Patents

Literature

32 results about "Lubricant substance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Bituminous paving composition and process for bituminous paving

The invention provides a bituminous composition, a process for preparing a bituminous paving composition and process for bituminous paving having lower mixing, paving, and compaction temperatures than for conventional hot-mix paving while retaining sufficient performance characteristics of conventional hot-mix paving. The inventive paving process comprises the steps of injecting a heated foamable solution comprising a lubricating substance into a heated, asphalt binder to provide a heated, foamed mixture; adding the heated, foamed mixture to a suitable, heated aggregate; further mixing the heated, foamed mixture and heated aggregate to coat the heated aggregate with the heated, foamed, asphalt binder to form a heated paving material; supplying the heated paving material to a paving machine; applying the heated paving material by the paving machine to a surface to be paved; and compacting the applied paving material to form a paved surface.

Owner:ALM HLDG CO

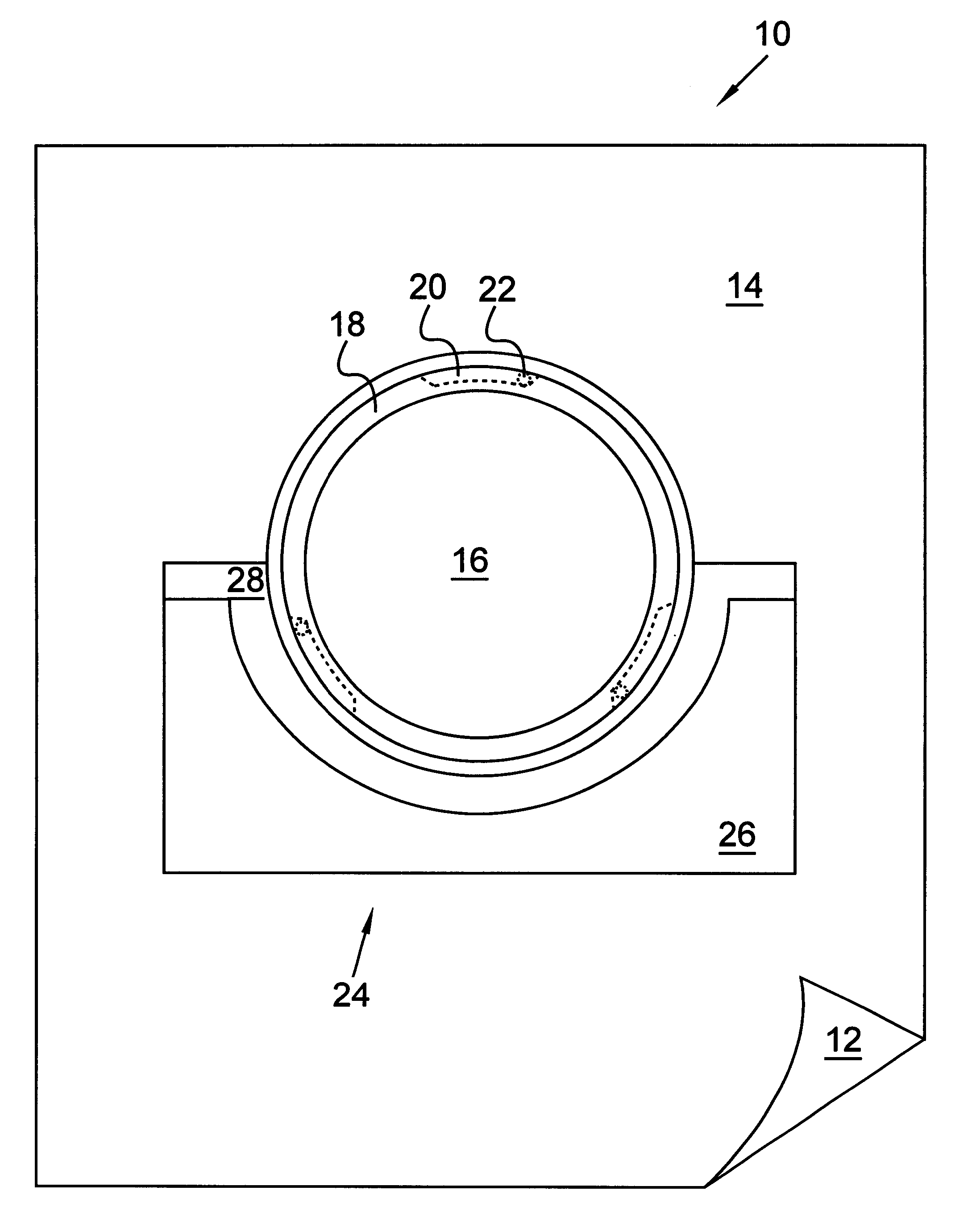

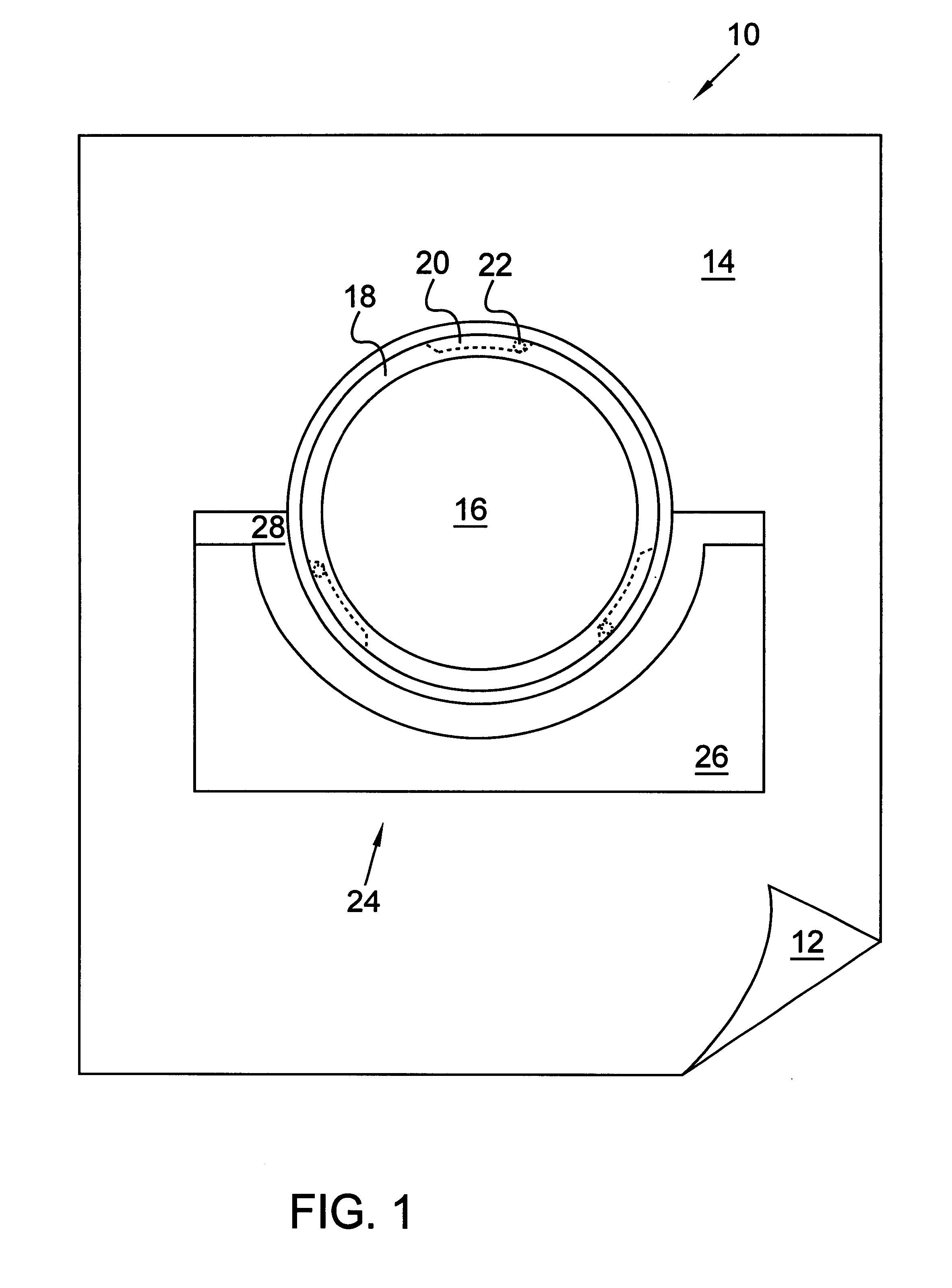

