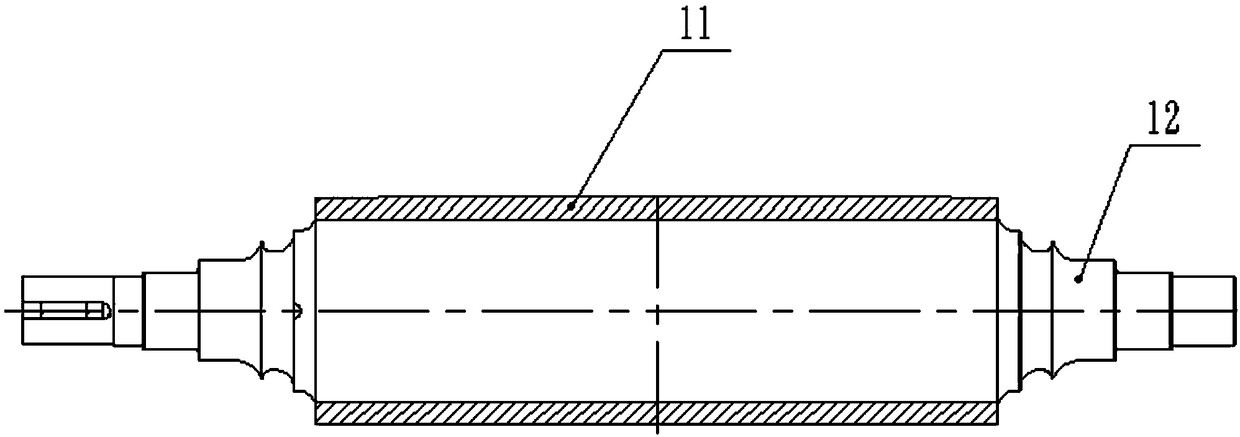

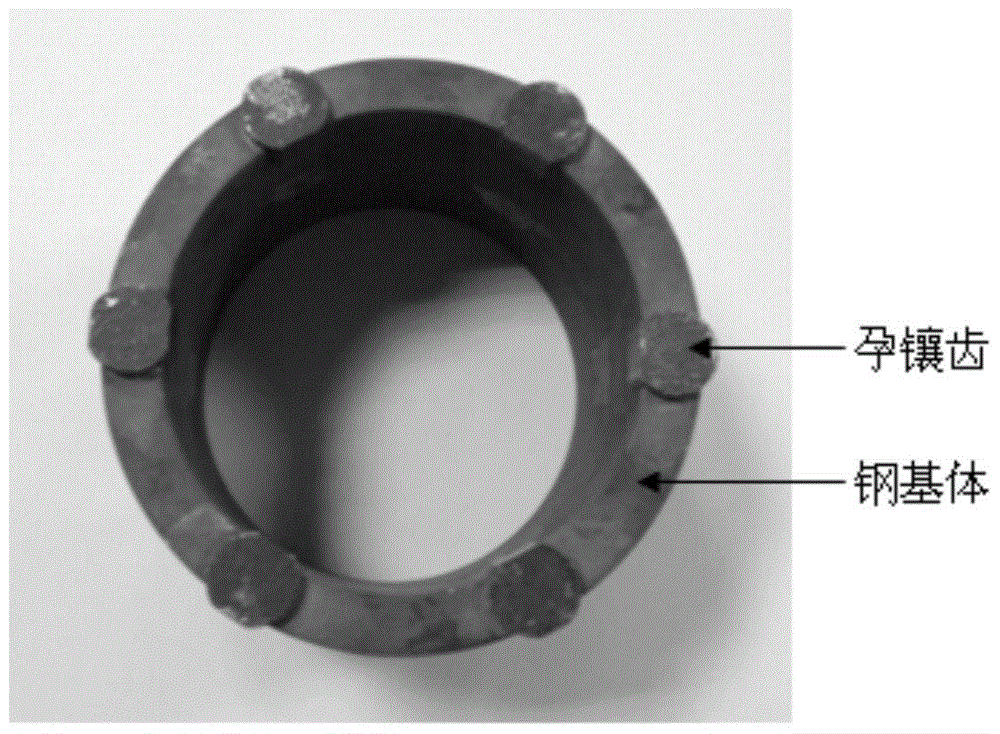

Rubber covered roller of island structure and preparation method thereof

ActiveCN108948459AIncrease coefficient of frictionImprove wear resistanceDomestic articlesPolymer scienceHardness

Owner:南京金三力辊业科技有限公司

Laser tempering quenching method

PendingCN114774639AFine grainIncrease the dislocation densityFurnace typesHeat treatment process controlLaser quenchingFacula

The invention discloses a laser tempering quenching method. The technical problem that in the prior art, due to the fact that heat treatment is not in place or the density or hardness of a base body is different, the hardness of the quenched surface is still extremely uneven after heat treatment is solved. Comprising the steps of preparation before machining, primary scanning laser tempering, natural cooling, secondary scanning laser quenching, detection and the like, and the specific principle is that gas assistance and two times of non-constant-speed scanning are adopted to achieve the purpose of strengthening a part to be quenched; the two scanning speeds are inconsistent, the first scanning speed is high, the second scanning speed is low, the power is kept consistent and the gas flow is kept unchanged in the whole process, and gas is blown to the laser spot position of the surface to be quenched at a fixed angle at any moment in the quenching process, so that the purpose of uniform surface hardness of the quenched surface is achieved.

Owner:XIAN BESAME LASER TECH CO LTD

Single-component water-based top-coat for plastic runway and preparation method thereof

InactiveCN111534171AImprove wear resistanceUniform wear resistancePolyurea/polyurethane coatingsAcrylic resinGraphene

The invention discloses a single-component water-based top-coat for a plastic runway. The single-component water-based top-coat is prepared from the following raw materials in parts by weight: 45-55 parts of waterborne acrylic resin, 30-40 parts of waterborne polyurethane resin, 1-5 parts of a water-soluble graphene aqueous dispersion, 0.3-0.5 part of a wetting agent, 0.2-0.4 part of a defoaming agent, 5-7 parts of a cosolvent, 0.3-0.5 part of a thickening agent, 0.5-0.7 part of a preservative and 3-6 parts of deionized water. The single-component water-based top-coat for the plastic runway has the advantage of relatively good wear resistance; the invention also provides a preparation method of the single-component water-based top-coat, and the graphene in the raw materials can be uniformly dispersed in the single-component water-based top-coat, so that the wear resistance of the top-coat is improved.

