Pigment dispersing composition

A pigment dispersion and composition technology, applied in pigment paste, organic dyes, chemical/physical processes, etc., can solve the problems of lower contrast of liquid crystal display devices, difficulty in combining pigment particles, and lower light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0161]

[0162] The preparation method of the pigment dispersion composition of the present invention is not particularly limited, for example, it can be obtained by the following method: using a pigment and a pigment dispersant and a solvent, utilizing a vertical or horizontal sand mill, pin mill, slot mill (slit mill), ultrasonic disperser, etc., obtained by microdispersing beads made of glass, zirconia, etc. with a particle size of 0.01 to 1 mm.

[0163] In addition, before the beads are dispersed, it is also possible to use a two-roller, three-roller, ball mill, drum mill (Tron Mill), disperser, kneader, co-kneader (Konider), homogenizer, mixer, single A screw or twin-screw extruder or the like performs kneading and dispersing treatment while applying a strong shearing force.

[0164] In addition, the details of kneading and dispersion are described in "Paint Flow and Pigment Dispersion" by T.C. Patton (1964 publication of John Wiley and Sons Company) and the like.

[0...

Embodiment 1

[0169]

[0170] The components of the following composition (1) were mixed, stirred and mixed for 3 hours using a homogenizer at a rotation speed of 3000 r.p.m. to prepare a mixed solution containing a pigment.

[0171] [composition (1)]

[0172] · C.I. Pigment Red 254 [(a) Pigment] 90 parts

[0173] · C.I. Pigment Red 177 [(a) Pigment] 10 parts

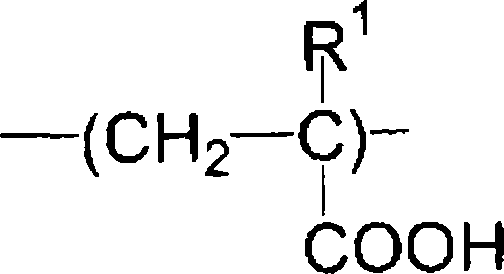

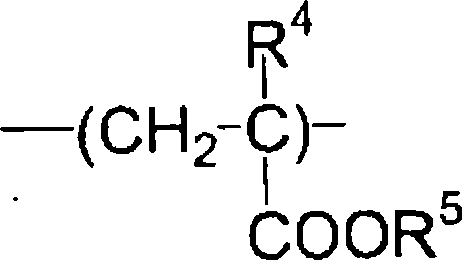

[0174] ・Cyclohexyl methacrylate / benzyl methacrylate / methacrylic acid copolymer (=45 / 40 / 15 [weight ratio], weight average molecular weight 20000, acid value 100) (polymer 1: (d) disperse 30 parts of 30% solution of acetic acid 1-methoxy-2-propyl ester solvent

[0175] Solspers 24000GR (manufactured by Lubrizol Japan; (polyester-based dispersant) [(c) dispersant] 40 parts

[0176] 820 parts of 1-methoxy-2-propyl acetate [(b) solvent]

[0177] Next, the mixed solution obtained above was subjected to a dispersion treatment for 6 hours in a bead disperser Disper-Matt (manufactured by GETZMANN) using 0.1 mmφ zirconia beads, and then ...

Embodiment 2

[0185] In addition to replacing 30 parts of 30% solution of 1-methoxyl-2-propyl acetate solvent as (d) dispersant in Example 1 with cyclohexyl methacrylate / methacrylic acid Butyl ester / methacrylic acid copolymer (=45 / 44 / 11 [weight ratio], weight average molecular weight 20000, acid value 71) (polymer 2: (d) dispersant) of acetic acid 1-methoxyl-2 Except for 30 parts of the 30% solution of the propyl ester solvent, a red pigment dispersion composition was prepared in the same manner as in Example 1, and the same evaluation as in Example 1 was performed. The results are shown in Table 1 below.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com