Patents

Literature

73results about How to "Achieve the appearance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

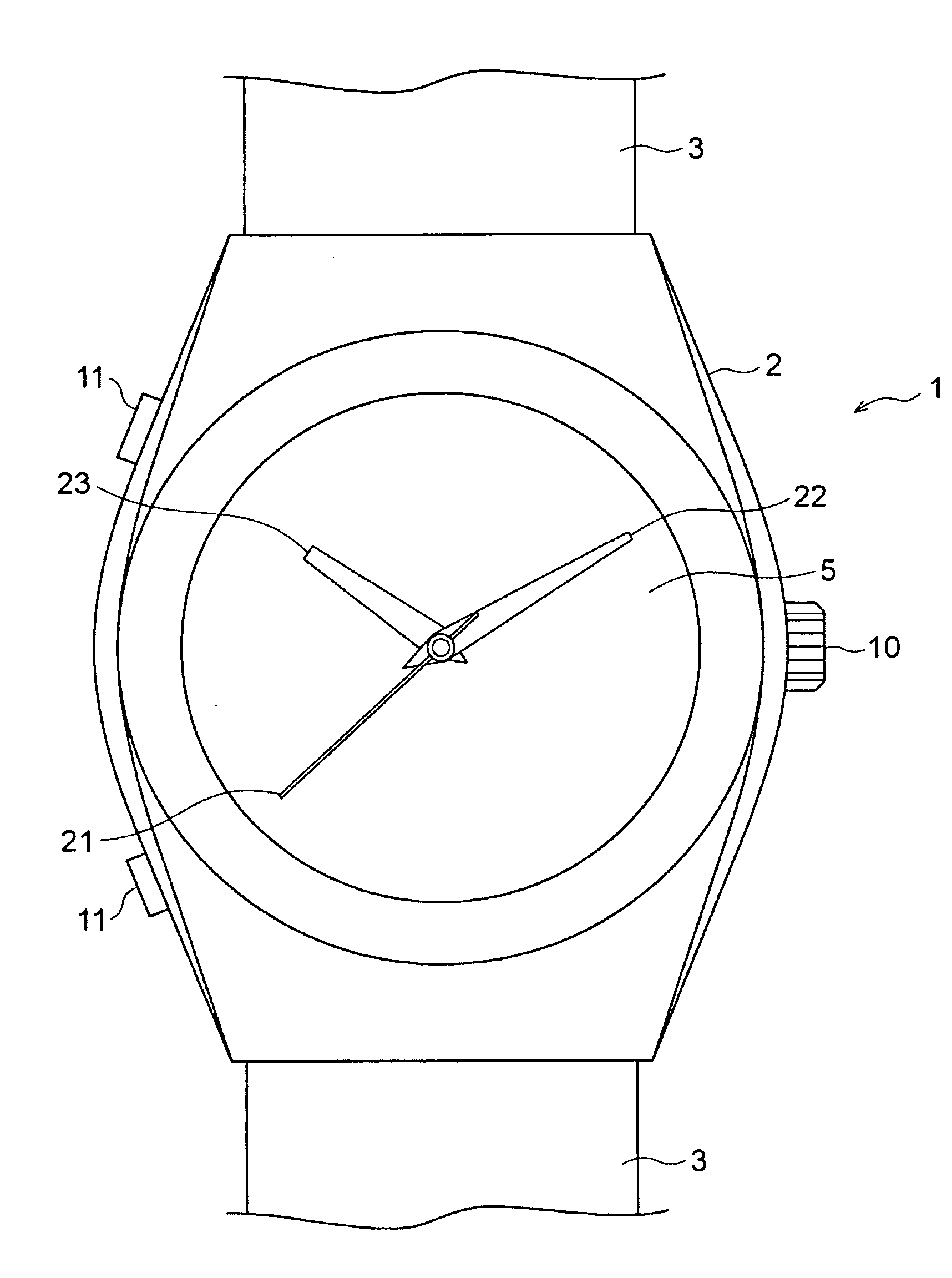

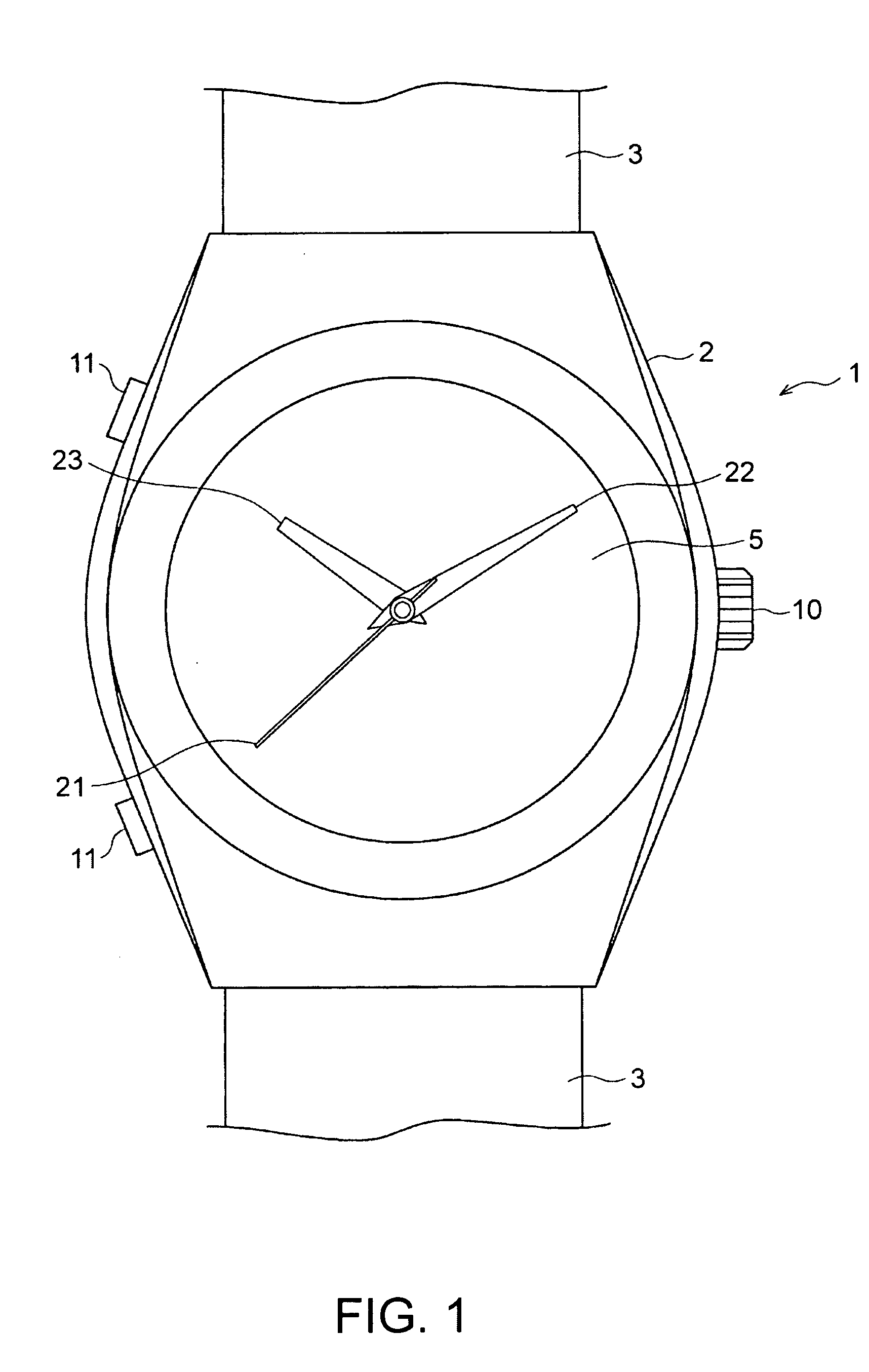

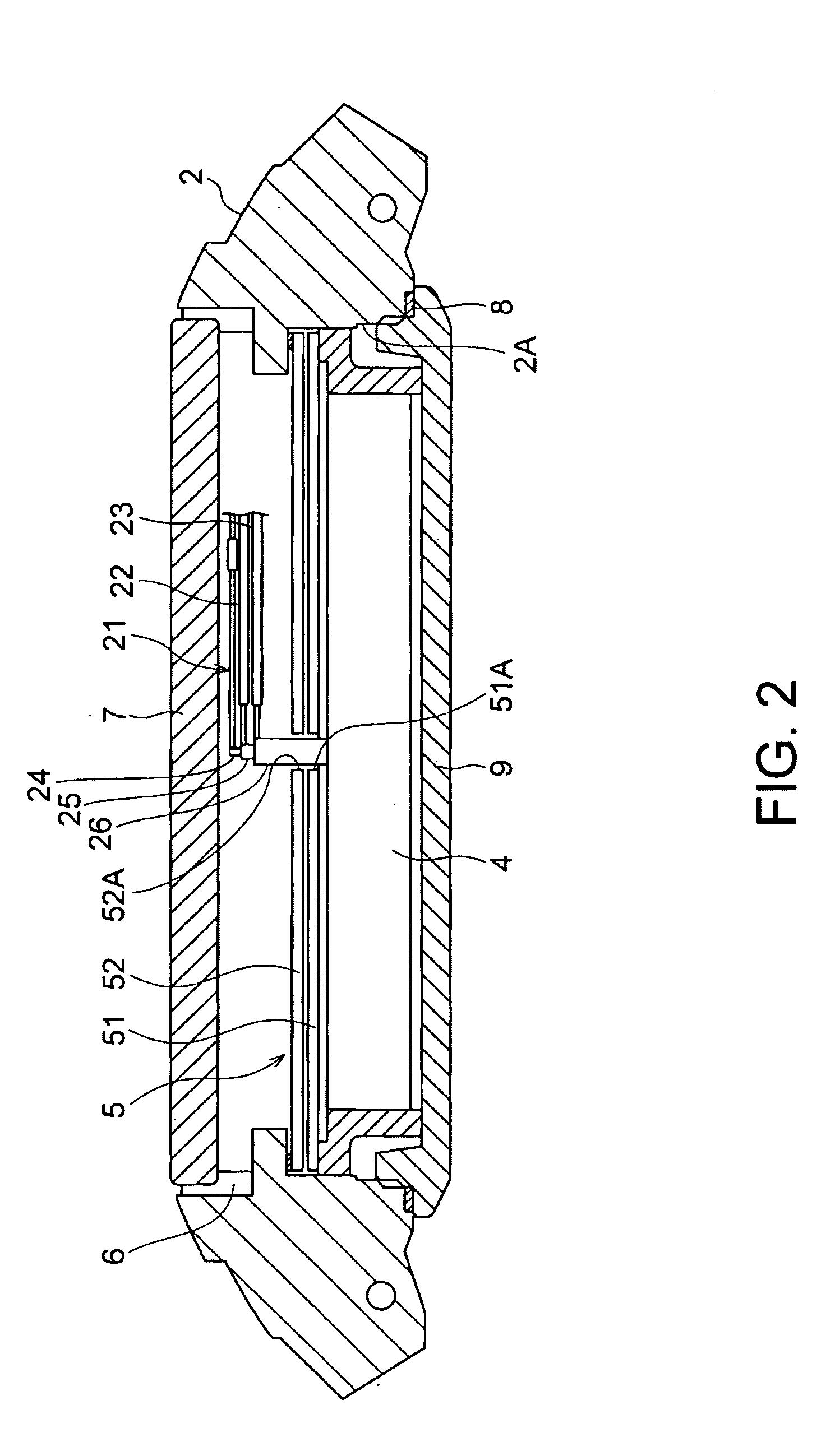

Electronic component and electronic device

InactiveUS20080123473A1Good lookingQuality improvementVisual indicationElectric indicationDisplay deviceEngineering

An electronic component comprising a display panel having an image retention characteristic, and a decorative member disposed layered to the display panel. The decorative member passes the display state of at least a portion of the display panel so that the display can be seen.

Owner:SEIKO EPSON CORP

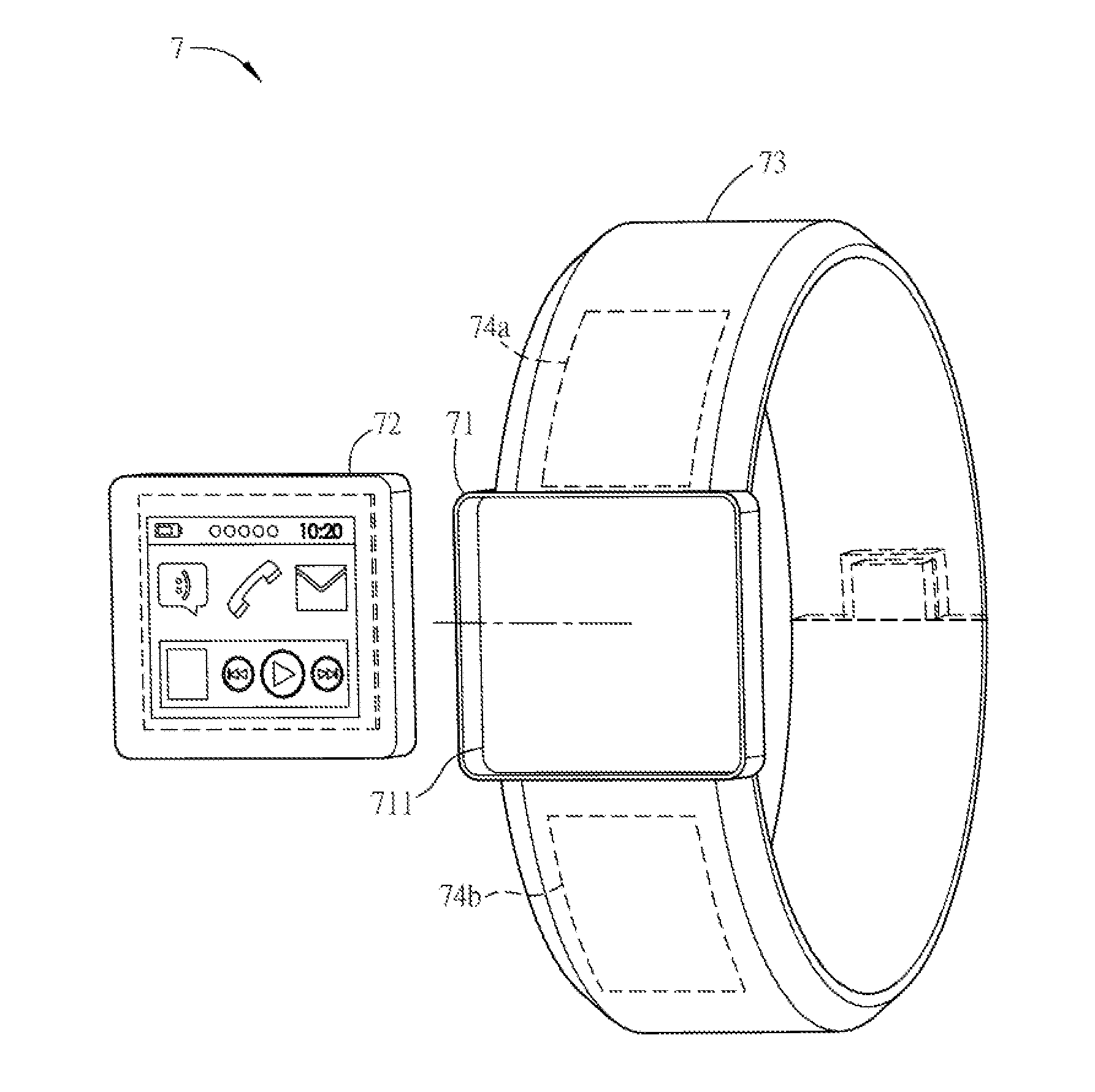

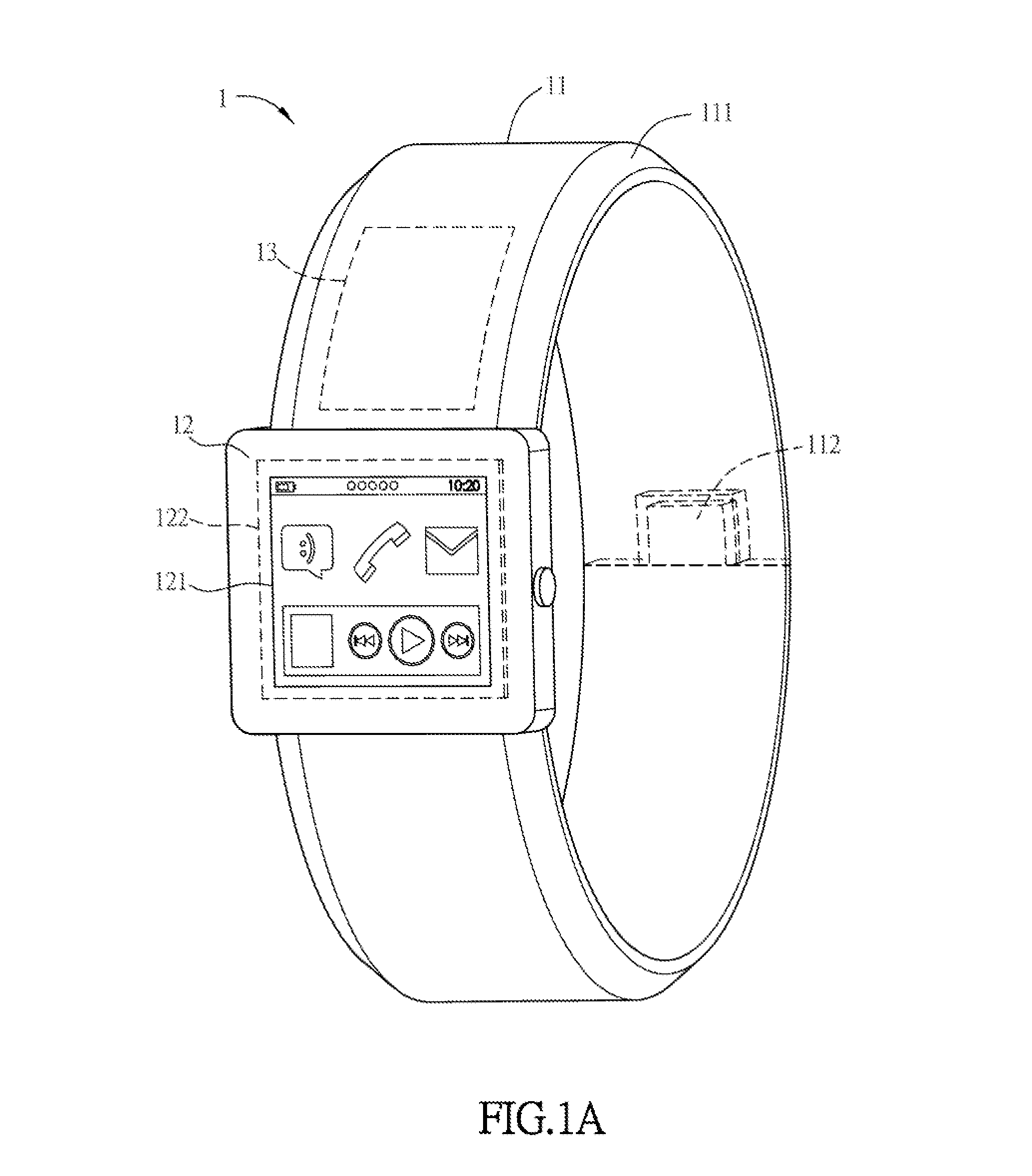

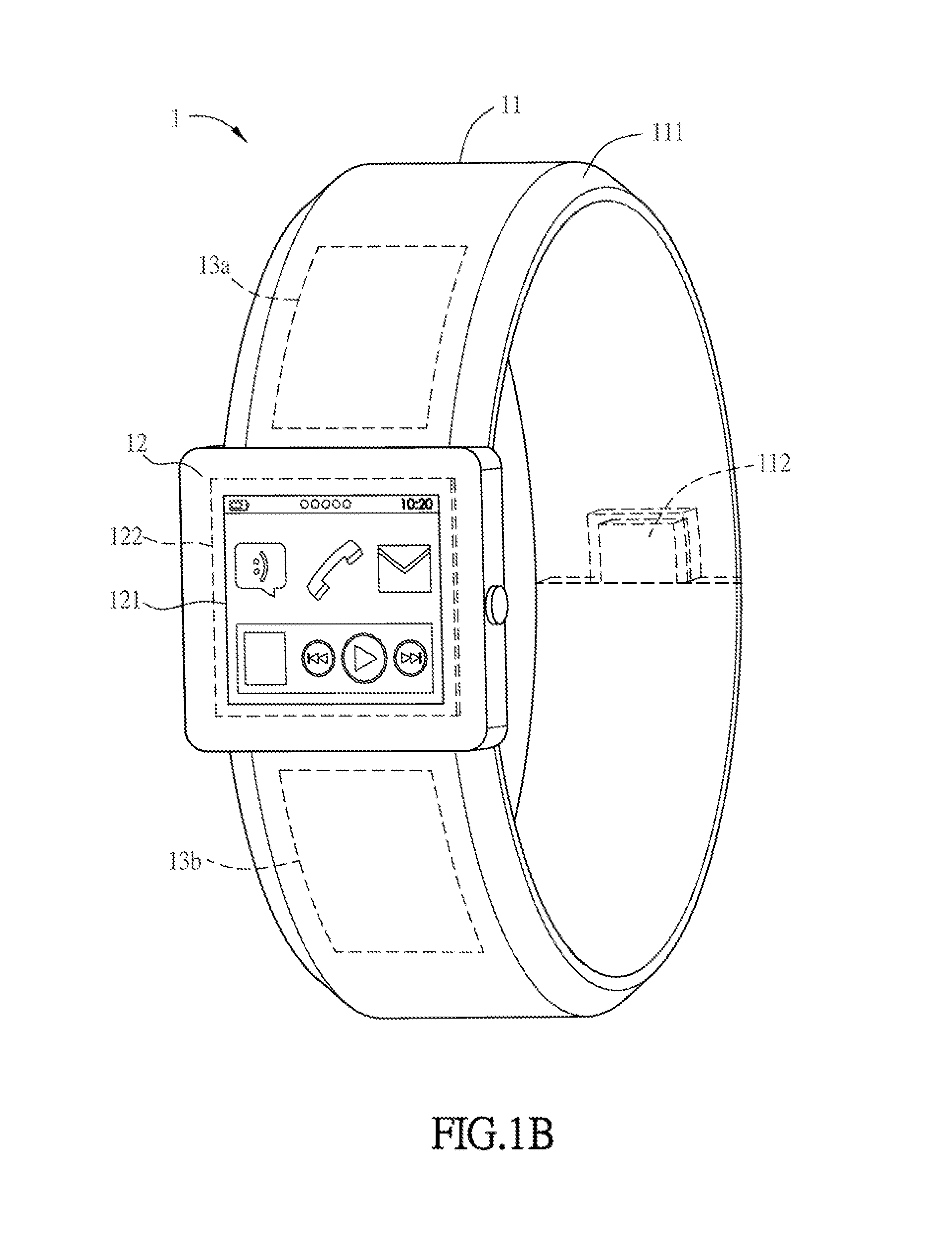

Smart wearable device

InactiveUS20160026308A1Quality improvementWonderful user experienceCathode-ray tube indicatorsDetails for portable computersBand shapeTouch Senses

A smart wearable device comprises a body, a display module and at least one slide-on-strap touch-sensing structure. The display module is disposed on the body and comprises a display unit and a processing unit coupled with the display unit. The slide-on-strap touch-sensing structure is coupled with the processing unit and two slide-on-strap touch-sensing structures are disposed on the opposite sides of the display unit. The slide-on-strap touch-sensing structure senses at least one trigger event. By disposing the area of the touch input on two sides of the display unit, the image or items displayed by the display unit won't be shaded during the user's operation.

Owner:HANNSTAR DISPLAY NANJING +1

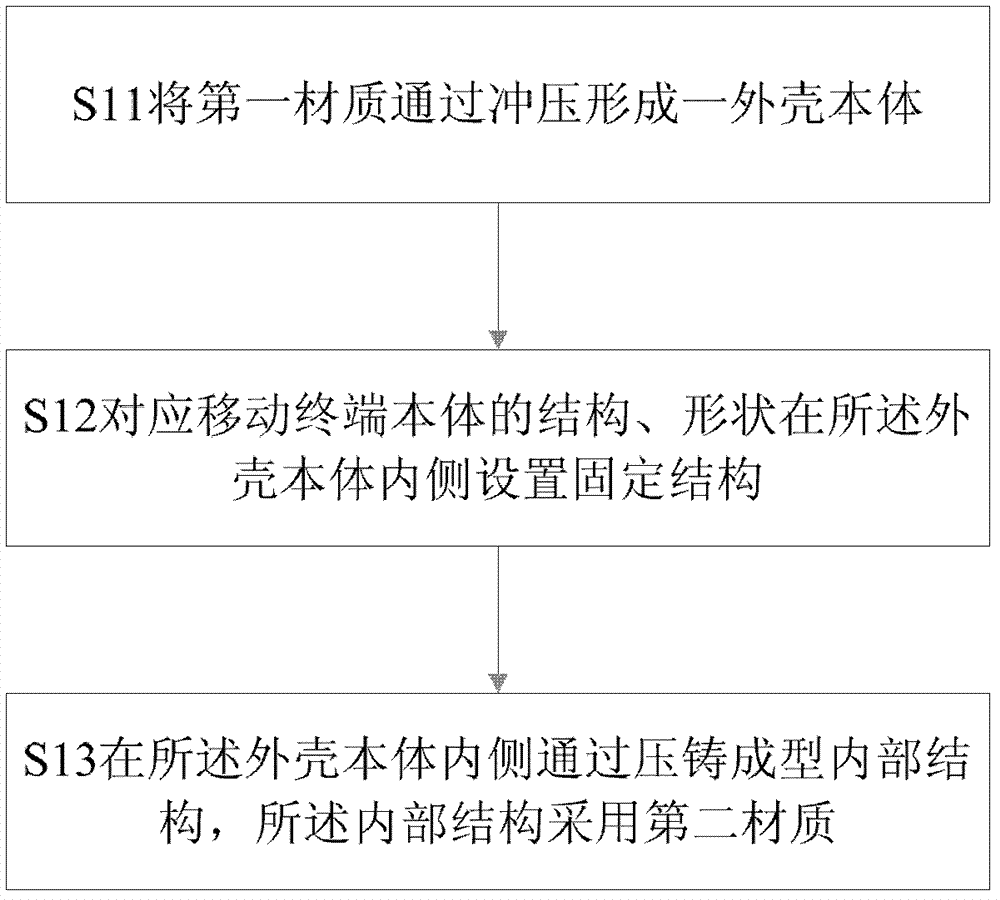

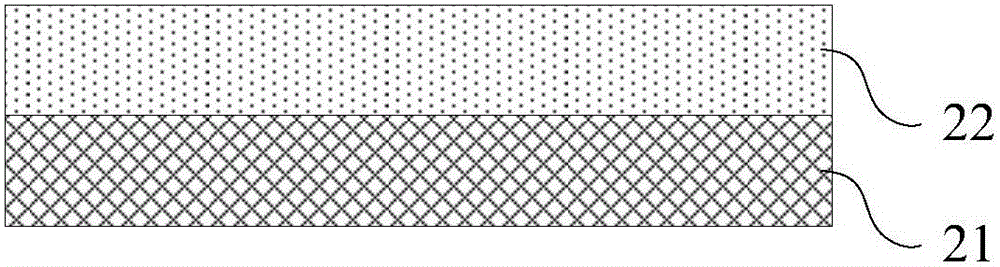

Outer casing adopting composite structure and manufacture process thereof

InactiveCN103249267AReduce weightReduce manufacturing costMetal casingsEngineeringComposite structure

The invention discloses an outer casing adopting a composite structure and a manufacture process thereof. The outer casing adopting the composite structure comprises an outer casing main body and an internal structure, wherein the internal structure is fixed on the inner side of the outer casing main body, the outer casing main body is made of a first material, and the internal structure is made of a second material. Through the composite structure and the manufacture process, the outer casing of a mobile terminal has the advantages of the two materials, so that the required appearance effect is realized, and the weight of parts is reduced; the outer casing is closely connected with the mobile terminal; and the manufacturing cost of parts is reduced by 30-60% compared to the manufacturing cost of parts which are all made of stainless steel materials.

