Outer casing adopting composite structure and manufacture process thereof

A technology of composite structure and manufacturing process, which is applied in the field of communication, can solve the problems of heavy weight, inconvenience, and high cost of the shell, and achieve the effects of reduced manufacturing cost, tight connection, and reduced weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

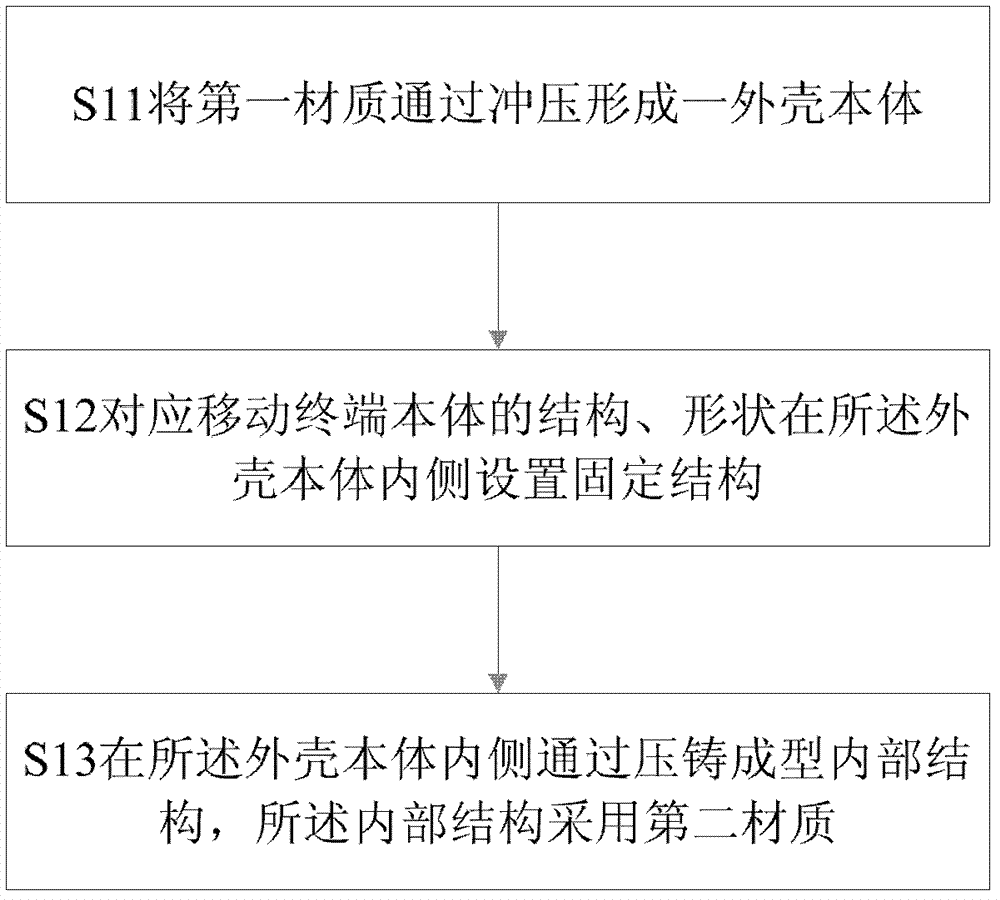

[0024] The implementation of the present invention will be described in detail below with reference to the drawings and examples, so as to fully understand and implement the implementation process of how to use technical means to solve technical problems and achieve technical effects in the present invention.