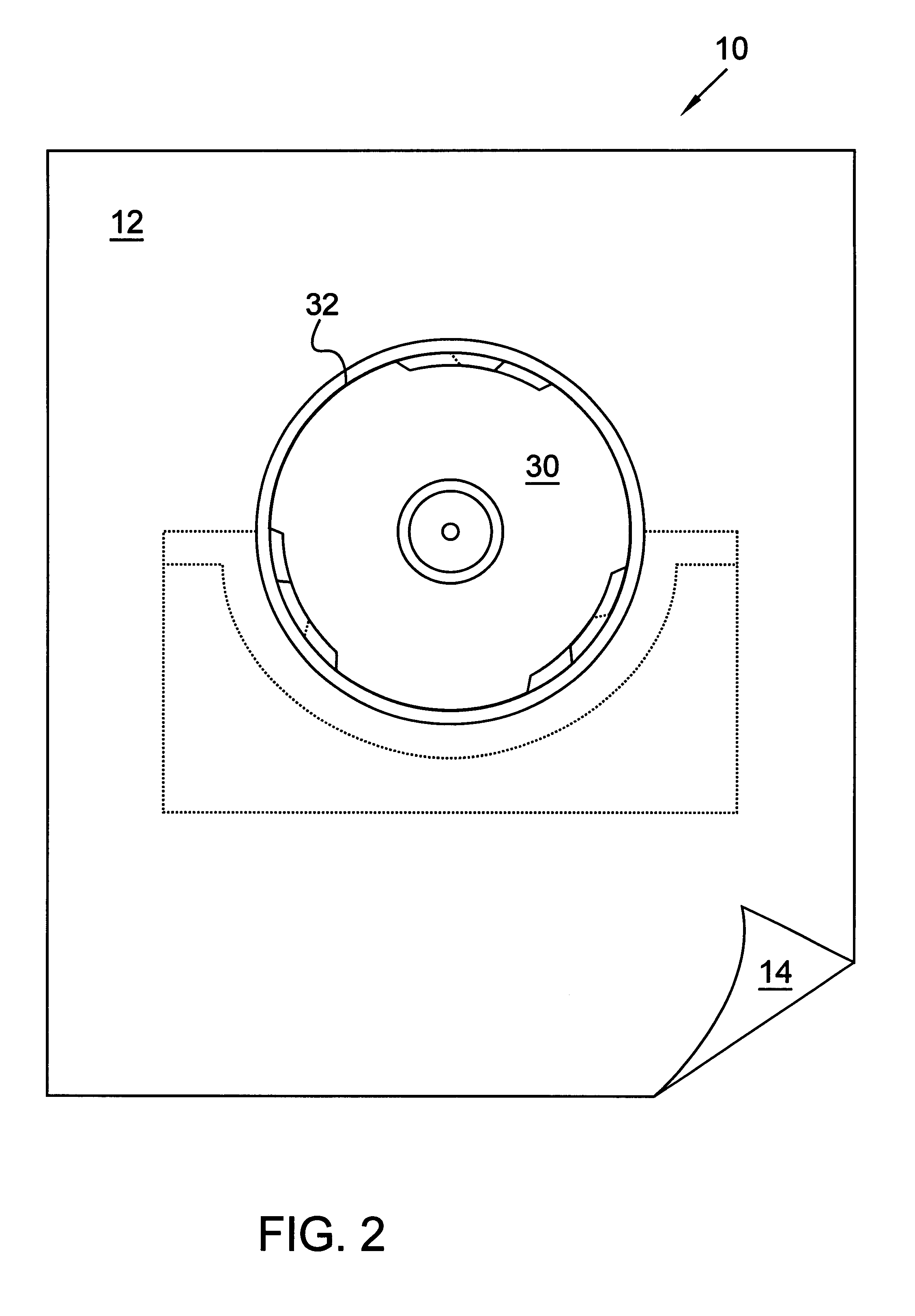

Surgical drape for colonoscopy

InactiveUS6357445B1Reduce the possibilityObstruct passageRestraining devicesDiagnosticsLubricant substanceEntire face

A flexible surgical drape has an adhesive side and a non-adhesive side. The adhesive side is adhesive across substantially its entire face. The drape consists of a flexible sheet suitable for covering a substantial portion of a patient's body. A pocket for catching patient secretions and other fluids is attached to the adhesive side of the drape. The drape contains an opening capable of receiving a removable valve, which, when in place, seals off the opening and prevents the passage of gases, secretions, and fluids that are typically present during a medical procedure. The valve can be made to lock into the opening so as to reduce the likelihood of its inadvertent removal. An examining tool such as a colonoscope fits through a hole extending through the valve and thus can be passed from one side of the drape to the other. A reservoir suitable for holding a lubricating substance is securely attached to and forms part of the valve, and the examining tool when inserted through the valve passes through this lubricating substance and is coated by it.

