Manufacturing method for curved surface cover plate and curved surface cover plate

A manufacturing method and technology for cover plates, which are applied in manufacturing tools, glass molding, glass manufacturing equipment, etc., can solve the problems of many processes, high cost, serious homogeneity, etc., and achieve simple process, process cost saving, and integration. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

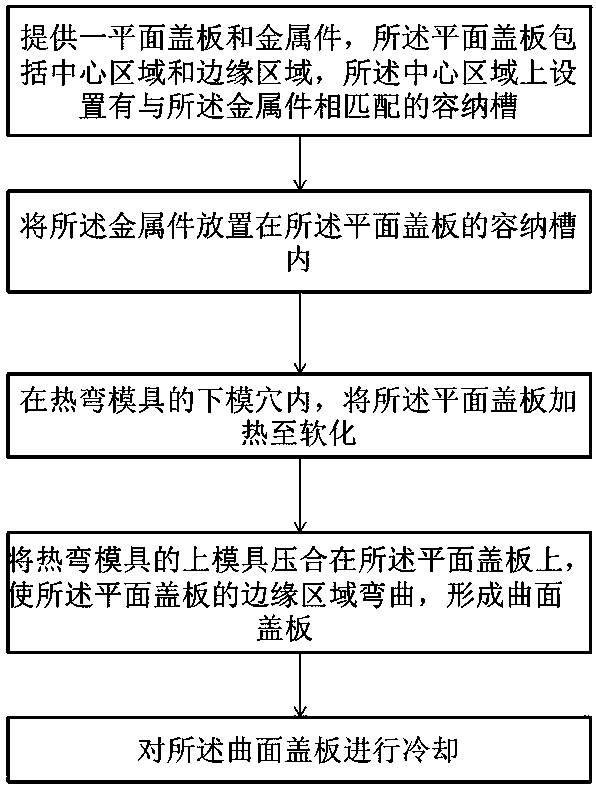

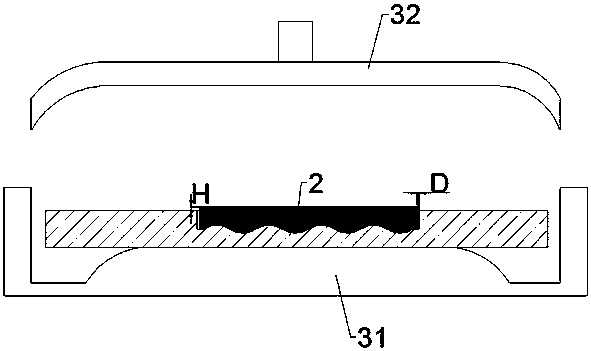

[0028] Such as figure 1 As shown, a method for manufacturing a curved cover plate 1B includes:

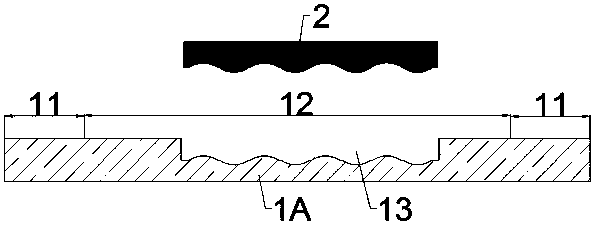

[0029] Step 1: Provide as figure 2 As shown in the planar cover 1A and the metal part 2, the planar cover 1A includes a central area 12 and an edge area 11, and the central area 12 is provided with a receiving groove 13 matching the metal part 2;

[0030] In this step 1, the flat cover plate 1A is preferably but not limited to a glass cover plate or a plastic cover plate; the metal piece 2 can be a hollow piece, and the logo, Product information or appearance decoration such as trademarks, characters, model parameters, or patterns. At this time, the receiving groove 13 not only needs to match the edge shape of the metal part 2 in terms of edge shape, but also needs to protrude and fill in the corresponding position. In the hollow area of the metal part 2; the metal part 2 can also be a flat concave-convex part, and the product information or appearance such as logo, trademark,...

Embodiment 2

[0045] Such as Figure 4 As shown, a curved cover 1B is preferably but not limited to be obtained by the method for manufacturing the curved cover 1B described in the first embodiment.

[0046] The curved cover plate 1B includes a flat central area 12 and a curved edge area 11, and the central area 12 is provided with a receiving groove 13; it also includes a metal piece 2 matching the receiving groove 13, and the metal piece 2 It is integrally arranged in the accommodating groove 13 .

[0047] The curved cover 1B is preferably but not limited to a glass cover or a plastic cover; the metal piece 2 can be a hollowed-out piece, and logos, trademarks, characters, and model parameters are formed by making the metal piece 2 into a hollowed-out structure or decorative patterns or other product information or appearance decoration, at this time, the receiving groove 13 not only needs to match the edge shape of the metal part 2 in terms of edge shape, but also needs to protrude and f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com