Patents

Literature

35results about How to "Reduce surface treatment costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hot stamping die steel and production method thereof

InactiveCN104928586AImprove the quality of heat treatmentImprove strength and toughnessSolid state diffusion coatingHot stampingHardness

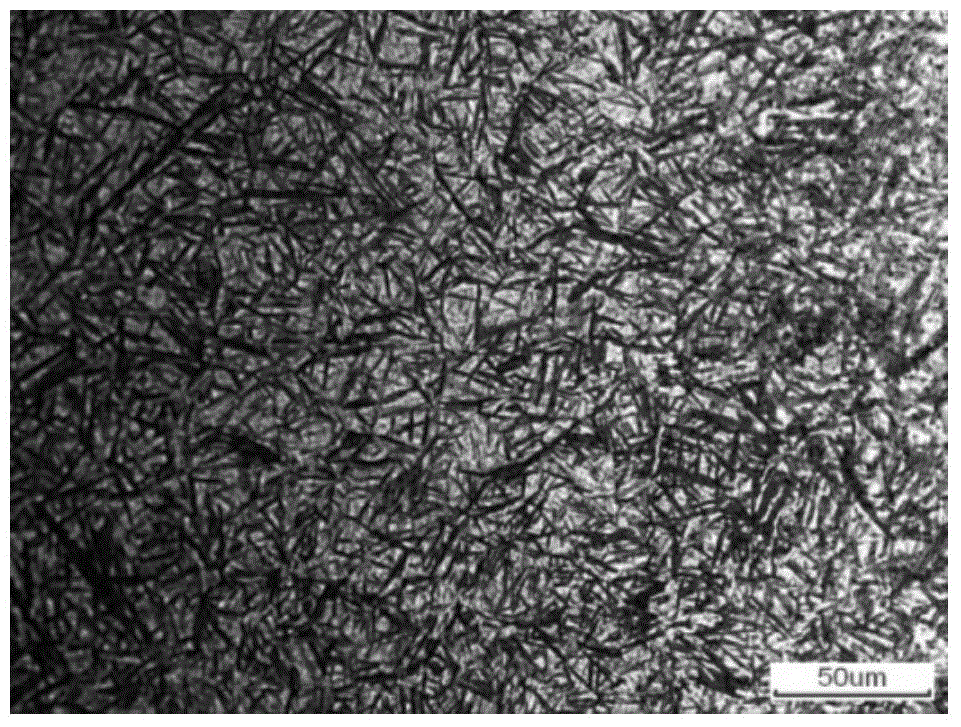

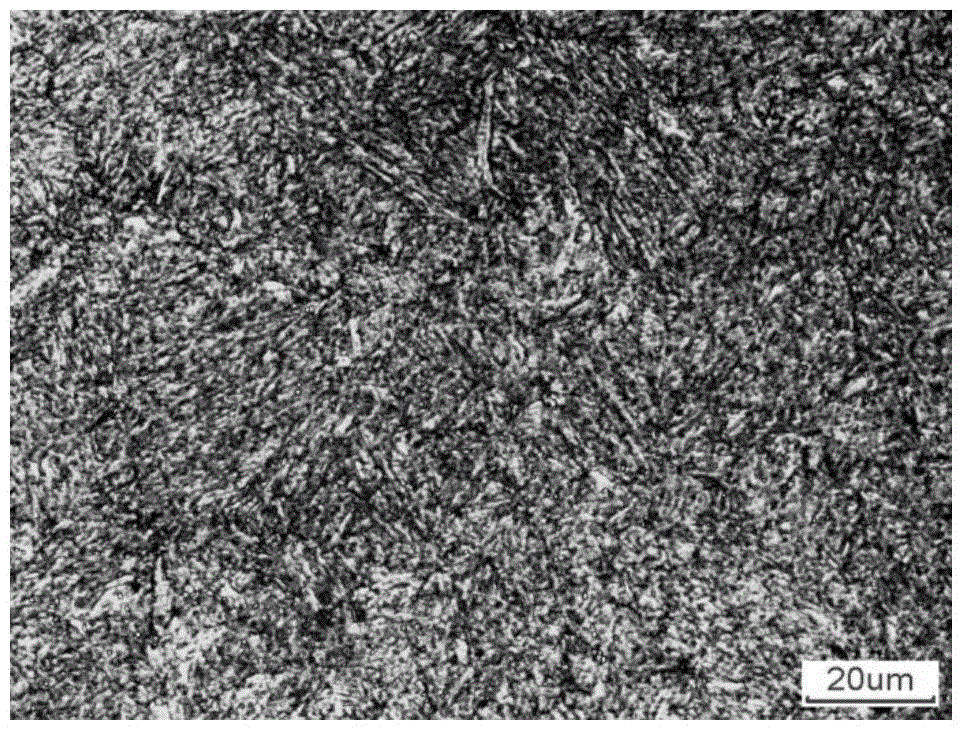

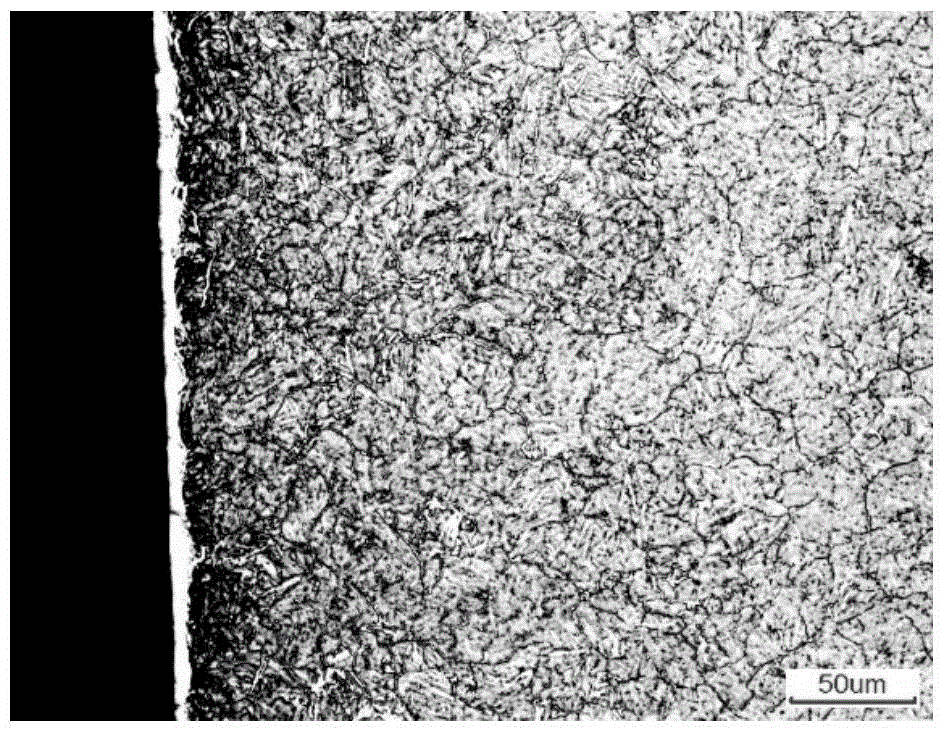

The invention provides hot stamping die steel and a production method thereof. The hot stamping die steel is composed of, by weight, 0.45-0.50% of C, 0.1-0.3% of Si, 0.1-0.3% of Mn, 2.0-2.3% of Cr, 2.3-2.5% of Mo, 0.8-1.0% of V, smaller than or equal to 0.03% of P, smaller than or equal to 0.03% of S and the balance Fe and other inevitable impurities and meets the relational expressions that Mo / Cr=1-1.25 and V / Cr=0.35-0.43. By means of the electroslag remelting process, the ultrafine thermal treatment process, the vacuum thermal treatment process and the plasma nitriding surface treatment process, the produced and obtained hot stamping die steel is low in cost and high in comprehensive performance; the hot stamping die steel has a thermal conductivity coefficient of 34.3 W / m.k, quenching and tempering hardness of 50-53 HRC, ballistic work of 180-210 J, surface hardness of 850-1040 HV0.3 and diffusion thickness of 230-300 microns, and a white bright layer is ceaseless after nitriding.

Owner:BAOSHAN IRON & STEEL CO LTD

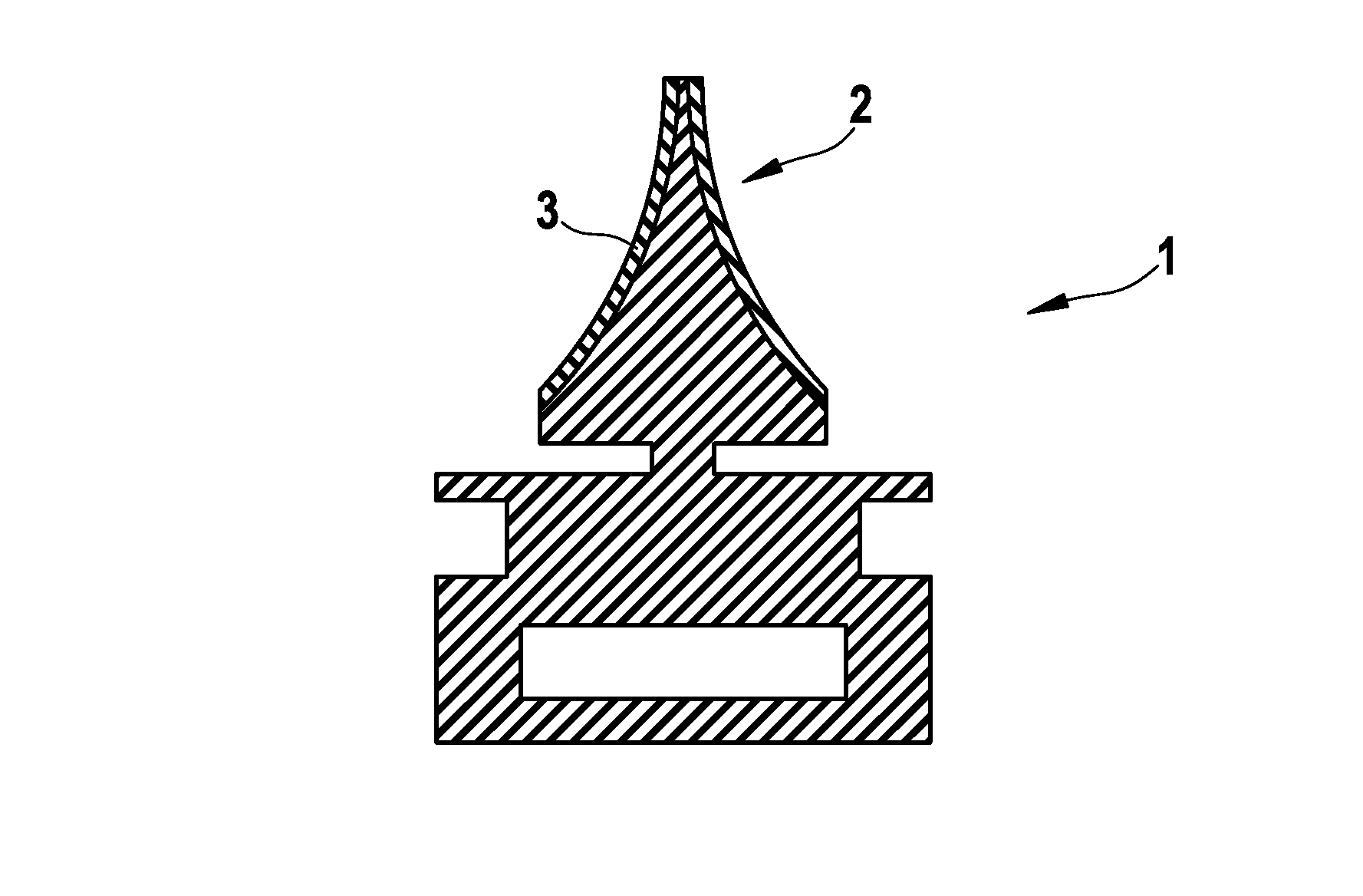

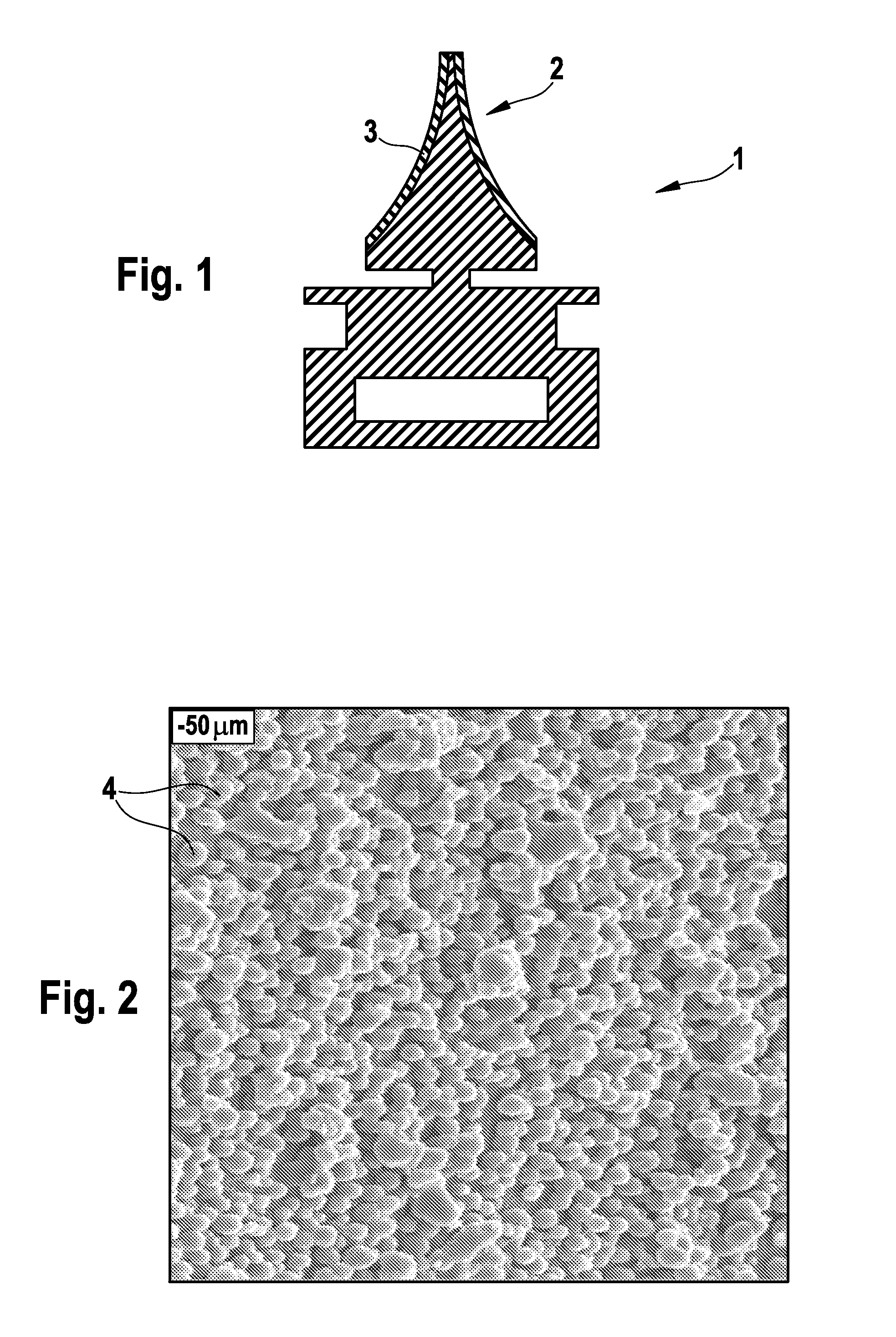

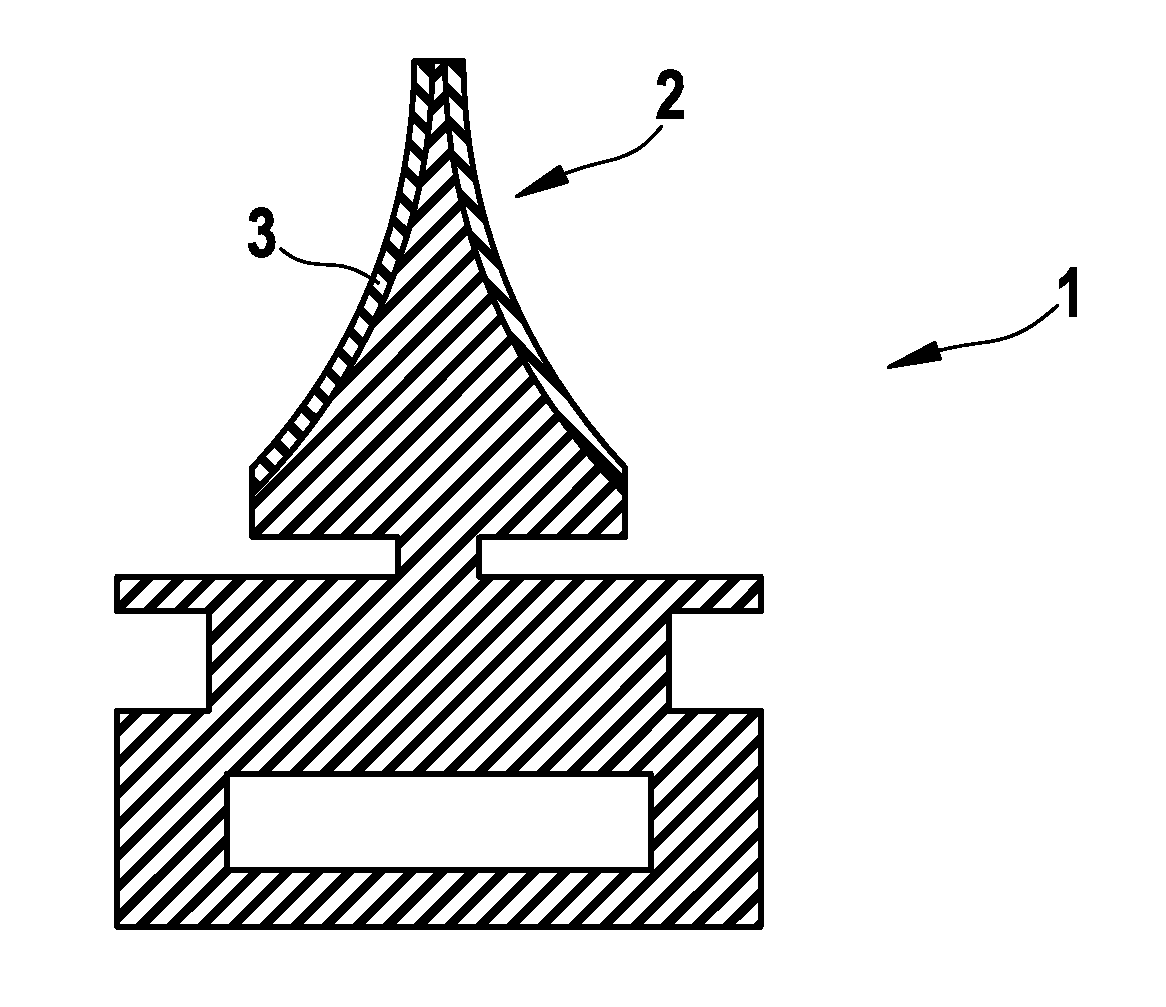

PCVO plasma impregnation composite reinforced method for precise vane hot forging die

InactiveCN1392285AReduce surface treatment costsIncrease productivitySolid state diffusion coatingChemical vapor deposition coatingLayer thicknessMaterials science

The PCVD plasma impregnation process of hot forging die includes surface deoiling, polishing, supersonic cleaning in acetone and alcohol dewatering of the die after quenching at 1070 deg.c and tempering at 530 deg.c; plasma nitriding in a industrial PCVD vacuum furnace; and PCVD plating. The die thus treated has surface structure comprising base, diffusion layer of solid solution of nitrogen in alpha-Fe with the nitriding layer thickness being 150-180 micron, TiN film layer of 2.0 micron thickness or TiCN film layer of 1.5 micron thickness. Thus treated surface has hardness at high as Hv1800-2200 and high film attaching strength suitable for harsh friction wear condition.

