Environment-friendly multi-layer composite ceramic product and preparation method thereof

A multi-layer composite and ceramic product technology, applied in the field of ceramic manufacturing, can solve the problems of uncertain raw material components, health and color effects, etc., achieve good combination, considerable social and economic benefits, and save raw materials cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

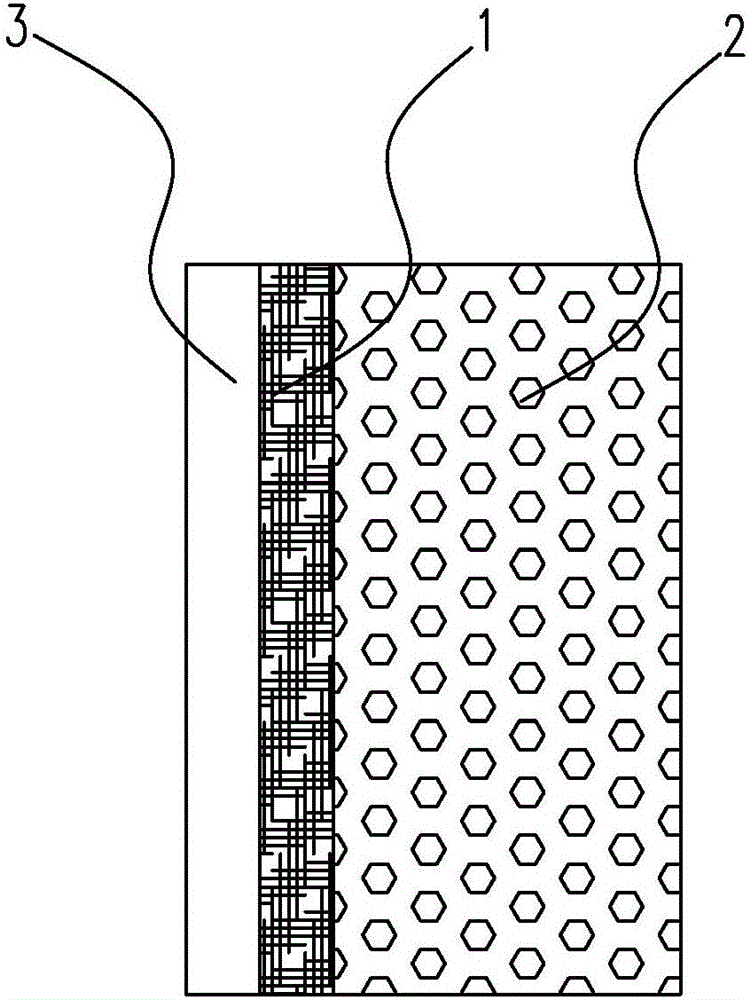

[0030] refer to figure 1 As shown, when making handicrafts, furnishings or works of art, multilayer composite ceramic products have an outer body 1 with a beautiful appearance and an inner body 2 that is energy-saving and environmentally friendly, and also includes a glaze layer attached to the outer body. 3;

[0031] The parts by weight of the raw materials of the inner layer are as follows: 39 parts of red loam, 18 parts of bentonite, 12 parts of talc, 8 parts of calcium carbide, 9 parts of plant fiber, 8 parts of stucco, 1 part of curing agent, and 5 parts of lead-boron frit;

[0032] The parts by weight of the raw materials of the outer layer are as follows: 44 parts of kaolin, 21 parts of dolomite, 18 parts of feldspar, 8 parts of quartz, 5 parts of talc, 3 parts of bone meal, and 1 part of alumina;

[0033] Glaze material layer 3 adopts transparent glaze.

specific Embodiment 2

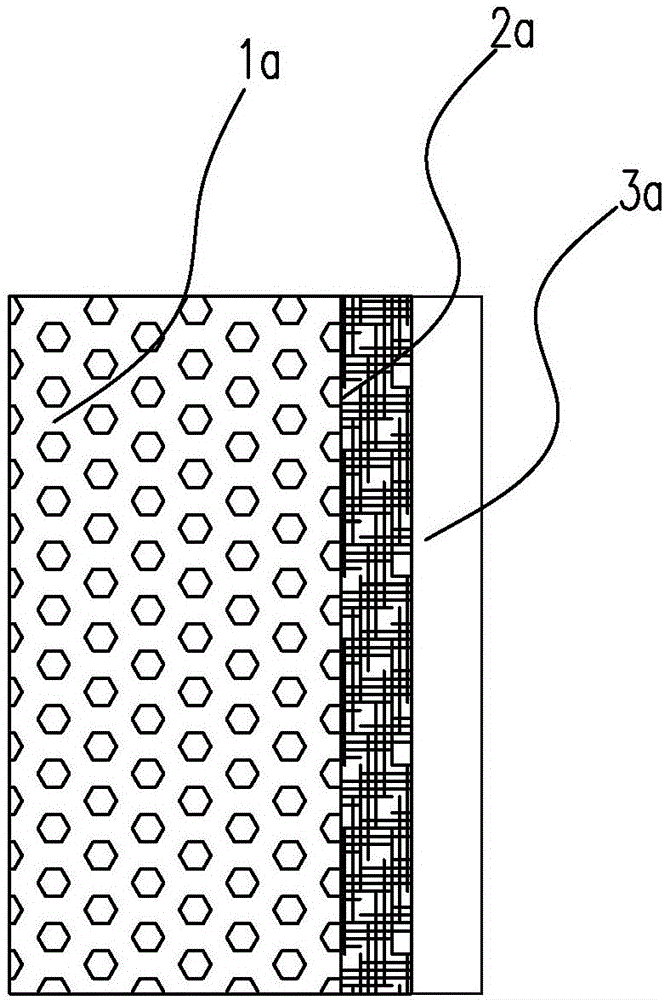

[0035] When multi-layer composite ceramic products are used to make tea sets, the outer body 1a with good retro effect is energy-saving and environmentally friendly, and the inner body 2a is healthy, beautiful and breathable, and the glaze attached to the inner body is also included. Layer 3a;