Owner:YULONG COMPUTER TELECOMM SCI (SHENZHEN) CO LTD

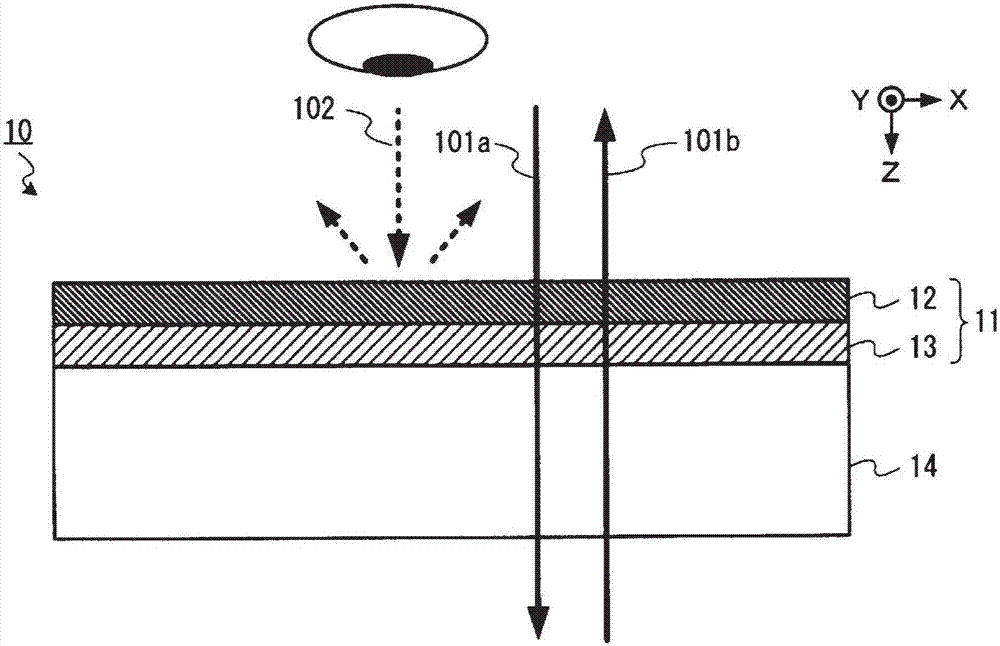

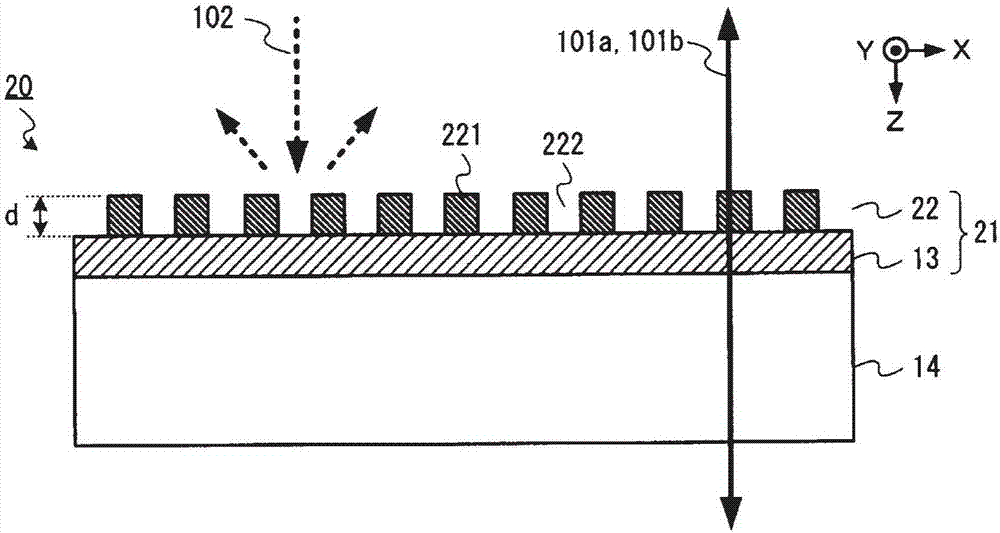

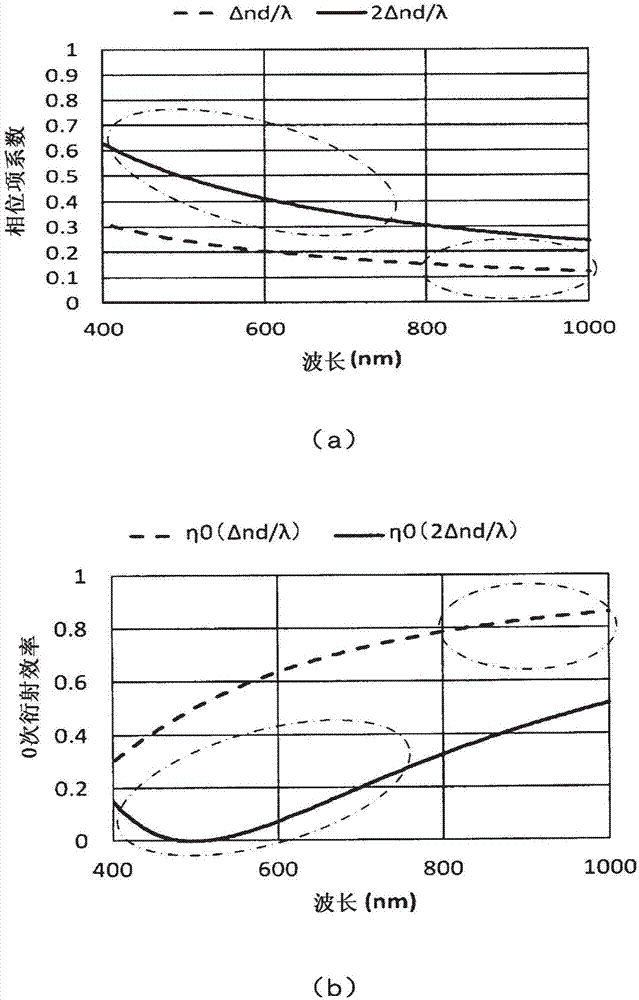

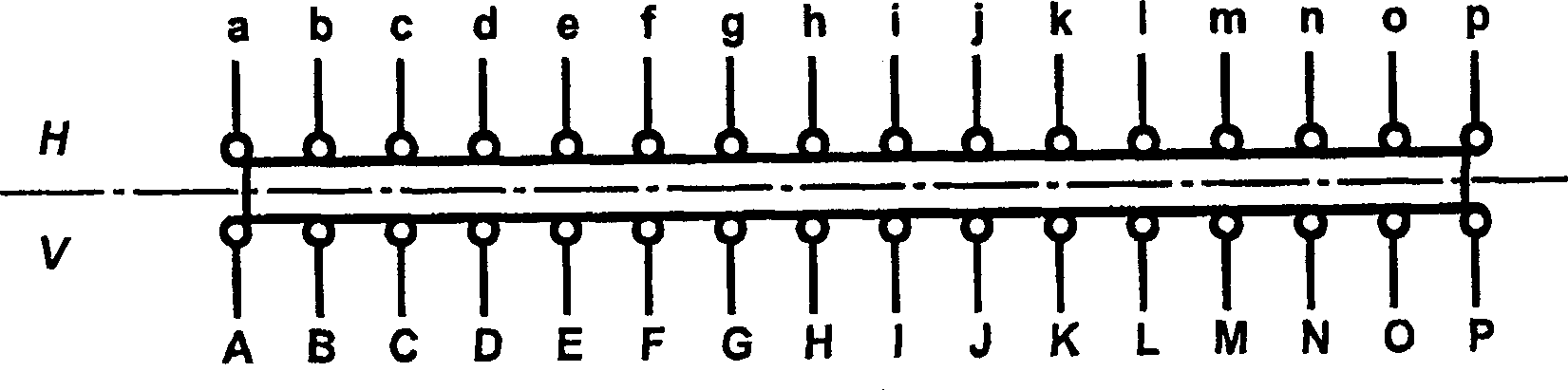

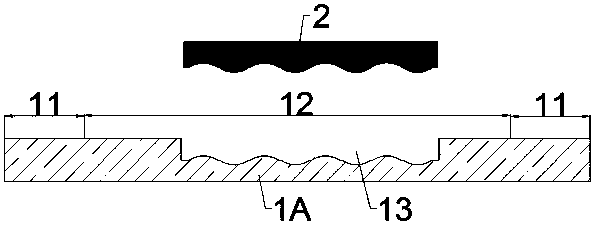

Optical device and optical member

ActiveCN107209304AHigh reflective scatteringHigh in-line transmittanceTelevision system detailsRadiation pyrometryElectricitySelective reflection

An optical member according to the present invention and equipped with a reflection / scattering section (11) including a selective reflection section (13) for reflecting visible light (102), for example, and transmitting infrared light (101a), for example, and also including a scattering section (12) for scattering the visible light 102 and provided on at least a first side (visible side) of the selective reflection section, wherein the rectilinear propagation transmittance of the infrared light (101a) is 75% or higher. The scattering section (12) may have a diffraction structure, may be a concavoconvex surface formed on the first-side surface of a reflective member belonging to the selective reflection section (13), or may have a particle-containing resin layer. The reflective member of the selective reflection section (13) may be a dielectric multilayer film or a cholesteric phase liquid crystal layer. Furthermore, the reflection / scattering section (11) may have a cholesteric phase liquid crystal layer having multiple regions with different axes of orientation in one plane.

Owner:ASAHI GLASS CO LTD

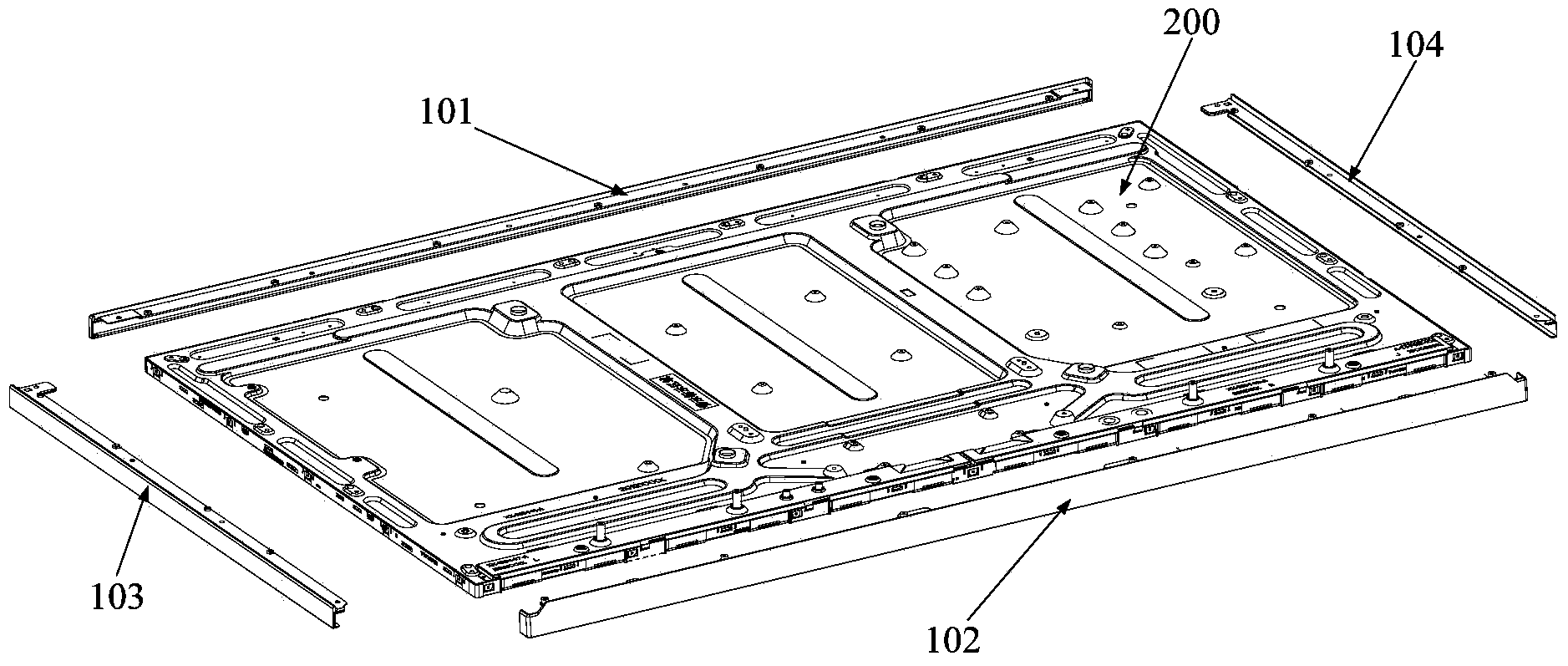

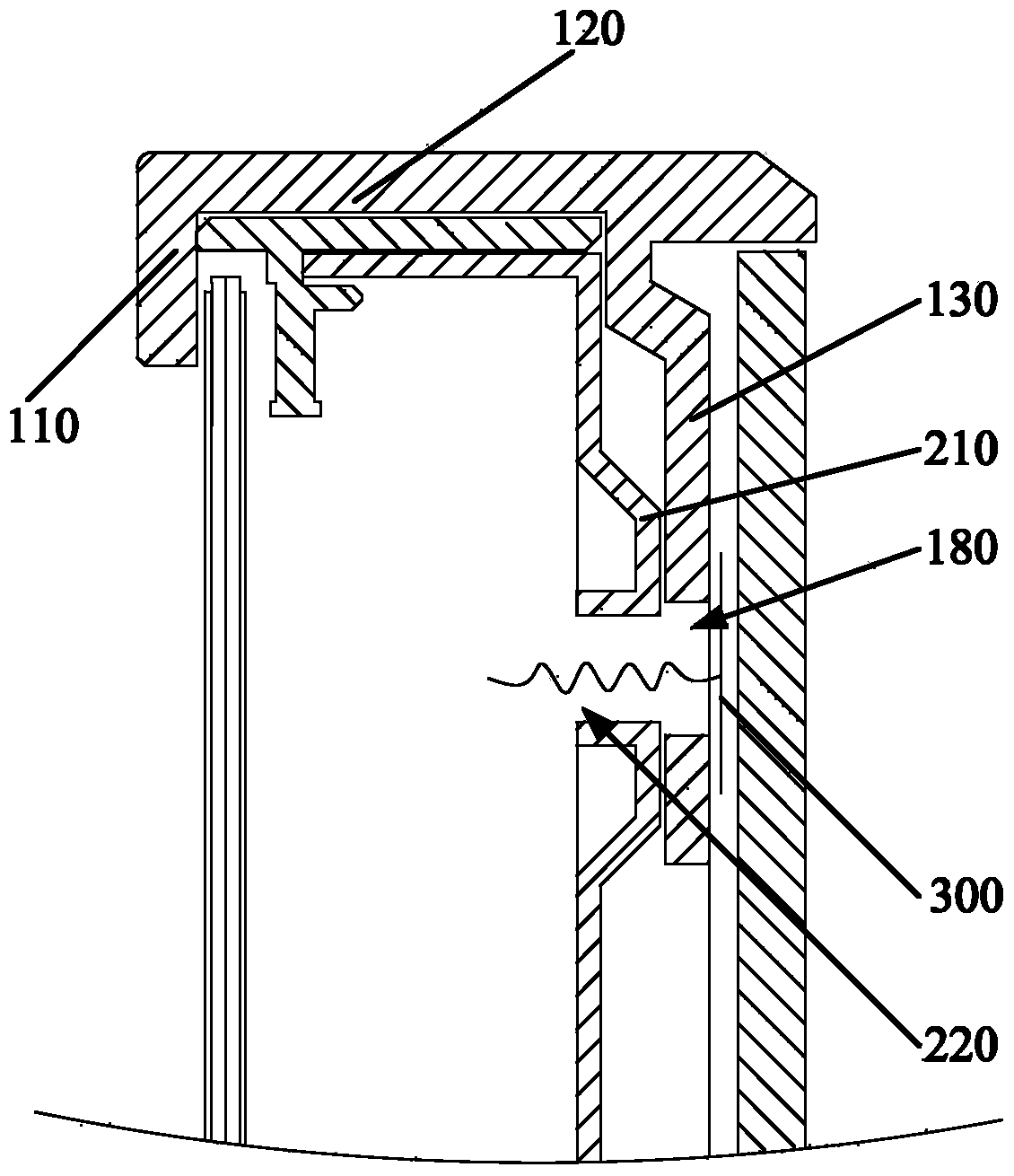

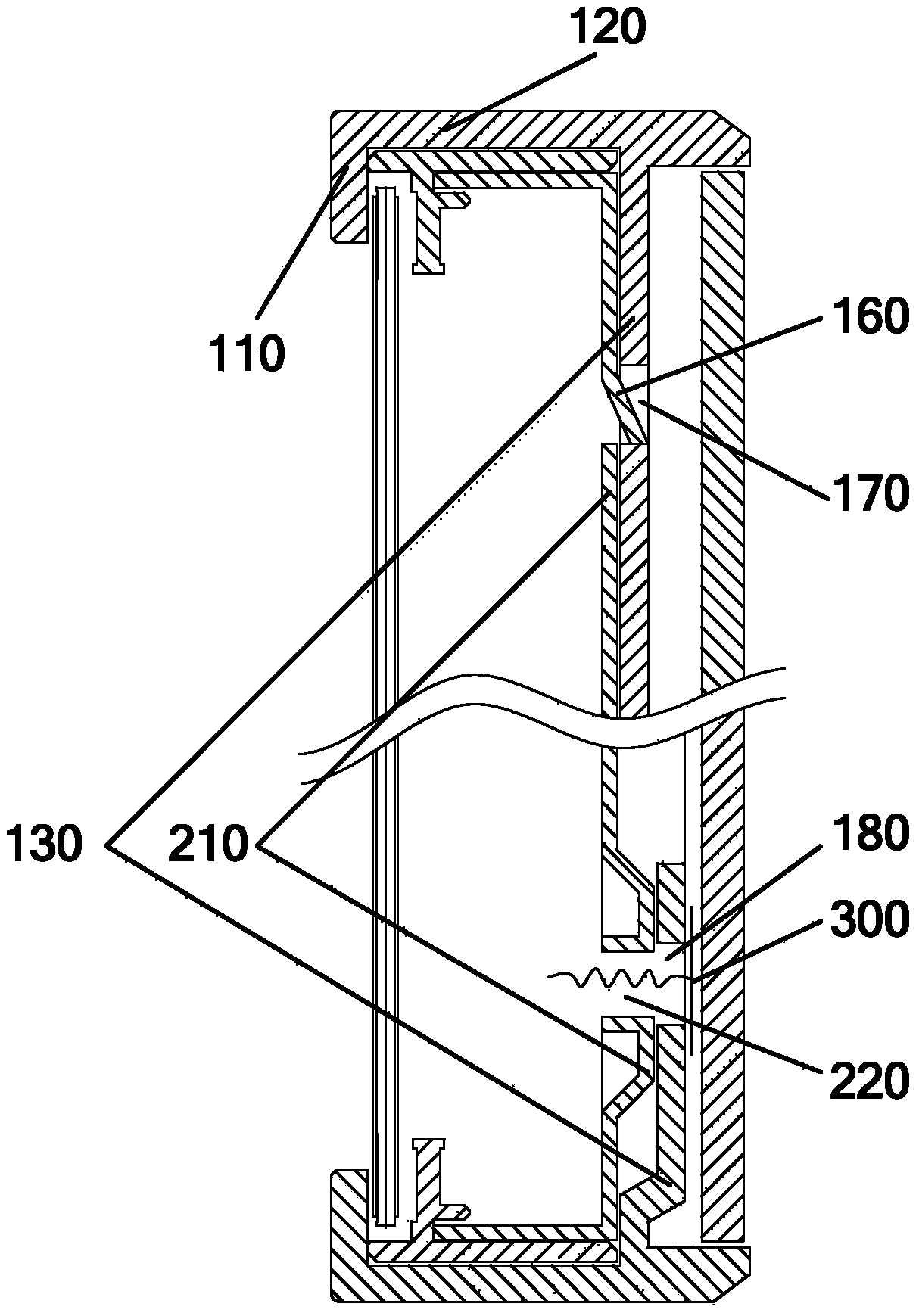

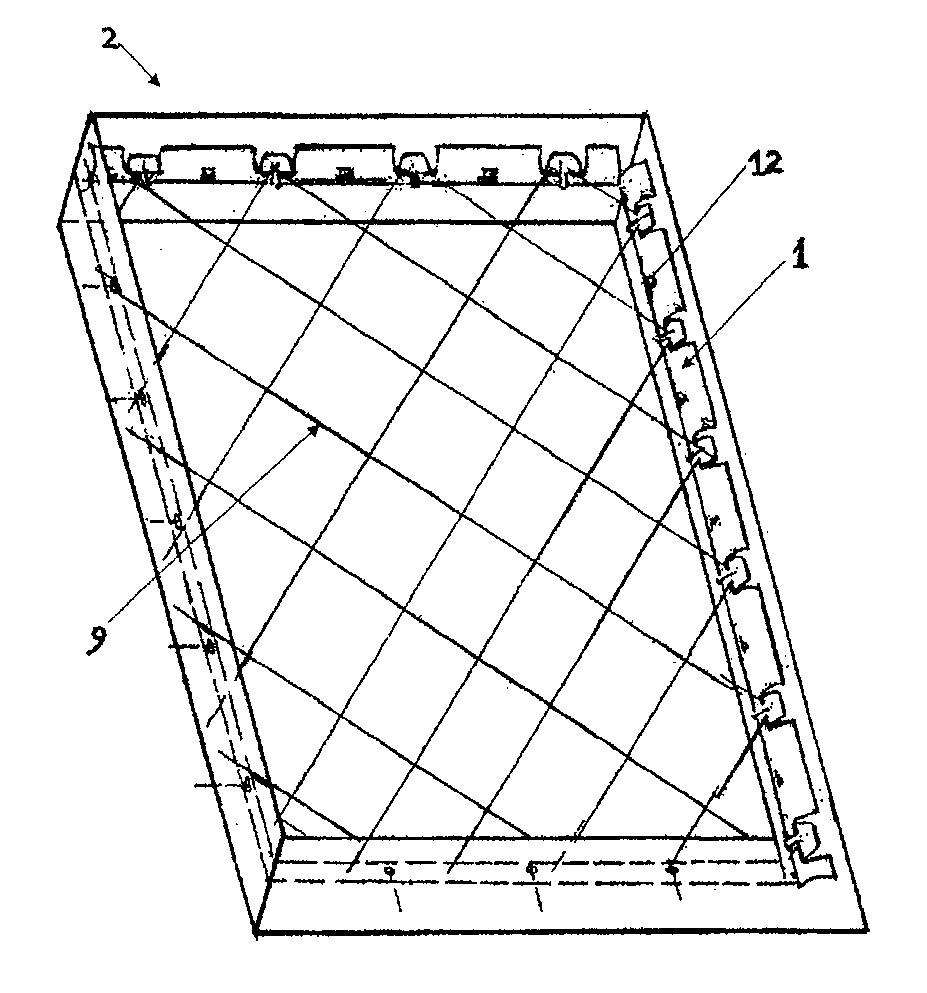

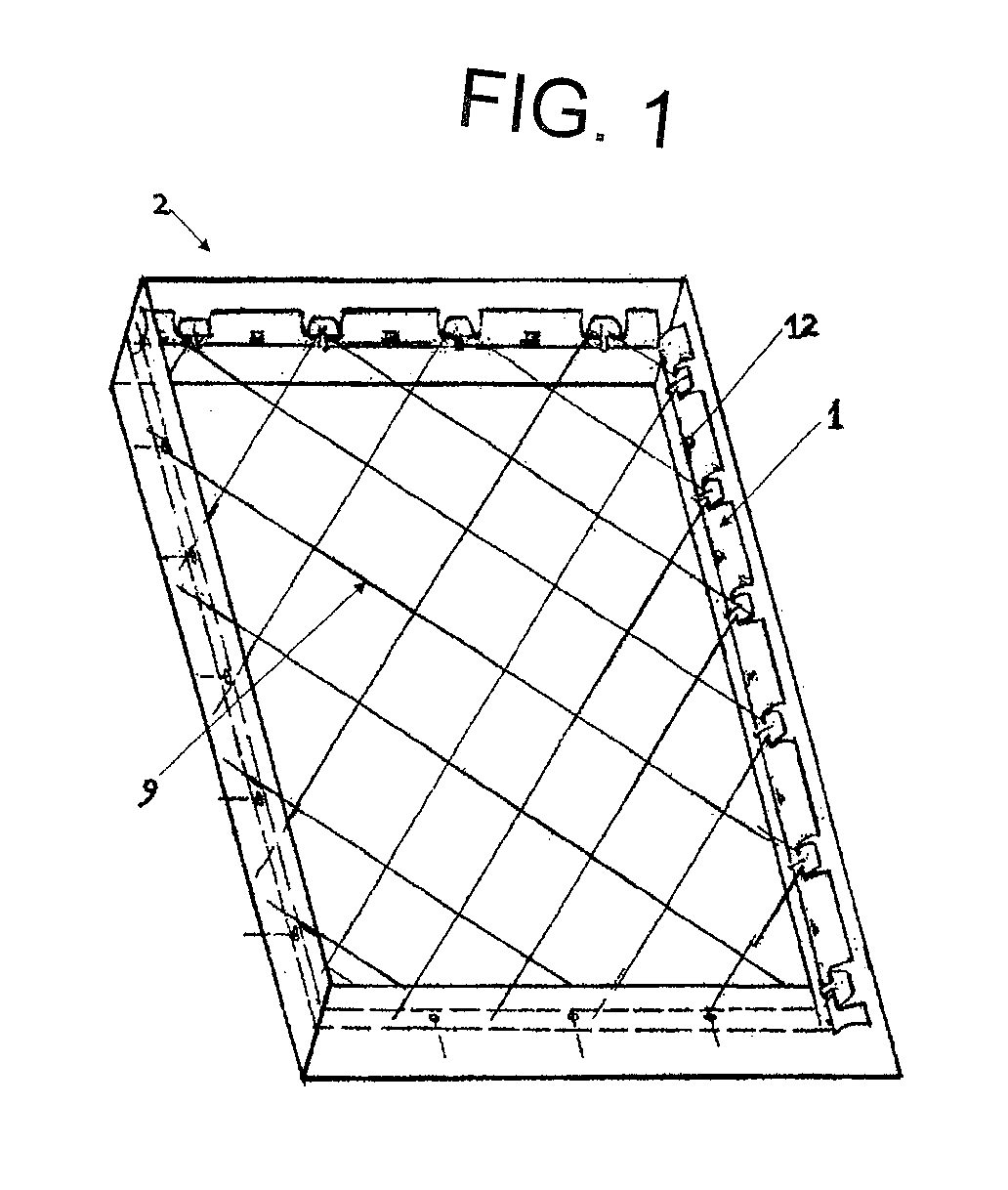

Display device and television

InactiveCN103476213AAchieve the appearanceEasy to installTelevision system detailsCasings/cabinets/drawers detailsDisplay deviceEngineering

The invention provides a display device and a television. The display device comprises a front shell and a display module. The front shell is connected with the display module. The front shell is of a rectangular frame structure formed by splicing frame components, the frame components comprise pressing edges, lateral edges and bottom edges, the pressing edges and the bottom edges are connected with the lateral edges respectively, and the pressing edges and the bottom edges are parallel and located on the same side as the lateral sides. According to the technical scheme, the frame width of the front shell is determined by the width of a front shell wrapped screen, the structural thickness of a rubber frame assembly inside the screen and the wall thickness of the front shell itself, besides the necessary width of the front shell wrapped screen and the necessary structural thickness of the rubber frame assembly inside the screen, only the wall thickness of the front shell itself needs to be considered, so that the problem that the wall thickness of the front shell is increased due to increasing of the thickness of screws and the structure thickness of inserting tongues. Therefore, the front shell can be used for fixing a panel, and meanwhile, the appearance effect that the display device is narrow in frame is realized.

