Anti-shrinkage PVC edge band and preparation method thereof

An edge banding and anti-shrinking technology, applied in the field of anti-shrinking PVC edge banding and its preparation, can solve the problems of material brittleness, chipping damage, product toughness decline, etc., and achieve the effect of good shrinkage resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

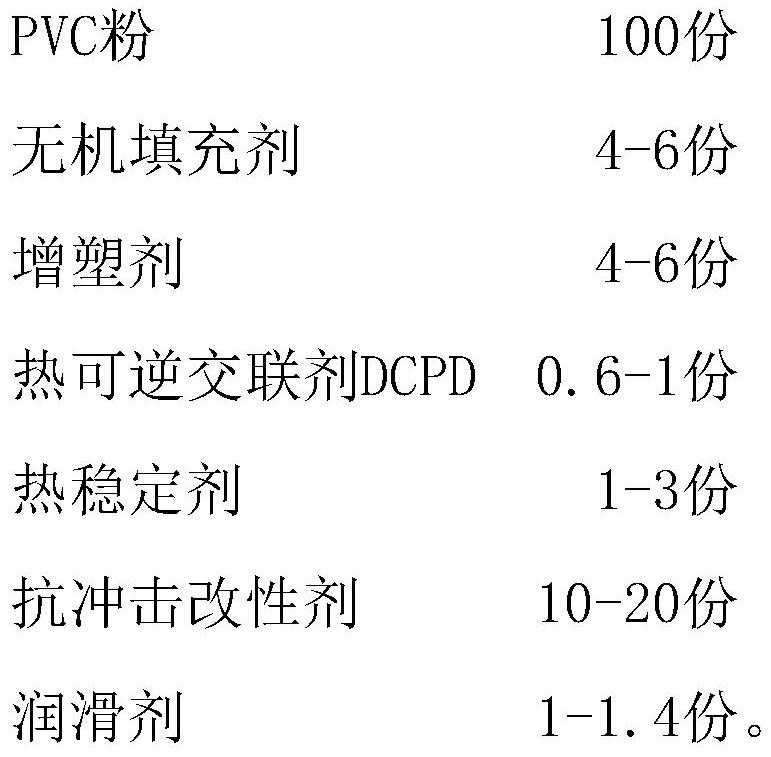

[0026] An anti-shrinkage PVC edge banding, comprising the following raw materials in parts by weight:

[0027]

[0028] Wherein, the PVC powder is SG-1000.

[0029] Wherein, the inorganic filler is heavy calcium carbonate.

[0030] Wherein, the plasticizer is dioctyl terephthalate.

[0031] Wherein, the heat stabilizer is a calcium-zinc composite heat stabilizer.

[0032] Wherein, the impact modifier is composed of NBR and MBS in a weight ratio of 2:1.

[0033] Wherein, the lubricant is composed of synthetic wax and stearic acid in a ratio of 2:1 by weight.

[0034] The preparation method of a kind of anti-shrinkage PVC edge banding described above comprises the following steps: (1) After mixing and dispersing each raw material, put it into a twin-screw extruder for extrusion granulation, obtain PVC masterbatch, and extrude granulation The temperature is 168°C; (2) Extrude the PVC masterbatch on the twin-screw extrusion molding machine. 160°C.