Owner:SHAW TIMOTHY A

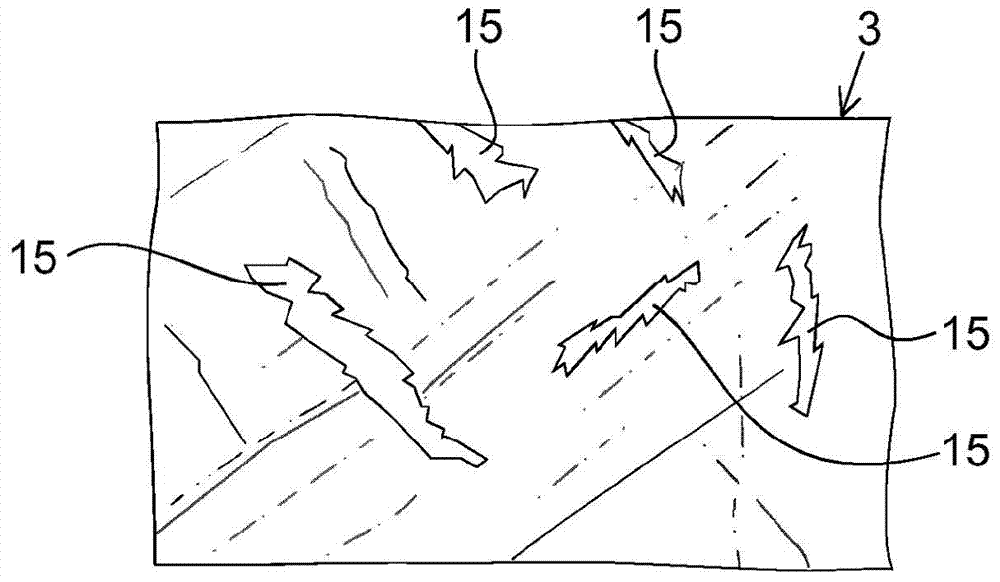

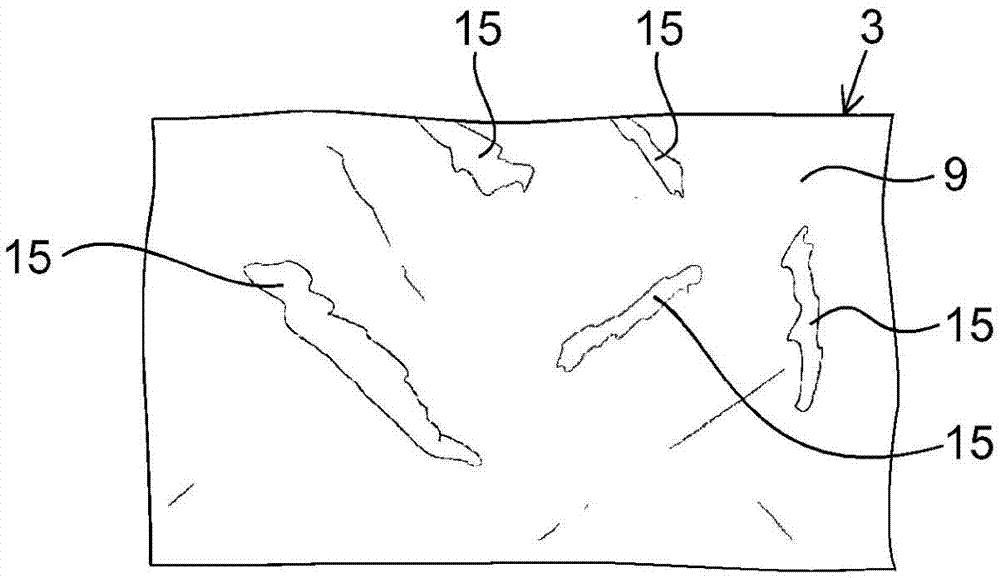

Surface treatment method and repair method

A method for forming a dense coating on a limited region of a subject body is disclosed. The method is composed of the steps of: applying one selected from the group of a compressed body of a powder of a metal and a sintered compressed body of a powder of a metal to a working electrode; executing discharge deposition to deposit a first coating from the working electrode on the subject body by applying the subject body as a workpiece of the discharge deposition; executing discharge deposition to deposit a second coating from the working electrode on the first coating by applying the subject body as a workpiece of the discharge deposition; and heating the subject body in one selected from the group of a vacuum, an air and an oxidizing atmosphere so as to densify the second coating or oxidizing the second coating at least in part to generate a solid lubricant substance.

