Clock 12-scale preparation method and clock 12-scale preparation fixture

A clock and scale technology, applied in the field of clock twelve scale preparation, can solve the problems of long process and process, poor design stability, high product price, etc., and achieve the effect of simple process, low cost and meeting consumer demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

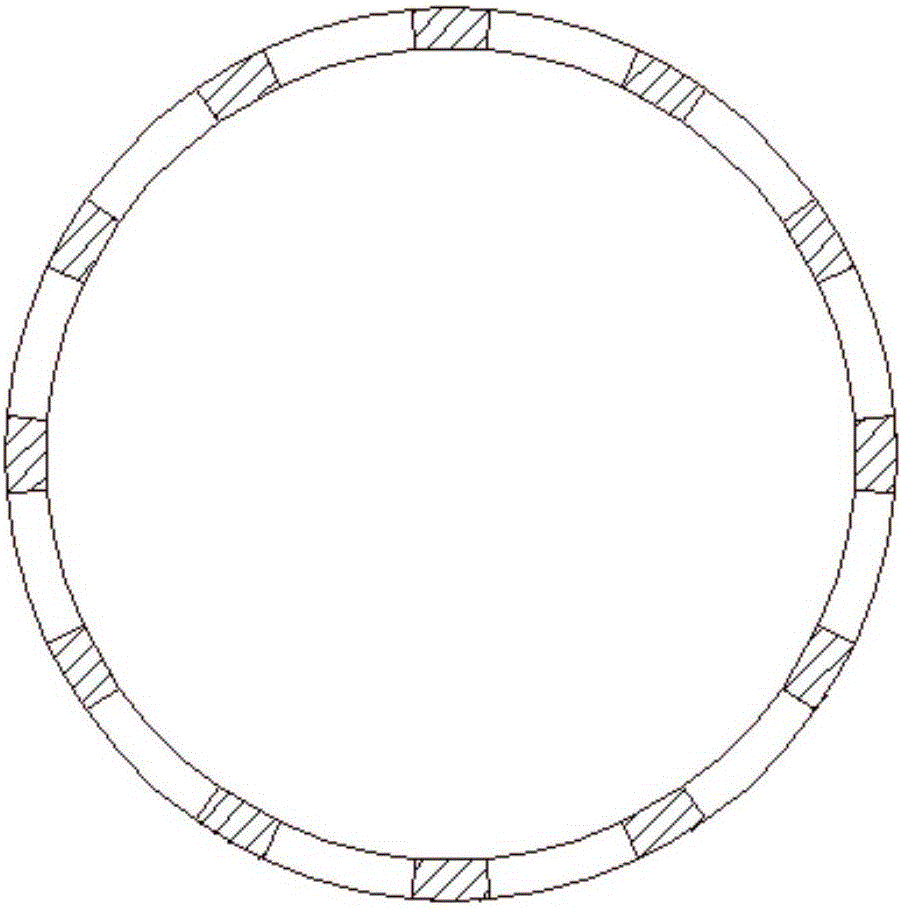

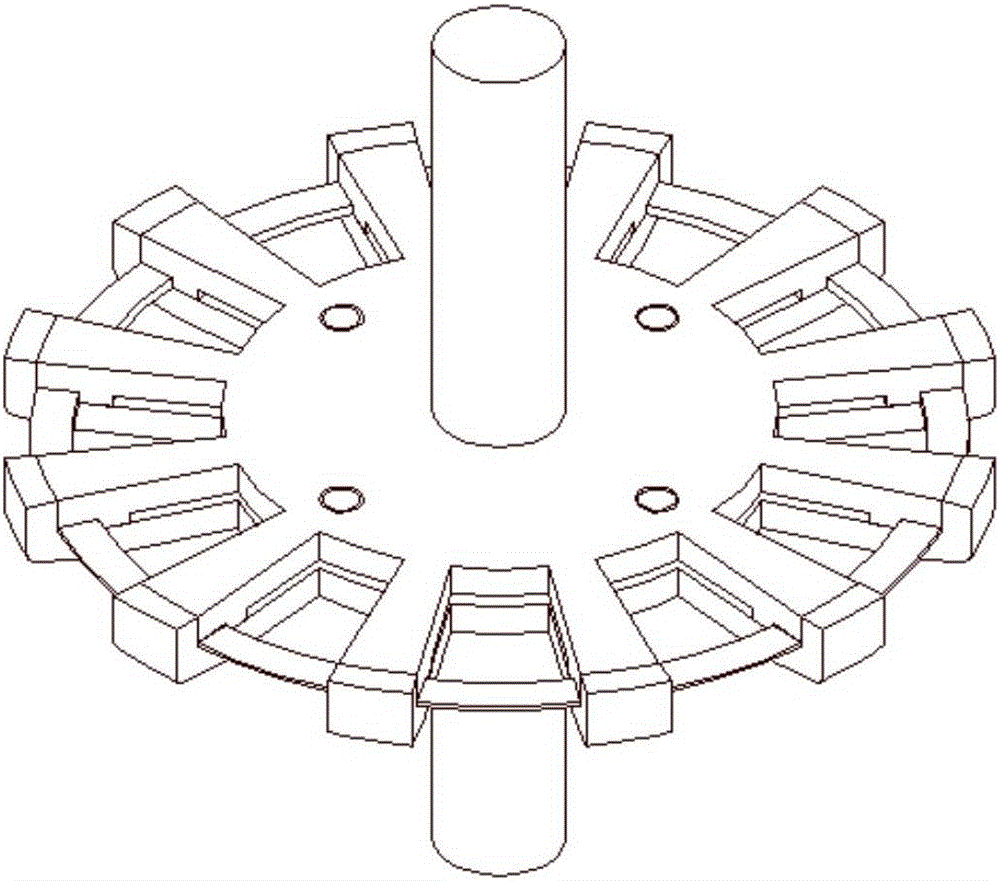

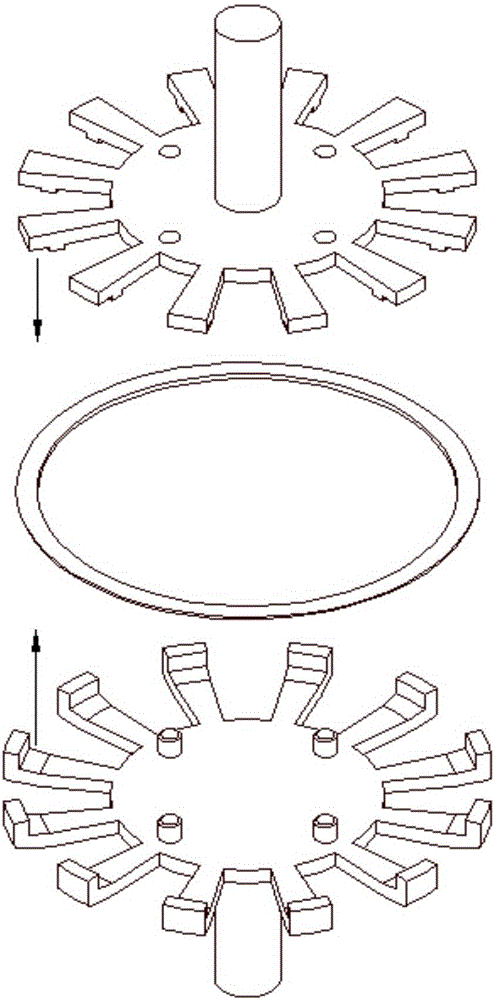

[0043] The preparation jig of embodiment preferably has such as Figure 4 and Figure 5 shown in the structure, Figure 4 and Figure 5 The top and bottom components are shown separately. The positioning hole 1 of the top-mounted component is used to match and assemble with the positioning column 5 of the bottom-mounted component; the handle 2 of the top-mounted component plays a supporting role, and the width can be set according to the figure, and the handle 6 of the bottom-mounted component works with the handle 2 of the top-mounted component same. The main function of clamping post 3 is to fix the product and block the inner side of the product, to avoid product sliding and inner coloring. The clamping jaw 7 and the clamping post 3 are used in pairs, and the main function is to fix the product and block the outer side of the product, avoiding product movement and outer coloring, and the clamping post 3 and claw 7 can be adjusted according to the actual product; fixture f...

Embodiment 1

[0049] Watch frame body pretreatment

[0050] The surface of the stainless steel body is polished so that the surface is like a mirror after treatment, and then the body is ultrasonically cleaned and dried.

[0051] Watch frame body coloring treatment

