Patents

Literature

60results about How to "Meet decoration needs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ink-jet penetrated polished semitransparent ceramic sheet, and preparation method thereof

The invention relates to an ink-jet penetrated polished semitransparent ceramic sheet. The ink-jet penetrated polished semitransparent ceramic sheet comprises a semitransparent green body containing an ink dyeing assistant agent, and an ink jet penetrating layer penetrating into the semitransparent green body. According to a preparation method, the ink dyeing assistant agent is added into the semitransparent green body, and ink jet penetrating technology is adopted, so that penetration of patterns into the semitransparent green body is realized, polishing is carried out directly after sintering, green body surface particle flatness is excellent, stain resistance is excellent, pattern wear resistance is excellent, and requirements on highlight products are satisfied, adding of a transparent glaze layer onto the surface of the green body is not necessary, cost is reduced, a problem that bonding of the glaze layer with the green body is poor is solved, production deformation cracking is avoided, the preparation method of the green body is simple, adding of non-transparent preform body is unnecessary, and in addition, the semitransparent green body contains the ink dyeing assistant agent, so that the color of the patterns used for decoration is bright, sharpness is high, and decoration requirements can be satisfied preferably.

Owner:MONALISA GRP CO LTD

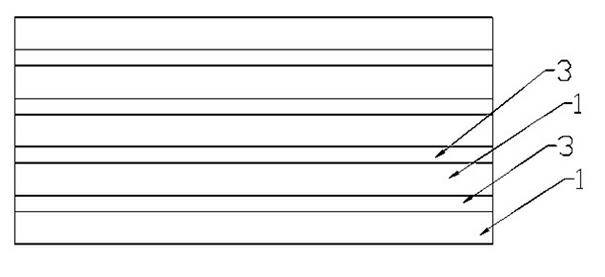

High-density composite board specially used for wood floor and manufacturing method thereof

ActiveCN102409835AChange material propertiesMeet the decoration needsWood working apparatusFlooringHigh energyHigh pressure

The invention relates to a high-density composite board specially used for a wood floor and a manufacturing method thereof. The manufacturing method comprises the following steps of: taking wood from a reproducible quickly growing tree as a main raw material; forming a wood modifier by water-soluble phenolic resins, preservatives, sulphonating lignin and liquid bentonite; modifying a veneer or wood strip and then forming a blank together with non-woven fabrics; and gluing the blank under high temperature and high pressure, thereby manufacturing the high-density composite board with a density of 0.8-1.2g / cm<3>. The wood property of wetting swelling and drying shrinkage of the wood is changed, thereby being capable of meeting the demands of the wood floor on various indexes, such as hardness, dimensional stability, appearance, foot feeling, mechanical property, environmental protection, and the like. Instead of natural hard wood, the high-density composite board specially used for the wood floor is used for manufacturing the wood floor, thereby meeting a floor decorative requirement of people while protecting a natural forest, reducing the usage of high energy-consumption floor decorative materials such as cement and ceramic tiles, and indirectly achieving an effect of energy conservation and emission reduction.

Owner:内蒙古清研沙柳产业工程技术中心有限公司

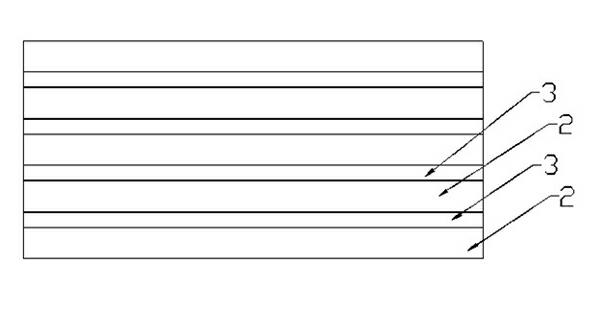

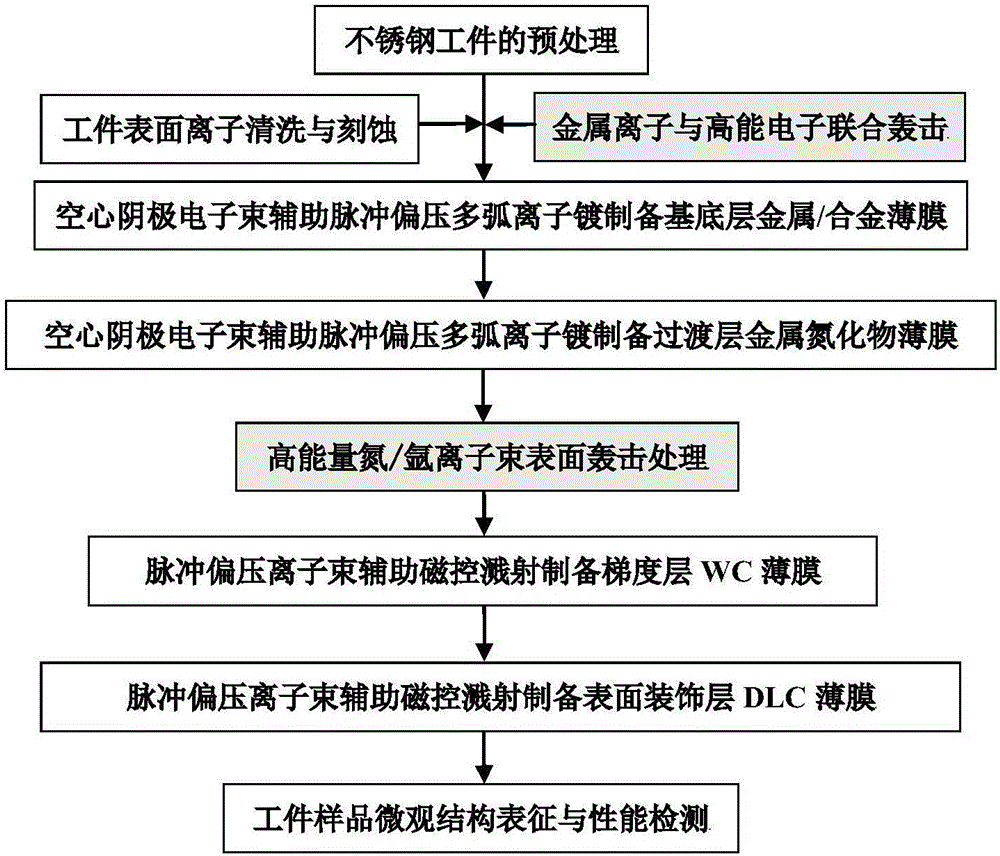

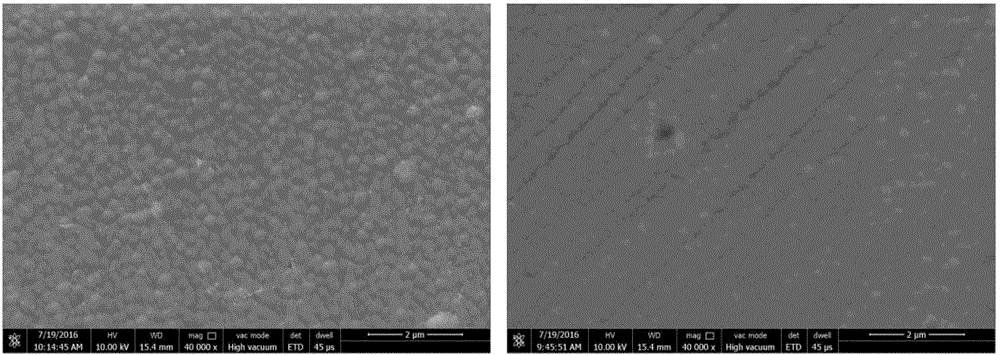

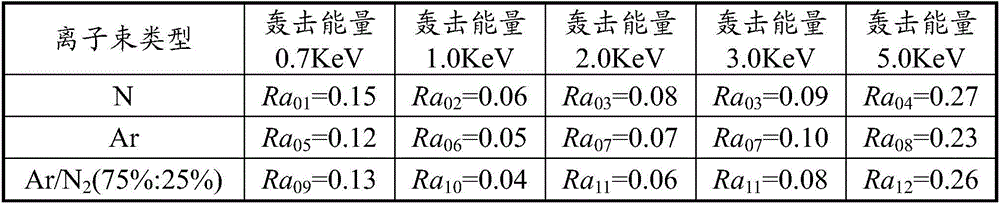

Functionally-graded diamond-like carbon film as well as preparation method and product of functionally-graded diamond-like carbon film

ActiveCN106244986AReduce manufacturing costImprove defectsVacuum evaporation coatingSputtering coatingCarbon filmCorrosion

The invention relates to a functionally-graded diamond-like carbon film as well as a preparation method and a product of the functionally-graded diamond-like carbon film. The preparation method of the functionally-graded diamond-like carbon film comprises the following steps: (1) depositing a metal base layer on the surface of a work piece by virtue of hollow cathode electron beams secondarily combined with pulsed-bias multi-arc ion plating; (2) depositing a metal nitride transition layer on the surface of the metal base layer by virtue of hollow cathode electron beams accompanied with pulsed-bias multi-arc ion plating; (3) depositing a tungsten carbide gradient layer on the surface of the metal nitride transition layer by virtue of pulsed-bias multi-arc ion plating accompanied with magnetron sputtering; (4) depositing a diamond-like carbon decorative layer on the surface of the tungsten carbide gradient layer by virtue of pulsed-bias multi-arc ion plating accompanied with magnetron sputtering. The functionally-graded diamond-like carbon film prepared by the preparation method provided by the invention has the advantages of high glossiness, high interface bonding strength and high surface hardness and is also excellent in wear resistance, corrosion resistance and scratching resistance.

Owner:ZHUHAI ROSSINI WATCH IND +1

Decorative construction method for imitating effect of natural marbles by polyurethane coating

InactiveCN101660336AFeel mildMeet the needs of decorationCovering/liningsPolyurethane coatingVarnish

The invention provides a decorative construction method for imitating an effect of natural marbles by a polyurethane coating. The method comprises the following steps of: 1, polishing raw materials; 2, sparing a transparent base coating of polyurethane; 3, polishing; 4, spraying a high yellow resistant white base coating of polyurethane; 5, polishing; 6, spraying a high yellow resistant white basecoating of polyurethane; 7, polishing; 8, spraying a high yellow resistant matt white finish coating of polyurethane; 9, GLAZE spraying; 10, gaining marble textures by beating; 11, sparing a high yellow resistant transparent base coating of polyurethane; 12, polishing; and 13, spraying a high yellow resistant matt varnish of polyurethane, and obtaining the finished product. The method achieves the effect of imitating the natural marbles, offers a warm touch feel in winter and meets decoration requirement.

Owner:上海展辰涂料有限公司 +2

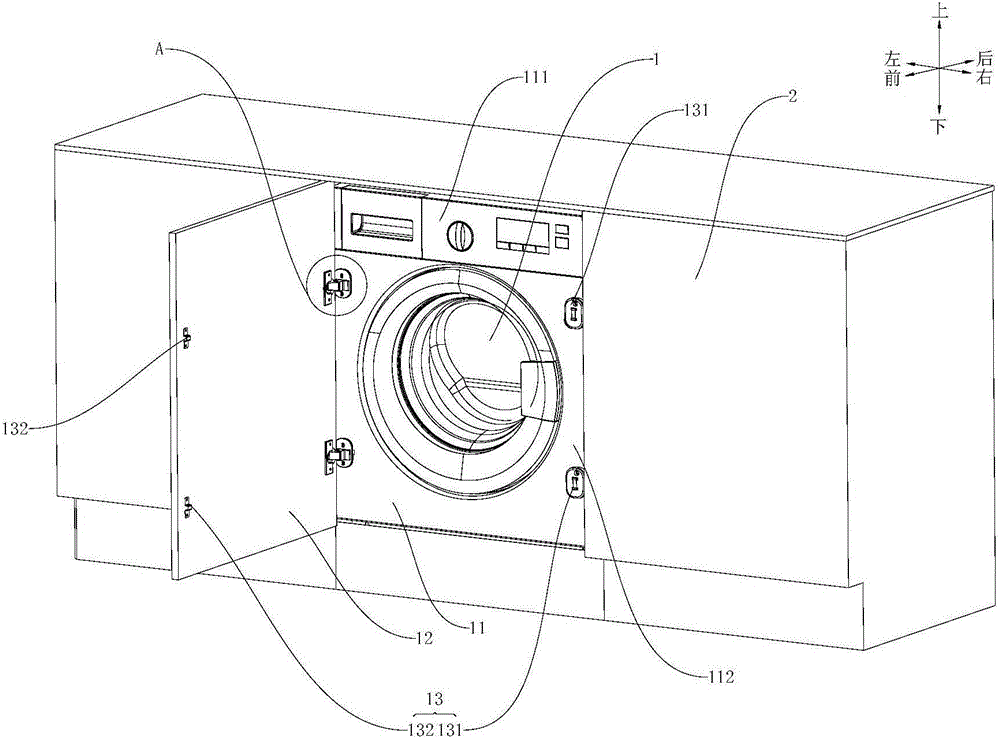

Shell assembly for washing machine and washing machine

ActiveCN105063970AImprove assembly effectMeet the decoration needsOther washing machinesTextiles and paperMechanical engineeringEngineering