Embodiment 2

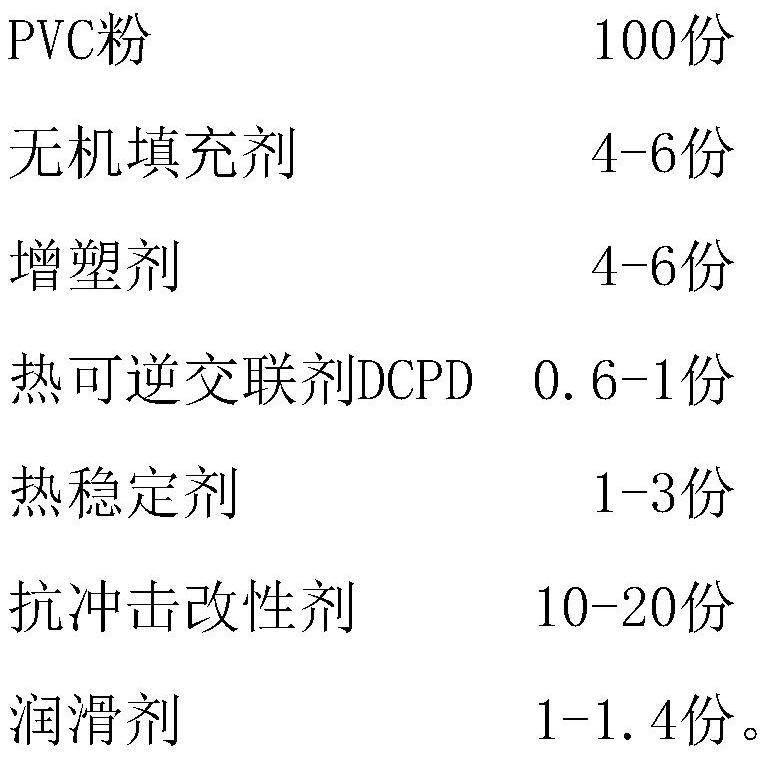

[0036] An anti-shrinkage PVC edge banding, comprising the following raw materials in parts by weight:

[0037]

[0038] Wherein, the PVC powder is SG-1000.

[0039] Wherein, the inorganic filler is composed of heavy calcium carbonate and kaolin in a ratio of 1:1 by weight.

[0040] Wherein, the plasticizer is dioctyl adipate.

[0041] Wherein, the heat stabilizer is a calcium-zinc composite heat stabilizer.

[0042] Wherein, the impact modifier is composed of NBR and MBS in a weight ratio of 1:1.

[0043] Wherein, the lubricant is synthetic wax.

[0044] The preparation method of a kind of anti-shrinkage PVC edge banding described above comprises the following steps: (1) After mixing and dispersing each raw material, put it into a twin-screw extruder for extrusion granulation, obtain PVC masterbatch, and extrude granulation The temperature is 150°C; (2) Extrude the PVC masterbatch on a twin-screw extrusion molding machine. ℃.

Embodiment 3

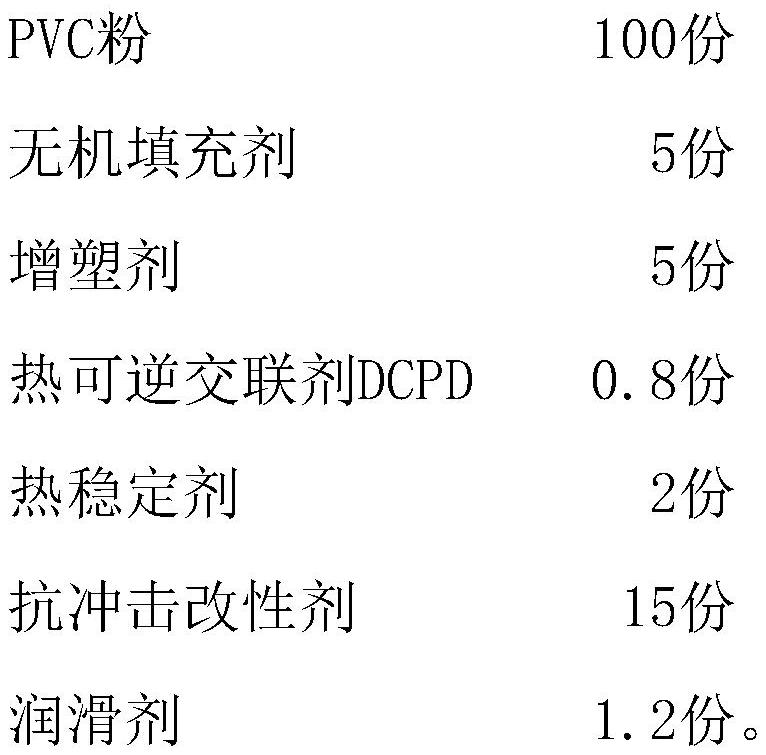

[0046] An anti-shrinkage PVC edge banding, comprising the following raw materials in parts by weight:

[0047]

[0048] Wherein, the PVC powder is SG-1000.

[0049] Wherein, the inorganic filler is composed of heavy calcium carbonate and quartz powder in a weight ratio of 2:1.

[0050] Wherein, the plasticizer is composed of dioctyl terephthalate and methyl chlorostearate in a weight ratio of 3:1.

[0051] Wherein, the heat stabilizer is a calcium-zinc composite heat stabilizer.

[0052] Wherein, the impact modifier is composed of NBR and MBS in a weight ratio of 3:1.

[0053] Wherein, the lubricant is stearic acid.

[0054]The preparation method of a kind of anti-shrinkage PVC edge banding described above comprises the following steps: (1) After mixing and dispersing each raw material, put it into a twin-screw extruder for extrusion granulation, obtain PVC masterbatch, and extrude granulation The temperature is 175°C; (2) Extrude the PVC masterbatch on a twin-screw ext...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com