Production formula and construction technology of ultra-wear-resistant ground

A technology of construction technology and production formula, which is applied in the field of production formula and construction technology of super wear-resistant ground, can solve problems such as poor strength, polluted environment, and dust, and achieve the effect of improving wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

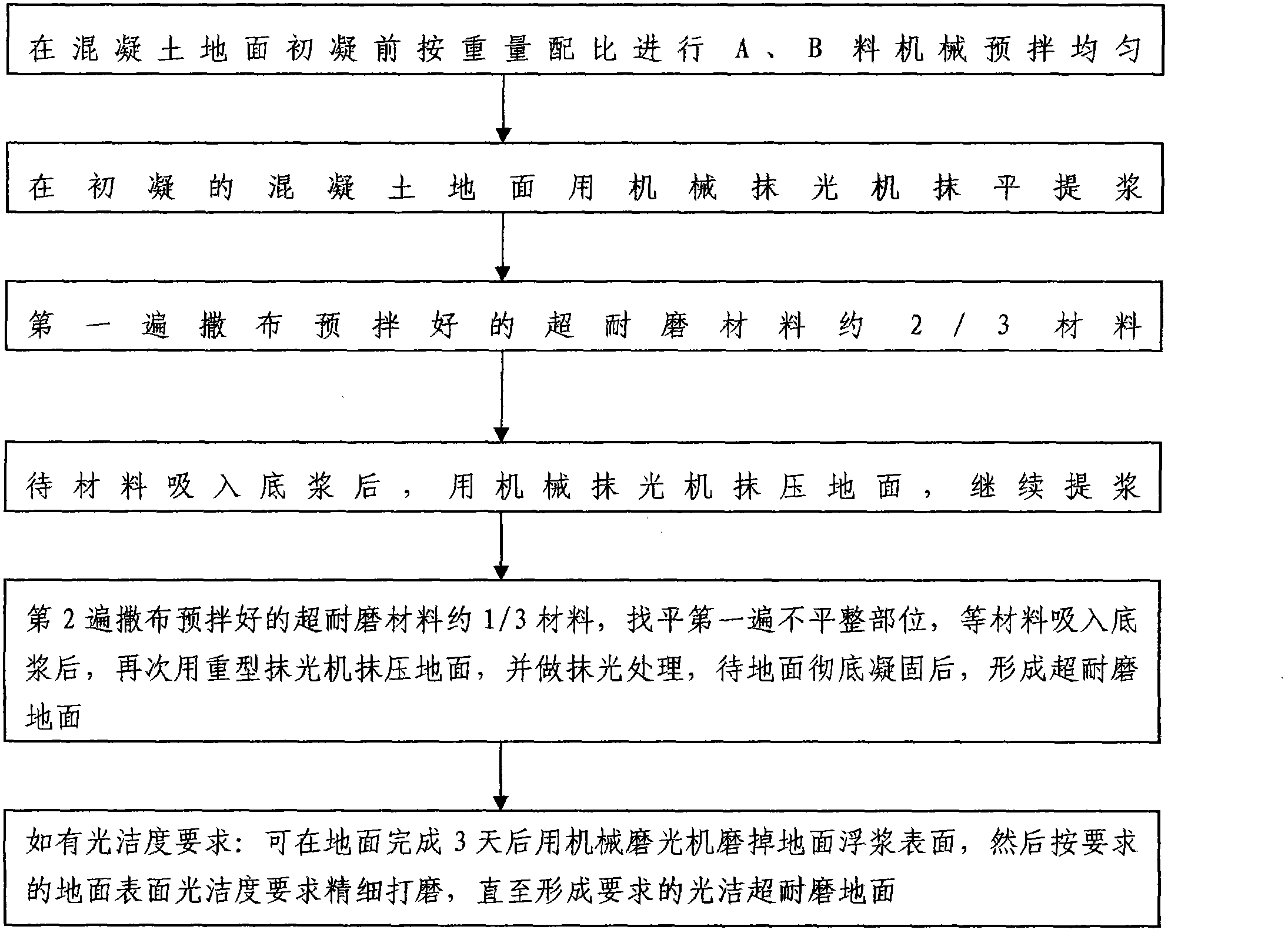

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0024] The invention provides a super wear-resistant ground formula and construction technology that are premixed and mixed with group A dry powder materials and group B liquid materials.

[0025] The production formula of the super wear-resistant floor of the present invention comprises A group of dry powder materials and B group of liquid materials.

[0026] Among them, the dry powder materials of Group A include: 40% Portland cement, 6 mesh to 120 mesh wear-resistant aggregate (that is: 50% quartz sand, or corundum, or bottom slag, or tin-titanium alloy, or ferrosilicon alloy, etc. ), 2-10% silicon powder, 0.1% to 0.5% water reducer, titanium dioxide within 2%, some anti-crack fibers, some pigments (namely iron oxide green, chromium oxide green, iron oxide red, iron oxide yellow , iron oxide blue, or iron oxide black, etc.), 2% to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com