Impregnated tooth applicable to high-abrasiveness hard formation and preparation method thereof

A hard formation and impregnated technology, which is applied in the direction of earthwork drilling, drilling equipment, drill bits, etc., can solve the problem that the formula design of impregnated teeth is not strong enough, the impregnated matrix does not match the drilled rock formation, and the impregnated matrix Low hardness and wear resistance, etc., to achieve good self-sharpening, not easy to fall off prematurely, and strong bezel setting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

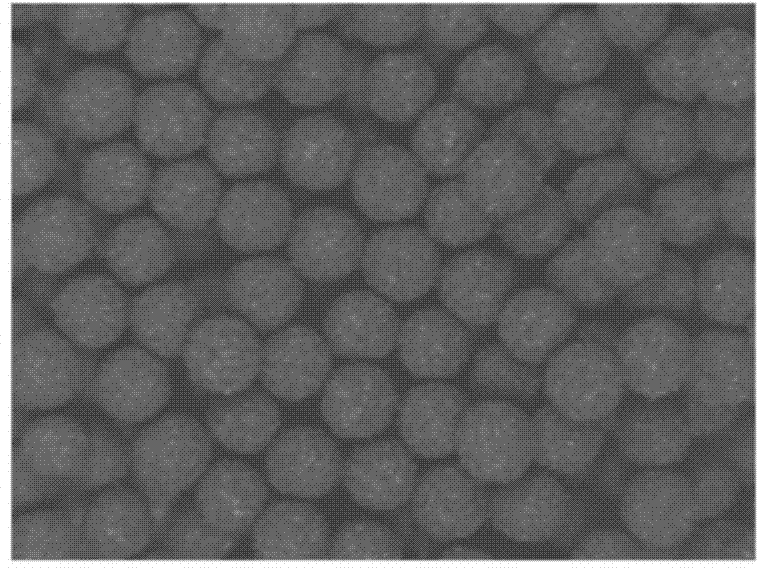

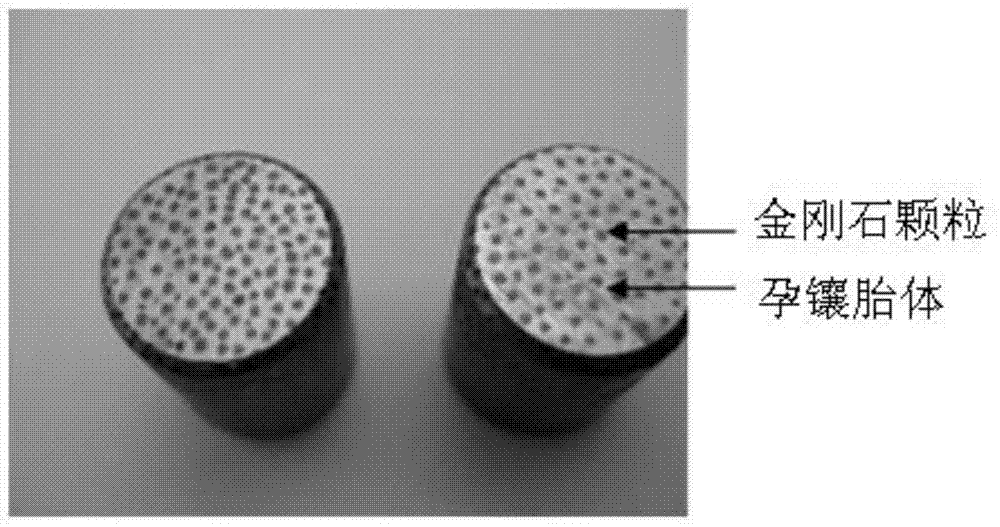

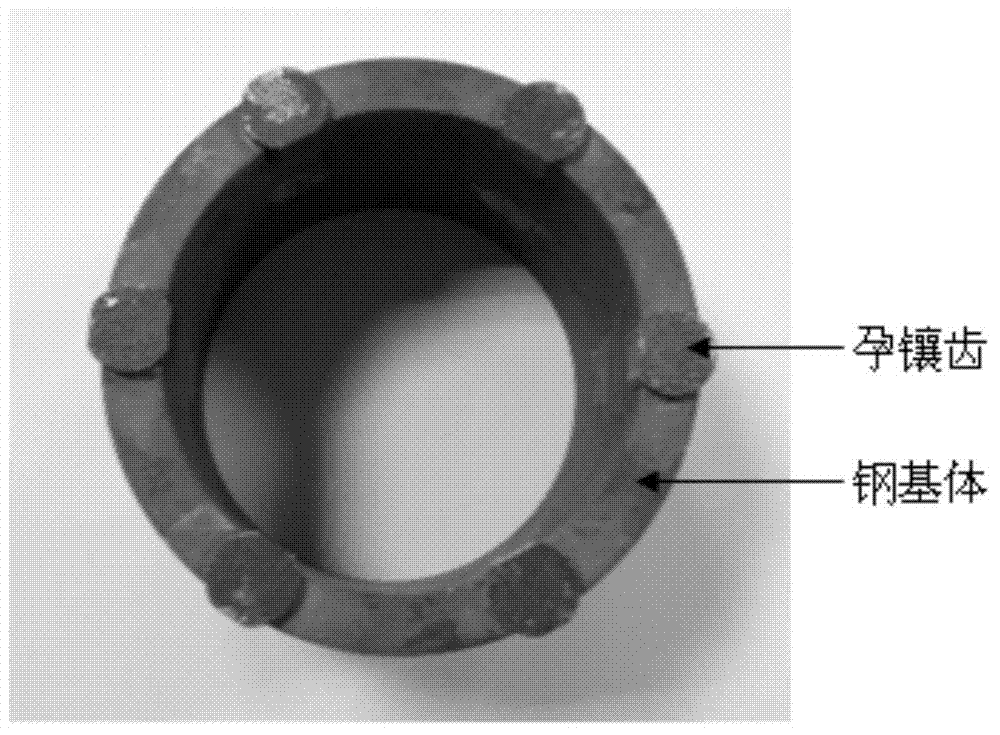

[0027] Take by weighing 11.82 grams of tungsten carbide, 2.73 grams of cobalt powder, 1.82 grams of copper powder, 0.91 grams of nickel powder, and 0.91 grams of manganese powder, mix well and add alcohol solution made of glycerol (the volume ratio of glycerol and alcohol is 3:1 , the same below) Wet particle size 30-35 mesh, 2.24 grams of diamond (diamond concentration 120%), mix well and then granulate, the diameter of the pellet is about 1.2mm, the photo of the prepared pellet is as follows figure 1 As shown, the prepared spheres were put into the mold, and pressed into Φ13 / 16mm (diameter 13mm, length 16mm, cylindrical) impregnated teeth under the process of sintering temperature 1080°C, sintering pressure 50MPa, and holding time 6min. Photos of pregnant inlays such as figure 2 It can be seen from the figure that the diamond particles on the cross-section of the impregnated tooth are relatively large and distributed evenly in the impregnated matrix.

[0028] The compactio...

Embodiment 2