Owner:HISENSE VISUAL TECH CO LTD

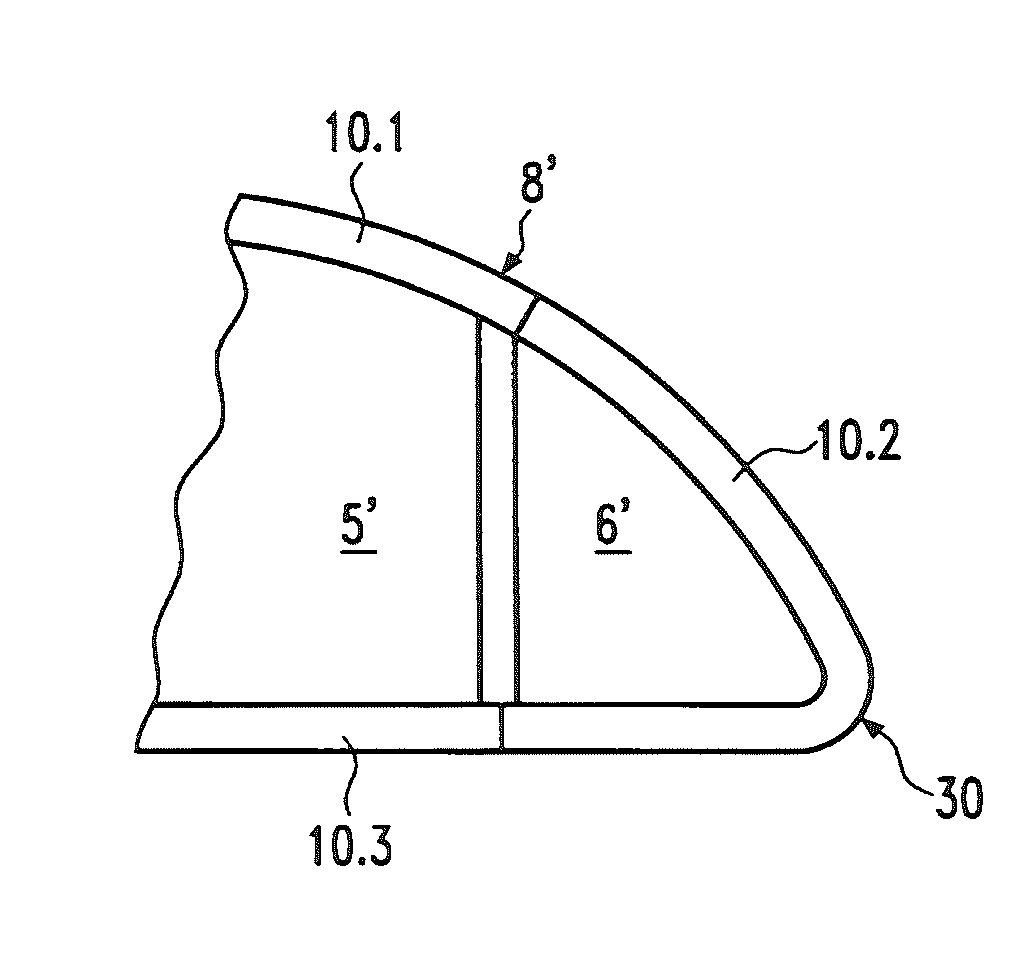

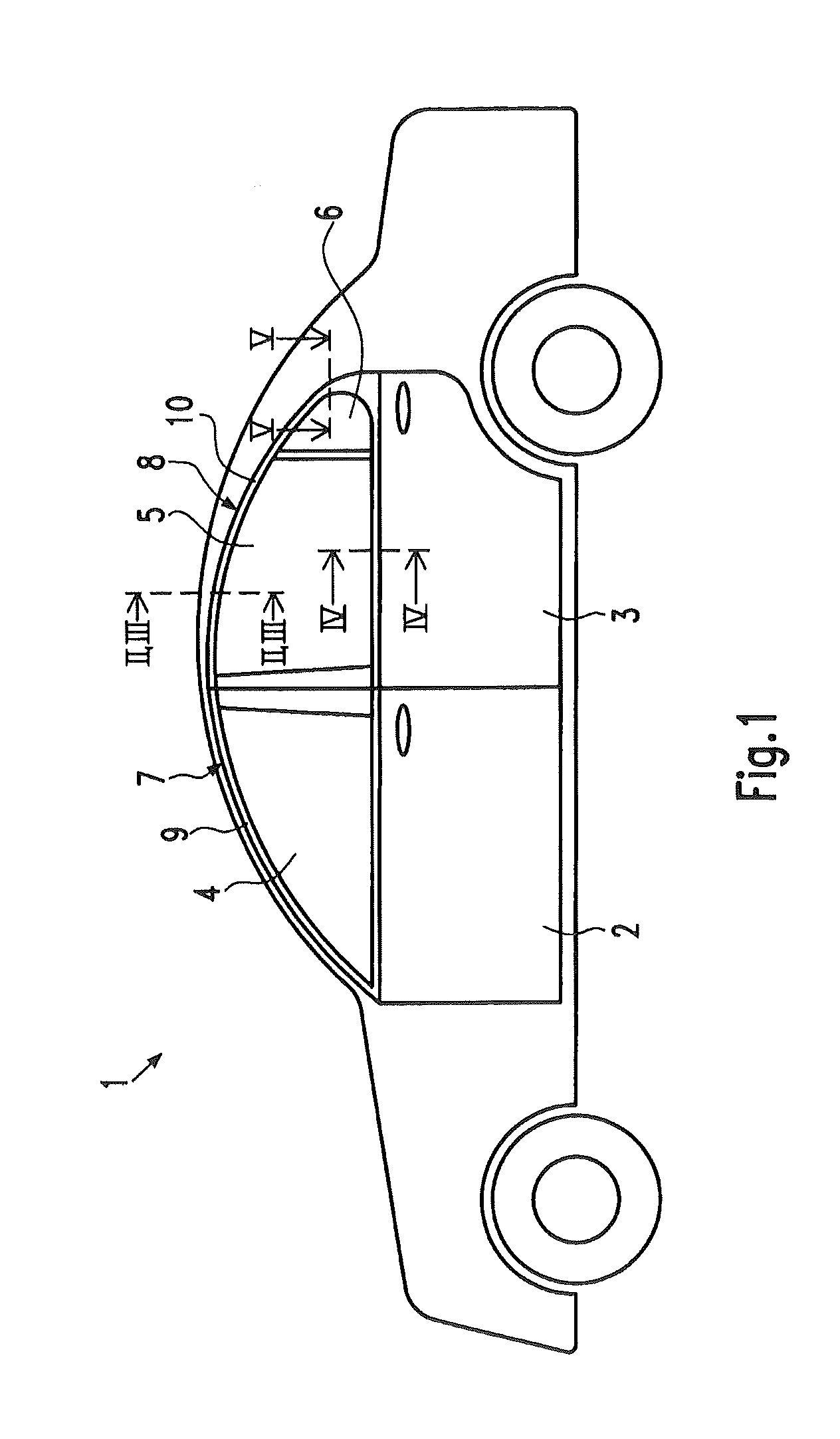

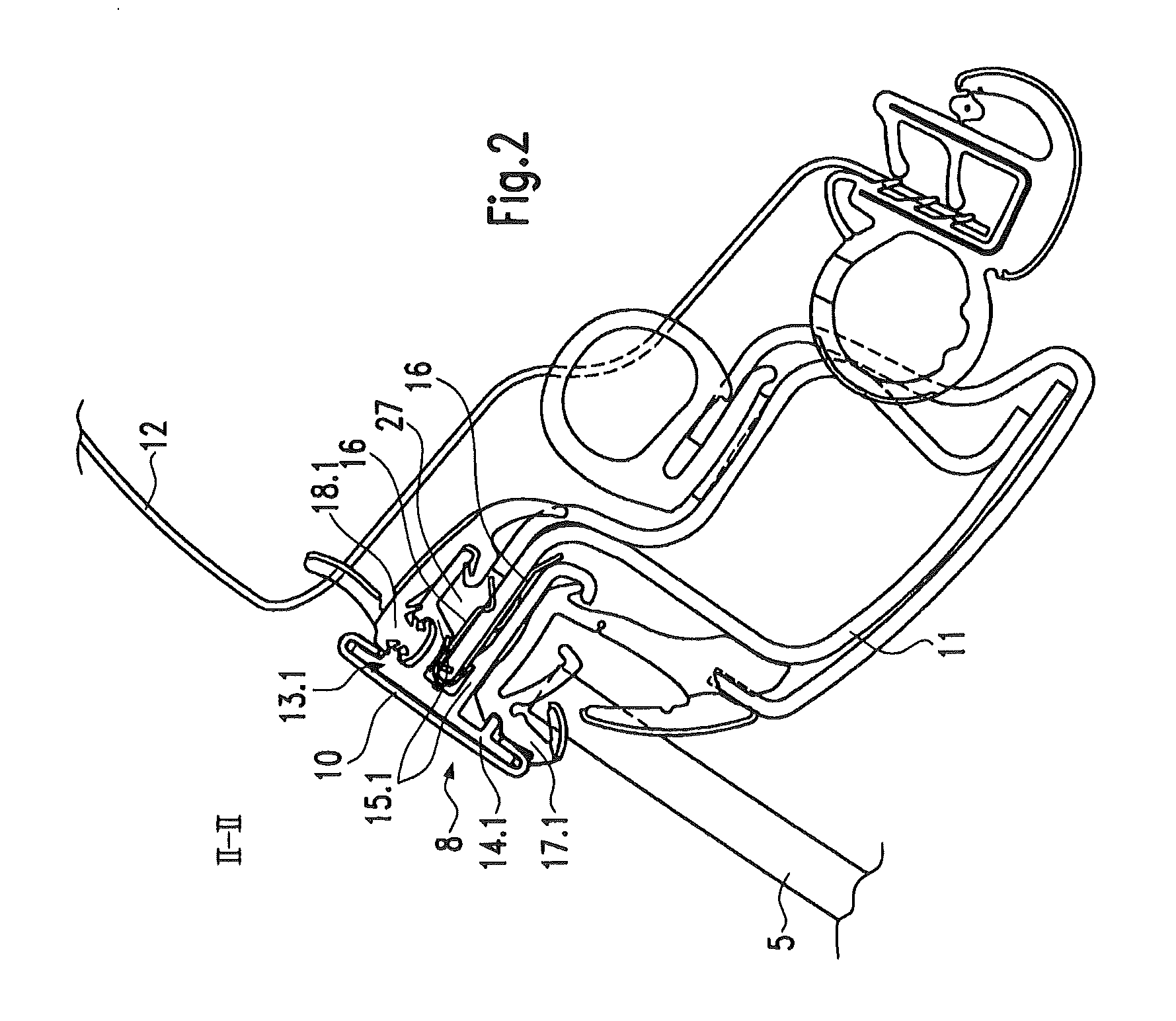

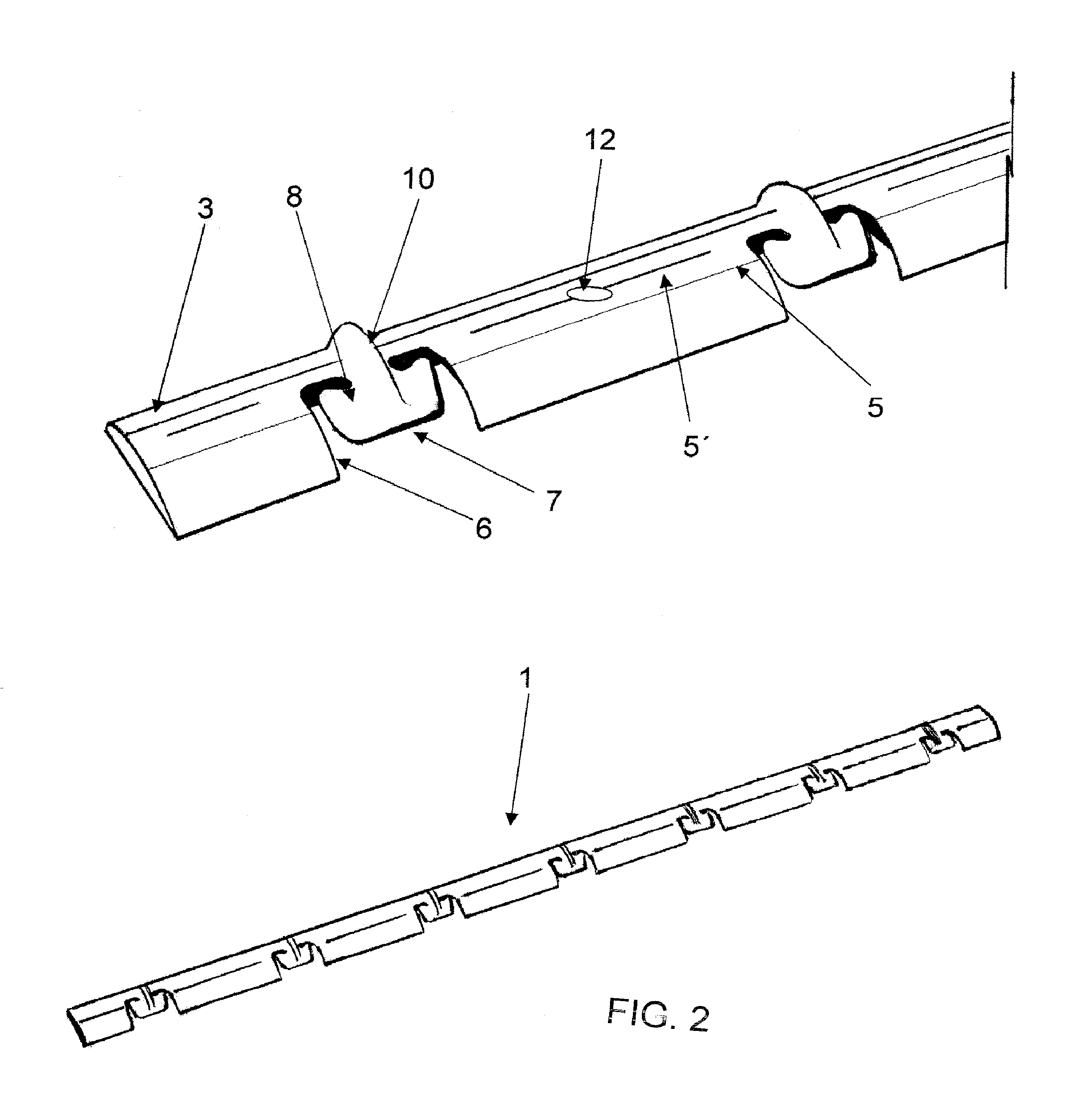

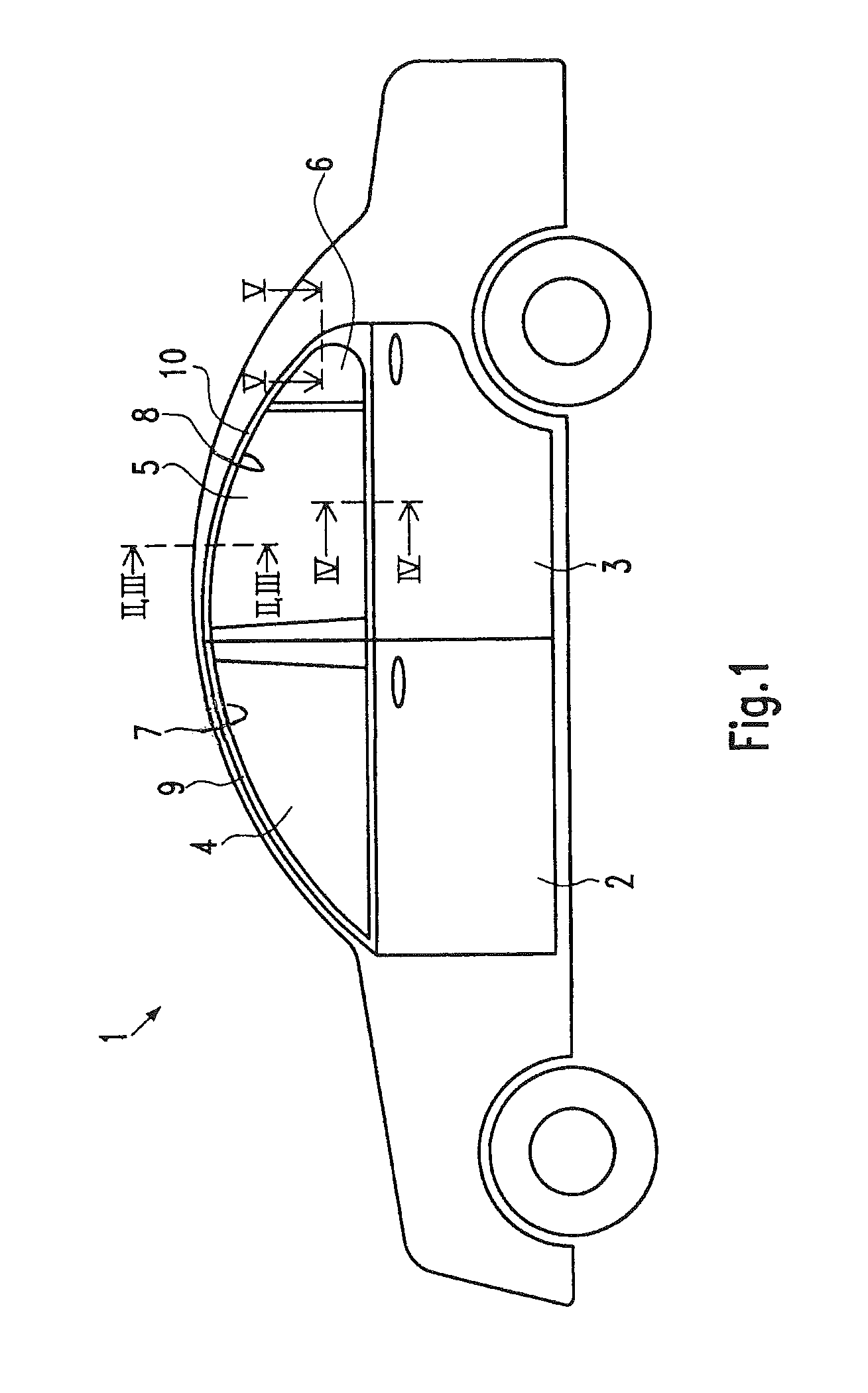

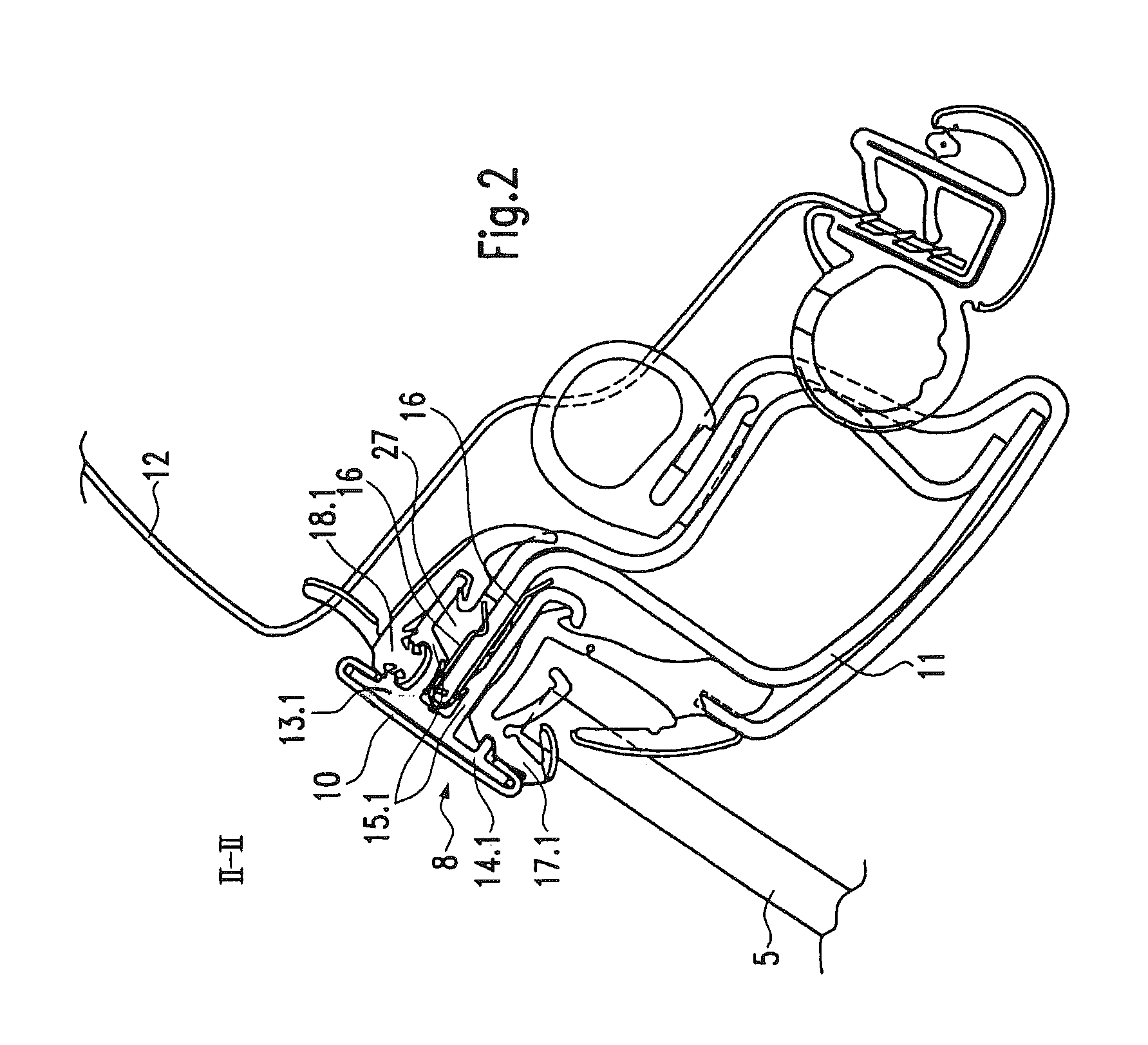

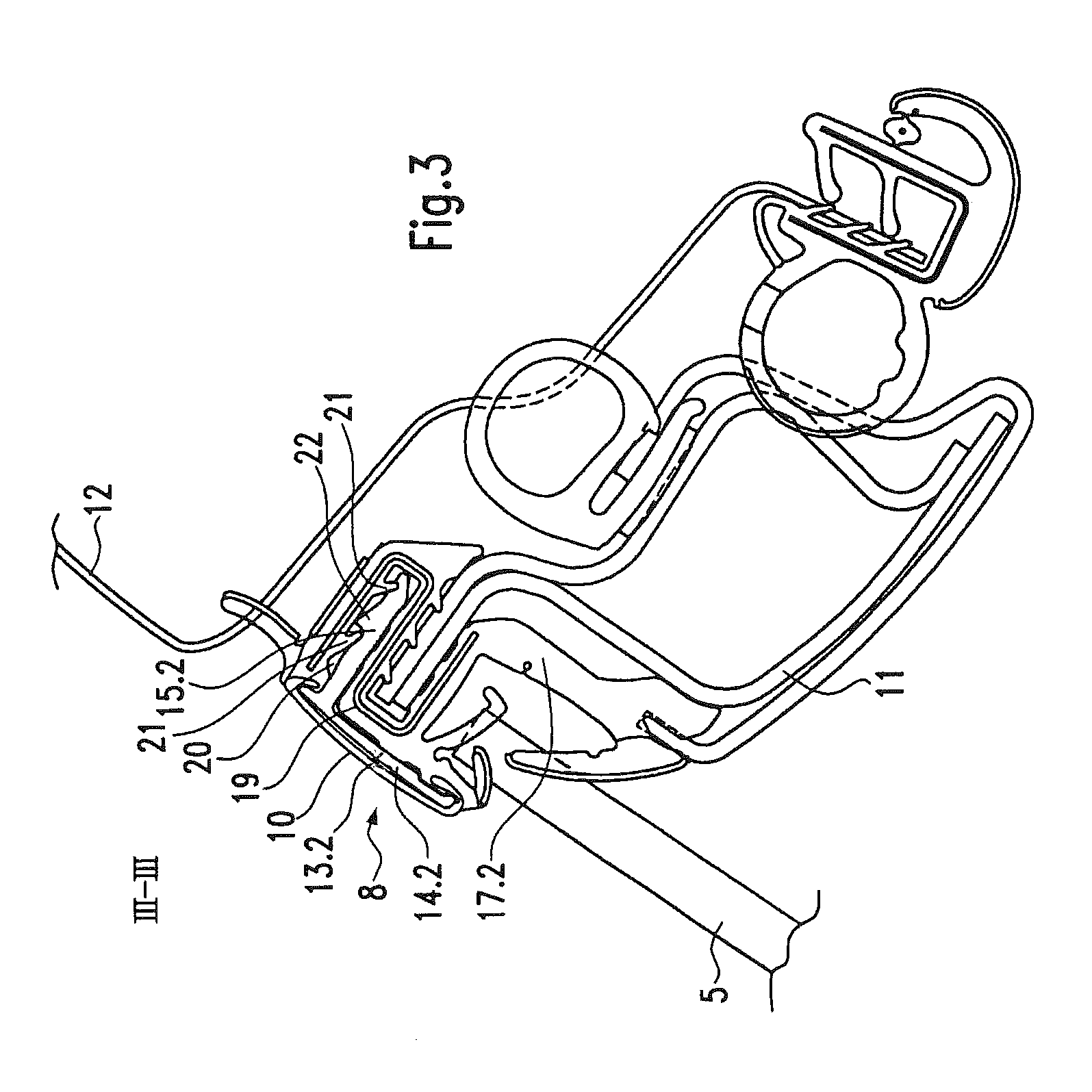

Window frame

A window frame (7, 8, 8′) for a window (4, 5, 6, 5′, 6′) of a passenger car, has at least one seal having one or a plurality of sealing profiles (17.1, 17.2, 17.3, 17.4, 18.1, 18.4) that abut one another at seams in the longitudinal direction of the seal, and further have a fastening profile cooperating with the seal and comprising one or more fastening profile pieces (13.1, 13.2, 13.3, 13.4) that abut one another on at least one seam in the longitudinal direction of the fastening profile. The fastening profile pieces (13.1, 13.2, 13.3, 13.4) have a metal ornamental moulding (9, 10, 10.1, 10.2, 10.3) attached to them and a moulding flange (14.1, 14.2, 14.3, 14.4) fastened with at least one fastening element (15.1, 15.2, 15.3, 15.4) to secure the fastening profile to the passenger car. The ornamental moulding (9, 10) is crimped on the moulding flange (14.1, 14.2, 14.4) of the fastening profile piece or pieces (13.1, 13.2, 13.3, 13.4) such that it covers the seam in one piece. The invention additionally relates to a method of producing such a window frame.

