Linear compressor and manufacturing method thereof

A linear compressor and surface treatment technology, applied in mechanical equipment, engine components, engine parameters, etc., can solve the problems of high manufacturing cost of linear compressors, piston wear, high cost, etc., to simplify the surface treatment process and prevent performance. The effect of reducing and preventing clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

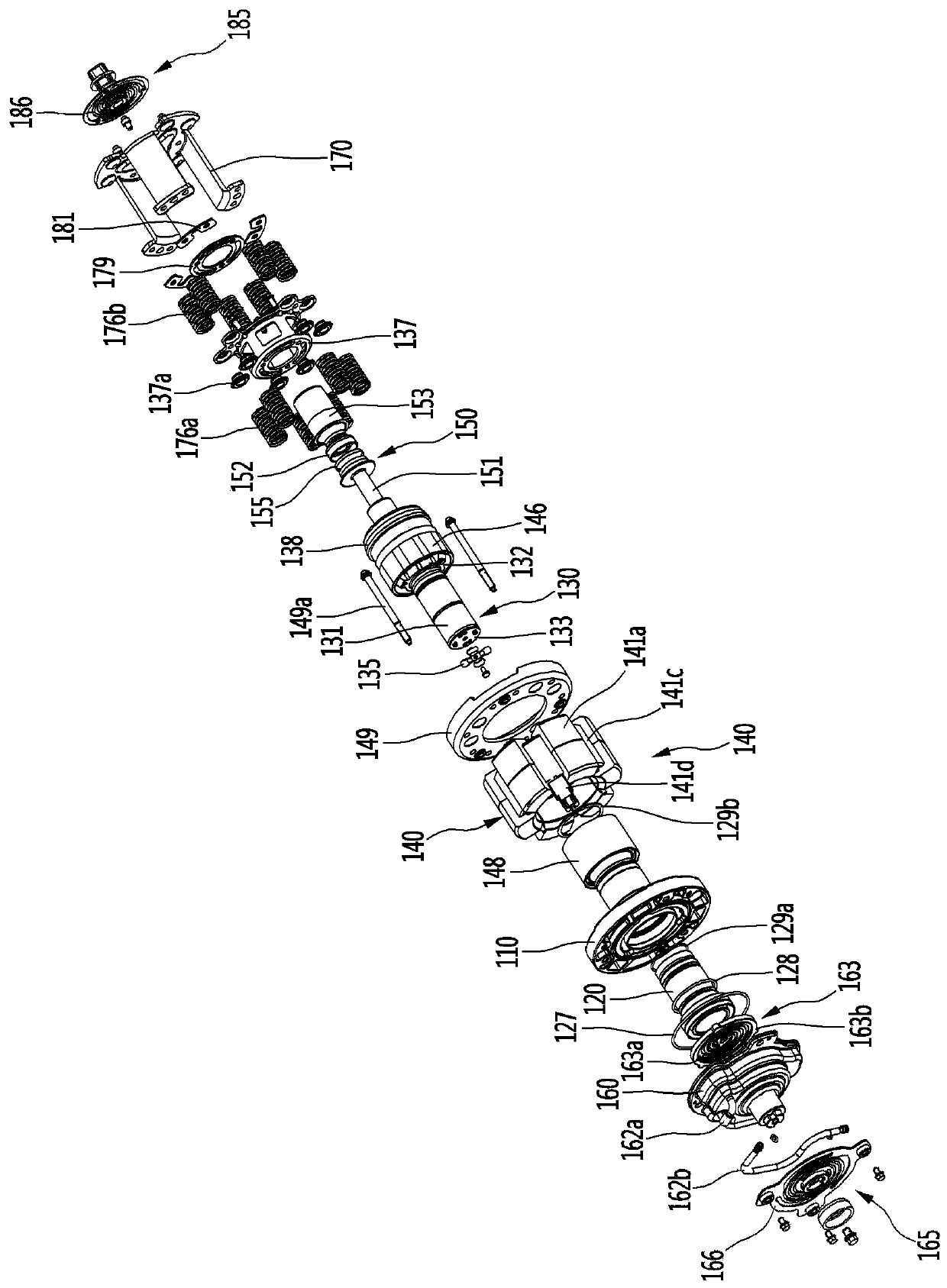

[0069] Hereinafter, specific embodiments of the present invention will be described with reference to the drawings. However, the technical idea of the present invention is not limited to the disclosed embodiments, and those skilled in the art who understand the technical idea of the present invention can easily suggest other embodiments within the scope of the same technical idea.

