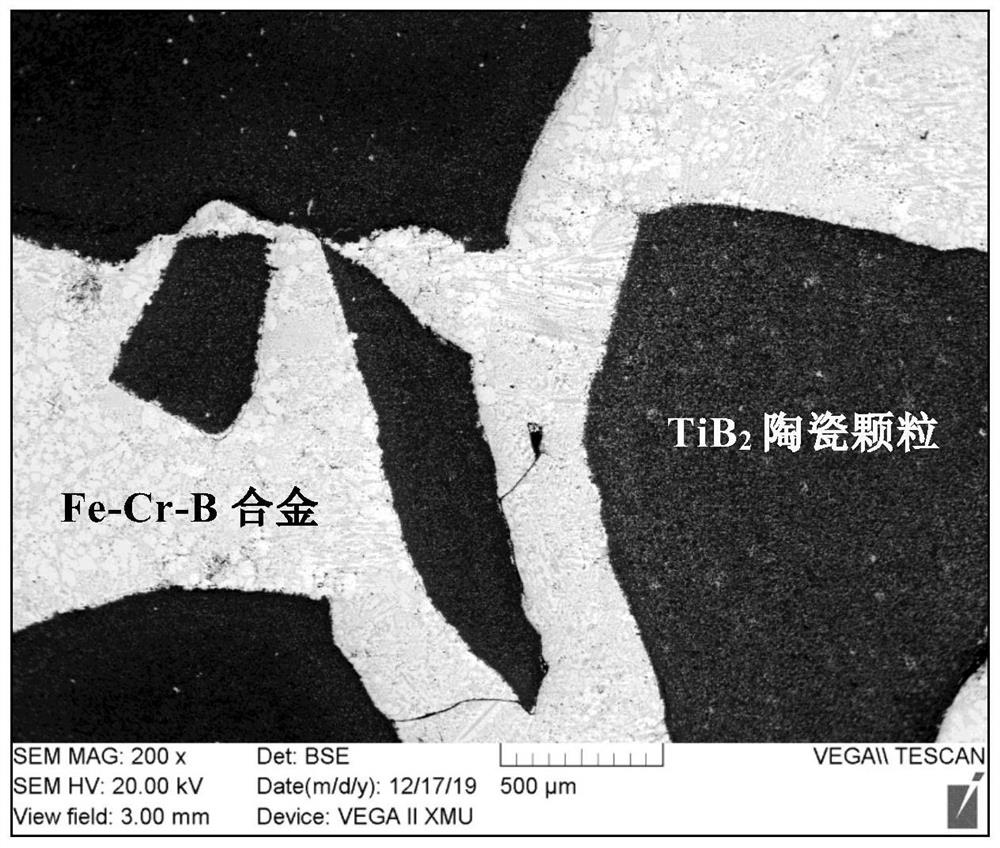

Preparation method of TiB2 reinforced Fe-Cr-B alloy-based composite lining plate

A composite liner, fe-cr-b technology, applied in the field of wear-resistant materials, can solve the problem of poor bonding ability between ceramic particles and the matrix interface affecting the wear resistance of materials, achieve excellent wettability, simplify processing technology, enhance The effect of bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] This embodiment includes the following steps:

[0032] Step 1. Put TiB 2 powder and Fe-Cr alloy powder were added to the polyvinyl alcohol solution and stirred evenly to obtain TiB 2 Ceramic blank; the TiB 2 TiB in ceramic blank 2 The mass content of the Fe-Cr alloy powder is 84.5%, the mass content of the Fe-Cr alloy powder is 7.5%, and the content of the polyvinyl alcohol solution is 8.0%; the mass content of the chromium element in the Fe-Cr alloy powder is 50.0%, and the rest is iron element ; The mass content of polyvinyl alcohol in the polyvinyl alcohol solution is 5.0%, and the content of distilled water is 95.0%;

[0033] Step two, the TiB obtained in step one 2 The ceramic blank is put into the mold, and the pressure of 30MPa is applied for 20min to press to obtain TiB 2 ceramic body;

[0034] Step three, the TiB obtained in step two 2 After the ceramic body is dried, it is loaded into a vacuum sintering furnace, and the temperature is raised to 1800 °C ...

Embodiment 2

[0039] This embodiment includes the following steps:

[0040] Step 1. Put TiB 2 powder and Fe-Cr alloy powder were added to the polyvinyl alcohol solution and stirred evenly to obtain TiB 2 Ceramic blank; the TiB 2 TiB in ceramic blank 2 The mass content of powder is 87.5%, the mass content of Fe-Cr alloy powder is 4.5%, and the content of polyvinyl alcohol solution is 8.0%; the mass content of chromium element in the Fe-Cr alloy powder is 60.0%, and the rest is iron element ; The mass content of polyvinyl alcohol in the polyvinyl alcohol solution is 5.0%, and the content of distilled water is 95.0%;

[0041] Step two, the TiB obtained in step one 2 The ceramic blank is put into the mold, and the pressure of 30MPa is applied for 20min to press to obtain TiB 2 ceramic body;

[0042] Step three, the TiB obtained in step two 2 After the ceramic body is dried, it is loaded into a vacuum sintering furnace, and the temperature is raised to 1800 °C at a rate of 10 °C / min and a...

Embodiment 3

[0046] This embodiment includes the following steps:

[0047] Step 1. Put TiB 2 powder and Fe-Cr alloy powder were added to the polyvinyl alcohol solution and stirred evenly to obtain TiB 2 Ceramic blank; the TiB 2 TiB in ceramic blank 2 The mass content of powder is 85.0%, the mass content of Fe-Cr alloy powder is 7.0%, and the content of polyvinyl alcohol solution is 8.0%; the mass content of chromium element in the Fe-Cr alloy powder is 54.0%, and the rest is iron element ; The mass content of polyvinyl alcohol in the polyvinyl alcohol solution is 5.0%, and the content of distilled water is 95.0%;

[0048] Step two, the TiB obtained in step one 2 The ceramic blank is put into the mold, and the pressure of 30MPa is applied for 20min to press to obtain TiB 2 ceramic body;

[0049] Step three, the TiB obtained in step two 2 After the ceramic body is dried, it is loaded into a vacuum sintering furnace, and the temperature is raised to 1800 °C at a rate of 10 °C / min and a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com