Production method of rib fabric portion

A technology of knitted parts and ribs, which is applied in the field of manufacturing rib knitted parts, and can solve problems such as roughness and bulkiness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

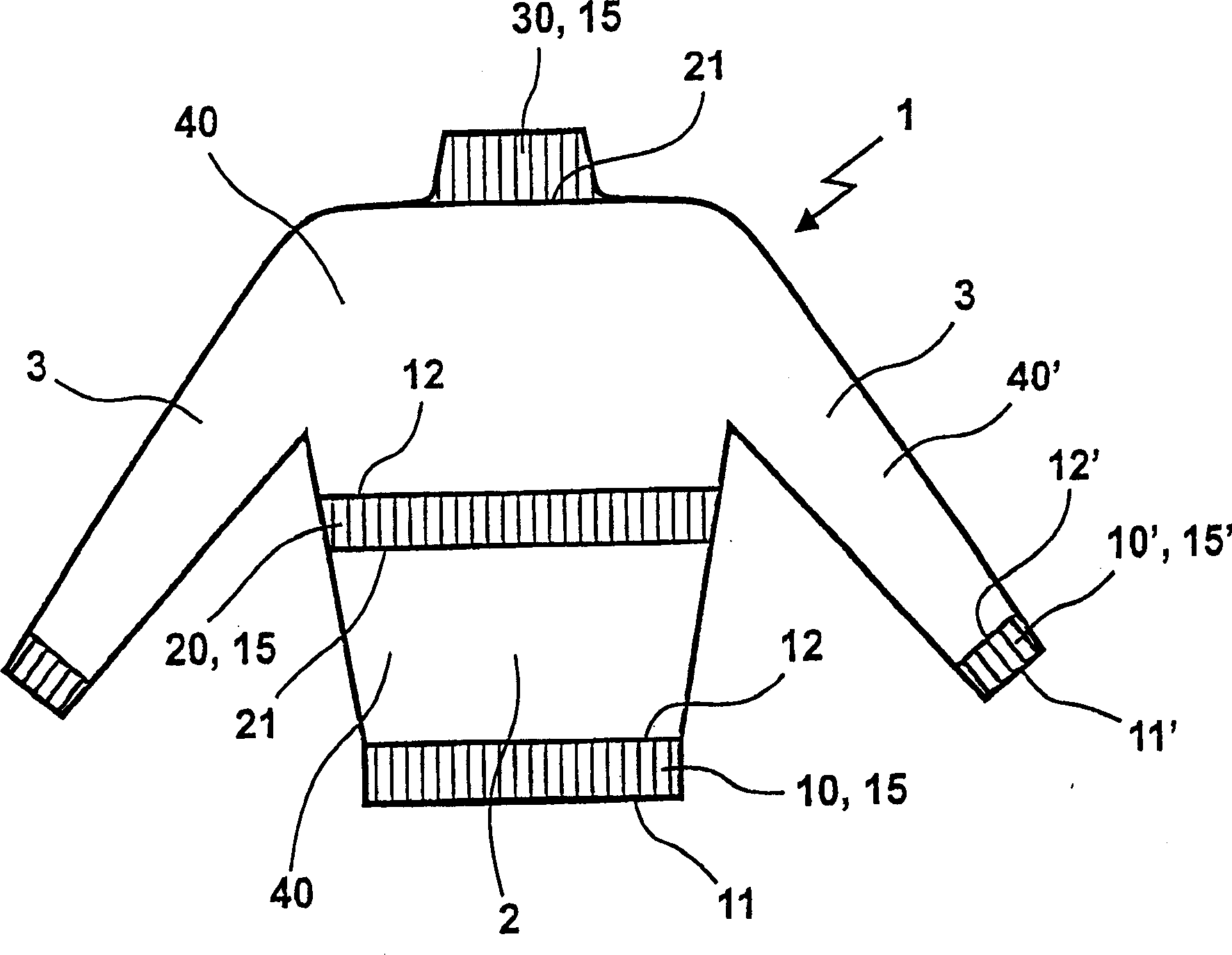

[0032] figure 1 Shown is a knitted pullover made from tubular finished fabric having rib knit sections 10 and 10' starting at the torso and arms, another rib knit section 20 in the mid-torso area and rib knit at the neck Part 30. The torso portion 2 is formed by a jersey knit portion 40 between the rib knit portions 10 , 20 and 30 . The arm 3 above the cuff 10' is also formed from a jersey portion 40. Reference numerals 11, 11' designate the initial knitting course of the cuff 10, 10' and 12, 12' designate the transitional knitting course of the jersey portion 40, 40'. 15, 15' represent ribbed knitting courses. In the rib knit parts 20 and 30 , 21 designates the transition area from the plain knit part 40 to the rib knit parts 20 , 30 . 12 and 12' again indicate the transition zone from the rib knit portion 20, 10' to the jersey knit portion 40, 40'.

