Tatting class imitated knitted fabric and weaving method thereof

A technology of imitating knitting and fabrics, applied in the field of textile fabrics, can solve the problems of unfavorable knitting soft hand feeling, high yarn twist coefficient, complex process, etc., and achieve the effect of simple weaving method, soft hand feeling and strong knitting feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

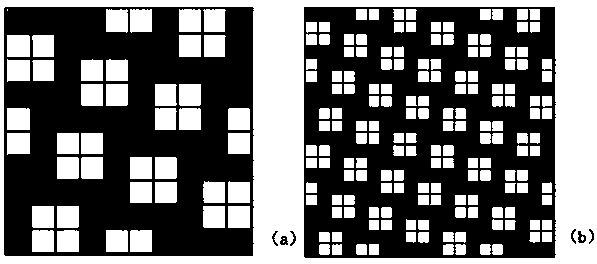

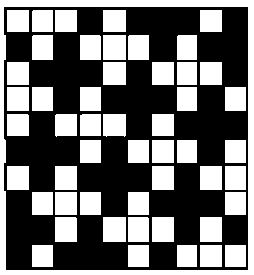

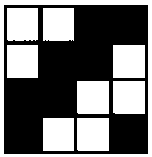

[0024] A woven imitation knitting fabric, comprising a surface layer tissue and an inner layer structure, the surface layer structure and the inner layer structure are connected by connecting the bottom layer and the upper layer to form a double-layer knotted structure, and the surface layer structure is made of imitation knitted fabric The weave converted from the appearance pattern pattern of the coil ring, the inner weave is a twill weave, the number of warp yarns and weft yarns of the surface weave must be less than the number of warp yarns and weft yarns of the inner weave respectively; the warp yarns and weft yarns of the surface weave The degree of thickness needs to be greater than the thickness of the warp and weft yarns of the inner weave respectively; the arrangement density of the warp and weft yarns of the surface weave in the fabri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com