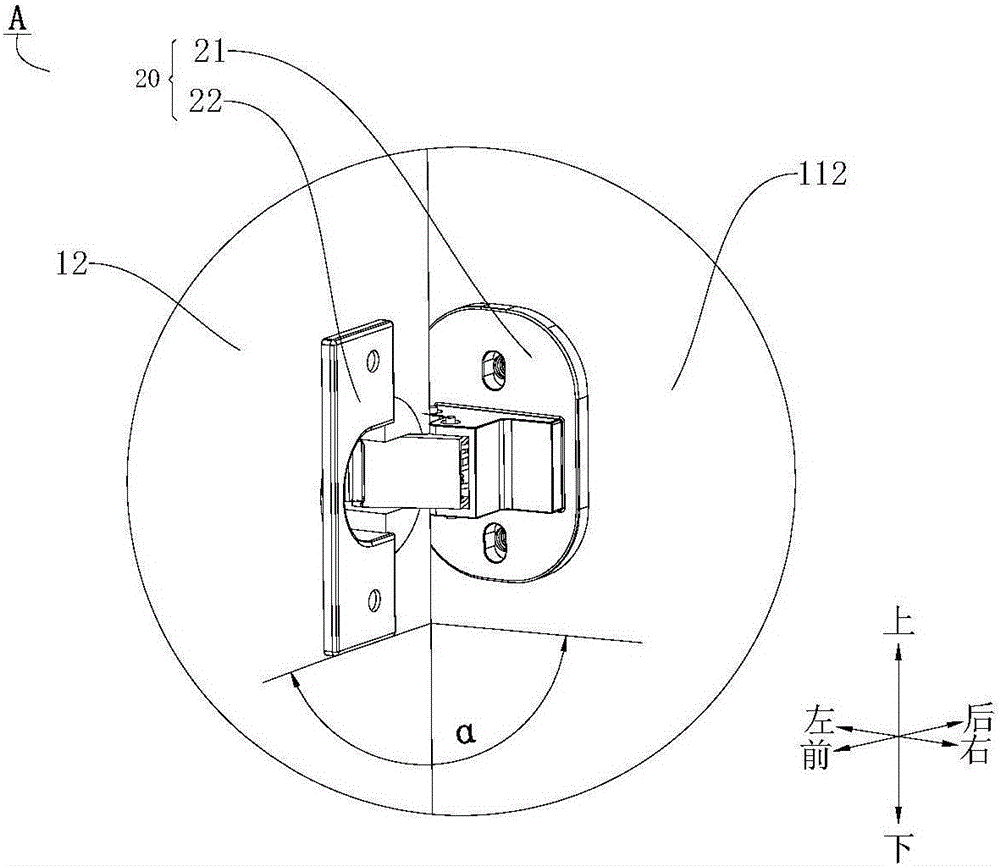

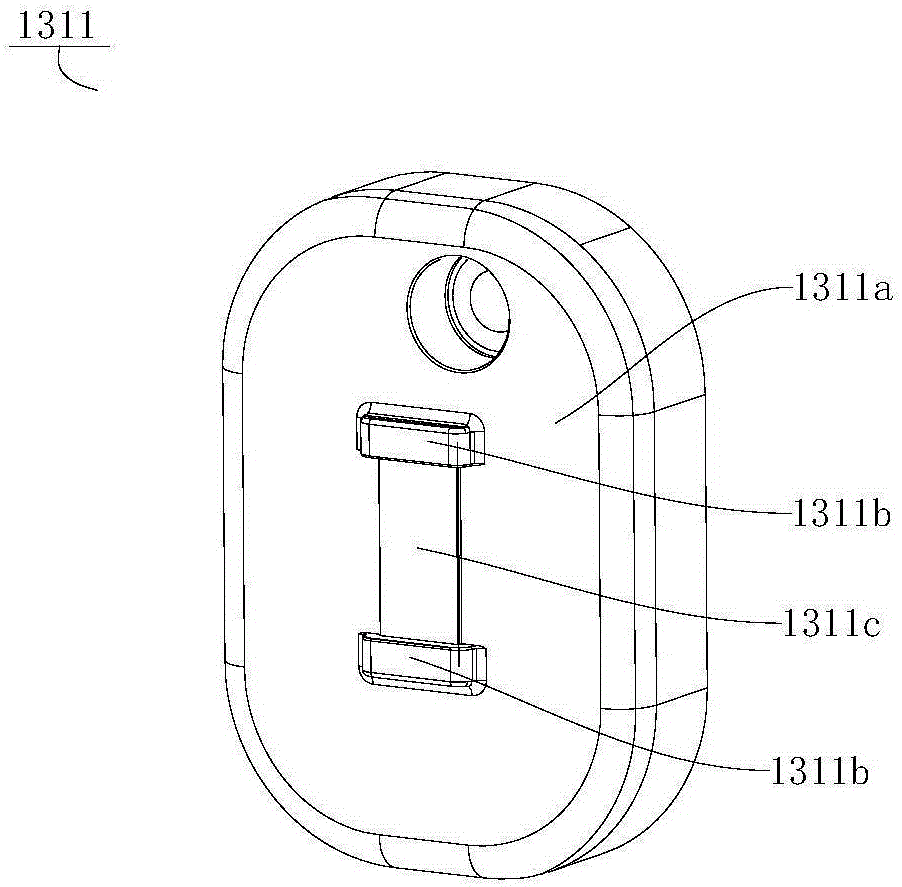

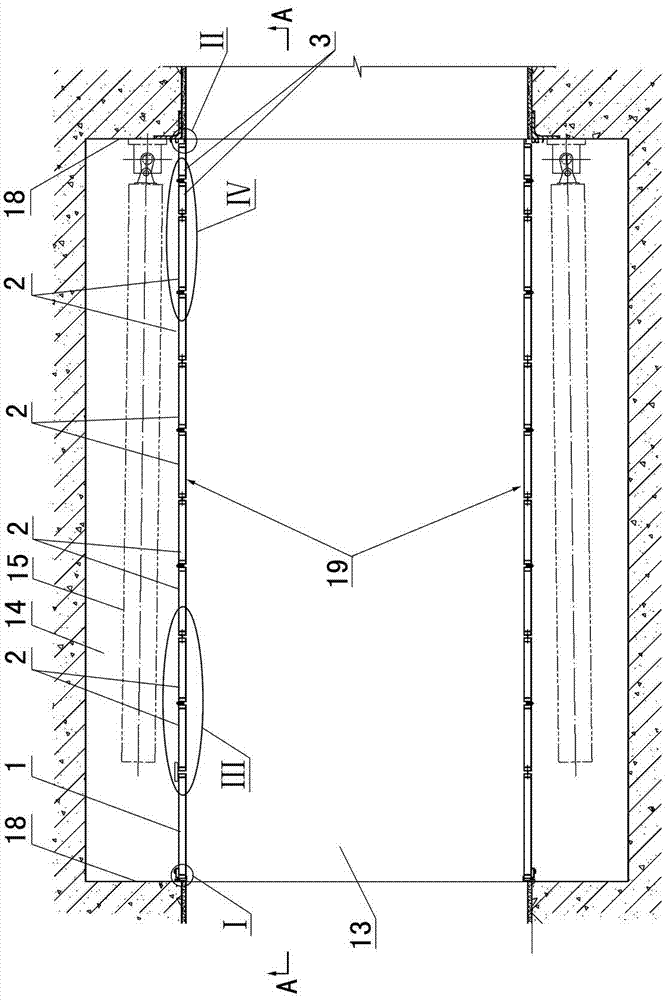

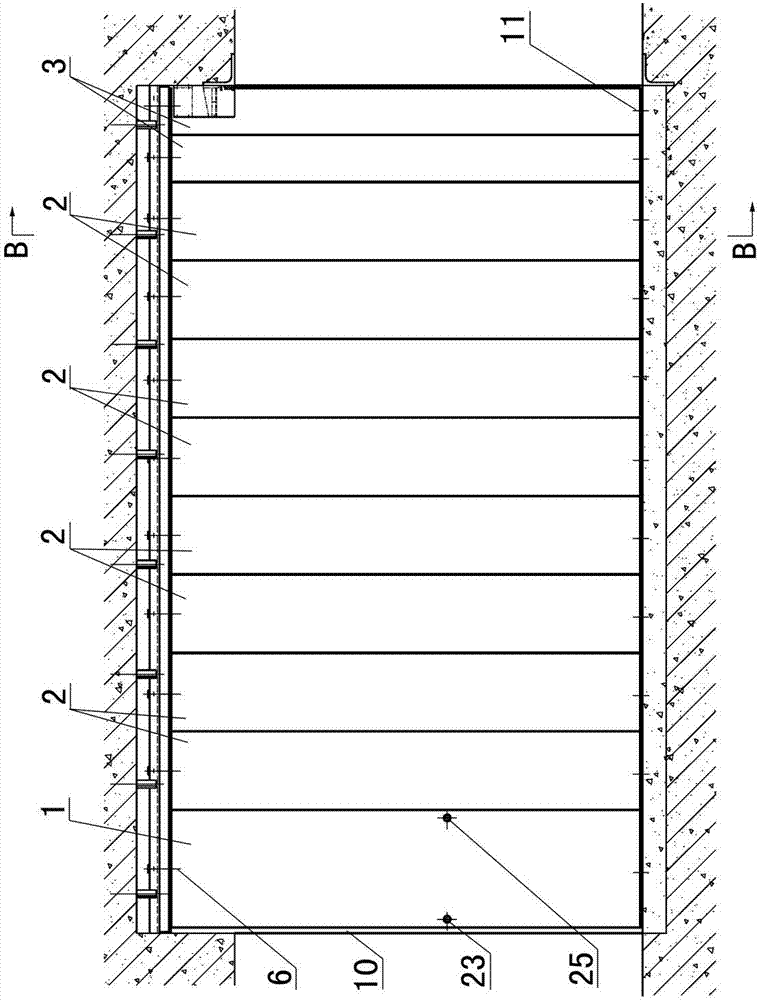

The invention discloses a shell assembly for a washing machine and the washing machine. The washing machine is suitable for being placed in a cabinet and comprises a shell, a cover body, a hinge assembly and a buckling assembly. The shell is arranged inside the cabinet and comprises a mounting panel, and the mounting panel is arranged on the side, facing an opening of the cabinet, of the shell. One end of the hinge assembly is connected with the mounting panel, and the other end of the hinge assembly is connected with the cover body so that the cover body can open or close the opening. The buckling assembly comprises a first buckling part and a second buckling part suitable for being buckled with the first buckling part. The first buckling part is arranged on the mounting panel, and the second buckling part is arranged on the cover body. According to the washing machine, the washing machine can be integrally embedded in the cabinet, the cover body can be tightly attached to the mounting panel when closing the opening so that the cover body can be limited in the opening closed position, and therefore the assembling effect of the washing machine and the cabinet can be improved.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

Leopard spot glaze with wide sintering range, as well as preparation method and application thereof

The invention provides a leopard spot glaze with a wide sintering range. The glaze comprises ground glaze and cover glaze, wherein the ground glaze is prepared from the following components in parts by weight: 30-70 parts of basic transparent glaze, 3-7 parts of MnO, 4-7 parts of Fe2O3, 3-5 parts of Cr2O3 and 30-50 parts of low-temperature clinker; and the cover glaze is prepared from the following components in parts by weight: 20-50 parts of basic transparent glaze, 8-10 parts of vanadium-zirconium blue, 3-5 parts of ZnO and 50-80 parts of low-temperature clinker. The glaze has a wide sintering range, has vivid leopard spot decorating effect, and can well enrich the decorating means of art and craft ceramics.

Owner:山西省玻璃陶瓷科学研究所(有限公司)

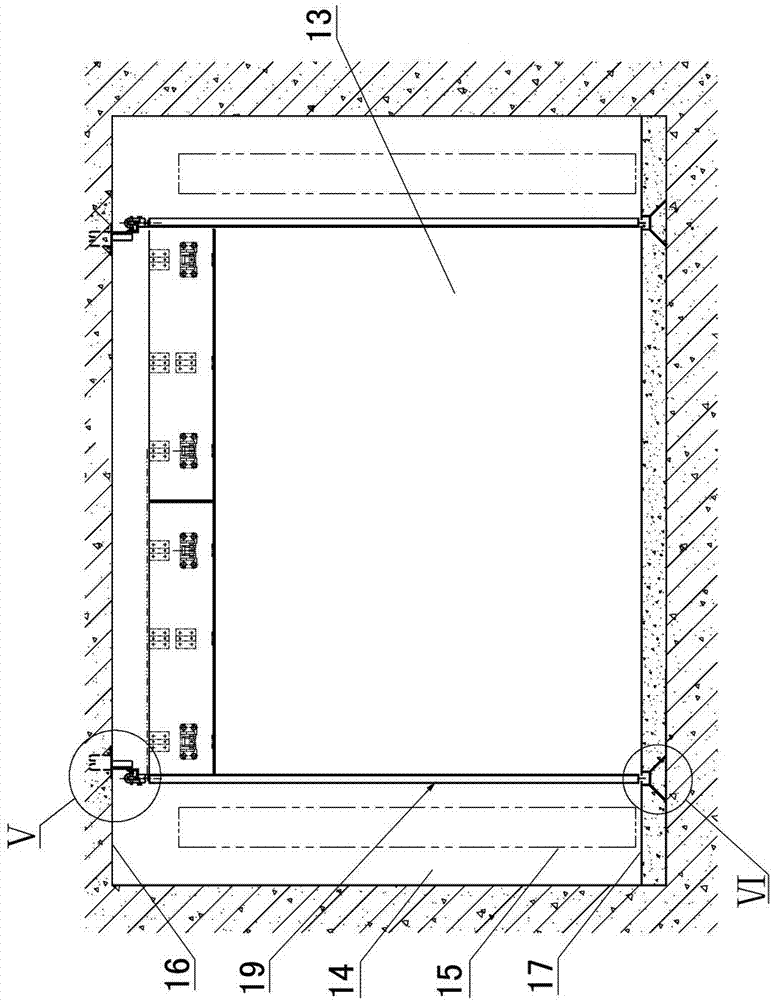

Folding type disguising door of protective section of subway entrance and subway exit

ActiveCN103089122AQuick closeMeet the decorative performance requirementsWar-like protectionEngineeringMechanical engineering

A folding type disguising door of a protective section of a subway entrance and a subway exit comprises door leaves. The door leaves are arranged on doorways of protective door concealing chambers at the left side and the right side of a personnel gallery. The door leaves are composed of a free door leaf, at least one middle door leaf and a side door leaf. A mortise lock is arranged at one side of each free door leaf. A door frame is arranged on a side wall, near each free door leaf, of the protective door concealing chamber and a spring bolt hole matched with the mortise lock is formed in the door frame. The other side of each free door leaf is provided with a closed lock matched with the middle door leaf in use. A guide rail is arranged on a ceiling above each door leaf and a guide rail groove is formed in the ground below each door leaf. The disguising door has functions of decoration and disguising so that a function of a disguising protective door is achieved and rapid closing of the protective door is not influenced.

Owner:4TH DESIGN & RES INST OF ENGINEER CENT STAFF PLA

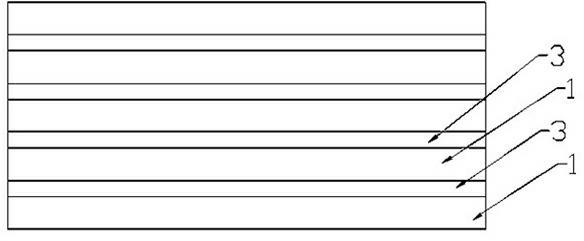

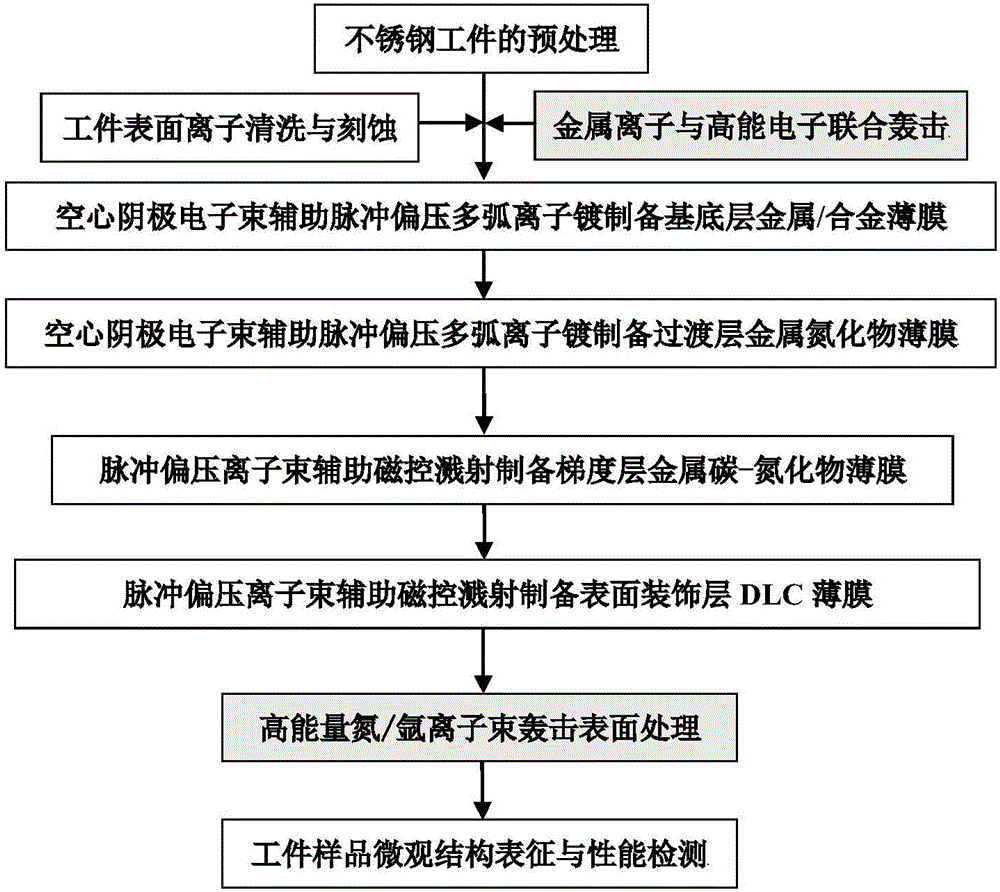

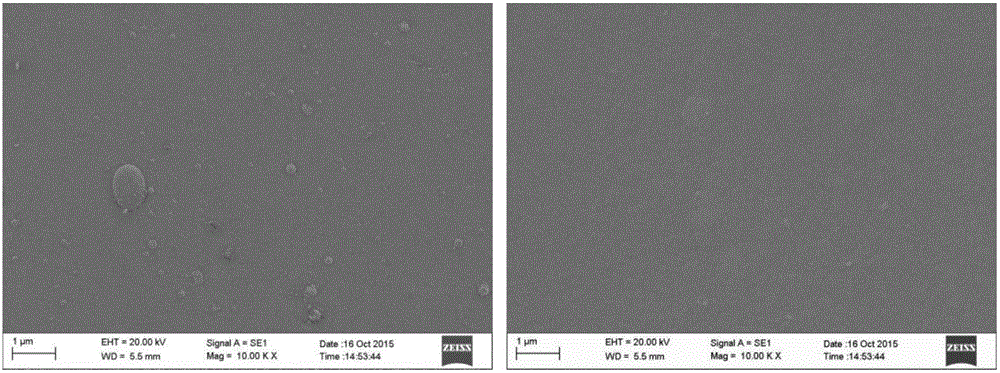

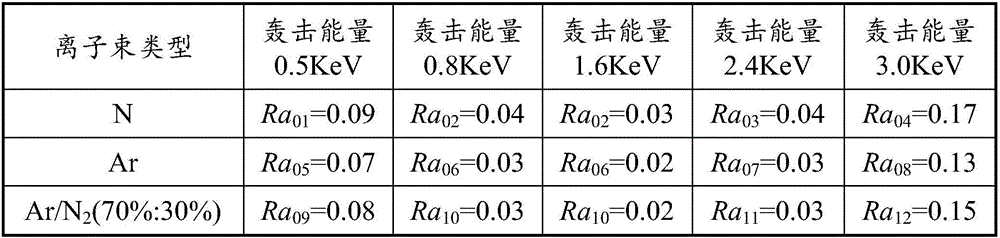

Functionally-gradient diamond-like carbon film and preparing method and product of functionally-gradient diamond-like carbon film

ActiveCN106119783AMaintain good performanceReduce manufacturing costVacuum evaporation coatingSputtering coatingCarbon filmDiamond-like carbon

The invention relates to a functionally-gradient diamond-like carbon film and a preparing method and product of the functionally-gradient diamond-like carbon film. The preparing method of the functionally-gradient diamond-like carbon film includes the steps that firstly, hollow cathode electron beam auxiliary pulsed bias voltage multi-arc ion plating is used for depositing a metal substrate layer on the surface of a workpiece; secondly, hollow cathode electron beam auxiliary pulsed bias voltage multi-arc ion plating is used for depositing a metal nitride transitional layer on the surface of the metal substrate layer; thirdly, pulsed bias voltage ion beam auxiliary magnetron sputtering is used for depositing a metal carbon-nitride gradient layer on the surface of the metal nitride transitional layer; and fourthly, pulsed bias voltage ion beam auxiliary magnetron sputtering is used for depositing a diamond-like carbon decoration layer on the surface of the metal carbon-nitride gradient layer. The diamond-like carbon film prepared through the preparing method has the beneficial effects of being high in glossiness, high in interface bonding strength and high in surface hardness, and in addition, wear resistance, corrosion resistance and scratching preventing performance are good.