Owner:XI AN JIAOTONG UNIV +1

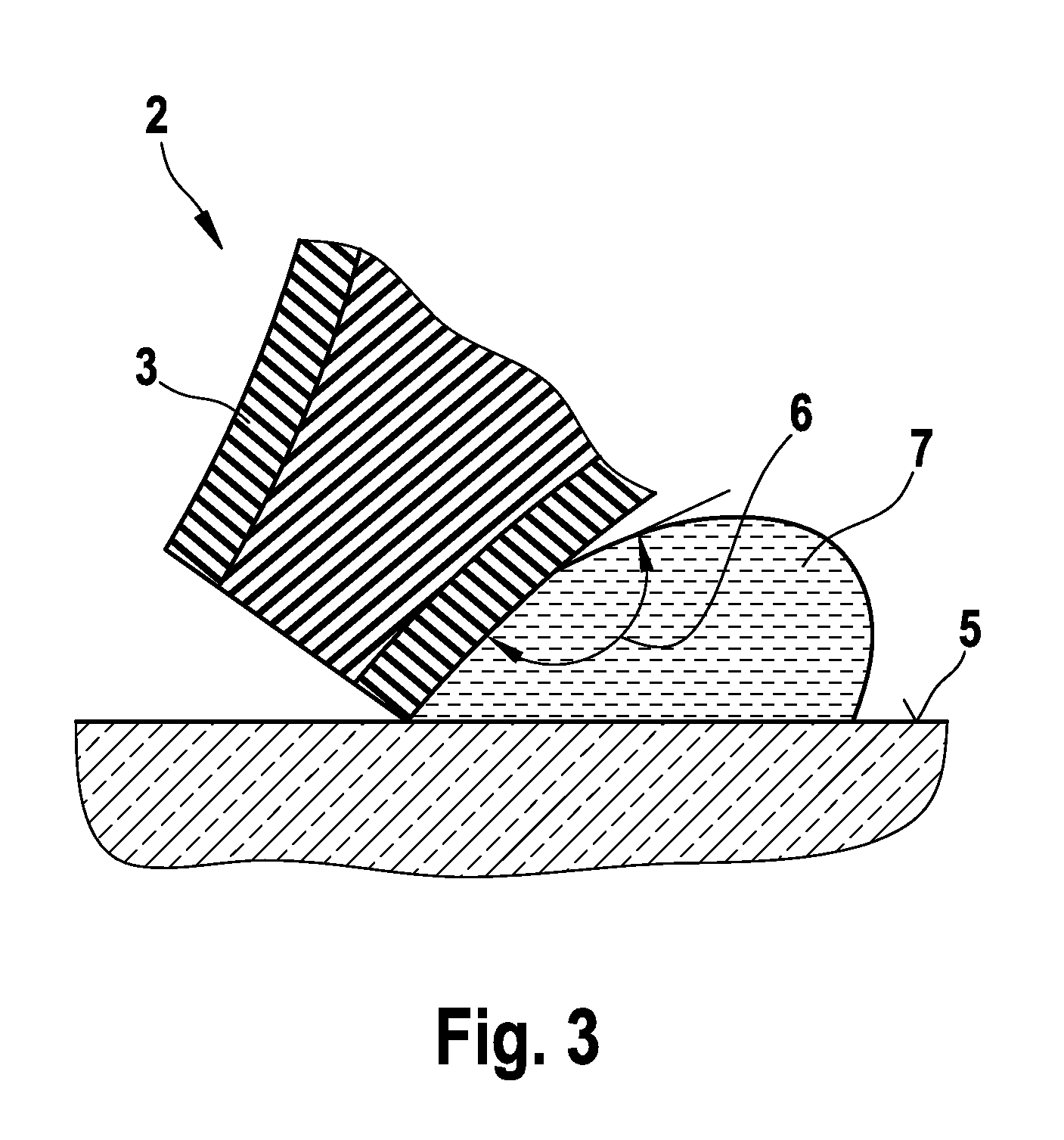

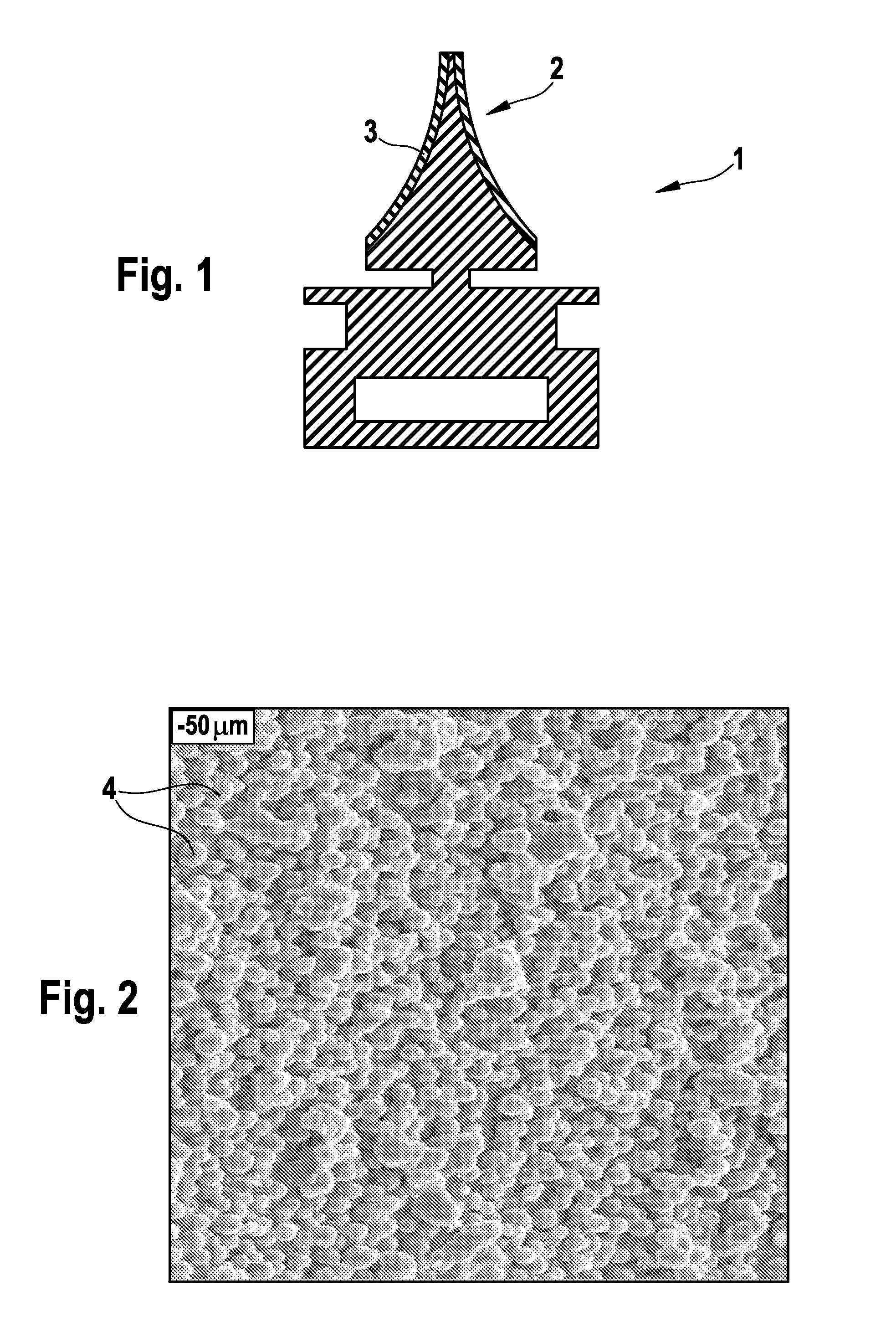

Wiper blade rubber and method for the production thereof

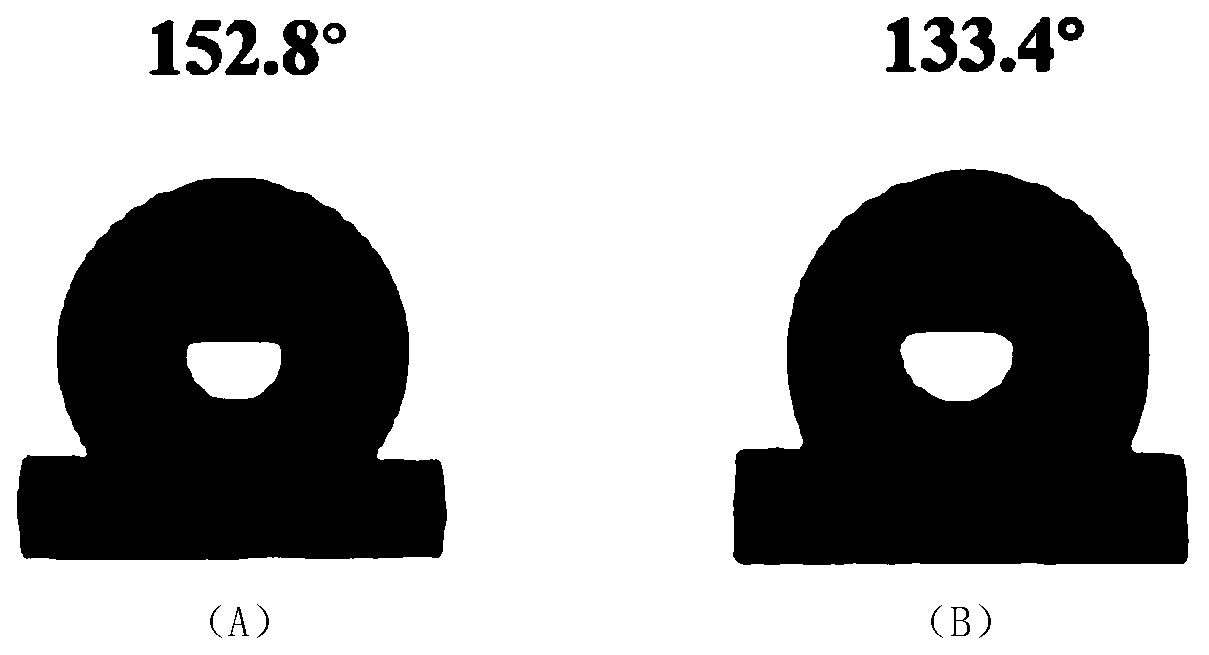

ActiveUS8361595B2Improve wipe qualityImprove wiping effectDecorative surface effectsRecord information storageElastomerSurface layer

The invention relates to a wiper blade rubber and a method for the production thereof, in particular for a rail wiper of a motor vehicle, made from a formed, vulcanizable elastomer material the surface of which comprises a surface layer which is hydrophobic, with a contact angle with respect to water greater than 90°, preferably greater than 120°, and a surface structure with raised regions and / or recesses in the micrometer range.

Owner:ROBERT BOSCH GMBH

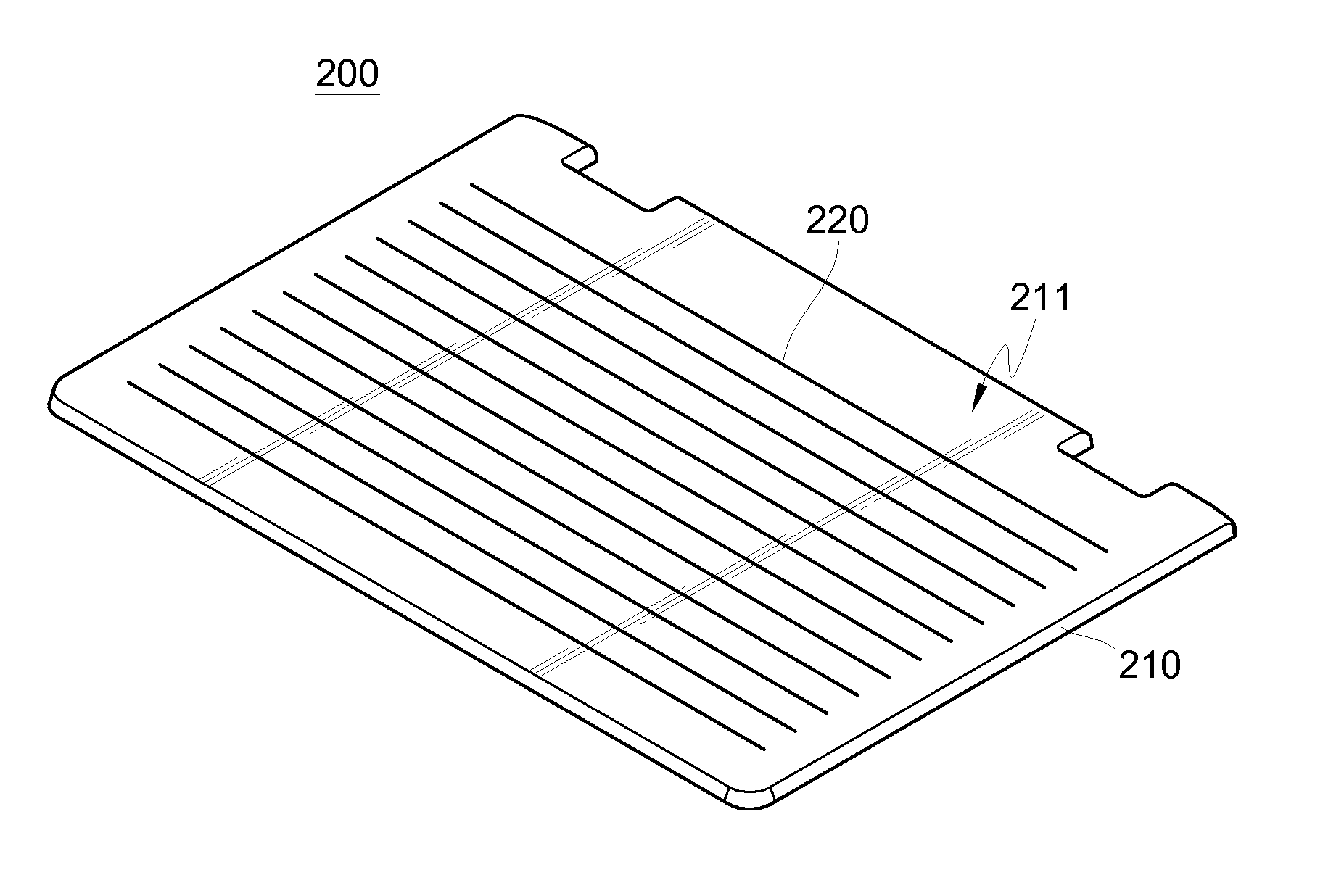

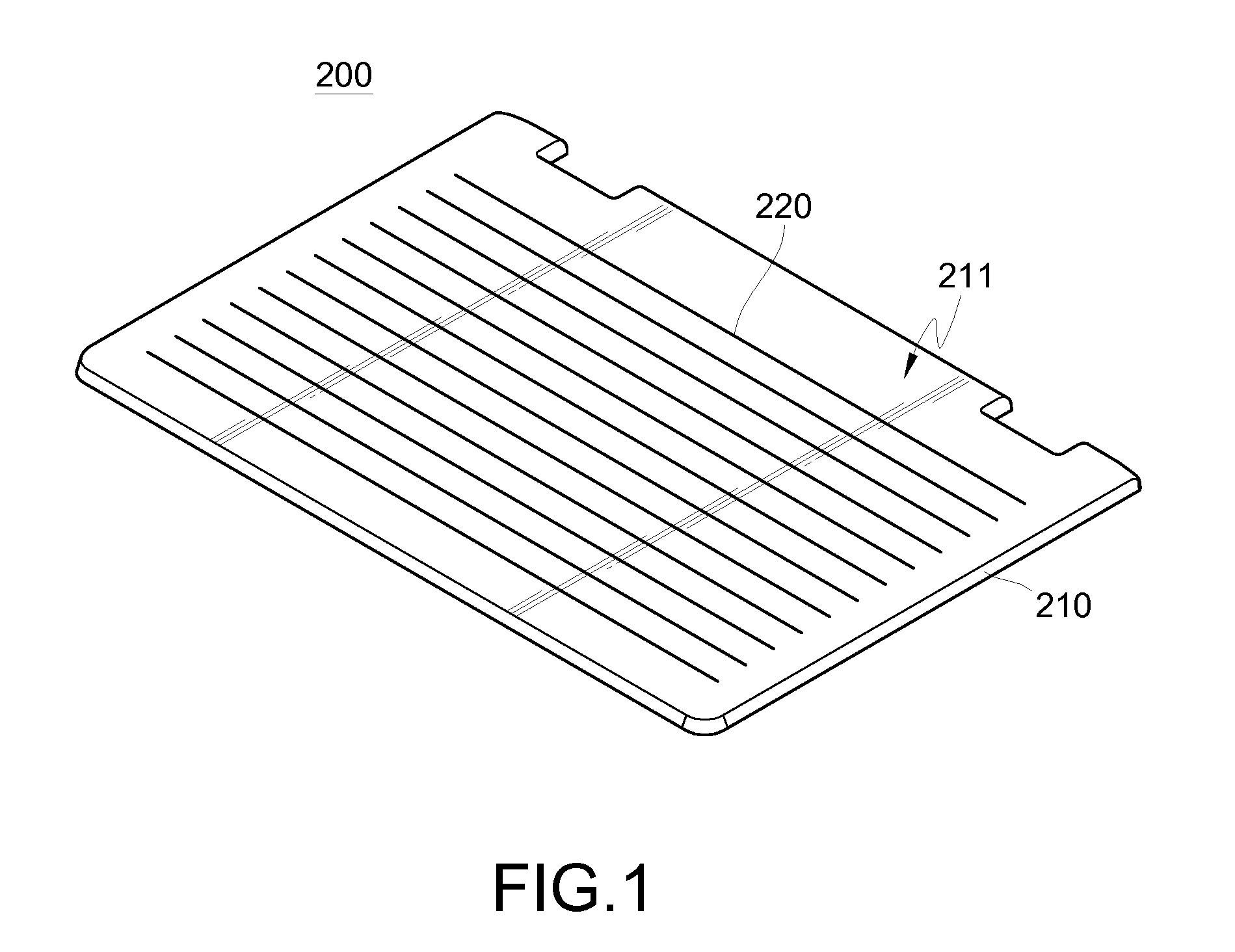

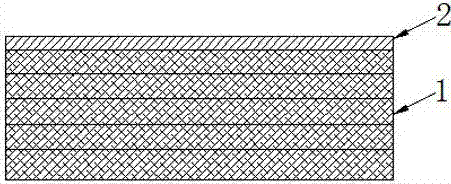

Electronic product shell material laminating structure and manufacture method thereof

InactiveCN102615888ASimplify the surface treatment processReduce surface treatment costsLamination ancillary operationsSynthetic resin layered productsPlastic filmSurface cover

The invention discloses an electronic product shell material laminating structure and a manufacture method thereof. One layer of plastic film covers on the laminating structure of the composite material; and the composite material covered with the plastic film is laminated, solidified and shaped by pressurizing and heating a die to form the electronic product shell material laminating structure composed of the composite material part and the plastic film so as to simplify the subsequent surface treatment process. The surface of the electronic product shell material laminating structure only needs to be polished once, supplemented with soil or sprayed, or the product can achieve a final finished product effect without polishing, supplementing with oil and spraying, and the surface treatment cost is lowered.

Owner:KUSN TONG YIN INDAL ELECTRONICS MAKING

Wiper blade rubber and method for the production thereof

ActiveUS20100095472A1Improve wipe qualityImprove wiping effectDecorative surface effectsRecord information storageMobile vehicleElastomer

The invention relates to a wiper blade rubber and a method for the production thereof, in particular for a rail wiper of a motor vehicle, made from a formed, vulcanizable elastomer material the surface of which comprises a surface layer which is hydrophobic, with a contact angle with respect to water greater than 90°, preferably greater than 120°, and a surface structure with raised regions and / or recesses in the micrometer range.

Owner:ROBERT BOSCH GMBH

Implementation method, application method and connection structure for welding tin-solderable conductor and tin-unsolderable matrix

InactiveCN105186253AAvoid electroplating copperAvoid tinningLine/current collector detailsSoldering apparatusCoaxial cableElectrical conductor

The invention discloses an implementation method for welding a tin-solderable conductor and a tin-unsolderable matrix. The implementation method comprises the following steps: preparing the tin-solderable conductor and the tin-unsolderable matrix; welding a tin-solderable metal layer which is formed on the tin-solderable conductor and the tin-unsolderable matrix through coating in advance; and cooling to congeal the soldering tin so as to fix connection between the tin-solderable conductor and the tin-unsolderable matrix. The implementation method, the application method and the connection structure for a welding tin-solderable conductor and a tin-unsolderable matrix has the advantages of improving the reliability and aesthetic property for coaxial cable welding, reducing the cost, improving the efficiency and reducing pollution.