[0031] Weigh 13.11 grams of tungsten carbide, 1.87 grams of cobalt powder, 1.87 grams of copper powder, 0.94 grams of nickel powder, and 0.94 grams of manganese powder. The diamond concentration is 120%), mix well and then granulate, the pellet diameter is about 1.2mm, then put the prepared pellets into the mold, press into Φ13 / 16mm pregnant teeth.

[0032] The compaction degree of the impregnated tooth prepared in this example was 97.1%, the bending strength of the impregnated tooth was 580 MPa, and the compressive strength was 1610 MPa.

[0033] The above impregnated teeth were brazed to prepare a Φ100 / 75mm coring test drill bit, and the micro-drill bench was used to simulate the working conditions in the laboratory to conduct a drilling test on granite. 2 , rotation speed 1000rpm, cooling water flow rate 3.12L / min drilling process conditions, measured average ROP is 2.10m / h, wear amount is 0.085mm / h, service life is 188h.

Embodiment 3

[0035] Weigh 11.82 grams of tungsten carbide, 2.73 grams of cobalt powder, 1.82 grams of copper powder, 0.91 grams of nickel powder, and 0.91 grams of manganese powder. Diamond concentration 120%), mix well and then granulate, the pellet diameter is about 1.0mm, then put the prepared pellets into the mold, press into Φ13 under the process of sintering temperature 1080℃, sintering pressure 40MPa, holding time 6min / 16mm impregnated teeth.

[0036] The compaction degree of the impregnated tooth prepared in this example is 98.1%; the bending strength of the impregnated tooth is 730 MPa, and the compressive strength is 1665 MPa.

[0037] The above impregnated teeth were brazed to prepare a Φ100 / 75mm coring test drill bit, and the micro-drill bench was used to simulate the working conditions in the laboratory to conduct a drilling test on granite. 2, rotation speed 1000rpm, cooling water flow 3.12L / min drilling process conditions, the measured average ROP is 1.96m / h, wear amount i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com