Owner:ZHUHAI ROSSINI WATCH IND +1

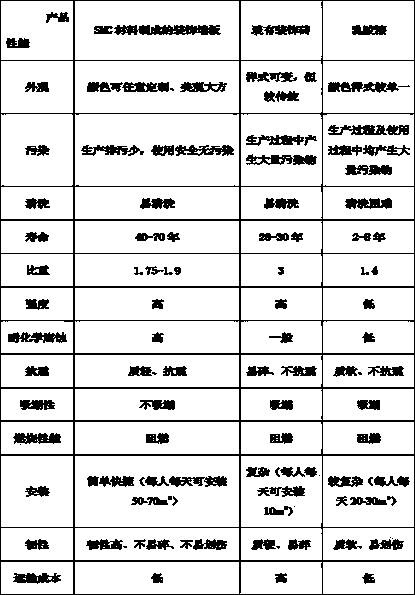

New applications of sheet molding compound (SMC) material

InactiveCN103410290AEasy to handleReduced service lifeCovering/liningsFencingSheet moulding compoundMaterials science

The invention belongs to the field of chemical materials and relates to new applications of a sheet molding compound (SMC) material, in particular to applications of the SMC material in building ornaments. According to tests, by applying the SMC material to the building ornaments, unexpected technical effects are achieved, and the people's requirements for decoration are met.

Owner:SICHUAN D&F ELECTRICAL TECH

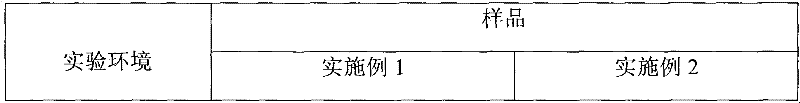

Construction method for preventing polyurethane clear lacquer film from blushing

InactiveCN102049375AAvoid blushingNo whitish phenomenonPretreated surfacesPolyurea/polyurethane coatingsLacquerTest chamber

The invention relates to a construction method for preventing a polyurethane clear lacquer film from blushing. The method comprises the following steps: step (1), conducting sanding on materials; step (2), conducting coloring on the materials; step (3), brushing or spraying anti-blushing sealing priming lacquer; step (4), brushing or spraying polyurethane clear priming lacquer, and then repeating step (4) for two times; and step (5), brushing or spraying polyurethane clear finishing lacquer, and obtaining the polyurethane clear lacquer film after drying for 24 to 36 hours. Compared with the prior art, the invention has the benefits that the method can effectively prevent the polyurethane clear lacquer film from blushing; after the polyurethane clear lacquer film is placed in the atmospheric environment or in the constant temperature and humidity test chamber for one month after construction, no blushing phenomenon occurs; and the polyurethane clear lacquer film obtained after construction is fresh and natural, has the effect of imitation of natural marble, is tangible in winter and bulky in hand, feels gentle and can meet the demands of decoration.

Owner:上海展辰涂料有限公司

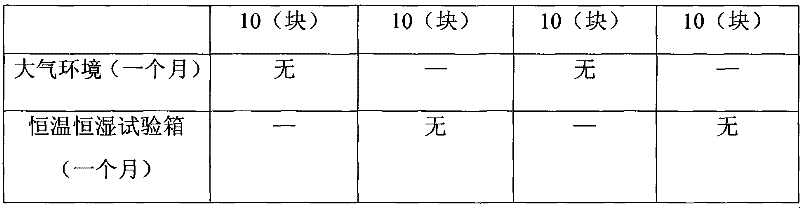

Plated piece and preparation method thereof

ActiveCN103572207AReduce internal stressImprove bindingLayered productsVacuum evaporation coatingSiliconMetal substrate

A coated article includes a metal substrate, a TiSiN layer formed on the metal substrate, and a TiN layer formed on the TiSiN layer. The TiSiN layer consists essentially of elemental Ti, elemental Si, and elemental N in non-homogenous deposition. The elemental Si within the TiSiN layer has a mass percentage gradually decreasing from the bottom of the TiSiN layer near the substrate to the top of the TiSiN layer away from the substrate. The elemental N has a mass percentage gradually increasing from the bottom of the TiSiN layer near the substrate to the top of the TiSiN layer away from the substrate. The TiN layer consists essentially of elemental Ti and elemental N. A method for making the coated article is also described.

Owner:FIH PRECISION ELECTRONICS LANG FANG CO LTD

Television background wall and construction method thereof

InactiveCN101906868AMeet psychological needsSatisfy material enjoymentBuilding constructionsVisual perceptionCable television

The invention discloses a television background wall and a construction method thereof. The construction method of the television background wall comprises the following steps of: sanding base materials; spraying white polyurethane base coat; sanding; spraying white nitryl base coat; spraying yellow drawing paint; spraying red nitryl crackle paint; sanding; spraying transparent nitryl base coat; sanding; and spraying transparent nitryl finishing coat. The invention has simple method, low cost and high practicability; in addition, the television background wall manufactured by the method has simple and bright appearance, and color lines are interlaced together to form a color reticular structure so as to provide simple, plain and magnificent visual effect for people.

Owner:上海展辰涂料有限公司

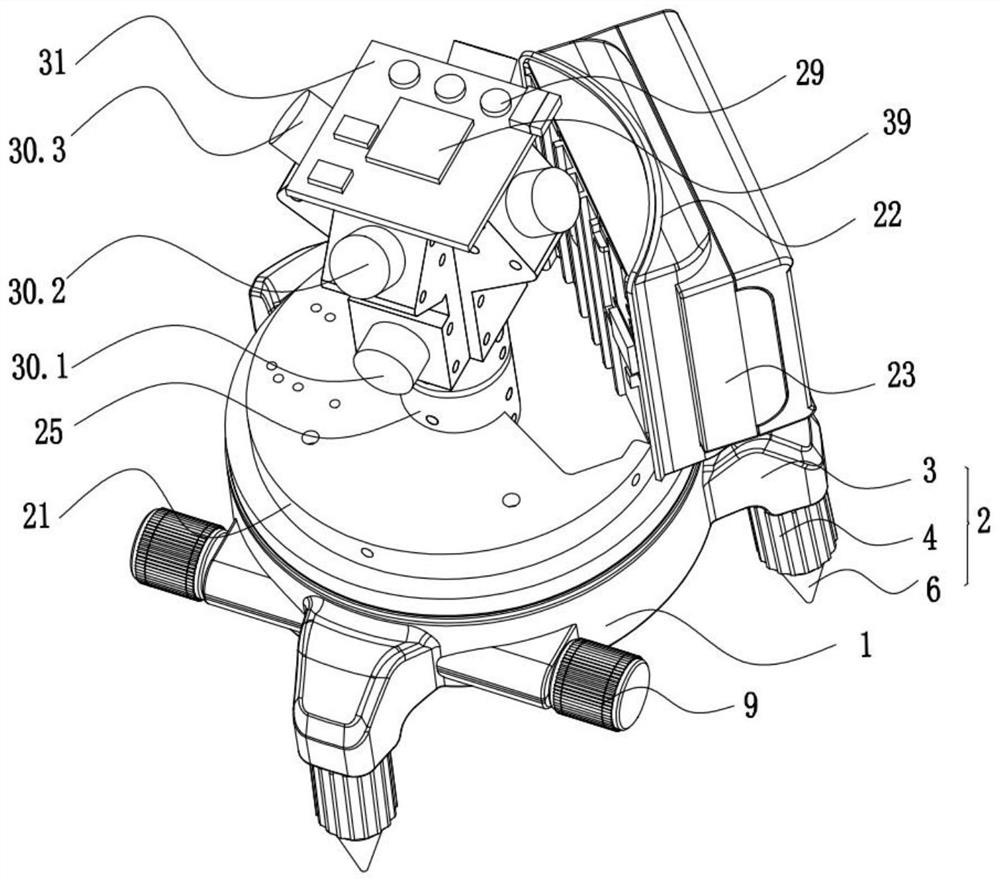

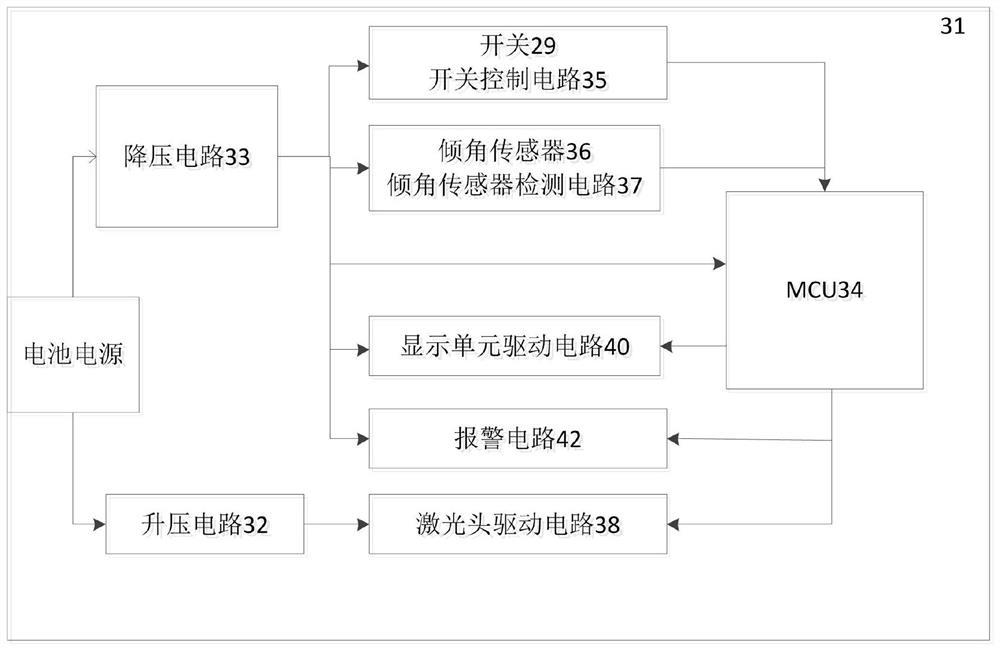

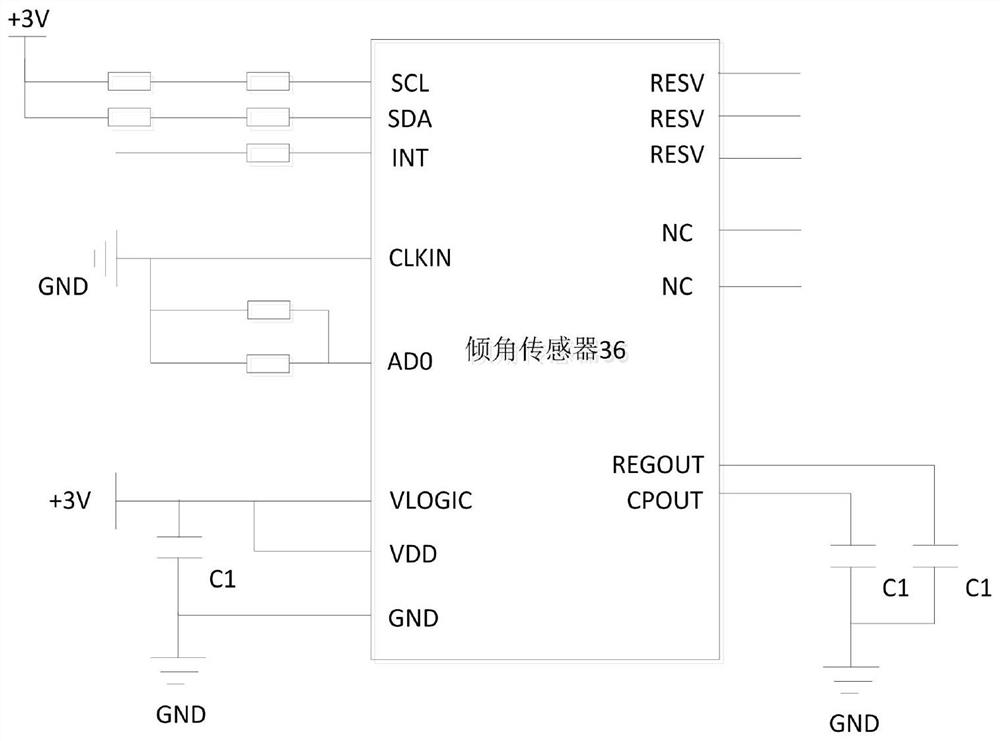

Laser demarcation device

PendingCN112268552AHigh sensitivityHigh precisionSpeed measurement using gyroscopic effectsPlumb lines for surveyingEngineeringLaser line

The invention discloses a laser demarcation device, which comprises a base, a battery bin, a shell, a laser window located on the shell, a supporting seat located in the shell, a laser head, a controller, a display unit and a switch, wherein the supporting seat is arranged on a rotating seat, the laser head, the controller and the switch are arranged on the supporting seat, the controller comprises an inclination angle sensor, at least one measuring axis of the inclination angle sensor is parallel to at least one laser ray emitted by the laser head, and the base is an angle-adjustable base. According to the demarcation device, the assembly process is simplified, the production cost is greatly saved, and the function of projecting oblique lines can be achieved.