Owner:COMBA TELECOM TECH (GUANGZHOU) CO LTD

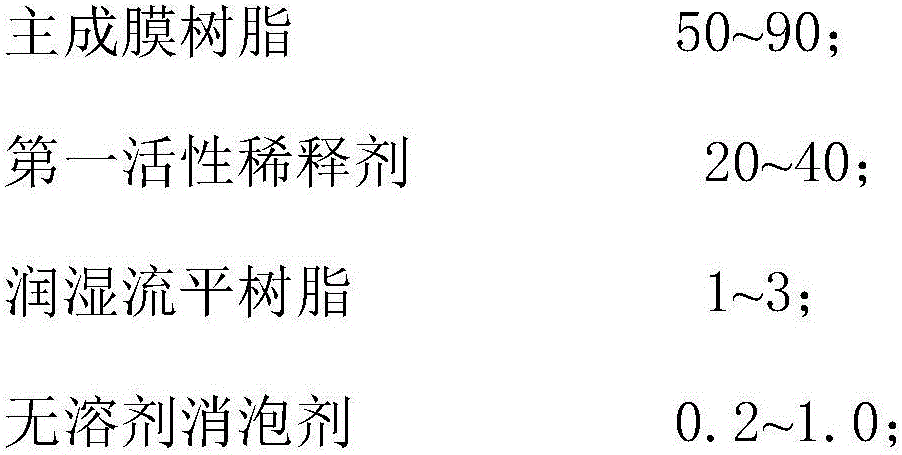

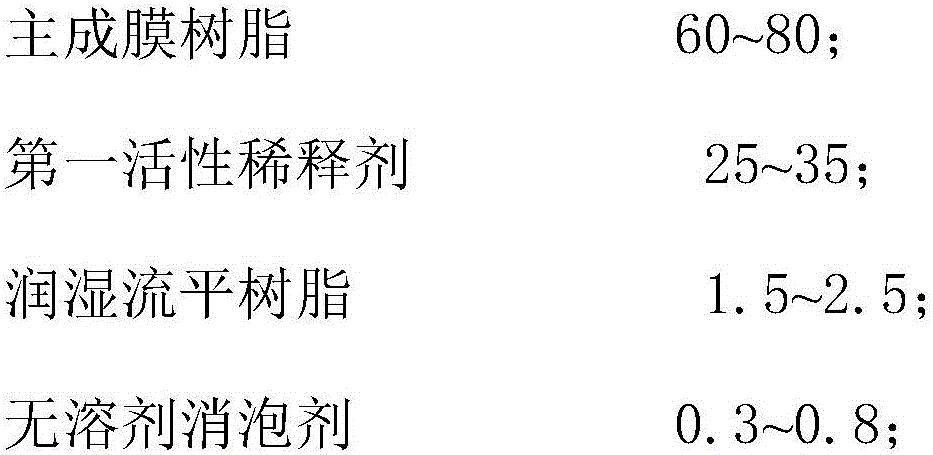

Solvent-free epoxy rust confining coating capable of coating in wet and rust environment

InactiveCN106634447AEnsure safetyImprove adhesionAnti-corrosive paintsEpoxy resin coatingsActive agentSolvent free

The invention relates to a solvent-free epoxy rust confining coating capable of coating in a wet and rust environment. The solvent-free epoxy rust confining coating consists of two components A and B; the weight of the component A is 1.5 to 2.5 times that of the component B; in percentage by weight, the component A is prepared from 50 to 90 percent of main film forming resin, 20 to 40 percent of first reactive diluent, 1 to 3 percent of wetting leveling resin and 0.2 to 1.0 percent of solvent-free defoaming agent; in percentage by weight, the component B is prepared from 60 to 90 percent of curing agent, 2 to 10 percent of modifier and 5 to 15 percent of second reactive diluent. The main film forming resin is bisphenol F-type epoxy resin, an active agent is hyperbranched polyether-polyester resin terminated by phenolic hydroxy and carboxyl, the curing agent is mannich amide, and the modifier is ketimine. The rust confining primer disclosed by the invention has a low requirement for surface processing, can be constructed on a wet surface, is high in stability of a rusted position, and is excellent in long-acting protection performance on an integral object.

Owner:GUANGZHOU RAILWAY GRP CORP

Chemical nickel, palladium and gold plating technique for printed circuit board

InactiveCN105112892AAvoid contactPrevent black disk problemLiquid/solution decomposition chemical coatingEtchingAlloy

The invention discloses a chemical nickel, palladium and gold plating technique for a printed circuit board. The chemical nickel, palladium and gold plating technique for the printed circuit board comprises the steps of deoiling, hot water washing, dual water washing, micro-etching, dual water washing, presoaking, treatment through a palladium activating agent, dual water washing, deposition of chemical nickel, dual water washing, deposition of chemical palladium, dual water washing, deposition of chemical gold and the like. According to the chemical nickel, palladium and gold plating technique for the printed circuit board, chemical palladium plating is introduced, diffusion and migration of nickel are prevented by means of a palladium layer, contact between the nickel and a gold leaching solution is also prevented, and thus the common problem of black discs of existing chemical nickel and gold surface treatment techniques is effectively solved; a chemical plated palladium layer is completely dissolved in welding flux, no hyperphosphate layer appears at an alloy connector, a new chemical plated palladium layer can be exposed to be used for generating good nickel-tin alloy when the original chemical plated palladium is dissolved, and thus the reliability of welding spots is improved; a plated palladium layer with larger hardness is introduced, a thin clad layer can has good abrasion resistance and gold line printing performance, can serve as a key touch surface and is suitable for being applied to products with high connection reliability, and meanwhile surface treatment cost is reduced.

Owner:黄石西普电子科技有限公司

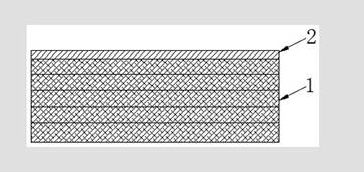

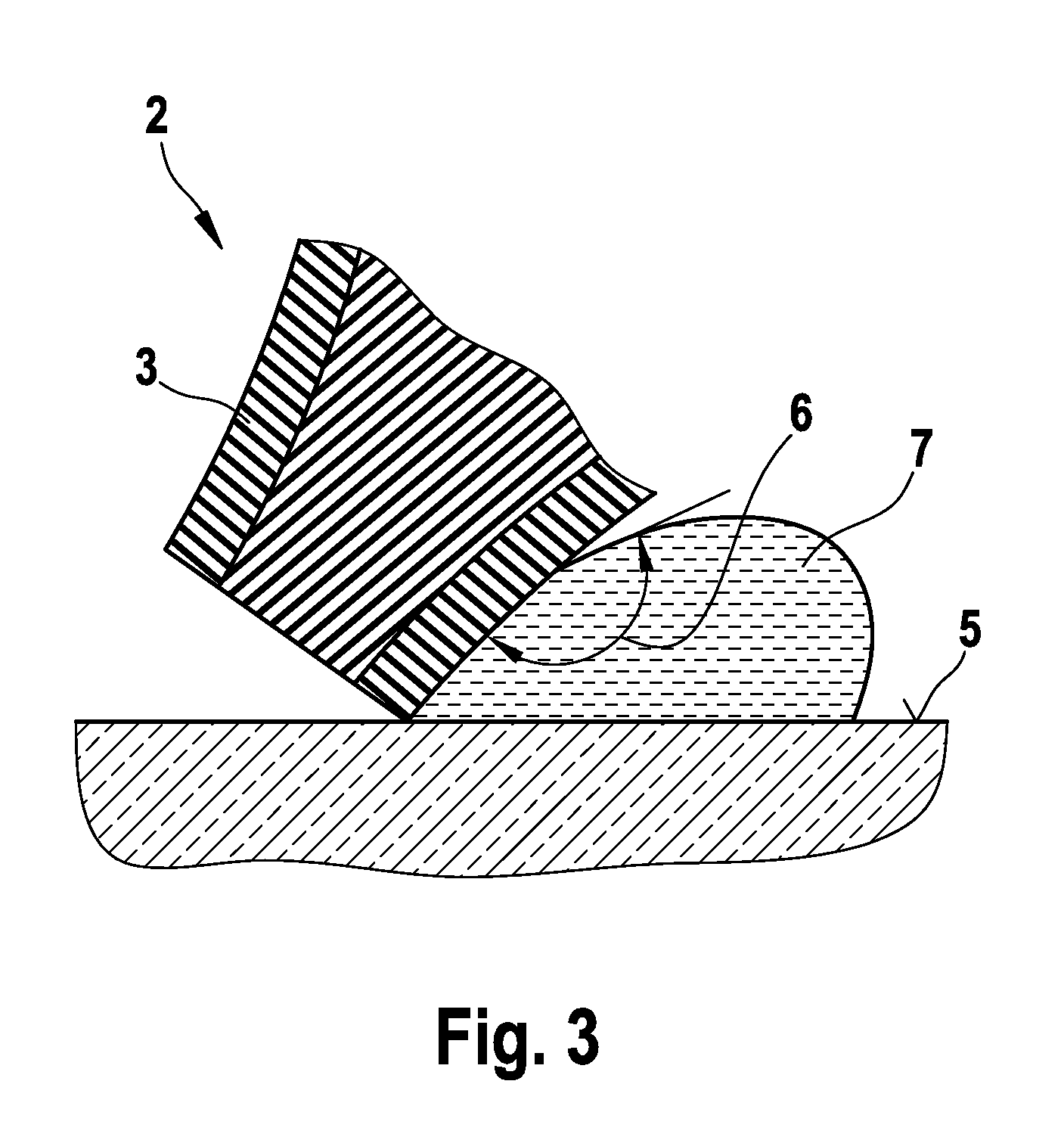

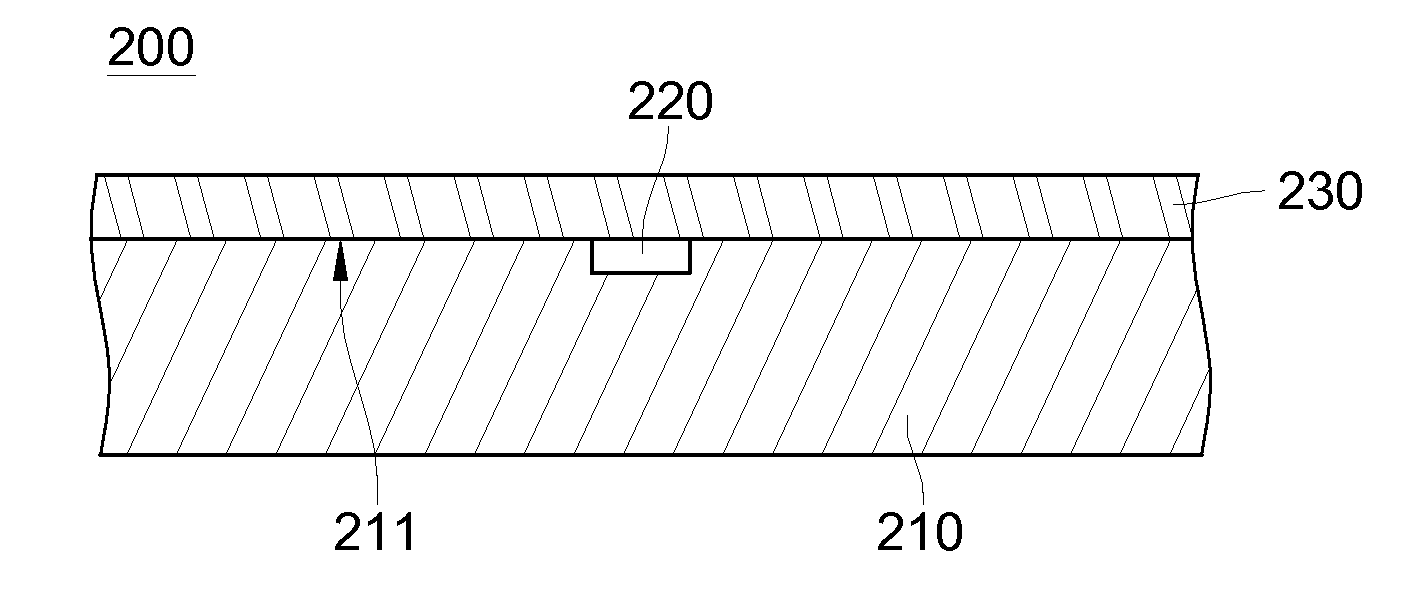

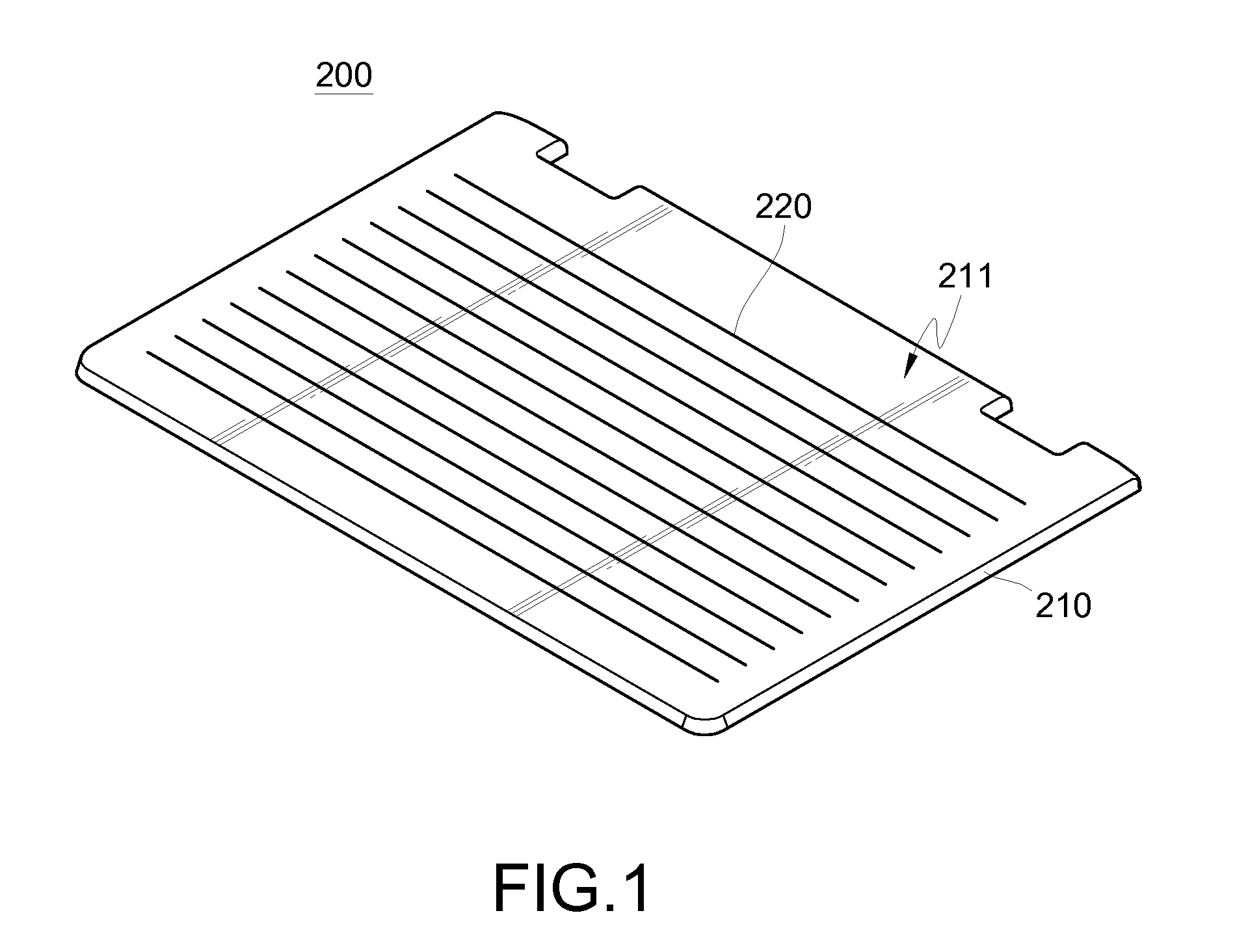

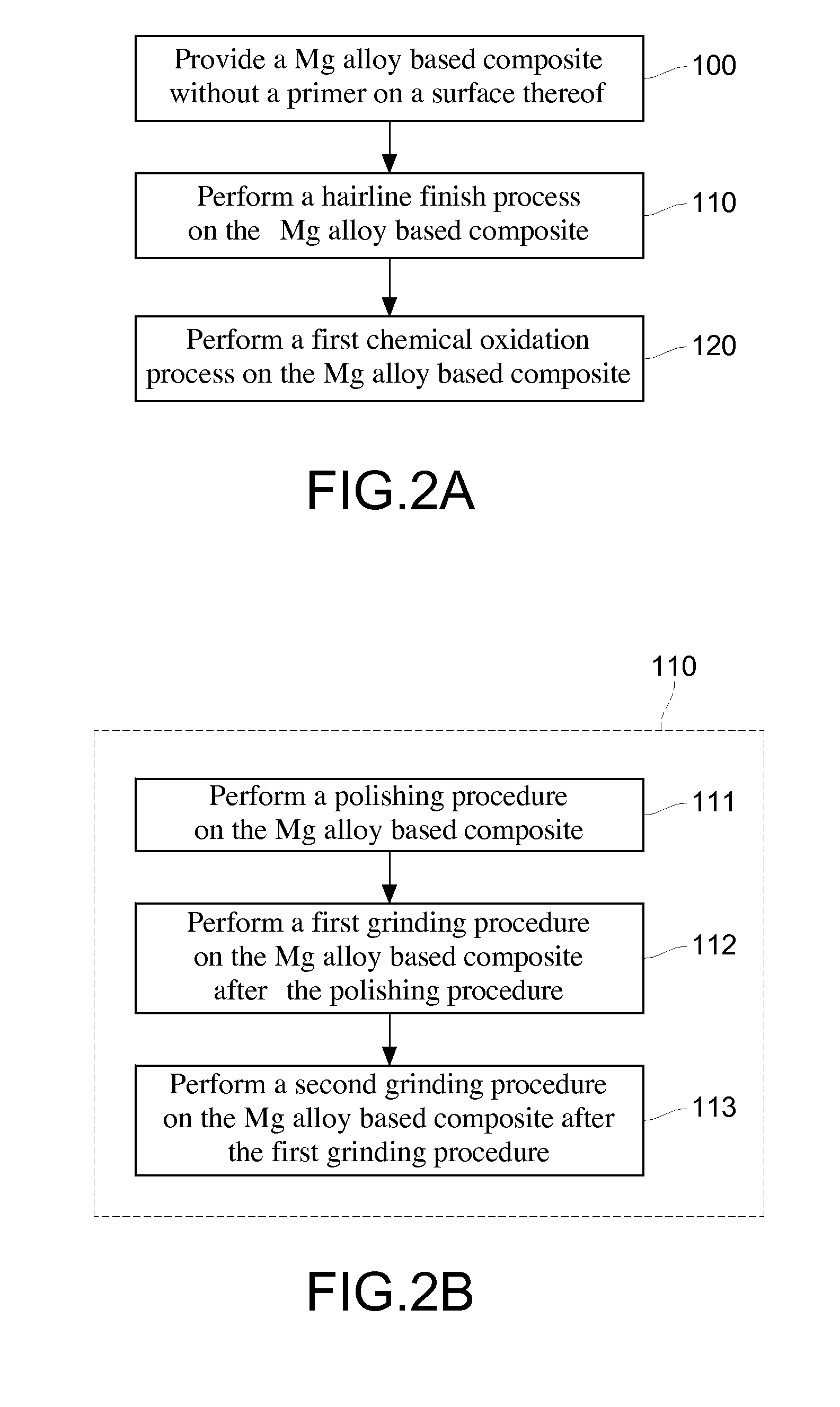

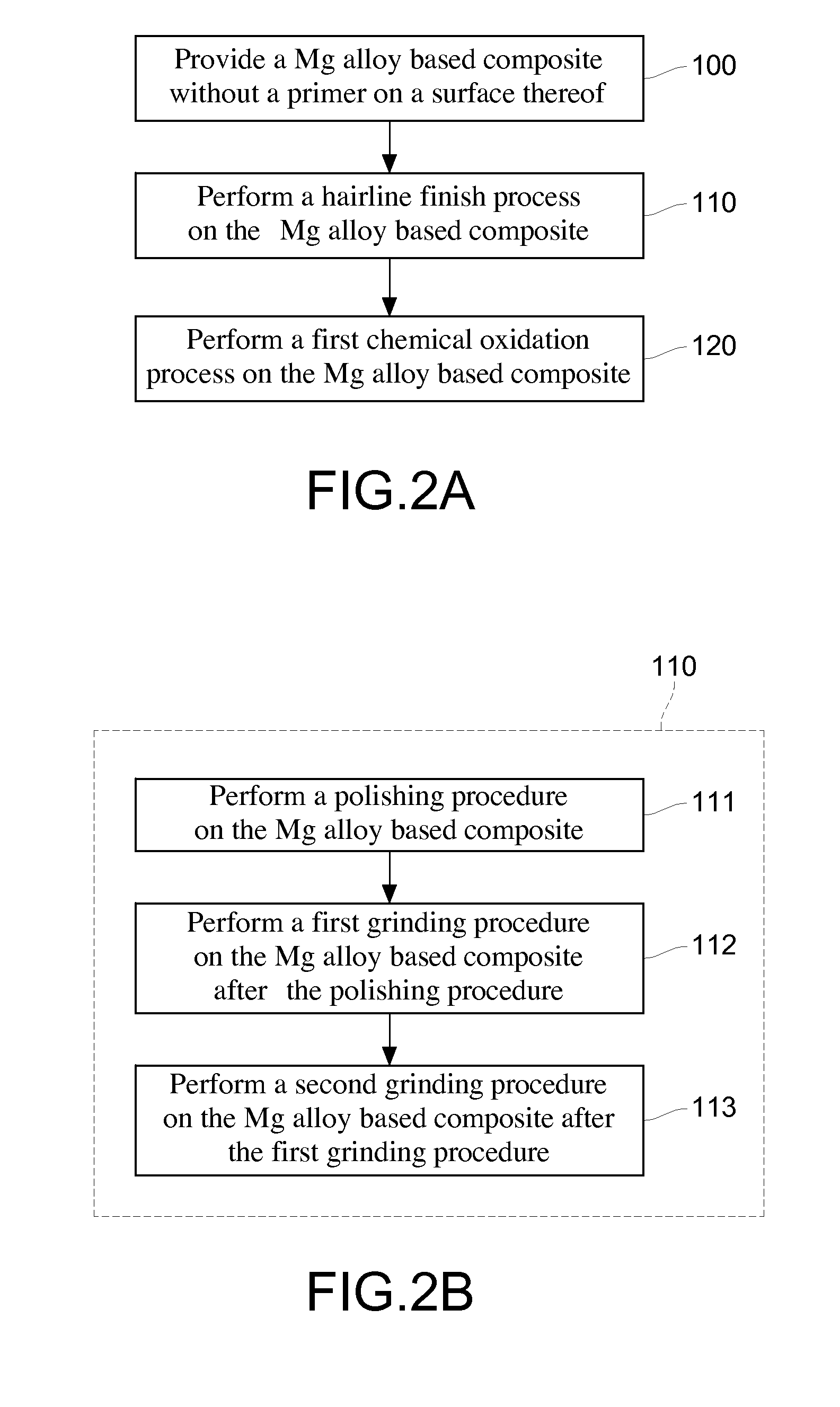

Surface treatment method of magnesium alloy article and structure thereof

InactiveUS20120125487A1Process of surface is simplifiedReduce surface treatment costsSolid state diffusion coatingSuperimposed coating processMagnesium alloyOxidation process