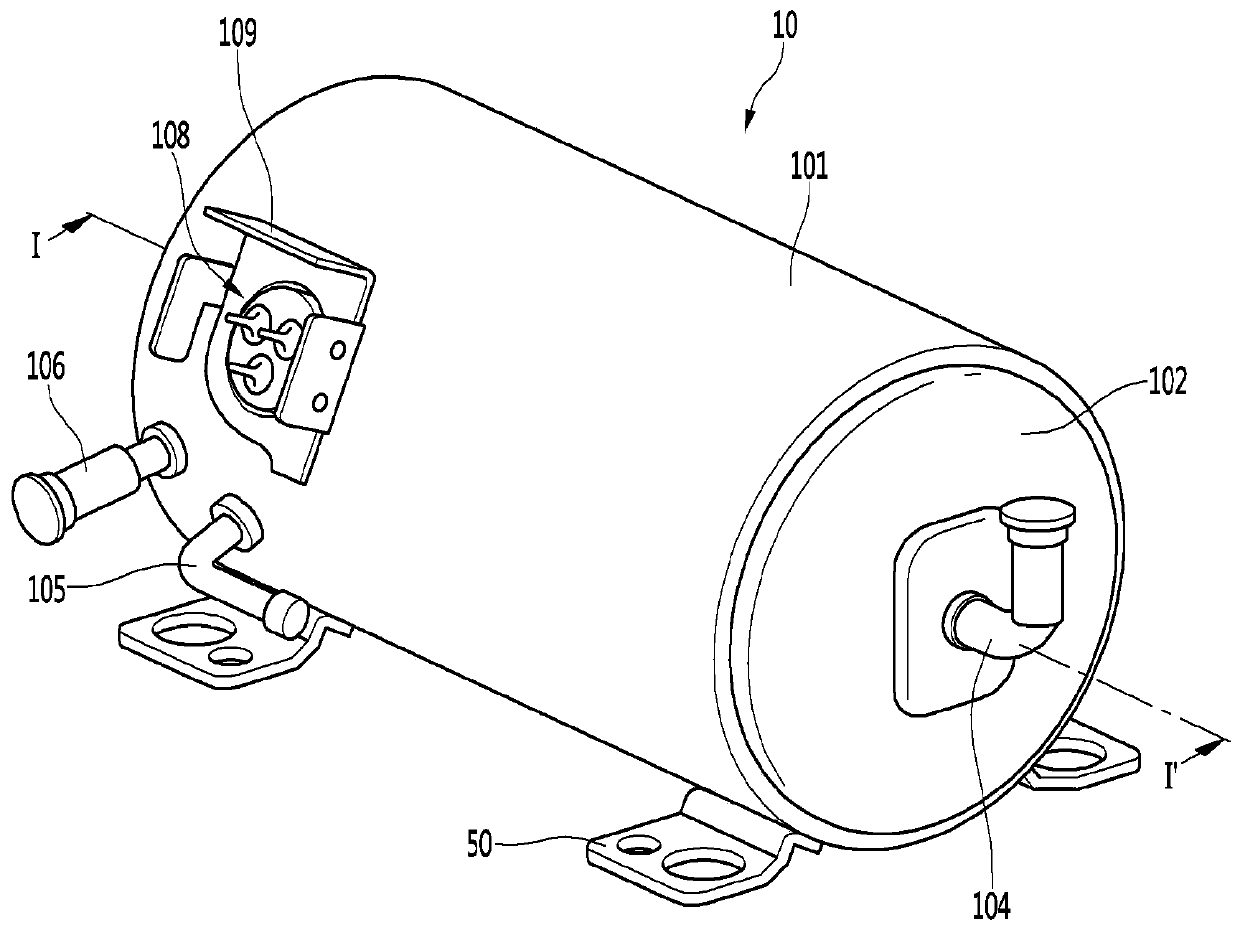

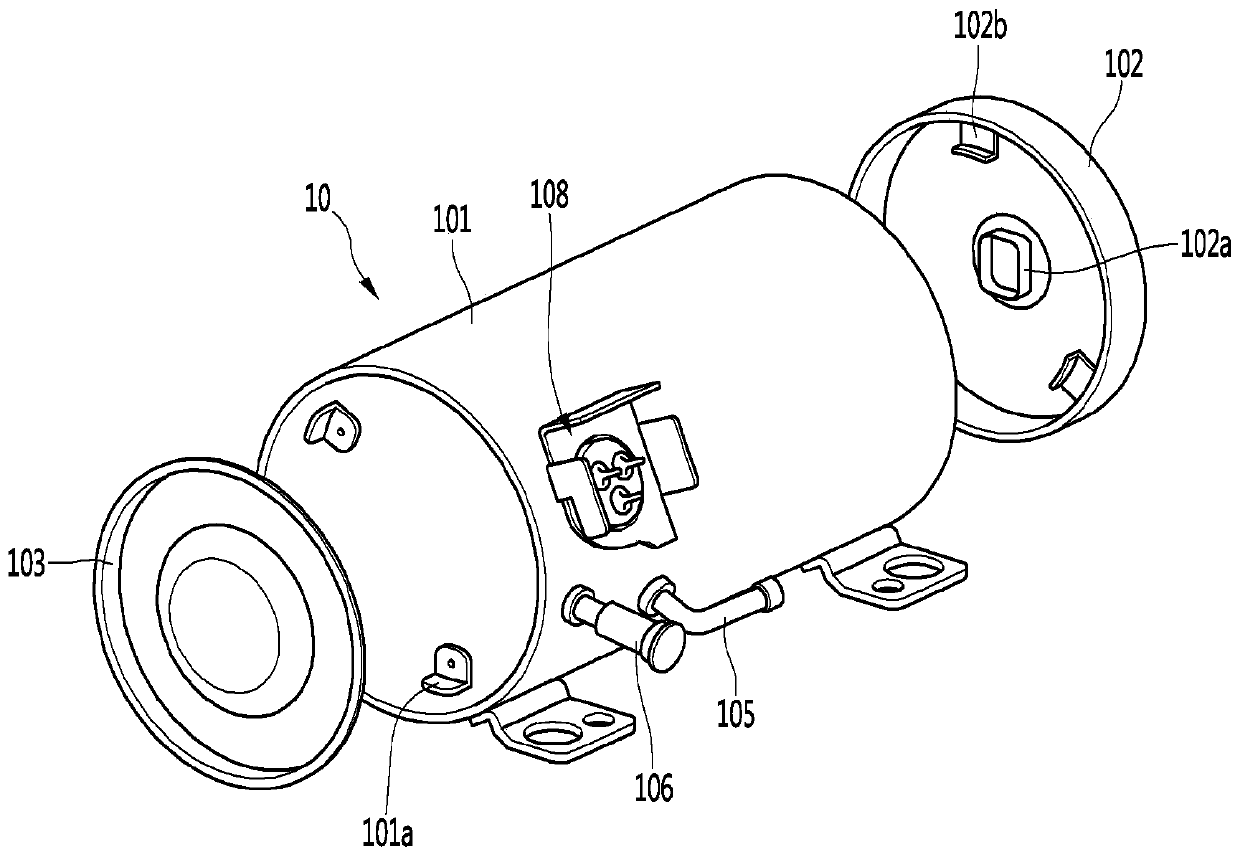

[0070] figure 1 is an external perspective view showing the structure of a linear compressor according to an embodiment of the present invention, figure 2 It is an exploded perspective view of a housing and a housing cover of the linear compressor according to the embodiment of the present invention.

[0071] refer to figure 1 and figure 2 , The linear compressor 10 of the embodiment of the present invention includes: a housing 101 ; and housing covers 102 , 103 combined with the housing 101 . In a broad sense, the first housing cover 102 and the second housing cover 103 can be understood...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com