Patents

Literature

57results about How to "Bright hair color" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

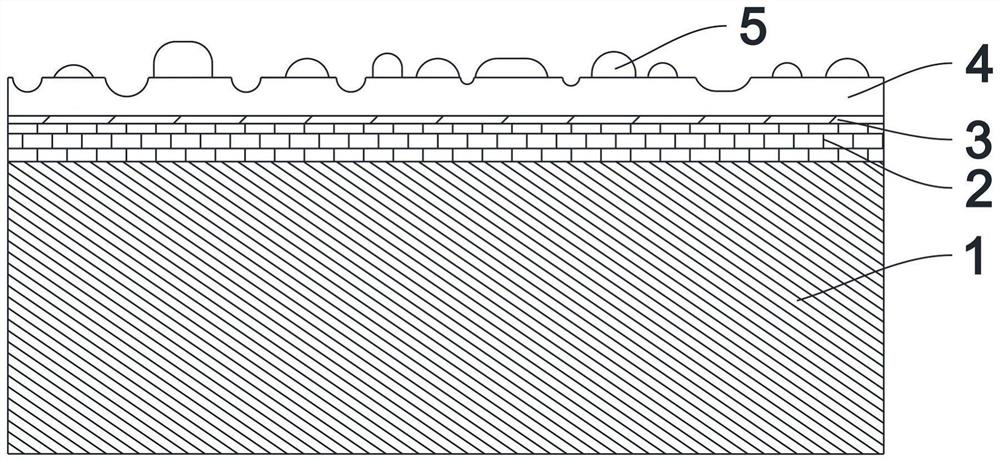

Ink-jet penetrated polished semitransparent ceramic sheet, and preparation method thereof

The invention relates to an ink-jet penetrated polished semitransparent ceramic sheet. The ink-jet penetrated polished semitransparent ceramic sheet comprises a semitransparent green body containing an ink dyeing assistant agent, and an ink jet penetrating layer penetrating into the semitransparent green body. According to a preparation method, the ink dyeing assistant agent is added into the semitransparent green body, and ink jet penetrating technology is adopted, so that penetration of patterns into the semitransparent green body is realized, polishing is carried out directly after sintering, green body surface particle flatness is excellent, stain resistance is excellent, pattern wear resistance is excellent, and requirements on highlight products are satisfied, adding of a transparent glaze layer onto the surface of the green body is not necessary, cost is reduced, a problem that bonding of the glaze layer with the green body is poor is solved, production deformation cracking is avoided, the preparation method of the green body is simple, adding of non-transparent preform body is unnecessary, and in addition, the semitransparent green body contains the ink dyeing assistant agent, so that the color of the patterns used for decoration is bright, sharpness is high, and decoration requirements can be satisfied preferably.

Owner:MONALISA GRP CO LTD

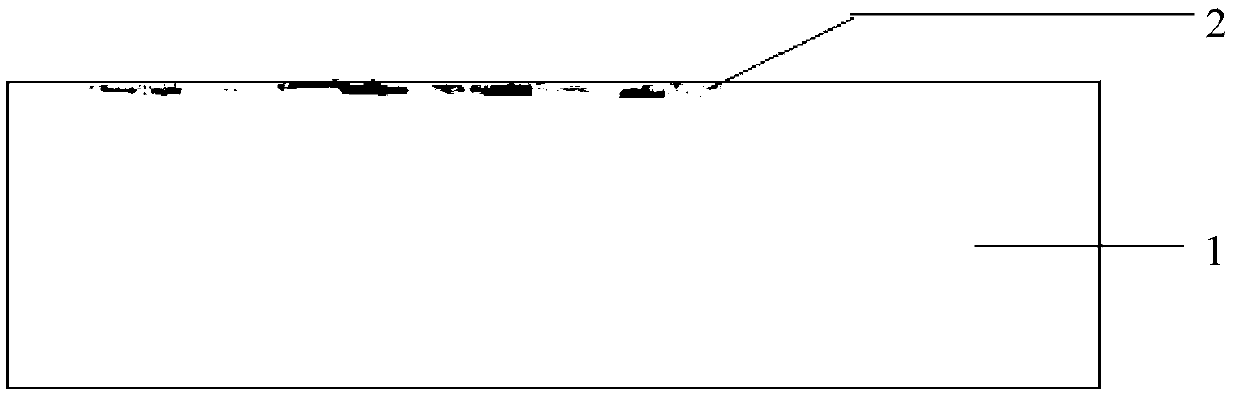

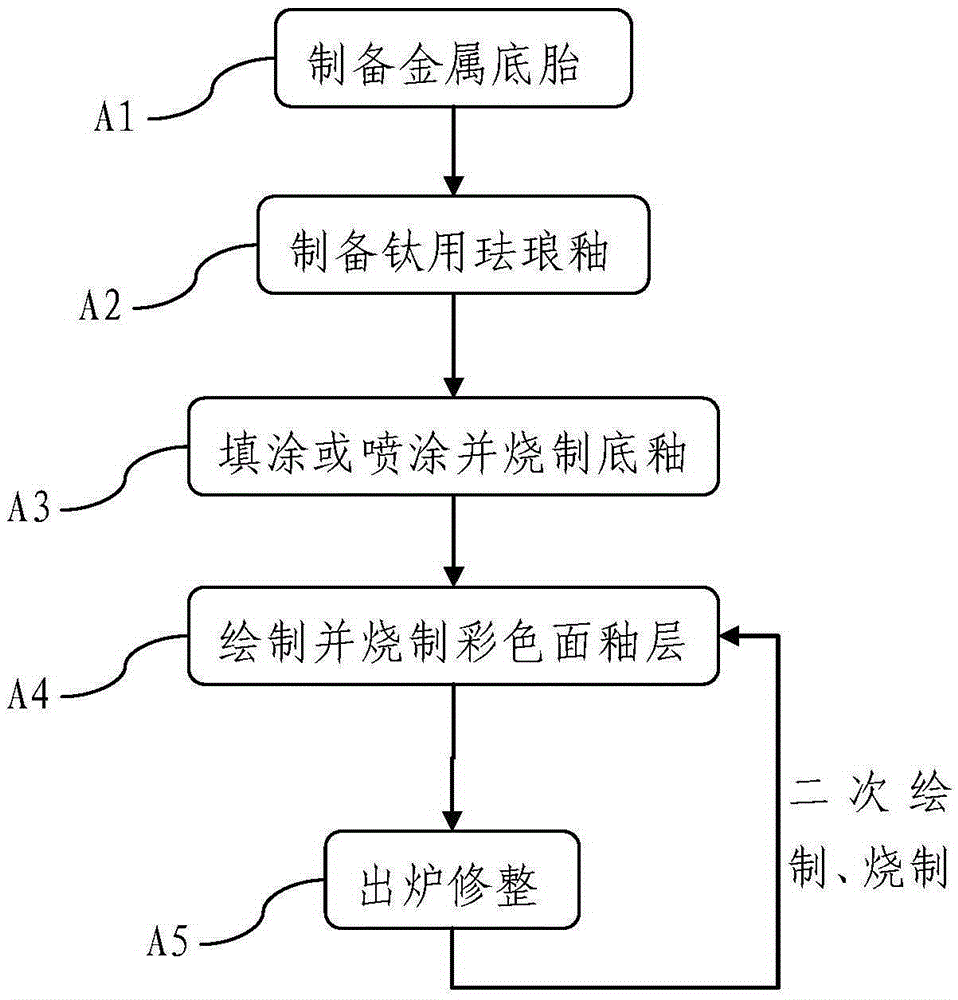

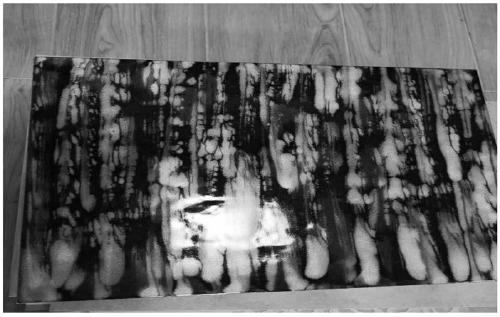

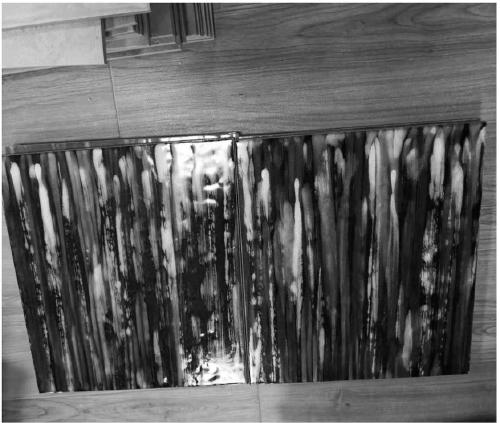

Titanium blank colored enamel product and manufacturing method

InactiveCN105313572ANot easy to crack and fall offNot easy to oxidize and rustDecorative surface effectsSpecial ornamental structuresTitanium oxideBorax

The invention relates to a titanium blank colored enamel product and a manufacturing method. The titanium blank colored enamel product comprises a metal bottom blank and a titanium enamel glaze layer, wherein the metal bottom blank is manufactured by using industrial pure titanium with the purity of more than 99%; a ground glaze layer of the titanium enamel glaze layer is prepared from 10% of titanium oxide, 35% of high-purity quartz, 32% of borax, 3.5% of barium oxide, 4% of zinc oxide, 3.2% of calcium oxide, 3% of magnesium oxide, 4.3% of aluminum oxide and 5% of lead oxide; a colored cover glaze layer is prepared from the mixture of 5% of the titanium oxide, 38% of the high-purity quartz, 34% of the borax, 2.5% of the zinc oxide, 3.2% of the calcium oxide, 6.5% of potassium oxide, 3.8% of the aluminum oxide and 7% of the lead oxide, and a coloring agent type metal oxide at the weight ratio of 100 to (0.5-12); and the titanium blank colored enamel product prepared by the steps of preparing the metal bottom blank and titanium enamel glaze, firing the ground glaze layer and the colored cover glaze layer, discharging from a furnace and trimming can be firmly glazed, has the bright and flat glaze and high rigidity and intensity, and is not easy to oxidize and get rusty.