A surface treatment method of a magnesium alloy article includes, instead of forming a primer on a magnesium alloy based composite first, directly performing a hairline finish process on the magnesium alloy based composite, to form a hairline structure on a surface of the magnesium alloy based composite, and performing a chemical oxidation process on the magnesium alloy based composite, to form a glossy film covering the hairline structure on the magnesium alloy based composite, thereby forming a magnesium alloy article structure. Alternatively, another chemical oxidation process is performed before the hairline finish process, to form an oxide film on the surface of the magnesium alloy based composite.

Owner:GETAC TECH CORP

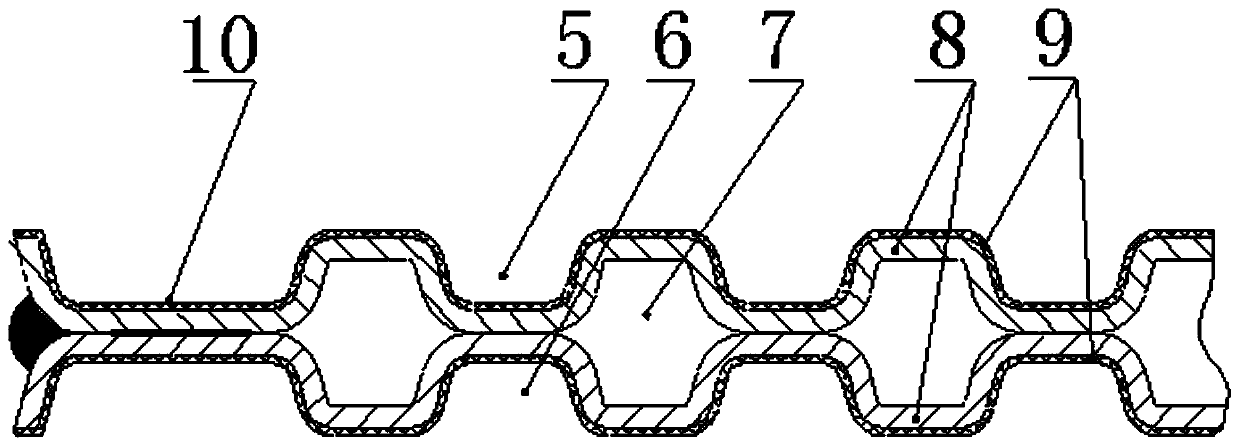

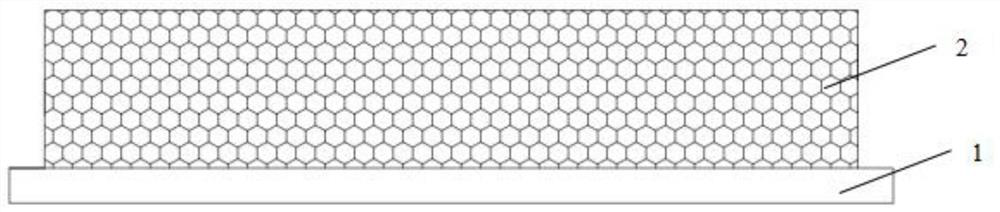

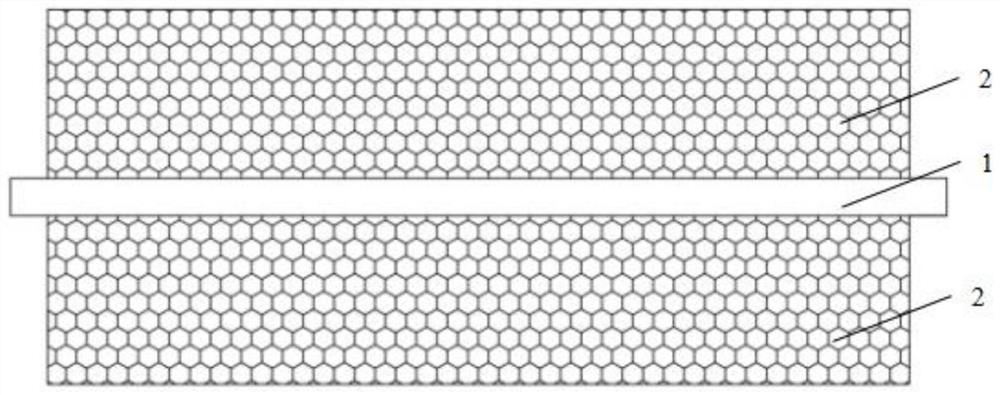

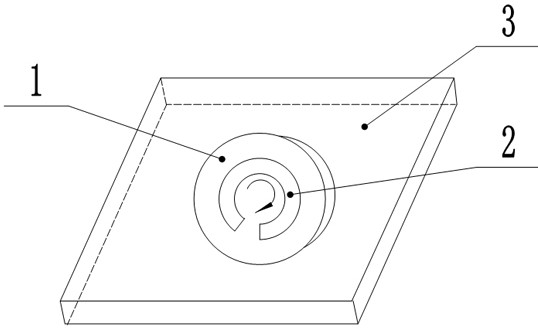

Metal plate single surface and graphite composite bipolar plate and preparation method

InactiveCN110212212AImprove corrosion resistanceReduce surface treatment costsFinal product manufactureCollectors/separatorsHydrogenOxygen

The invention discloses a metal plate single surface and graphite composite bipolar plate. The bipolar plate comprises a hydrogen unipolar plate and an oxygen unipolar plate, wherein each unipolar plate is a composite unipolar plate formed by synthesizing a metal pole plate and graphite, a conducting layer is arranged on the surface of each metal pole plate, flexible graphite paper is pasted to one surface of each metal pole plate, and the pasting mode between the flexible graphite paper and each metal pole plate is breakpoint pasting. According to a preparation method, the flexible graphite paper is subject to the pretreatment of sealing internal micro-channels, planar base material plates are cut out, the conducting layers are formed on the surfaces of the planar base material plates, and the flexible graphite paper subject to the pretreatment is pasted to one surface of each planar base material plate; each planar base material plate with the graphite paper pasted to one surface ismold-pressed into one unipolar plate, and the hydrogen unipolar plate and the oxygen unipolar plate are connected in a sealed mode to form the bipolar plate. The bipolar plate has the advantages thatthe corrosion resistance of the bipolar plate is improved, and surface treatment cost of the metal bipolar plate is lowered.

Owner:DALIAN JIAOTONG UNIVERSITY

PCVO plasma impregnation composite reinforced method for precise vane hot forging die

InactiveCN1156598CReduce surface treatment costsIncrease productivitySolid state diffusion coatingChemical vapor deposition coatingLayer thicknessTin

The PCVD plasma impregnation process of hot forging die includes surface deoiling, polishing, supersonic cleaning in acetone and alcohol dewatering of the die after quenching at 1070 deg.c and tempering at 530 deg.c; plasma nitriding in a industrial PCVD vacuum furnace; and PCVD plating. The die thus treated has surface structure comprising base, diffusion layer of solid solution of nitrogen in alpha-Fe with the nitriding layer thickness being 150-180 micron, TiN film layer of 2.0 micron thickness or TiCN film layer of 1.5 micron thickness. Thus treated surface has hardness at high as Hv1800-2200 and high film attaching strength suitable for harsh friction wear condition.