Owner:IHI CORP

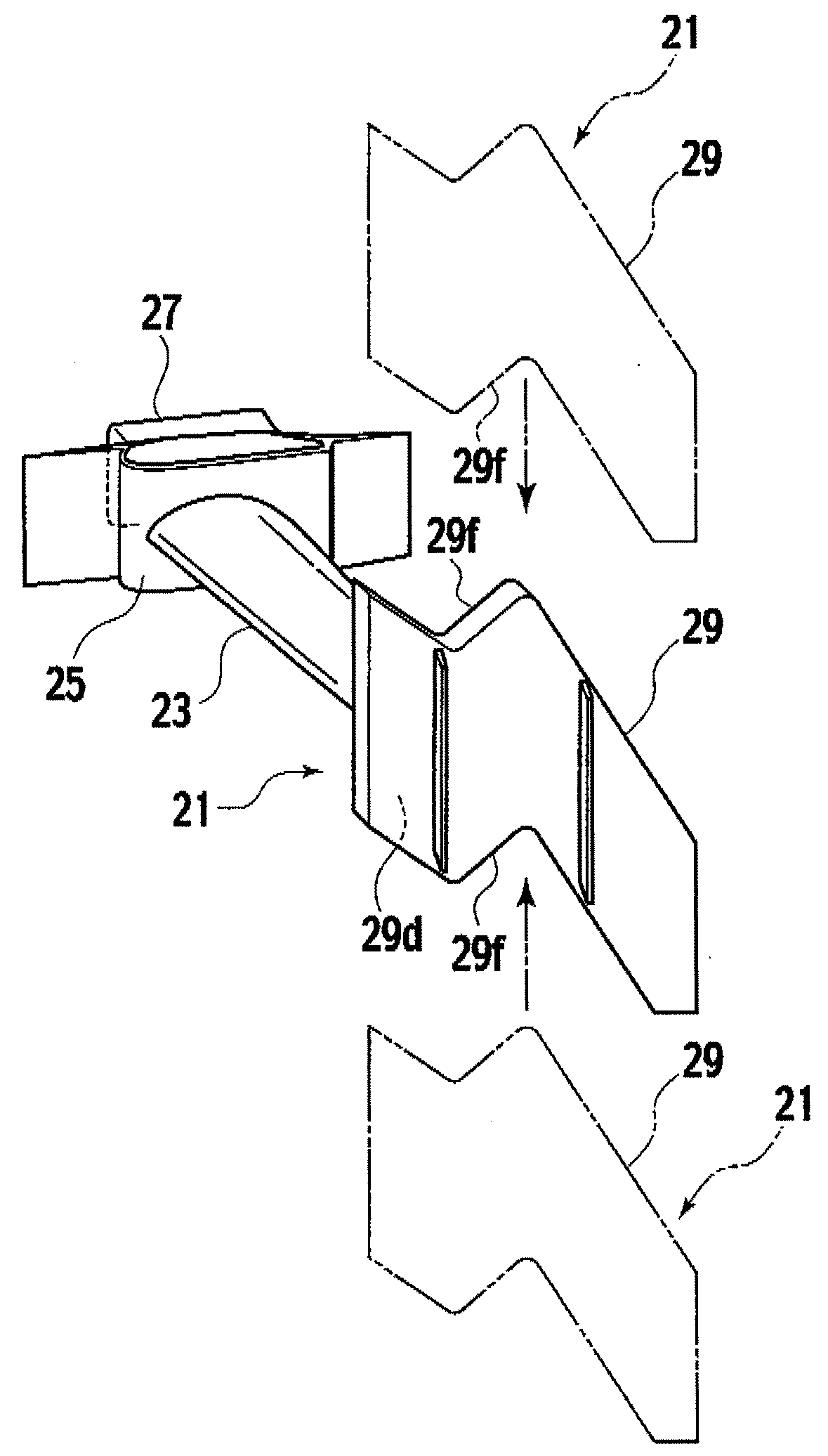

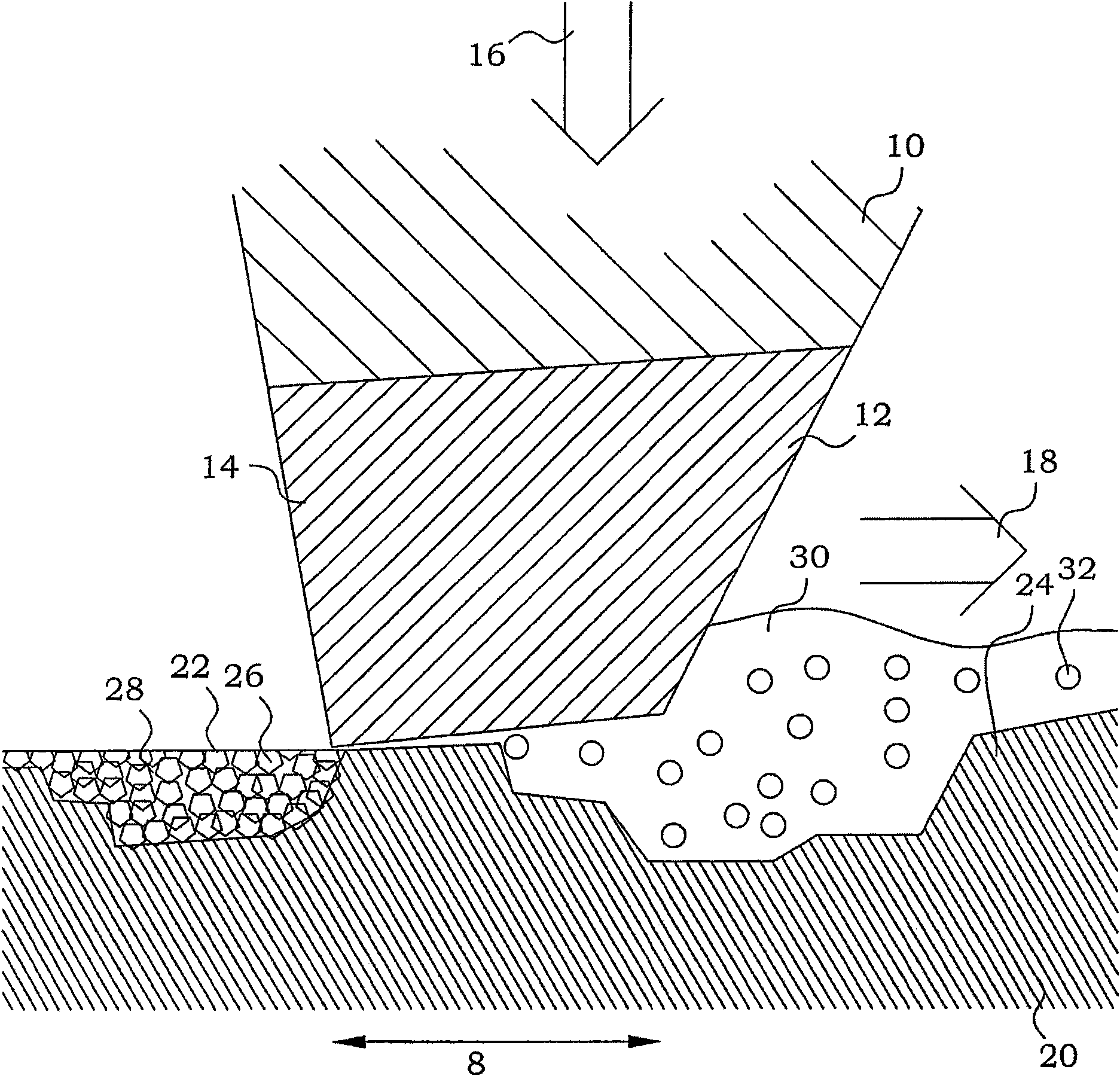

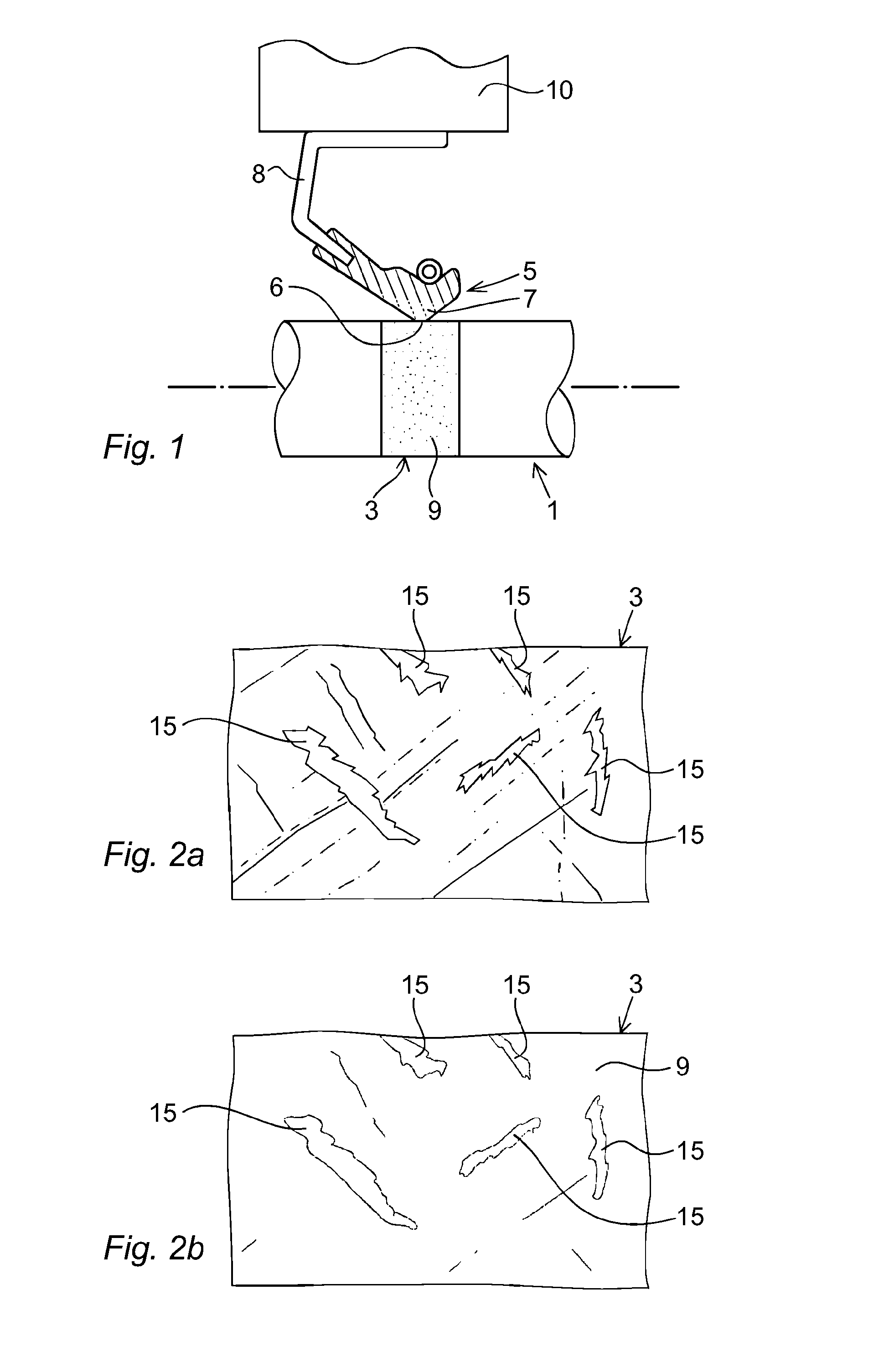

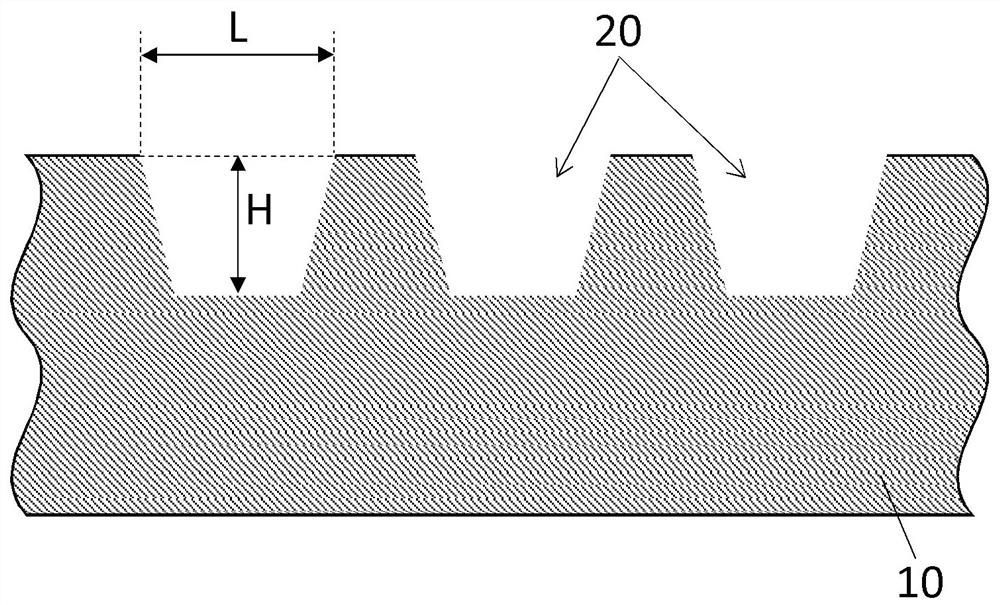

Manufacturing of low-friction elements

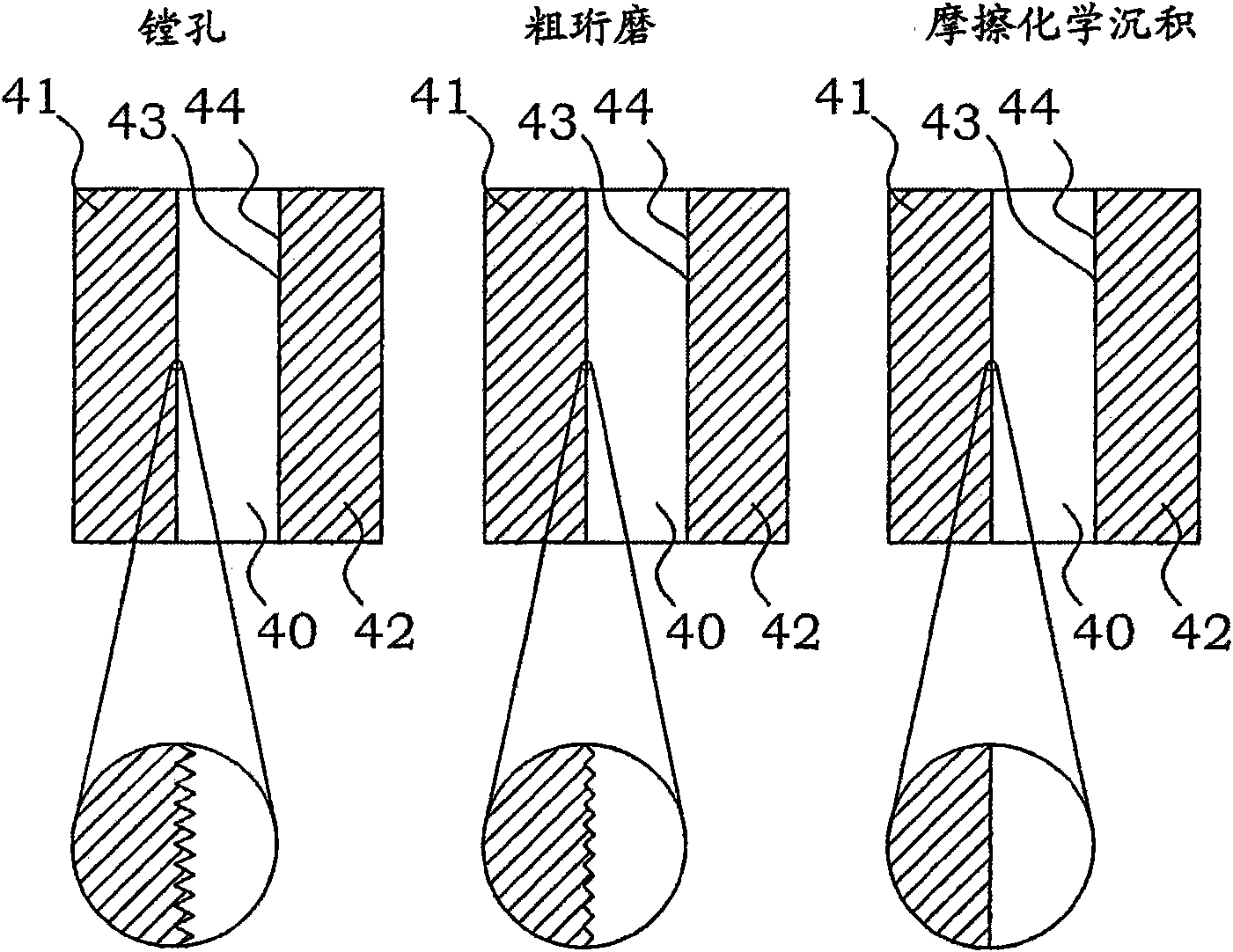

ActiveCN101918612AReduce coefficient of frictionLow friction facetCylinder headsCylindersSurface layerLubricant substance

A manufacturing method of mechanical elements comprises providing (210) of a mechanical element having a rough curved surface preferably with a surface roughness of more than Sa = 0.1 mum. The method is characterized by tribochemically depositing (214) solid lubricant substance directly onto the rough curved surface in transverse directions. A mechanical element has a curved surface. The curved surface has a surface layer of a tribochemically deposited solid lubricant substance. The mechanical element is obtainable by the above method. A tool for manufacturing of such a mechanical element comprises a support portion, at least one tool working surface, means for providing a force pressing the tool towards the curved surface and driving means for moving said at least one tool working surface in two different directions along said curved surface. The working surface comprises an oxide, carbide and / or suicide of an element capable of forming a stable sulfide.

Owner:APPLIED NANO SURFACES SWEDEN AB

Surface treatment method and repair method

A method for forming a dense coating on a limited region of a subject body is disclosed. The method is composed of the steps of: applying one selected from the group of a compressed body of a powder of a metal and a sintered compressed body of a powder of a metal to a working electrode; executing discharge deposition to deposit a first coating from the working electrode on the subject body by applying the subject body as a workpiece of the discharge deposition; executing discharge deposition to deposit a second coating from the working electrode on the first coating by applying the subject body as a workpiece of the discharge deposition; and heating the subject body in one selected from the group of a vacuum, an air and an oxidizing atmosphere so as to densify the second coating or oxidizing the second coating at least in part to generate a solid lubricant substance.

Owner:IHI CORP

Bituminous paving composition and process for bituminous paving

Owner:ALM HLDG CO

Anti-snoring composition

The invention relates to an anti-snoring composition characterized in that it comprises at least one lubricating substance and at least one bioadhesive substance which can cause the lubricating substance to adhere to mucocilliary cells situated at pharynx level.