Owner:CADEA FUR ANWENDUNG & REALISIERUNG COMPUNTERSTUTZTER SYST MBH

Device with protection net and assembly procedure suitable as barrier for all kinds of openings

InactiveUS20110154739A1High tenacityHigh enduranceFixed grillesBuilding repairsGlass fiberPlastic materials

This invention refers to a device with protection net and assembly procedure, suitable as a barrier for every kind of opening. It uses profiles especially designed and made up of plastic material (polyamide) with fiberglass, thus allowing mass production and easy handling. It also counts on assembly and tie means integrally related to a safety mesh-like net to be used as a retaining barrier in balconies, terraces, windows, and stairways preferably. It will reduce the risk of children and / or careless people falls in a safe, economical and esthetical manner.

Owner:GRUN ANDREA LUISA

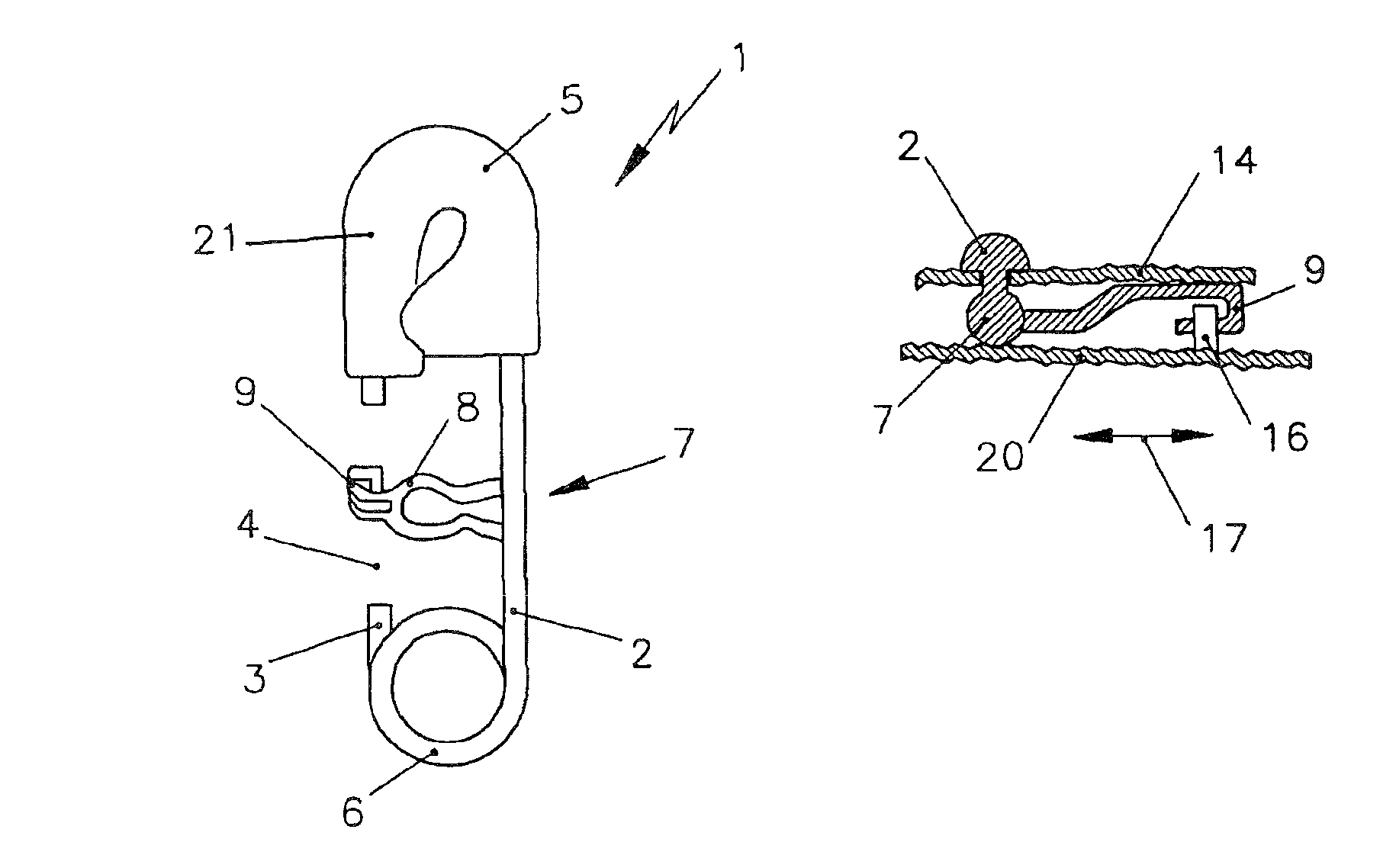

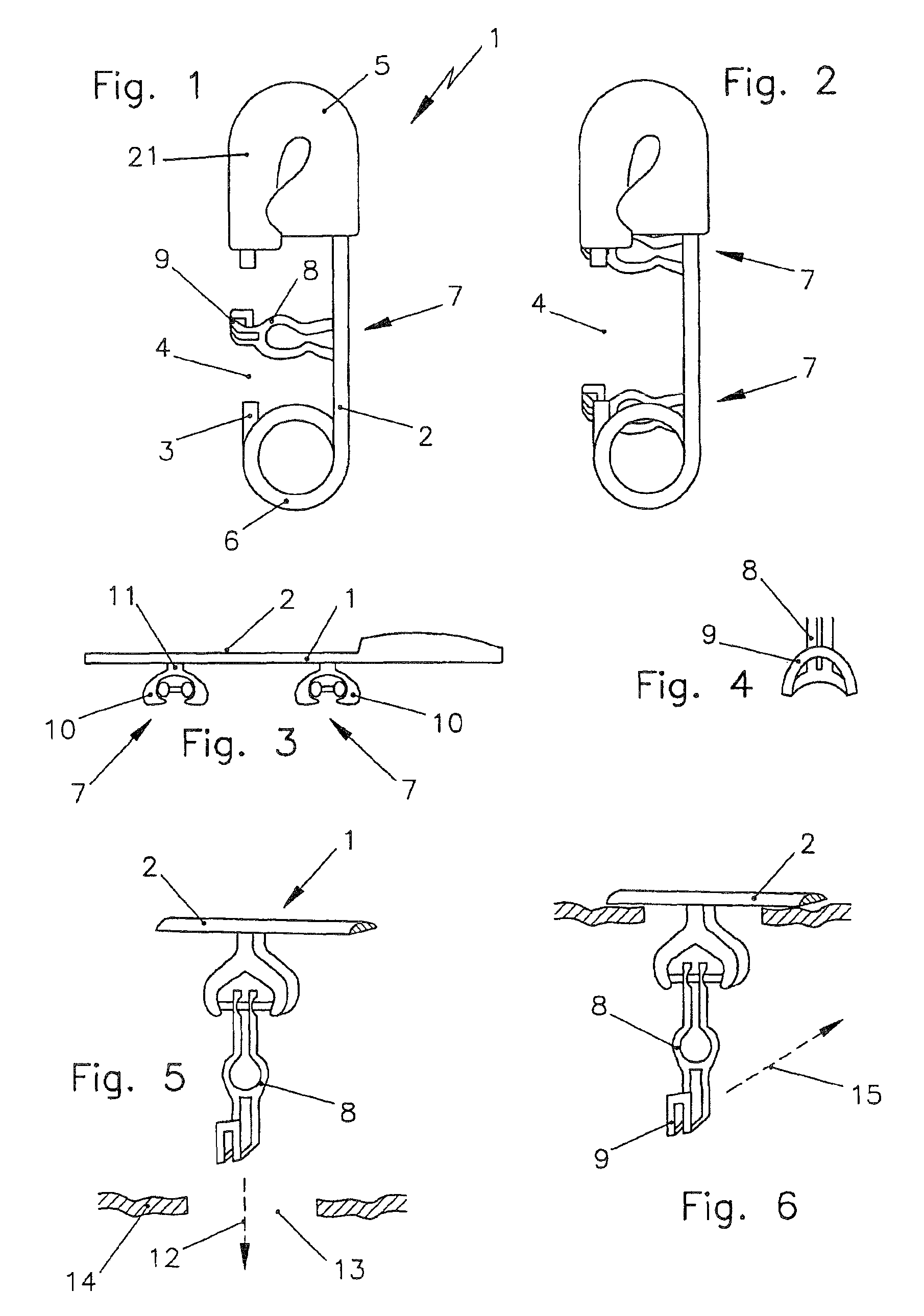

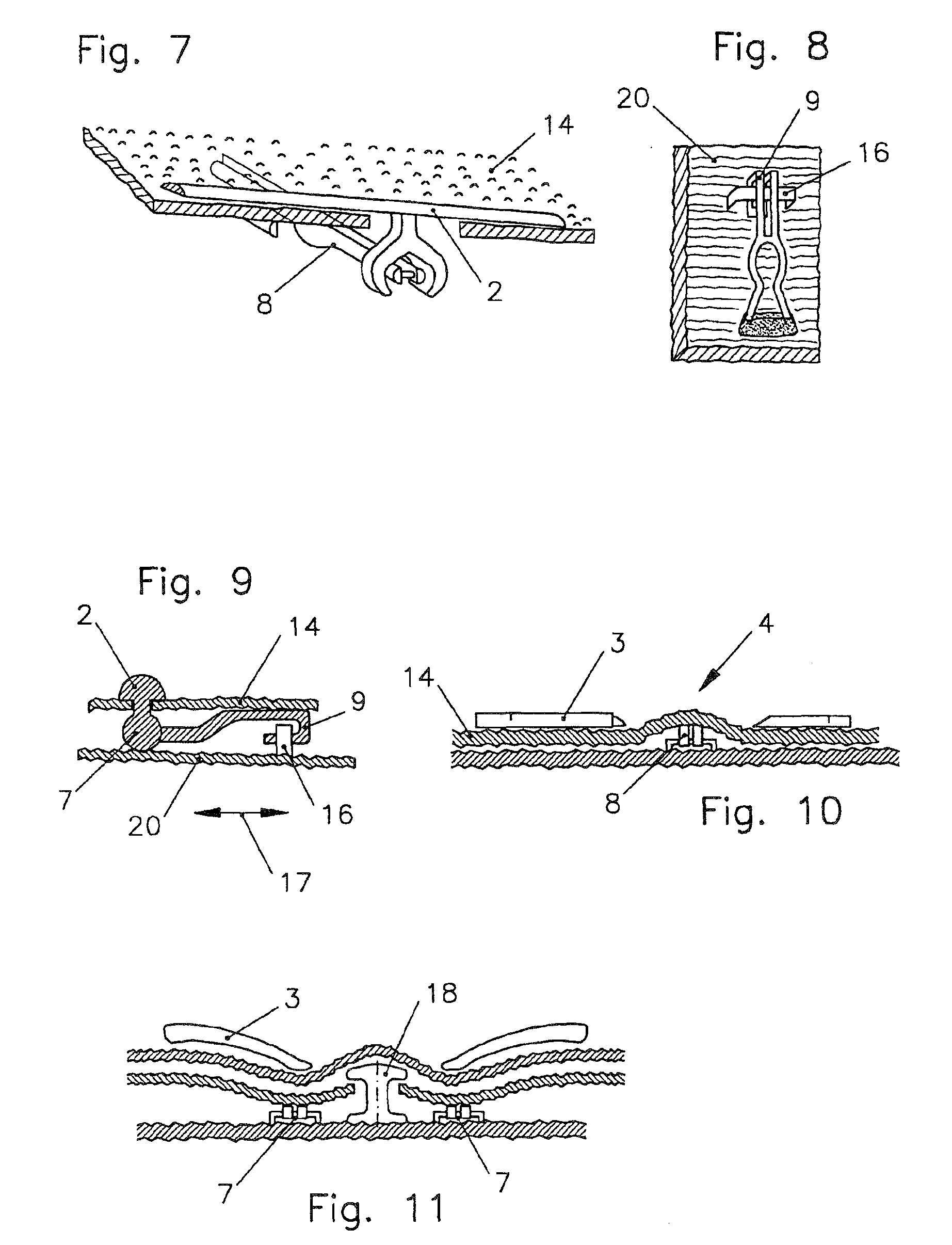

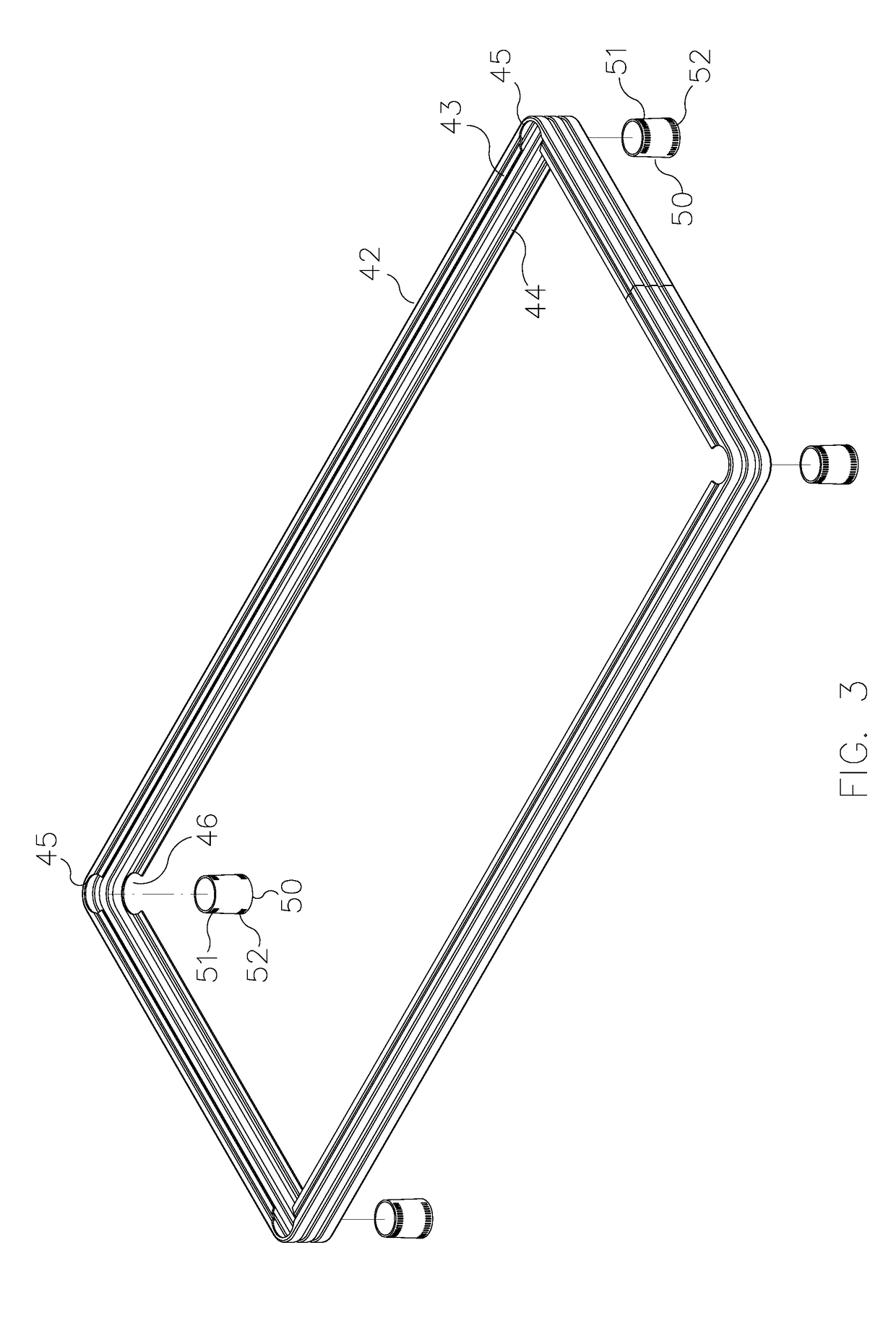

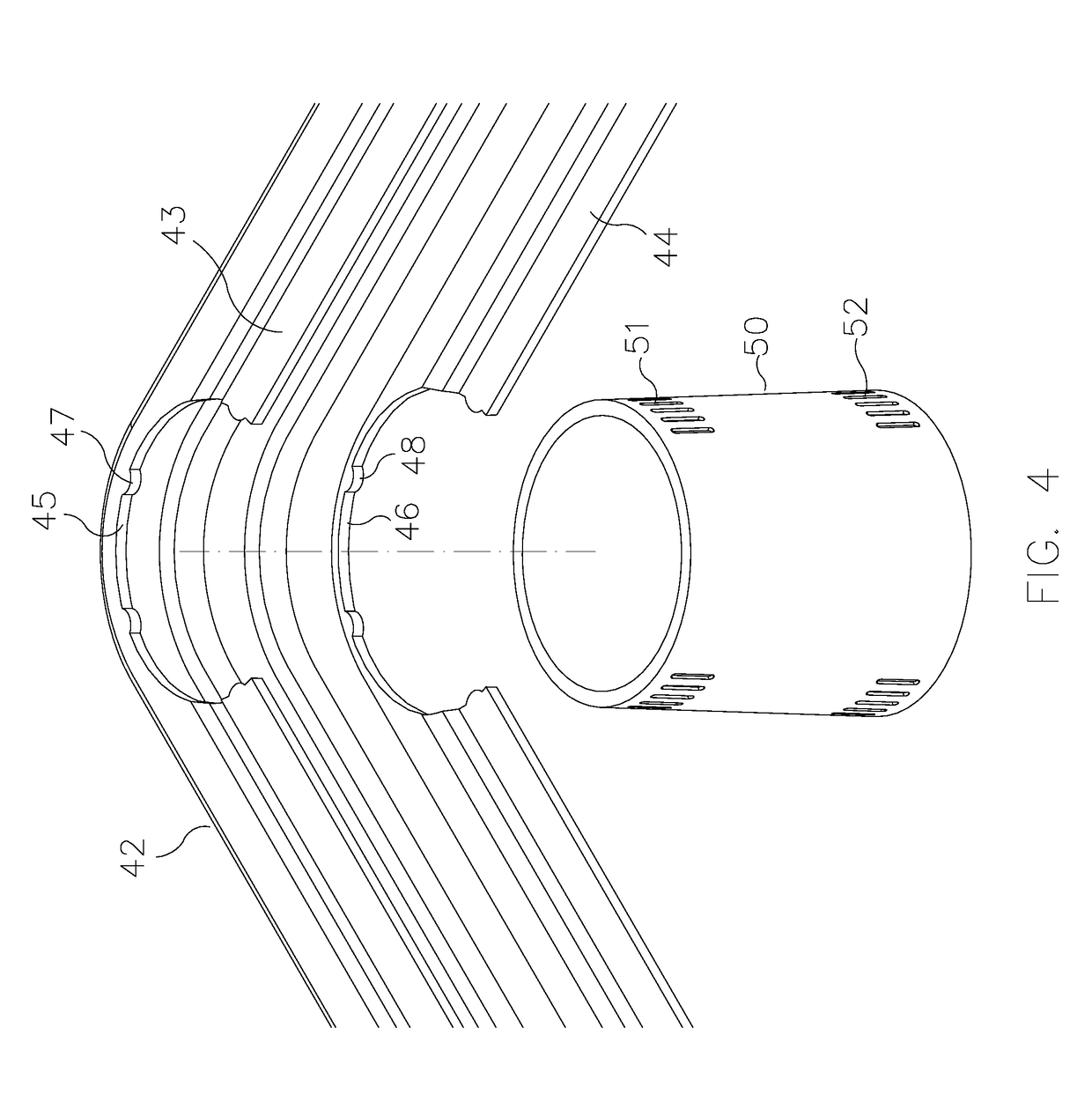

Closure for joining at least two pieces of material

InactiveUS8108974B2Achieve the appearanceAbsorb tensile stressSnap fastenersClothes buttonsEngineeringMechanical engineering

Disclosed is a closure for joining at least two pieces of material, especially layers of material (14, 20). Said closure comprises two closure elements (2, 3) which are spaced apart in some sections. The first closure element (2) is provided with at least one fastening means (7) while the second closure element (3) is fitted with an especially central gap (4).

Owner:T GILMOR

Self-repair coating for surfaces of flexible macromolecular base materials, method for preparing self-repair coating and application thereof

InactiveCN109486397ARandom combinationFlexible enoughPolyurea/polyurethane coatingsPolyesterCross-link

The invention discloses a self-repair coating for the surfaces of flexible macromolecular base materials, a method for preparing the self-repair coating and application thereof. Raw materials in a formula for the self-repair coating include, by weight, 10-25 parts of flexible polyester polyol, 4-15 parts of rigid polyester polyol, 5-16 parts of curing agents, 0.1-0.3 part of catalysts, 0.2-1 partof auxiliaries and 50-70 parts of solvents. The curing agents are trimers of diisocyanate monomers. The self-repair coating, the method and the application have the advantages that the trimers of thediisocyanate monomers are used as the curing agents for the self-repair coating, the high cross-link density can be guaranteed, accordingly, paint films have the required density and smooth surfaces,and the self-repair coating is solvent-resistant and has high-transmittance appearance; the polyester polyol with different degrees of softness is compounded, accordingly, the self-repair coating is high in cross-link density, the paint films have sufficient flexibility, and the flexibility of flexible thin films subsequently can be prevented from being destroyed.

