Comb-shaped high-strength polyester and preparation method thereof

A high-strength, polyester technology, applied in the field of comb-shaped high-strength polyester and its preparation, can solve the problems of inability to large-scale industrialization, strict condition control requirements, complicated synthesis steps, etc., and achieve good optical transparency and rheological properties. , maintain the elongation at break, the effect of simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

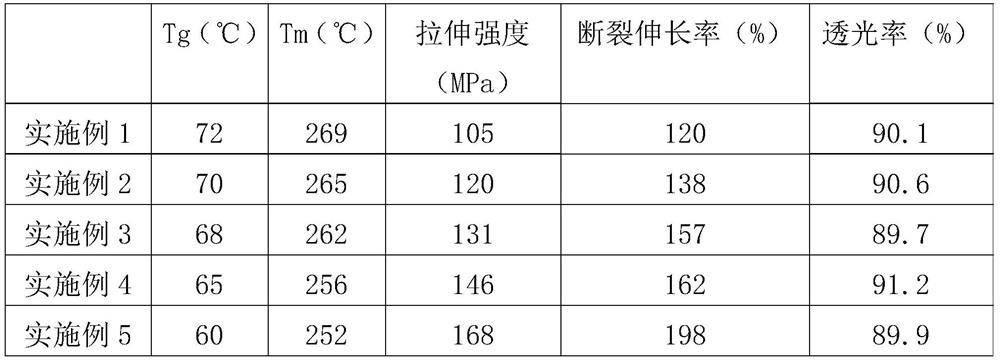

Embodiment 1

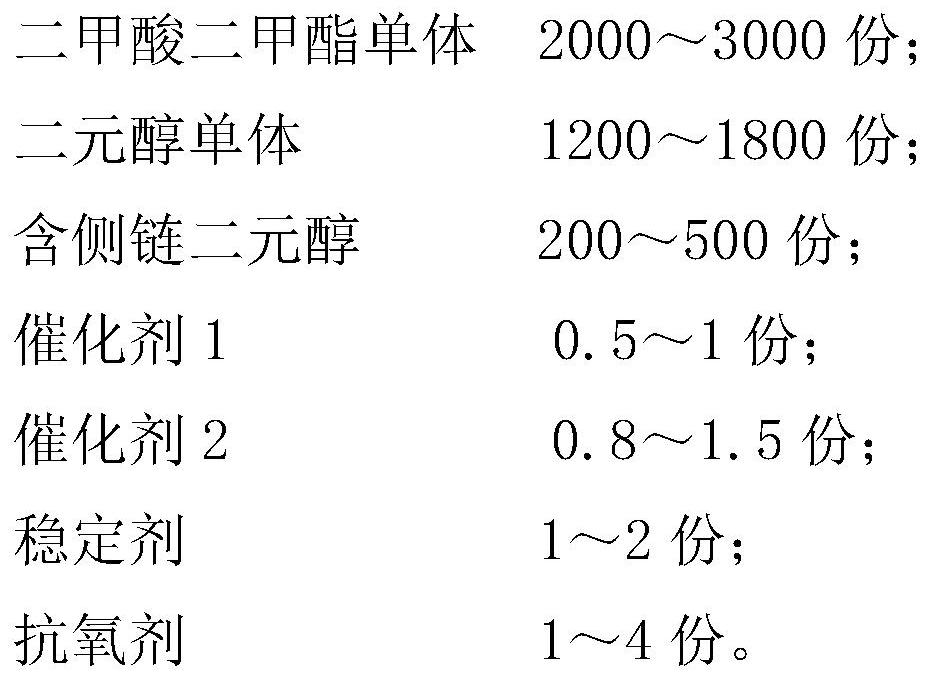

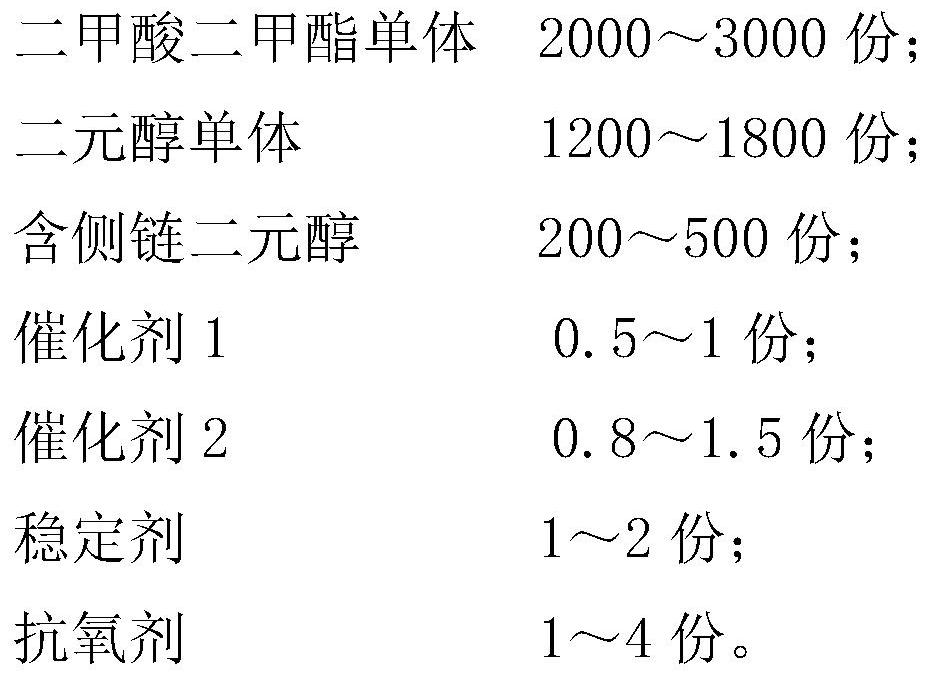

[0024] The comb-shaped high-strength polyester in this example is synthesized from the following raw materials in mass ratio: dimethyl terephthalate 2000g, ethylene glycol 1500g, 1,2-hexanediol 200g, zinc acetate 0.8g, ethylene glycol 1 g of antimony alcohol, 1 g of trimethyl phosphate, 2 g of antioxidant 1010 (tetra[β-propionic acid] pentaerythritol ester).

[0025] The preparation process of the comb-shaped high-strength polyester in the present embodiment is as follows:

[0026] Dimethyl terephthalate, ethylene glycol, 1,2-hexanediol, zinc acetate, ethylene glycol antimony, trimethyl phosphate and antioxidant 1010 were weighed and mixed evenly, and added to 5L reaction In the kettle, stir for 10 minutes under the preheating condition of 80°C, then replace the air in the kettle, and repeat the vacuum pumping and nitrogen gas three times. Raise the temperature of the jacket of the reaction kettle to 230°C, and maintain the pressure inside the kettle at about 200kPa. Judge th...

Embodiment 2

[0030] The comb-shaped high-strength polyester in this example is synthesized from the following mass ratio raw materials: dimethyl terephthalate 2500g, propylene glycol 1800g, 1,2-decanediol 250g, calcium acetate 1.0g, ethylene glycol antimony 1.2 g, 1.2 g of triphenyl phosphite, 2.5 g of antioxidant 1010 (tetrakis [β-propionic acid] pentaerythritol ester).