Owner:王宇坤

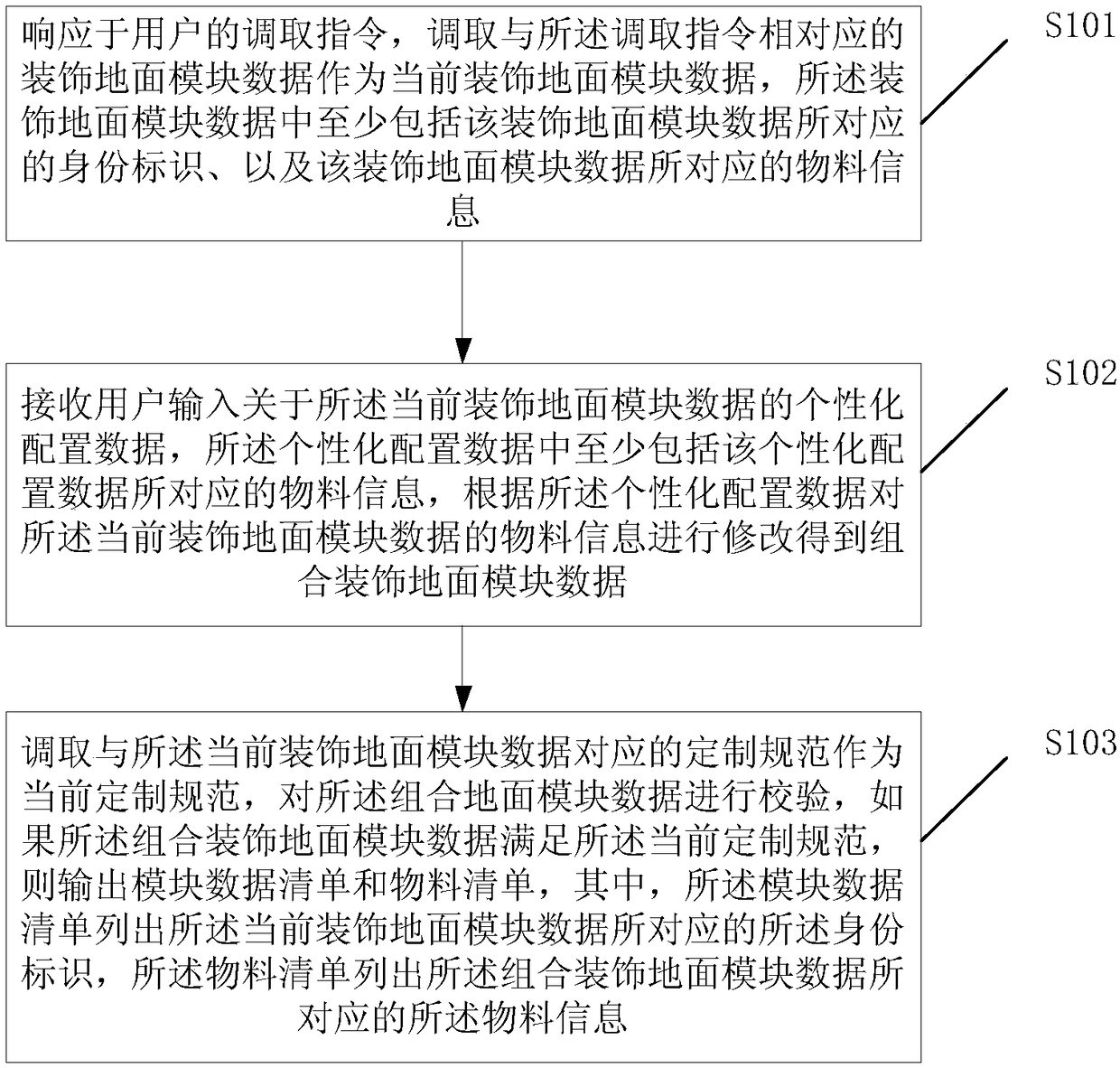

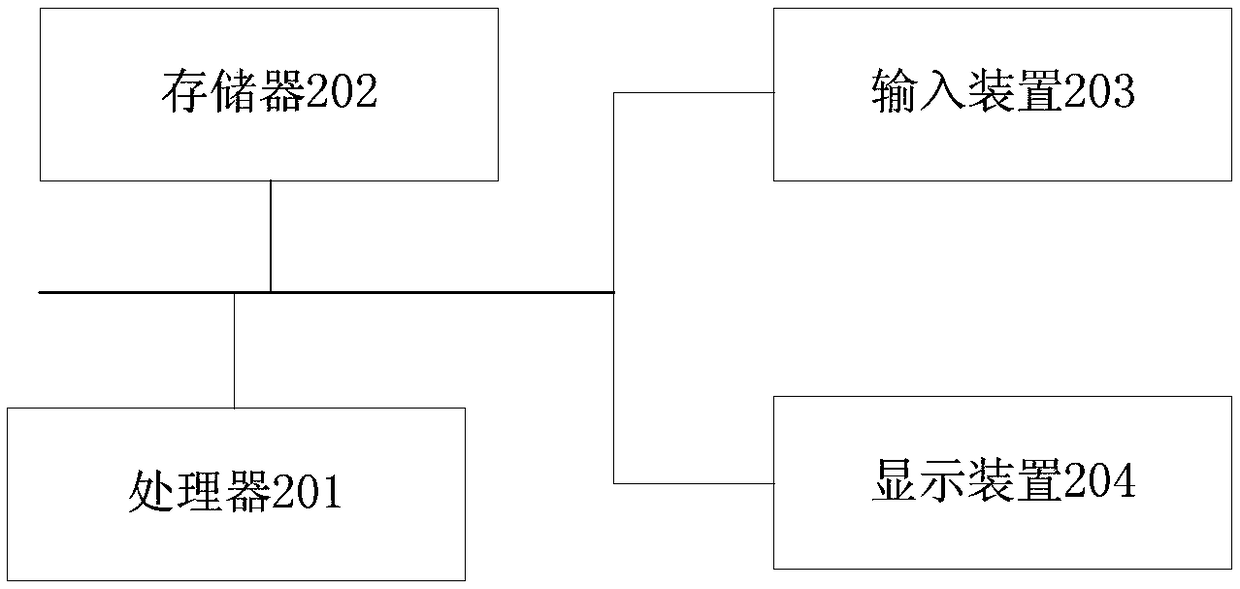

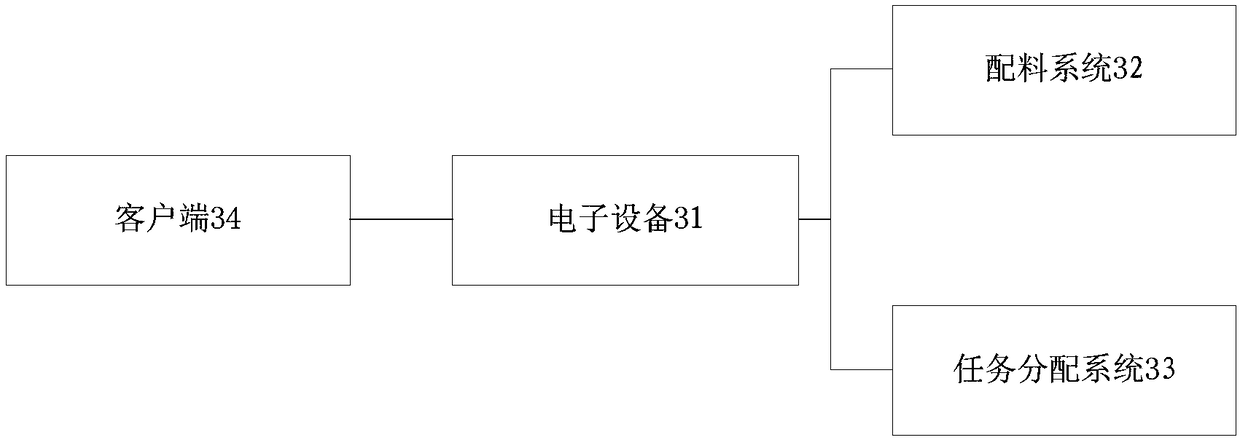

Building ground decoration industrial data processing method, electronic device and storage medium

PendingCN108229014AIncrease profitMeet decoration needsGeometric CADSpecial data processing applicationsPersonalizationUser input

The invention discloses a building ground decoration industrial data processing method, an electronic device and a storage medium. The method includes the steps of responding to a calling instructionof a user, calling decoration group module data corresponding to the calling instruction as current decoration ground module data, receiving individualized configuration data related to the current decoration ground module data and input by the user, modifying material information of the current decoration ground module data according to the individualized configuration data to obtain combined decoration ground module data, calling a customizing standard corresponding to the current decoration ground module data as a current customizing standard, verifying the combined ground module data, andoutputting a module data list and a material list if the combined decoration ground module data meets the current customizing standard. With the building decoration part modularization as the core, the industrial production organization as the basis and the on-site decoration type construction as the means, a novel assembly type ground system suitable for industrialization on the Internet era is obtained.

Owner:ZHEJIANG YASHA DECORATION

Method for producing woven traditional-handwork-like carpet

InactiveCN1851079ARich and varied colorsThe composition is novel and uniqueWoven fabricsFloor carpetsYarnEngineering

The invention relates to the producing method of the machine plaiting imitating traditional handwork rug, it includes the following steps: dying the yarn: the feather yarn used for the machine plaiting rug is stained period dying according to the needing of matching colors, the same thread of yarn is dyed to two different colors in the degree of color depth; falling canister: the falling canister is performed according to the fine hair yarn using arrange of the common machine plaiting produce; preparing the cotton latitude: the pure cotton latitude satisfying the plaiting intension needing of the above machine is seethed the 45-50 minutes in advance, cooled, tossing to dry and drying by the fire 10 hours under the temperature 80-85 degree to perform the shrinking dealing, then it is fell coil to standby; the pattern designing; the machine plaiting rug; the offspring handling; handling according to the offspring handling of the traditional handwork rug. The invention adopts the sect dying feather yarn, the plaiting rug of the cotton latitude, the handwork casting the channel, the pressing the light, repairing again and the tangling the border, so the produced machine plaiting rug produced has the sensing sight and the using effect resembling with the handwork rug to satisfy the decorating needing of the high taste client.

Owner:HONGYE CARPET QIANAN CITY

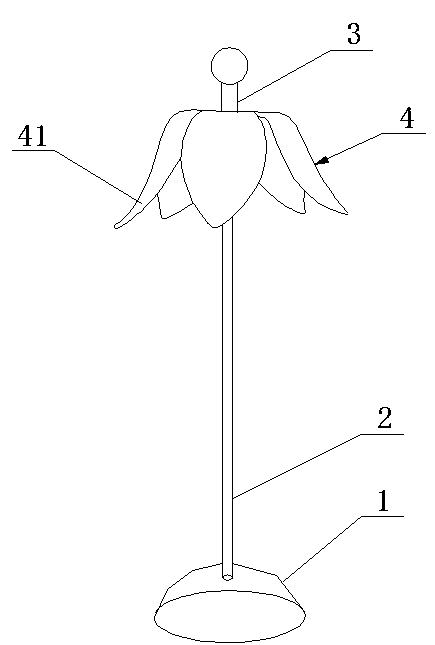

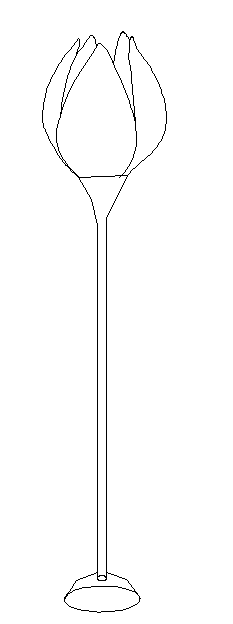

Foldable floor lamp

InactiveCN103851399AMeet decoration needsDifferent decorative effectsGlobesLight fasteningsEngineeringPetal

The invention relates to a foldable floor lamp which comprises a base, a support rod and a lamp holder. A lampshade is mounted on the lamp holder. The lampshade comprises petal-shaped lampshade faces. The lampshade faces are annularly distributed on the lamp holder and rotatably connected with the lamp holder. Every two optional adjacent lampshade faces are in zipper fit. The foldable floor lamp has the advantages that the petal-shaped lampshade faces are used, the lampshade can be closed to form a flower bud or spread to form a flower according to needs, different decorating effect can be achieved, and the decoration requirements of different indoor environments can be satisfied.