Owner:XI AN JIAOTONG UNIV +1

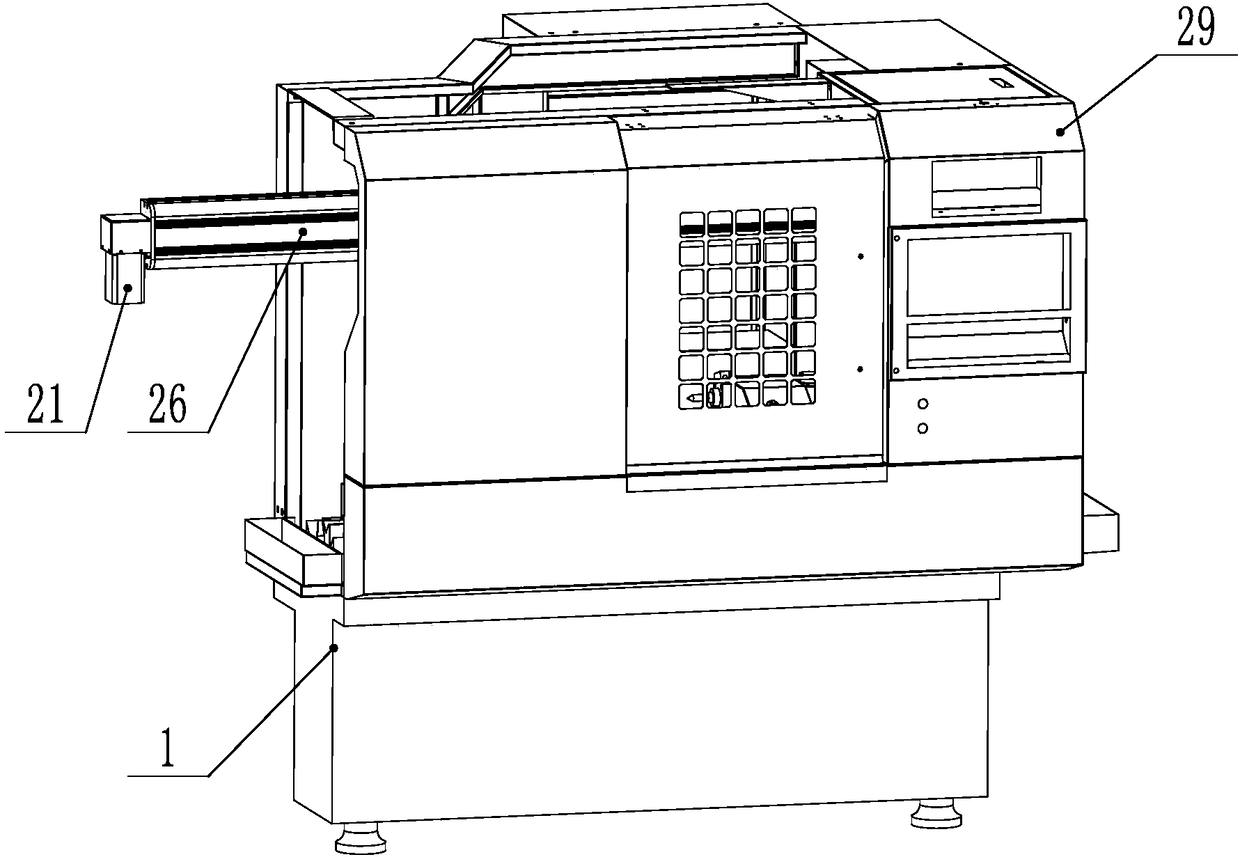

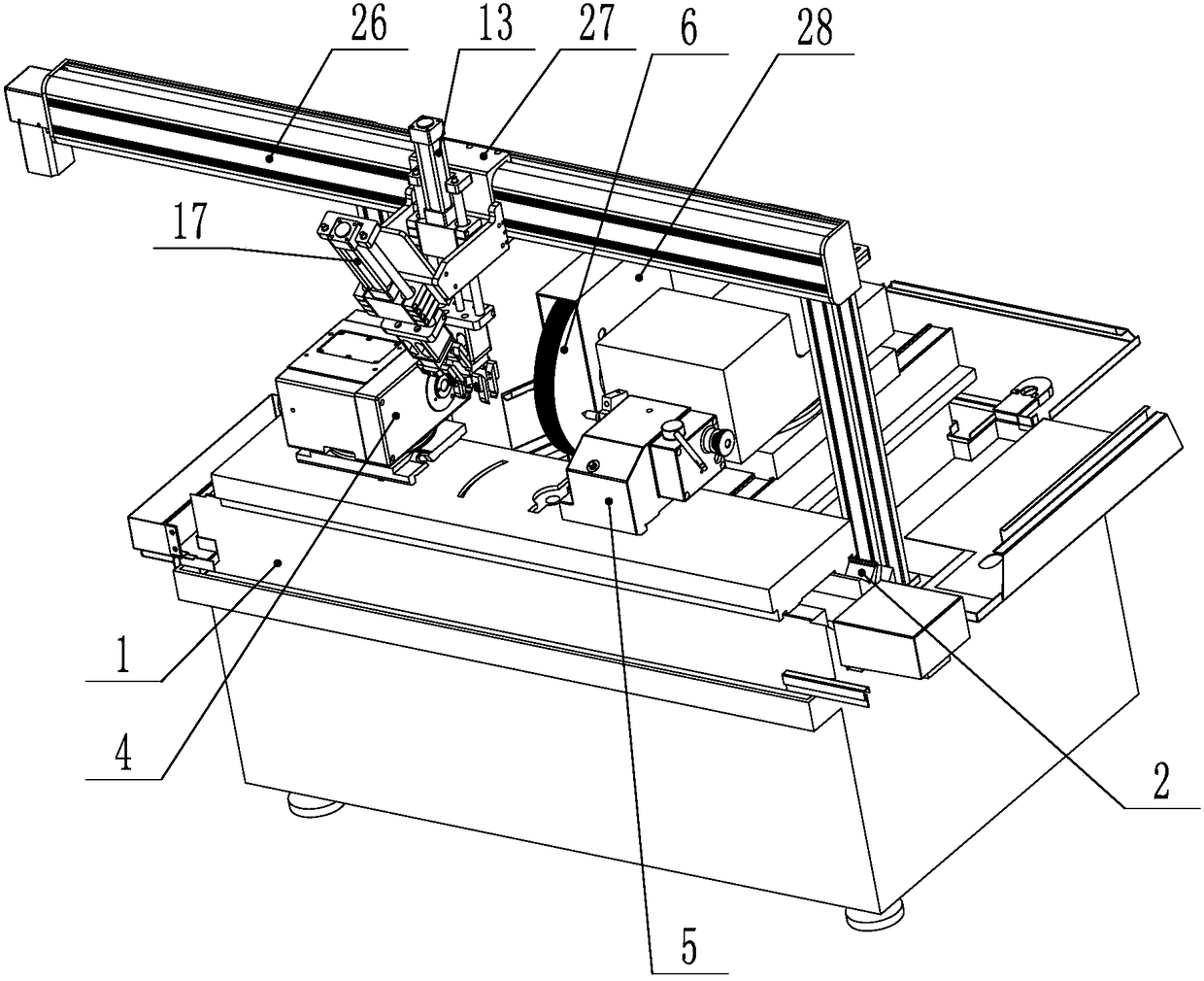

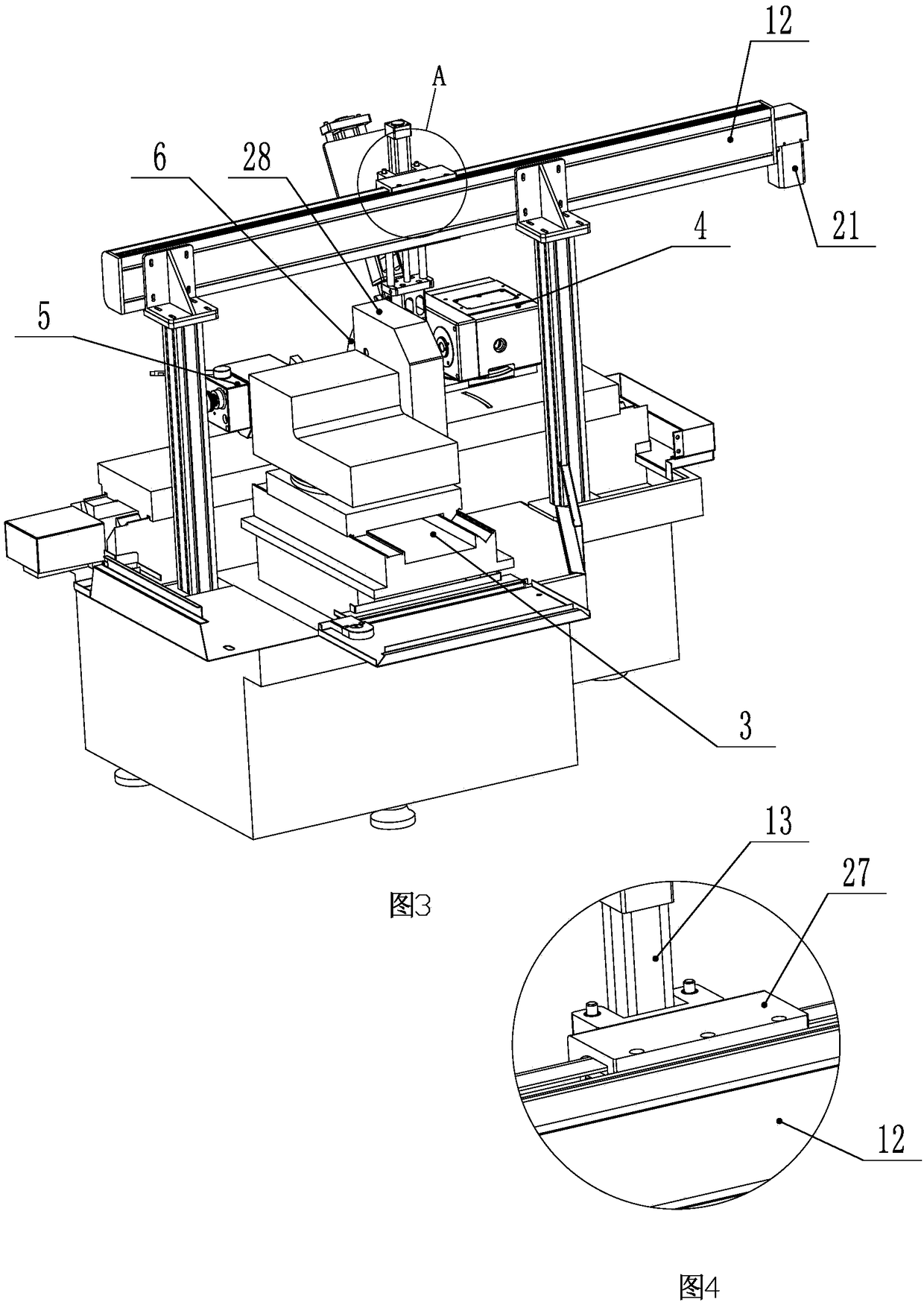

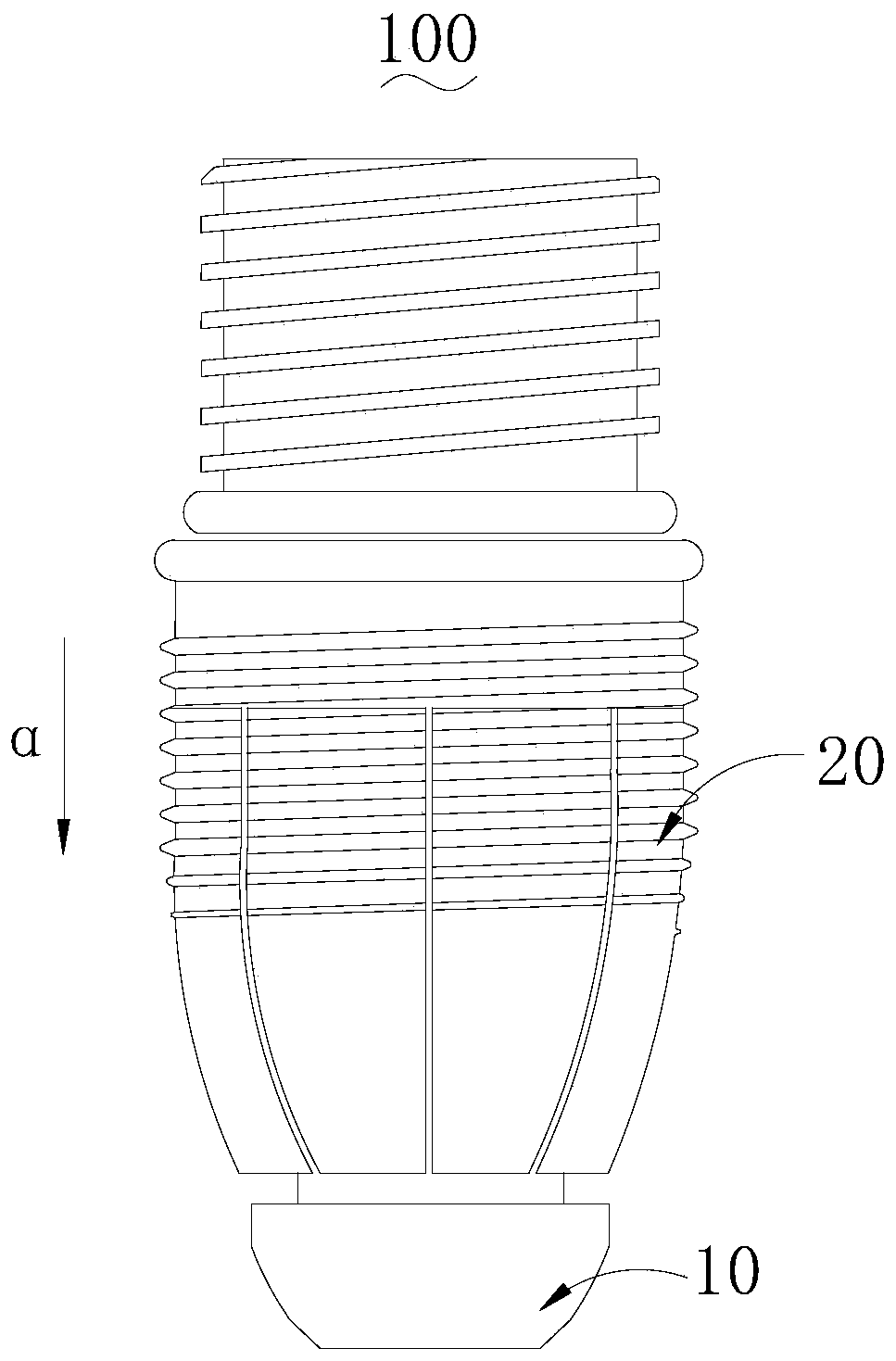

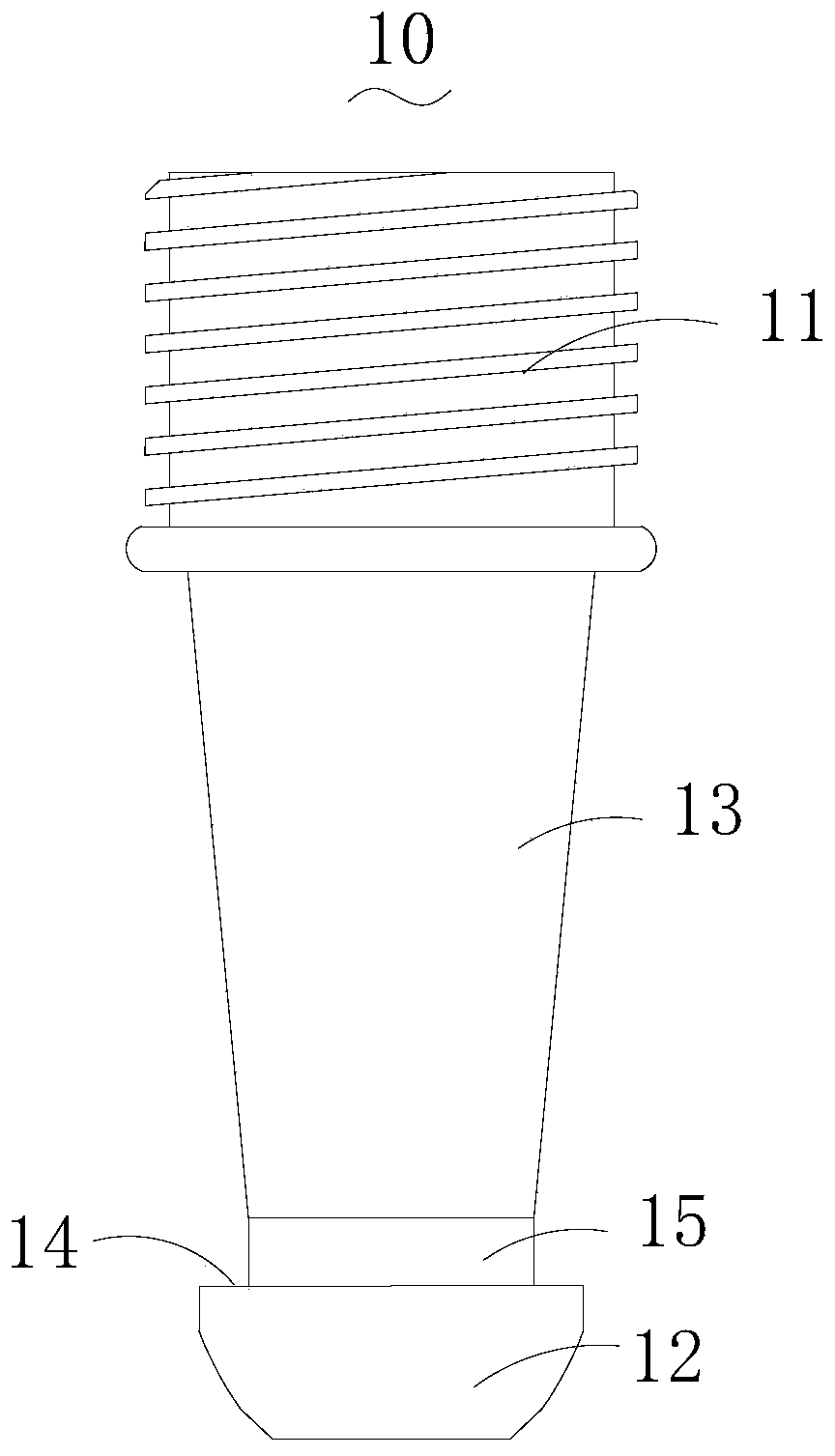

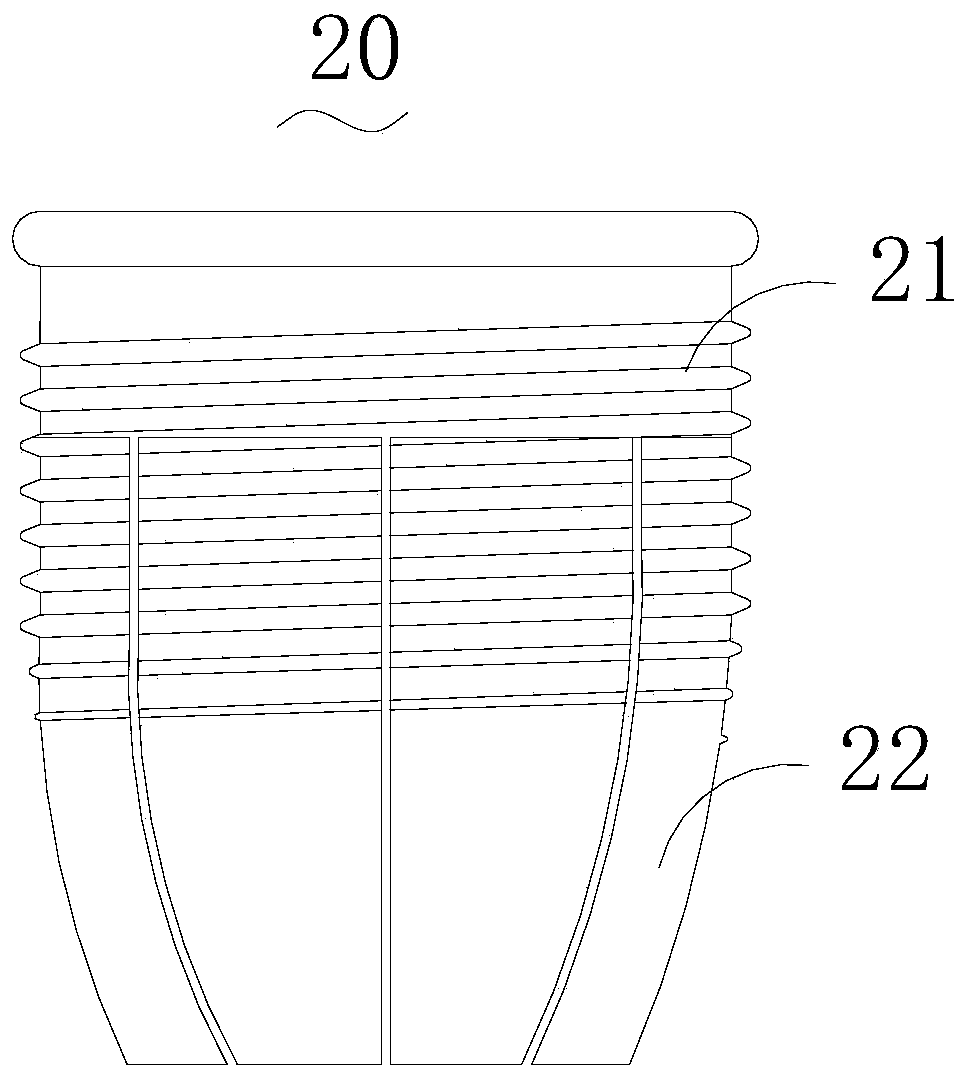

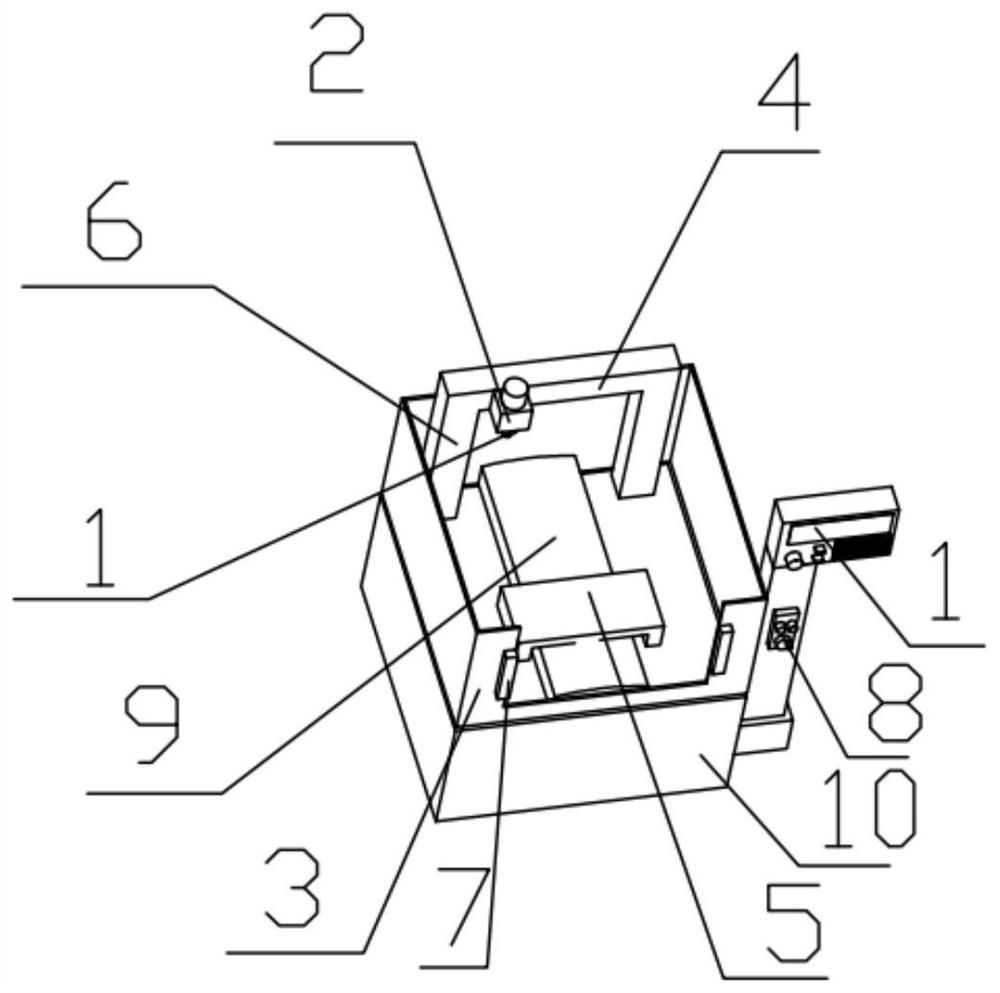

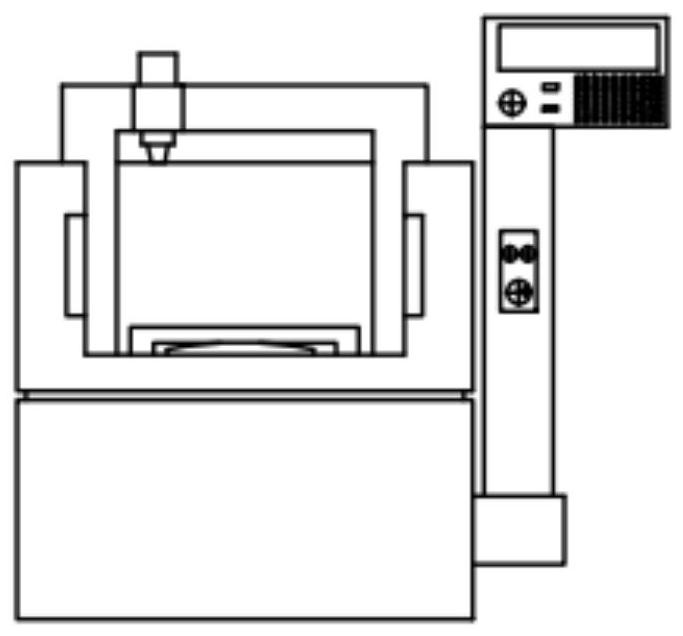

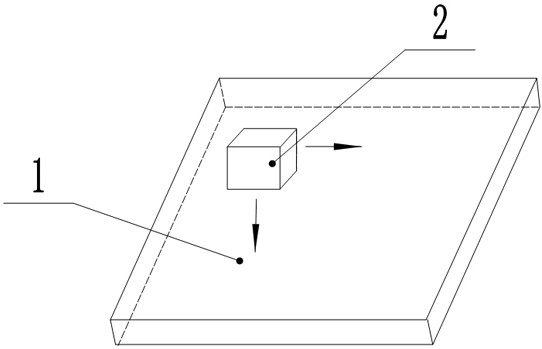

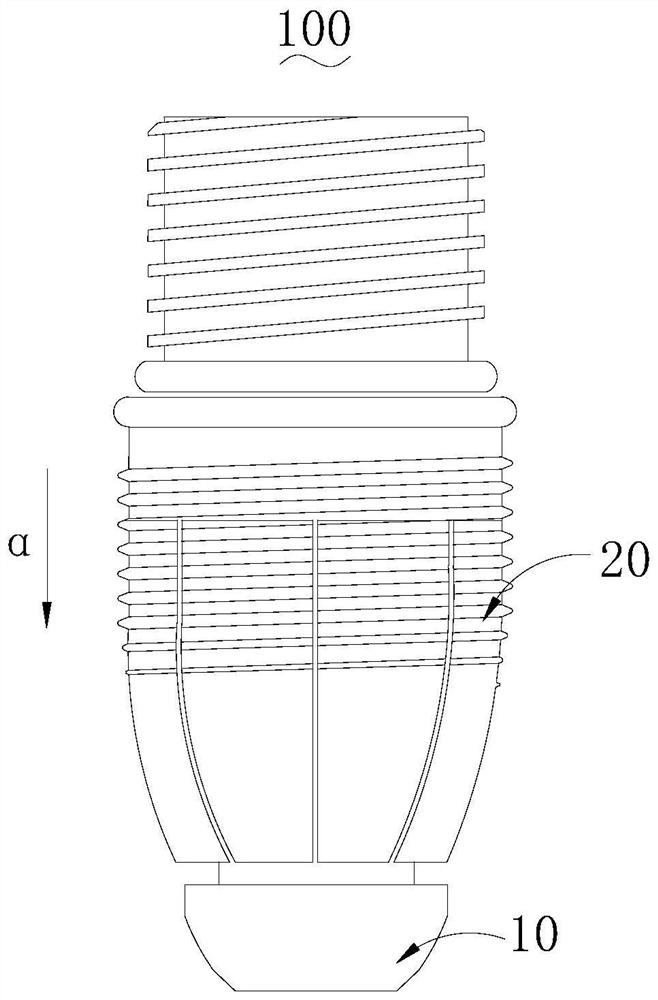

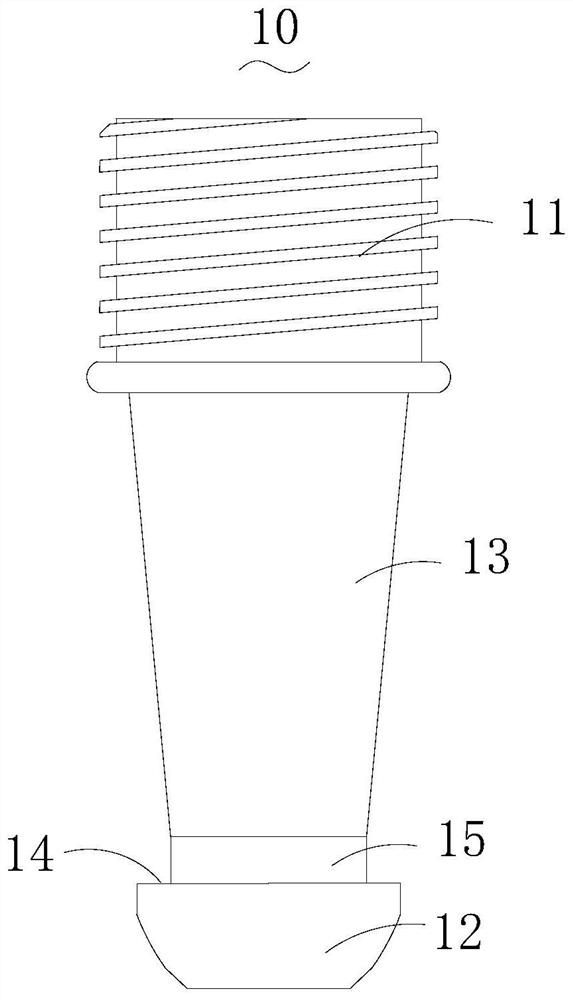

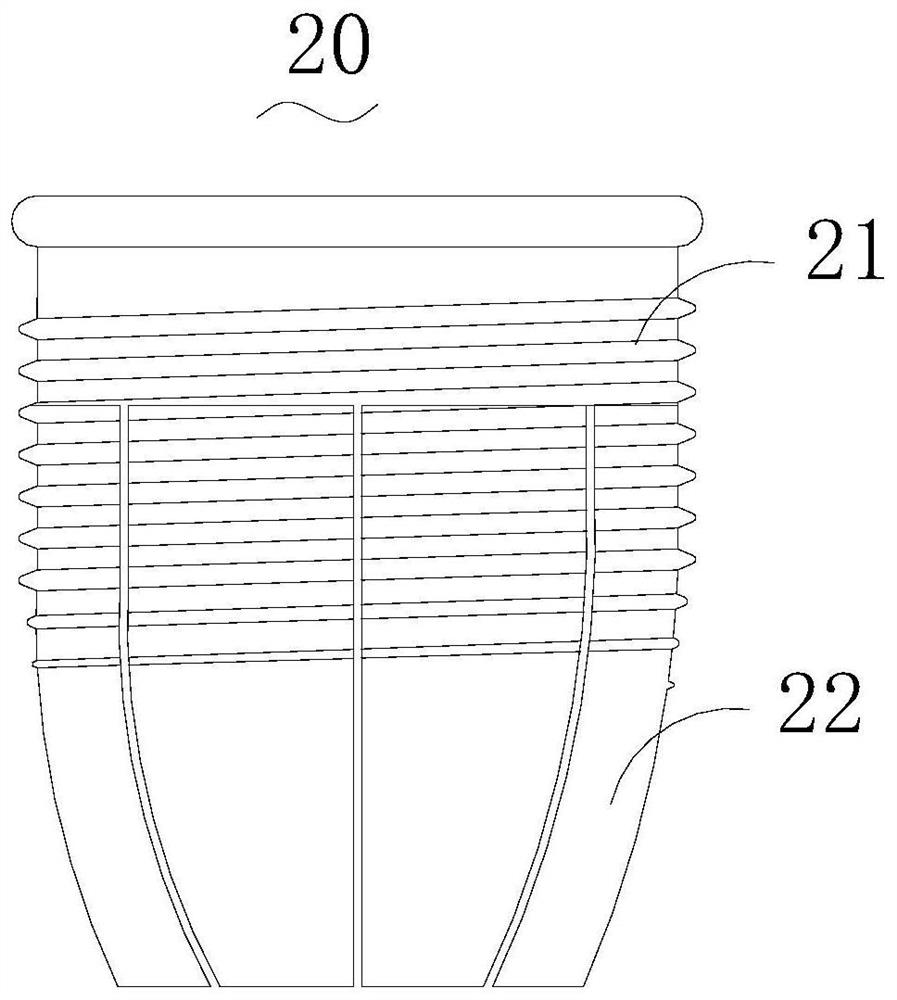

Machine tool for surface treatment of shaft-type workpieces

PendingCN108247519AReduce surface treatment costsGood effectProgramme-controlled manipulatorGrinding carriagesClockwiseTailstock