Owner:ZHEJIANG SHICHUANG OPTICAL FILM MFG

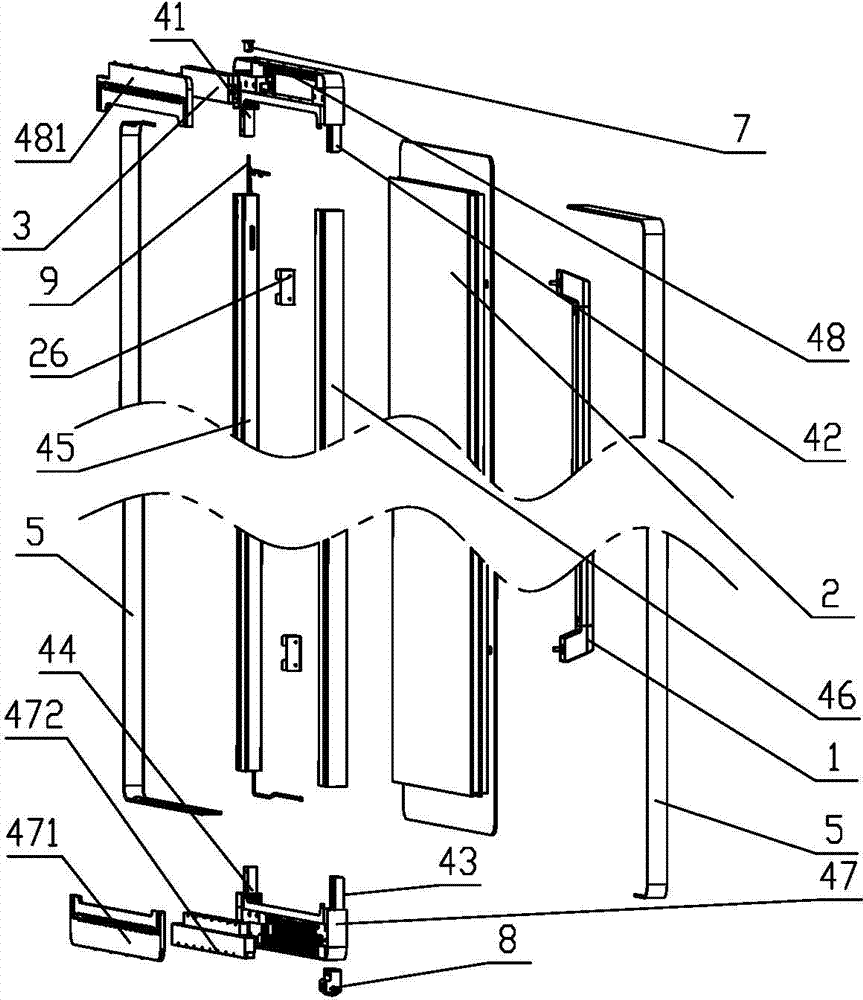

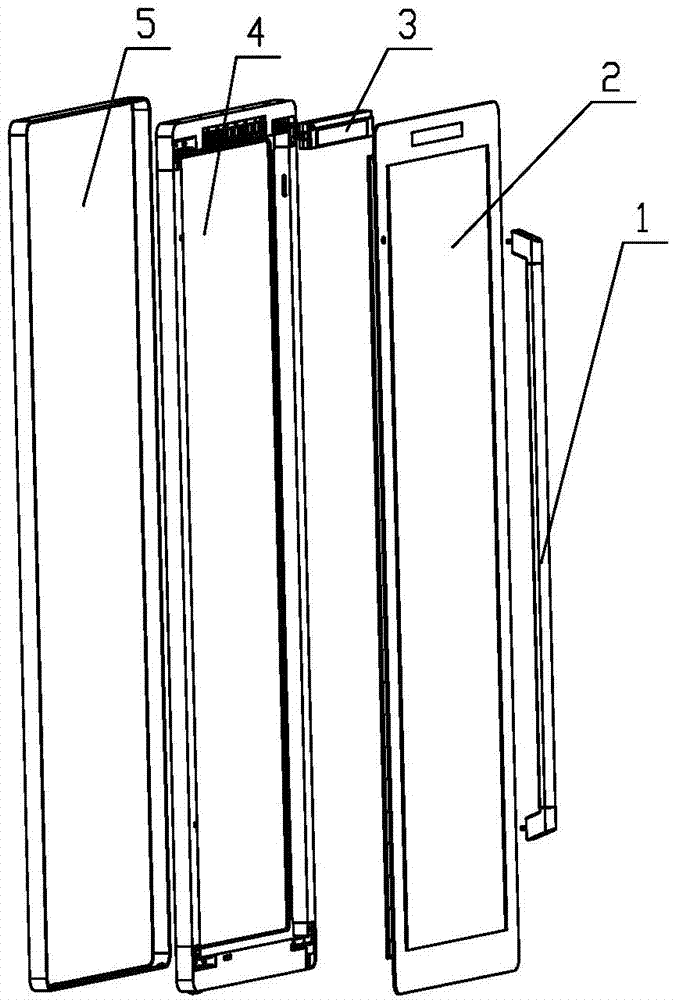

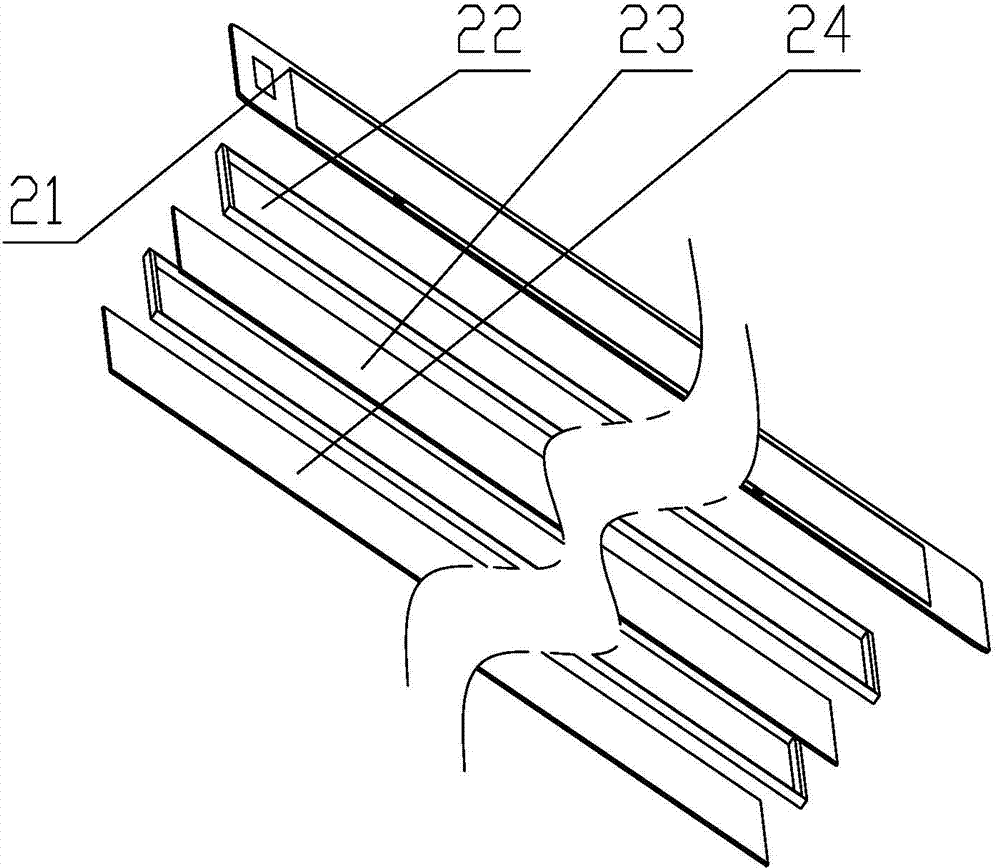

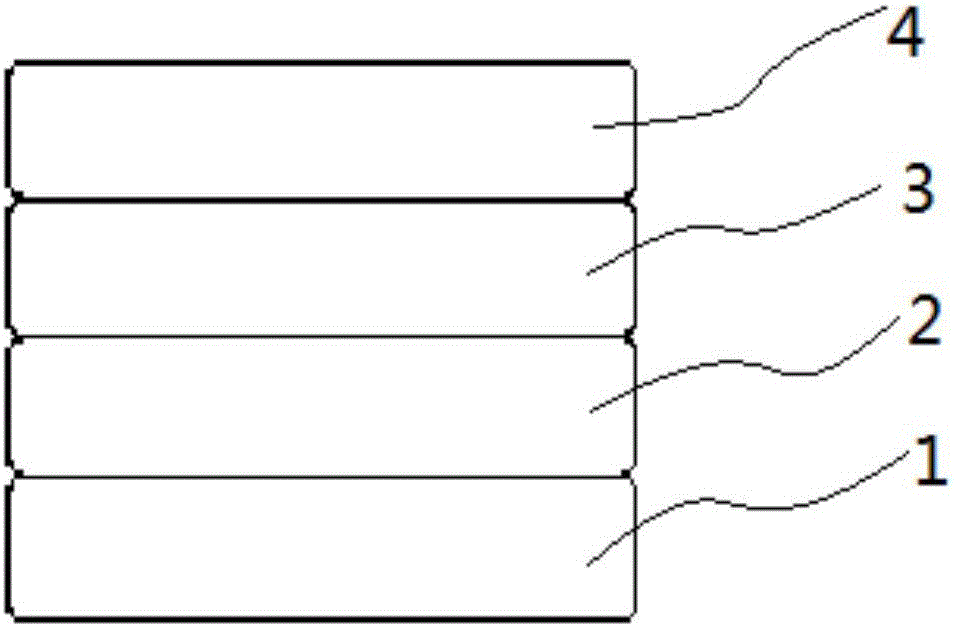

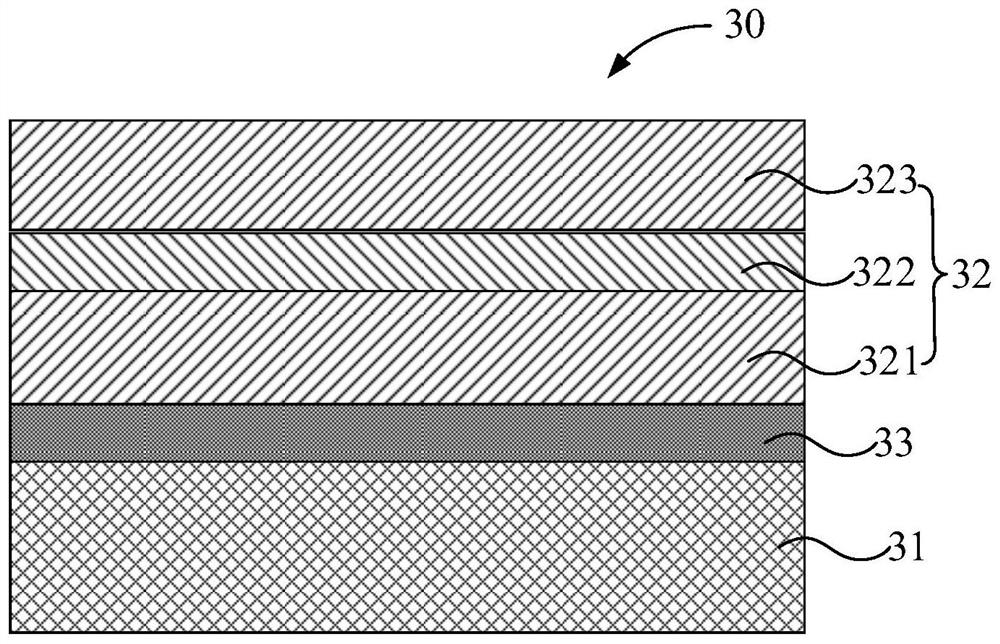

Glass door mounting structure and electric appliance

ActiveCN104499897AReduce thicknessThe overall thickness is thinDomestic cooling apparatusLighting and heating apparatusPolyvinyl chlorideEngineering

The invention relates to the field of electric appliances and discloses a glass door mounting structure and an electric appliance. The glass door mounting structure comprises a glass door unit. The glass door unit comprise outer glass, middle glass and inner glass which are arranged sequentially from outside to inside; a screen bar is disposed between the outer glass and the middle glass, and another screen bar is disposed between the middle glass and the inner glass; the screen bars are used for separating the outer glass, the middle glass and the inner glass so that the outer glass, the middle glass and the inner glass are spaced; the screen bars are disposed at the top and bottom of the glass door unit. The glass door unit comprises the screen bars made of PVC (polyvinyl chloride); the thickness of the glass door unit can be effectively reduced to decrease the whole thickness of a glass door by decreasing the width of the screen bars, the thickness of the glass door is two thirds of that of like products and is even less than that of a prior double-layer glass door.

Owner:GREE ELECTRIC APPLIANCES INC

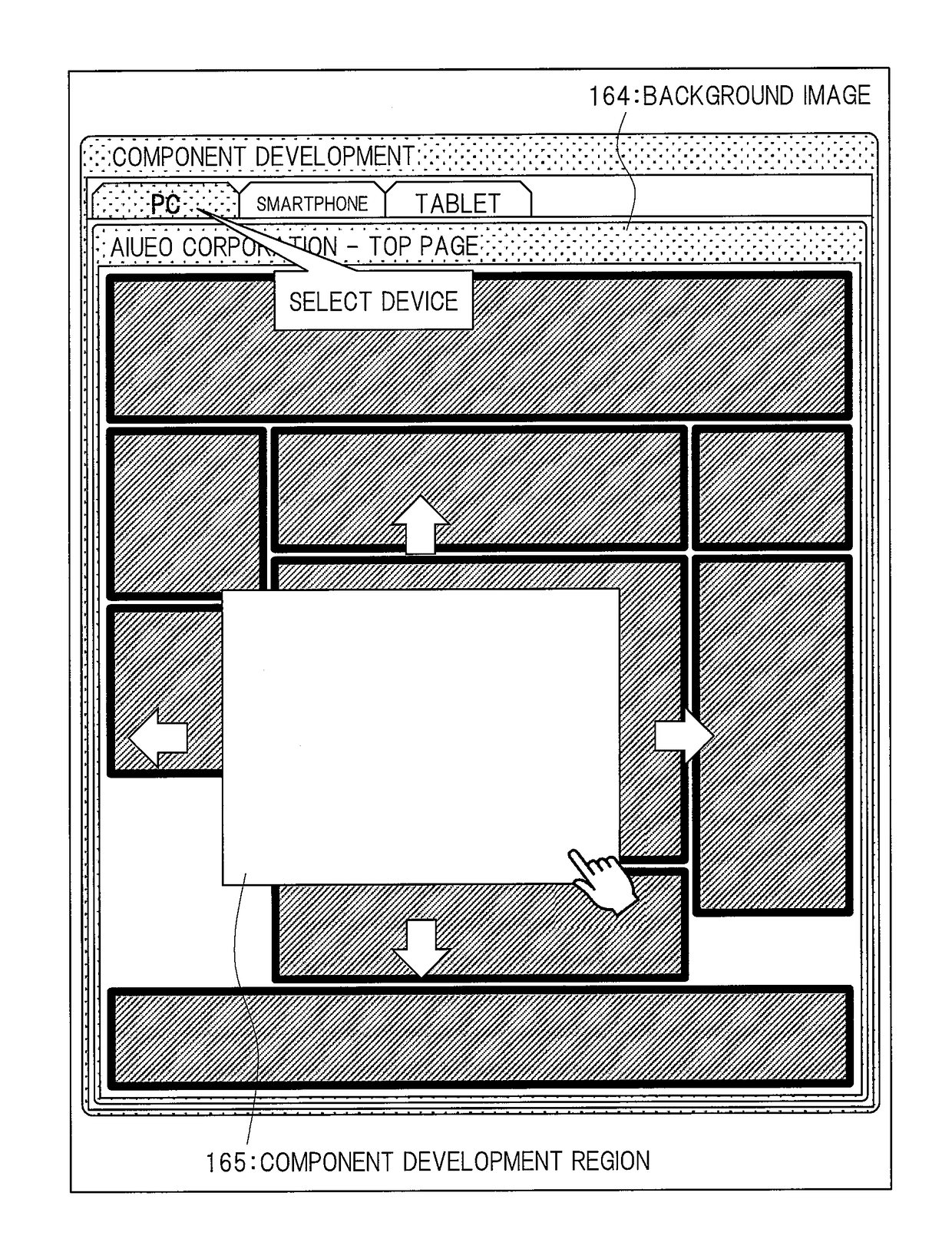

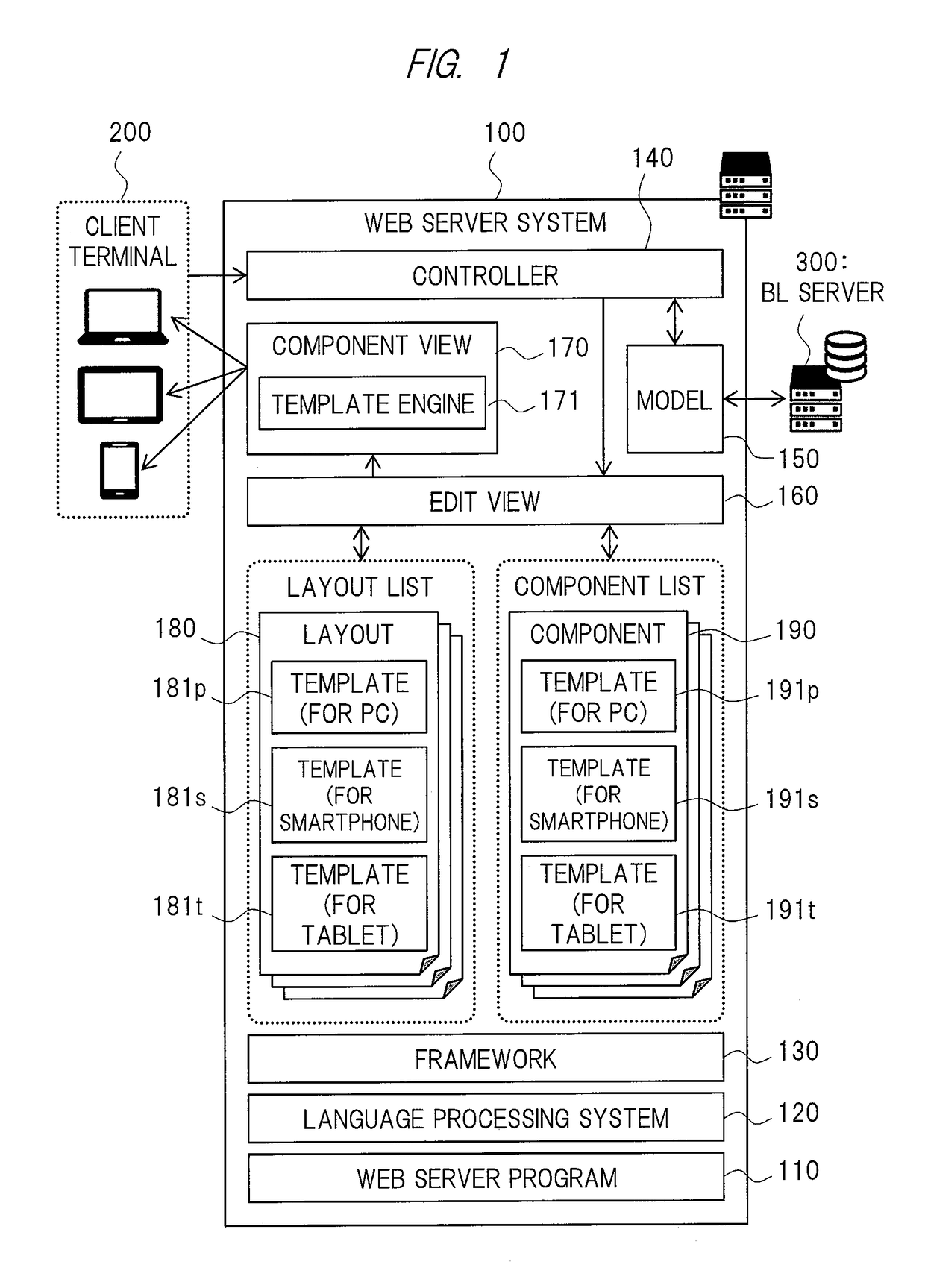

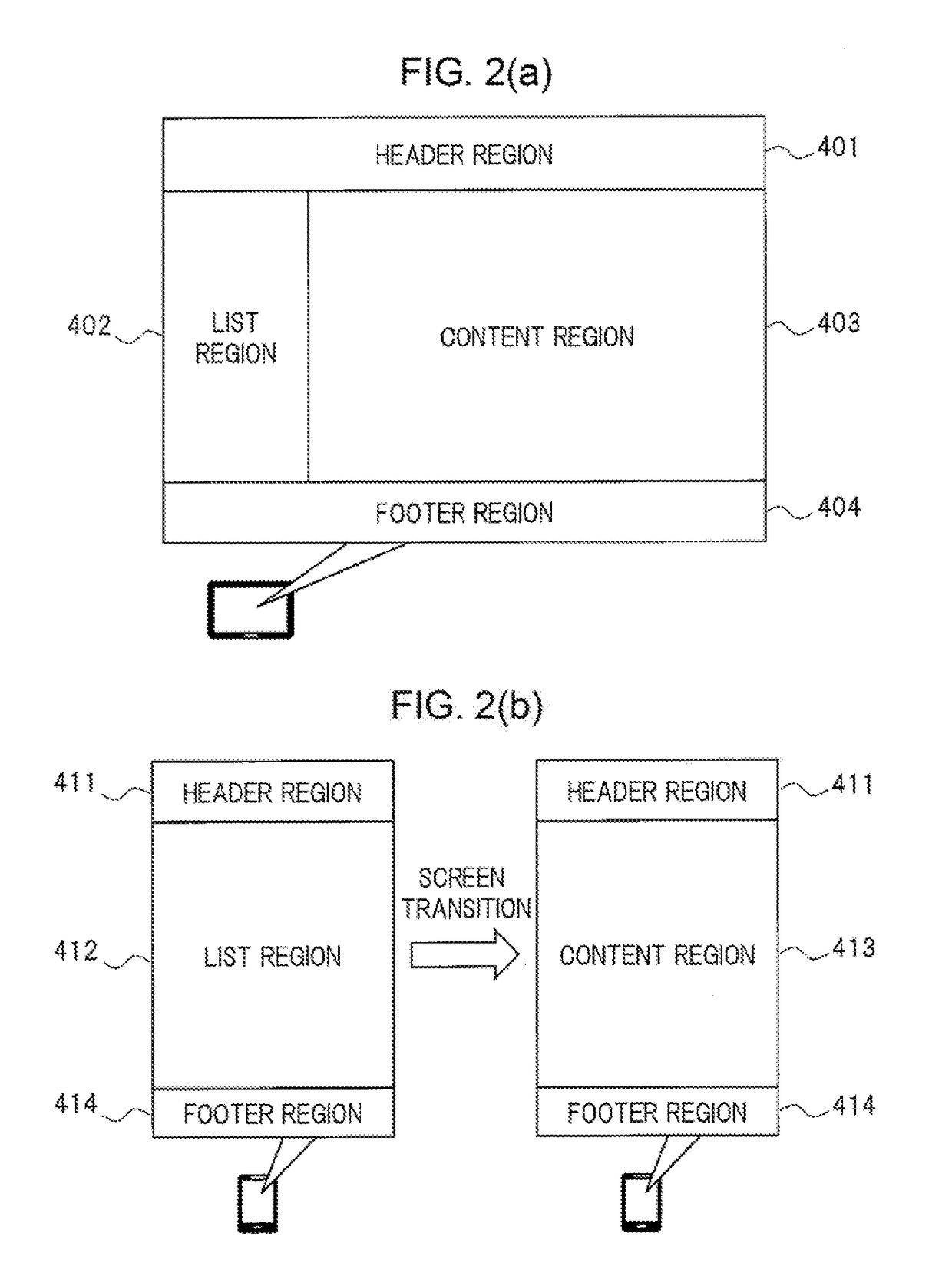

Development support system

InactiveUS20170286068A1Improve developmentAchieve the appearanceNatural language data processingIntelligent editorsSupporting systemDevice type

In a system of developing a screen by reusing a componentized element, the component can be developed while achieving consistency and harmony with an appearance of an entire screen. According to an embodiment, the system has: a component development controller that receives a request for development of a reusable component; a component development model that acquires information containing a source code of the component; and a component development view that displays a predetermined background image on a developer terminal and a component development region for displaying an appearance of the component which is a development target so as to overlap on the background image. When the source code of the component which is the development target is edited, the component which is the development target is displayed based on the source code in the component development region to provide the appearance defined by a template compatible with the device type.

Owner:NOMURA RESEARCH INSTITUTE

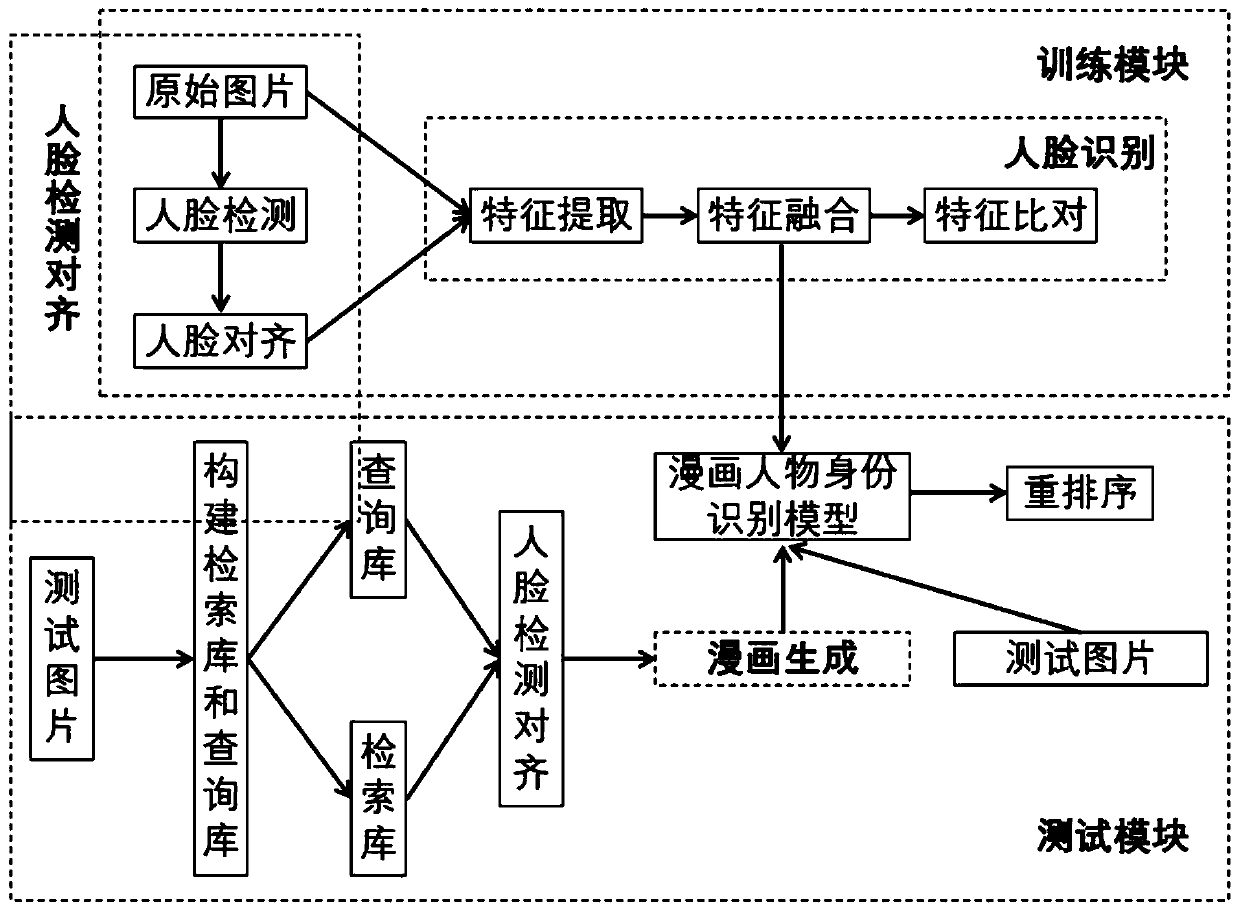

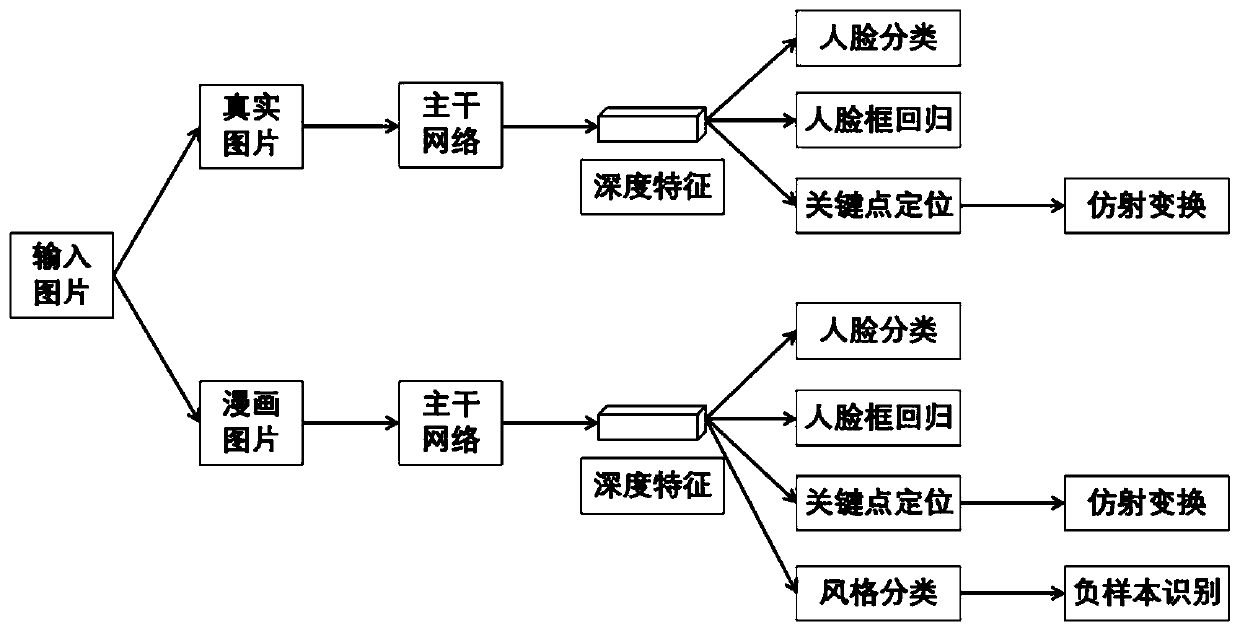

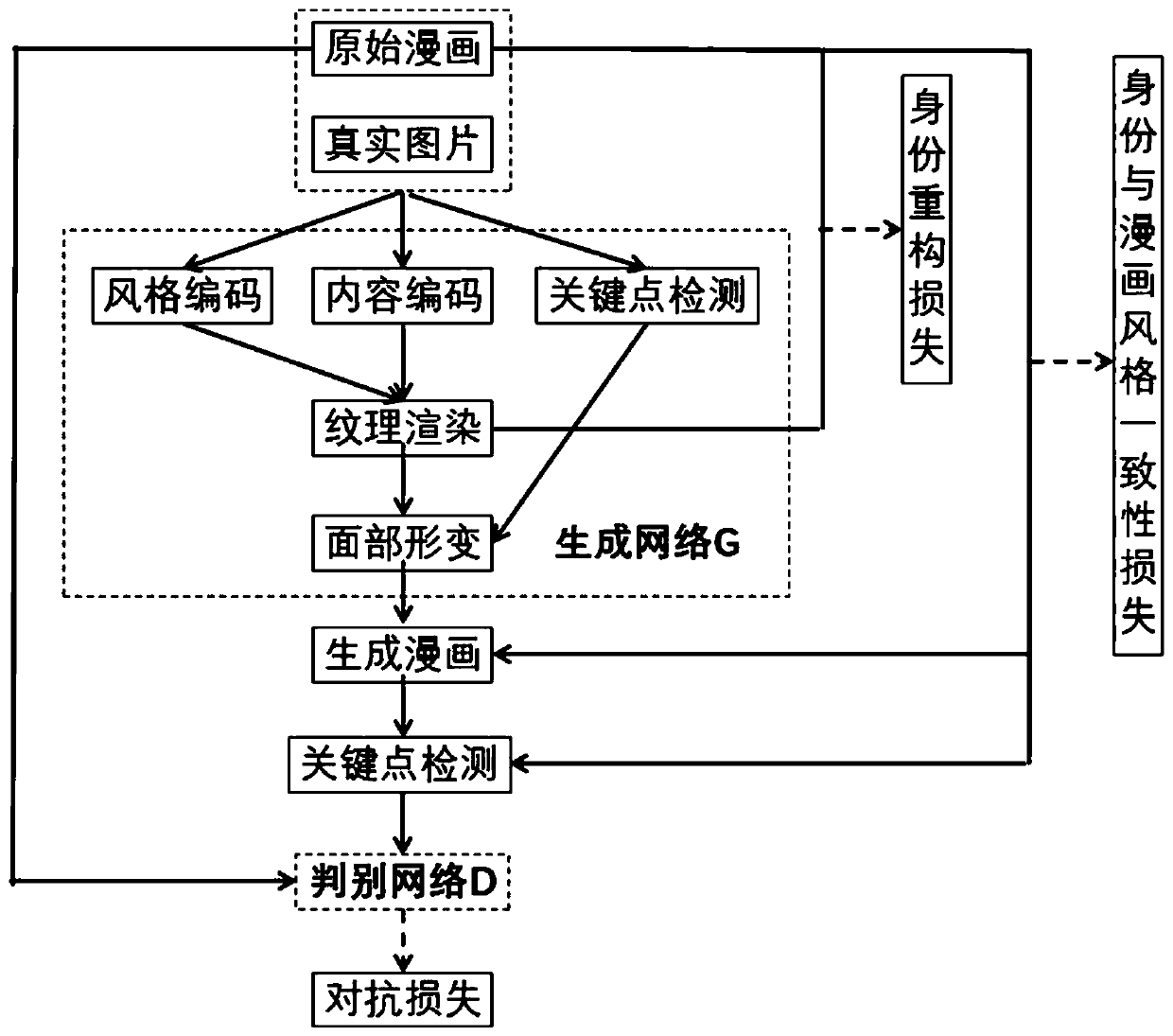

Cartoon character identity recognition method based on generative adversarial network