Owner:重庆星维烽电子商务有限公司

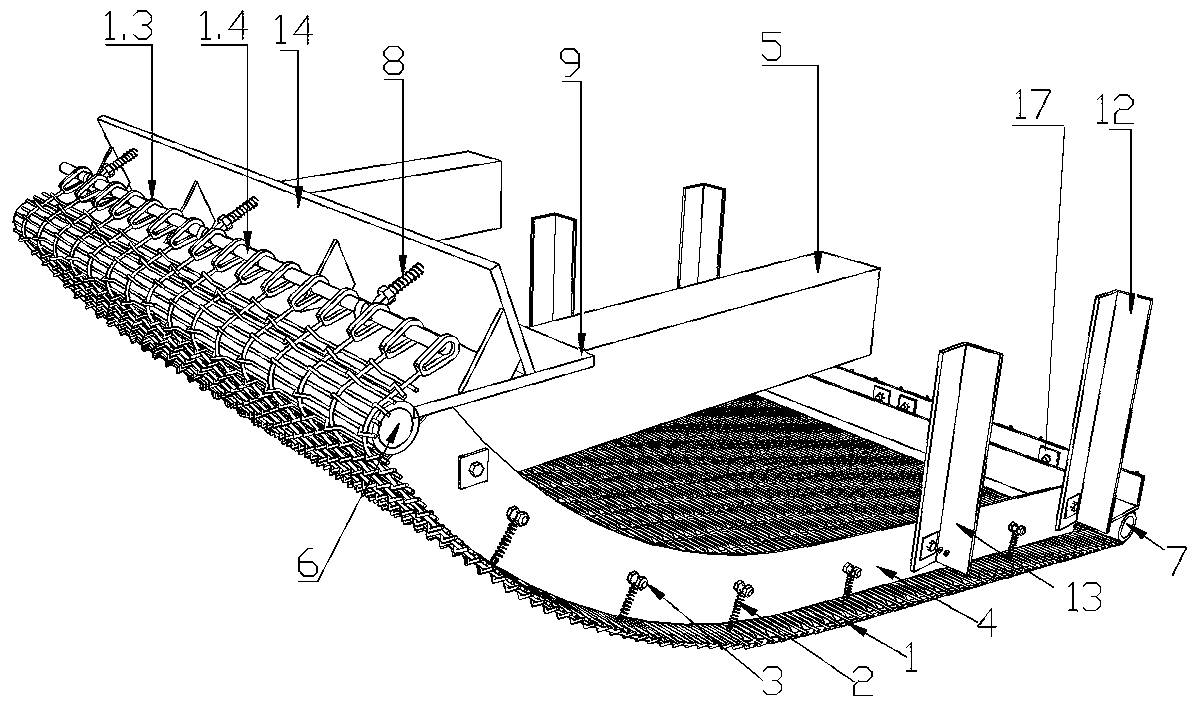

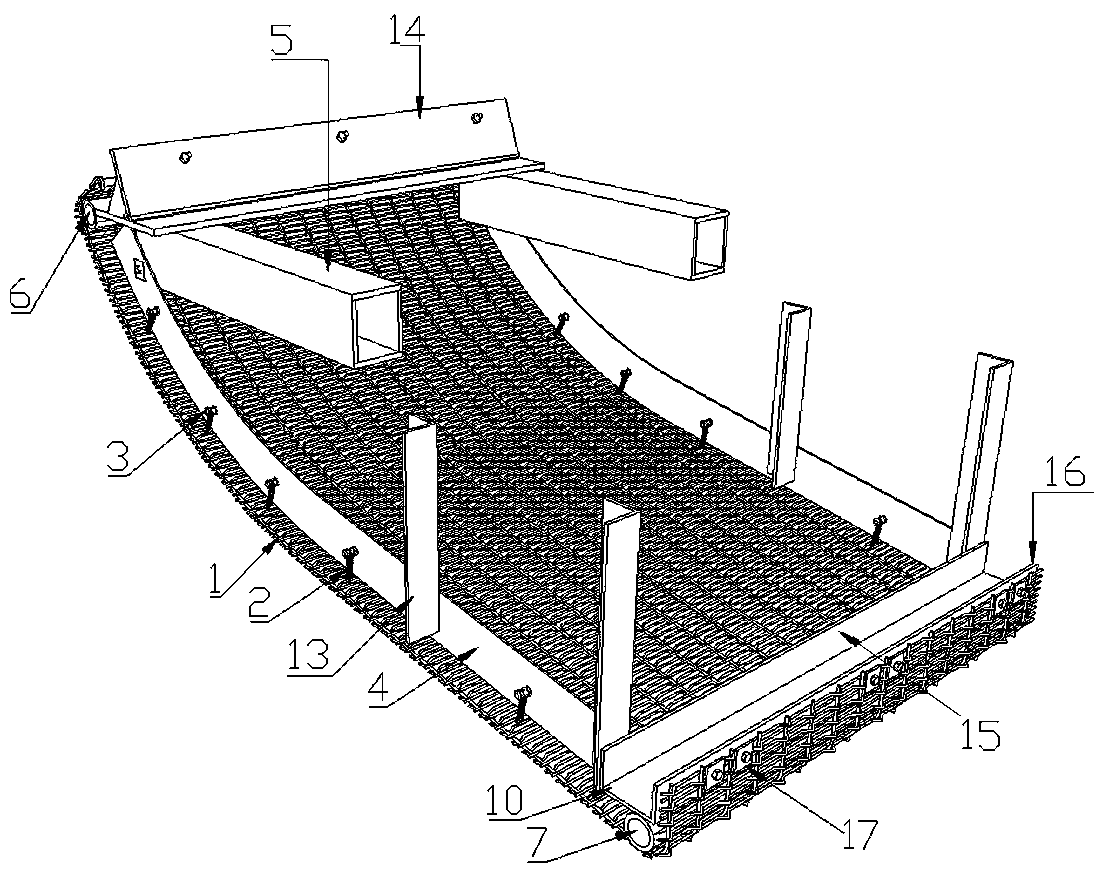

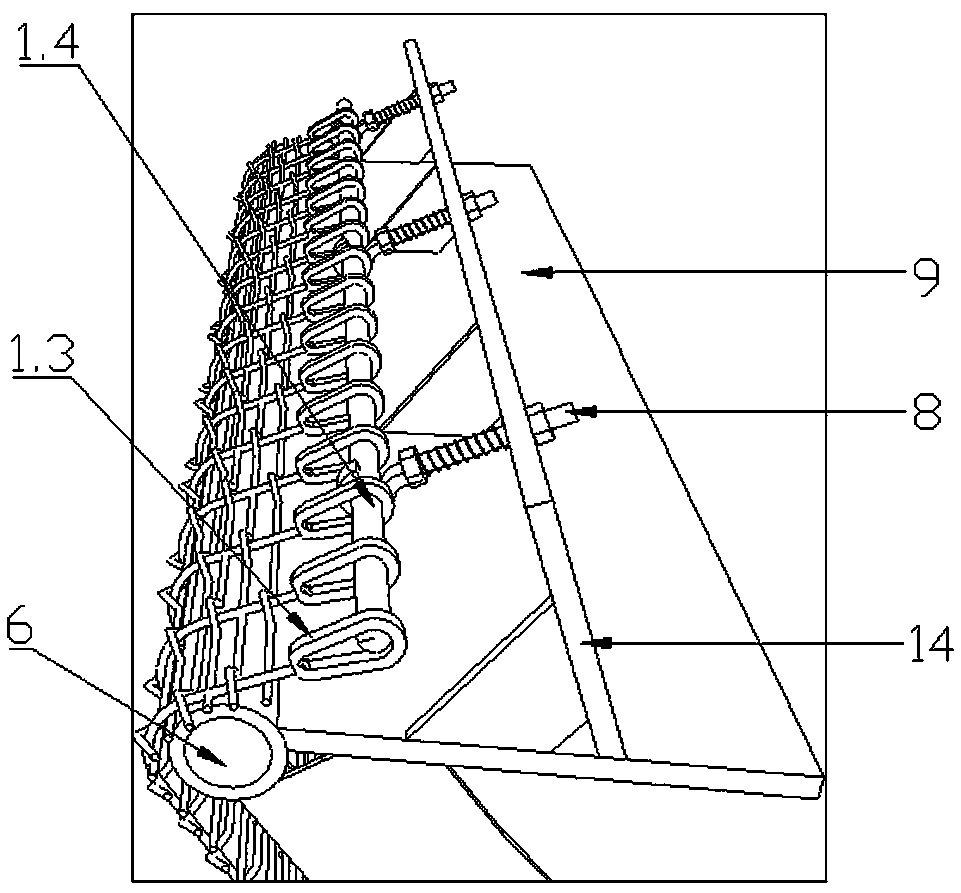

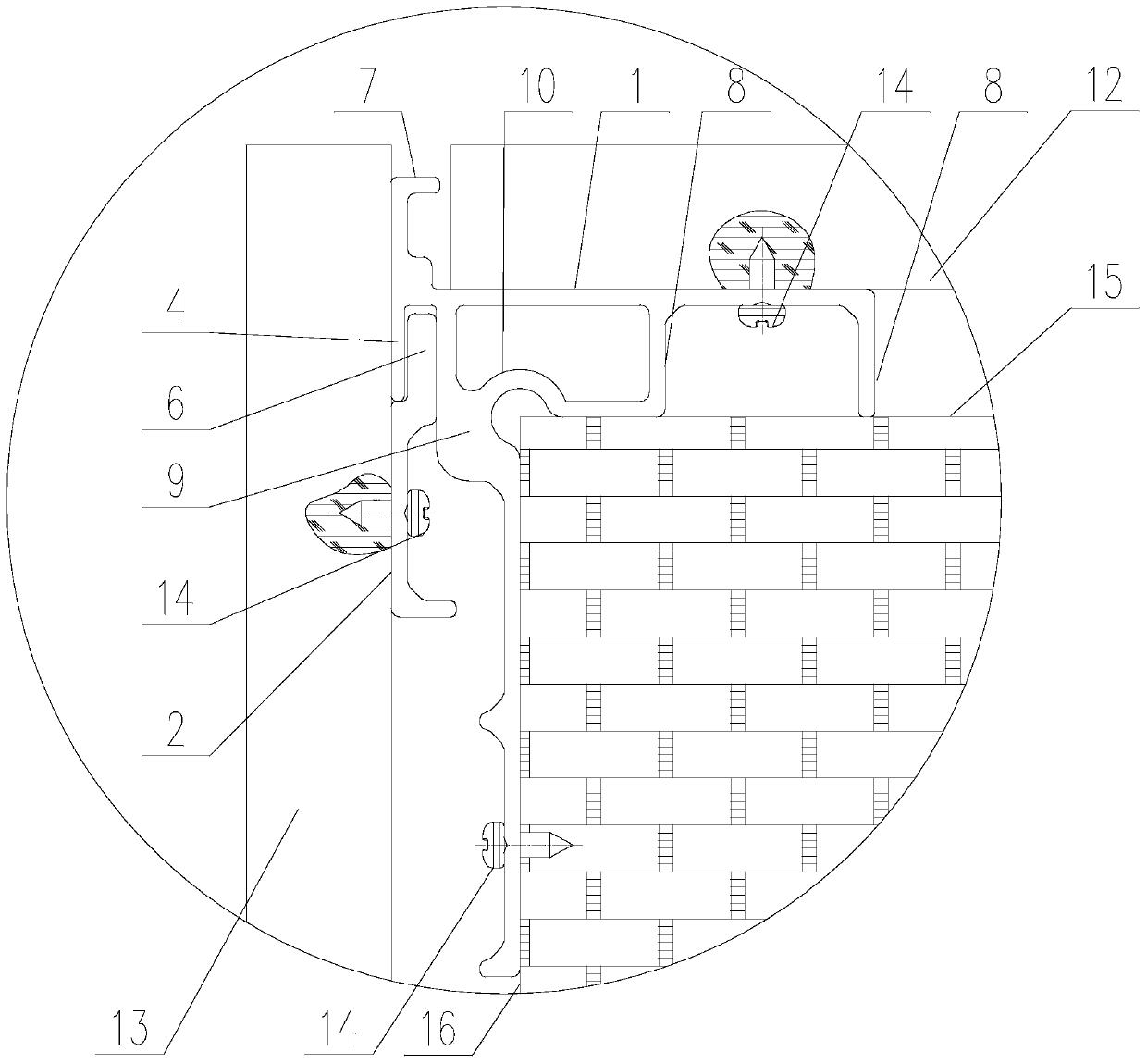

Tensioning metal net suspended ceiling system and construction method thereof

The invention discloses a tensioning metal net suspended ceiling system and a construction method thereof. The suspended ceiling system comprises a suspended ceiling frame and a metal net laid on thesuspended ceiling frame. The suspended ceiling frame comprises an upper tensioning support, a lower fixing base, two arc-shaped keels arranged between the upper tensioning support and the lower fixingbase, a tensioning end top-support round tube, a fixed end top-support round tube, a tension bolt group, a compression bolt group, a base layer cross bar and a first base layer vertical rod; the upper tensioning support comprises a rectangular horizontal bearing plate and a tensioning plate arranged on the top face of the horizontal bearing plate, and the included angle between the tensioning plate and the horizontal bearing plate is 30 degrees to 70 degrees; the tensioning plate is provided with a hole through which a tensioning bolt passes; and in the long edge direction of the horizontal bearing plate, the tensioning end top-support round tube is arranged at the end close to the long edge of the outer side of the horizontal bearing plate. The system is reasonable in design, simple to assemble, high in practicability, low in cost and easy to maintain later. Compared with an existing suspended ceiling structure, the suspended ceiling structure is simple and good in using effect.

Owner:DECORATION CO LTD OF CHINA CONSTR 3RD ENG BUREAU

Wall decorative material with Chinese art paper texture and application

InactiveCN108442624AWith rice paper textureStrong three-dimensional senseCovering/liningsCoatingsTextileMetallurgy

The invention relates to a wall decorative material with Chinese art paper texture and application. The wall decorative material with the Chinese art paper texture uses glass fiber surface felt or glass fiber cloth as a base material, a surface coating material is coated on the surface of the base material, and the wall decorative material is obtained after curing. The coating method is roller coating, spraying or batch coating. The glass fiber surface felt or the glass fiber cloth is a novel wall decorative material and has fabric effect and strong stereoscopic impression, and can form decorative wall materials of various styles.

Owner:KAINUO QINGDAO CHEM BUILDING MATERIALS

Novel making method of machine-woven imitation traditional hand-made carpet

InactiveCN109957871ARich and varied colorsThe composition is novel and uniqueCarpetsWoven fabricsYarnEngineering

The invention discloses a novel making method of a machine-woven imitation traditional hand-made carpet. The method comprises the following steps: (1) dyeing yarns: carrying out space dye on the woolyarns used for making the machine-woven carpet according to the color matching requirement so as to enable the same yarn to be dyed with two colors with different distinct shades, wherein wool yarns for producing the machine-woven carpet is the same batch of pure wool white yarns, 12 metric counts *3 strands of the yarns are adopted, and 12-slot section dyeing is performed according to the requirement of color matching in different slots; (2) doffing; (3) preparing cotton weft: boiling pure cotton weft threads, meeting the machine weaving strength requirement, for 50-70min in advance, coolingand spin-drying, and drying for 12h for shrinkage at 70-80 DEG C, and doffing for later use; (4) carrying out pattern design; (5) obtaining a machine-woven carpet; (6) carrying out post-treatment: carrying out ditching, calendering, re-trimming and edge wrapping operations according to the traditional hand-made carpet post-treatment process.

Owner:天津鑫生源地毯有限公司

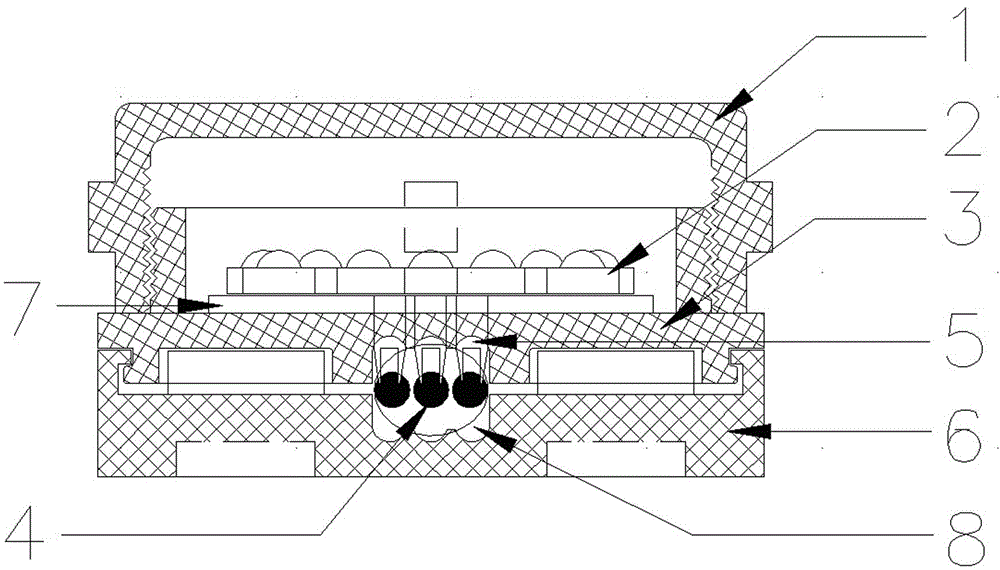

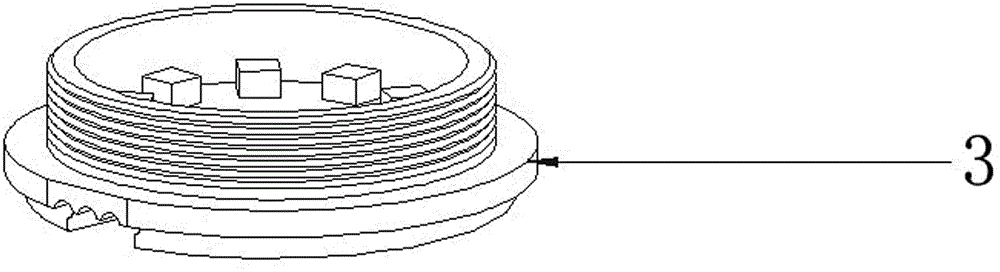

LED point light source lamp

InactiveCN104913208AEasy to adjust freelyMeet decoration needsPoint-like light sourceElectric circuit arrangementsElectricityInsulation layer

The invention relates to a lighting lamp, in particular to an LED point light source lamp for building brightening decoration. The LED point light source lamp comprises a lamp body (3) which is movably connected to a base (6), and a light source board (7) is arranged on the lamp body (3); LED lamp beads (2) and a driving circuit are arranged on the light source board (7), and wire passing grooves (8) allowing wires (4) of the light source board to pass through are formed between the lamp body (3) and the base (6); and conductive electrodes (5) are led out of the lower portion of the light source board (7), and under the external force effect, the conductive electrodes enter the wire passing grooves (8) and are connected with the wires (4). The acupuncture-shaped electrodes are adopted to puncture wire insulation layers to be electrically connected with the wires to get electricity, and a traditional method that the wires are welded to the electrodes of the light source board through an electric soldering iron is improved; the light source board is fixed to the lamp body through the electrodes, and the trouble of screw fixing is removed; meanwhile, free adjustment of a gap between lamps in the cascading process is further facilitated, and the requirement of a building of a special structure for decoration is met.

Owner:河南新飞利照明科技有限责任公司

Coloring process of cold-rolled titanium material

InactiveCN113088846AShort processImprove the efficiency of surface shading processingSolid state diffusion coatingTitaniumNitrogen gas

The invention discloses a coloring process of a cold-rolled titanium material, and belongs to the technical field of titanium material machining. The coloring process of the cold-rolled titanium material comprises the step that in the mixed atmosphere of nitrogen and inert gas, the cold-rolled titanium material subjected to degreasing treatment is subjected to annealing treatment, and then the titanium material with the colored surface is obtained. According to the coloring process, surface coloring treatment can be conducted on the cold-rolled titanium material while annealing treatment is conducted on the cold-rolled titanium material, the technological process is shortened, and the treatment efficiency is improved.

Owner:湖南湘投金天钛金属股份有限公司

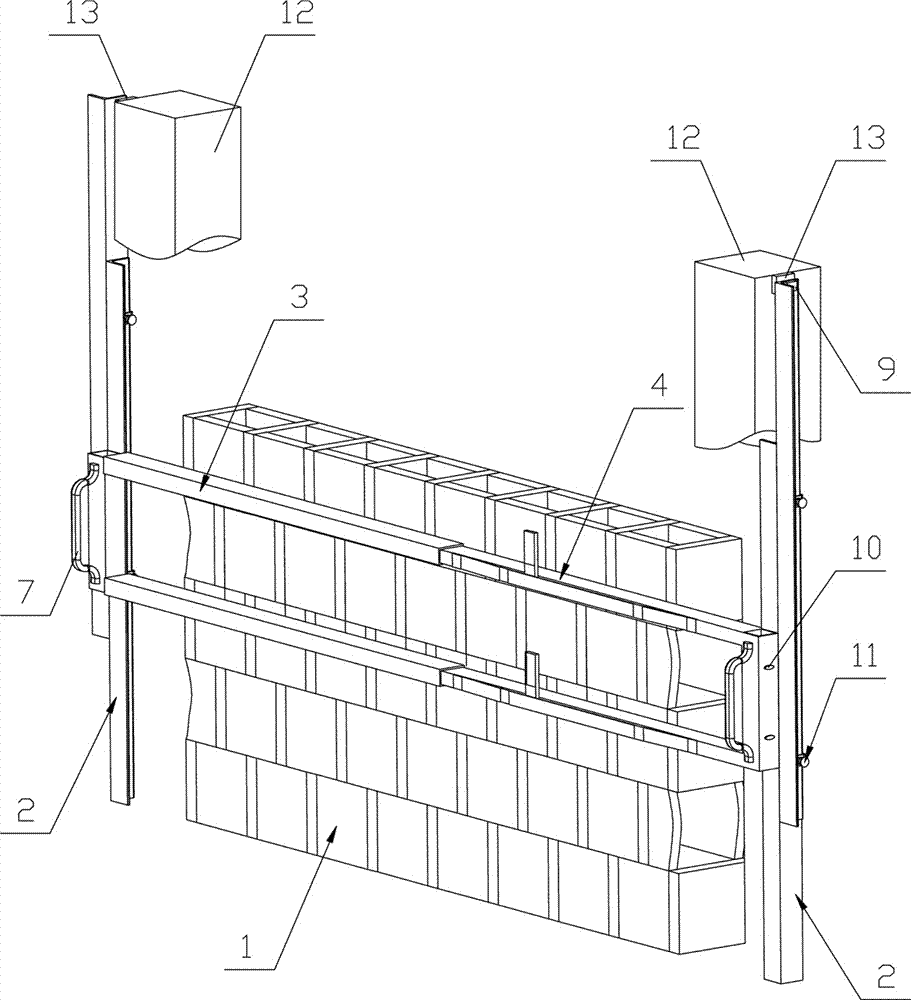

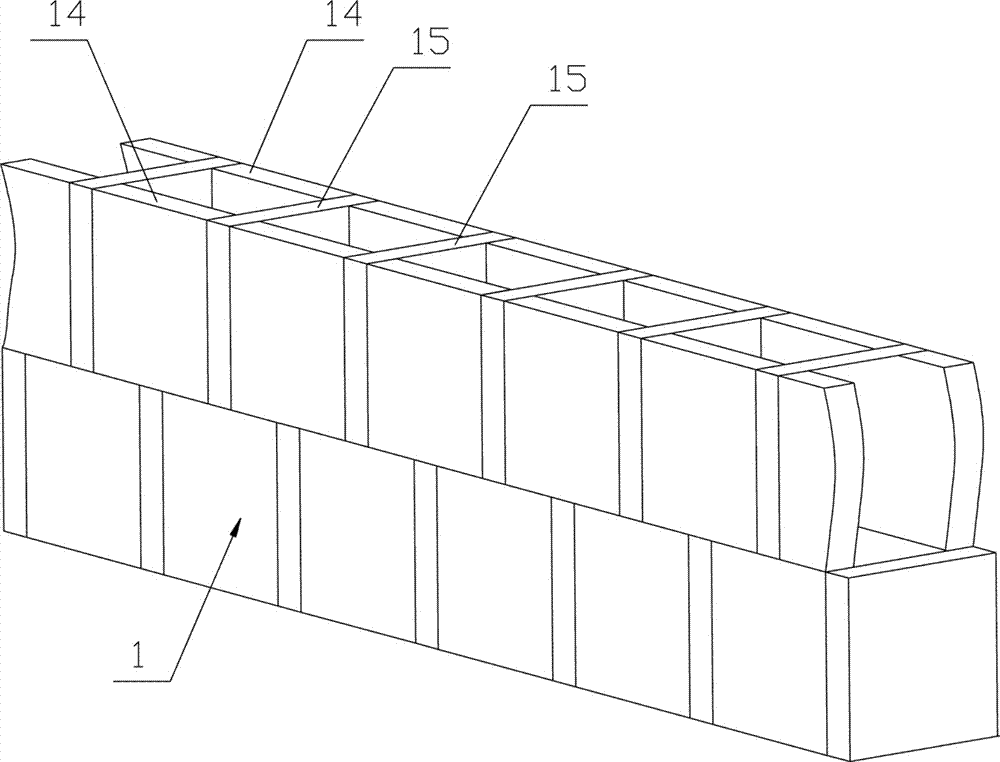

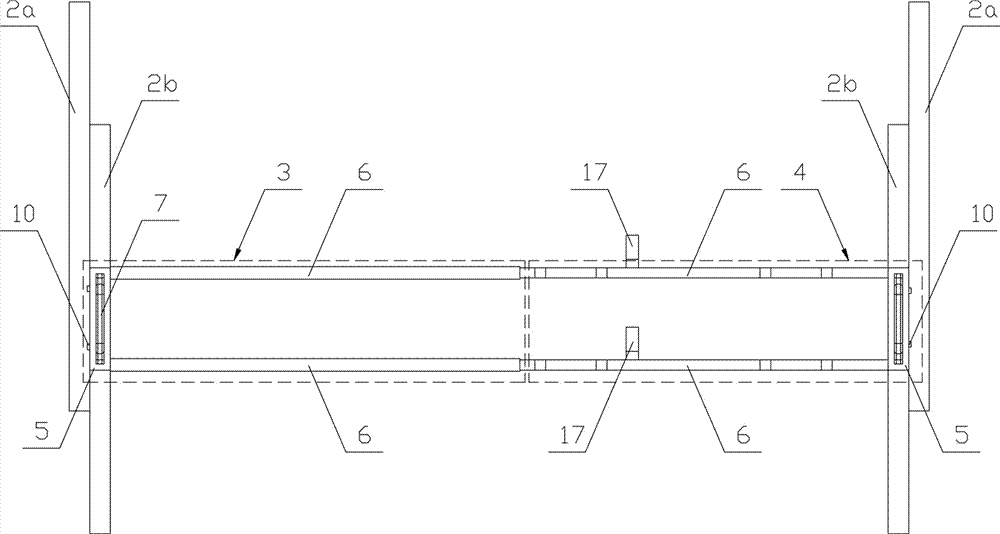

Lightweight, high strength, inexpensive and heat insulated rowlock wall masonry method

A light-weight, high-strength, cheap, and heat-retaining void wall masonry method, comprising the following masonry steps: (1) equipped with autoclaved aerated block bricks of the same specification; (2) building a profiling mechanism, which consists of The left and right two iron columns and the left and right formers are composed of the left and right formers, and the left and right formers are composed of the positioning side and the former; (3) adjust the installation height and height of the left and right formers on the left and right columns. Spacing; (4) Several groups of parallel bricks and small bricks are laid alternately along the direction of the formwork to build the first layer of the empty bucket wall. (5) according to the method described in step (3) and step (4), complete the masonry of the upper stratum empty bucket wall successively; the present invention has low masonry cost and convenient operation, The construction efficiency is high, and the empty bucket wall formed by masonry is light in weight, high in compressive strength, and good in insulation effect, which is convenient for installing expansion bolts on the wall and subsequent interior decoration, and is suitable for high-rise buildings.

