Flowing color decorative effect ceramic tile and preparation method thereof

A decorative effect, ceramic tile technology, applied in the field of architectural ceramic decoration, can solve the problems of single decorative technique, monotonous, difficult to meet the requirements and vision of consumer product value, etc., and achieve the effect of bright color and flexible collocation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

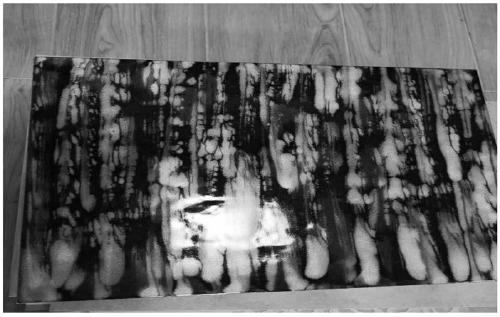

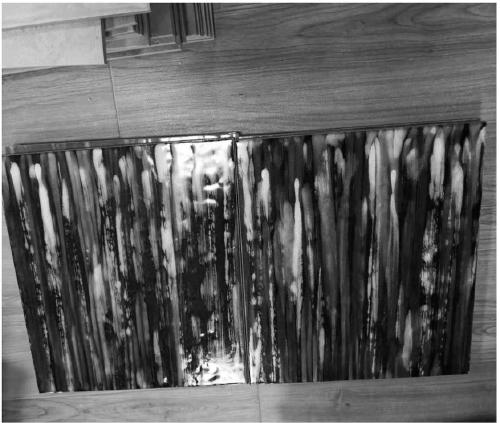

Image

Examples

preparation example Construction

[0039] Disclosed herein is a method for preparing a flow-color decorative effect ceramic tile.

[0040] First, a green body is prepared. The green body can be prepared from known ceramic raw materials according to conventional methods, such as raw material batching → wet ball milling → sieving and iron removal → spray tower powder preparation → mold pressing → drying the green body to obtain the green body. In one example, the main raw materials used in the green body are composites of clay and sand such as Qing potassium sand, sodium stone powder, terrazzo powder, Lihong potash sand, Nanfeng low-temperature sand, Bangsha, ball soil, Dongji mud, and black talc. .

[0041] In some embodiments, the green body is pressed using molds with various design style textures and positioning dimensions. Different from ordinary lines, concave-convex, and special-shaped textures, in this embodiment, the mold patterns have positioning on the same green body, and the mold patterns within ea...

Embodiment 1

[0082] (1) Prepare the green body: the green body formula is (parts by weight): Qing potassium sand 8wt%, sodium stone powder 9wt%, terrazzo powder 9wt%, Lihong potassium sand 7wt%, Nanfeng sand 8wt%, Bangsha 30wt%, ball 20wt% of soil, 7wt% of Dongji mud, and 2% of black talc are processed by ball milling and spray drying to form green powder. The base powder is pressed into a mold to obtain a green body. The green body size is 310×310mm. The chemical composition analysis of the green body is: IL (loss on ignition): 4.396%, SiO 2 : 7.851%, Al 2 o 3 : 9.01%, Fe 2 o 3 : 1.16%, TiO 2 : 0.35%, CaO: 0.74%, MgO: 0.84%, K 2 O: 3.29%, Na 2 O: 1.92%, P 2 o 5 : 0.15% SO 3 : 0.25%. After the billet of this formula is fired under the conditions of firing temperature of 1200°C and firing time of 60 minutes, it is detected that the water absorption rate of the product is ≤0.5%, the shrinkage rate of the green body is below 7.1%, and the sintering performance of the green body is...

Embodiment 2

[0090] The difference from Example 1 is that the formulation of the crystallization surface glaze is shown in A1 in Table 2, and the formulation of the crystallization effect glaze is shown in F1 in Table 4. The formula of the roller pattern is shown in C5 in Table 6.

[0091] The resulting ceramic tiles are Figure 4 As shown, its surface presents a natural flowing color effect, resembling the flowing color of green clouds.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com