PendingCN111160264AAccelerateHigh precisionCharacter and pattern recognitionMetadata still image retrievalComputer visionGenerative adversarial network

The invention discloses a cartoon character identity recognition method based on a generative adversarial network, and the method comprises the steps: obtaining a real pedestrian image and a cartoon pedestrian image, and building a retrieval library containing a real pedestrian and a query library containing a cartoon pedestrian; constructing a face detection alignment model, and performing face detection alignment on the pictures in the retrieval library and the query library; constructing a cartoon generation model, and converting real pedestrians and faces into corresponding cartoon pictures; constructing a cartoon character identity recognition model, extracting fusion features of pictures in the retrieval library and the query library, and calculating similarity scores between fusionfeatures of cartoon pedestrians and real pedestrians; calculating similarity scores between the cartoon pedestrian fusion features, reordering the similarity scores between the cartoon pedestrians andthe real pedestrians by utilizing the similarity scores between the cartoon pedestrians, and setting a threshold value to obtain real pedestrians corresponding to the cartoon pedestrians in the retrieval library in the query library. The method has the advantages of high precision and high speed for cartoon character identity recognition.

Owner:SUN YAT SEN UNIV

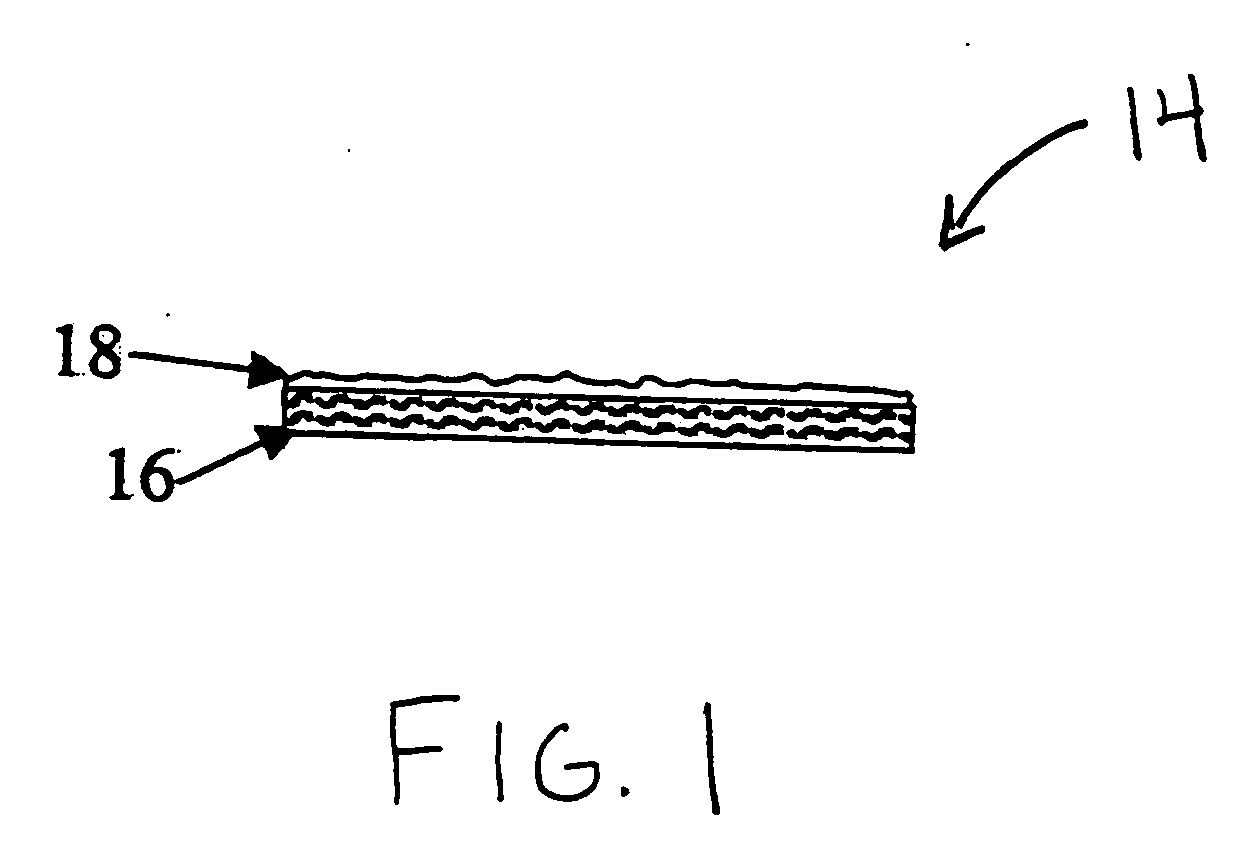

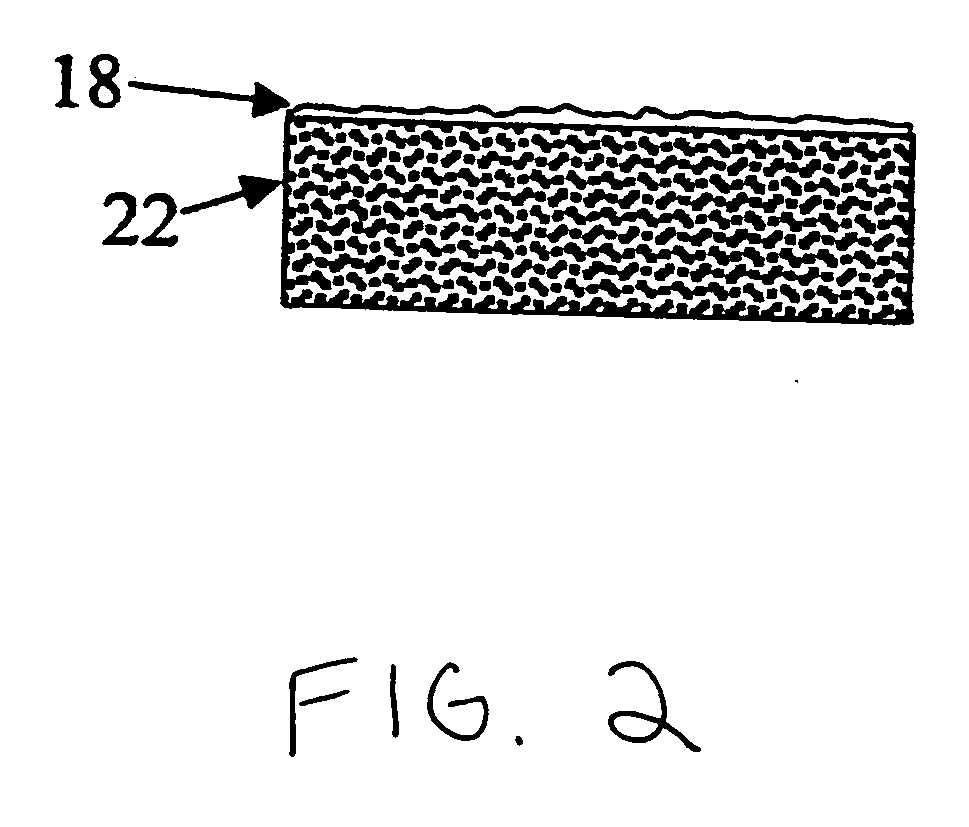

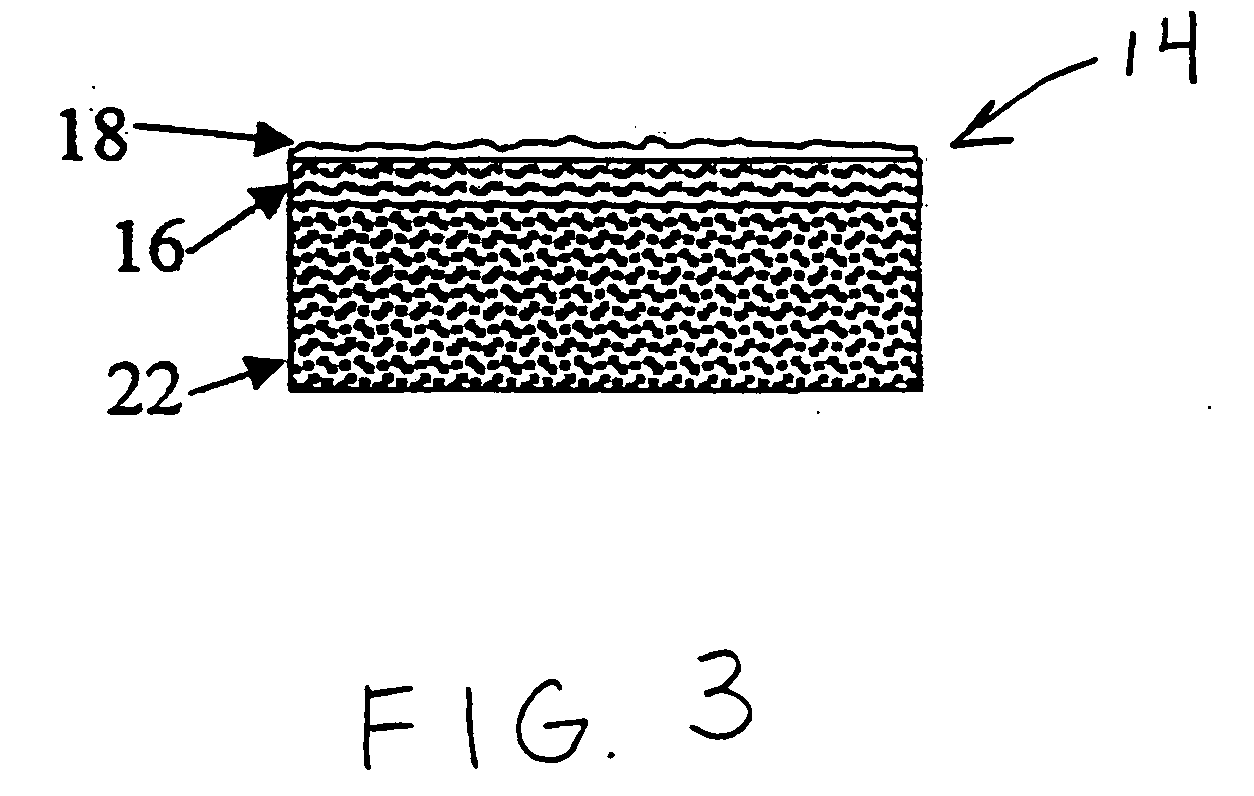

Acoustical panel coating and process of applying same

InactiveUS20060128863A1Maintain performanceAchieve the appearanceLayered productsPretreated surfacesMaterials scienceCoating

A coating composition and process of applying the coating to a substrate are provided herein. The coating composition includes filler particles, binder and a liquid carrier, such as water. The filler particles have an average particle size in the range from about 100 to about 600 microns and preferably in the range from about 200 to about 450 microns. The coating composition comprises from about 15% to about 50% by weight liquid carrier and from about 35% to about 90% by dry solids weight filler particles. The coating composition preserves the acoustic performance characteristics of the substrate to which it is applied, while imparting a textured appearance to the substrate, making the substrate virtually indistinguishable from surrounding panels.

Owner:FELEGI JOHN JR +6

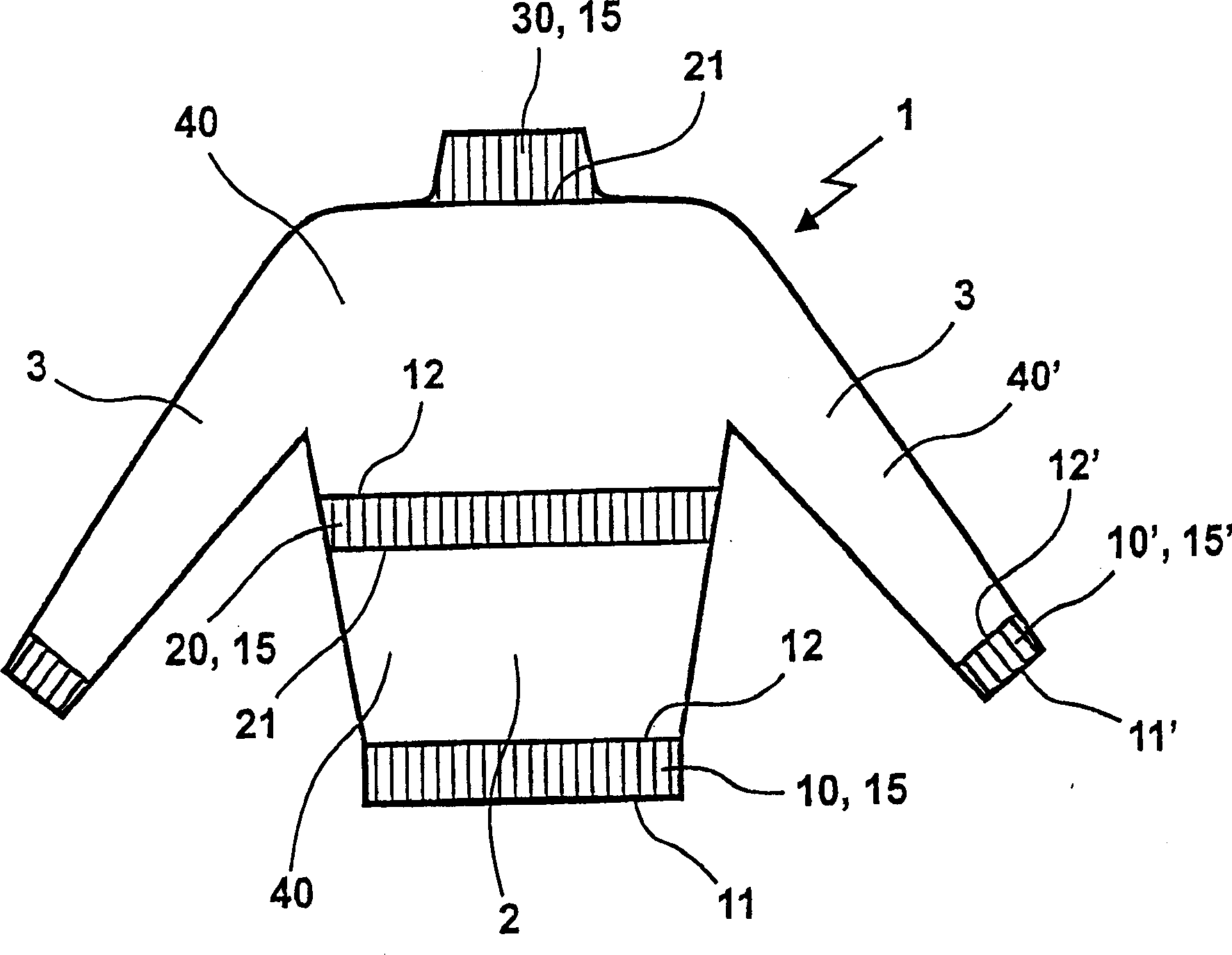

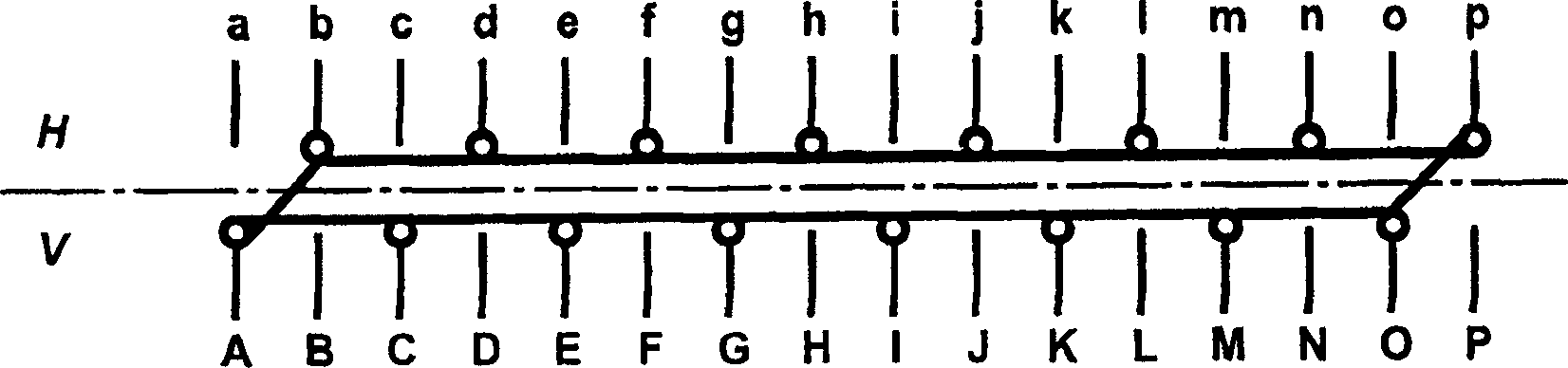

Production method of rib fabric portion

ActiveCN1495307AChange appearanceAchieve resilienceFlat-bed knitting machinesBiomedical engineeringTextile

In a textile knitting process to make the ribbed section forming part of a hosiery garment, a mesh is formed by each needle forming part of the non-ribbed section, on a flatbed knitting machine esp. having two facing needle beds. The visible aspect of the rib-knitted section is formed by one, or two neighbouring plain stitches, following which two needles form no stitches. To create the reverse stitch on the needles on the opposing needle bed, one needle forms a reverse stitch and a second needle forms no stitch.

Owner:KARL MAYER STOLL R&D GMBH

Appearance product with grains and patterns and production method thereof

InactiveCN102615757ASimple processAchieve the appearanceSynthetic resin layered productsGlass/slag layered productsMetallurgy

Owner:KUSN TONG YIN INDAL ELECTRONICS MAKING

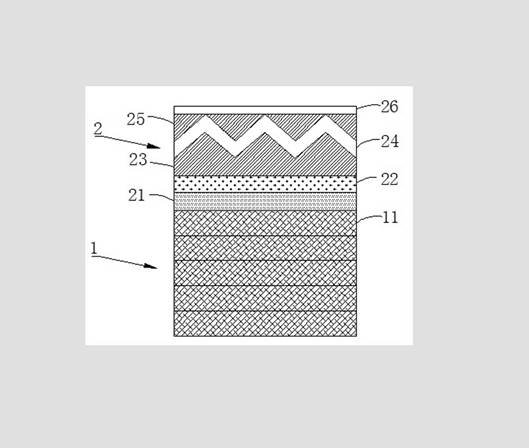

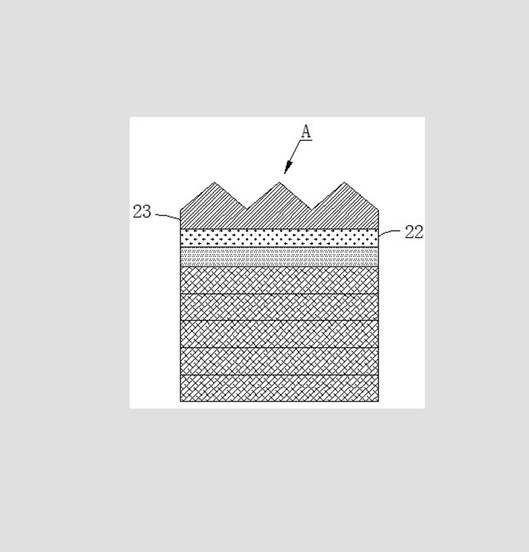

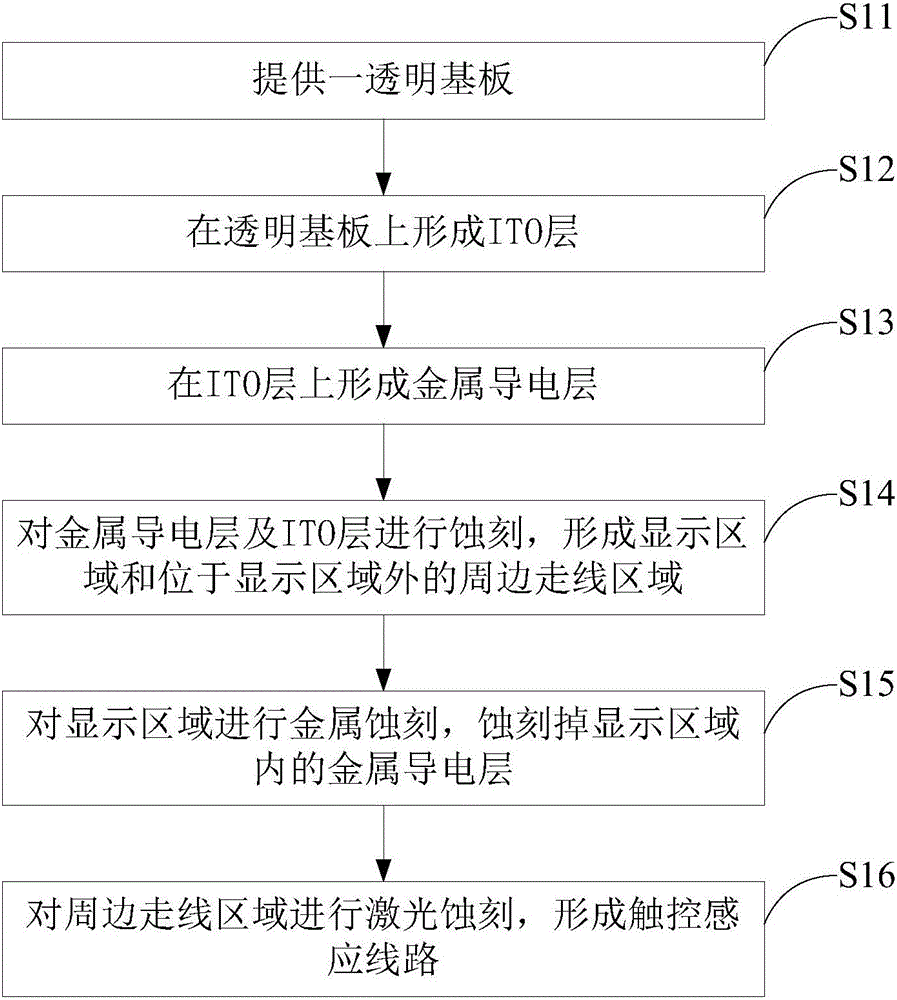

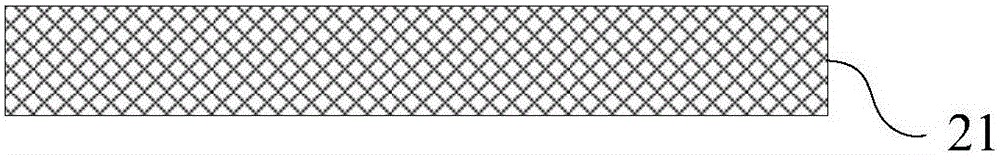

Capacitive screen and preparation method thereof

InactiveCN106168867AImprove process yieldImprove process stabilityInput/output processes for data processingCapacitive sensingMetal

The invention discloses a capacitive screen and a preparation method thereof, an ITO layer with the surface being a metal conducting layer is arranged on a transparent substrate, the metal conducting layer and the ITO layer are subjected to chemical etching to form a display area and periphery routing areas of the display area, the periphery routing areas are subjected to laser etching further, and a touch sensing circuit is formed. According to the manner, the occupied space of the touch sensing circuit of the capacitive screen can be effectively reduced, the screen occupation rate of the product is improved, the appearance effect of a narrow frame of the product can be realized, and the process yield and the technological stability of the product are effectively promoted.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

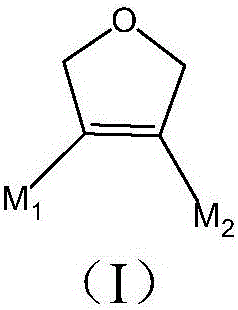

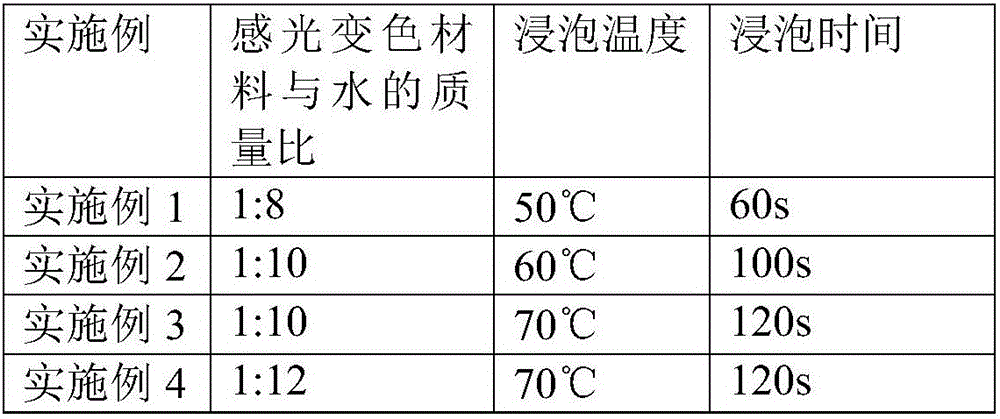

Aluminum alloy surface treatment method and photosensitive color-change aluminum alloy obtained by same

The invention relates to the technical field of aluminum alloy surface treatment, in particular to an aluminum alloy surface treatment method and a photosensitive color-change aluminum alloy workpiece obtained by the same. The aluminum alloy surface treatment method at least comprises the following steps that 1, the aluminum alloy workpiece is subjected to anodic oxidation, so that a porous alumina film layer is generated on the surface of the aluminum alloy workpiece; 2, the aluminum alloy workpiece subjected to anodic oxidation is subjected to photosensitive color-change material filling, so that the porous alumina film layer is filled with a photosensitive color-change material; 3, the aluminum alloy workpiece subjected to photosensitive color-change material filling is dyed; and 4, the dyed aluminum alloy workpiece is subjected to hole sealing. According to the aluminum alloy surface treatment method, the photosensitive color-change function and appearance effect of the aluminum alloy surface are achieved, and the appearance competitiveness of aluminum alloy materials is effectively improved.