Owner:顾业明

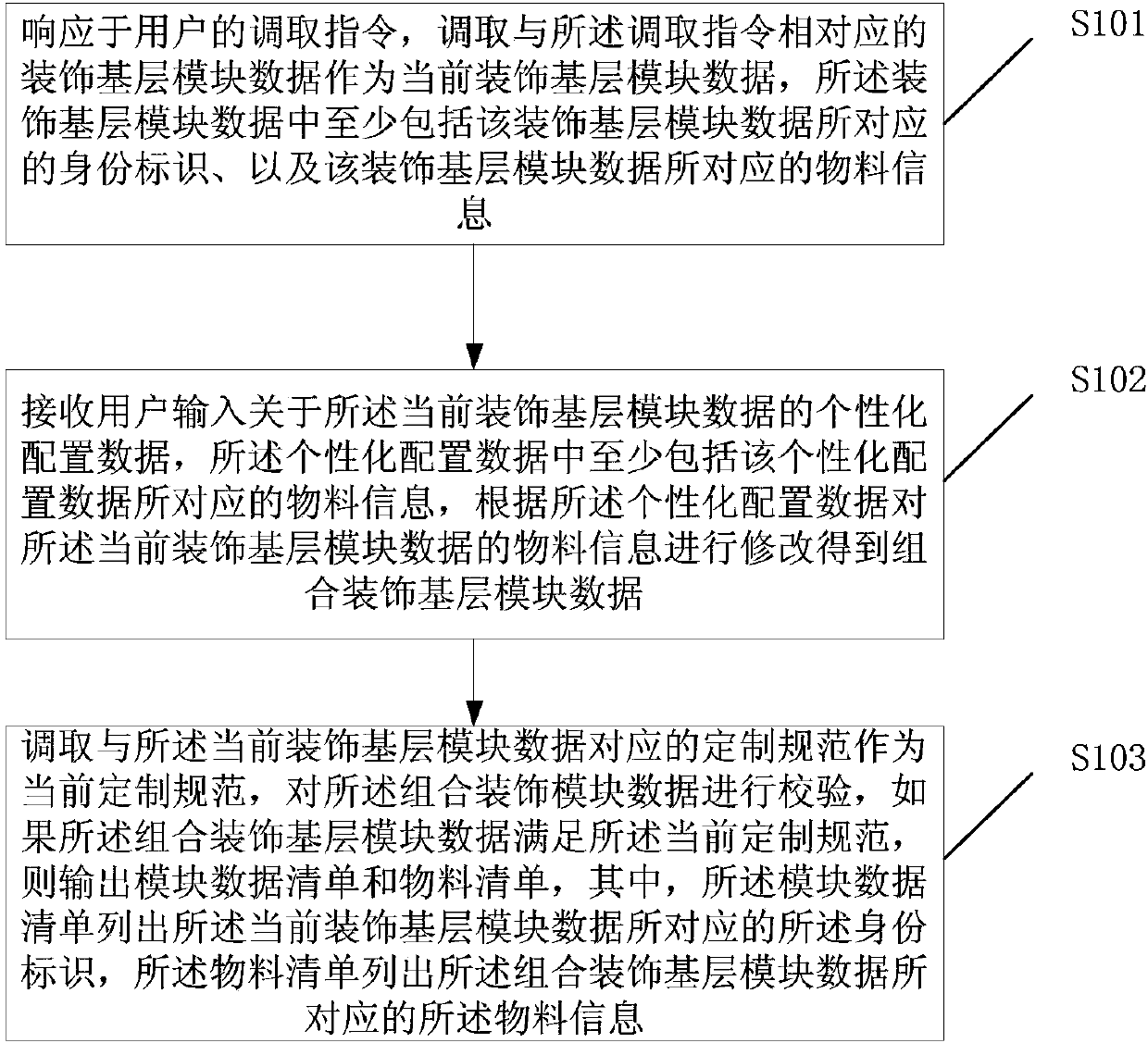

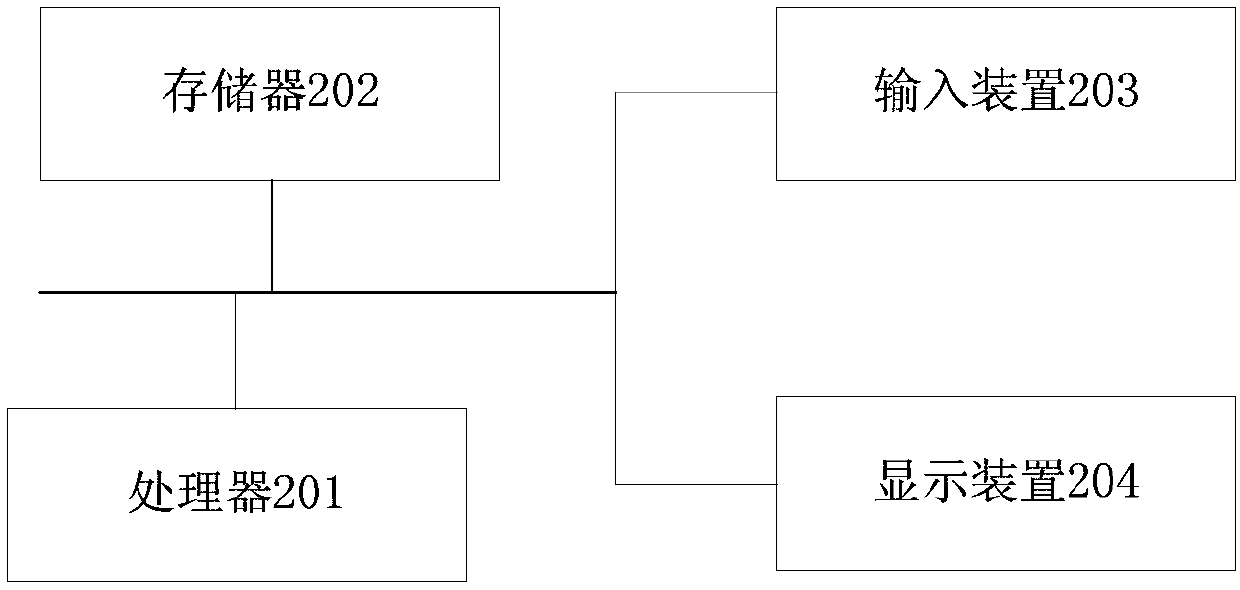

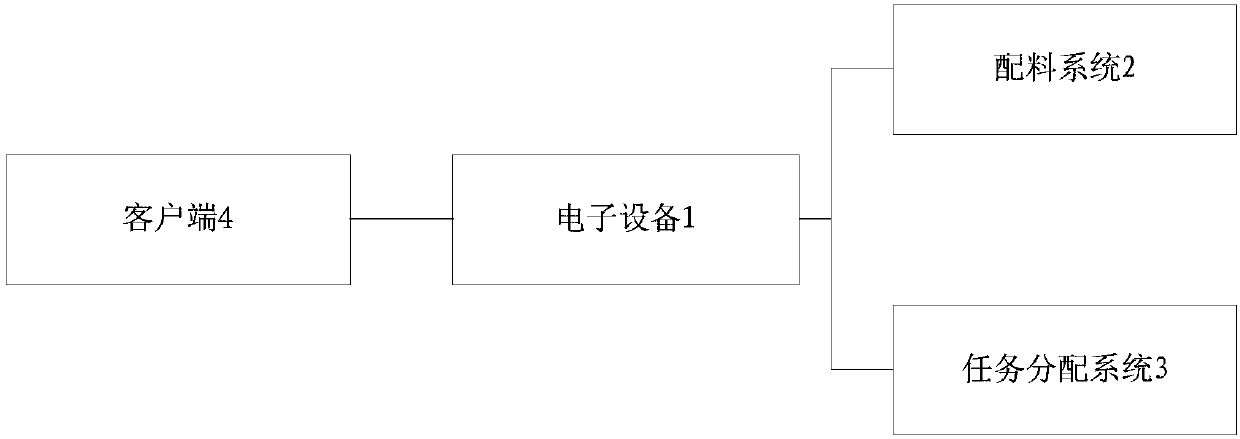

Industrialized data processing method for building decoration base layer, electronic equipment and storage medium

PendingCN109992806AIncrease profitMeet decoration needsGeometric CADData processing applicationsPersonalizationUser input

The invention discloses an industrialized data processing method for a building decoration base layer, electronic equipment and a storage medium, and the method comprises the steps: responding to a calling instruction of a user, and calling decoration base layer module data corresponding to the calling instruction as current decoration base layer module data; receiving personalized configuration data about the current decoration base layer module data input by a user, and modifying the material information of the current decoration base layer module data according to the personalized configuration data to obtain combined decoration base layer module data; calling a customization specification corresponding to the current decoration base layer module data as a current customization specification, verifying the combined decoration base layer module data, and if the combined decoration base layer module data meets the current customization specification, outputting a module data list anda material list. According to the invention, the modularization of building decoration components is taken as the core, the industrialized organization production is taken as the basis, and the on-site assembly type construction is taken as the means, so that the novel assembly type base layer system suitable for the industrialization of the Internet era is realized.

Owner:ZHEJIANG YASHA DECORATION

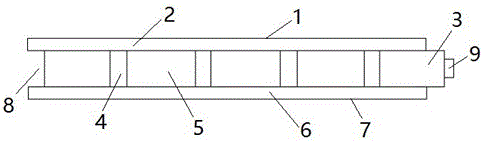

Microcrystalline wood floor structure

InactiveCN106320652ASimple structureNo pollution in the processSynthetic resin layered productsConstructions elementsEngineeringUltimate tensile strength

The invention provides a microcrystalline wood floor structure which comprises a microcrystalline plate glass layer, a polymerization layer, a supporting layer and a bonding layer. The supporting layer is arranged between the bonding layer and the polymerization layer, the microcrystalline plate glass layer is arranged on the upper end face of the polymerization layer, and a cavity is formed in the supporting layer. By the adoption of the technical scheme, the whole microcrystalline wood floor structure can be effectively improved, is pollution-free and is firm after splicing installation. In addition, the pollution of a microcrystalline wood floor can be reduced by adopting the special polymerization layer and the supporting layer, the strength is reliable, the cost is lower, and practicability is better. Furthermore, the microcrystalline wood floor structure is relatively convenient to dismount and maintain, and the decorating demand of people can be met.

Owner:湖州维细高分子材料有限公司

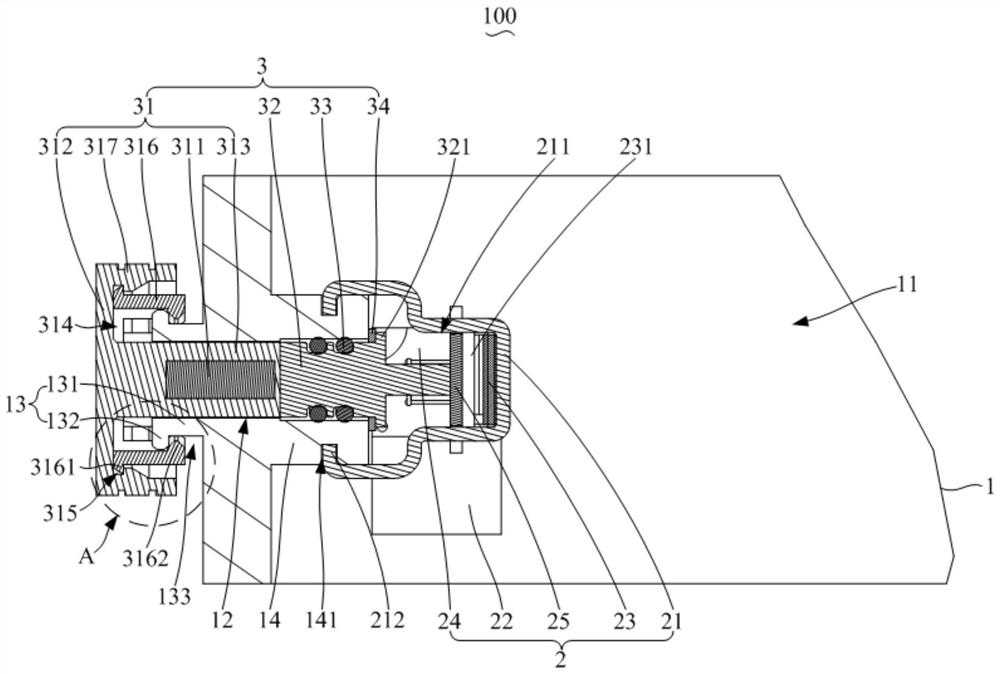

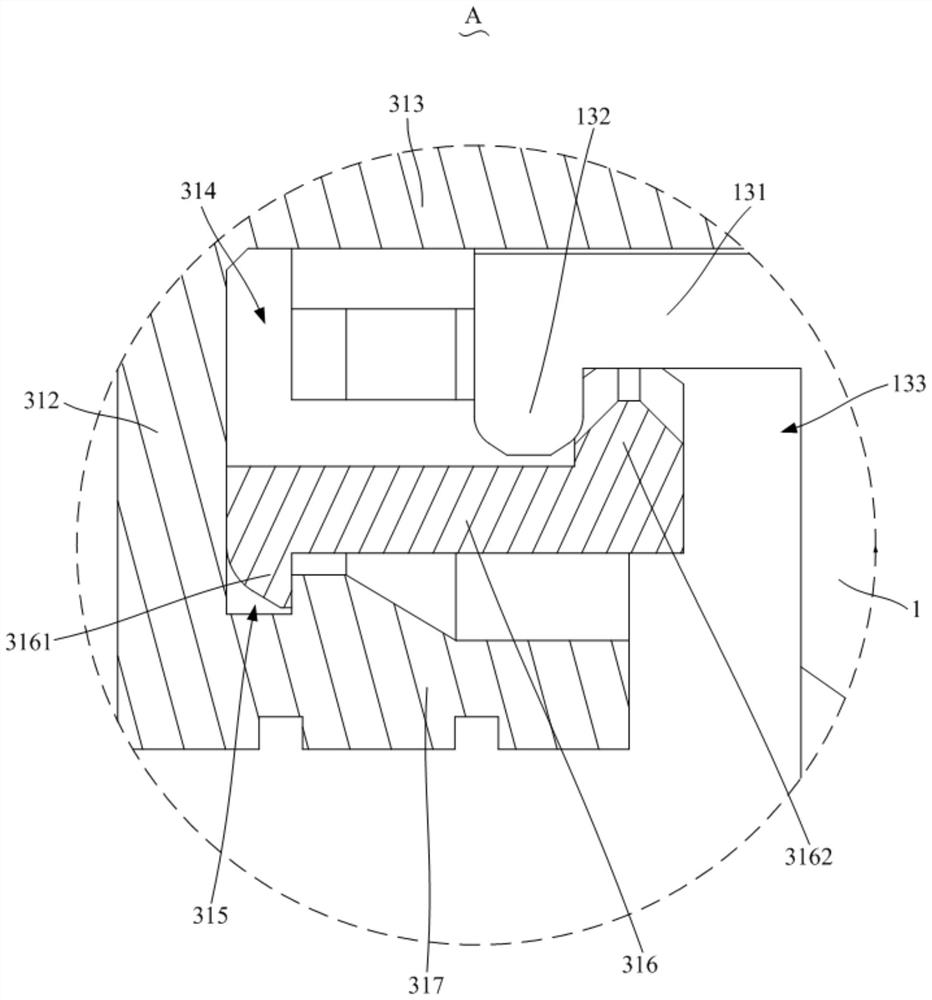

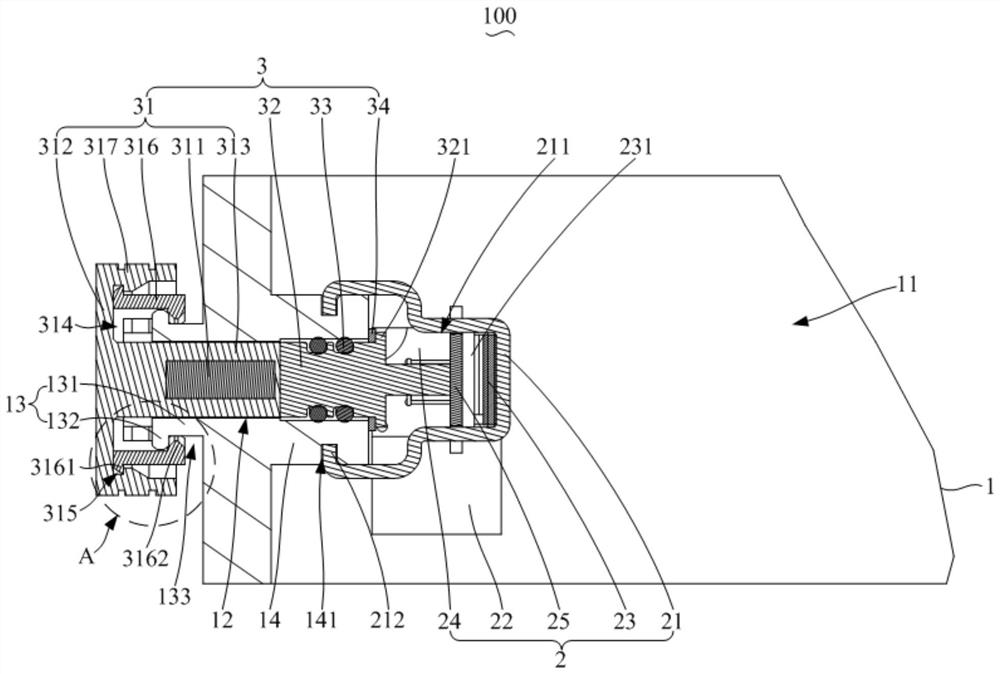

Key structure and wearable equipment

ActiveCN113963971ARealize detachableRealize button functionElectric switchesKey pressingSoftware engineering