The invention belongs to the technical field of machining, and particularly provides a machine tool for surface treatment of shaft-type workpieces. A transverse guide rail and a longitudinal guide rail are arranged on a tool body, a headstock and a tailstock which are used for clamping the workpieces are arranged on the transverse guide rail, and a polishing mechanism for polishing the workpiecesis arranged on the longitudinal guide rail, and comprises a spindle motor and a spindle driven by the spindle motor to rotate; and a cloth wheel synchronously rotating along with the spindle is arranged on the spindle, and comprises multiple stacked annular cloth pieces, the middle portions of the multiple annular cloth pieces are fixedly connected to form a cylinder with a mesopore, the mesoporeis used for being connected with the spindle, the polishing mechanism is controlled by a controller to act, and the controller controls the cloth wheel to rotate in the same direction or rotate clockwise or anticlockwise. By means of the machine tool, the cost of surface treatment of the shaft-type workpieces is low, the effect is good, the efficiency is high, and operation is convenient.

Owner:浙江杰克机床股份有限公司

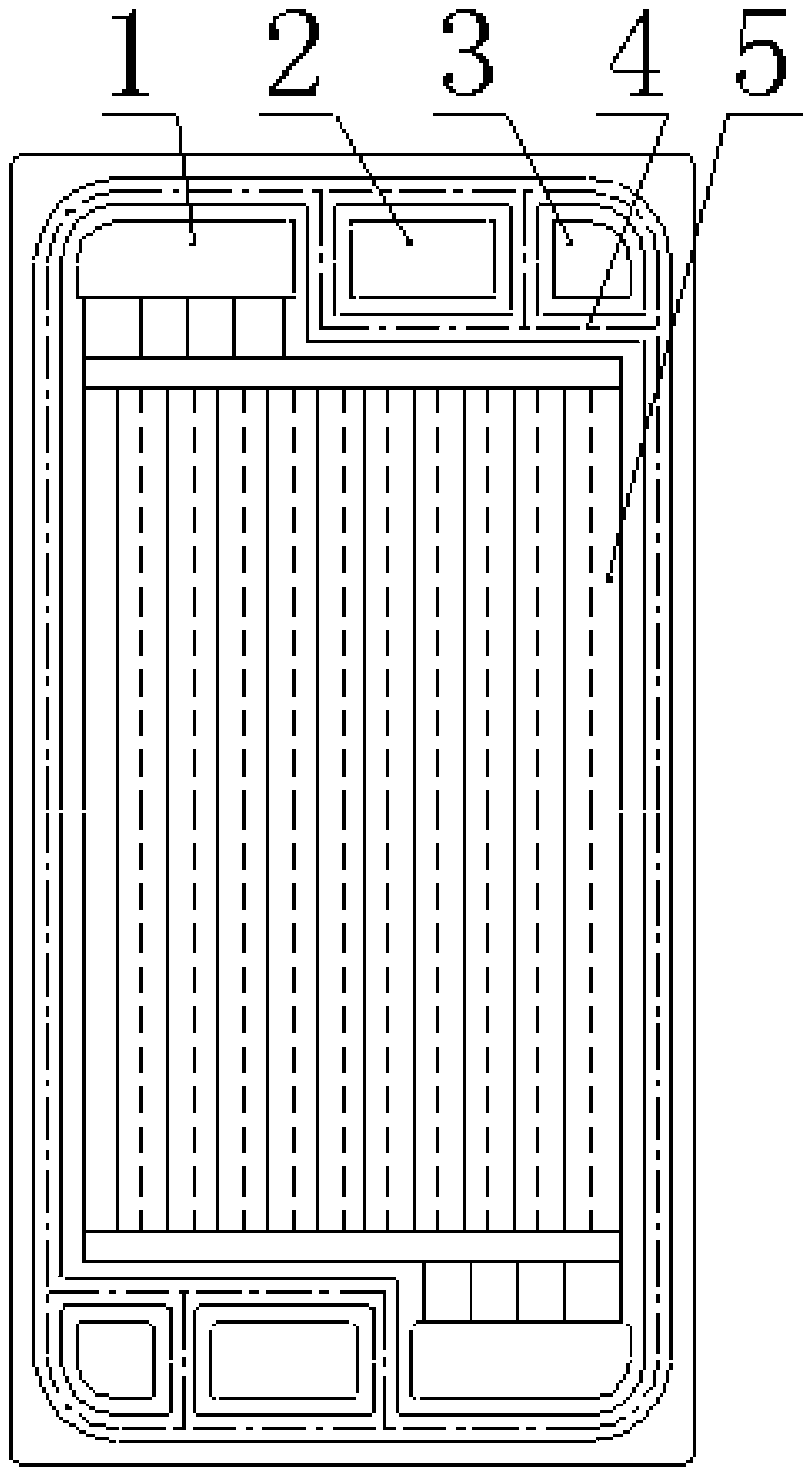

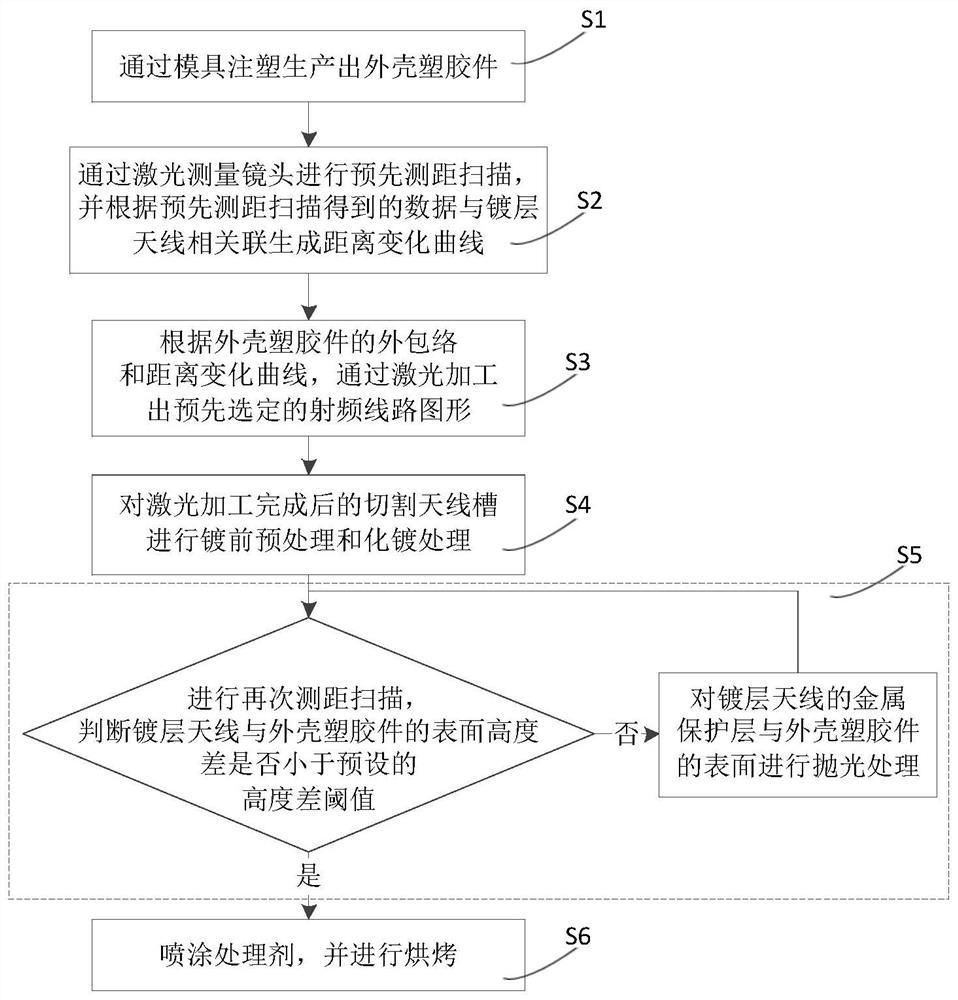

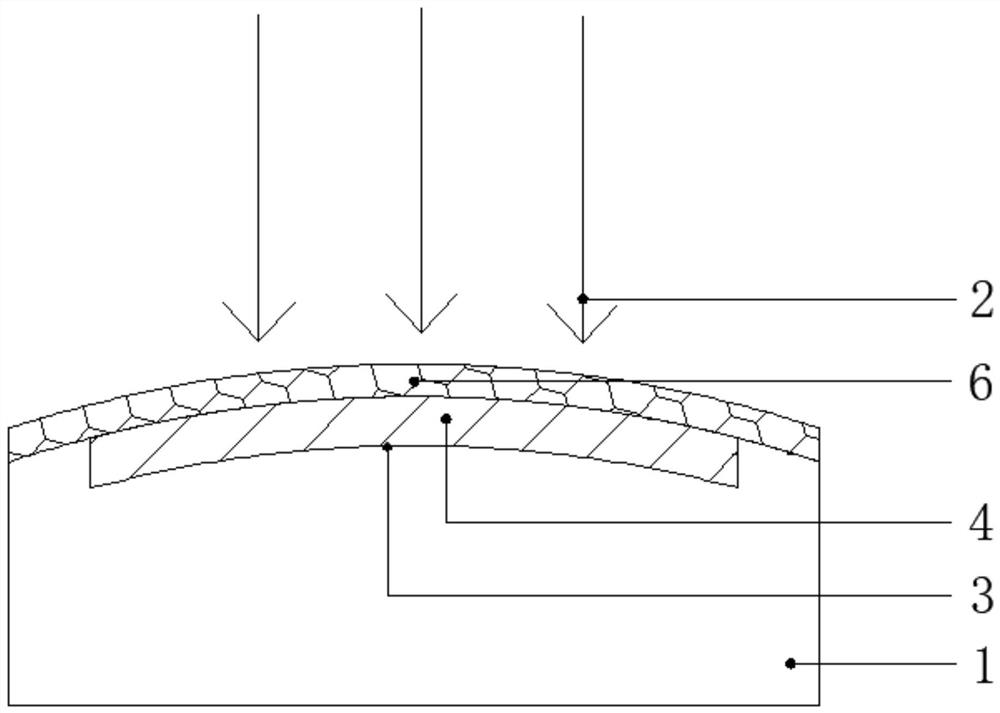

Manufacturing method and system of integrated antenna-containing shell

ActiveCN113889752ASmall surface height differenceSurface height difference improvementAntenna supports/mountingsAntenna adaptation in movable bodiesChemical platingIntegrated antenna

The invention provides a manufacturing method and system for an integrated antenna-containing shell. The manufacturing method comprises the steps that S1, producing a shell plastic part; S2, carrying out pre-ranging scanning through a laser measuring lens, and generating a distance change curve; S3, processing a preselected radio frequency circuit pattern through laser according to the outer envelope of the shell plastic part and the distance change curve; S4, carrying out pre-plating pretreatment and chemical plating treatment on an antenna groove; S5, carrying out distance measurement scanning again until the surface height difference between the coating antenna and the shell plastic part is lower than a preset height difference threshold value; and S6, srapying a treating agent, and carrying out baking. The method and system can adapt to outer enveloping of the shell plastic part, the height difference between the coating antenna and the shell plastic part is greatly improved, repeated dismounting, mounting and polishing of the coating clamp for a product are not needed, the machining technology is greatly simplified, the production cost is effectively reduced, and the production efficiency and the yield are improved.

Owner:SHENZHEN CICENT COMM TECH CO LTD

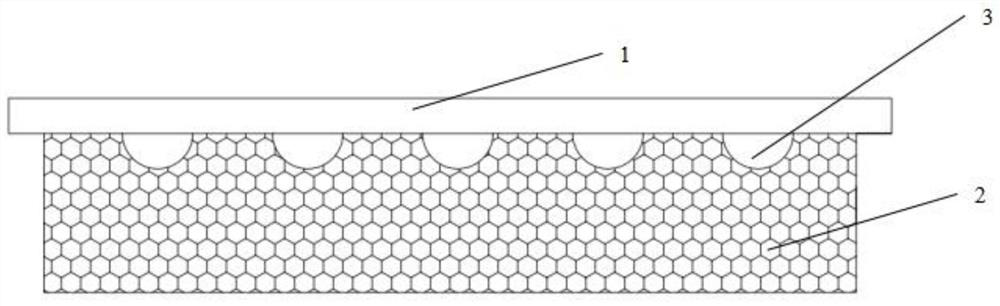

Full-through-hole metal fiber sintered body fuel cell bipolar plate and fuel cell stack

The invention discloses a full-through-hole metal fiber sintered body fuel cell bipolar plate and a fuel cell stack, the full-through-hole metal fiber sintered body fuel cell bipolar plate comprises a conductive partition plate and a flow field plate, the flow field plate is arranged on one side or two sides of the conductive partition plate, and the flow field plate is made of a metal fiber sintered body; the flow field plate and the conductive partition plate are in integrated sintering connection, welding connection or cementing connection. According to the all-through-hole metal fiber sintered body fuel cell bipolar plate and the fuel cell stack provided by the invention, the metal fiber sintered body is adopted as the flow field plate, so that fluid diffusion is uniform, the effective reaction area of gas is doubled, and the power density of the cell is improved; the metal fiber felt serves as a cooling channel of the cell stack, so that the cooling efficiency is improved; the cell stack volume is reduced; and the cell stack volume power is improved.

Owner:WESTERN METAL MATERIAL

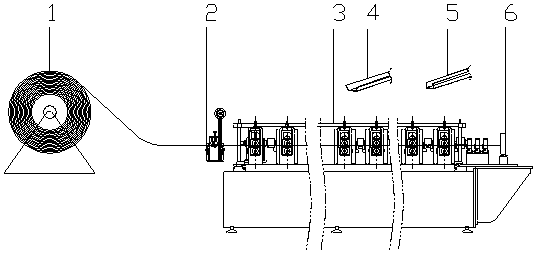

Displayer metal frame simple in process and manufacturing process and manufacturing equipment thereof

ActiveCN111451410AReduce processing stepsReduce surface treatment costsMetal-working feeding devicesDigital data processing detailsManufacturing engineeringDisplay device

The invention discloses a displayer metal frame simple in process and a manufacturing process and manufacturing equipment thereof. The manufacturing process comprises the following steps that metal sheets / coils with appearance films on single-side surfaces or dual-side surfaces are prepared, and the appearance films comprise protection layers, or comprise appearance layers and protection layers covering the appearance layers; the metal sheets / or coils are subjected to continuous rolling / bending to form a metal frame strip, and after cutting, a metal frame single side is obtained; and multiplemetal frame single sides are assembled to obtain the metal frame. All raw materials can be directly subjected to unified surface treatment, through the protection layers, surfaces, with appearances, of the metal sheets / coils are prevented from being damaged in the rolling / bending forming process, surface treatment of a single piece can be avoided, a machining procedure is reduced, the surface treatment cost is reduced, product quality stability is ensured, the assembling process is simplified, and the production efficiency is greatly improved.

Owner:苏州金利美金属科技有限公司

Forming method of overlapping structure of housing of electronic product

The invention discloses a molding method for a laminated structure of an electronic product casing, comprising: step 1, taking carbon fiber cloth and soaking it in thermosetting resin for 3-7 hours, taking glass fiber cloth and soaking it in thermoplastic resin for 3-9 hours; step 2, taking 2 ~ 4 layers of carbon fiber cloth and 1 layer of glass fiber cloth are stacked alternately until a certain height is reached to obtain a composite material stack; step 3, at least one plastic layer is arranged on the upper surface of the composite material stack, the at least one Each plastic layer has an image on its surface, and the images on the at least one plastic layer together form a complete pattern, and the thickness of each plastic layer is 20 μm to 50 μm; step 4, placing the composite material above in a mold In this process, the mold is pressurized and heated so that the plastic layer and the composite material are laminated and fused, and then the mold temperature is rapidly lowered to form a laminated shell structure, and the pressure of the mold is 2 to 4×10 5 Pa, the heating temperature is 190-250°C.

