Preparation method of microcrystalline diamond ceramic brick

A diamond and ceramic tile technology, which is applied in the field of building ceramics, can solve the problems of poor anti-fouling, no wear resistance, thick surface microcrystalline layer, etc., and achieve the effects of cost reduction, good anti-fouling, and bright color.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A preparation method of microcrystalline diamond tiles, comprising the following steps:

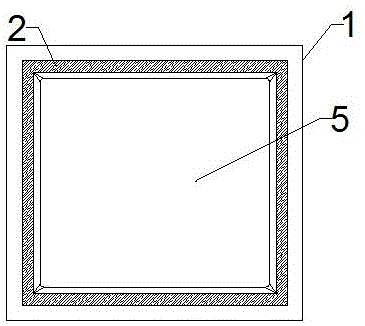

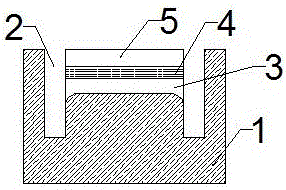

[0031] 1) Mix the raw materials for the base brick adobe, and use a press with a tonnage of 1,000 tons to press the base brick adobe. There are regular grooves around the edge of the base brick adobe surface, and the edge of the base brick adobe surface inside the groove is flat. The groove is 5mm away from the edge of the base brick adobe, the groove width is 0.5cm, and the depth is 0.2mm;

[0032] 2) Spread glaze on the surface of the base brick adobe, which plays the role of decoration and isolation of the bottom layer;

[0033] 3) Ink-jet printing pattern on the glaze;

[0034] 4) Apply a layer of diamond glaze on the surface of the pattern, and then apply a circle of transparent glaze around it. After the application, use a 2200-ton press to press and fill the diamond glaze and transparent glaze;

[0035] 5) Firing in the kiln. One firing in the kiln is completed in two stag...

Embodiment 2

[0038] A preparation method of microcrystalline diamond tiles, comprising the following steps:

[0039] 1) Mix the raw materials for the base brick adobe, and use a press with a tonnage of 8,000 tons to press the base brick adobe. There are regular grooves around the surface of the base brick adobe, and the edge of the base brick adobe surface inside the groove is flat. The groove is 15mm away from the edge of the base brick adobe surface, the groove width is 1.5cm, and the depth is 0.9mm;

[0040] 2) Spread glaze on the surface of the base brick adobe, which plays the role of decoration and isolation of the bottom layer;

[0041] 3) Ink-jet printing pattern on the glaze;

[0042] 4) Apply a layer of diamond glaze on the surface of the pattern, and then apply a circle of transparent glaze around it. After the application, use a 2200-ton press to press and fill the diamond glaze and transparent glaze;

[0043] 5) Firing in the kiln, one firing in the kiln is completed in two ...

Embodiment 3

[0046] A preparation method of microcrystalline diamond tiles, comprising the following steps:

[0047] 1) Mix the raw materials for the base brick adobe, and use a press with a tonnage of 9,000 tons to press the base brick adobe. There are regular grooves around the surface of the base brick adobe, and the edge of the base brick adobe surface inside the groove is flat. The groove is 30mm away from the edge of the adobe surface of the base brick, the groove width is 3cm, and the depth is 3mm;

[0048] 2) Spread glaze on the surface of the base brick adobe, which plays the role of decoration and isolation of the bottom layer;

[0049] 3) Ink-jet printing pattern on the glaze;

[0050] 4) Apply a layer of diamond glaze on the surface of the pattern, and then apply a circle of transparent glaze around it. After the application, use a 2200-ton press to press and fill the diamond glaze and transparent glaze;

[0051] 5) Firing in the kiln, one firing in the kiln is completed in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com