Owner:杨仲华

Method for producing electric-melting zirconia used for turquoise pigment and glaze

ActiveCN101703958ANarrow particle size distributionThe particle size distribution range is reasonableGrain treatmentsZirconium oxidesCalorescenceAtmospheric pressure

The invention relates to a method for producing electric-melting zirconia used for turquoise pigment and glaze, which is characterized in that: in a process of fine crushing, a feed particle size D50 is controlled between 20 and 25mu m, the working air pressure of a nozzle of a jet mill is 0.8MPa, a cyclonecluster is adjusted to 45Hz, a grader is adjusted to 18Hz, and the size distribution after the crushing meets the conditions that: D10 is not less than 3mu m, D50 is kept between 14 and 15mu m, and the difference between D90 and D10 is not more than 30mu m. The method has the advantages that: the narrow size distribution range of zirconia powder is realized, and reasonable grain size distribution is realized; and the electric-melting zirconia is favorable for color development of the turquoise pigment and glaze compared with the traditional electric-melting zirconia, comprehensively improves the blue degree of corresponding pigment and glaze, reduces a brightness value, makes the pigment develop more bright and vivid color in the glaze, and improves the beautifulness of corresponding ceramic products. The electric-melting zirconia after reasonable particle size control and adjustment can improve the high temperature resistance of the turquoise pigment and glaze more obviously than the electric-melting zirconia which is not controlled, and still can keep bright tone at the temperature higher than 1,200DEG C so as to promote the application to high temperature pigments.

Owner:BENGBU ZHONGHENG NEW MATERIALS SCI & TECH CO LTD

4-8 degree soft surface wearing-resistant easily cleaned rustic tile

The invention relates to a 4-8 degree soft surface wearing-resistant easily cleaned rustic tile which comprises a blank, a ground coat layer with glossiness of 2-3 degrees, a printing layer and a surface glaze layer, wherein the surface glaze layer comprises a clinker I, a matte clear glaze and wearing resistant granules; the surface glaze layer is treated by using multiple polishing processes which specifically comprise three steps: 1, polishing by using a polishing tool with elastic characteristics, wherein the polishing tool has a polishing medium of a grinding material combined through anelastic resin, and the grinding material has fineness of 128 meshes; 2, polishing by using a polishing tool with a grinding rub, wherein the grinding rub has grinding material fineness of 320 meshes;3, polishing by using a grinding piece as a polishing tool, wherein t he grinding piece has grinding material fineness of 500 meshes. By optimizing a formula and improving polishing methods, the wearing resistance, the sliding resistance, the dirt absorption prevention capability and the glossiness of a glaze surface can be greatly improved.

Owner:FOSHAN SHI WAN YING BRAND CERAMICS CO LTD

Flowing color decorative effect ceramic tile and preparation method thereof

The invention relates to a flowing color decorative effect ceramic tile and a preparation method thereof. The preparation method comprises the steps of sequentially applying a ground coat, applying acrystallization cover glaze, applying a crystallization effect glaze on a tile blank, and then firing.

Owner:MONALISA GRP CO LTD

Transparent glaze and manufacturing method thereof

The invention provides transparent glaze and a manufacturing method thereof, and relates to glaze for ceramic. The transparent glaze compries the following components in percntage by mass: 0.2 to 2 percent of Na2O, 0.5 to 5 percent of K2O, 9 to 12 percent of Al2O3, 4 to 8 percent of CaO, 1 to 5 percent of MgO, 0 to 10 percent of ZnO, 2.0 to 4 percent of ZrO, 10 to 30 percent of high-temperautre frit with the loss on iginition of 1 to 6 percent, and the balance of SiO2. The transparent glaze is prepared by th steps of throwing materials according to the ratio, performing ball milling, measuring the residue rate, grinding, adjusting the proportion to be 1.35 to 1.4, glazing, firing and obtaining the finished product. Sodium potassium feldspar is replaced by potassium feldspar and the high-temperature frit is added, so that the firing range of the transparent glaze is increased, the starting melting point of glaze water is reduced, the glaze firing temperature is prevented from lowering, the glaze can be burned at the temperature of 1,260 DEG C while the glaze surface is not overburned, zinc oxide is reduced from 8 to 2.5, and stained paper in the glaze burned at the temperature of 1,060 DEG C can be precipitated into the glaze.

