A kind of mixing tool surface treatment method

A technology for stirring tools and surface treatment, applied in the field of friction stir welding, can solve the problems of expensive equipment, softening of stirring tools, complicated processes, etc., and achieves the effects of low cost, avoiding poor processing performance and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

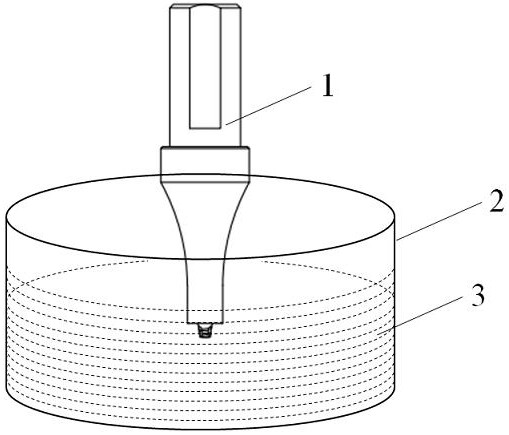

[0024] like figure 1 Example 1 shown: GH 4169 stirring tool surface treatment

[0025] Step 1: Clean the surface of the GH 4169 stirring tool to remove oil stains, and then pickle to remove surface oxides;

[0026] Step 2: Coat a layer of FB301 flux on the surface of the stirring tool 1, place it in a vacuum furnace to keep warm and activate the flux, and set the temperature to 800°C;

[0027] Step 3: Put the BNi-2 nickel-based solder 3 in the furnace 2 and heat it to 1100±20°C;

[0028] Step 4: Take the stirring tool 1 out of the vacuum furnace, and immerse it in the solder for brazing reaction for 20 minutes;

[0029] Step 5: Take out the stirring tool after the brazing reaction and place it in water to cool;

[0030] Step 6: Dip the cooled stirring tool into nitric acid solution and ultrasonically clean it to remove the residual solder.

[0031] Through the brazing reaction, a 20 μm thick Cr-B intermetallic compound was formed on the surface of the stirring tool.

Embodiment 2

[0032] Embodiment 2: surface treatment of hard alloy steel YG10 stirring tool

[0033] Step 1: Use alcohol to clean the surface of the hard alloy steel YG10 stirring tool to remove oil stains, and then pickle to remove surface oxides;

[0034] Step 2: Coat a layer of FB101 flux on the surface of the stirring tool, place it in a vacuum furnace to keep warm and activate the flux, and set the temperature to 500°C;

[0035] Step 3: Put B-Ag50CuZnCdNi silver-based solder in a furnace and heat to 650±20°C;

[0036] Step 4: Take the stirring tool out of the vacuum furnace, and immerse it in the solder for brazing reaction for 10 minutes;

[0037] Step 5: Take out the stirring tool after the brazing reaction and place it in water to cool;

[0038] Step 6: Dip the cooled stirring tool into nitric acid solution and ultrasonically clean it to remove the residual solder.

[0039] Through the brazing reaction, a 15 μm thick intermetallic compound was formed on the surface of the stirrin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com