Owner:SHENZHEN TINNO WIRELESS TECH

Tatting class imitated knitted fabric and weaving method thereof

The invention belongs to the technical field of fabric weaving, and particularly discloses a tatting class imitated knitted fabric and a weaving method thereof. The appearance effect of the imitated knitted fabric can be achieved through a weave structure; a fluffy and soft hand feeling of the imitated knitted fabric is achieved through design of fabric specifications such as the weave design, the raw materials and density of the fabric, the yarn thickness, the twist coefficient of yarn and the arrangement ratios of warp and weft yarn in surface and inner weaves; the tatting fabric with a unique imitated knitted fabric appearance and hand feeling can be produced through a dobby machine. The production process is simple and feasible, the tatting class imitated knitted fabric is attractive, soft and bulky, and the woven middle-thickness fabric is very attractive in appearance, has a comfortable and soft hand feeling and good heat preservation properties, and can be used as household clothing, bedding, scarves and the like.

Owner:HANGZHOU YINYAN SILK WEAVING

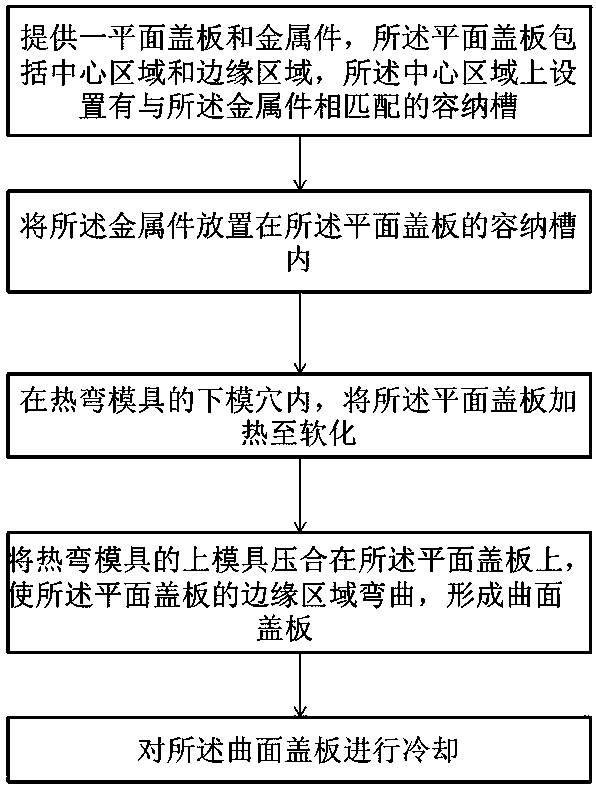

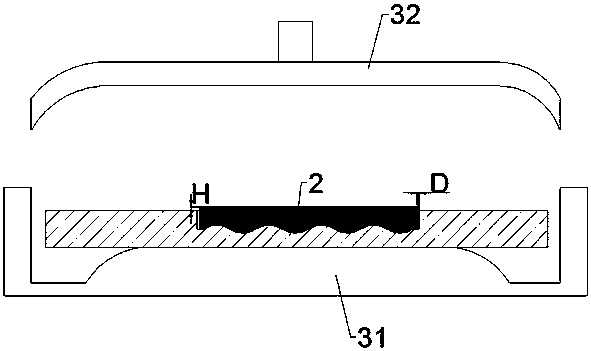

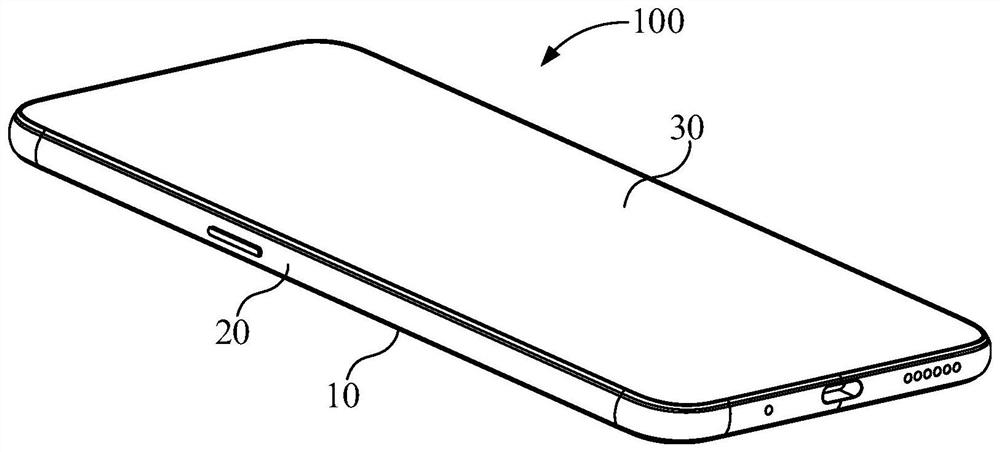

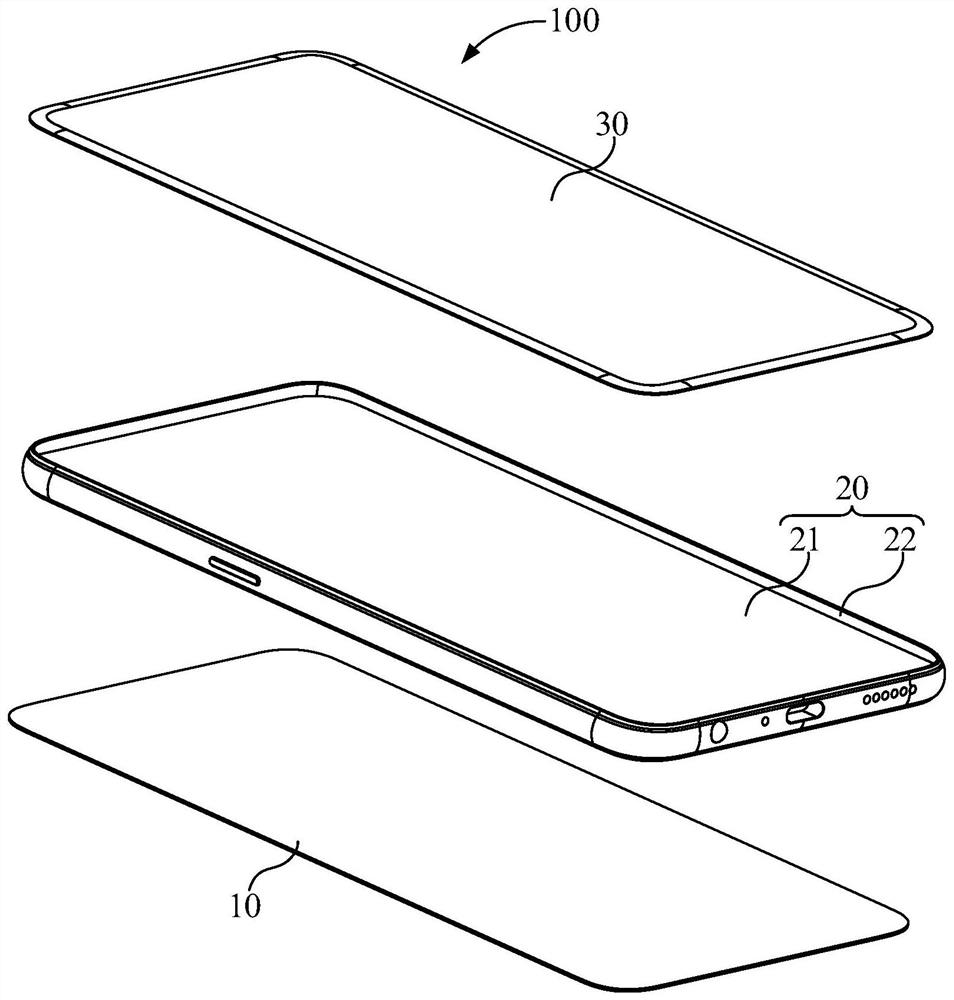

Manufacturing method for curved surface cover plate and curved surface cover plate

PendingCN108449453AAchieve bendingAchieve the appearanceGlass reforming apparatusTelephone set constructionsEngineeringSurface cover

The invention discloses a manufacturing method for a curved surface cover plate and the curved surface cover plate. The manufacturing method comprises the following steps of step 1, providing a planecover plate and a metal part, wherein the plane cover plate comprises a central area and an edge area, and a containing groove matched with the metal part is arranged in the central region; step 2, placing the metal part in the containing groove of the plane cover plate; step 3, heating the plane cover plate to be softened in a lower mold cavity of a hot bending mold; step 4, pressing a upper moldof the hot bending mold on the plane cover plate in order to bend the edge area of the plane cover plate to form the curved surface cover plate; and step 5, cooling the curved surface cover plate. According to the manufacturing method, product information or an appearance decoration integrated with the curved surface cover plate is formed by the metal part while the hot bending process is carriedout, the technology is simple, the integration degree is high, and the appearance and the existing ink appearance are differentiated.

Owner:TRULY OPTO ELECTRONICS

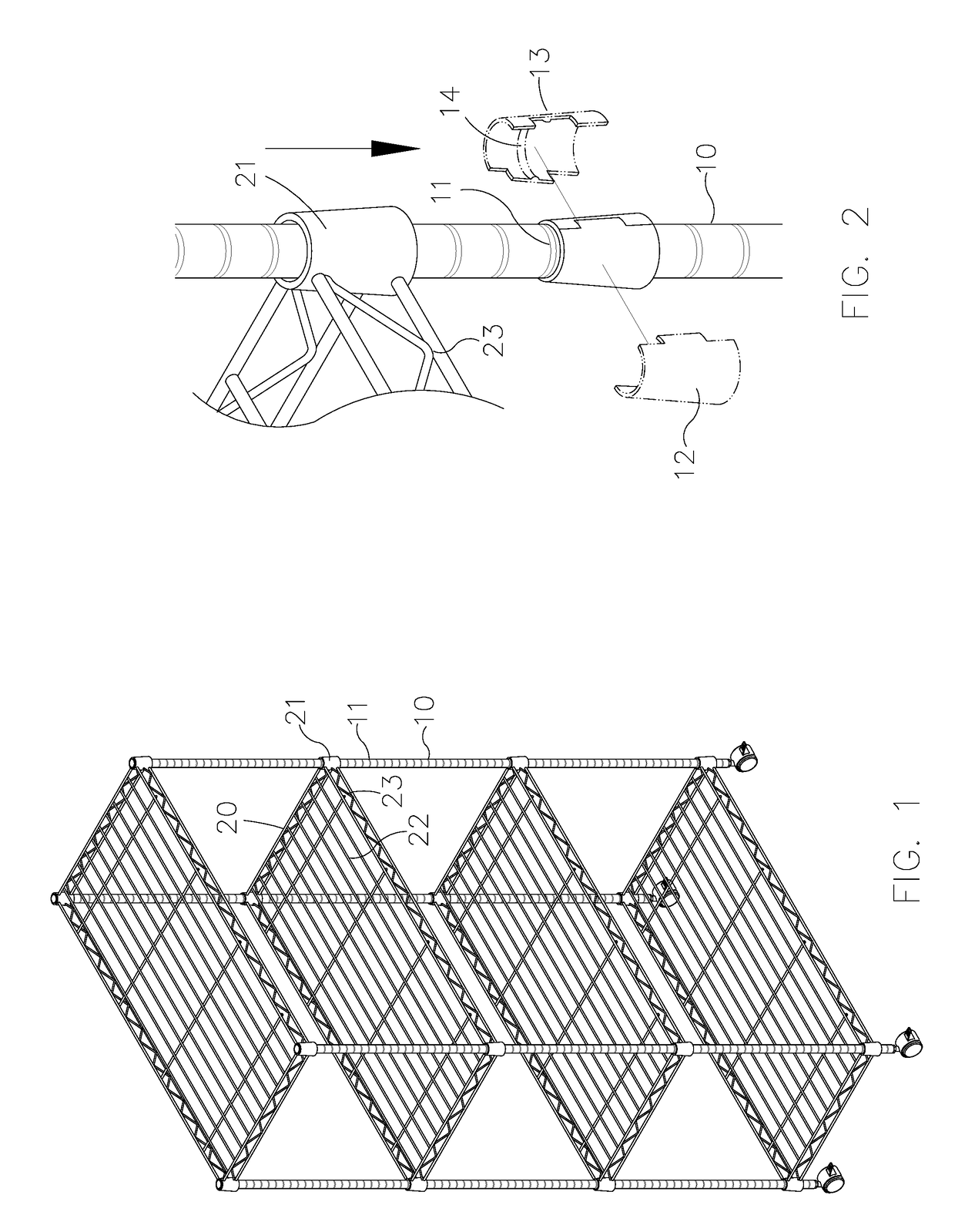

Connection structure for storage shelf

InactiveUS20180372136A1Connection securityFirmly connectedFurniture partsDismountable cabinetsFixed frameEngineering

A connection structure for a storage shelf, the storage shelf contains four posts fitting with plural support plates respectively by using multiple plastic fitting elements, and each support plate includes a metal sheet and a fixing frame. The fixing frame has four fitting sleeves fitted with the four posts individually by using the multiple plastic fitting elements. A first peripheral tab and a second peripheral tab extend inwardly from an inner wall of the fixing frame, and the first peripheral tab is located above the second peripheral tab. The fixing frame has four first grooves, and the fixing frame also has four second grooves. Each fitting sleeve has plural first vertical ribs surrounding an outer wall thereof and corresponding to the first peripheral tab, and each fitting sleeve has plural second vertical ribs surrounding the outer wall of each fitting sleeve and corresponding to the second peripheral tab.

Owner:WIRE MASTER IND

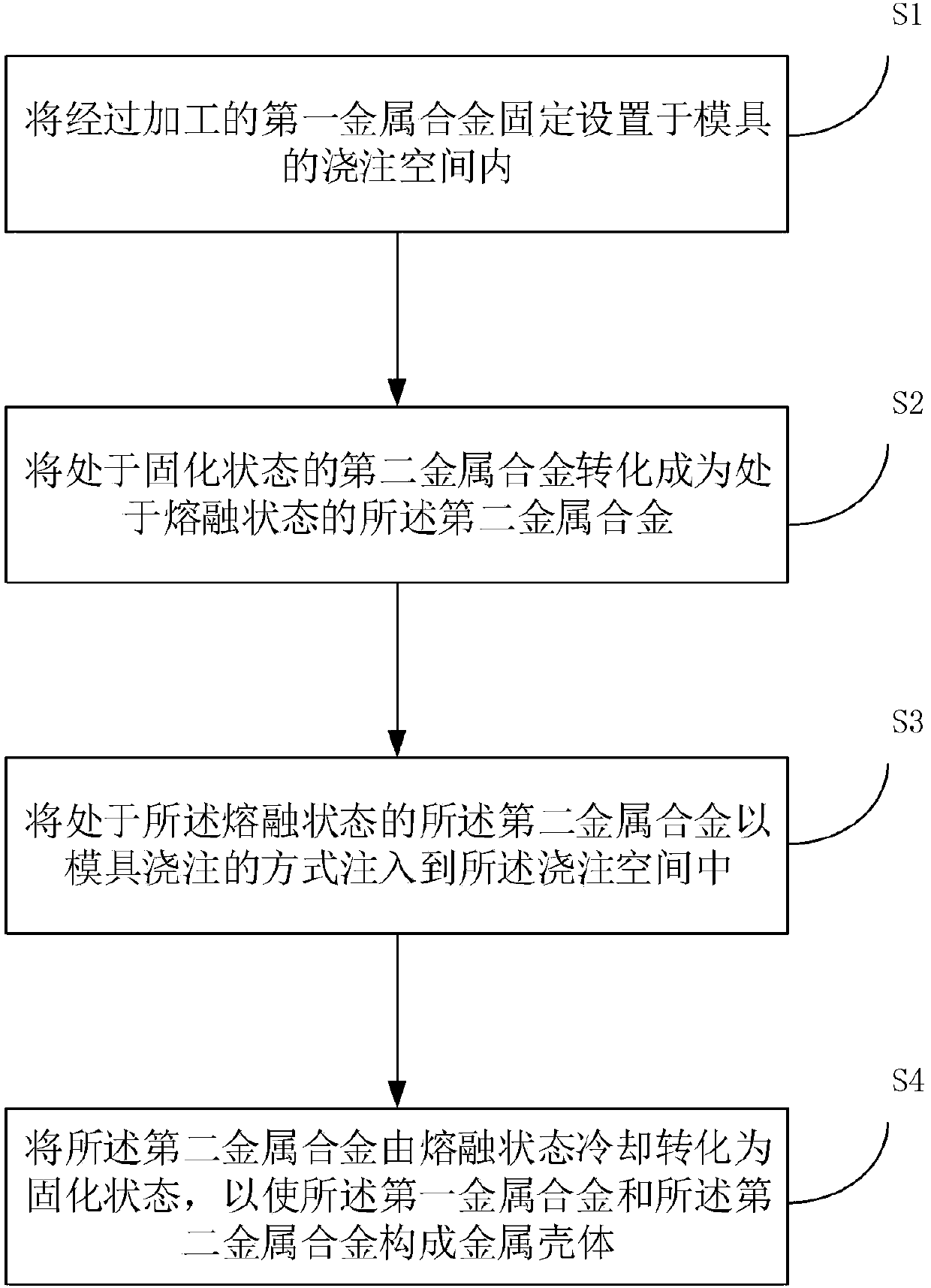

Die casting method of metal housing and electronic device

The invention provides a die casting method of a metal housing and an electronic device. The method comprises the following steps: fixedly arranging a processed first metal alloy into a pouring spaceof a die; converting the second metal alloy in a curing state into a second metal alloy in a melting state; pouring the second metal alloy in the melting state into the pouring space through the die;and cooling and converting the second metal alloy from the melting state into the curing state so as to form the metal housing with the first metal alloy and the second metal alloy, wherein the metalhousing fits the pouring space by shape; the first metal alloy is embedded o the second metal alloy in the curing state; and the first metal alloy is arranged on the outer surface of the metal housing. With the adoption of the die casting method, the whole metal housing is nice in appearance; and moreover, the metal housing is high in durability and good in use effect.

Owner:LENOVO (BEIJING) LTD

Composite appearance product with patterns and production method thereof

ActiveCN102615882ASimplify the surface treatment processAchieve the appearanceSynthetic resin layered productsGlass/slag layered productsPolyethylene glycolMaterials science

The invention discloses a composite appearance product with patterns and a production method thereof, which are manly characterized in that a composite stack and a decorative formed film are placed in a mould simultaneously, the decorative formed film is composed of a back glue layer, an ink layer, a production surface UV (ultraviolet) material layer, a release layer and a PET(polyethylene glycol terephthalate) layer, the decorative formed film is integrally joined with composite while the composite is formed, and accordingly the surface UV material layer, the ink layer and the back glue layer of the product with the decorative formed film are joined to the composite. The composite appearance product with patterns composed of a composite part, the back glue layer, the ink layer and the product surface UV material layer is produced by tearing the decorative formed film after mould opening, so that surface treatment process for the composite appearance product is simplified, and the appearance effect that the traditional composite cannot reach is realized.