The invention discloses a key structure and wearable equipment, the key structure comprises a shell, a trigger assembly and a key assembly, the shell is provided with a mounting cavity and a key hole communicated with the mounting cavity, the trigger assembly is arranged in the mounting cavity and corresponds to the key hole, the key assembly comprises a pressing piece and a key rod, at least part of the key rod is movably arranged in the key hole and corresponds to the trigger assembly, and one end of the pressing piece movably penetrates through the key hole and is detachably connected with the end, away from the trigger assembly, of the key rod; and the pressing piece is pressed and / or rotated, so that the key rod is driven to trigger the triggering assembly. The invention aims to provide the detachable waterproof key structure, the key is convenient and quick to replace, the key structure is applied to the wearable equipment, the convenience of a user is effectively improved, the appearance of the wearable equipment can be more diversified, and the decoration requirement of the user is met.

Owner:GEER TECH CO LTD

Construction method for preventing transparent polyurethane paint film for outdoor solid wood product from being whity

The invention discloses a construction method for preventing a transparent polyurethane paint film for an outdoor solid wood product from being whity. The method comprises the following steps of: (1) sanding materials; (2) spraying or brushing anti-tarnishing liquid; (3) coloring the materials; (4) brushing or spraying outdoor transparent polyurethane priming paint; and (5) brushing or spraying transparent polyurethane finish paint. By using the construction method, the transparent polyurethane paint film for the outdoor solid wood product can be effectively prevented from being whity and tarnishing; a product obtained after construction is fresh and natural and full and round in handfeel and mild in feeding when being touched in winter; and the demand for decoration can be met.

Owner:青岛富臣化工有限公司

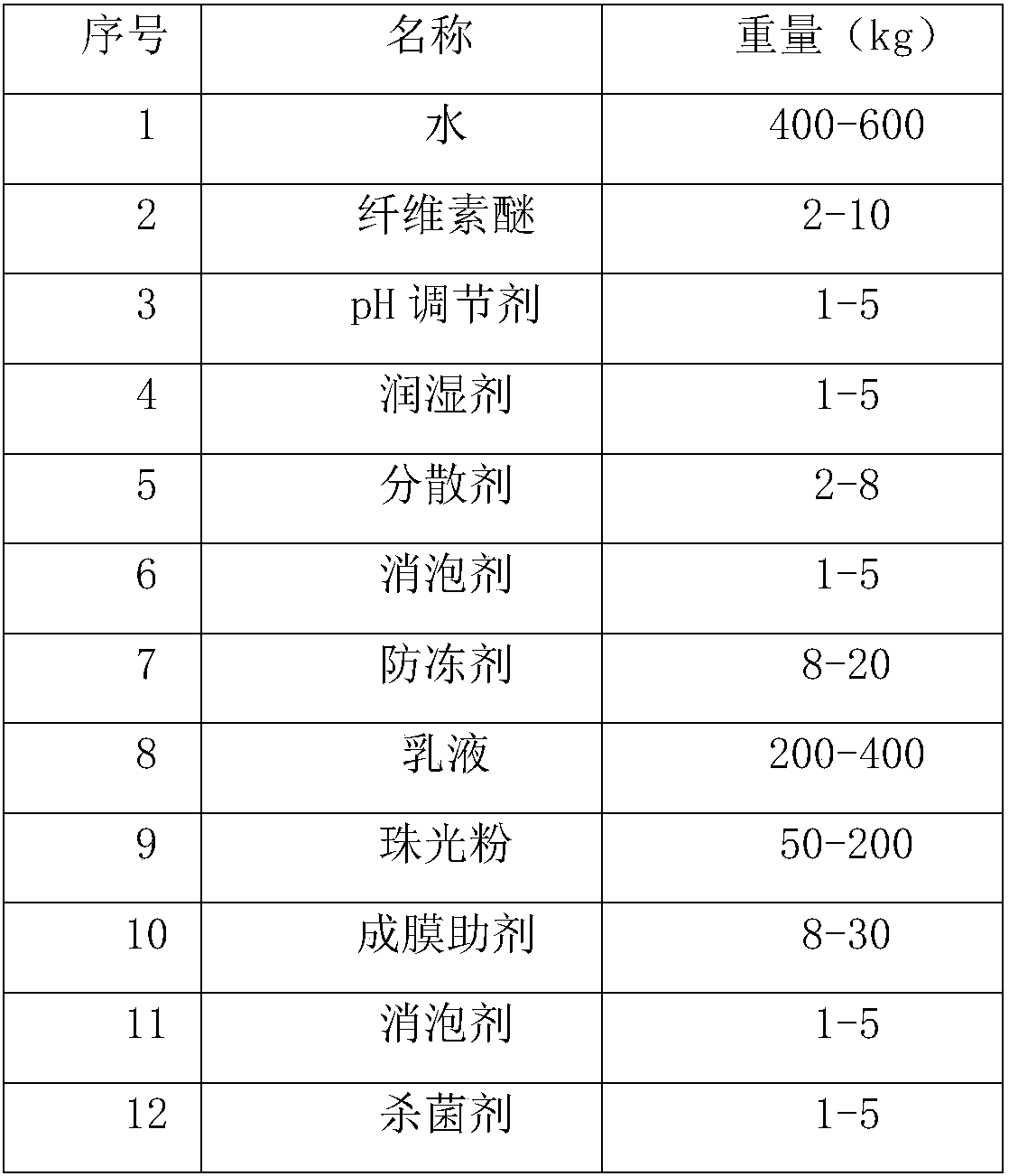

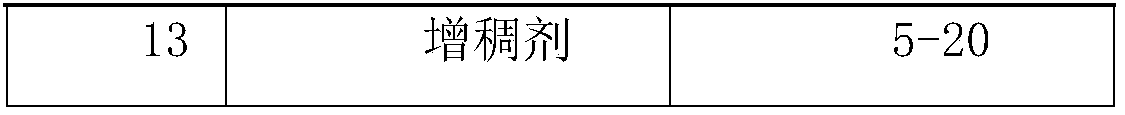

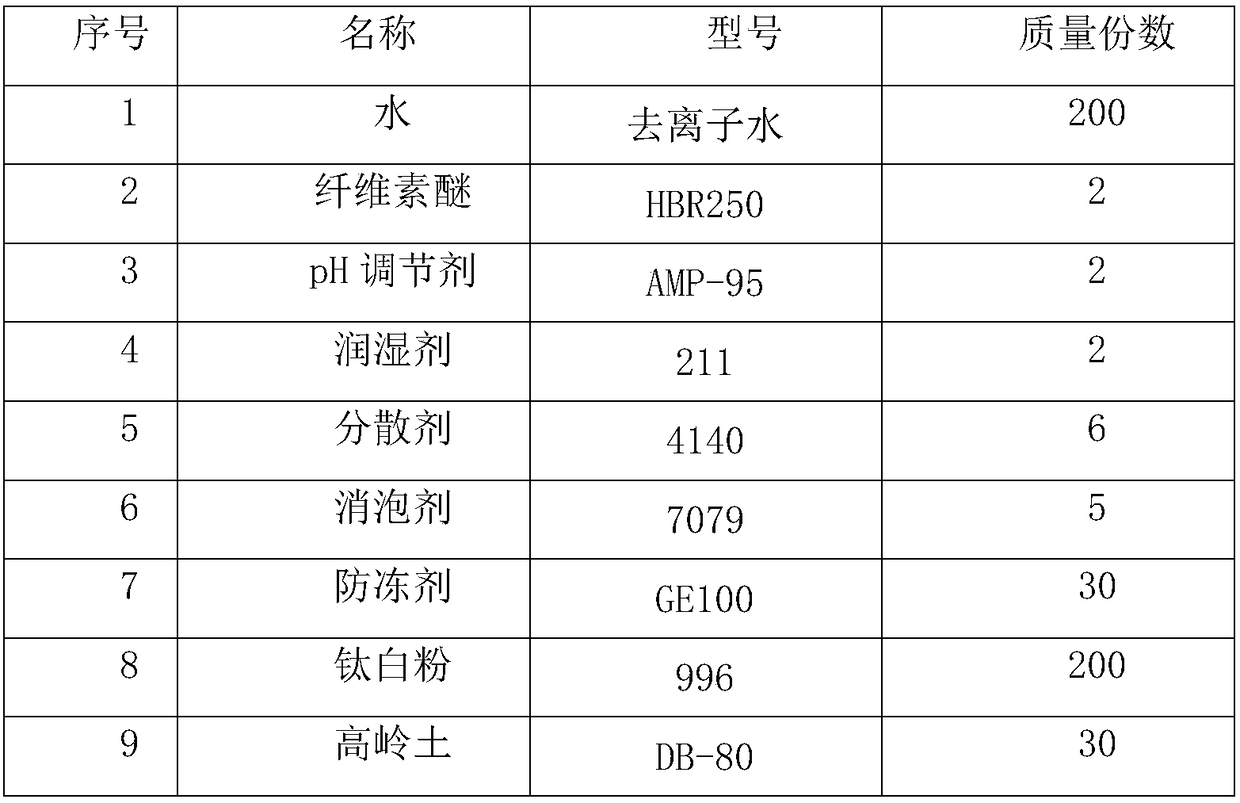

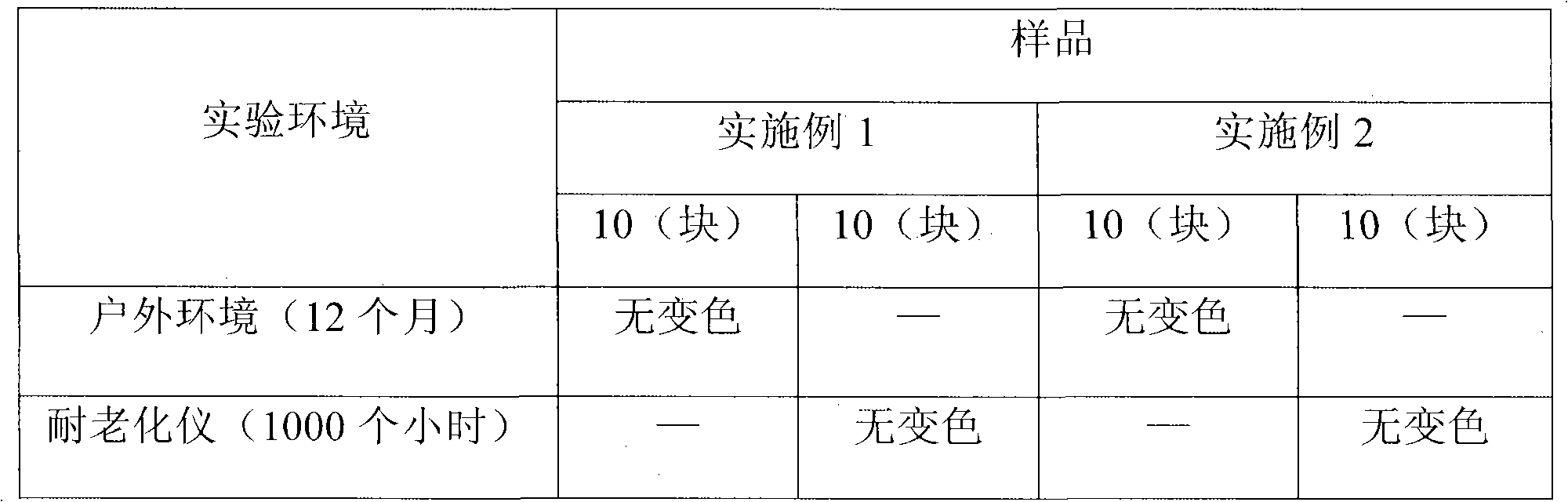

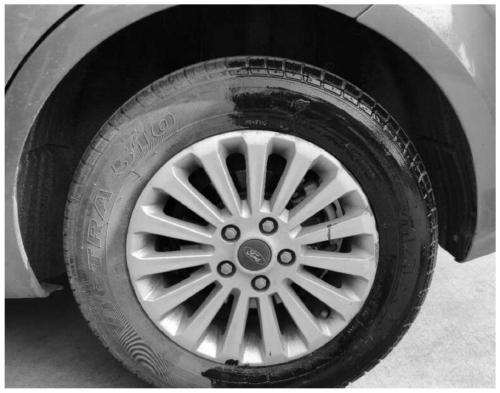

Automobile tire decoration agent and preparation method thereof

InactiveCN109868046ASatisfy appearanceMeet decoration needsLuminescent paintsUnspecified rubber coatingsColor filmSolvent

The invention discloses an automobile tire decoration agent. The decoration agent is characterized by comprising the following raw materials: resin, a solvent, a pigment, a dispersing agent and deionized water. The decoration agent provided by the invention has the advantages of a quick drying speed of the color film, strong adhesion and excellent comprehensive properties such as water resistance,and the characteristics of a rich and gorgeous color, strong selectivity and excellent decorative effects.