Owner:PERSEE MEDICA

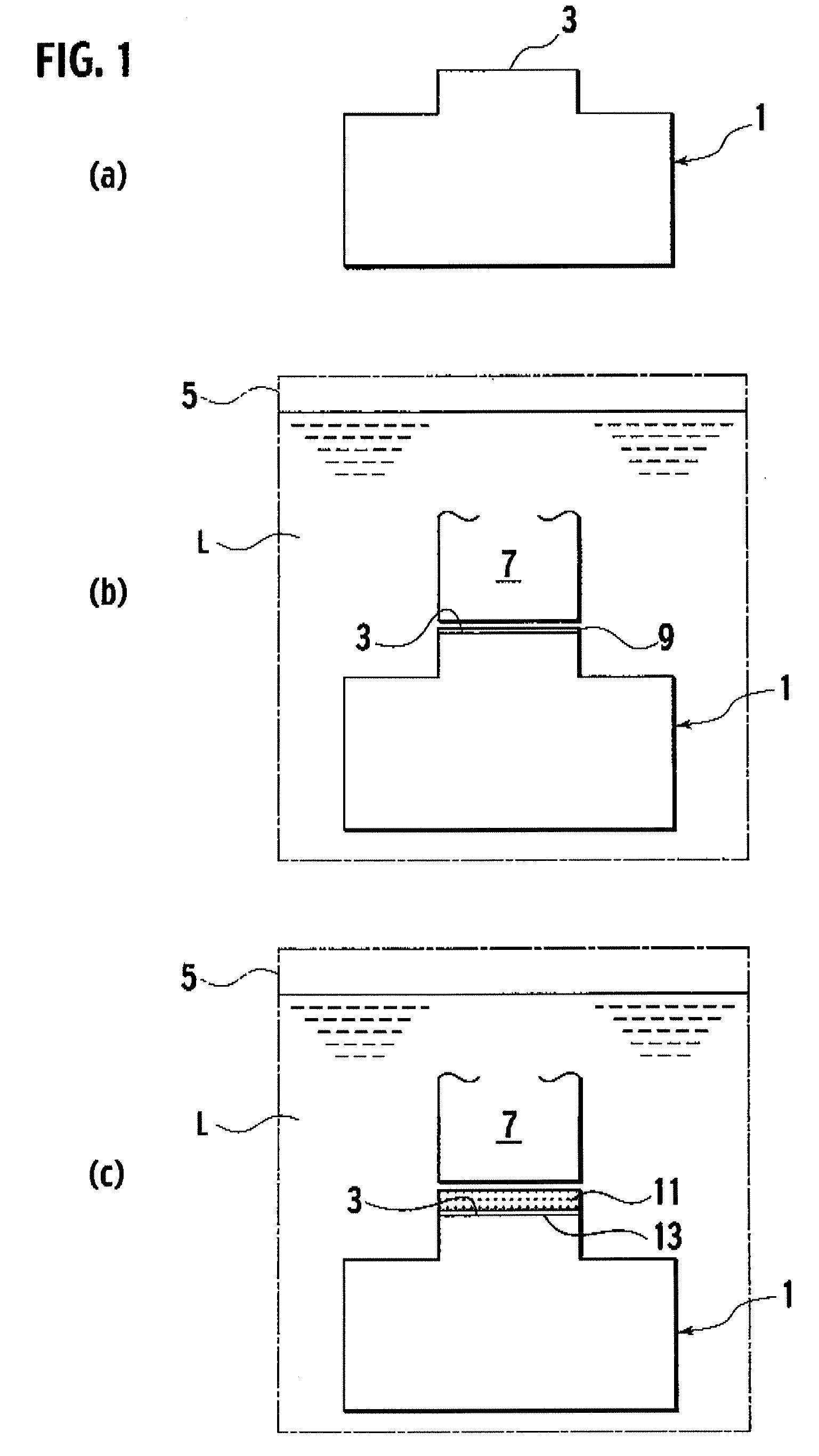

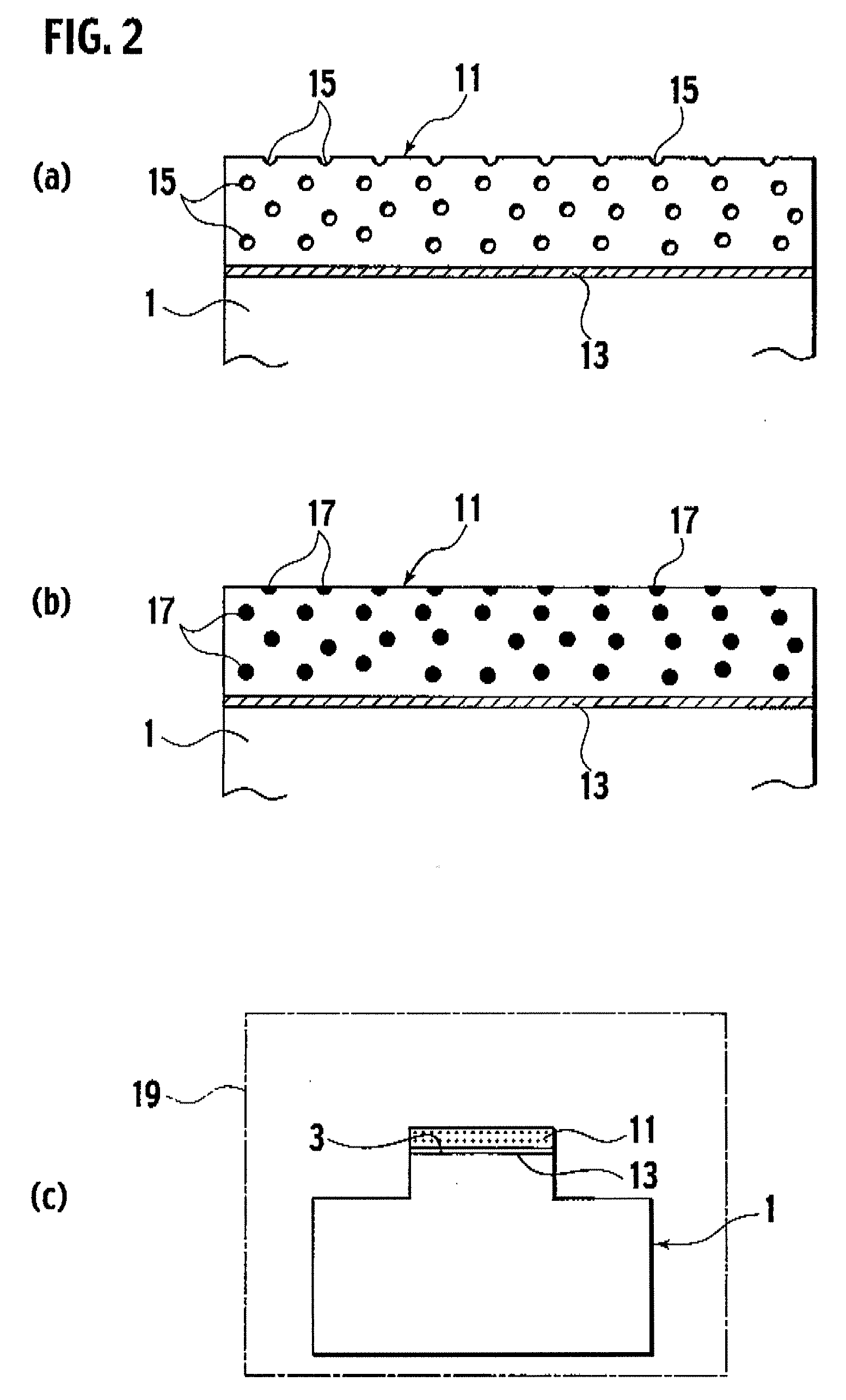

