Composite appearance product with patterns and production method thereof

A composite material and manufacturing method technology, applied in chemical instruments and methods, synthetic resin layered products, layered products, etc., can solve the problems of unfavorable market share, high cost, complex surface treatment process of composite materials, etc. Appearance effect, effect of simplified surface treatment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

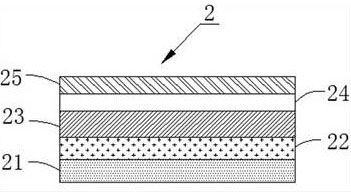

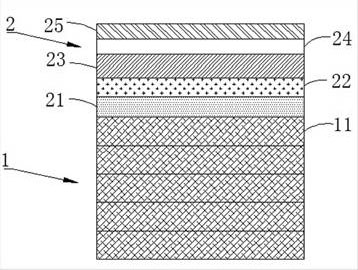

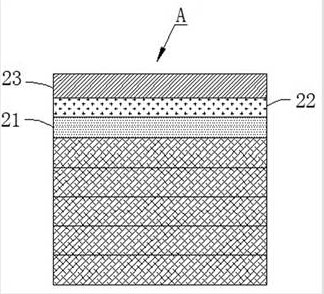

[0029] Embodiment: A method for making a composite material appearance part with a pattern, stacking several layers of plastic fiber cloth 11 soaked in resin in advance to form a composite material stack 1, the composite material stack has two opposite two surfaces, at least one of the two surfaces is covered with a decorative molding film 2, and the decorative molding film is successively composed of a back glue layer 21, an ink layer 22, a product surface UV material layer 23, a release layer 24 and a PET layer 25. and the decorative molding film 2 covers the composite material stack 1 at the adhesive layer 21, and then pressurizes and heats the mold so that the composite material stack is solidified and molded together with the decorative molding film After the mold is opened, the decorative molding film is torn off at the release layer 24 to obtain the patterned composite material appearance part A of the present invention. The patterned composite material appearance part c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com