Cigarette paper employing natural baccy fiber

A technology of tobacco fiber and cigarette paper, applied in the fields of natural cellulose pulp/paper, fiber raw material processing, papermaking, etc., can solve the problems of limited expressiveness of features, and achieve the effect of distinctive personalization, changing appearance, and simple process

Active Publication Date: 2007-08-15

YUNNAN REASCEND TOBACCO TECH GRP

View PDF0 Cites 21 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At the same time, due to the pursuit of differentiation and personalization of cigarette products in recent years, personalized cigarette papers such as colored cigarette papers and special embossed cigarette papers have also appeared, but their technical means basically come from substances other than tobacco components, and their characteristic expression is limited

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

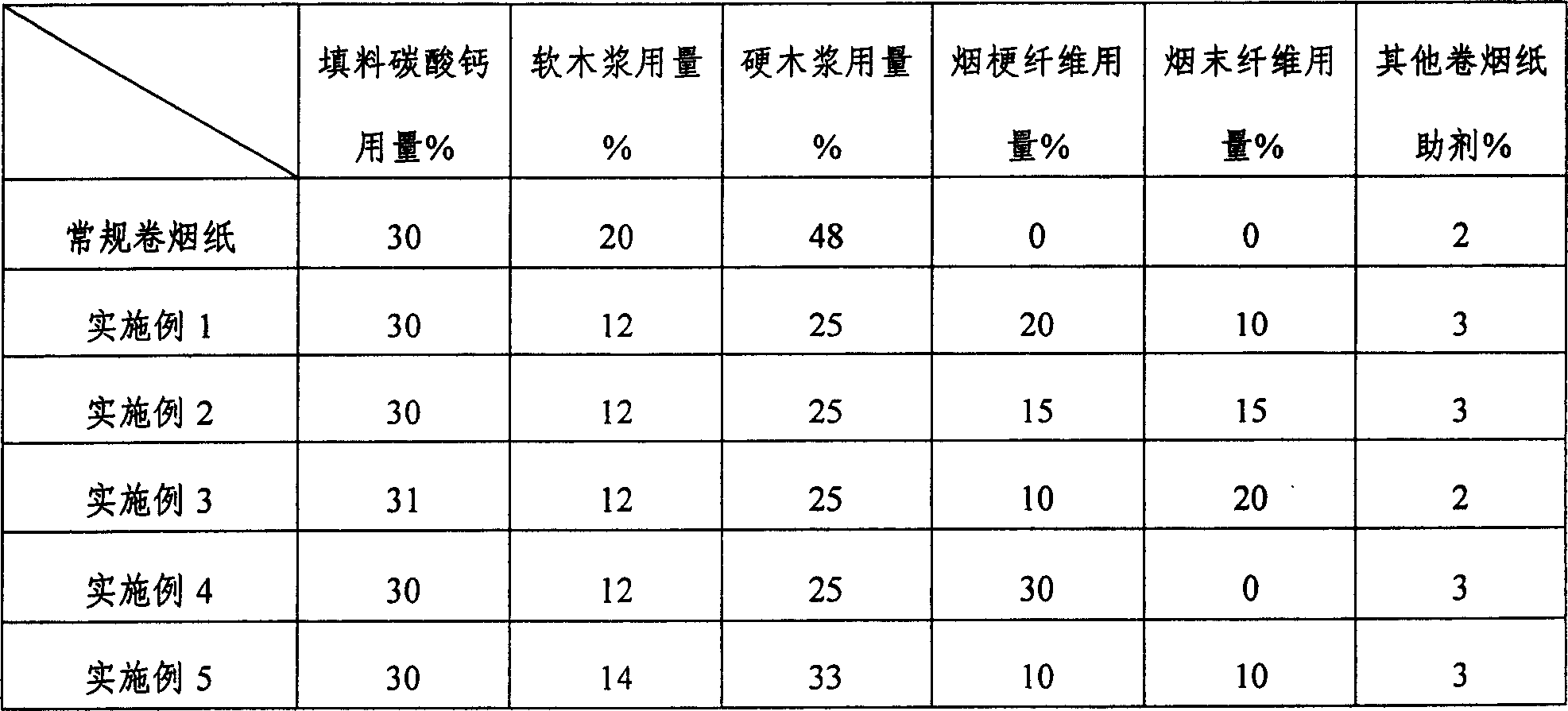

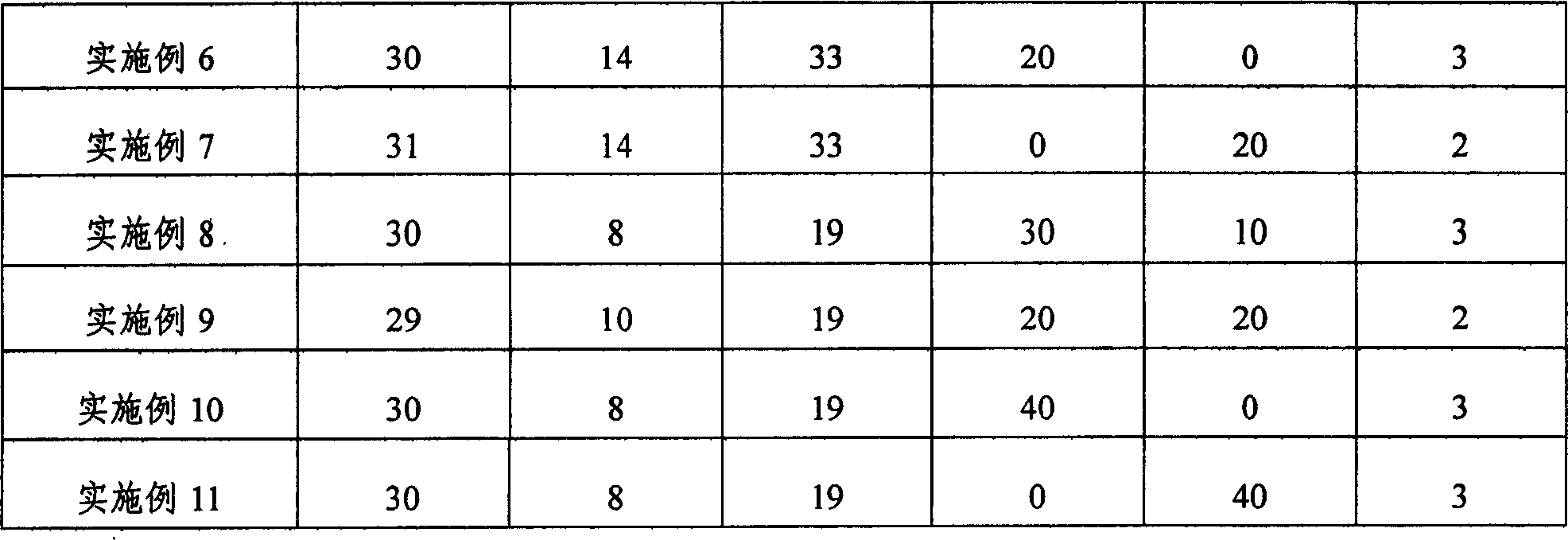

[0027] Through the specific examples given in Table 4 below, the present invention can be further clearly understood. However, they do not limit the present invention.

[0028] Table 4.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a cigarette paper which uses natural tobacco fiber as main material, wherein the natural tobacco fiber is one of stem fiber or tobacco end fiber, or their mixture. The material comprises 0-40% stem fiber, 0-40% tobacco end fiber, 20-30% stuff calcium carbonate, 5-20% soft wood pulp, 20-50% hard wood pulp, and 1-5% cigarette agents. Tests have proved that the inventive cigarette has higher quality.

Description

technical field [0001] The invention relates to a cigarette paper, more specifically, a cigarette paper using natural tobacco fibers. Background technique [0002] Cigarette paper, also known as cigarette coil paper, is a thin special paper for industrial use, and is mainly used for wrapping shredded tobacco in cigarettes in the tobacco industry. [0003] Cigarette paper, as a special type of paper, occupies a relatively high position in tissue paper, and at the same time, as a cigarette auxiliary material, it also occupies a place in the cigarette industry. Existing cigarette paper is mainly composed of inorganic fillers, fibers and combustion regulators. The commonly used inorganic filler is calcium carbonate, and its dosage is usually 25% to 35% of the weight of the cigarette paper. Other special fillers are also used to change the properties of the cigarette paper. Commonly used fibers include flax fiber and wood pulp fiber, and their dosage is usually 65% to 75% of ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): D21H11/00D21H17/67

Inventor 罗丽莉杨伟祖沈靖轩

Owner YUNNAN REASCEND TOBACCO TECH GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com