Owner:HUBAO NEW MATERIAL TECH SHANGHAI CO LTD

A kind of impregnated tooth suitable for strong abrasive hard formation and its preparation method

Owner:KINGDREAM PLC CO +1

High-tenacity high-strength cast steel wear-resistant material and preparation method thereof

The invention discloses a high-tenacity high-strength cast steel wear-resistant material and a preparation method thereof. The method comprises the technology steps of raw material preparation, raw material hot melting, TIN adding according to a ratio, cast steel annealing, cast steel quenching and tempering and cast steel quality detection, through a series of thermal treatment technologies of isothermal quenching, high-temperature tempering and the like, the high-tenacity high-strength cast steel wear-resistant material has good tensile performance, and is not prone to deform or break, and by adding an appropriate amount of TIN in a hot melting process, the elongation at break is higher than or equal to 12%; V shape impact energy is higher than or equal to 45 J, the rockwell hardness HRCis 40-45, cast steel has higher impact resistance, the wear resistance performance of the cast steel is 1.5 times the wear resistance performance of an NM450 wear-resistant plate, the cast steel hasthe good wear resistance performance, wear resistance degrees of the cast steel are even, by conducting annealing in an annealing furnace at 900+ / -3 DEG C in cooperation with a fan and blades, the produced cast steel is even in wear resistance, and the problems that cast steel is poor in weldability, high in welding stress and prone to break, and has many welding defects due to the fact that various portions are made from different materials are solved.

Owner:JIKAI HEBEI MECHATRONICS TECH CO LTD

Trigger of tool switch and production technique of trigger.

The invention discloses a trigger of a tool switch and a production technique of the trigger. The trigger is prepared from, by weight, 20-35 parts of zinc borate, 0.5-4 parts of nano lanthanum oxide, 2-15 parts of magnesium oxide, 0.5-4 parts of nano cerium oxide, 1-5 parts of graphite fibers, 5-15 parts of chromium, 3-8 parts of nickel powder, 5-10 parts of attapulgite, 8-13 parts of manganese, 15-35 parts of aluminum powder, 20-40 parts of iron oxide and 1200-1600 parts of iron powder. The production technique of the trigger comprises the steps that when the temperature of a blast furnace reaches 200-350 DEG C, the raw materials are added, and a fluxing agent is added into the blast furnace at the same time; when the temperature of the blast furnace reaches 700-800 DEG C, a refining agent is added; when the temperature of the blast furnace reaches 700-800 DEG C again, a modificator is added for modification; and when the temperature of the blast furnace reaches 720-770 DEG C, slagging-off and discharging out of the furnace are conducted, and pouring is conducted rapidly, so that the trigger is obtained. The production technique is simple and environmentally friendly; the machined trigger has good performance in the aspects of tensile strength, bending strength, percentage elongation after fracture and the like, and market requirements are met completely.