Owner:福建省佳圣轩工艺品有限公司

Background wall brick preparing method and background wall preparing method

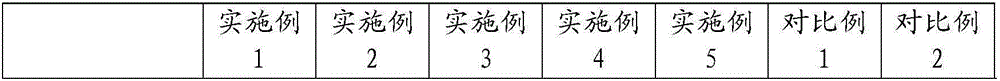

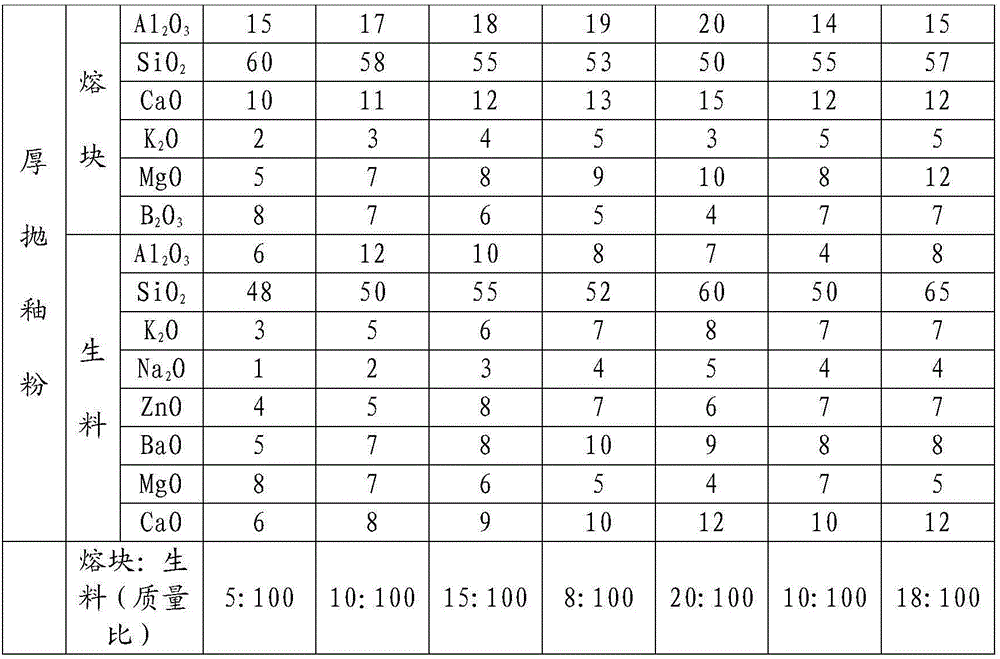

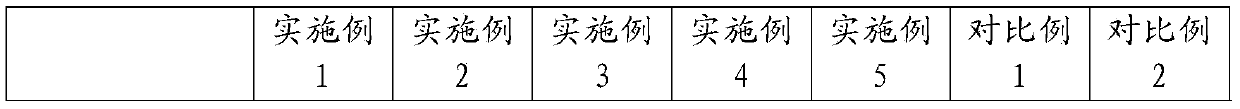

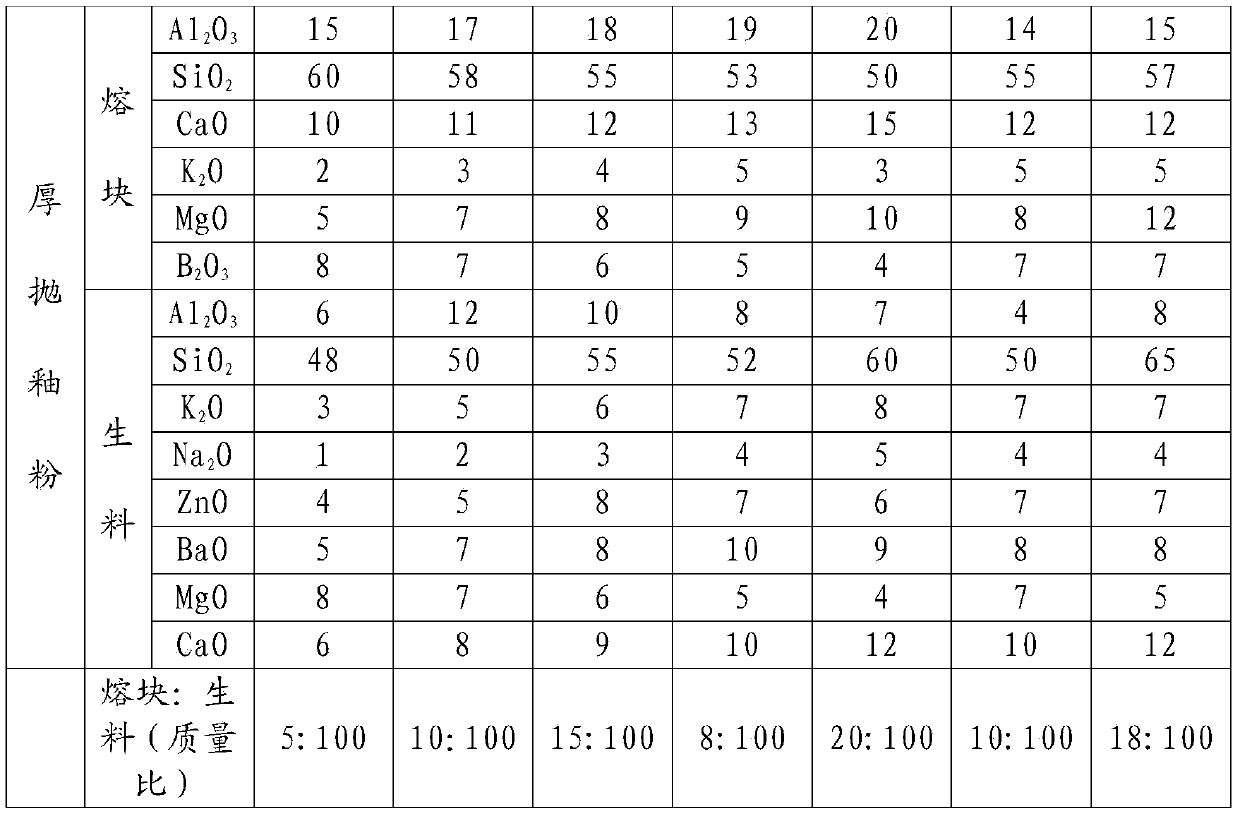

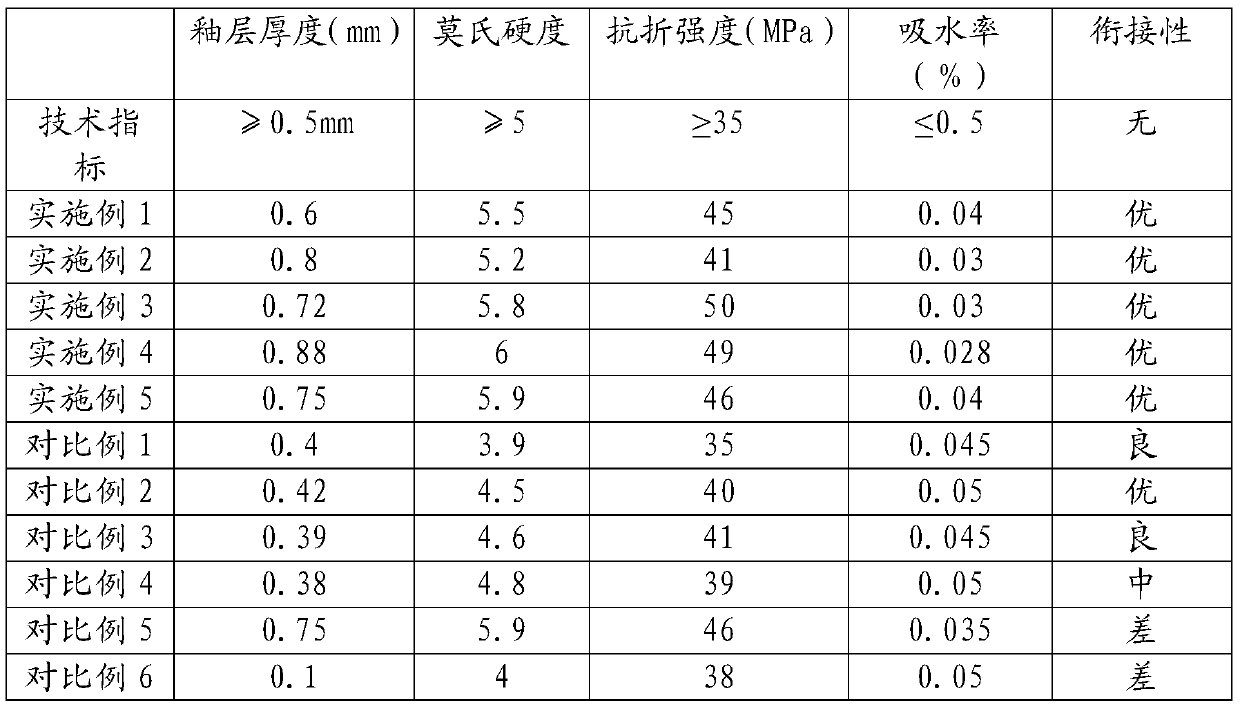

ActiveCN106007800AGood melting performanceReduce high temperature viscosityCovering/liningsInkjet printingHardness

The invention provides a background wall brick preparing method. The background wall brick preparing method comprises the following steps: 1, forming a green body and drying the green body to obtain the dry green body; 2, applying ground coat enamel on the surface of the dry green body to obtain a first green brick; 3, inkjet printing the ground coat enamel of the first green brick to obtain a second green brick; 4, drying the second green brick to obtain a third green brick; 5, applying cover glaze on the inkjet-printed side of the third green brick to obtain a fourth green brick; 6, drying the fourth green brick to obtain a fifth green brick; 7, roasting the fifth green brick at high temperature to obtain a sixth green brick; 8, polishing the sixth green brick to obtain the background wall brick. The background wall brick is large in moh hardness and breaking strength and low in water absorption. The invention further provides a background wall preparing method, and the background wall is good in link and attractive and elegant in appearance.

Owner:HEYUAN DONGYUAN EAGLE CERAMICS CO LTD +2

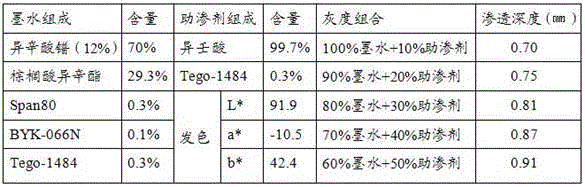

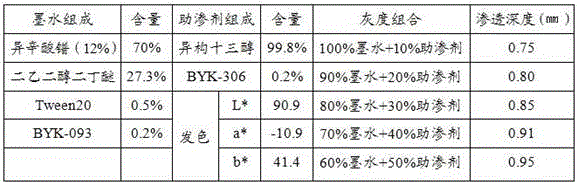

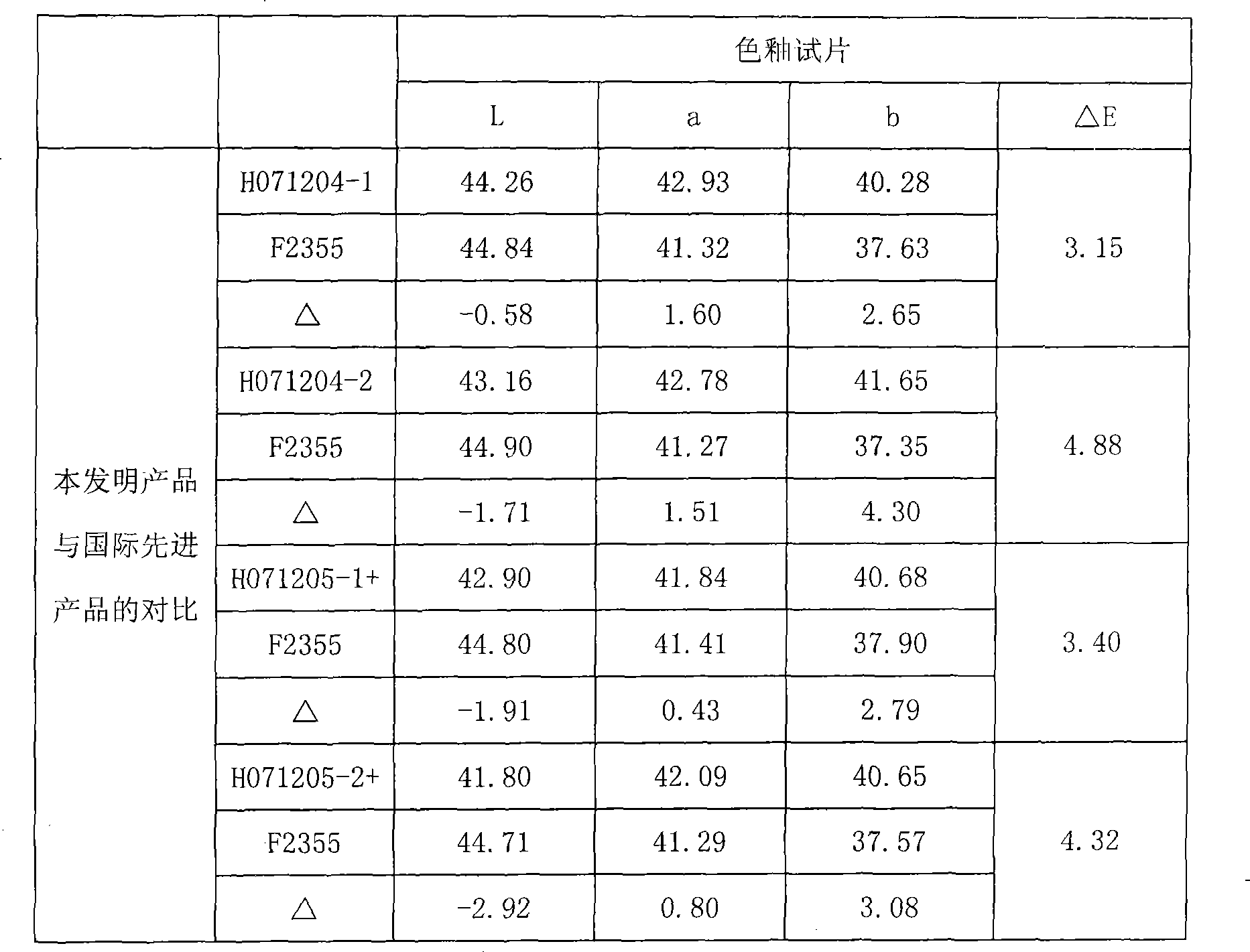

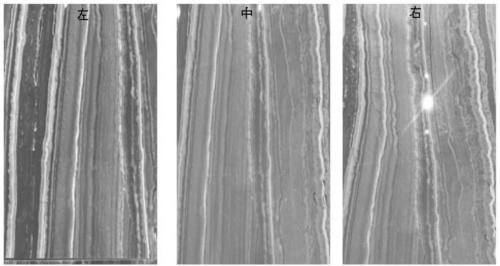

Praseodymium yellow ceramic jet-ink infiltrating ink and preparation method thereof

The invention discloses praseodymium yellow ceramic jet-ink infiltrating ink and a preparation method thereof. The praseodymium yellow ceramic jet-ink infiltrating ink comprises 65 to 75% of organic praseodymium salt, 25 to 35% of a solvent and 0.1 to 2% of an additive in percentage by mass; the organic praseodymium salt is carboxylic acid praseodymium. According to the invention, the organic praseodymium salt is used for preparing the praseodymium yellow ceramic infiltrating ink of which the penetration depth can be controlled within 0.1 to 1.5 millimeters, the infiltrating ink is bright-colored in chromogenic reaction and does not deteriorate within 8 months, the viscosity of the ink at the temperature of 40 DEG C is 20-25m Pa*s, the surface tension of the ink is 25-29mN / m, and the infiltrating ink has good ink-jet printing performance and can be used in a variety of mainstream nozzles.