[0031] The preparation process of the comb-shaped high-strength polyester in the present embodiment is as follows:

[0032] Weigh dimethyl terephthalate, propylene glycol, 1,2-decanediol, calcium acetate, ethylene glycol antimony, triphenyl phosphite and antioxidant 1010 and mix them evenly, and add them to a 5L reactor , stirred at 80°C for 10 minutes under preheating conditions, then replaced the air in the kettle, and repeated vacuum pumping and nitrogen gas 3 times. Raise the temperature of the jacket of the reaction kettle to 240°C, and maintain the pressure inside the kettle at about 200kPa. The degree of the tran...

Embodiment 3

[0036] The comb-shaped high-strength polyester in this example is synthesized from the following raw materials in mass ratio: 2,000 g of dimethyl isophthalate, 1,500 g of neopentyl glycol, 400 g of 1,2-decanediol, and 0.7 g of p-toluenesulfonic acid , antimony ethylene glycol 1.5g, trimethyl phosphate 1g, antioxidant 1010 (tetra[β-propionate] pentaerythritol ester) 2g.

[0037] The preparation process of the comb-shaped high-strength polyester in the present embodiment is as follows:

[0038] Dimethyl isophthalate, neopentyl glycol, 1,2-decanediol, p-toluenesulfonic acid, ethylene glycol antimony, trimethyl phosphate and antioxidant 1010 were weighed and mixed evenly, and added Put it into a 5L reaction kettle, stir for 10 minutes under the preheating condition of 80°C, then replace the air in the kettle, and repeat the vacuum pumping and nitrogen gas three times. Raise the temperature of the jacket of the reaction kettle to 245°C, and maintain the pressure inside the kettle ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com