[0052] Add copper-plating water and nickel-plating water to the electrolytic tank, adjust the concentration of the solution, and connect the electrodes; then assemble the above products and fixtures, and place them on the cathode of the copper-plating electrolytic tank, and adjust the current intensity to 100-150mA , electroplating for 10-15 minutes, and a layer of pink copper is plated on the metal surface; then the product is placed on the cathode of the nickel-plating electrolytic cell, the current intensity is adjusted to 100-120mA, and the electroplating is 8-10 minutes, the surface will be coated with a layer of bright nickel After plating, take out the product to wash and dry. Then put the product into the vacuum coati...

Embodiment 2

[0056] Frame body pre-processing

[0057] Brush the surface of the ceramic frame body. After the treatment, the surface of the brushed surface is uniform. Then ultrasonically clean the body and dry it.

[0058] Frame body coloring

[0059] Dilute the water-based ceramic primer and water-based ceramic paint with water to a certain viscosity (15-20s), then spray the primer on the surface of the ceramic frame body, let it stand for 3-5 minutes, and then bake it in a high-temperature oven for 5-5 minutes 10 minutes, the temperature is 150-160 degrees, take out the product after cooling; then assemble the outer frame body and the jig, fix the position, spray the diluted water-based ceramic paint on the surface of the outer frame, let it stand for 3-5 minutes, and then put it in the high temperature oven Carry out progressive sintering in the oven, first sinter at 170-180°C for 5-10 minutes, then adjust the temperature to 200-220°C, sinter for 10-15 minutes, then cool and take out ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com