Owner:山东国瓷康立泰新材料科技有限公司

Preparation method of penetrating tile

The invention relates to a preparation method of a penetrating tile. The method includes the steps of: A. pressing powder into a green body, and then performing drying; B. performing slurry sprinkling on the green body obtained in step A; C. performing secondary drying on the slurry sprinkled green body, and conducting drying; D. carrying out inkjet printing of oily penetrating ink on the green body obtained by step C; and E. performing firing in a kiln, and conducting calcinations, polishing and edging, thus obtaining the penetrating tile. The preparation method of the penetrating tile provided by the invention can make oily penetrating ink effectively penetrate the slurry layer.

Owner:FOSHAN DONGPENG CERAMIC +2

Scarlet glaze material for ceramics and preparation method thereof

The invention relates to a scarlet glaze material for ceramics, which is prepared from 30-50 parts of potash feldspar, 20-40 parts of quartz, 5-15 parts of marble, 8-15 parts of kaolin, 6-10 parts of clear frit, 0.1-0.5 part of cadmium carbonate, 4-12 parts of scarlet pigment and 50-70 parts of water. The preparation method comprises the following steps: evenly mixing the 30-50 parts of potash feldspar, 20-40 parts of quartz, 5-15 parts of marble, 8-15 parts of kaolin, 6-10 parts of clear frit and 50-70 parts of water, and carrying out ball milling for 15-20 hours until the fineness reaches 325 meshes; evenly mixing the 0.1-0.5 part of cadmium carbonate and 4-12 parts of scarlet pigment, and carrying out ball milling until the fineness reaches 325 meshes; and finally, evenly mixing the two mixtures to obtain the scarlet glaze material for ceramics. The glaze material has the advantages of favorable combination performance with the green body, pure and bright color, high stability and high gloss.

Owner:CHAOZHOU QINGFA CERAMICS

Process for producing ferrozirconium red material

InactiveCN101429053AImprove high temperature resistanceSmall particle sizePigmenting treatmentSodium metasilicateAcid washing

The invention discloses a method for preparing ferrozirconium red stain, which is characterized by comprising the following steps in turn: (1) liquid-phase reaction, which is to perform liquid-phase reaction on zirconium oxychloride, ferrous sulfate and sodium metasilicate pentahydrate in water; (2) separation and drying, which is to separate and dry solid-liquid suspended substances generated by liquid-phase reaction; (3) precalcination, which is to crush dried substances and calcine the crushed substance for 2 to 3 hours at a temperature of between 750 and 850 DEG C; (4) mixing, which is to mix products of precalcination uniformly with lithium fluoride, sodium fluorosilicate and sodium fluoride; (5) calcination, which is to calcine the mixture in the four step for 2 to 5 hours at a temperature of between 900 and 1,000 DEG C; and (6) post processing, which is to treat sintered solid substances by grinding, acid washing, water scrubbing, drying and sieving. The method for combination of liquid-phase reaction and solid-phase reaction improves the encapsulation rate of high-temperature solid-phase reaction, and synthesizes ferrozirconium red stain products which have beautiful chromogenic colors and strong chromogenic force and are stable at high temperature.

Owner:广东万兴无机颜料股份有限公司

Method for producing electric-melting zirconia used for yellow zirconium praseodymium glaze

ActiveCN101695679AImprove rednessImprove yellownessGrain treatmentsZirconium oxidesNarrow rangeChemical reaction

The invention relates to a method for producing electric-melting zirconia used for a yellow zirconium praseodymium glaze, which is characterized in that: in the fine crushing process, the feed particle size D50 is controlled in the range of 20 to 25 mu m, the working air pressure of a nozzle of an airflow mill is 0.7 Mpa, a cyclone cluster is regulated to 40 frequency, and a grader is regulated to 35 frequency; and after the crushing, the powder particle size distribution meets D10 which is not less than 1.5 mu m, D50 is maintained in the range of 6 to 6.5 mu m, and the difference between D90 and D10 is not more than 8 mu m. The method has the advantages of realizing narrow range of particle size distribution and reasonable grain size distribution of the zirconia powder, making the proportion of effective particles favorable for high-temperature chemical reaction in the zirconia powder increased, comprehensively improving the degree of red color and the degree of yellow color of corresponding coloring materials and reducing brightness value to make the coloring materials brighter and lively in the glaze, and improving the beauty degree of corresponding ceramic products.

Owner:BENGBU ZHONGHENG NEW MATERIALS SCI & TECH CO LTD

3D infiltrated crystallization glaze and application thereof

The invention discloses a 3D infiltrated crystallization glaze and application thereof. The glaze comprises a ground glaze and a cover glaze, wherein the cover glaze comprises the following raw materials: potassium feldspar, soda feldspar, quartz, kaolin, calained talc and a dyeing assistant agent. The glaze formula can really achieve a 3D in-glaze decoration effect and realize the unification ofthe surface decoration effect, the abrasive resistance and the hardness; in addition, the glaze is low in raw material cost, stable in performance, high in transparency, strong in transparent feeling,bright in color, and clear in pattern texture, is favorably compared with raw gemstone basically, and completely subverts the decoration effect of existing infiltrated glaze. By adopting the 3D infiltrated crystallization glaze provided by the invention, the consumption of infiltrated ink can be reduced by 35% relative to that of common infiltrated glaze, meanwhile, the consumption of the dyeingassistant agent can be reduced by 30% relative to that of the common infiltrated glaze, so that the production cost is reduced, the market popularization is benefited, the competitiveness is improved,and the reduction of the consumption of the dyeing assistant agent can reduce the tendency of crazing of ink jet infiltrated product glaze, so that the defects of finished products are reduced, and the rate of finished products is improved by 1%-3%.

Owner:广东道氏陶瓷材料有限公司

Firing technique of blue-and-white underglaze red

The invention discloses a firing technique of blue-and-white underglaze red, which comprises the following steps: 1) preparation of blank and glaze; 2) preparation of billet: making the blank into the billet, trimming, and airing for later use; 3) blue-and-white underglazing: drawing patterns or writing characters on the billet surface with a blue material and a copper red material, carrying out glaze application, and airing to obtain a blue-and-white billet; 4) firing: putting the blue-and-white billet into a kiln, controlling the kiln in an oxidizing atmosphere, heating to 300 DEG C at 100-120 DEG C / hour, and continuing heating to 950 DEG C at 150-200 DEG C / hour; and while controlling the kiln in a reducing atmosphere, heating to 1260-1360 DEG C at 40-60 DEG C / hour, keeping the temperature for 1-2 hours, stopping heating, cooling, and discharging out of the kiln to obtain the finished product. The blue material of the blue-and-white underglaze red porcelain has the advantages of bright color development and stable and uniform coloration, the red material has the advantages of bright coloration, no flying red and no blackening. The blue and red colors of the blue-and-white underglaze red porcelain contrast with each other and benefit each other.

Owner:马健

Blue zirconium silicate pigment for spray ink printing and preparation method of blue zirconium silicate pigment

The invention relates to a blue zirconium silicate pigment for spray ink printing and a preparation method of blue zirconium silicate pigment. The blue pigment with a particle size of less than 1 mu m and an operating temperature of above 1,300 DEG C is prepared by using gas-phase silicon dioxide (SiO2), zirconium oxychloride 8 hydrogen oxide (ZrOCl2.8H2O), polyethylene glycol (PEG) 1000, ammonia water, lithium fluoride (LiF) and ammonium metavanadate (NH4VO3) powder as raw materials. The molar percentage ratio of Si4 to Zr2 is 1.2 to 1; the molar percentage ratio of Li to Si4 is 0.3 to 1; the molar percentage ratio of V5 to Si4 is 0.0075 to 1; and the molar percentage ratio of PEG to SiO2 is (0.0015-0.0045) to 1. The blue zirconium silicate pigment has the characteristics of uniform chromaticity, high suspension property, high tinting strength, good high-temperature stability, bright colour, good decoration effect and the like, meets a requirement of ink for spray ink printing and has wide application prospects in production of architectural ceramics.

