Manufacturing method of nature marble tile with original stone color and clear pattern

A manufacturing method and marble technology, which are applied in the directions of copying/marking methods, patterns imitating natural patterns, manufacturing tools, etc., can solve the problems of not clear enough marble tile texture, traditional process flow, unsatisfactory gloss, etc., and achieve market economy. Remarkable benefit, good economic benefit, bright color effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

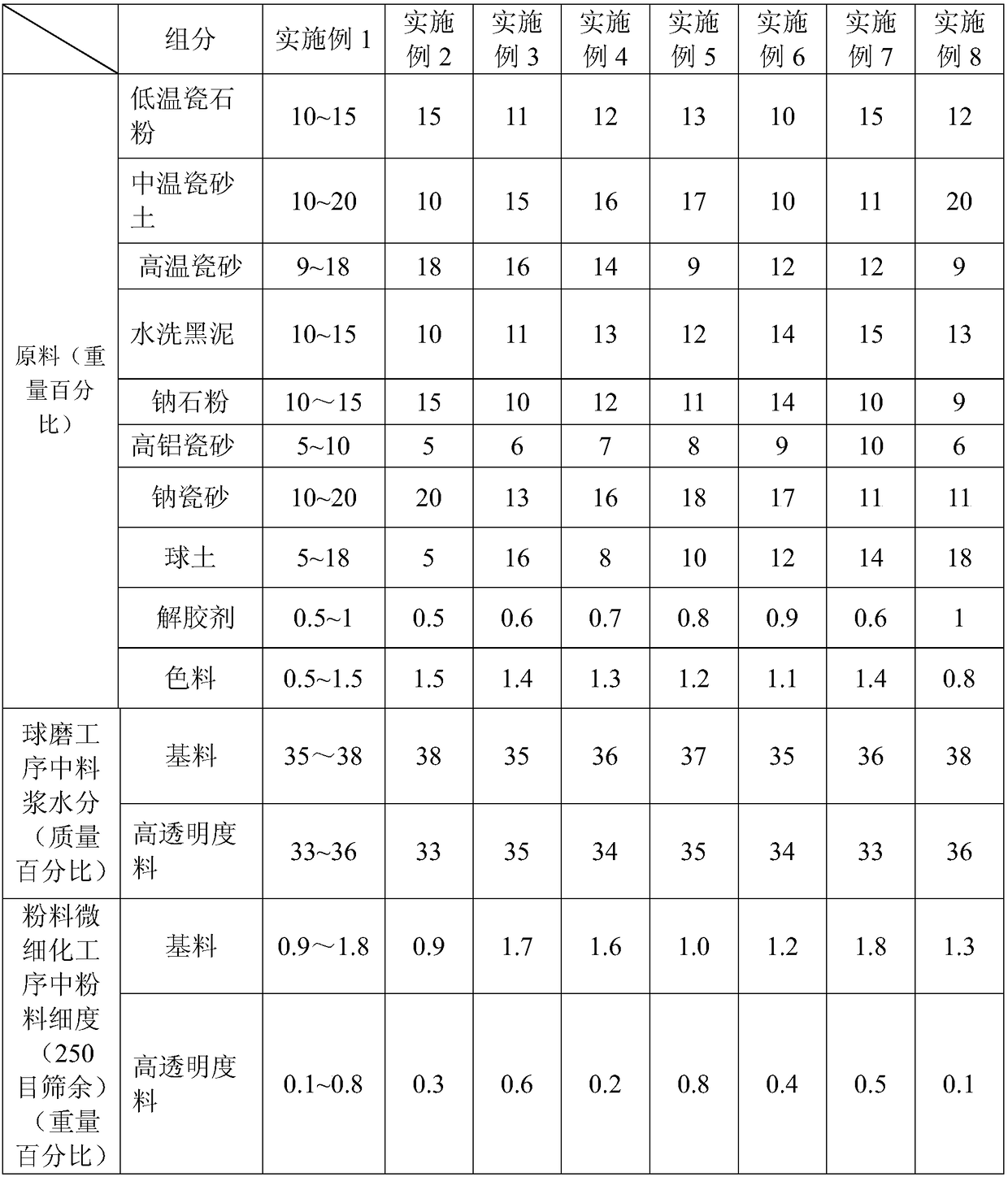

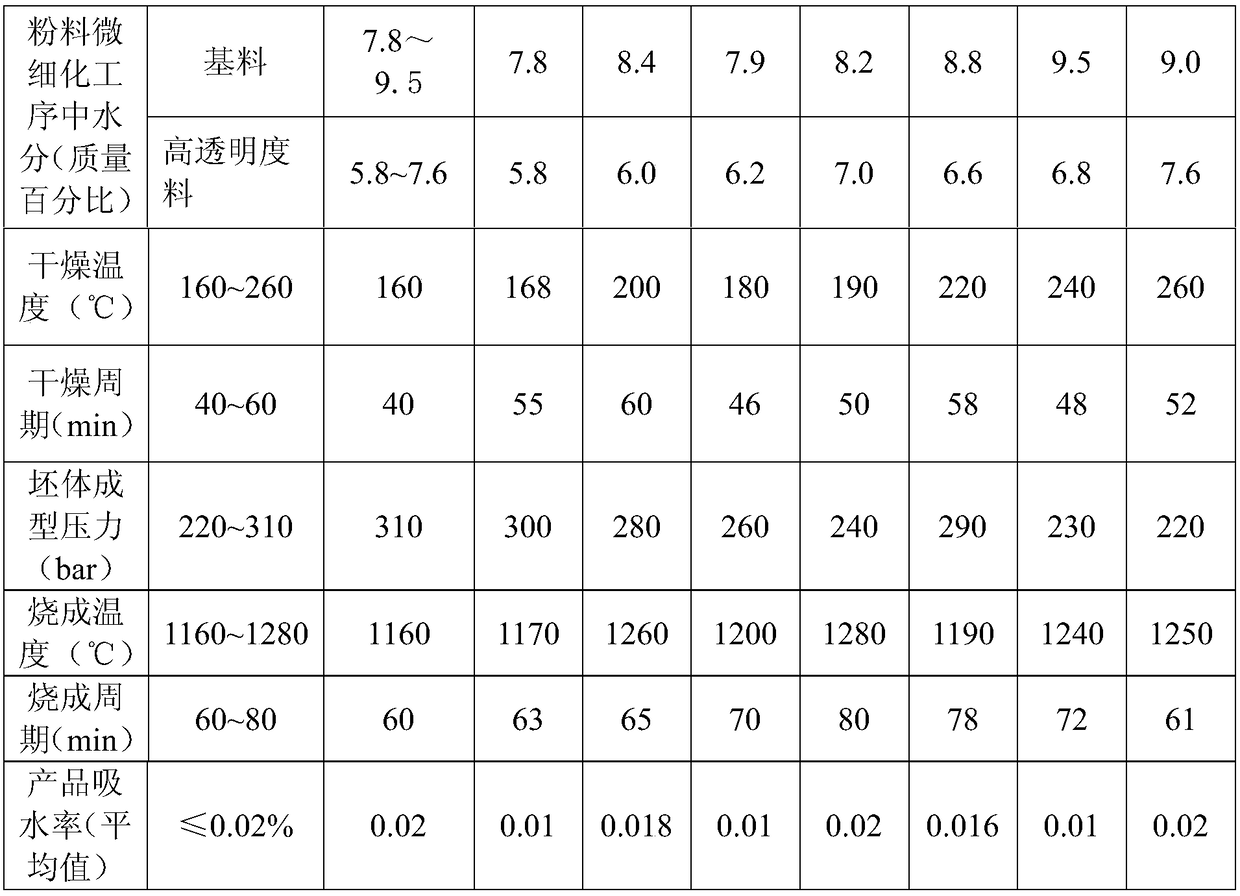

[0020] Below in conjunction with specific embodiment the present invention is described in further detail Table 1

[0021]

[0022]

[0023] A method for manufacturing natural marble tiles that restore stone color and have clear patterns. The process flow of the manufacturing method: material selection → batching → ball milling → color matching → powder making → cloth pressing → drying → glaze → inkjet plus screen printing → Firing→polishing→checking→packing→warehousing;

[0024] A spraying nano antifouling coating process is added between the cloth pressing process and the drying process;

[0025] The cloth pressing process includes: powder crushing → full-automatic computer control panel straight drop → line fine powder cloth falls on the mold → base material cloth → press molding;

[0026] The base material distributing process adopts 12 pipeline distributing;

[0027] The printing inkjet process flow: at least 3 times of printing before inkjet → inkjet style, one s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com