Owner:KUSN TONG YIN INDAL ELECTRONICS MAKING

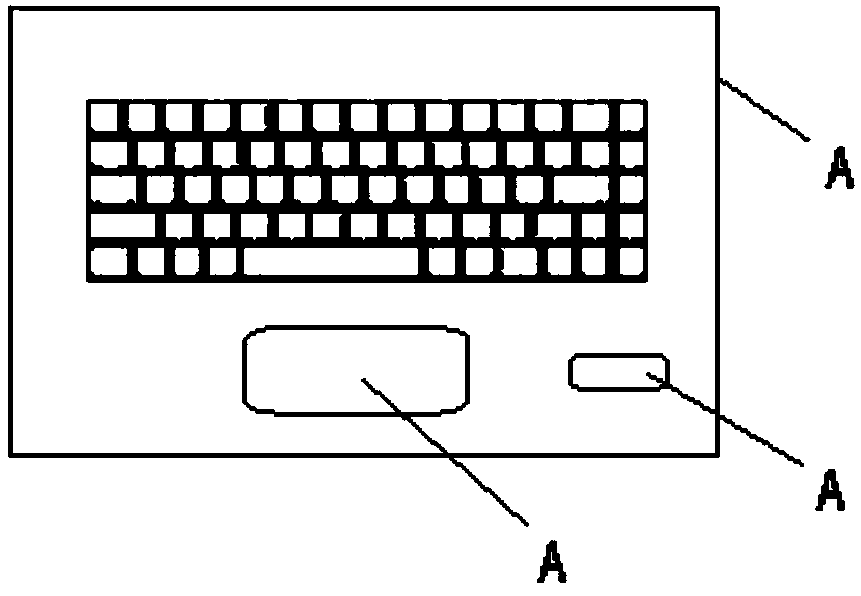

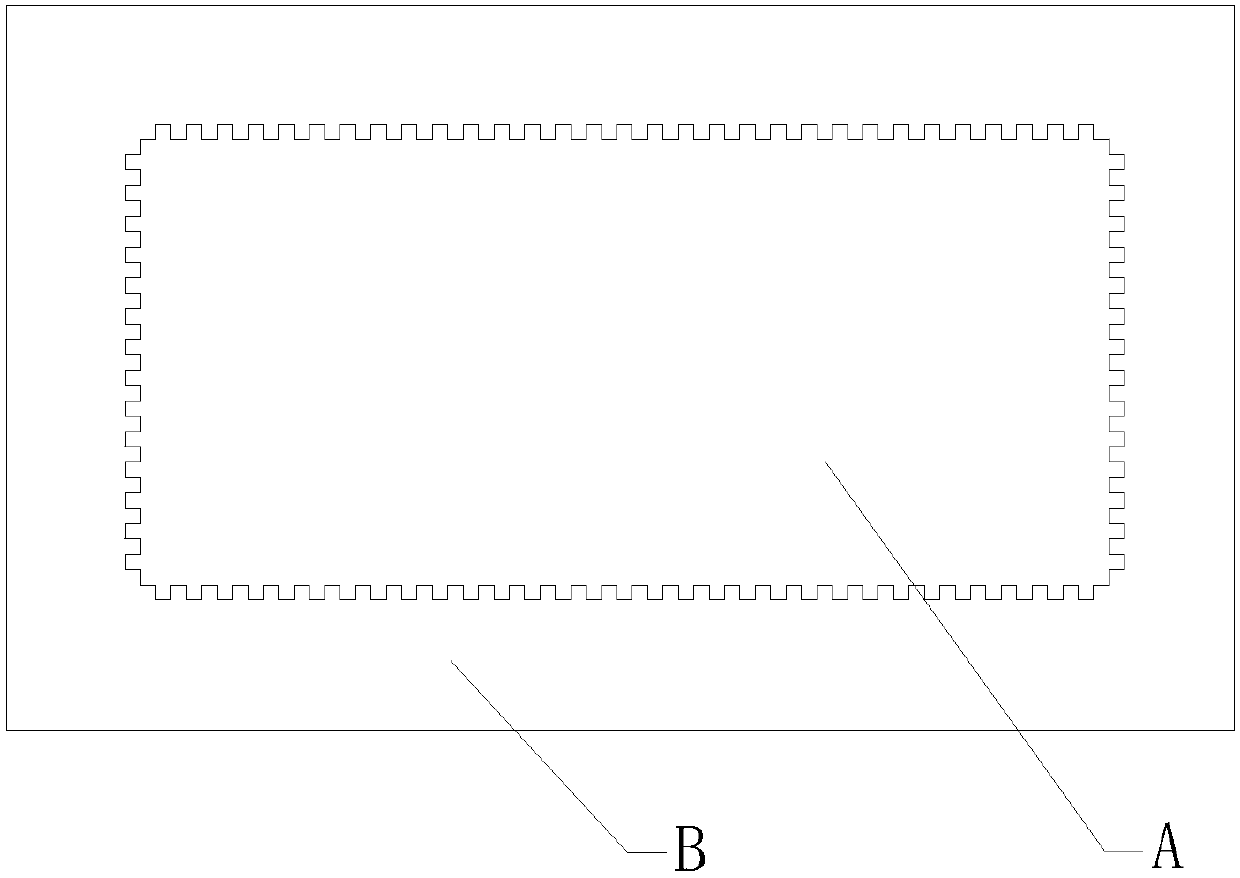

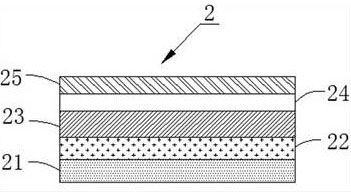

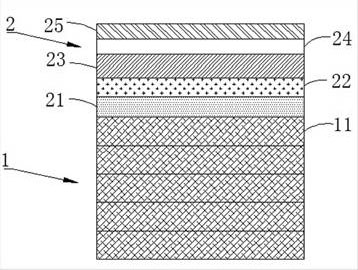

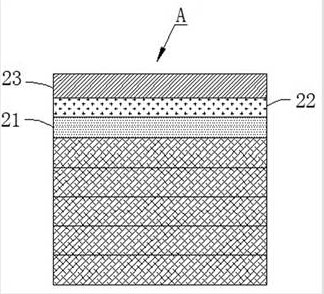

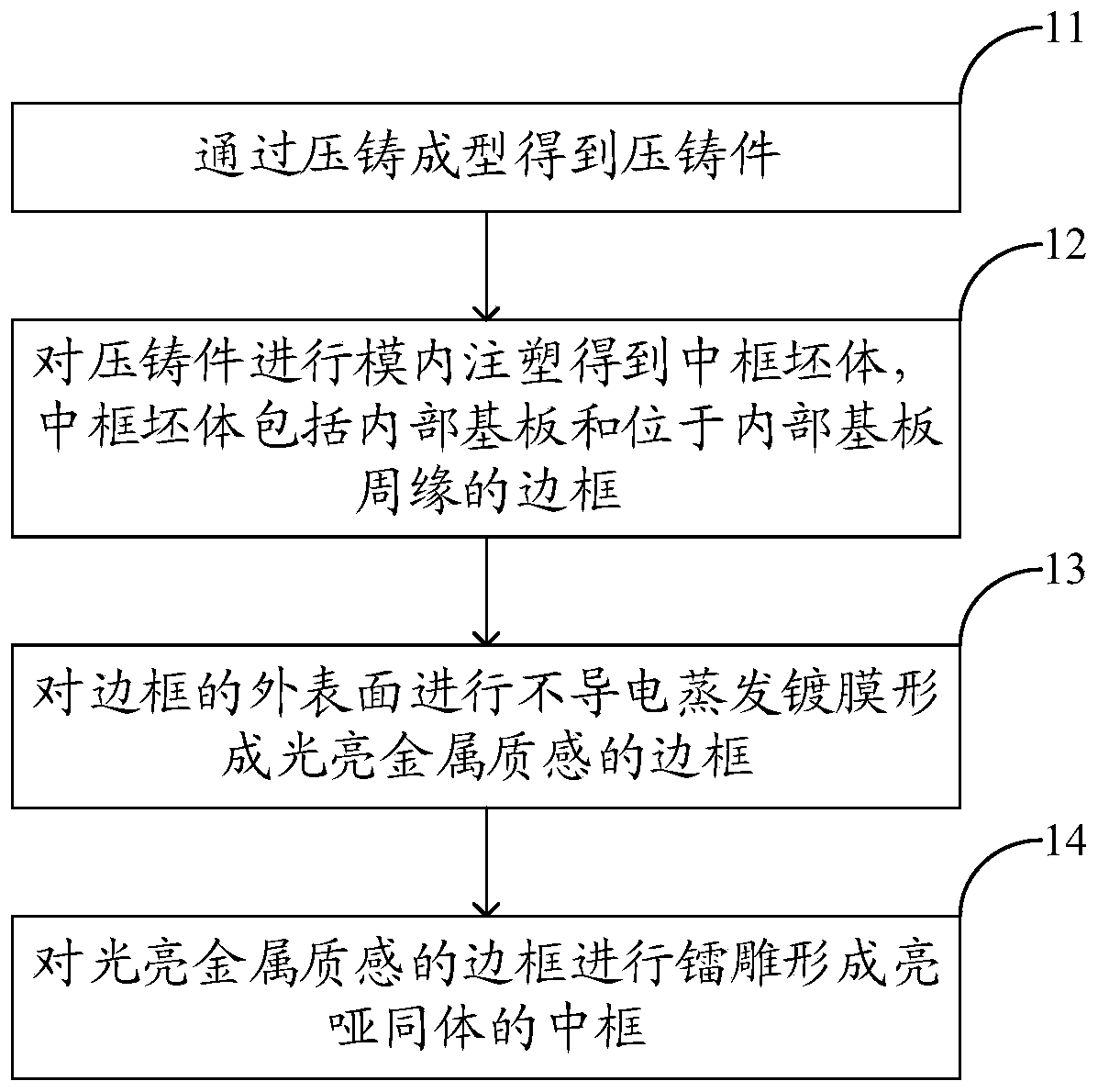

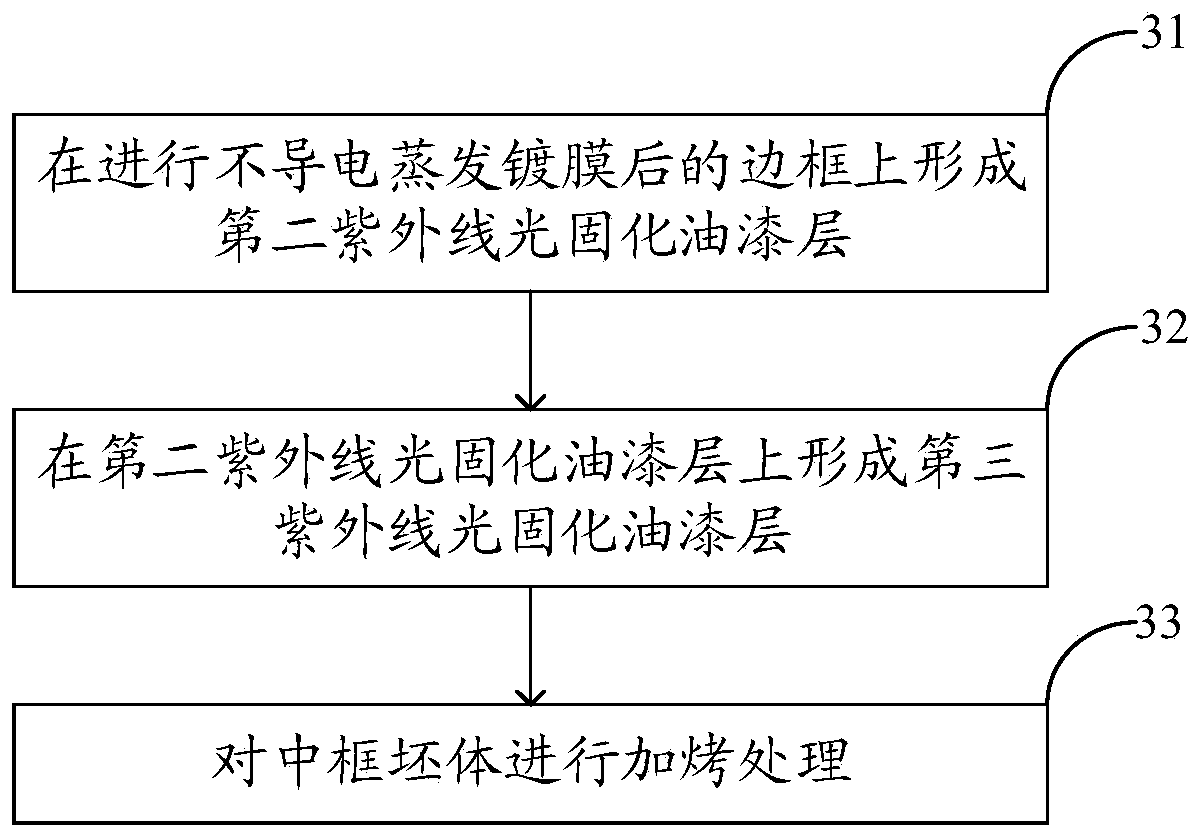

Intelligent terminal and manufacturing method for intelligent terminal middle frame

InactiveCN109760263AReduce manufacturing costShorten the manufacturing cycleVacuum evaporation coatingSputtering coatingEvaporationDie casting

The invention discloses an intelligent terminal and a manufacturing method for an intelligent terminal middle frame. The manufacturing method comprises the following steps that die-casting formation is conducted to obtain a die-casting piece; insert molding is conducted on the die-casting piece to obtain a middle frame blank body, and the middle frame blank body comprises an inner base plate and aframe positioned at the periphery of the inner base plate; the outer surface of the frame is subjected to non-conducting evaporation coating to form a frame with bright metal texture; and the frame with the bright metal texture is subjected to laser carving to form a middle frame with integrated bright and matte effect. According to the method, the manufacturing cost can be reduced, and the manufacturing period can be shortened while the integrated bright and matte appearance effect of the middle frame can be realized.

Owner:HUIZHOU TCL MOBILE COMM CO LTD

Window frame

A window frame (7, 8, 8′) for a window (4, 5, 6, 5′, 6′) of a passenger car, has at least one seal having one or a plurality of sealing profiles (17.1, 17.2, 17.3, 17.4, 18.1, 18.4) that abut one another at seams in the longitudinal direction of the seal, and further have a fastening profile cooperating with the seal and comprising one or more fastening profile pieces (13.1, 13.2, 13.3, 13.4) that abut one another on at least one seam in the longitudinal direction of the fastening profile. The fastening profile pieces (13.1, 13.2, 13.3, 13.4) have a metal ornamental molding (9, 10, 10.1, 10.2, 10.3) attached to them and a molding flange (14.1, 14.2, 14.3, 14.4) fastened with at least one fastening element (15.1, 15.2, 15.3, 15.4) to secure the fastening profile to the passenger car. The ornamental molding (9, 10) is crimped on the molding flange (14.1, 14.2, 14.4) of the fastening profile piece or pieces (13.1, 13.2, 13.3, 13.4) such that it covers the seam in one piece. The window frame may be produced by a defined method of construction.

Owner:CADEA FUR ANWENDUNG & REALISIERUNG COMPUNTERSTUTZTER SYST MBH

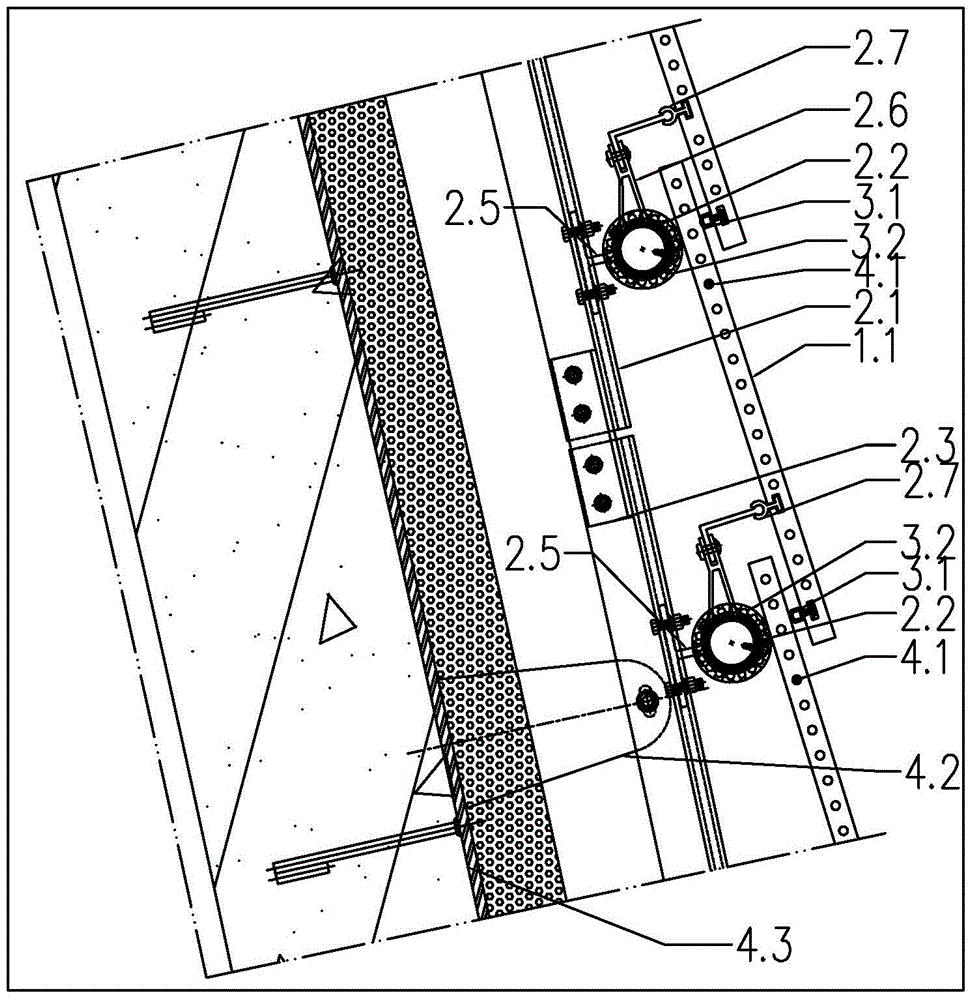

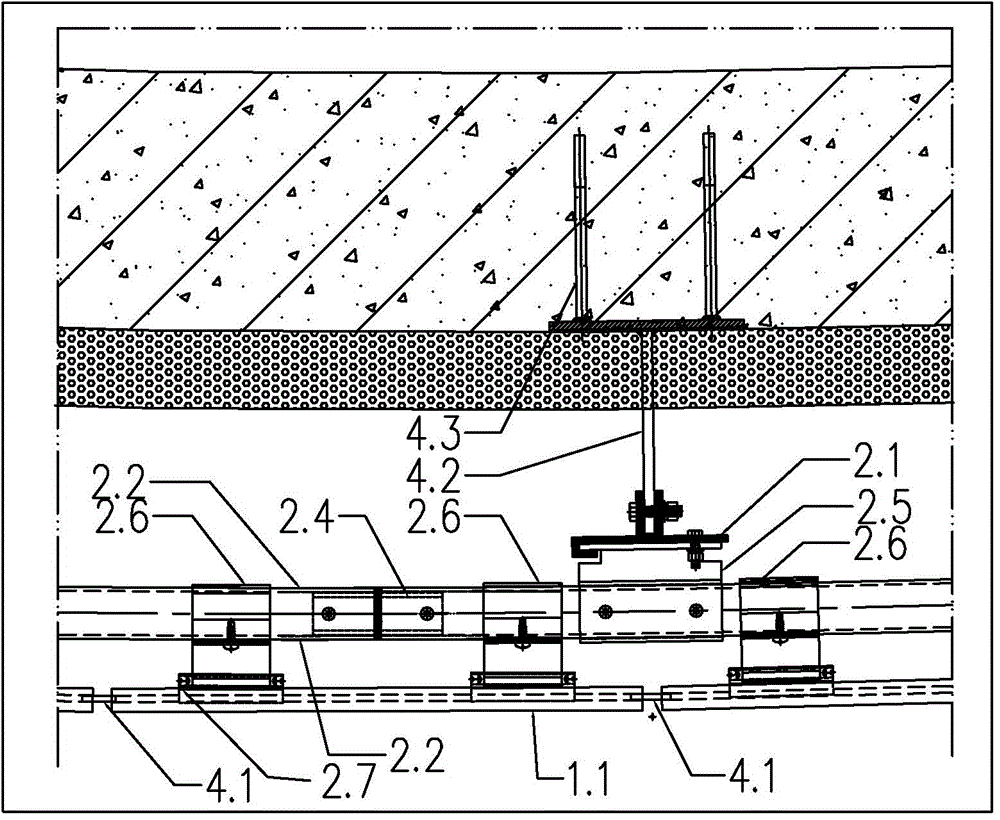

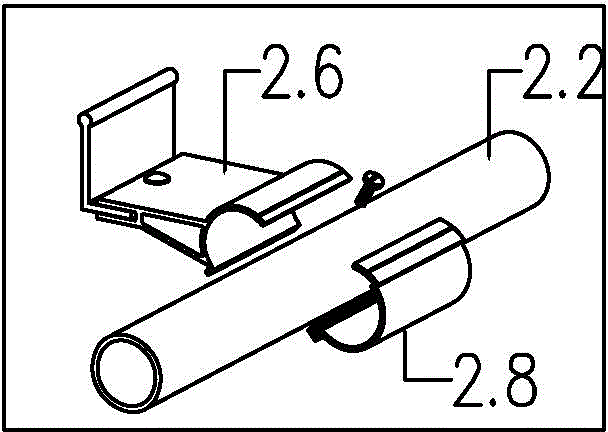

Double-curved-surface open type terracotta panel curtain wall

The invention provides a double-curved-surface open type terracotta panel curtain wall. The double-curved-surface open type terracotta panel curtain wall comprises a primary keel, secondary keels are fixedly arranged on the primary keel, a plurality of terracotta panel joint assemblies are arranged on the secondary keels, and each terracotta panel joint assembly is provided with a terracotta panel. The terracotta panel joint assemblies can rotate around the axes of the secondary keels and can be movably arranged on the secondary keels along the secondary keels. The terracotta panel joint assemblies are connected with terracotta panel hanging pieces arranged on the terracotta panels. Cambered surface concave-convex embedded structures are formed by the terracotta panel hanging pieces and the terracotta panel joint assemblies so that the terracotta panels can rotate relative to the terracotta panel joint assemblies. The terracotta panels are connected with the terracotta panel joint assemblies, the upper portion of each terracotta panel is lapped on the secondary keel to which the terracotta panels on the upper layer are connected, and the lower portion of each terracotta panel is lapped on the terracotta panels on the lower layer. The double-curved-surface open type terracotta panel curtain wall solves the problem that an existing terracotta panel curtain wall system can not meet the requirements of an architect for the effect of a terracotta panel curtain wall with the double-curved-surface scale-shaped appearance, and the scale-shaped curtain wall appearance effect can be achieved through the terracotta panels with different specifications and sizes.

Owner:JANGHO GRP

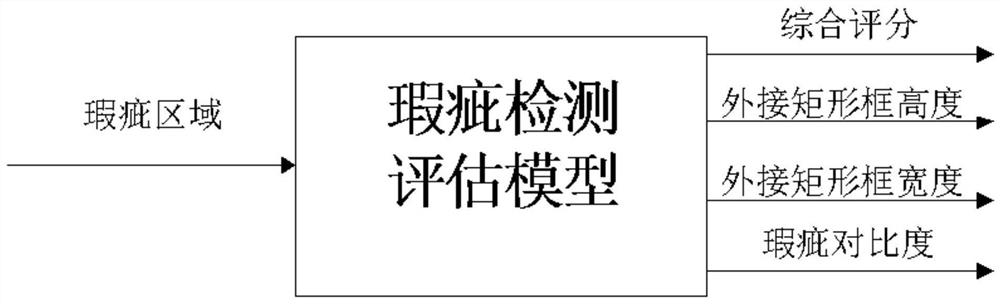

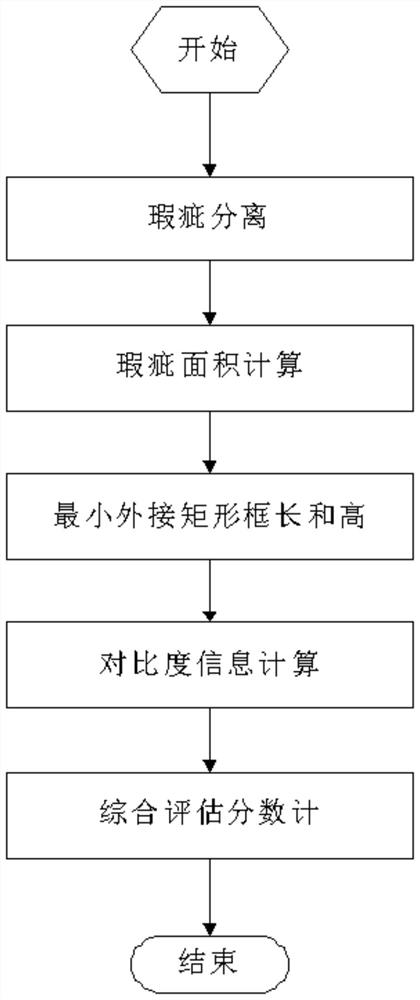

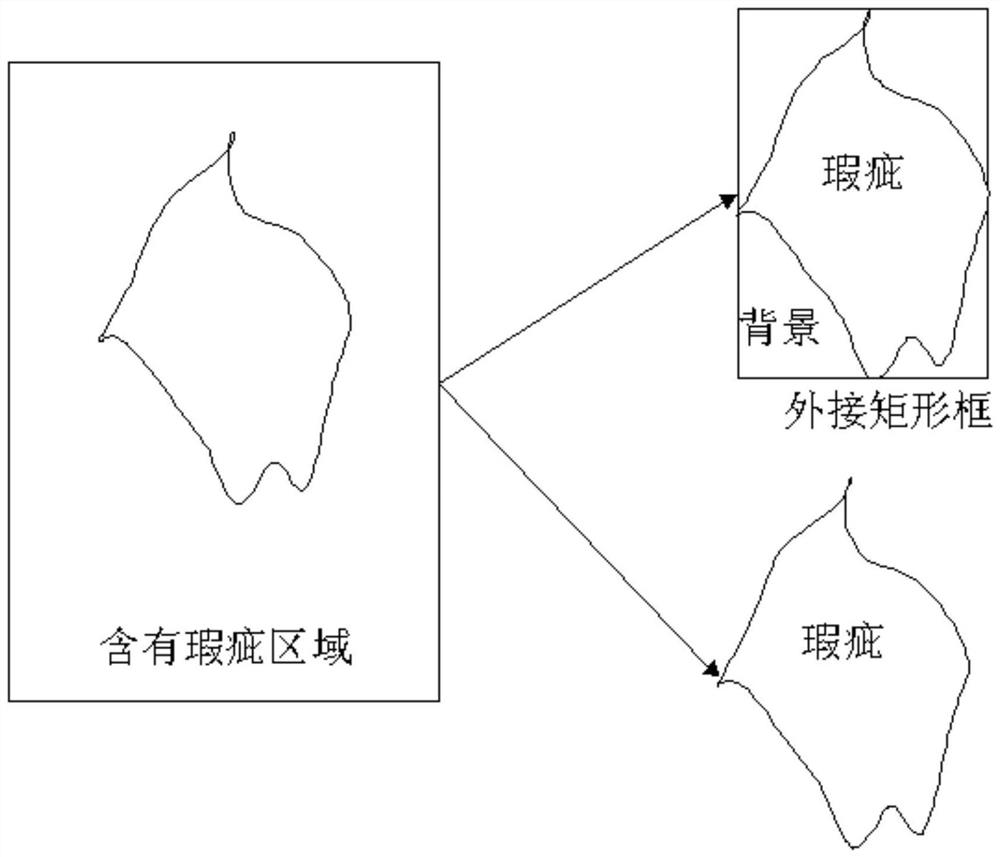

Defect quantitative evaluation method based on AOI detection

PendingCN113935981AAchieve the appearanceRealize automatic detection functionImage enhancementImage analysisMinimum bounding rectangleNoise removal

The invention relates to the technical field of AOI defect detection, and discloses an AOI-detection-based defect quantitative evaluation method, which comprises the following steps: S1, defect separation: on a detected defect picture, according to the area where the defect is located, the defect is separated from a background picture by using the steps of noise removal, gray stretching, filtering and image difference before and after filtering, the width of the minimum bounding rectangle is calculated according to the contour of the flaw, and the separated flaw graph and the bounding rectangle block diagram where the flaw is located are respectively stored. According to the AOI detection-based flaw quantitative evaluation method, the functions of appearance flaw quantitative evaluation and automatic detection can be realized, manual judgment through subjective experience is not needed, subjective factor interference is avoided as much as possible, the accuracy of a flaw detection result is improved, the flaw detection efficiency is also improved, and the labor intensity of workers is reduced.

Owner:深圳市玻尔智造科技有限公司

Plating compositions for electrolytic copper deposition, its use and a method for electrolytically depositing a copper or copper alloy layer onto at least one surface of a substrate

The present invention relates to a plating composition for electrolytic copper deposition, comprising copper ions, halide ions and at least one acid, at least one benzothiazole compound, at least onephenanzine dye and at least one ethanediamine derivative. The present invention further concerns the use of above plating composition and a method for electrolytically depositing a copper or copper alloy layer onto at least one surface of a substrate.

Owner:ATOTECH DEUT GMBH

Preparation method of integrally formed stainless steel insert structure

The invention relates to a preparation method of an integrally formed stainless steel insert structure. The preparation method comprises the following steps of first, carrying out machining on stainless steel powder to form a stainless steel outer frame insert blank according to a powder metallurgy technology; and second, carrying out CNC fine machining after carrying out forging and pressing on the stainless steel outer frame insert blank to form a stainless steel outer frame. The preparation method of the integrally formed stainless steel insert structure has the advantages that a cell phoneshell structural part which is integrally formed by the stainless steel powder metallurgy outer frame, a cast aluminum middle frame and a plastic assembly structure is implemented; and because a powder metallurgy forming structure part outer frame structure is adopted, the working rate and the use rate of stainless steel are increased, and the appearance effect of stainless steel is achieved.

Owner:GUANGDONG JANUS SMART GRP CO LTD +1

Manufacturing method of covering piece having function of adaptive cruise control system of vehicle

ActiveCN107650827AMeet two-way penetrationAchieve the appearanceNatural patternsVehicle componentsEngineeringAdaptive control

The invention relates to a manufacturing method of a covering piece having a function of an adaptive cruise control system of a vehicle. The manufacturing method comprises the following steps of usinga panel piece as the covering piece, and setting colored patterns on the front side or the back side of the panel piece; then performing vapor deposition on the surface of the colored patterns in a vacuum environment to form a metal layer and a nonmetallic layer, wherein the metal layer is covered by the nonmetallic layer; and finally protecting the metal layer and the nonmetallic layer, so as toobtain the covering piece. The covering piece manufactured by the manufacturing method disclosed by the invention can realize the appearance effect of metal mirror surface or matte metallic luster ora plurality of colored patterns, two-way penetrating of radar waves is effectively met, and the covering piece can be applied to marks of auto makers, grating decorative cover plates, grating decorative strips and the like.

Owner:嘉兴敏胜汽车零部件有限公司

Shell, manufacturing method thereof and electronic equipment

PendingCN113895129AAchieve the appearanceImprove bindingSynthetic resin layered productsLaminationColor textureElectronic equipment

The invention provides a shell, a manufacturing method thereof and electronic equipment, the shell comprises a substrate and an appearance membrane, and the appearance membrane is arranged on one side of the substrate; the appearance membrane comprises a base material layer, a color layer and a texture layer, and the base material layer is made of polyurethane; the color layer is arranged on the base material layer; the texture layer is arranged on the side, away from the base material layer, of the color layer. Wherein the texture layer is made of transparent polyurethane. According to the shell provided by the embodiment of the invention, the color layer is formed on the base material layer made of polyurethane, so that the shell can realize a rich color or gradient color pattern effect; meanwhile, the texture layer is formed on the color layer, and the texture layer is made of transparent polyurethane, so that the pattern of the color layer can be displayed, and the shell can achieve the rich color texture or gradient color texture pattern effect in cooperation with the texture of the texture layer.

Owner:REALME MOBILE TELECOMM SHENZHEN CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com