Owner:JINGDEZHEN CERAMIC INSTITUTE

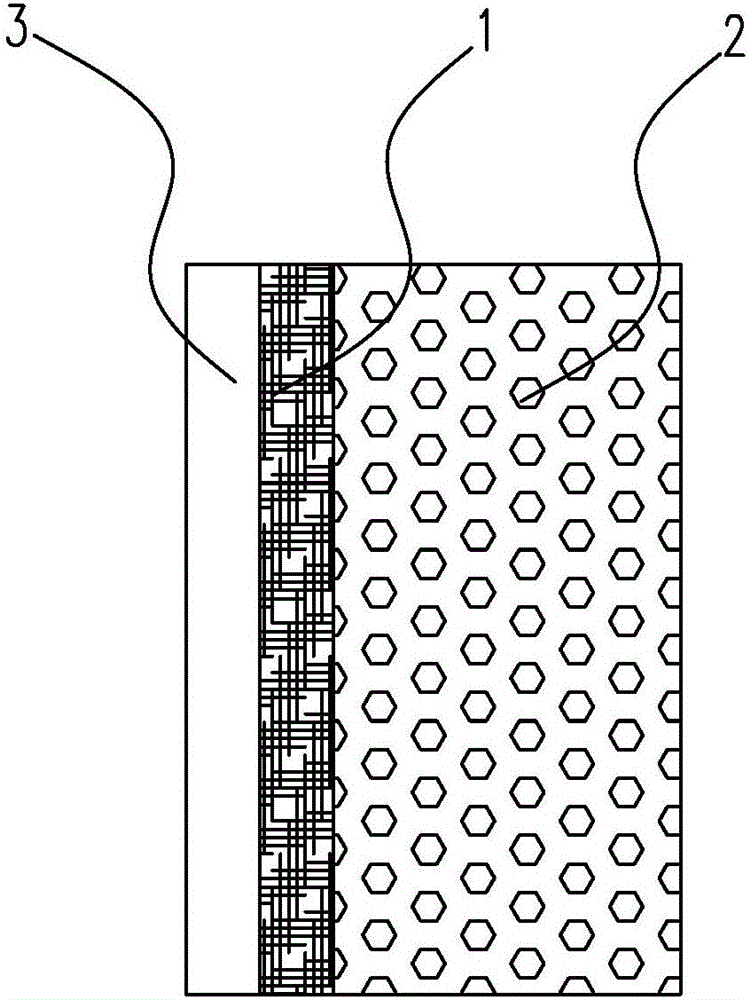

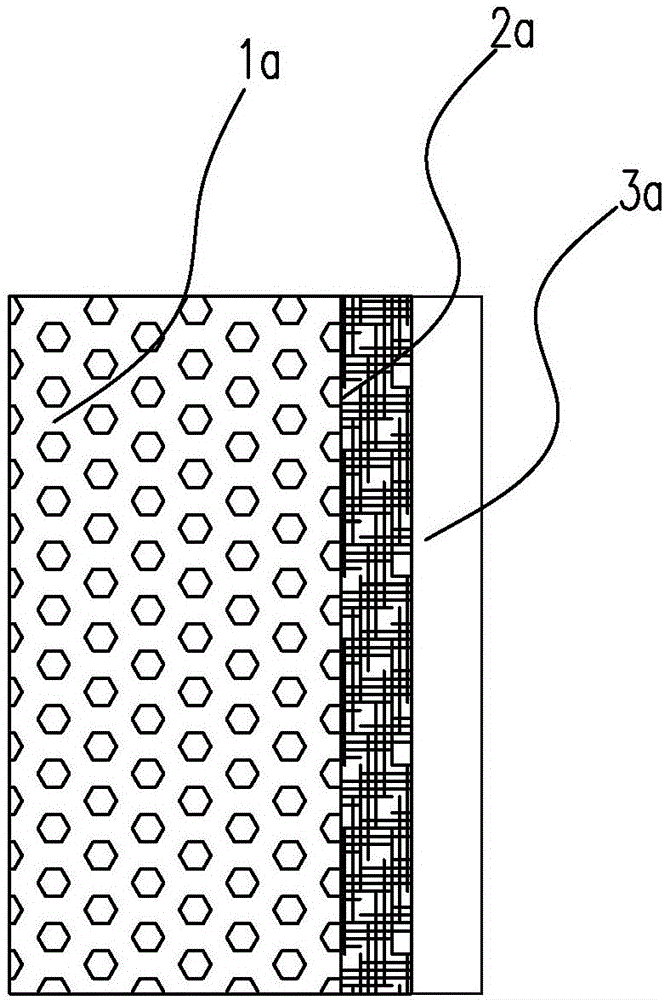

Environment-friendly multi-layer composite ceramic product and preparation method thereof

InactiveCN106673604AReduce thicknessWon't breakCeramic materials productionClaywaresSocial benefitsComposite ceramic

The invention relates to the technical field of ceramic manufacture, in particular to an environment-friendly multi-layer composite ceramic product as well as a preparation method and a production method thereof. The environment-friendly multi-layer composite ceramic product comprises an inner-layer blank body and an outer-layer blank body which are tightly combined by grouting. The environment-friendly multi-layer composite ceramic product is provided with the inner-layer blank body and the outer-layer blank body; the outer-layer blank body is made of attractive and high-grade raw materials, has good combination degree with a glaze and is brightly chromogenic and high in grade; the inner-layer blank body is made of cheap raw materials and energy-saving and environment-friendly waste, thereby saving raw material cost and manufacture cost; with adoption of the production process of the environment-friendly multi-layer composite ceramic product, the thickness of the outer-layer blank body can be reduced, tight combination of the inner-layer blank body and the outer-layer blank body is guaranteed, cracking or separation is avoided, the strength of the product meets daily requirement, and the product has substantial social benefit and economic benefit.

Owner:福建泉州顺盛达集团有限公司

Corrosion-resistant blue ceramic pigment and preparation method thereof

InactiveCN105419393ABright hair colorSimple preparation processPigmenting treatmentDiammonium phosphateZinc

The invention relates to a corrosion-resistant blue ceramic pigment and a preparation method thereof and belongs to the technical field of ceramic pigment production. The pigment is prepared from, by weight, 10-60 parts of potassium carbonate, 20-55 parts of diammonium phosphate, 20-65 parts of zirconium oxide, 10-30 parts of zinc oxide, 30-50 parts of aluminum oxide and 15-45 parts of cobaltous oxide. The preparation method comprises the steps of mixing the components to be uniform, conducting high temperature calcination at the temperature of 500-1000 DEG C, conducting cooling and pulverization, sieving the components with a 500-800-mesh sieve, conducting washing, after washing is ended, conducting further pulverization with a ball mill, sieving the components with a 100-300-mesh sieve, and obtaining the corrosion-resistant blue ceramic pigment. The ceramic pigment is bright in color development, and in addition, the pigment is simple in preparation process, resistant to corrosion and applicable to underglaze color, pigmented glaze and overglaze color.

Owner:赖清甜

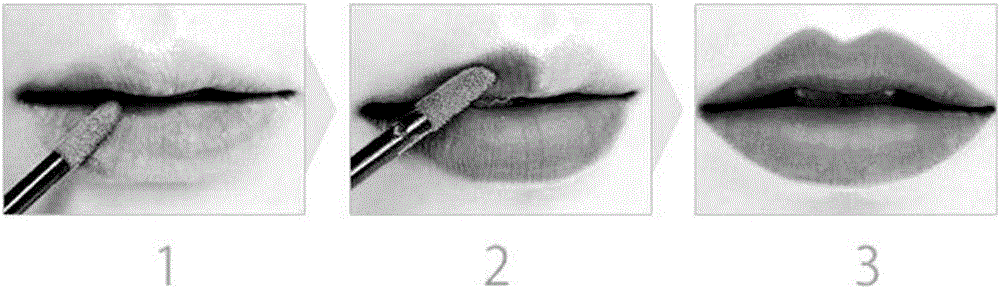

Hair coloring method using henna powder

InactiveCN107049873AFade slowlyExtended stayCosmetic preparationsHair cosmeticsAdditive ingredientPetal

The invention discloses a hair coloring method using henna powder. The method comprises the steps of preparing the henna powder and Chinese rose petals into slurry with water, then adding a collagen solution and olive oil, standing after uniform mixing, applying an obtained hair colorant onto hair, washing with the water at last, and applying essential oil on the hair. The method takes the henna powder as a major coloring ingredient; the Chinese rose petals are matched for use; the hair can be dyed to dark purple; a hair coloring effect is brighter than that of single use of the henna powder. Collagen is added into the hair colorant to react with a pigment; the staying time of the pigment on the hair can be prolonged; and the hair fades slowly. The olive oil and the essential oil have a moistening effect on the hair and enable the hair to be soft and smooth.

Owner:方耀

Preparation process of wear-resistant vintage brick with 4-8 degrees of soft surface

The invention relates to a preparation process of a wear-resistant vintage brick with a 4-8-degree soft surface. The preparation process comprises the following steps: (1) preparation and processing of glaze; (2) application of ground glaze: placing the ground glaze into a glaze spraying device, utilizing the glaze spraying device to cover the surface of an obtained bottom blank with the ground glaze and obtaining a glaze blank; (3) ink-jet printing: printing ceramic ink on the ground glaze by an ink-jet printer according to a color pattern prepared in advance and forming a decorative pattern;(4) spraying of cover glaze: spraying on the dried ground glaze surface with the decorative pattern by 50-60g / m<2> of water to reach a first-time slurry spraying position, carrying out waterfall-typespraying of cover slurry a according to a dosage of 400-450g / m<2>, reaching a second-time slurry spraying position after a conveying time of about 15 seconds, and carrying out waterfall-type sprayingof cover slurry b according to a dosage of 500-900g / m<2>; secondary drying: conveying the blank body sprayed with cover slurry twice into a drying kiln with the temperature of 120-220 DEG C, whereindrying period is 40 minutes; finally, carrying out firing, multistage polishing and graded package.