Owner:桐乡市搏腾贸易有限公司

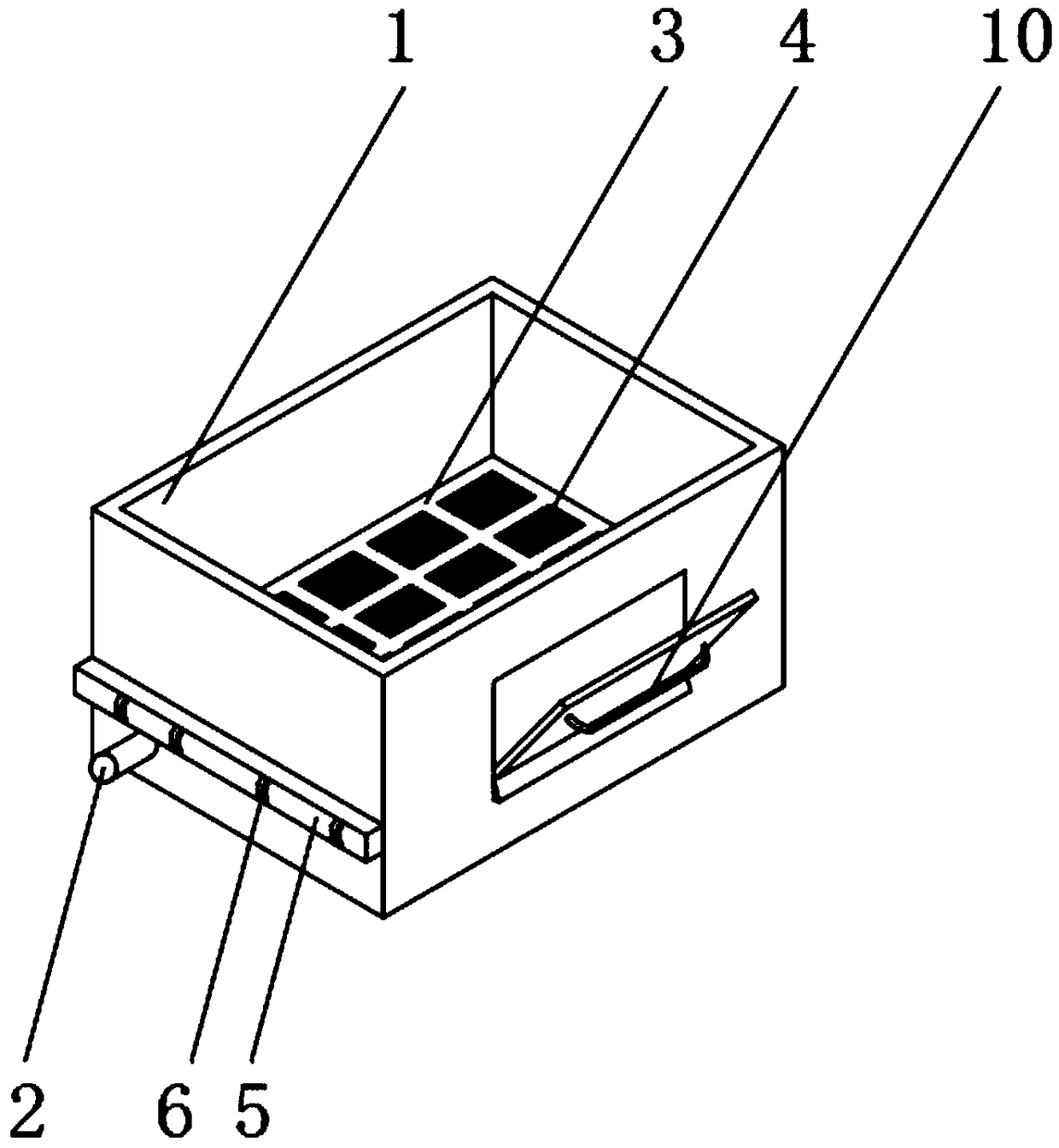

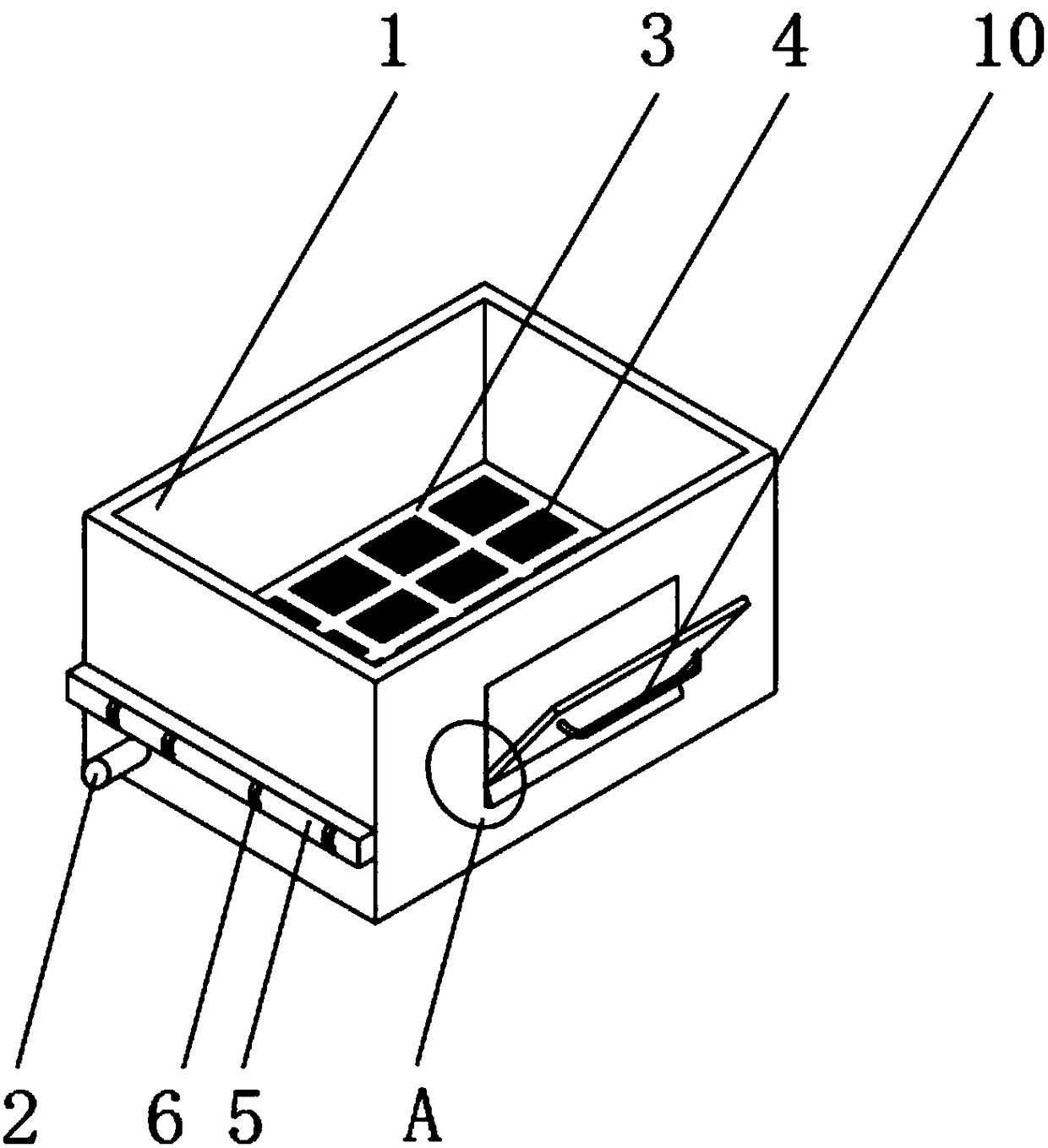

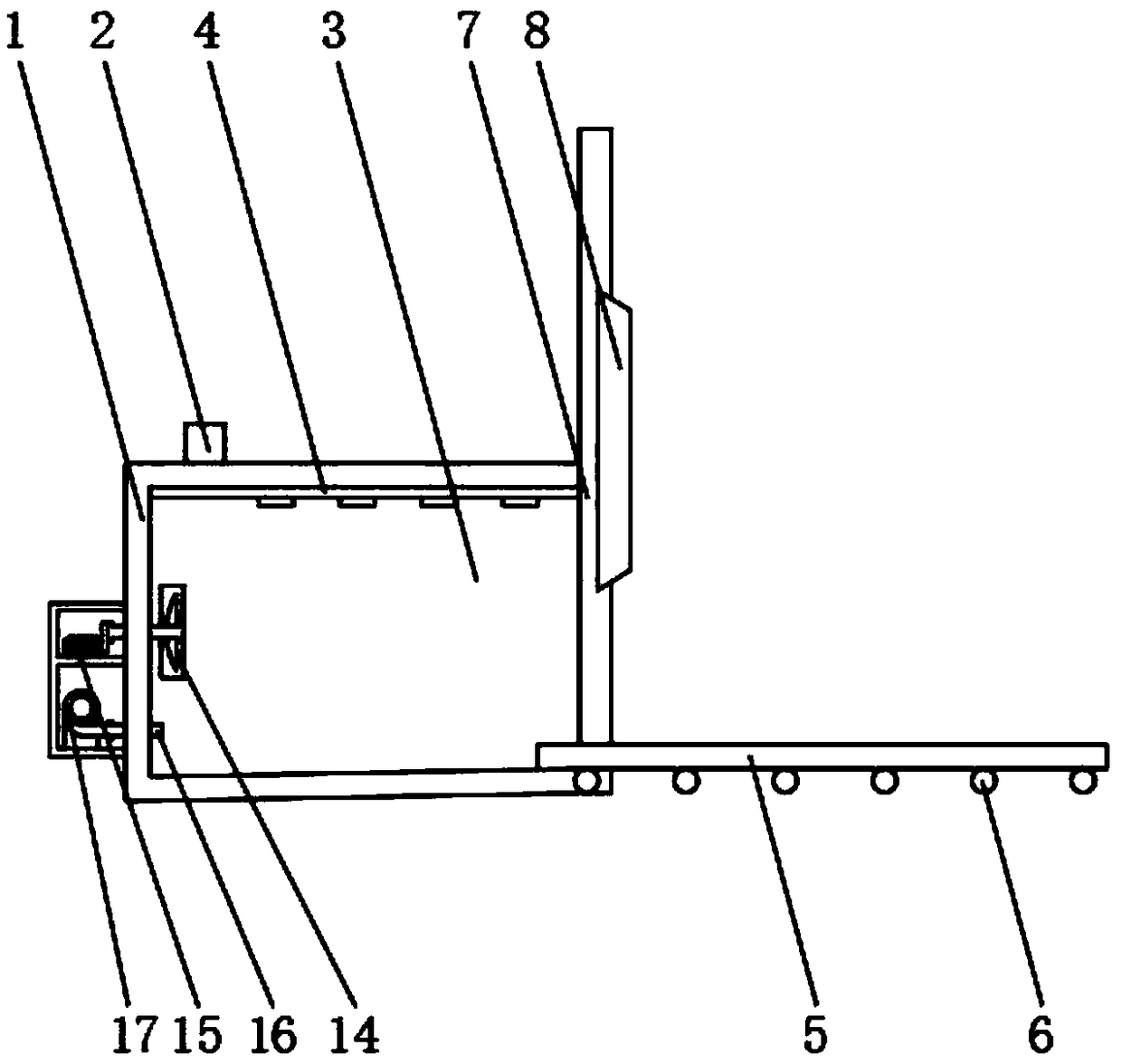

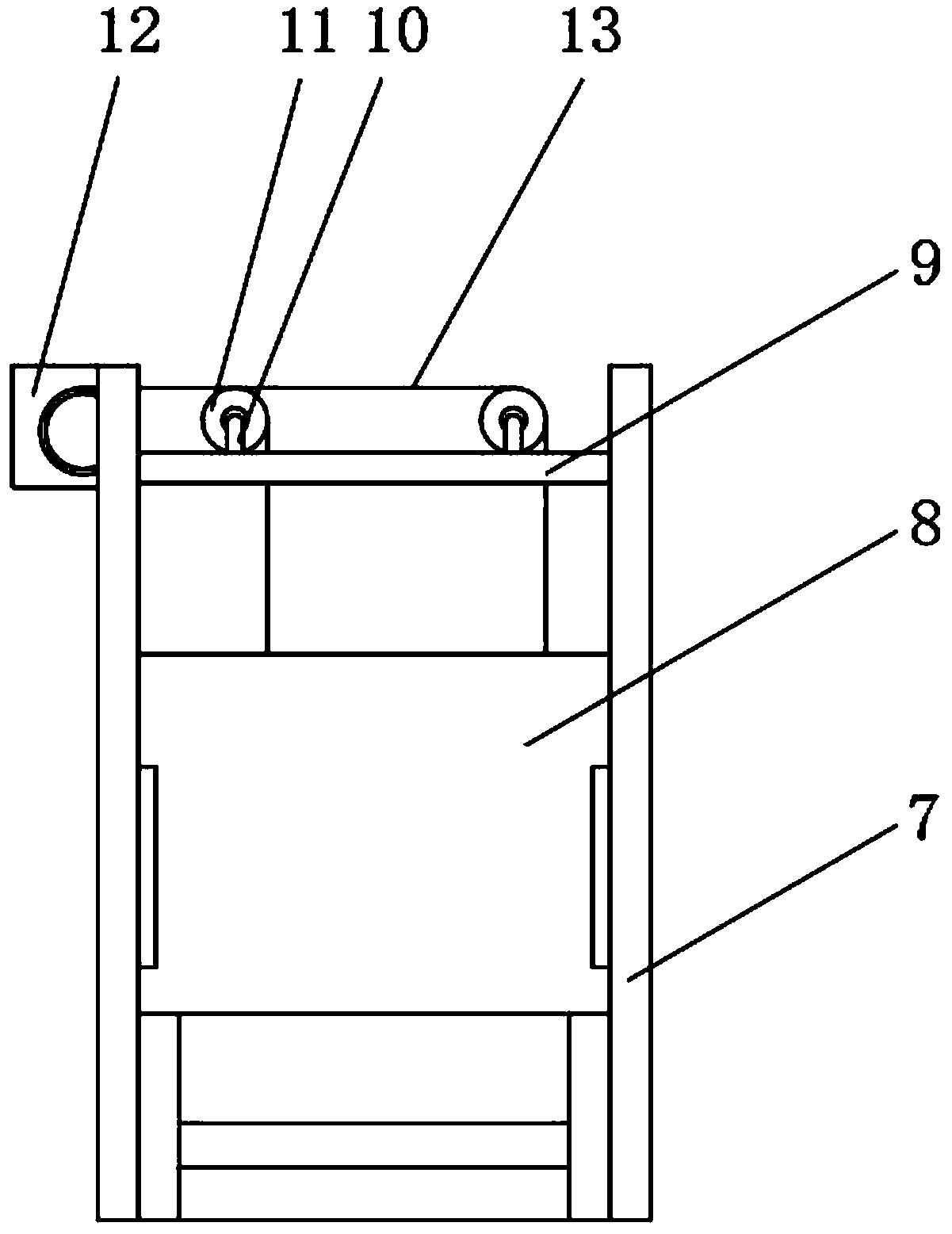

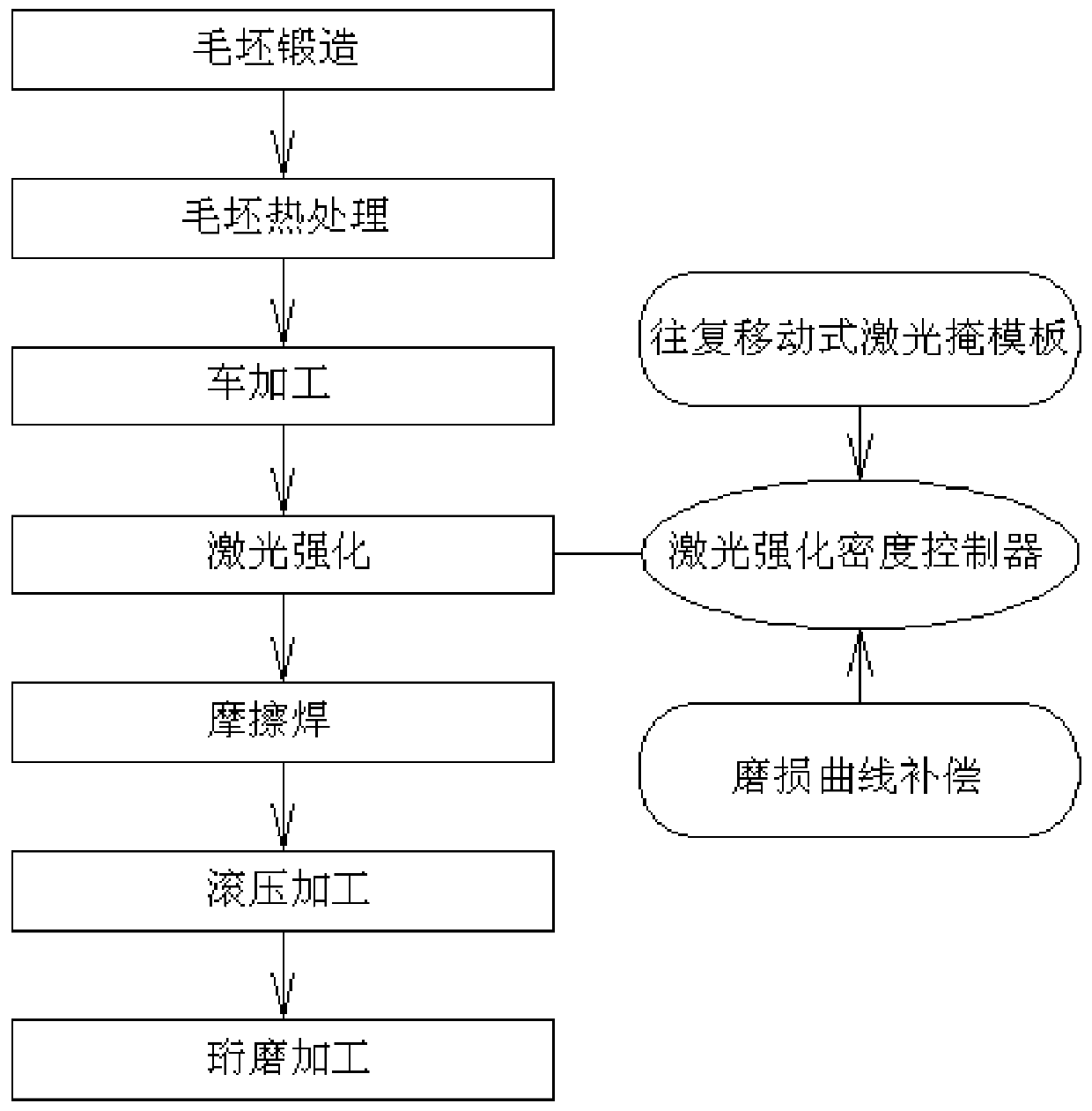

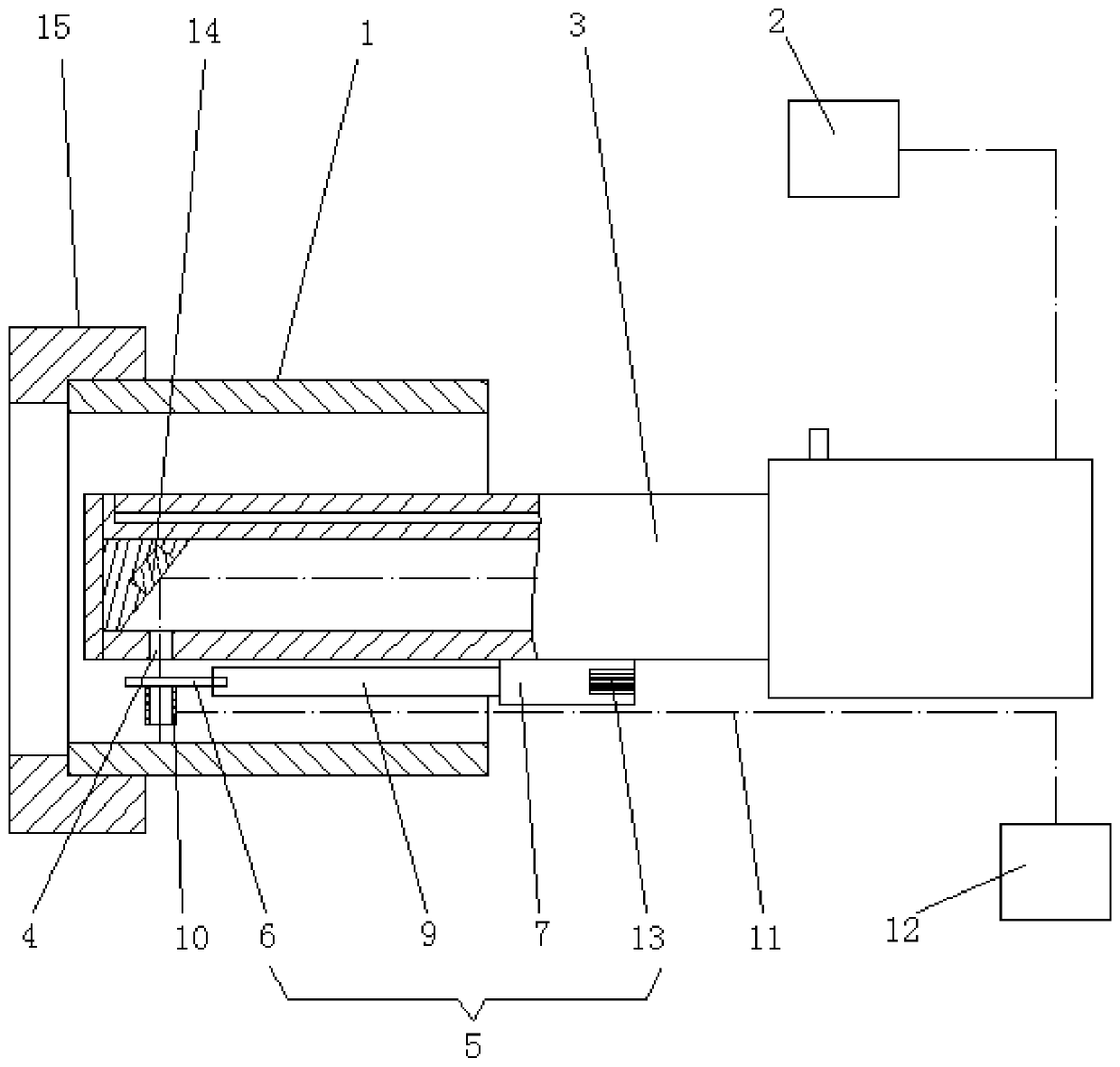

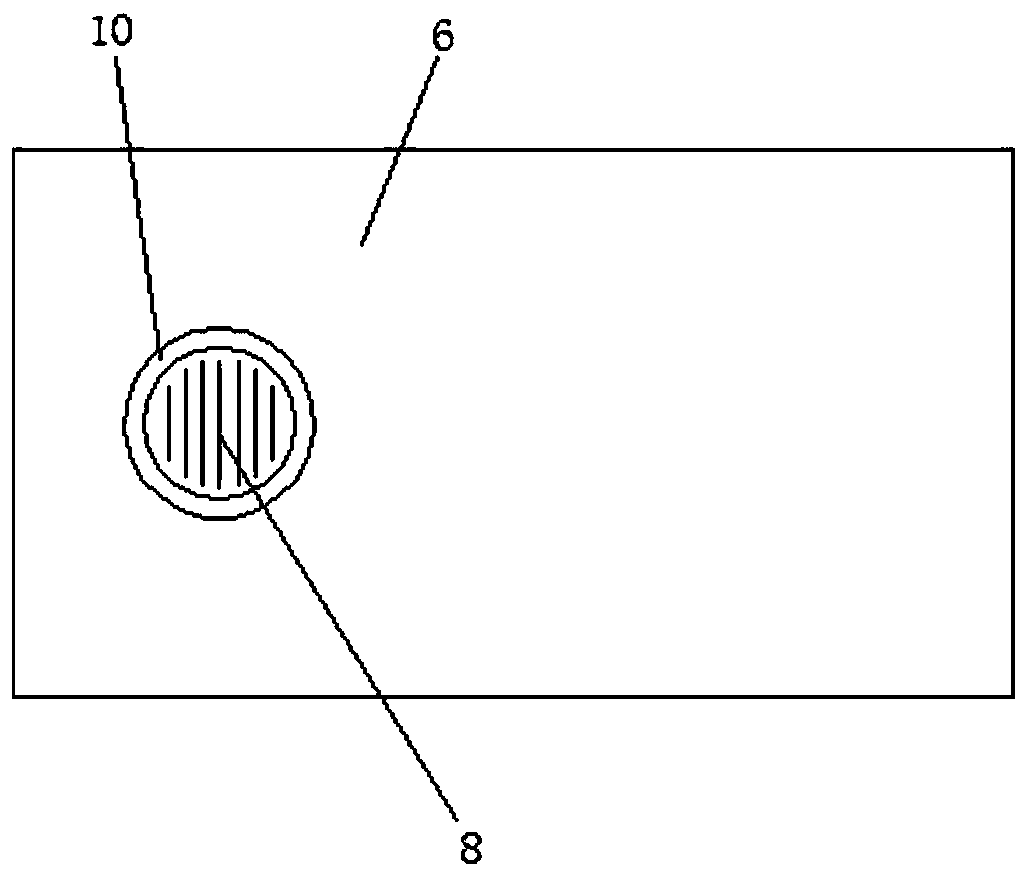

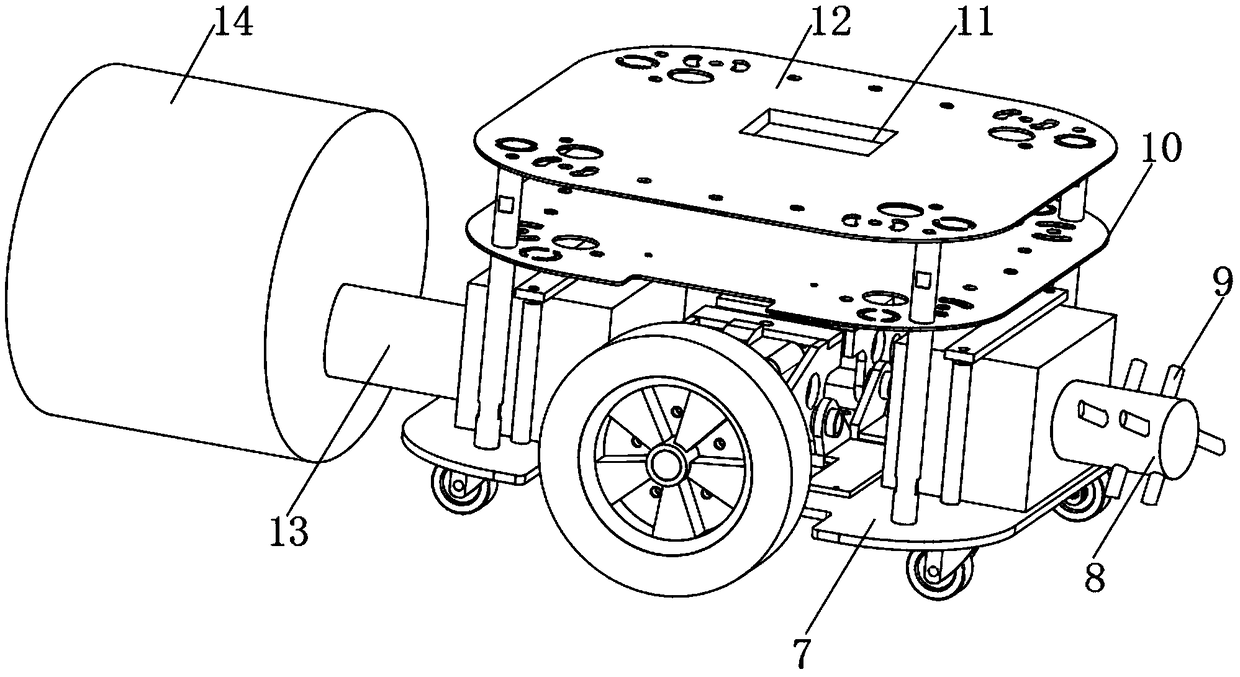

Manufacturing process of oil cylinder

The invention relates to the technical field of oil cylinder manufacturing, and discloses a manufacturing process of an oil cylinder. The manufacturing process of the oil cylinder sequentially comprises the following process steps of blank forging, blank heat treatment, turning, laser strengthening, honing and the like, wherein the laser strengthening step comprises the operation of carrying out strengthening treatment on the surface of an inner hole of the oil cylinder by using a laser strengthening treatment device, the laser strengthening treatment device comprises a laser generator and a light guide main shaft connected with the laser generator, the front end of the light guide main shaft is provided with a laser output port perpendicular to the axis of the light guide main shaft, anda laser strengthening density controller used for achieving the interrupted strengthening on the surface of the inner hole of the oil cylinder is arranged at the laser output port. According to the manufacturing process of the oil cylinder, the surface quality of the inner hole of the oil cylinder is improved, the abrasion between the oil cylinder and a piston is reduced, and then the stability ofequipment application is improved.

Owner:JIANGSU CHANGLING HYDRAULIC CO LTD

A preparation method of wc-co cemented carbide oil field nozzle

InactiveCN106623912BImprove organizationImprove toughnessTransportation and packagingMetal-working apparatusCompression moldingOil field

