Automobile tire decoration agent and preparation method thereof

A technology of automobile tires and decorative agents, applied in the field of daily chemicals, can solve problems such as gray appearance and tire discoloration, and achieve good hiding power, easy coloring, and excellent decorative effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

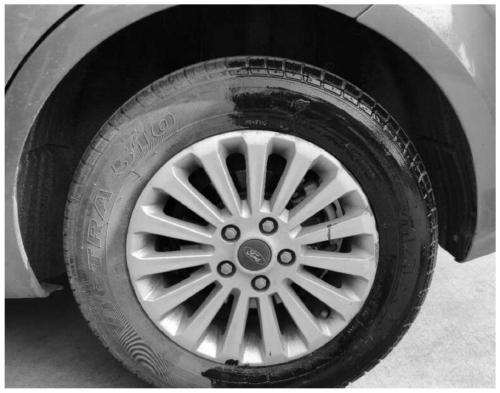

Image

Examples

Embodiment 1

[0035] Black Car Tire Decorator

[0036] Raw materials: 12kg of polyurethane resin, 5kg of carbon black pigment, 4kg of talcum powder, 1kg of white carbon black, 15kg of 95% ethanol, and 58kg of deionized water.

[0037] The preparation method is as follows:

[0038] (1) Pre-dispersion: Put 18kg of deionized water into the batching tank, then put it into a stirring and dispersing machine with a power of 22-35KW and a frequency conversion of 0-3000 rpm, start stirring slowly, and put in accurate metering while stirring Mix 5kg of carbon black pigment, 4kg of talcum powder and 1kg of white carbon black to obtain a thick color paste, which can be used for subsequent grinding.

[0039] (2) Grinding and dispersing: The pre-dispersed color paste is dispersed through colloid mill equipment, and the dispersed material liquid is filtered through a 100-mesh filter bag, which is used as the pigment thick paste used in the product. During the homogeneous dispersion of the thick slurry s...

Embodiment 2

[0043] Pearlescent red car tire decoration

[0044] Raw materials: Tongde resin 3AH054515kg, 95% ethanol 10kg, diethylene glycol monobutyl ether 5kg, pearlescent red powder 6kg, white carbon black 1kg, talcum powder 5kg, deionized water 55kg.

[0045] Preparation of headlight repair aerosol:

[0046] The preparation method is as follows:

[0047] (1) Preparation of agent liquid: 55kg of deionized water is added in the preparation pot, start stirring, slowly add 15kg Tongde resin 3AH0545, 5kg diethylene glycol monobutyl ether, 95% ethanol 10kg, 6kg pearlescent red powder, 1kg of white carbon black, 5kg of talcum powder and other materials, after basic mixing, disperse and stir at high speed for 20 minutes, and disperse evenly to obtain the dosage material.

[0048] (2) Filled tank finished product: with embodiment 1.

Embodiment 3

[0050] blue car tire decorator

[0051] Raw materials: 15kg of modified rubber emulsion, 5kg of 95% ethanol, 5kg of diethylene glycol monobutyl ether, 6kg of blue powder, 3kg of bentonite, 0.5kg of zinc stearate, and 55.5kg of deionized water.

[0052] The preparation method is as follows:

[0053] (1) Pre-dispersion: Put 15kg of deionized water into the batching tank, then put it into a stirring and dispersing machine with a power of 22-35KW and a frequency conversion of 0-3000 rpm, start stirring slowly, and put in accurate metering while stirring. Mix 6kg of blue powder, 3kg of bentonite, and 0.5kg of zinc stearate to obtain a thick color paste, which can be used for subsequent grinding.

[0054] (2) Grinding and dispersing: The pre-dispersed color paste is dispersed through colloid mill equipment, and the dispersed material liquid is filtered through a 100-mesh filter bag, which is used as the pigment thick paste used in the product. During the homogeneous dispersion of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com