Owner:FOSHAN SHI WAN YING BRAND CERAMICS CO LTD

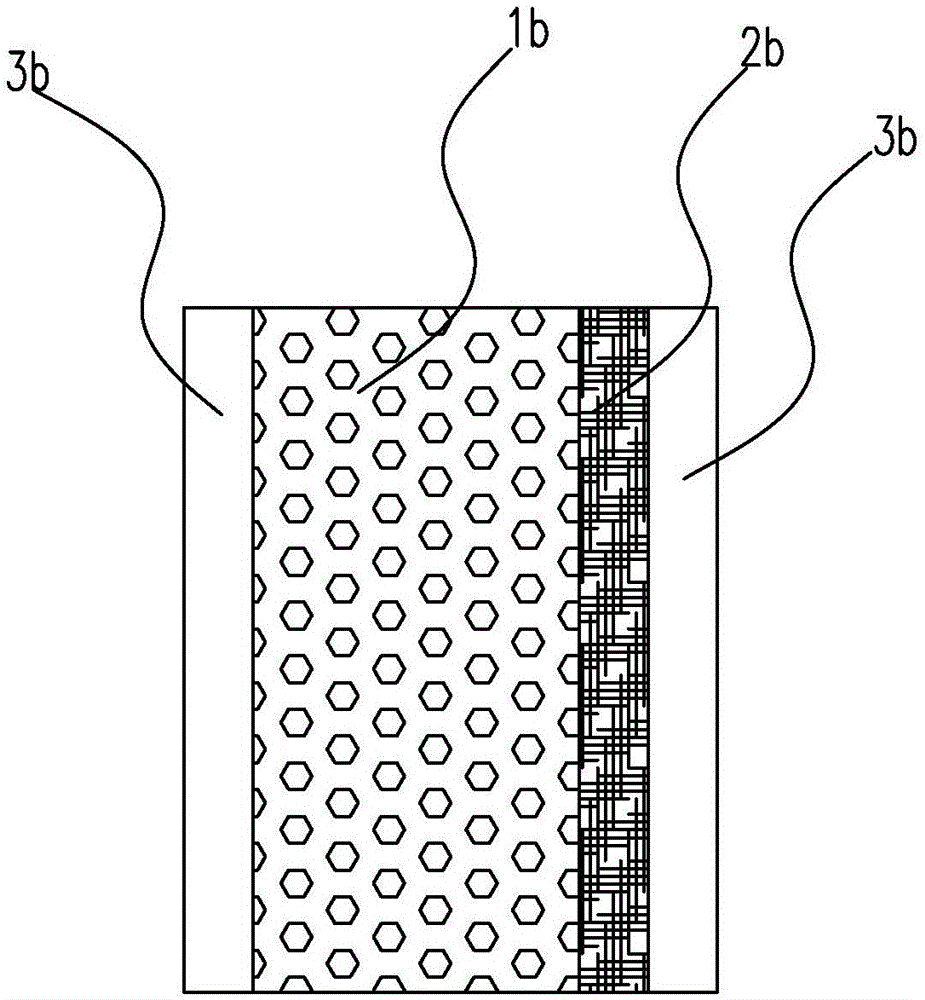

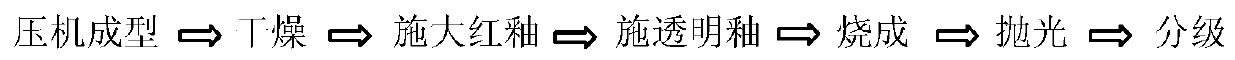

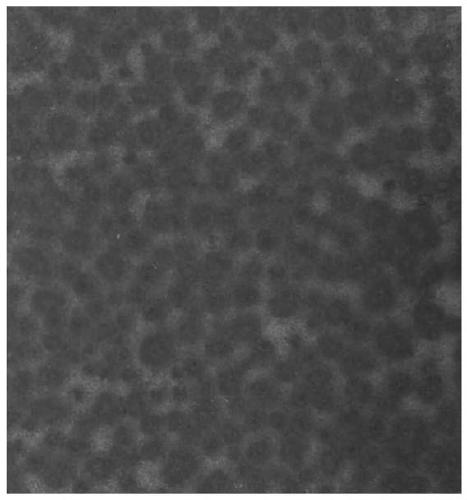

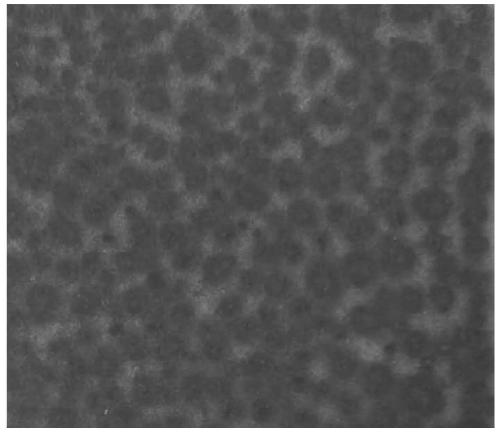

Red glaze as well as ceramic tile using red glaze and preparation method of ceramic tile

The invention provides a red glaze as well as a ceramic tile using the red glaze and a preparation method of the ceramic tile. The red glaze is prepared from basic glaze and a red pigment, wherein thebasic glaze is prepared from the following components in percentage by mass: 22 to 26 percent of potash feldspar, 8 to 12 percent of kaolin, 5 to 8 percent of burned talcum, 13 to 18 percent of calcite, 25 to 35 percent of quartz sand, 2 to 5 percent of zinc oxide, 3 to 8 percent of zirconium silicate and 4 to 7 percent of barium carbonate; the red pigment is 8 to 15 mass percent of the basic glaze.

Owner:MONALISA GRP CO LTD

Scarlet glaze material for ceramics and preparation method thereof

The invention relates to a scarlet glaze material for ceramics, which is prepared from 30-50 parts of potash feldspar, 20-40 parts of quartz, 5-15 parts of marble, 8-15 parts of kaolin, 6-10 parts of clear frit, 0.1-0.5 part of cadmium carbonate, 4-12 parts of scarlet pigment and 50-70 parts of water. The preparation method comprises the following steps: evenly mixing the 30-50 parts of potash feldspar, 20-40 parts of quartz, 5-15 parts of marble, 8-15 parts of kaolin, 6-10 parts of clear frit and 50-70 parts of water, and carrying out ball milling for 15-20 hours until the fineness reaches 325 meshes; evenly mixing the 0.1-0.5 part of cadmium carbonate and 4-12 parts of scarlet pigment, and carrying out ball milling until the fineness reaches 325 meshes; and finally, evenly mixing the two mixtures to obtain the scarlet glaze material for ceramics. The glaze material has the advantages of favorable combination performance with the green body, pure and bright color, high stability and high gloss.

Owner:CHAOZHOU QINGFA CERAMICS

Glazed tile with anti-slip and anti-slip effects and preparation method of glazed tile

ActiveCN114292100AAnti-skidWith anti-slip effectCeramic materials productionStatic friction coefficientGlaze

The invention relates to the technical field of ceramic tiles, and discloses a glazed tile with anti-slip and anti-slip effects and a preparation method thereof.According to the glazed tile, on one hand, printing fancy glaze containing high-temperature protruding powder and anti-slip glaze powder is printed on the surface of the ceramic tile, so that a pattern layer is rich in anorthite and baryta feldspar crystals; two crystal phases contained in the glaze layer can effectively form a surface height difference due to particle size difference, and a concave-convex surface layer is generated; on the other hand, a special HRT pit digging rubber roller engraving process is adopted and matched with the printed fancy glaze, so that a more obvious concave-convex effect can be formed, and the anti-sliding and anti-sliding effects of the glazed tile can be further improved; the wet water static friction coefficient of the glazed tile reaches 0.7 or above, the wear-resistant and antifouling level of the glaze reaches the fifth level, and the surface of the glazed tile presents various patterns in different shapes, so that the glazed tile is more attractive, natural and rich; according to the preparation method, destructive technological means such as slotting, cutting and anti-slip agent smearing are not needed for the brick surface, operation is easy, and the preparation cost is low.

Owner:GUANGDONG NEWPEARL CERAMIC GRP CO LTD +4

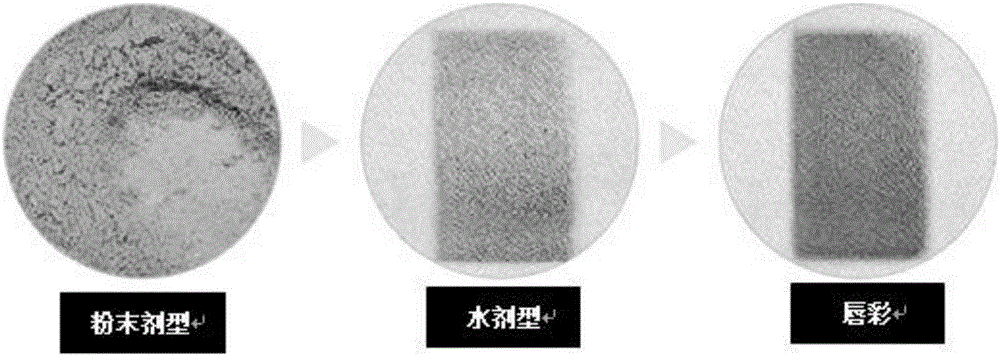

Long-lasting powder essence composition with improved coloring and skin feeling and preparation method thereof

ActiveCN106606427AGuaranteed waterproof functionBright hair colorCosmetic preparationsBody powdersEmulsionWater resistant

The present invention relates to a long-lasting powder essence composition with improved coloring and skin feeling and its preparation method. The powder essence composition is a high-fitting coloring powder not likely to smear or wear off. The composition turns into liquid the moment it is rubbed on the skin to offer a natural color tone like water color, keeps the color clear without getting cakey even when it is reapplied multiple times, and delivers a clearer color as it glides on the skin to break powder and water particles. The powder essence composition according to the present invention is also a powder emulsion, which makes the skin feel light and hydrated rather than sticky or stuffy when applied to the skin and stays long due to its water-resistant function. In addition, the powder essence composition according to the present invention contains different functional moisturizing agents to provide plenty of nourishment when applied to the skin. The composition makes the skin feel fresh and hydrated rather than stuffy or heavy, lightly sinks into the skin like nothing is applied on the skin, to display a strong tint function, stays long just with one touch and has a good water-resistant effect, so it does not bleed when in contact with water.