Owner:HUNAN CENTURY SPECIAL ALLOY

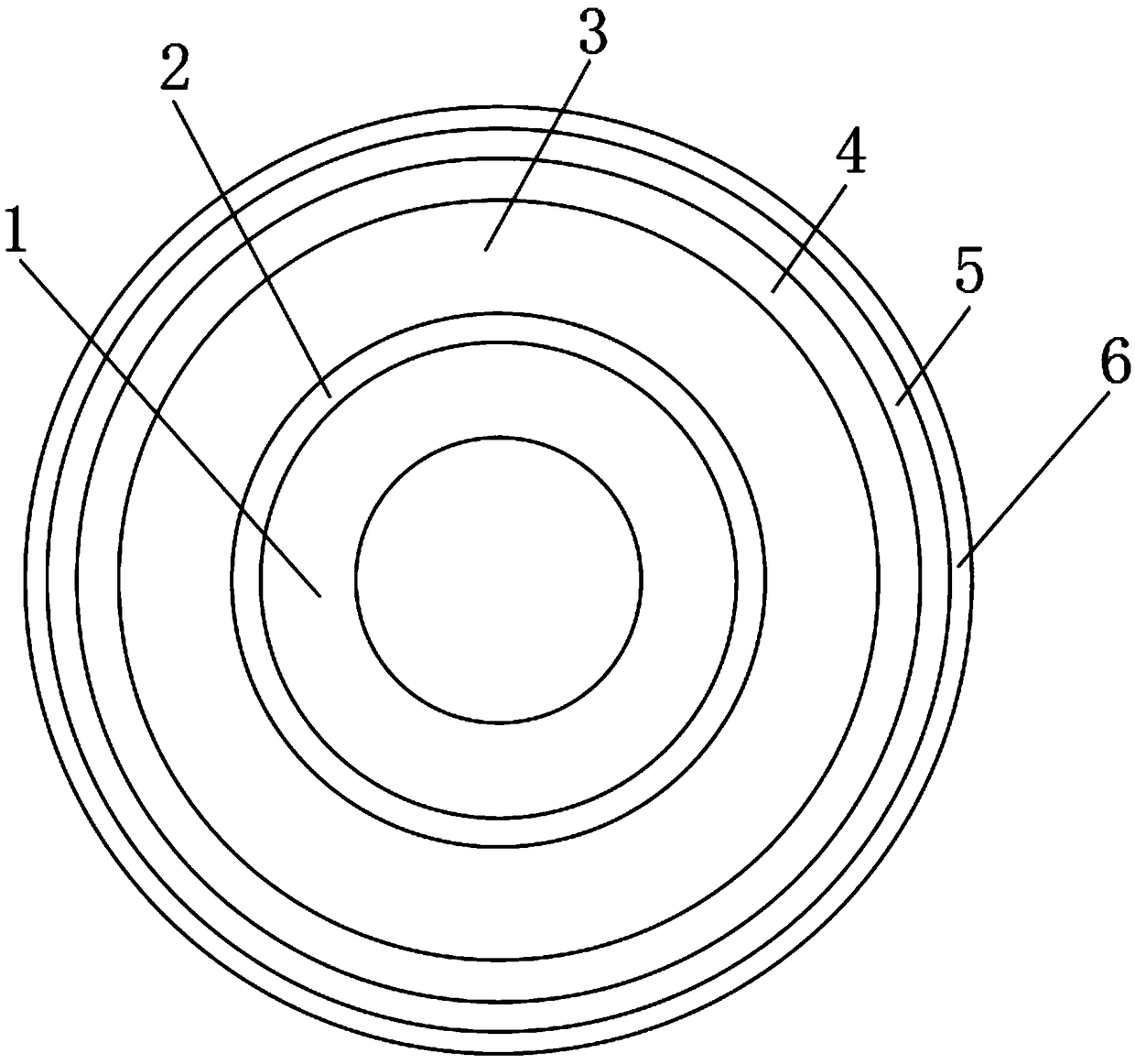

Online hollow cable and diameter expansion mechanism for processing same

ActiveCN109326378ALow chemical stabilityImprove conductivityPower cables with screens/conductive layersCable/conductor manufactureEngineeringElectrical performance

The invention discloses an online hollow cable and a diameter expansion mechanism for processing the same. The online hollow cable comprises an aluminum tube, a copper tube and an insulating jacket layer, the aluminum tube is mounted inside the copper tube in a sleeved manner, a main insulating layer is connected outside the copper tube in a sleeved manner, a semiconductive layer is connected outside the main insulating layer in a sleeved manner, a shielding protection layer is connected outside of the semiconductive layer in a sleeved manner, and the insulating jacket layer is connected outside the shielding protection layer. Structural features of conventional buses are changed according to characteristics of current; by adopting a tubular structure and shielding insulation technology, dead weight is reduced, and the online hollow cable is safe, reliable, energy-saving and material-saving. Aluminum is used to save copper, so that cost is lowered substantially, and the nation and thepeople can be benefitted; an insulation shielding material can be used in various severe natural conditions, has excellent electrical performance and chemical stability and is little in medium loss, flame-resistant and aging-resistant, and service life is longer than 40 years. The shielding material is a copper film or an aluminum film. A shielding magnetic field is uniform in distribution, localdischarging potential is improved, and electric energy loss is lowered.

Owner:朱光明

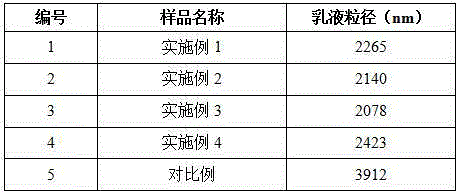

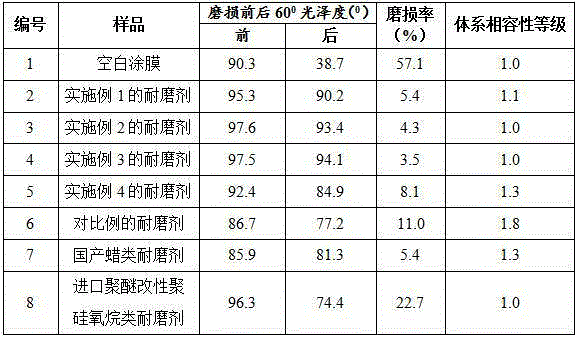

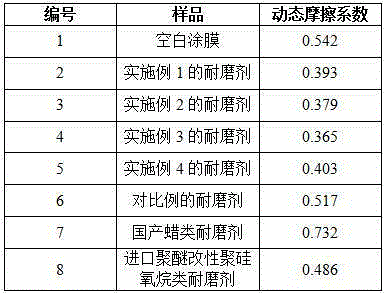

Coating wear-resistant agent and preparation method and application thereof

The invention discloses a coating wear-resistant agent and a preparation method and application thereof. The wear-resistant agent is prepared from ultra-high molecular weight polysiloxane, ternary-block polysiloxane, reinforce filler, organic solvent, compound emulsifier and water. The method includes the following steps of firstly, dissolving reinforce fibber in organic solvent to obtain a reinforce filler solution; secondly, adding ultra-high molecular weight polysiloxane, compound emulsifier and the reinforce filler solution into a dispersing kettle to be dispersed for 1-3 hours at a temperature of 80-120 DEG C, and decreasing the temperature to 20-40 DEG C after materials are evenly stirred; thirdly, dropwise adding water while dispersing, and continuing to conduct dispersion for 2-6 hours at a temperature of 20-40 DEG C after dropwise adding is completed; fourthly, transferring materials from the dispersing kettle into a homogenizer to be fully homogenized, and obtaining the coating wear-resistant agent. The coating wear-resistant agent is stable in performance, uniform in granularity, capable of being used for preparing coating, paint, ink, gloss oil, plastic and the like, high in system compatibility, and capable of providing excellent wear-resistant and scratch-resistant capacity and a smooth hand feeling.

Owner:INST OF CHEM ENG GUANGDONG ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com