Owner:HEZHOU SITONG INFORMATION TECH CO LTD

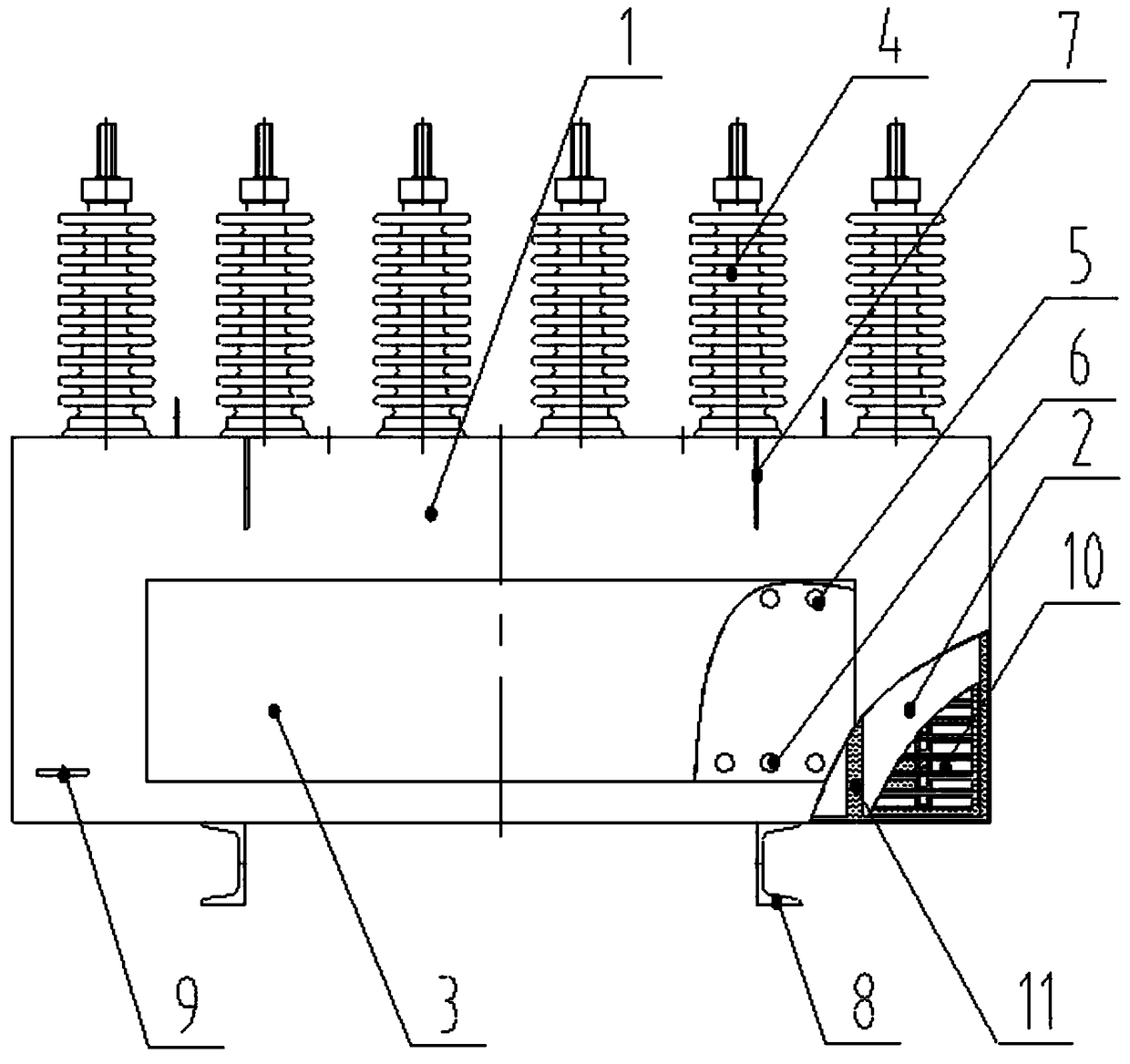

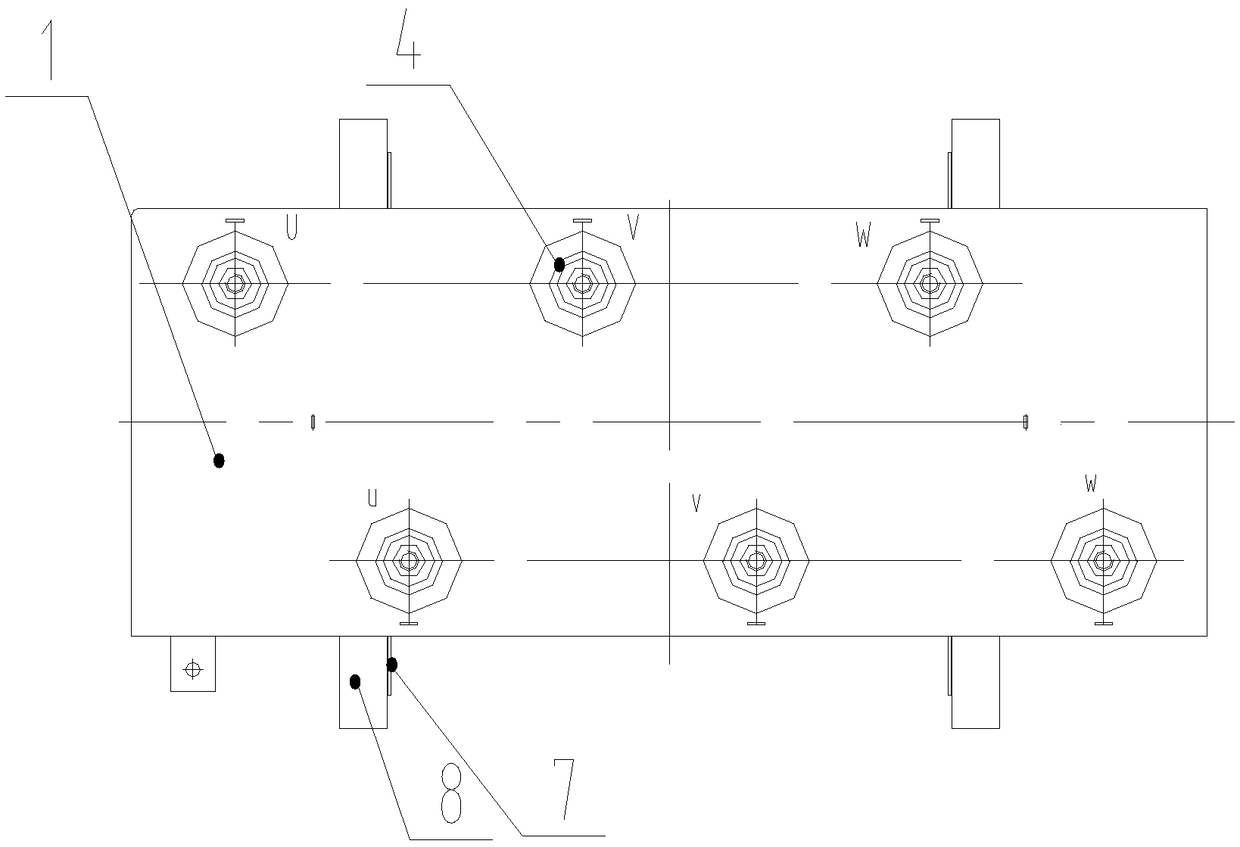

A box-type high-voltage power capacitor

InactiveCN109003811AImprove reliabilityReduce operating temperature riseCapacitorsEngineeringThermal expansion

The invention relates to a box-type high-voltage power capacitor, comprising a shell, a core and a compensating heat dissipation device; the shell is a hollow structure made of a stainless steel plate, and the gap inside is filled with an insulating impregnating agent; The core is mounted in the shell and immersed in the insulation impregnating agent; A sleeve connected with the core is arranged on the top of the shell; The compensating heat dissipation device is mounted on the outer side wall of the shell, and expands or contracts according to the thermal expansion and cold contraction of theinsulating impregnating agent to compensate for volume change, and also causes the circulating flow of the insulating impregnating agent to accelerate the dissipation of heat inside the shell. The invention has the advantages that the stainless steel plate is directly used on the capacitor instead of a common steel plate, and the surface treatment cost can be saved; the compensation heat dissipation device replaces an expander with more solder joints, reduces the possibility of oil leakage, improves the reliability of the capacitor, reduces the operation temperature rise of the capacitor andprolongs the service life of the capacitor.

Owner:GUILIN POWER CAPACITOR

Surface treatment method of magnesium alloy article and structure thereof

InactiveUS8894777B2Simple processReduce surface treatment costsSolid state diffusion coatingSuperimposed coating processMaterials scienceMagnesium alloy

Owner:GETAC TECH CORP

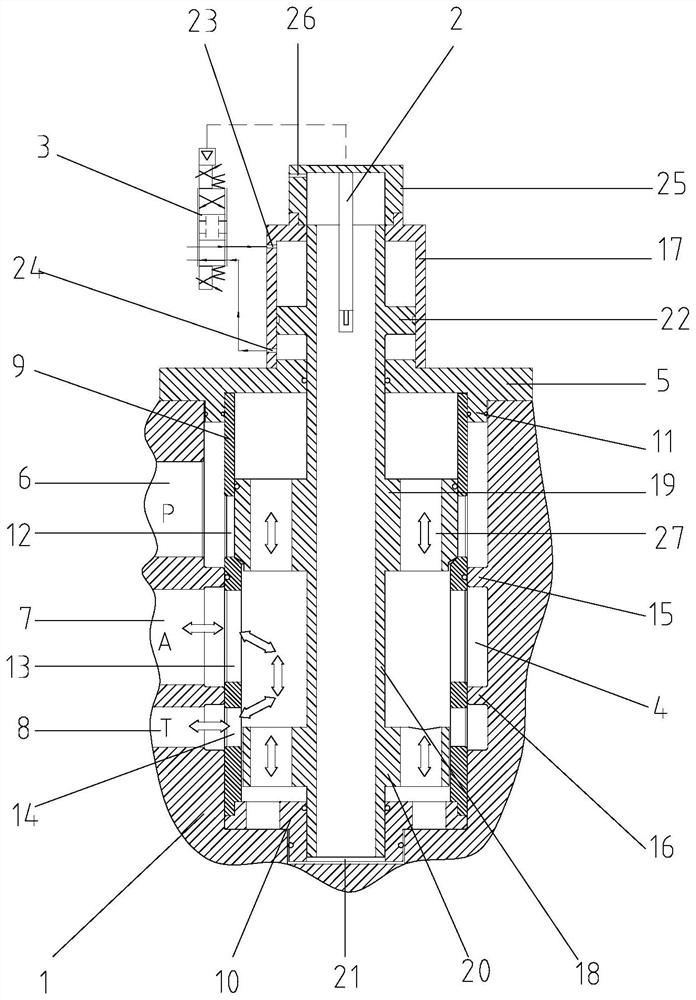

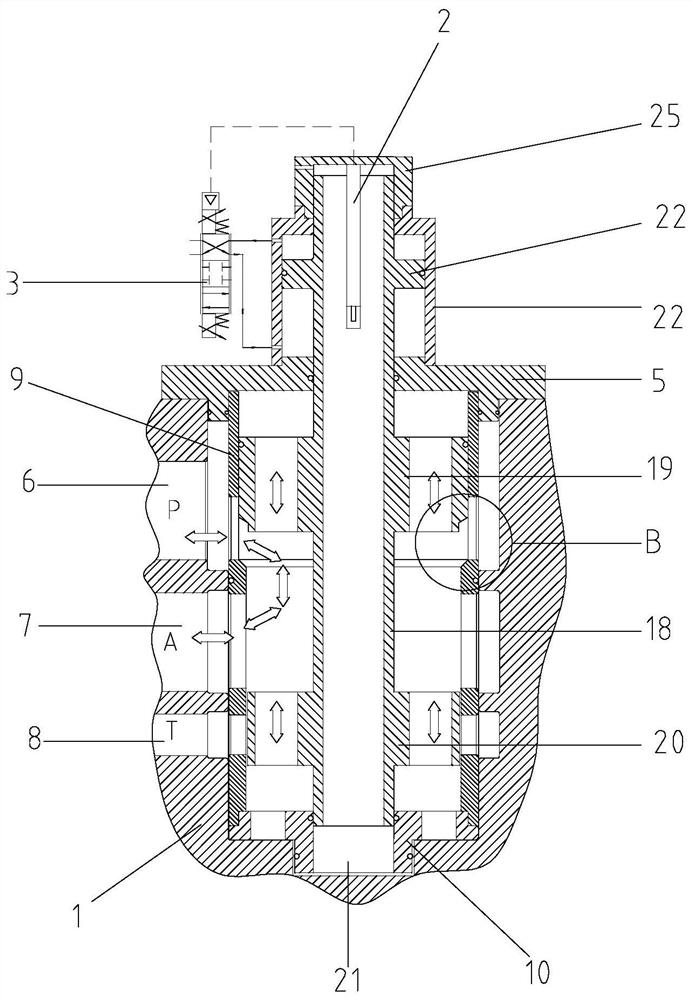

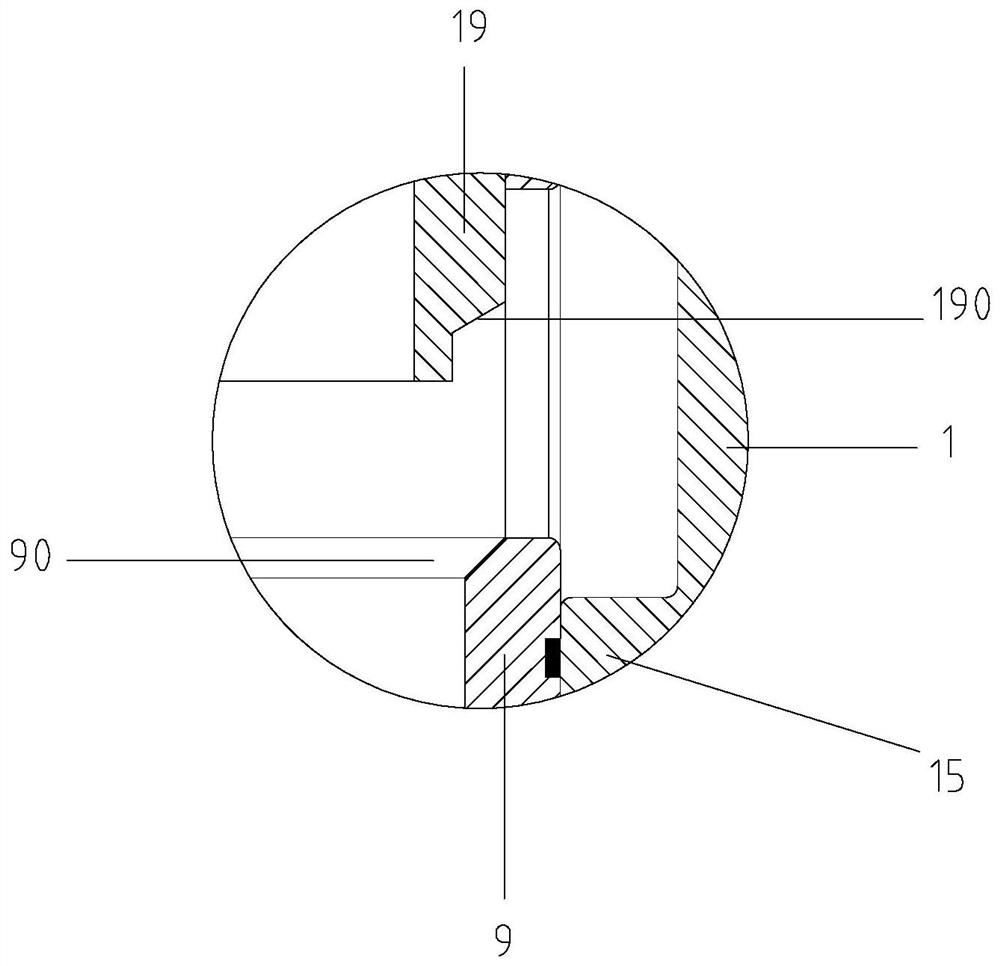

A Safety Three-way Proportional Throttle Valve Structure

ActiveCN109595358BRealize the limit effectPlay a sealing roleFluid-pressure actuator safetyOperating means/releasing devices for valvesEngineeringControl theory

The invention relates to the technical field of valves, and discloses a safe three-way proportional throttle valve structure. The safe three-way proportional throttle valve structure comprises a mainvalve seat, a displacement sensor and a pilot valve, wherein a P oil port, an A oil port and a T oil port which communicate with a main valve cavity are formed in the side surface of the main valve seat in sequence from top to bottom, a P through hole is formed in the corresponding position of the side surface of a valve sleeve and the P oil port, an A through hole is formed in the corresponding position of the side surface of the valve sleeve and the A oil port, a T through hole is formed in the corresponding position of the side surface of the valve sleeve and the T oil port, a driving cylinder is arranged on the outer side surface of a main valve cover, a hollow main valve element is arranged in the valve sleeve, a first main piston and a second main piston are arranged on the main valve element in sequence from top to bottom, a braking piston is arranged in the driving cylinder, a sensor positioning sleeve is arranged on the upper end of the driving cylinder, the upper end of the main valve element passes through the driving cylinder and extends into the sensor positioning sleeve, and the displacement sensor is fixed to the interior of a sensor positioning seat and coaxially extends into the main valve element. The safe three-way proportional throttle valve structure has the beneficial effects of good stability, safety in use and convenience in maintenance.

Owner:刘永

Electronic product shell material laminating structure and manufacture method thereof

InactiveCN102615888BSimplify the surface treatment processReduce surface treatment costsLamination ancillary operationsSynthetic resin layered productsPlastic filmTreatment costs

Owner:KUSN TONG YIN INDAL ELECTRONICS MAKING

Base machining method

ActiveCN111118259AExtended service lifeIncrease elasticitySolid state diffusion coatingFurnace typesManufacturing engineeringIndustrial engineering

The invention provides a base machining method. The base machining method comprises the following steps that fins of a blank piece are subjected to thermal refining, and a first intermediate with higher fin elasticity is obtained; and first surface treatment is carried out on the fin of the first intermediate to obtain a target workpiece with higher fin surface strength. According to the base machining method, the high-elasticity fin is obtained through thermal refining, and then the surface of the fin has relatively high strength through the first surface treatment, so that the fin has relatively high elasticity and relatively high strength, and the fin is prevented from being easily damaged in a service process, and the service life of the fin is prolonged.

Owner:许顺良

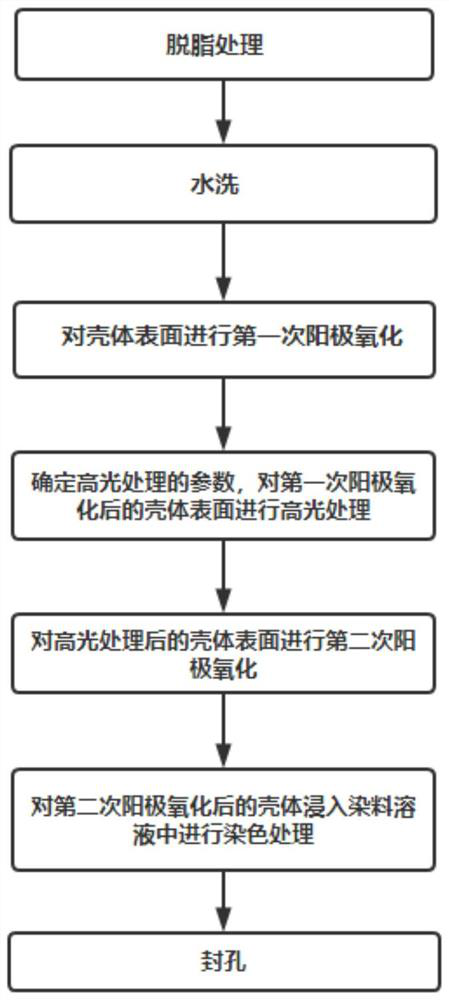

Shell highlight machining process and device thereof

InactiveCN113802165AReduce surface treatment costsHigh surface finishAnodisationMetallurgyPhysical chemistry

The invention relates to the field of shell surface treatment, in particular to a shell mirror surface highlight machining process and device, and the process comprises the following steps: (1) carrying out primary anodic oxidation on the surface of a shell; (2) determining parameters of highlight treatment, and carrying out highlight treatment on the surface of the shell subjected to primary anodic oxidation; (3) carrying out secondary anodic oxidation on the surface of the shell subjected to the highlight treatment; (4) immersing the shell subjected to secondary anodic oxidation into a dye solution for dyeing treatment; and (5) sealing holes of the dyed shell. After being machined according to the machining process disclosed by the invention, the surface shows a mirror-like effect, and the appearance is very clean.

Owner:广泰精密科技(苏州)有限公司

Printing oil capable of replacing packaging matt film and printing process

PendingCN114163918AReduce surface treatment costsEasy to recycleDuplicating/marking methodsPolyurea/polyurethane coatingsProcess engineeringEnvironmental geology

Owner:GUANGDONG GAOYI PACKAGING & PRINTING CO LTD

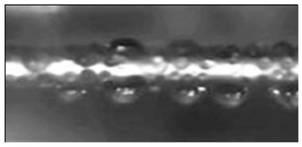

Method for achieving stable dropwise condensation on heat exchange surface and efficient heat exchanger

InactiveCN111085413ASteady Drop Condensation Heat Transfer PhenomenonEasy to operateSpecial surfacesCoatingsRubber materialVulcanization

The invention discloses a method for achieving stable dropwise condensation on a heat exchange surface. The method comprises the steps that a metal heat exchange surface is pretreated; a basic rubbermaterial is prepared, wherein the basic rubber material comprises the following raw materials of, in parts by weight, 100 parts of hydroxyl-terminated polydimethylsiloxane, 5 - 30 parts of nano silicon dioxide, 10 - 50 parts of a cross-linking agent or a coupling agent, 0.1 - 0.5 part of a catalyst and 2 - 10 parts of a functional additive; the basic rubber material is dispersed in a dispersion medium to prepare a coating material with the hydroxyl-terminated polydimethylsiloxane in mass fraction of 2.5% - 25%; and the coating material is sprayed onto the metal heat exchange surface to form asingle-component room-temperature vulcanized silicone rubber system coating. According to the method for achieving the stable dropwise condensation on the heat exchange surface, the extremely thin silicone rubber system coating is constructed on the metal heat exchange surface, so that stable and durable dropwise condensation is achieved on the heat exchange surface; and a heat exchange surface ofan efficient heat exchanger is treated through the method, the efficient heat exchanger is suitable for the steam condensation heat transfer process containing non-condensable gas, and the condensation and heat transfer efficiency of the process is improved.

