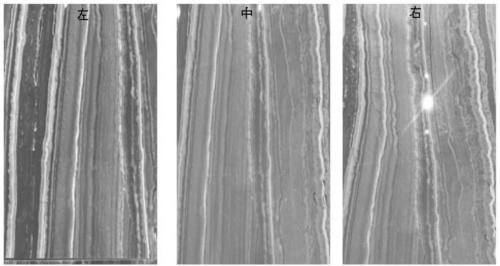

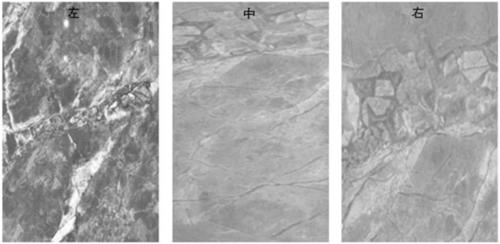

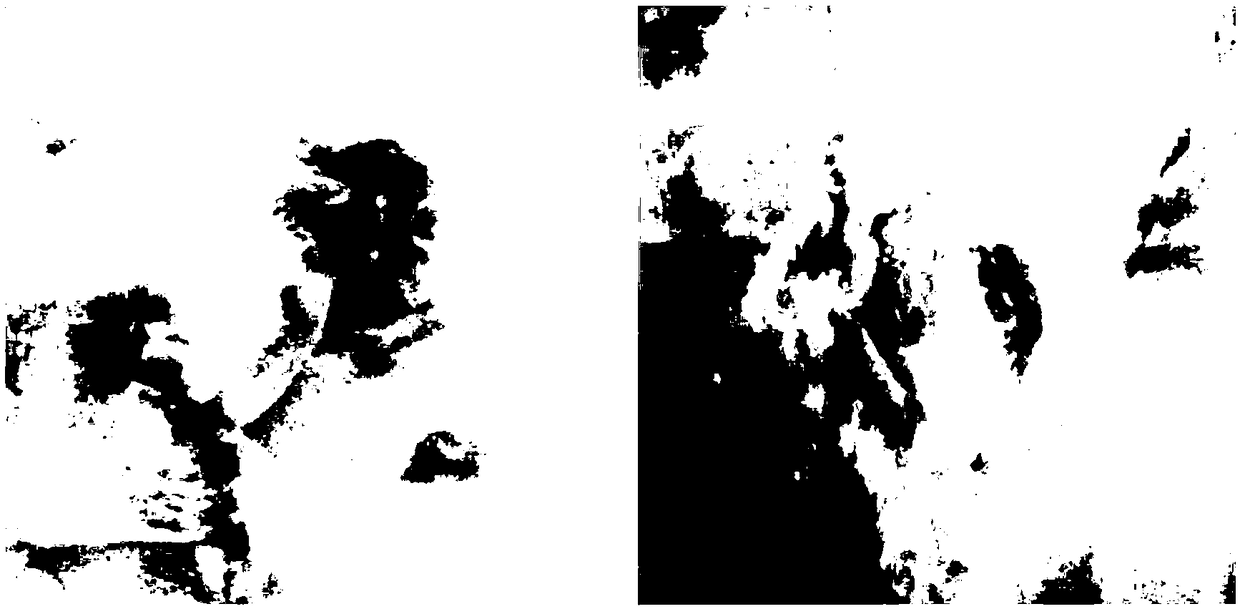

3D infiltrated crystallization glaze and application thereof

A technology of infiltration and crystallization, applied in the field of ceramics, can solve the problems of poor three-dimensional sense and permeability, unclear texture lines, insufficient hardness of the surface glaze, etc., to improve competitiveness, facilitate market promotion, and brighten hair color. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039]

[0040] A preparation method for permeable tiles, comprising the steps of:

[0041] 1) Spread the bottom glaze evenly on the green body through the bell jar, and the specific gravity of the bottom glaze is 1.78g / cm 3 , the glaze amount is: 93g / 300*600mm;

[0042] 2) Further apply the surface glaze on the bottom glaze through the bell jar glaze cloth, and the specific gravity of the applied surface glaze is 1.83g / cm 3 , the amount of glazing: 135g / 300*600mm, to get bricks;

[0043] 3) After the bricks are dried in the glaze line drying kiln, the glaze line inkjet plus penetration enhancer is printed, and the 13g / m 2 The bleed ink is spray-printed on the adobe in step 2), then put into the roller kiln for firing, and then polished to obtain the bleed brick.

Embodiment 2

[0045]

[0046] A preparation method for permeable tiles, comprising the steps of:

[0047] 1) Spread the bottom glaze evenly on the green body through the bell jar, and the specific gravity of the bottom glaze is 1.83g / cm 3 , the glaze amount is: 87g / 300*600mm;

[0048] 2) Further apply the surface glaze on the bottom glaze through the bell jar glaze cloth, and the specific gravity of the applied surface glaze is 1.78g / cm 3 , the amount of glazing: 143g / 300*600mm, to get bricks;

[0049] 3) After the brick is dried in the glaze line drying kiln, the inkjet inkjet plus penetration enhancer is used to print the glaze line, and the 19g / m 2 The bleed ink is spray-printed on the adobe in step 2), then put into the roller kiln for firing, and then polished to obtain the bleed brick.

Embodiment 3

[0051]

[0052] A preparation method for permeable tiles, comprising the steps of:

[0053] 1) Spread the bottom glaze evenly on the green body through the bell jar, and the specific gravity of the bottom glaze is 1.80g / cm 3 , the glaze amount is: 90g / 300*600mm;

[0054] 2) Further apply the top glaze on the bottom glaze through the bell jar glaze cloth, and the specific gravity of the applied top glaze is 1.78~1.83g / cm 3 , the amount of glazing: 140g / 300*600mm, to get bricks;

[0055] 3) After the brick is dried in the glaze line drying kiln, it is printed by inkjet and penetration enhancer on the glaze line, and the 10g / m 2 The bleed ink is spray-printed on the adobe in step 2), then put into the roller kiln for firing, and then polished to obtain the bleed brick.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com