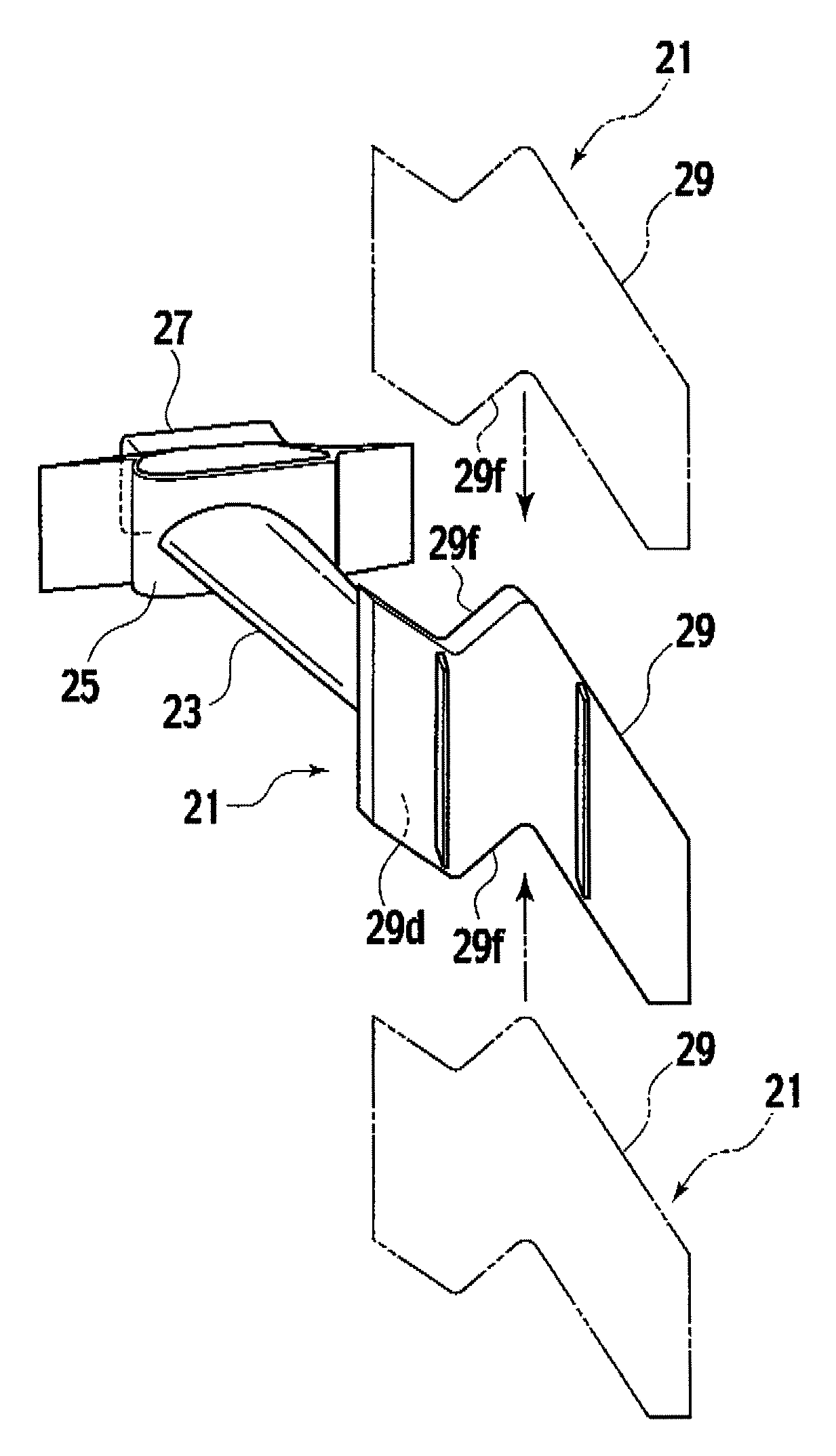

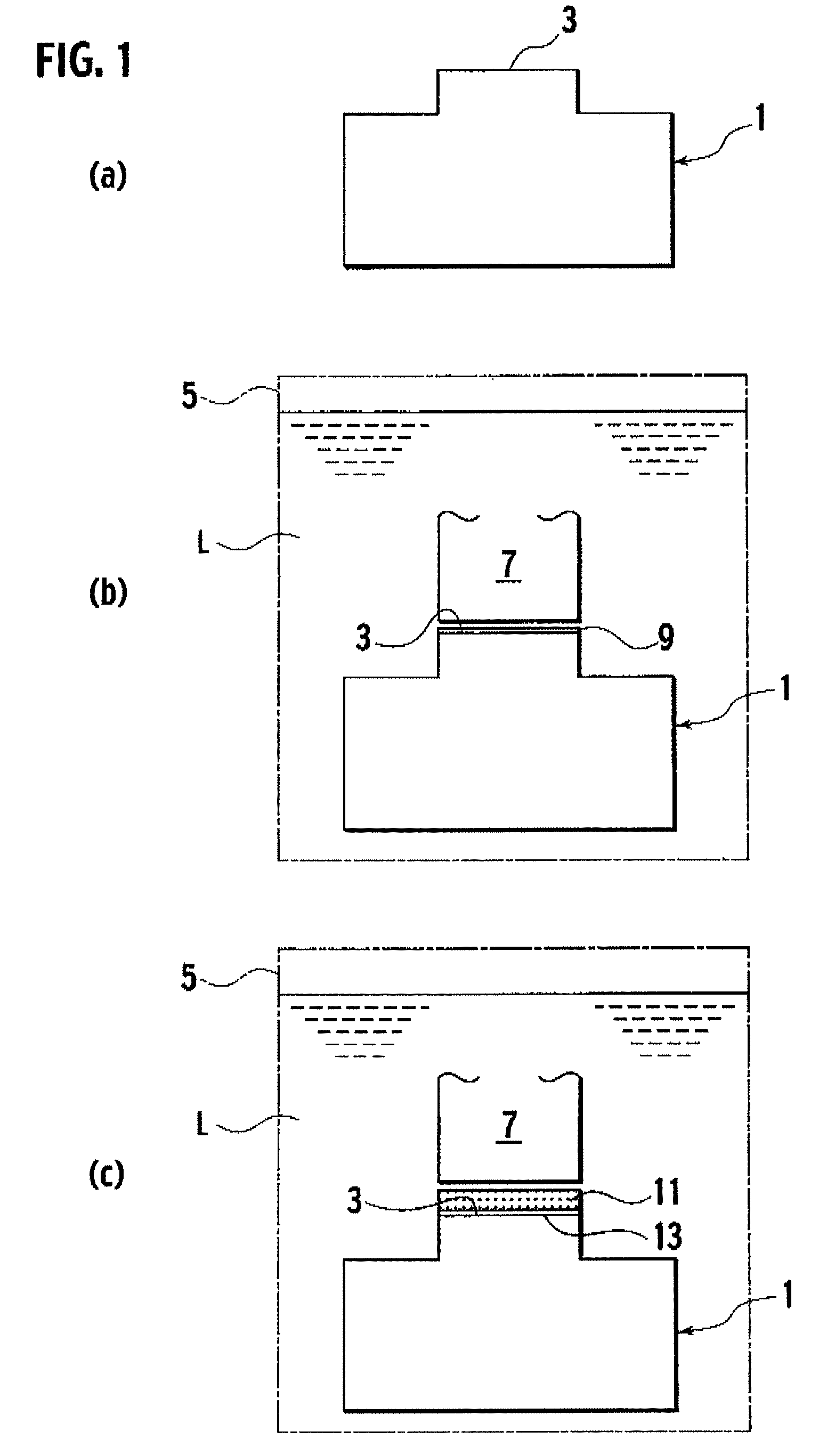