Owner:江苏中圣压力容器装备制造有限公司

A method for preparing a high-hardness, smooth, corrosion-resistant surface of ferrous metals

ActiveCN110774061BHigh surface hardnessImprove corrosion resistanceSeat surface grinding machinesSurface finishLubricant substance

This patent discloses a method for preparing a high-hardness, smooth, and corrosion-resistant surface of ferrous metals. The metal sample to be treated is made into a friction pair. The material of the pair is the same as that of the metal sample to be processed and the hardness is similar. The initial surface roughness of the two pairs is Ra ≤1.6um, and lubricated by lubricating substances, which are lubricating oil, grease and emulsion containing serpentine, attapulgite, kaolinite, montmorillonite and other minerals, using splash lubrication and forced lubrication. The contact form of the friction pair includes surface-to-surface contact and line-to-surface contact. The friction form includes sliding friction and rolling friction. The cumulative friction movement time is not less than 72 hours. This process method is relatively simple, and one process section can realize "improving surface hardness, The comprehensive goal of "smoothness and corrosion resistance" has a certain promotion value.

Owner:中建材科创新技术研究院(山东)有限公司

A method of machining a base

ActiveCN111118259BHigh hardnessImprove wear resistanceSolid state diffusion coatingFurnace typesEngineeringMechanical engineering

The invention provides a base processing method, comprising the following steps: performing tempering treatment on the fins of the blank to obtain a first intermediate body with higher fin elasticity; performing first surface treatment on the fins of the first intermediate body And obtain the target workpiece with higher fin surface strength. In the base processing method provided by the present invention, highly elastic fins are obtained through quenching and tempering treatment, and then the surface of the fins has greater strength through the first surface treatment, so that the fins have higher elasticity , and has greater strength, which ensures that the fins will not be easily damaged during service and prolongs the service life of the base.

Owner:许顺良

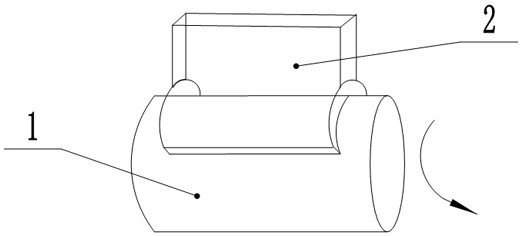

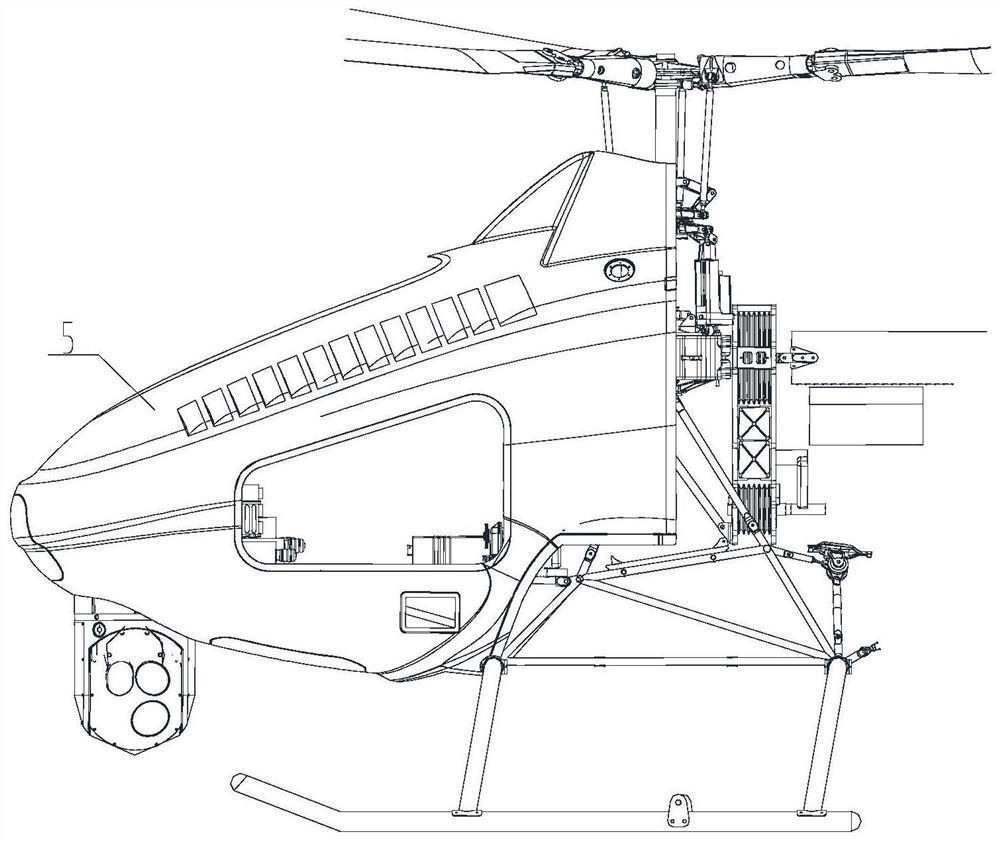

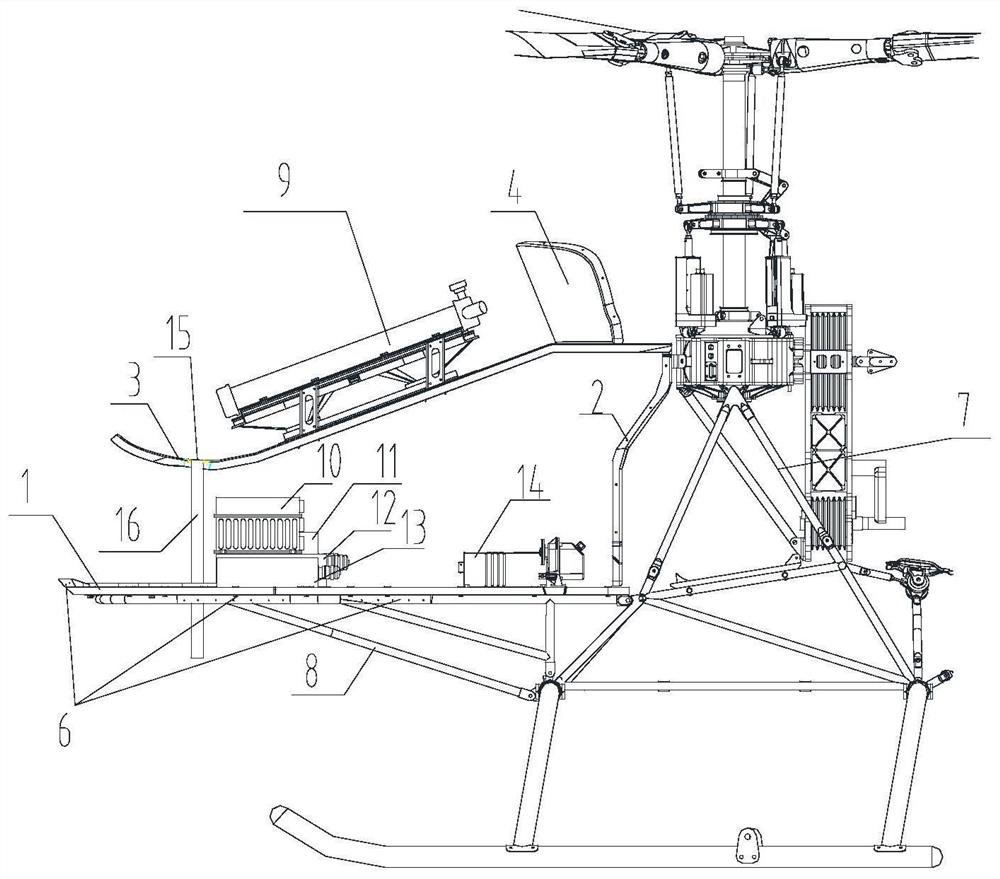

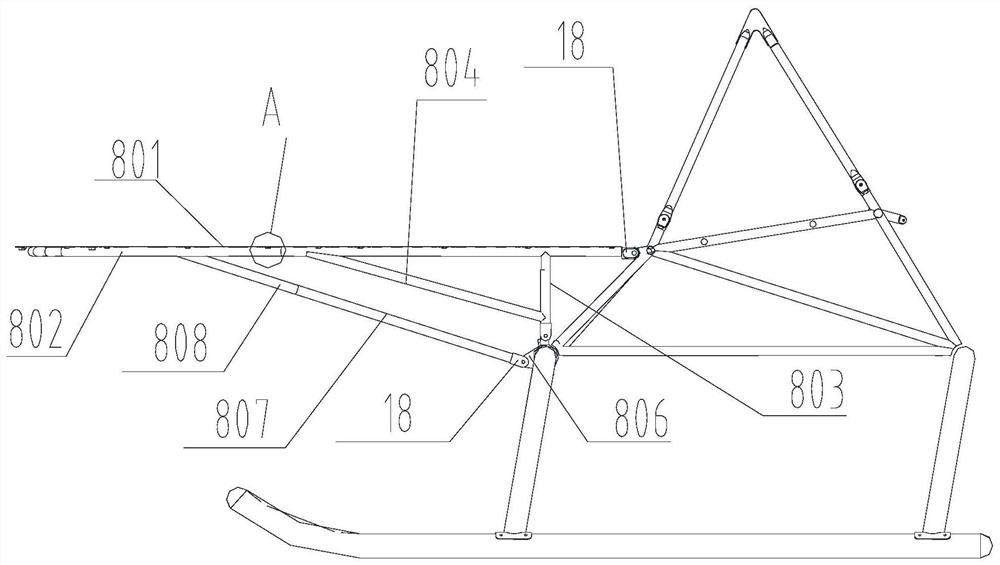

Unmanned helicopter equipment compartment

ActiveCN113291456BNo electromagnetic interferenceReduce surface treatment costsFuselagesRotocraftStructural engineeringMechanical engineering

The invention discloses an unmanned helicopter equipment cabin, which comprises an equipment cabin floor, a vertical equipment cabin rear partition, a radiator lower partition located above the equipment cabin rear partition for placing a radiator, and a radiator lower partition. The radiator rear bulkhead above the plate and the equipment compartment outer cover that forms the inner cavity of the equipment compartment with the radiator rear bulkhead, the radiator lower bulkhead, the equipment compartment floor and the equipment compartment rear bulkhead, wherein the equipment compartment outer cover is supported by the equipment compartment The board is connected to the floor of the equipment compartment, and a floor support assembly is connected between the floor of the equipment compartment and the rack. The invention divides the equipment cabin into upper and lower layers as a whole, which are separated by the lower partition of the radiator. The radiator is installed on the upper layer, and the avionics equipment, power supply equipment and flight control device are installed on the lower layer. The counterweight is discarded to increase the space utilization rate.

Owner:南京航天国器智能装备有限公司

Preparation method of ferrous metal with high hard, smooth and corrosion-resistant surface

ActiveCN110774061AHigh surface hardnessImprove corrosion resistanceSeat surface grinding machinesLubricant substanceLubrication

The invention discloses a preparation method of ferrous metal with a high hard, smooth and corrosion-resistant surface. The preparation method includes the following steps that a metal sample to be treated is made into friction pairs, materials of the friction pairs are the same as those of the metal sample to be treated and hardness is similar, initial surface smoothness Ra of the two pairs is less than or equal to 1.6[mu]m, lubricating materials are used for lubricating,include lubricating oil, grease, and emulsion which contain serpentine, attapulgite, kaolinite, montmorillonite and other minerals, and methods of splash lubrication and forced lubrication are adopted. Contact forms of the friction pairs include surface-to-surface contact and line-to-surface contact, friction forms include sliding friction and rolling friction, accumulated friction movement time is not less than 72 hours, the process method is relatively simple, and one process section can achieve a comprehensive goalof "improving the surface hardness, smoothness and corrosion resistance", and has a certain promotion value.

Owner:中建材科创新技术研究院(山东)有限公司

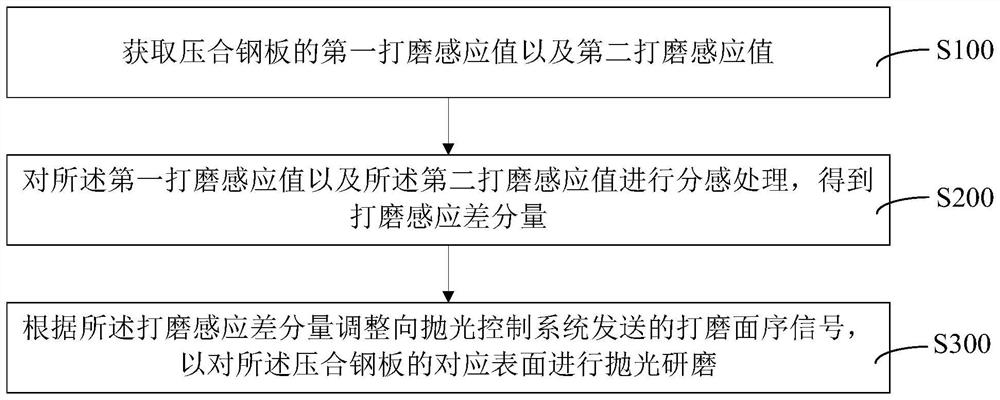

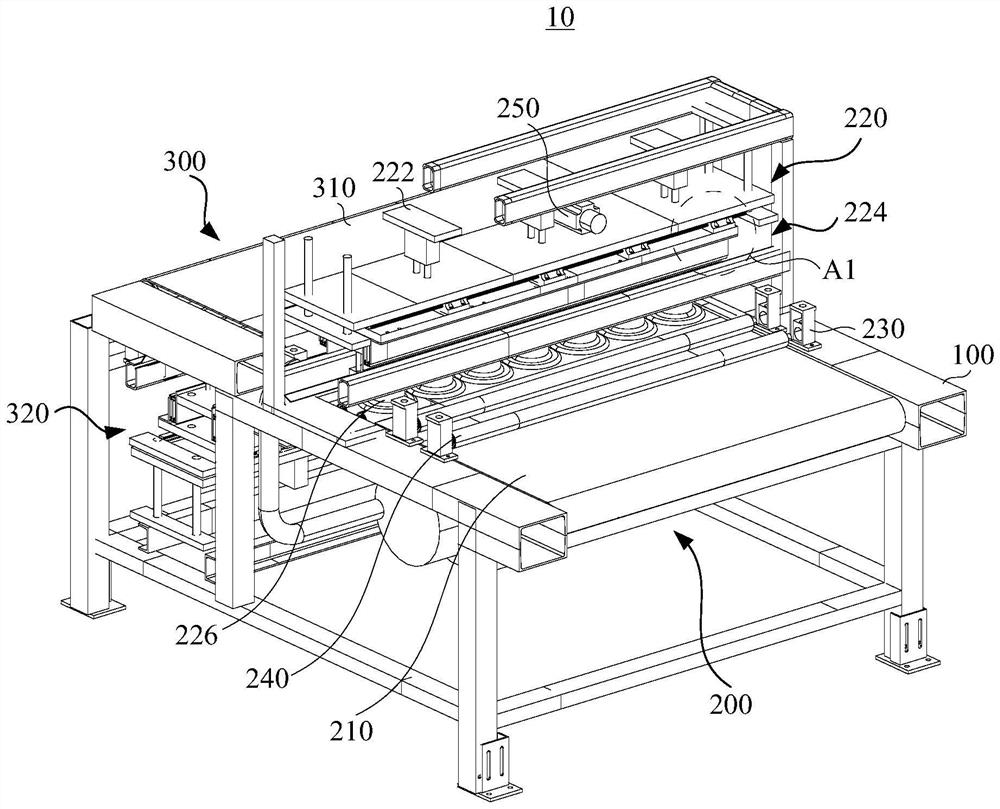

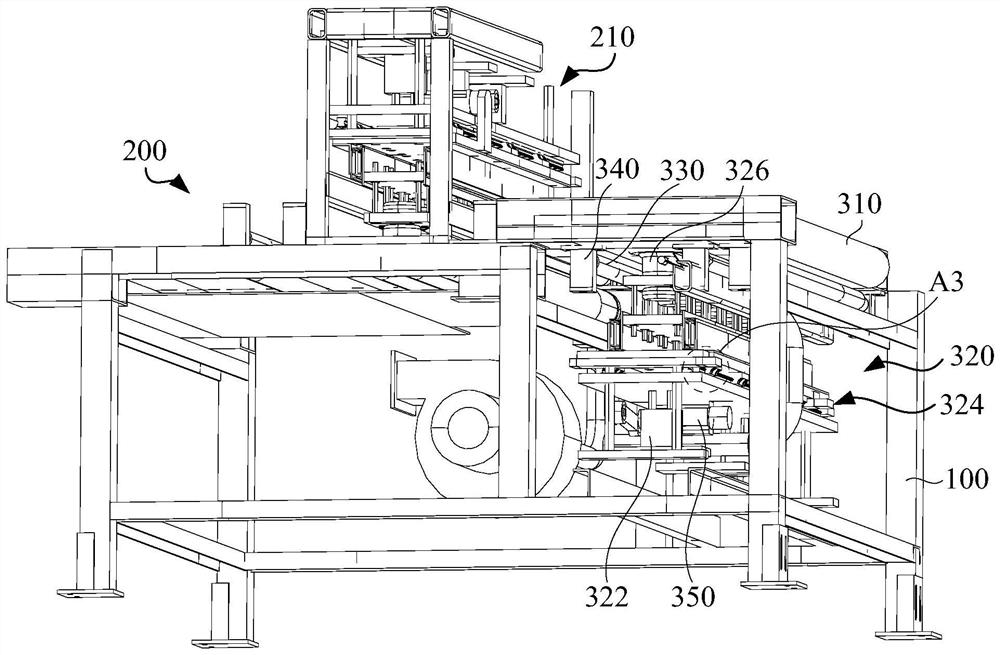

Press-fit steel sheet surface treatment method and press-fit steel sheet polishing device

ActiveCN114406887AImprove surface polishing efficiencyReduce surface treatment costsPolishing machinesGrinding feed controlPolishingControl system

The invention provides a press-fit steel plate surface treatment method and a press-fit steel plate polishing device. The method comprises the following steps: acquiring a first polishing induction value and a second polishing induction value of a laminated steel plate; performing sensing processing on the first polishing sensing value and the second polishing sensing value to obtain a polishing sensing difference component; and a grinding surface sequence signal sent to a polishing control system is adjusted according to the grinding induction difference component, so that the corresponding surface of the press-fit steel plate is polished and ground. After the press-fit steel plate is sensed, the sensing sequence between the polishers at different polishing positions is determined according to the obtained sensing value, that is, the polishing surface sequence signal for polishing the press-fit steel plate is determined according to the polishing sensing difference component, the press-fit steel plate does not need to be overturned, a plate overturning machine needing to be arranged is omitted, and the cost is reduced. And the surface polishing efficiency of the press-fit steel plate is improved, the surface treatment cost of the press-fit steel plate is effectively reduced, and therefore the production cost is effectively reduced.

Owner:CAMELOT QINGYUAN HYTEC TECH INVESTMENT

A kind of preparation method of nanoparticle-doped electrogalvanized layer

ActiveCN105088320BIncrease the level of detailAccelerated corrosionElectrolytic coatingsBinding forceImpurity

The invention discloses a preparation method of an electrogalvanizing layer doped with nanometer particles. Each liter of an electroplating liquid comprises the following components: 8-15g of zinc oxide, 80-150g of sodium hydroxide, 150ml of a ZN-500 brightening agent, 1-3ml of a ZN-500 low-area dispersing agent, 1ml of a ZN-500 impurity removing agent, 1ml of a ZN-500 water treating agent, 1.0-1.5g of nanometer titanium dioxide particles, and the balance of deionized water. According to the preparation method of the electrogalvanizing layer doped with the nanometer particles, disclosed by the invention, through the addition of the nanometer titanium dioxide particles, the fine degree of the crystallization of a galvanizing layer can be effectively improved, so that the galvanizing layer and a substrate have good binding force, and the corrosion resistance of the galvanizing layer and the wear resistance of the galvanizing layer are improved significantly; therefore, the thickness of the galvanizing layer can be effectively lowered, and the surface treating cost is reduced; in addition, the preparation process of the electrogalvanizing layer and the production process of the electrogalvanizing layer are environment-friendly, non-toxic and harmless.

Owner:EARTH PANDA ADVANCE MAGNETIC MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com