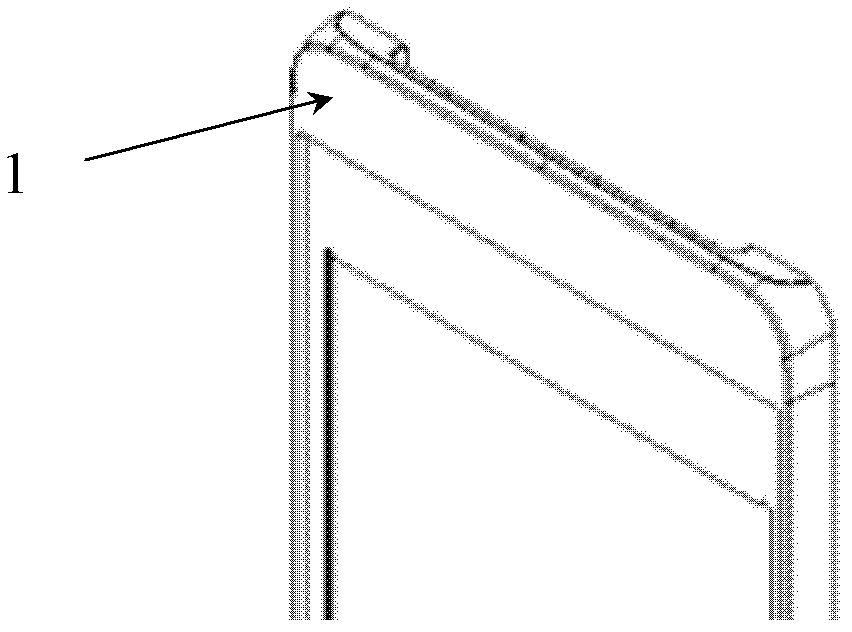

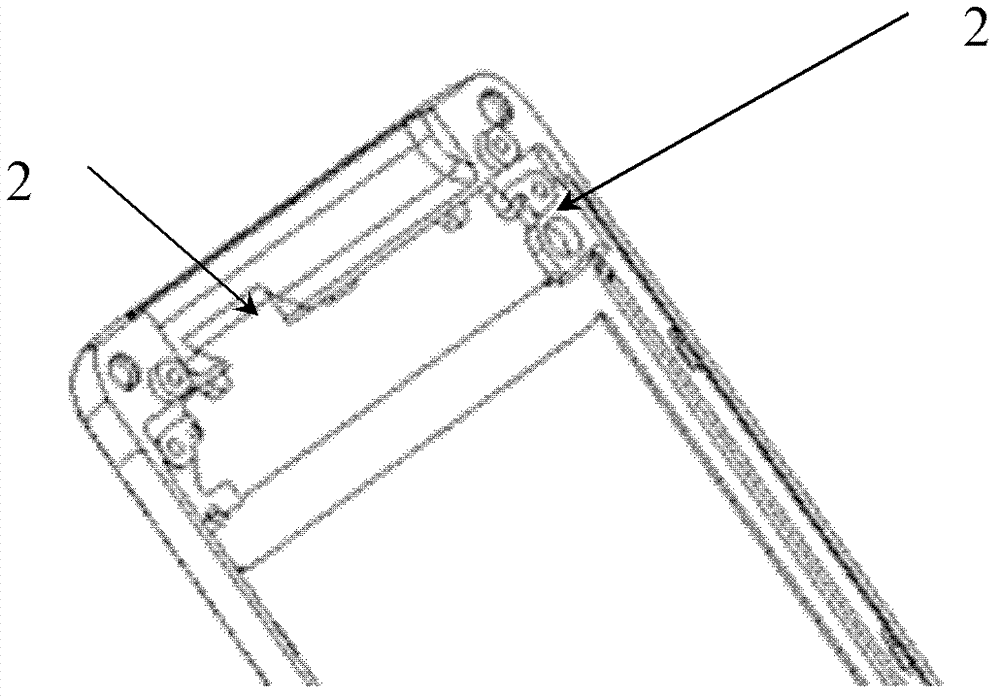

[0025] The core of the present invention is that the housing includes a housing body and an internal structure, the internal structure is fixed inside the housing body, the housing body is made of a first material, and the internal structure is made of a second material.

[0026] It should be noted that, according to application requirements, the above concept may have the following solutions:

[0027] 1) The first material is a material with a hardness greater than a threshold A, the second material is a material with a hardness less than a threshold B, and the threshold A is greater than or equal to the threshold B. The material whose hardness is higher than the thres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com