Owner:ZHONGSHAN DATIAN CAR CARE IND

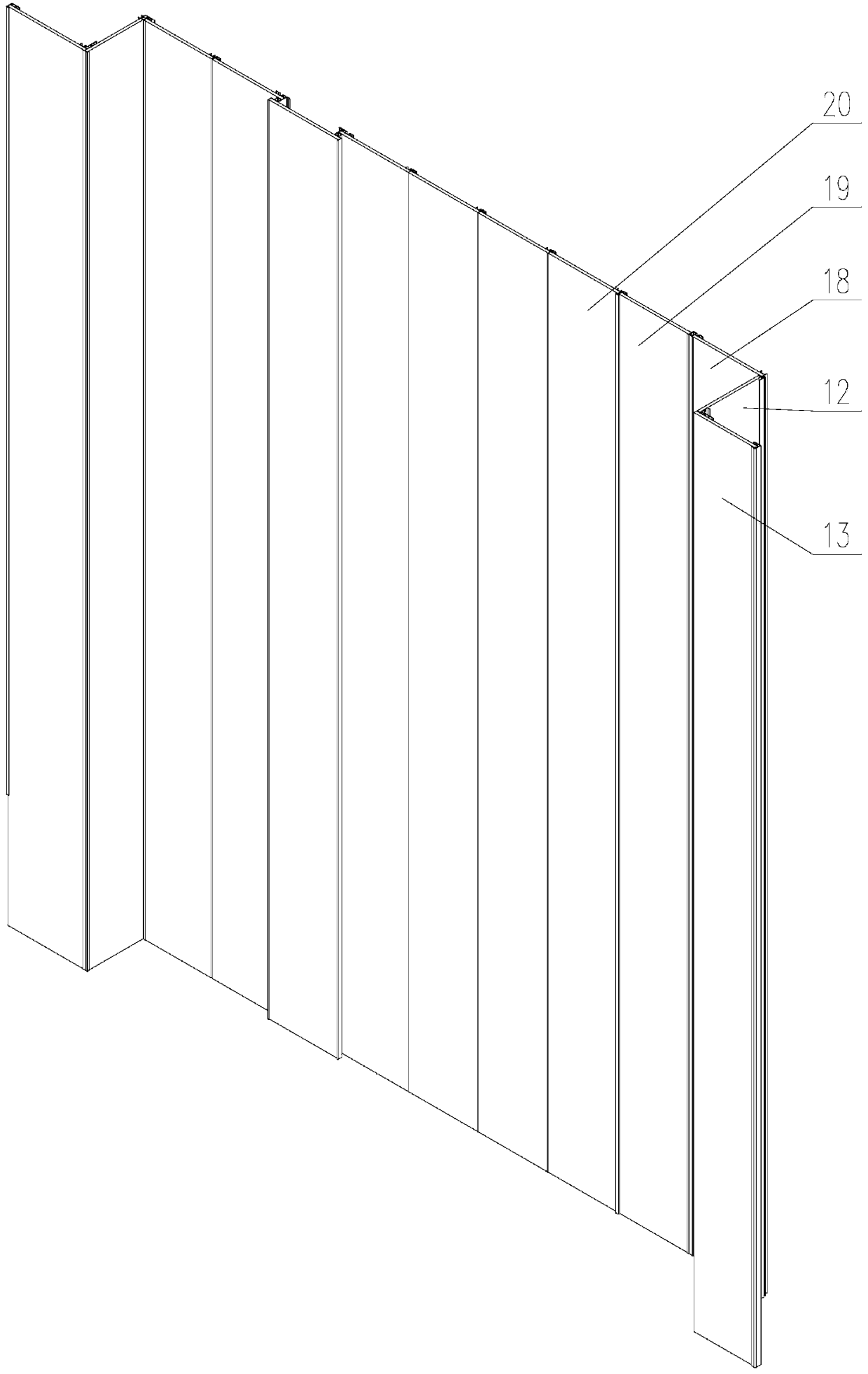

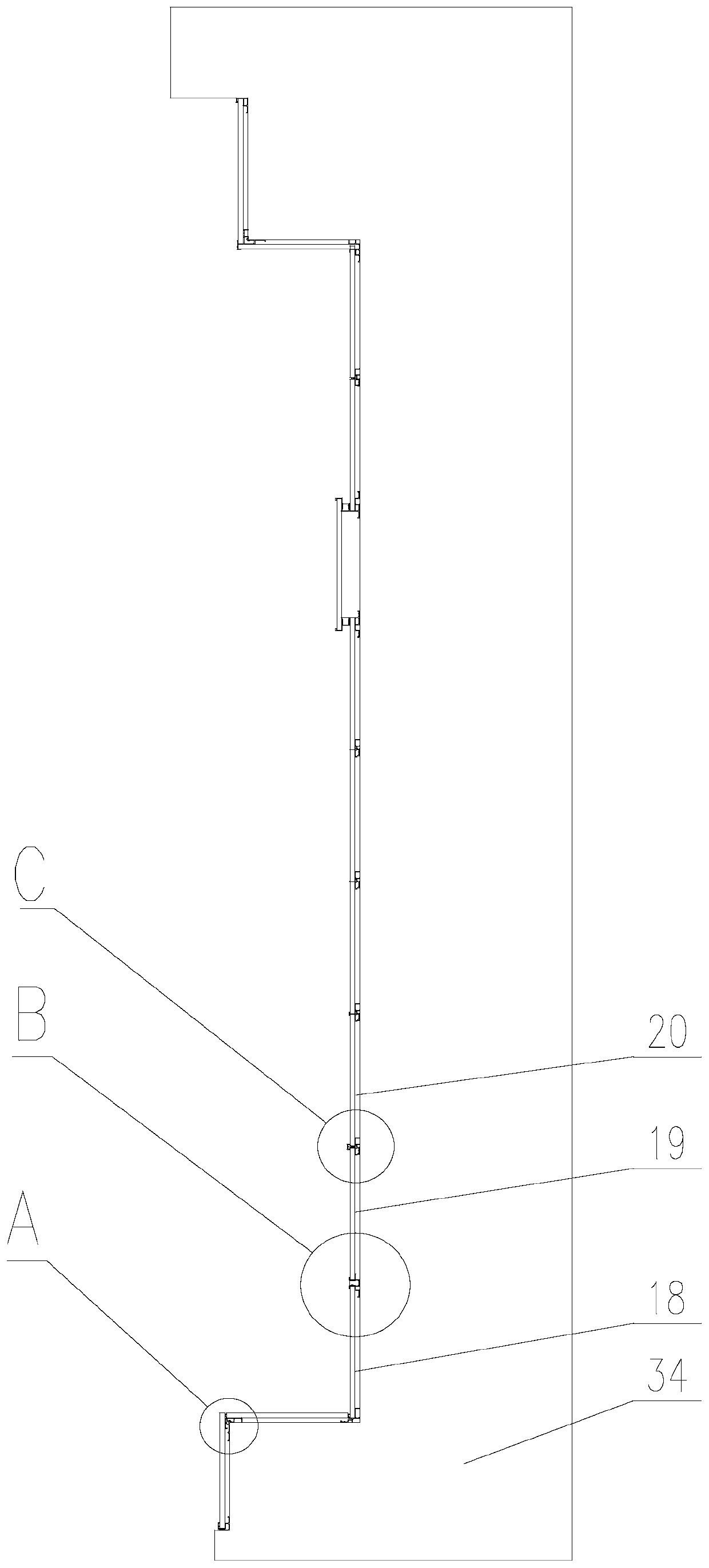

Wall decorative panel assembly

PendingCN111485691AQuick installationImprove stabilityCovering/liningsLighting support devicesEngineeringFastener

The invention discloses a wall decorative panel assembly, which comprises an external corner decorative panel A and an external corner decorative panel B. The external corner decorative panel A is connected with the external corner decorative panel B through an external corner line assembly. The external corner line assembly comprise a connecting strip A, a connecting strip B and a fixed strip. Thr connecting strip A is connected to the back of the external corner decorative panel A through fasteners. The connecting strip B is located between the external corner decorative panel B and an external corner surface B, and is connected to the back of the external corner decorative panel B through the fasteners. One side of the connecting strip B is inserted into one side of the connecting stripA. The fixed strip is located between the connecting strip B and the external corner surface B. One side of the fixed strip is connected with the connecting strip A. The fixed strip is connected withthe external corner surface B by the fasteners. The wall decorative panel assembly can not only fix the ends of two decorative panels located at an external corner line of the wall, improve the stability of the installation of a decorative panel, but also hide the external corner line assembly without being exposed, and satisfy the requirement that the external corner line is not required as decoration requirements for decorative parts.

Owner:成都劲启家居有限公司

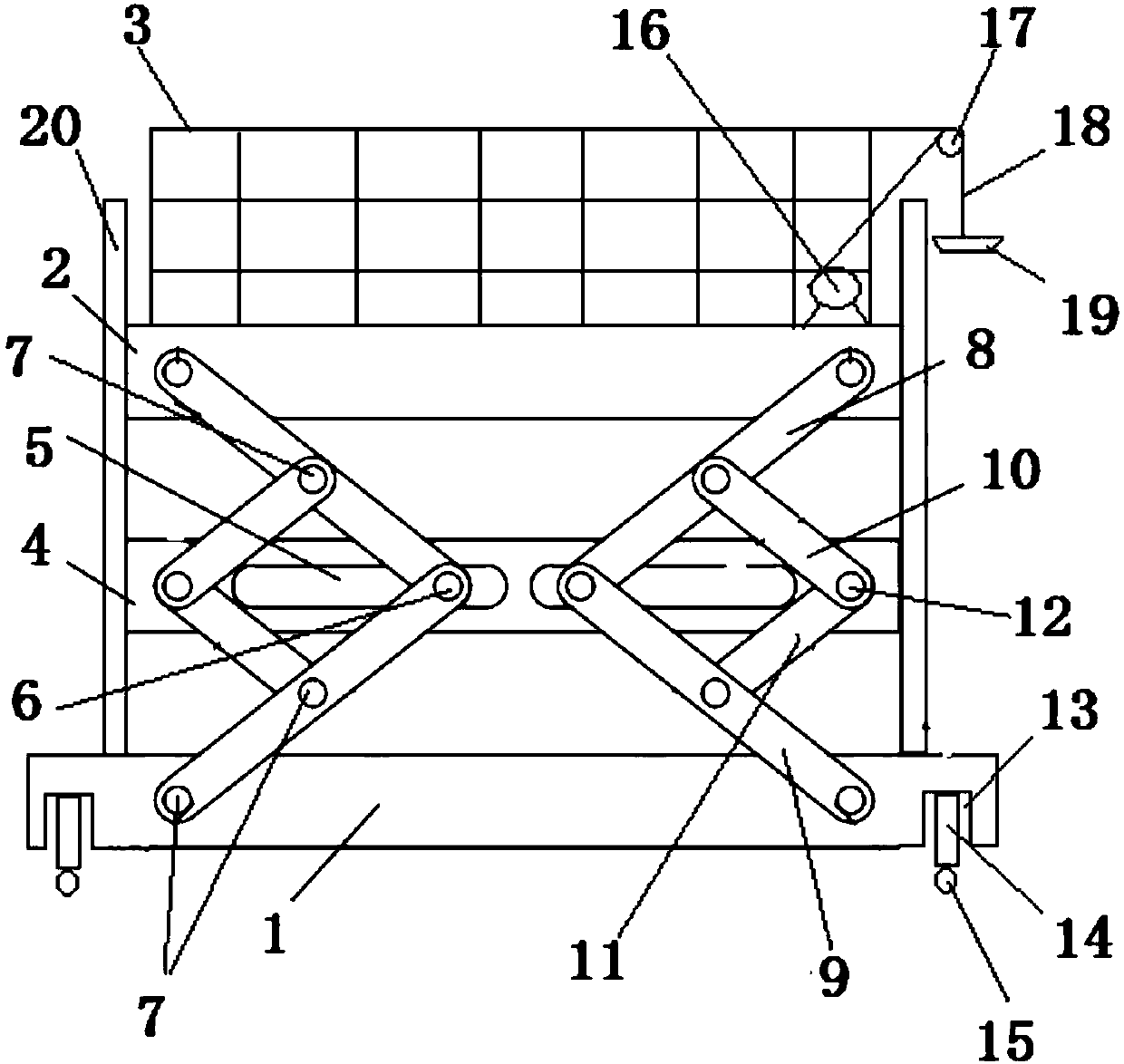

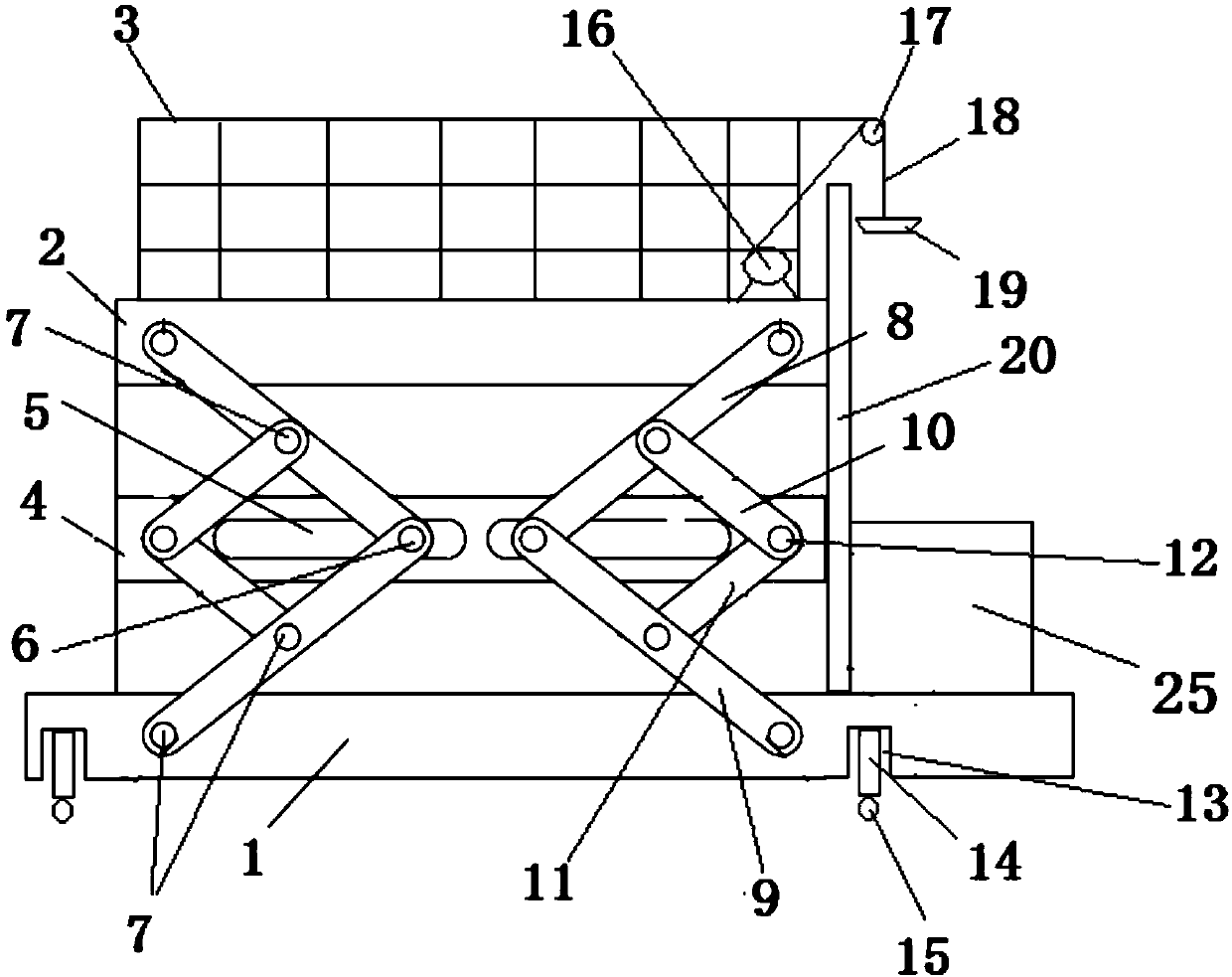

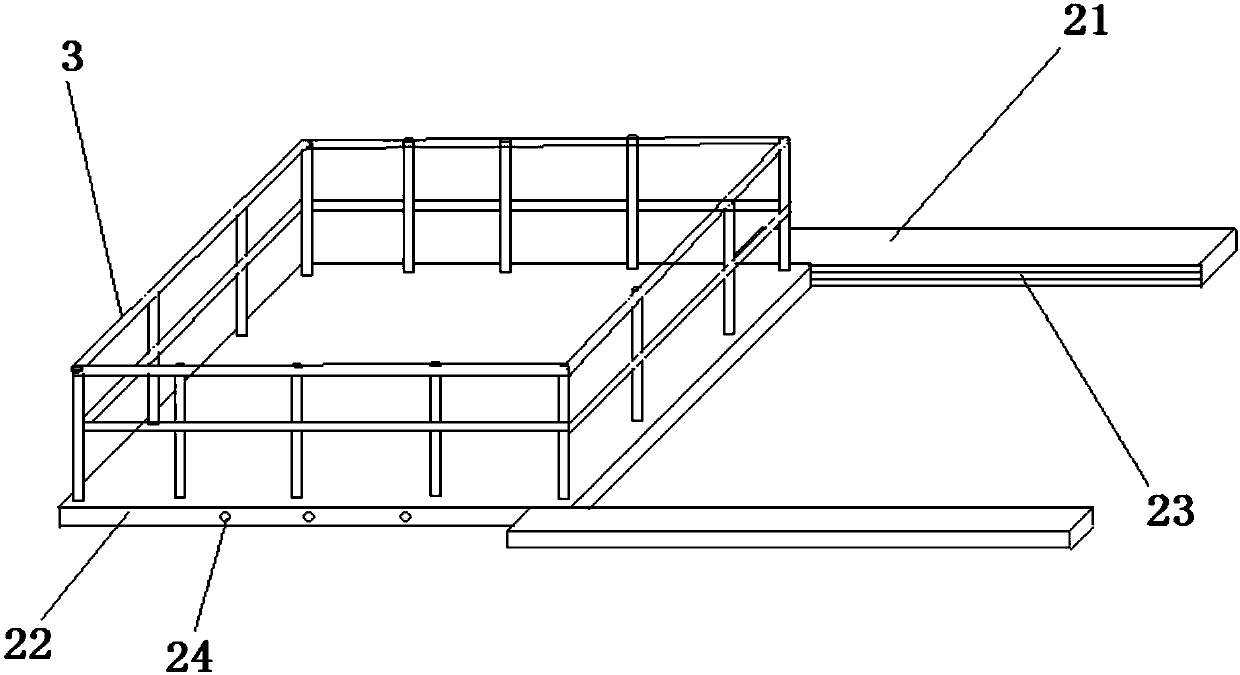

A lifting device for interior decoration

PendingCN109594755AMeet the decoration needsGuarantee efficiencyBuilding scaffoldsIndustrial engineering

Owner:上海嘉春装饰设计工程有限公司

Transparent heat-insulating paint

InactiveCN109575718AGuaranteed insulation effectGuaranteed performanceAnti-corrosive paintsReflecting/signal paintsAlcoholTransmittance

The invention discloses transparent heat-insulating paint. The transparent heat-insulating paint taking nano antimony tin oxide (ATO) as functional powder is prepared by taking waterborne hydroxyl acrylic acid and amino resin as film forming substances and nano ATO as heat-insulating functional powder. Hardness of a film formed by coating the paint on glass and baking at 170-180 DEG C, adhesive force is 0 grade, resistance to water, acid and alcohol is excellent, transmittance in a visible light area (380-780nm) is higher than 60%, near infrared rejection rate is higher than 50%, and content of nano ATO, coating dry film thickness and impact of coating orientation on heat-insulating effect are investigated. A colored transparent coating having good heat-insulating effect is prepared by adding waterborne color paste on the basis to meet special decoration needs.

Owner:马驰

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com