Owner:C&C INT CO LTD

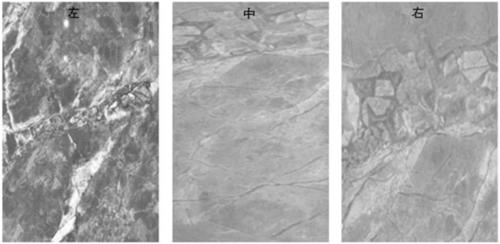

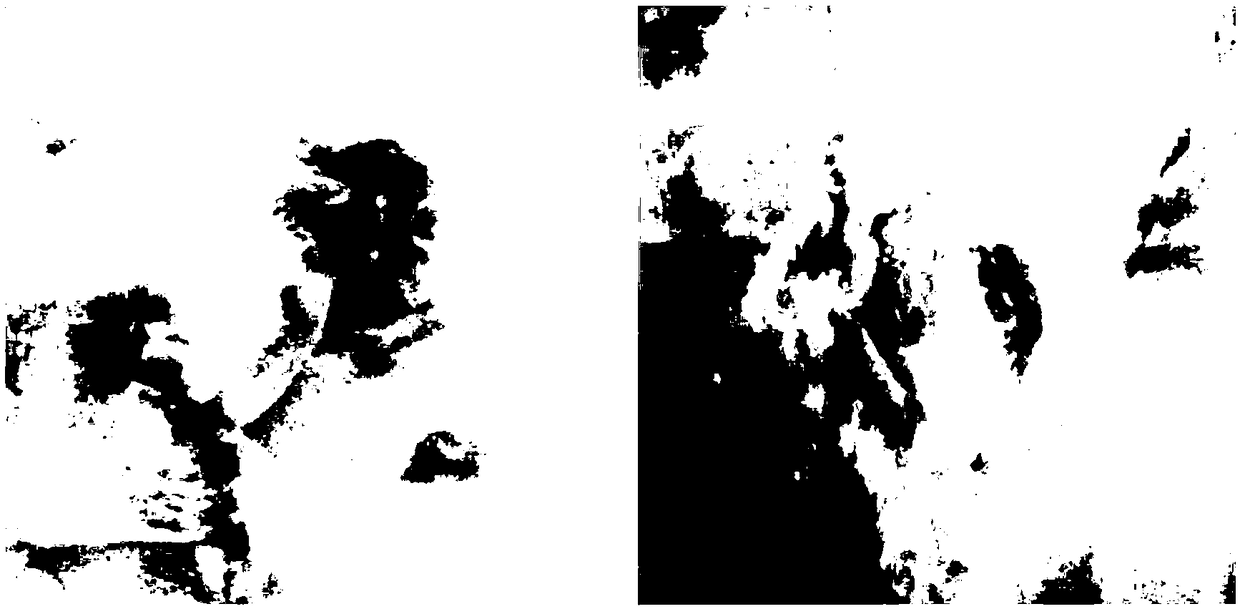

Manufacturing method of nature marble tile with original stone color and clear pattern

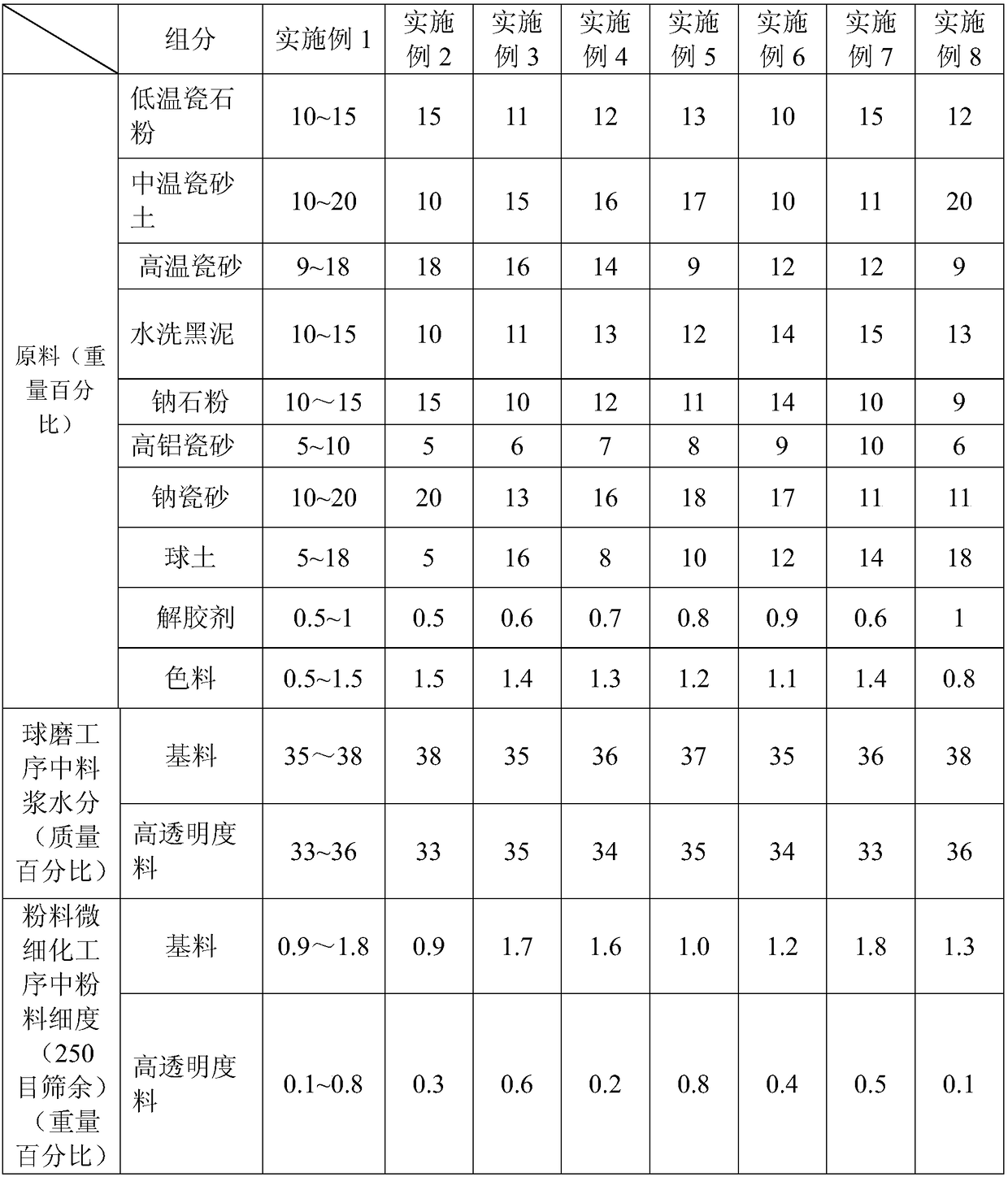

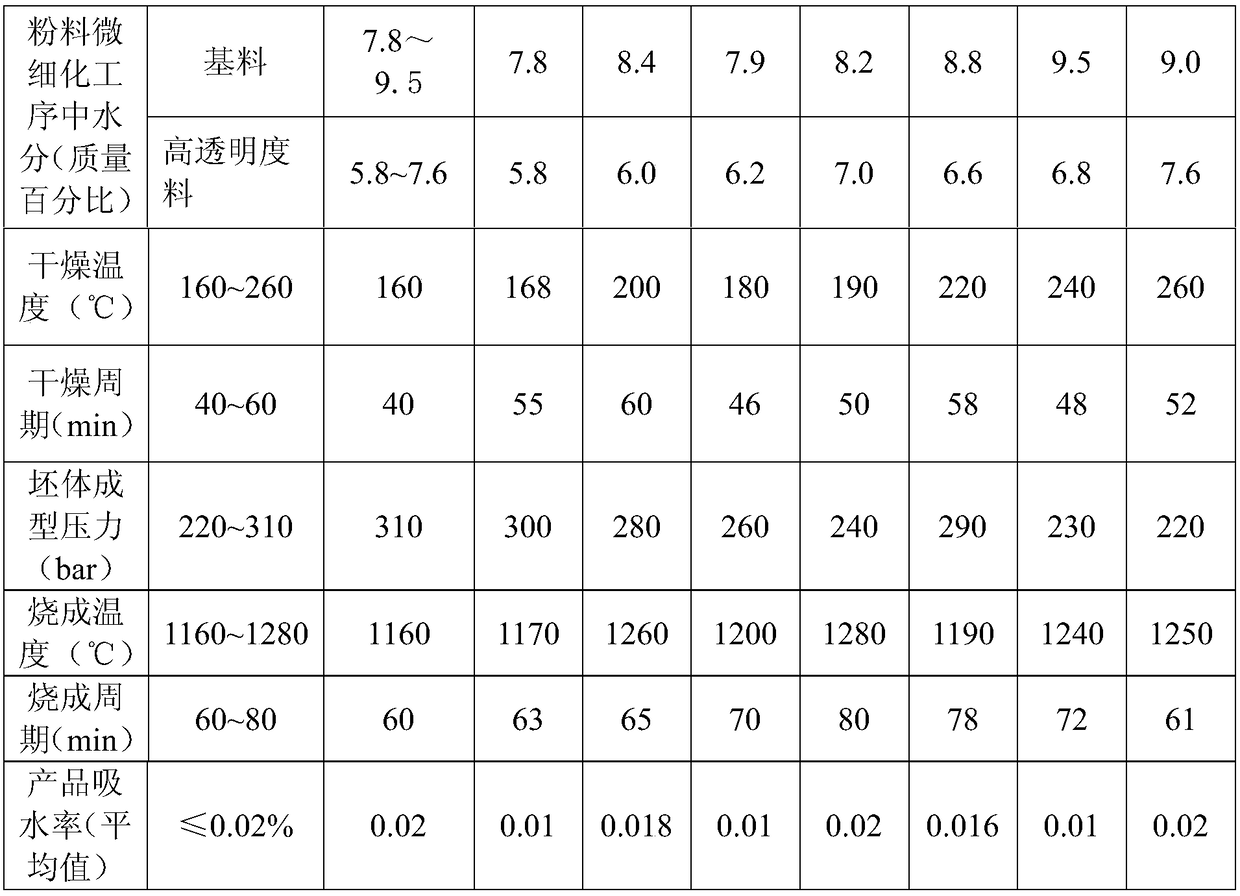

InactiveCN109333762AStrong coloring powerPure colorNatural patternsDuplicating/marking methodsCeramic glazeBall clay