[0036] The parts by weight of the raw material of the outer layer are as follows: 40 parts of red loam, 14 parts of bentonite, 18 parts of talc, 6 parts of calcium carbide, 7 parts of plant fiber, 9 parts of stucco, 3 parts of curing agent, and 3 parts of lead-boron frit;

[0037] The parts by weight of the raw materials of the inner layer are as follows: 35-45 parts of kaolin, 41 parts of dolomite, 24 parts of feldspar, 16 parts of quartz, 7 parts of talc, 4 parts of bone meal, and 2 parts of alumina;

[0038] The glaze material layer 3a adopts transparent glaze.

specific Embodiment 3

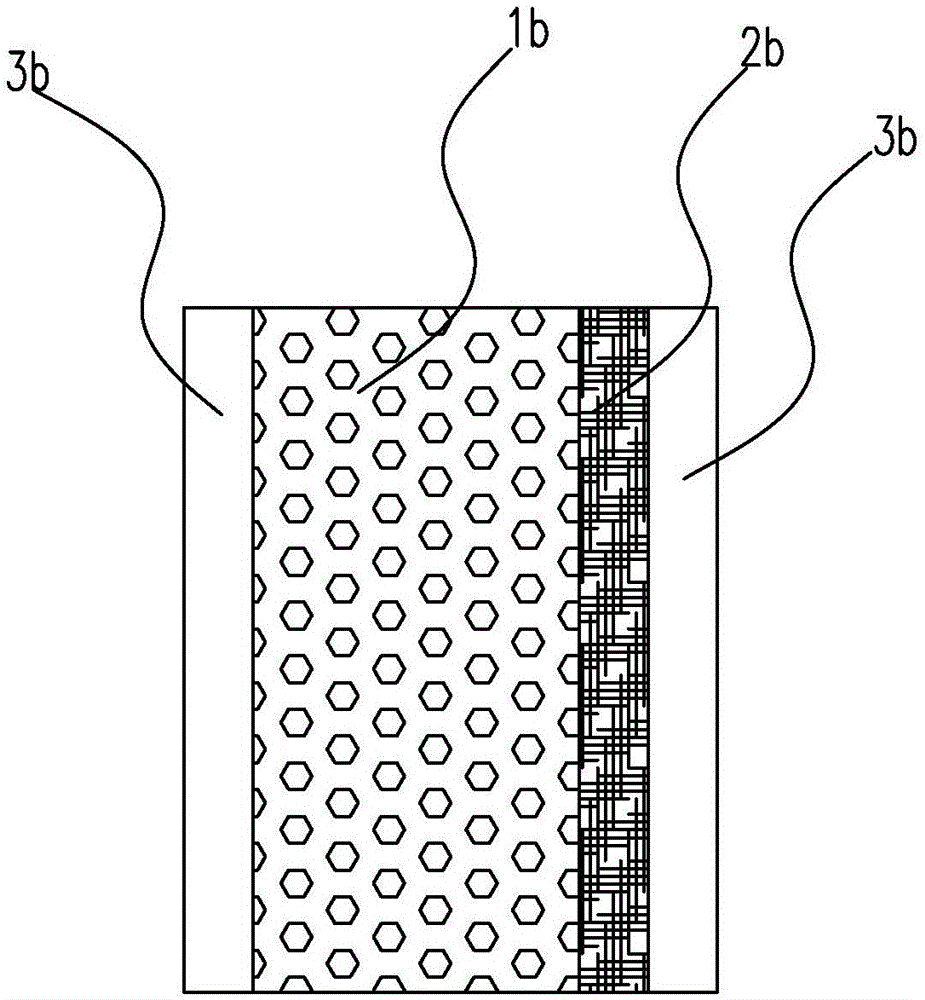

[0040] When multi-layer composite ceramic products are used to make tableware, it has an energy-saving and environmentally friendly outer body 1b, a healthy and beautiful inner body 2b, and a glaze layer attached to the outer body 1b and the inner body 2b 3b.

[0041] The parts by weight of the raw material of the outer layer are as follows: 44 parts of red loam, 11 parts of bentonite, 15 parts of talc, 9 parts of calcium carbide, 5 parts of plant fiber, 7 parts of stucco, 5 parts of curing agent, and 4 parts of lead-boron frit;

[0042] The parts by weight of the raw materials of the inner layer are as follows: 37 parts of kaolin, 28 parts of dolomite, 12 parts of feldspar, 9 parts of quartz, 9 parts of talc, 2 parts of bone meal, and 3 parts of alumina;

[0043] The glaze material layer 3b adopts transparent glaze.

[0044] A method for preparing an environment-friendly multilayer composite ceramic product, preparing the environment-friendly multilayer composite ceramic pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com