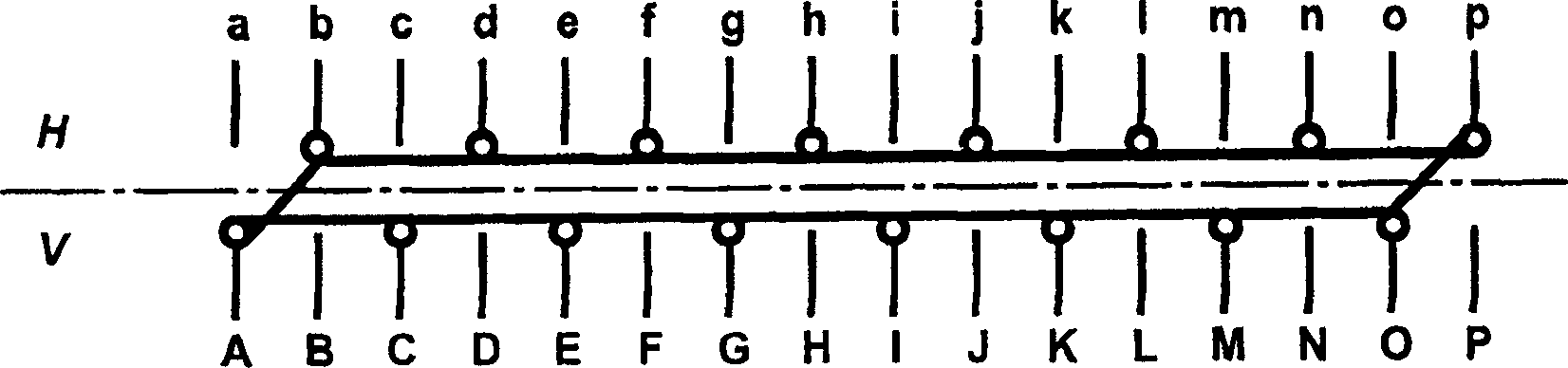

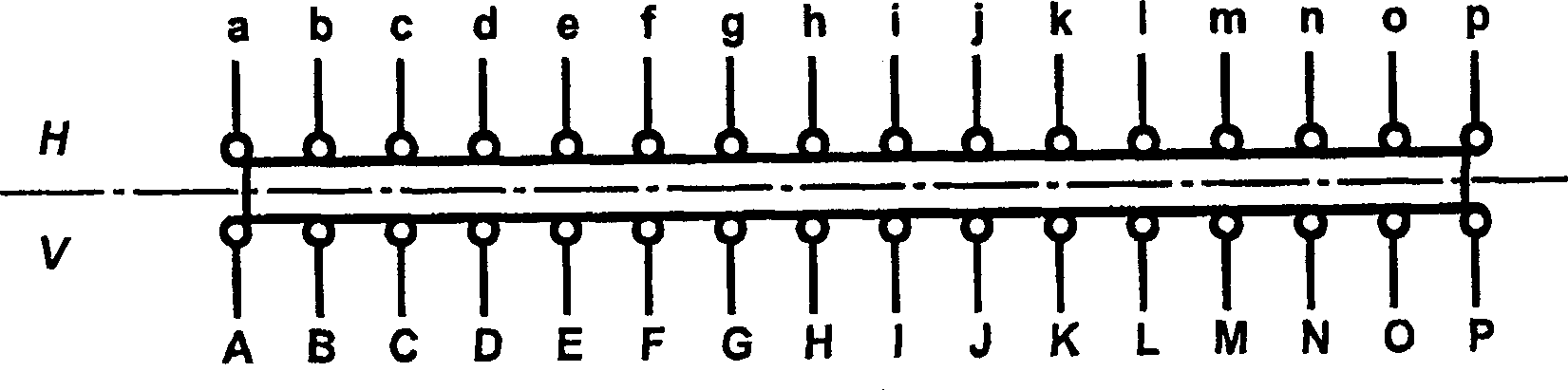

[0033] figure 2 Shown is a typical needle arrangement for forming a tubular finished knitted fabric, characterized...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com