Preparation of carbonaceous composite pellet containing manganese

A technology of compound pelletizing and briquetting, which is applied in the field of raw materials for manganese-based ferroalloy smelting, can solve the problems of high dosage of binders and additives, unfavorable industrial application, complex pellet composition, etc., so as to reduce production costs and improve resource utilization. Efficiency, the effect of simplifying the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

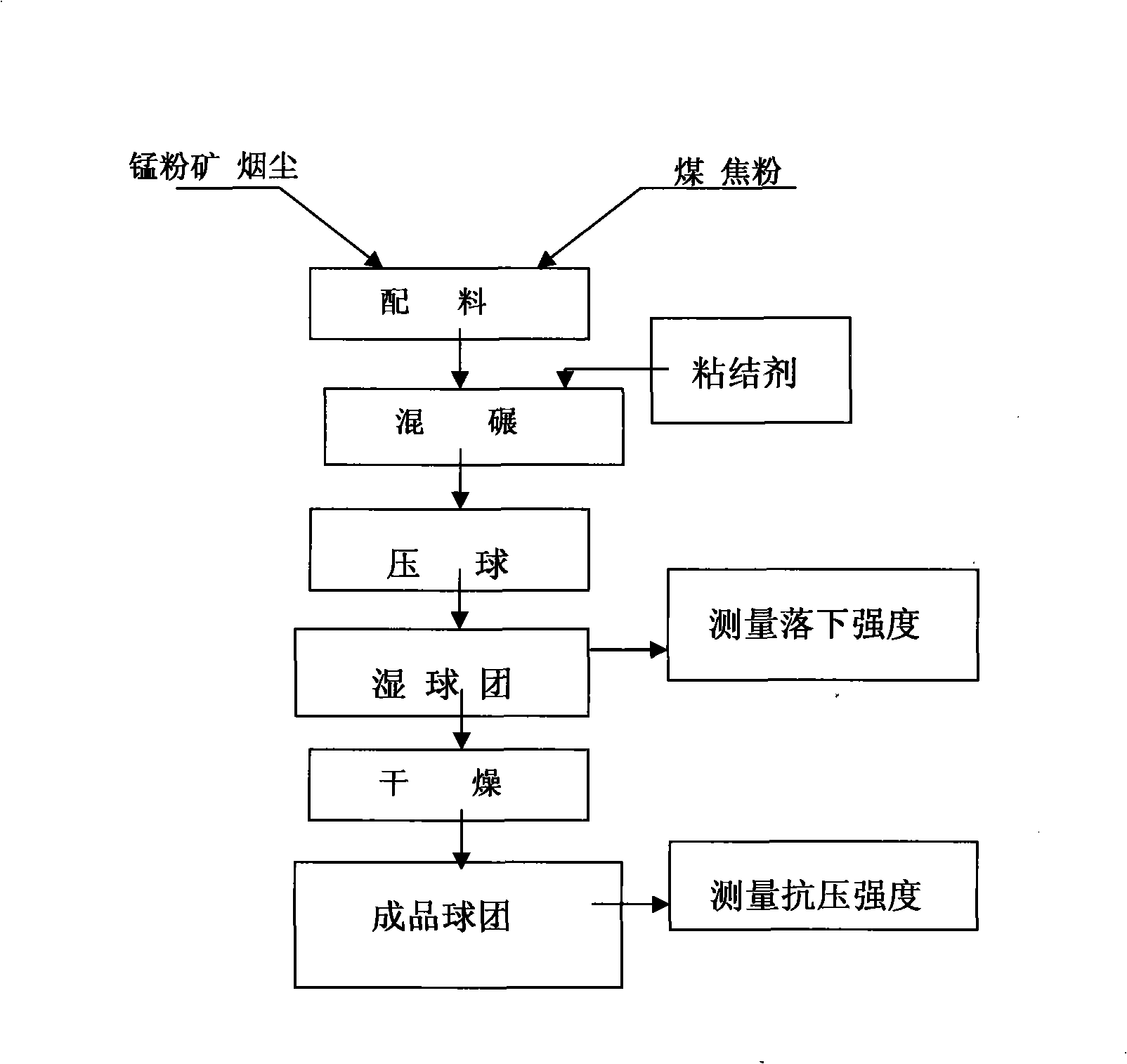

Method used

Image

Examples

Embodiment 1

[0040] (1) Material preparation and measurement

[0041] Table 4 Ingredients

[0042] name

Fine ore concentrate 1(%)

Sinter(%)

Smoke (%)

Coal 2(%)

Average moisture (%)

quantity

27.50

24.57

31.43

14.50

4.3

[0043] The amount of each batch is 800Kg.

[0044] (2) mixed grinding

[0045] Dry powder binder: 1.5% Supplementary water: 5% Mixing time: 5min

[0046] (3) Pressure ball

[0047] The speed of the pressure ball roller is 10n / min, and the pressure between the rollers is 6.5 MPa. The wet bulb was dropped three times without failure.

[0048] (4) dry

[0049] Drying temperature: 150°C, time: 2h, dry bulb moisture: 1.01%;

[0050] Table 5 Dry bulb strength values

[0051] name

Embodiment 2

[0053] (1) Material preparation and measurement

[0054] Table 6 Ingredients

[0055] name

Fine ore concentrate 3(%)

Imported ore (%)

Smoke (%)

Coal 2(%)

Average moisture (%)

quantity

19.78

34.07

29.63

14.52

3.85

[0056] The amount of each batch is 800Kg.

[0057] (2) mixed grinding

[0058] Dry powder binder: 2% Supplementary water: 6.15% Mixing time: 10min

[0059] (3) Pressure ball

[0060] The speed of the pressure ball roller is 5n / min, and the pressure between the rollers is 10MPa. The wet bulb was dropped three times without failure.

[0061] (4) dry

[0062] Drying temperature: 175°C, time: 2h, dry bulb moisture: 0.83%;

[0063] Table 7 Dry bulb strength values

[0064] name

Embodiment 3

[0066] (1) Material preparation and measurement

[0067] Table 8 Ingredients

[0068] name

Fine ore concentrate 2(%)

Imported ore (%)

Smoke (%)

Coal 1(%)

Average moisture (%)

quantity

27.40

29.30

24.60

16.70

5.2

[0069] The amount of each batch is 800Kg.

[0070] (2) mixed grinding

[0071] Dry powder binder: 2% Supplementary water: 3.8% Mixing time: 7.5min

[0072] (3) Pressure ball

[0073] The speed of the pressure ball roller is 7.5n / min, and the pressure between the rollers is 8.5MPa. The wet bulb was dropped three times without failure.

[0074] (4) dry

[0075] Drying temperature: 183°C, time: 2h, dry bulb moisture: 0.92%;

[0076] Table 9 Dry bulb strength values

[0077] name

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com