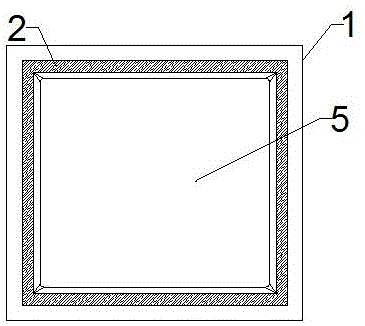

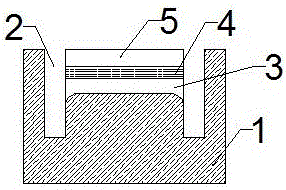

The invention provides a manufacturing method of a nature marble tile with an original stone color and a clear pattern. The manufacturing method comprises the processes of material selection, materialproportioning, ball milling, color modulation, powder preparation, cloth pressing, drying, glaze spraying, ink printing and screen printing, firing, polishing, sorting, packaging and warehousing. Theprocess of spraying a micron (nano) dirt-proof coating is additionally executed between the process of cloth pressing and the process of drying. The process of cloth pressing comprises the steps of powder crushing, full-automatic blanking through a computer control panel, distribution of line micropowder on a mold, base material (12 pipelines) blanking and compression molding. The process of printing and ink jetting comprises the steps that printing is conducted at least three times before ink jetting; ink jetting is conducted on multiple faces (nine faces) of each stone; at least 13 times ofprinting is conducted after ink jetting, and slight drying is conducted; scraped edges are coated with brick prime pulp, and firing is conducted. The nature marble tile with the original stone colorand the clear pattern mainly comprises, by weight, 10-%-15% of low-temperature porcelain stone powder, 10%-20% of intermediate-temperature porcelain sandy soil, 9%-18% of high-temperature porcelain sand, 10%-15% of washing black clay, 10%-15% of sodium stone powder, 5%-10% of high-aluminum porcelain sand, 10%-20% of sodium porcelain sand, 5%-18% of ball clay, 0.5%-1% of a dispergator and 0.5%-1.5%of pigment. According to the manufacturing method of the nature marble tile with the original stone color and the clear pattern, a deep permeable layer is achieved, the high resolution of 720 DP is achieved, and the texture is vivid and nature.

Owner:广东能强陶瓷有限公司

Yellow high-gloss glaze material for ceramics and preparation method thereof

The invention relates to a yellow high-gloss glaze material for ceramics, which is prepared from 30-50 parts of potash feldspar, 20-40 parts of quartz, 5-15 parts of marble, 8-15 parts of kaolin, 6-10 parts of clear frit, 1-4 parts of ceria, 1-4 parts of niobium oxide, 4-12 parts of yellow pigment and 50-70 parts of water. The preparation method comprises the following steps: evenly mixing the 30-50 parts of potash feldspar, 20-40 parts of quartz, 5-15 parts of marble, 8-15 parts of kaolin, 6-10 parts of clear frit and 50-70 parts of water, and carrying out ball milling for 15-20 hours until the fineness reaches 325 meshes; evenly mixing the 1-4 parts of ceria, 1-4 parts of niobium oxide and 4-12 parts of yellow pigment, and carrying out ball milling until the fineness reaches 325 meshes;and finally, evenly mixing the two mixtures to obtain the yellow high-gloss glaze material for ceramics. The glaze material has the advantages of favorable combination performance with the green body, pure and bright color, high stability and high gloss.

Owner:CHAOZHOU QINGFA CERAMICS

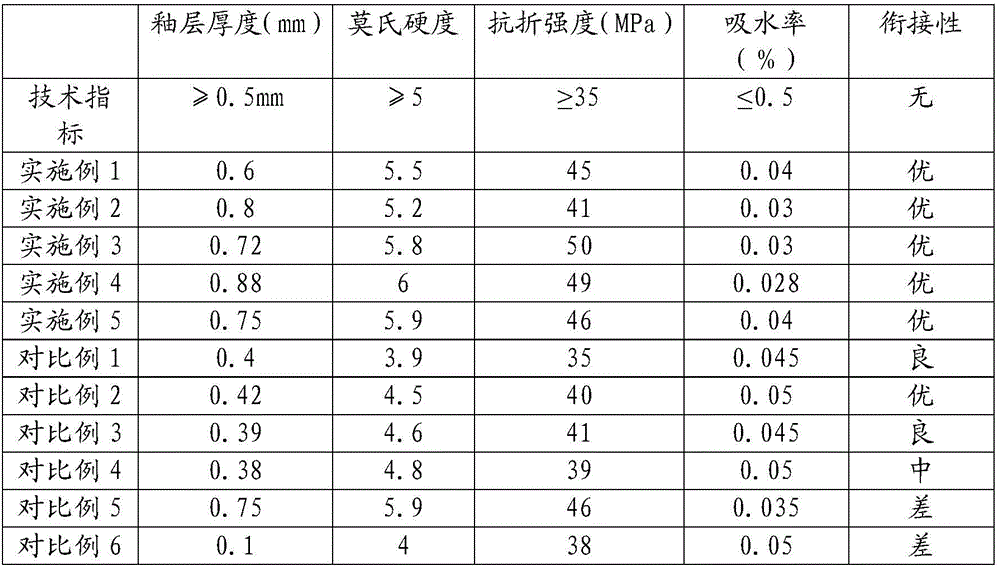

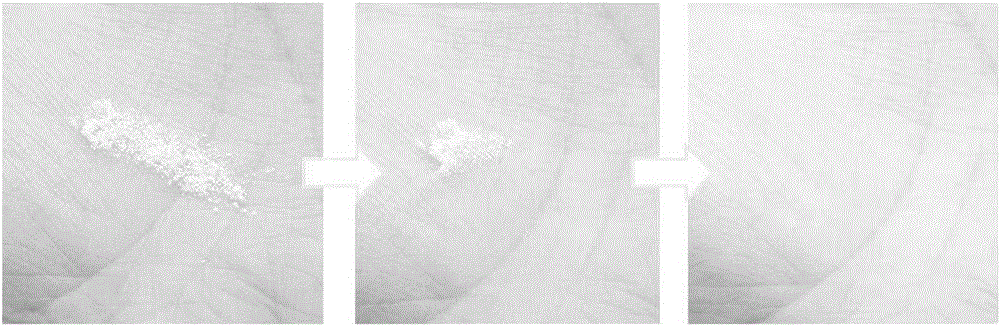

Ultrathin slurry sprinkling and glazing process

The invention relates to an ultrathin slurry sprinkling and glazing process. The ultrathin slurry sprinkling and glazing process comprises the following steps: preparing a porcelain tile bottom blankfor subsequent use; preparing a face slurry for subsequent use; first-time drying: conveying the bottom blanks in a drying kiln at the temperature of 120-220 DEG C in a period of 60-100 minutes; second-time face slurry sprinkling and applying: carrying out second-time sprinkling and applying, sprinkling 16-22 g / m<2> water on the surfaces of the dried bottom blanks to arrive at a first-time slurrysprinkling position, carrying out waterfall type face slurry sprinkling and applying according to the use amount of 320-450 g / m<2>, and arriving at a second-time slurry sprinkling position about 10-20seconds of transmitting time later; second-time drying: conveying the blanks with the face slurry into the drying kiln at the temperature of 120-220 DEG C again in a drying period of 35-45 minutes; 3D full-color high-definition printing: spraying permeation ink and a permeation aid which are used for preparing digital patterns on the surfaces of the blanks with the dried face slurry layer according to a design file by a 3D full-color high-definition printing machine; firing: firing the blanks in a kiln of which the highest temperature reaches 1160-1220 DEG C in the period of 60-80 minutes; and cooling and polishing to obtain back-to-ancients finished bricks.

Owner:FOSHAN SHI WAN YING BRAND CERAMICS CO LTD

Preparation method of microcrystalline diamond ceramic brick

The invention relates to the technical filed of building ceramics, in particular to a preparation method of a microcrystalline diamond ceramic brick. The preparation method comprises the following steps: 1) mixing and pressing raw materials for a green base brick into the green base brick; 2) applying surface glaze inside the surface of the green base brick; 3) performing inkjet and glaze penetration on the surface glaze to make a pattern; 4) applying a layer of diamond glaze on the surface of the pattern and then coating the periphery with a circle of transparent glaze; 5) firing in a kiln; 6) preparing a finished product through polishing, trimming and edging after firing. The microcrystalline diamond ceramic brick prepared by the preparation method has a thinner surface microcrystalline layer and is good in wear resistance and good in anti-fouling property.

Owner:四川省新万兴瓷业有限公司

Preparation Technology of Underglaze Red Nixing Pottery

The invention provides a preparation process of underglaze red nixing pottery. The preparation process comprises the steps of blank preparing, blank forming, blank drying, blank decorating and blank burning, wherein, in the blank decorating, a layer of clear glaze is applied on a dry blank body after describing patterns by using an underglaze red pigment and / or writing characters; the underglaze red pigment is prepared from the following raw materials in parts by weight: 12 to 15 parts of copper oxide, 58 to 65 parts of hydrophite, 19 to 25 parts of glass powder and 6 to 9 parts of diabase; the clear glaze comprises the following raw materials in parts by weight: 79 to 81 parts of glaze stone, 21 to 23 parts of glaze ash and 5 to 8 parts of fluorite. According to the invention, the underglaze red pigment can be directly applied on the blank of the nixing pottery without need of ground glaze, the process is simplified, the finished products are bright-colored, and the glaze is bright.

Owner:QINZHOU UNIV

A preparation method of background wall brick and preparation method of background wall

ActiveCN106007800BPromote meltingLow meltingCovering/liningsMohs scale of mineral hardnessBreaking strength

The invention provides a background wall brick preparing method. The background wall brick preparing method comprises the following steps: 1, forming a green body and drying the green body to obtain the dry green body; 2, applying ground coat enamel on the surface of the dry green body to obtain a first green brick; 3, inkjet printing the ground coat enamel of the first green brick to obtain a second green brick; 4, drying the second green brick to obtain a third green brick; 5, applying cover glaze on the inkjet-printed side of the third green brick to obtain a fourth green brick; 6, drying the fourth green brick to obtain a fifth green brick; 7, roasting the fifth green brick at high temperature to obtain a sixth green brick; 8, polishing the sixth green brick to obtain the background wall brick. The background wall brick is large in moh hardness and breaking strength and low in water absorption. The invention further provides a background wall preparing method, and the background wall is good in link and attractive and elegant in appearance.

Owner:HEYUAN DONGYUAN EAGLE CERAMICS CO LTD +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com