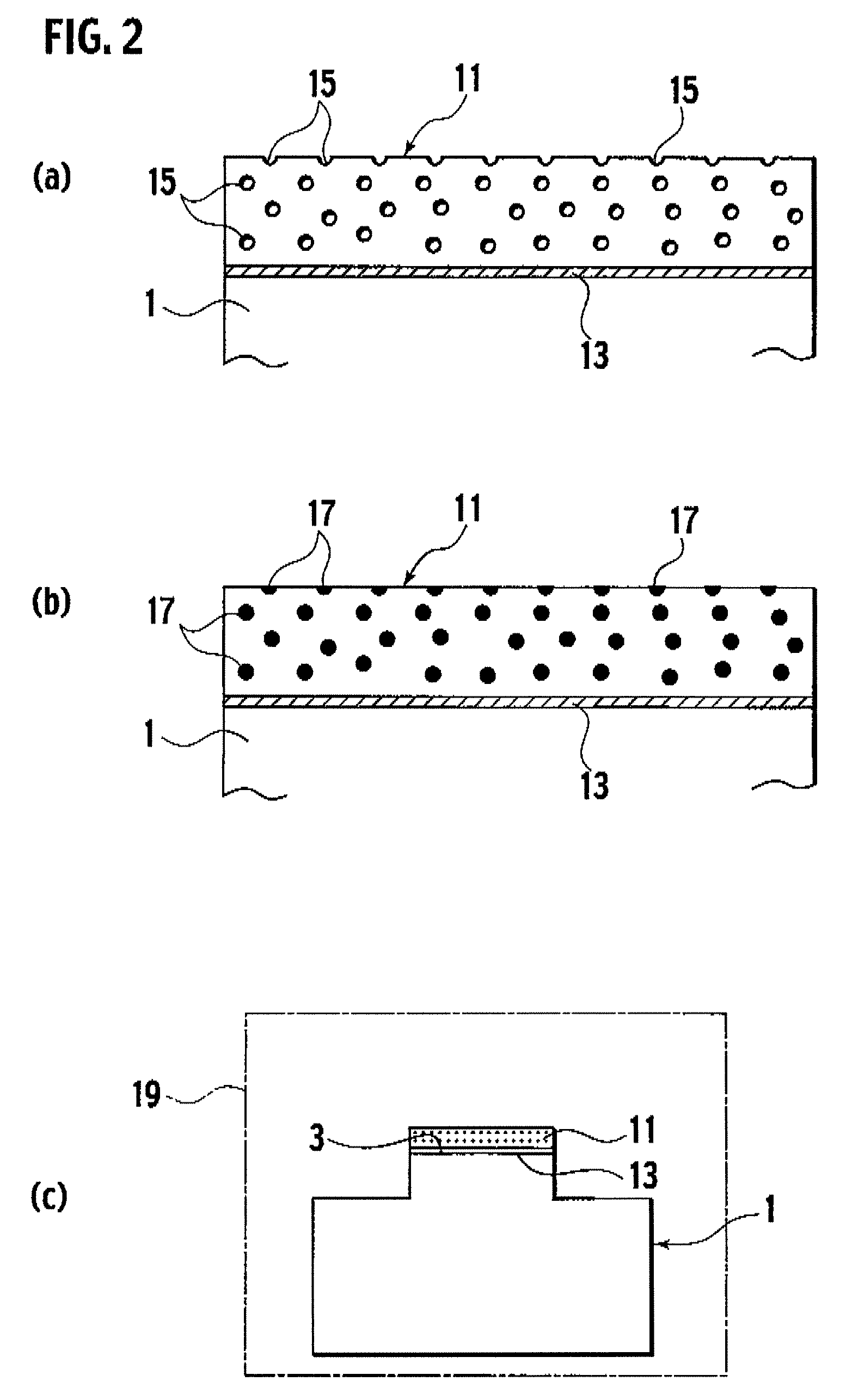

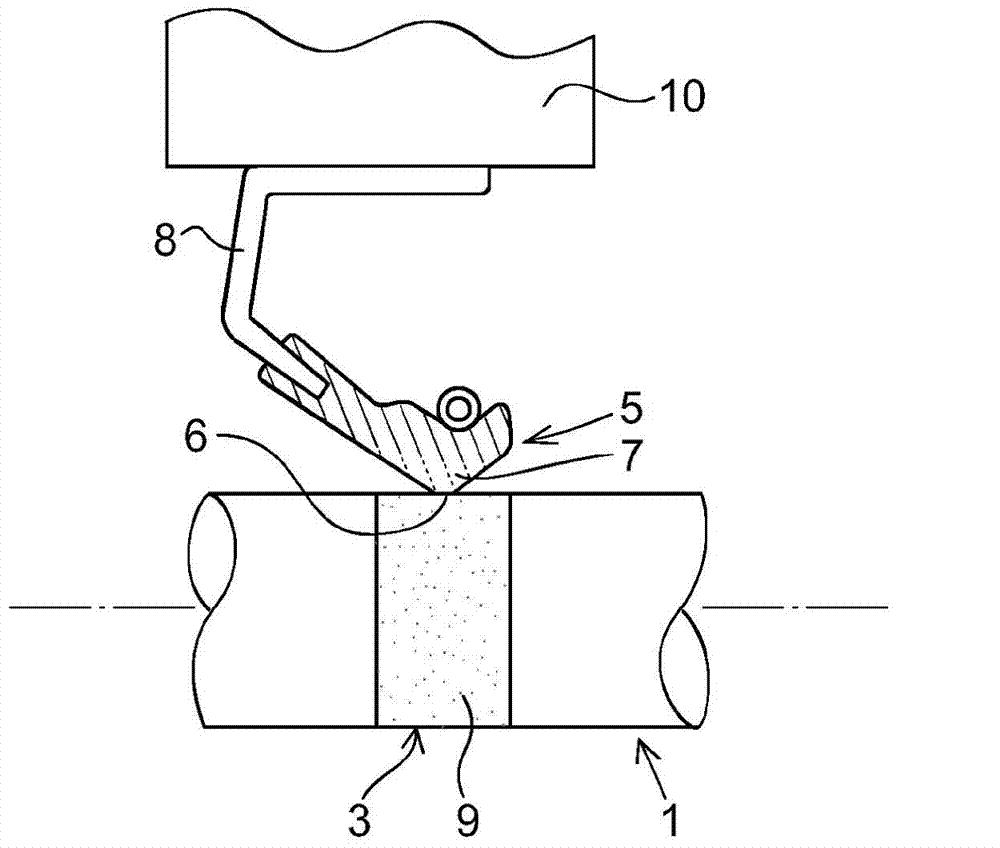

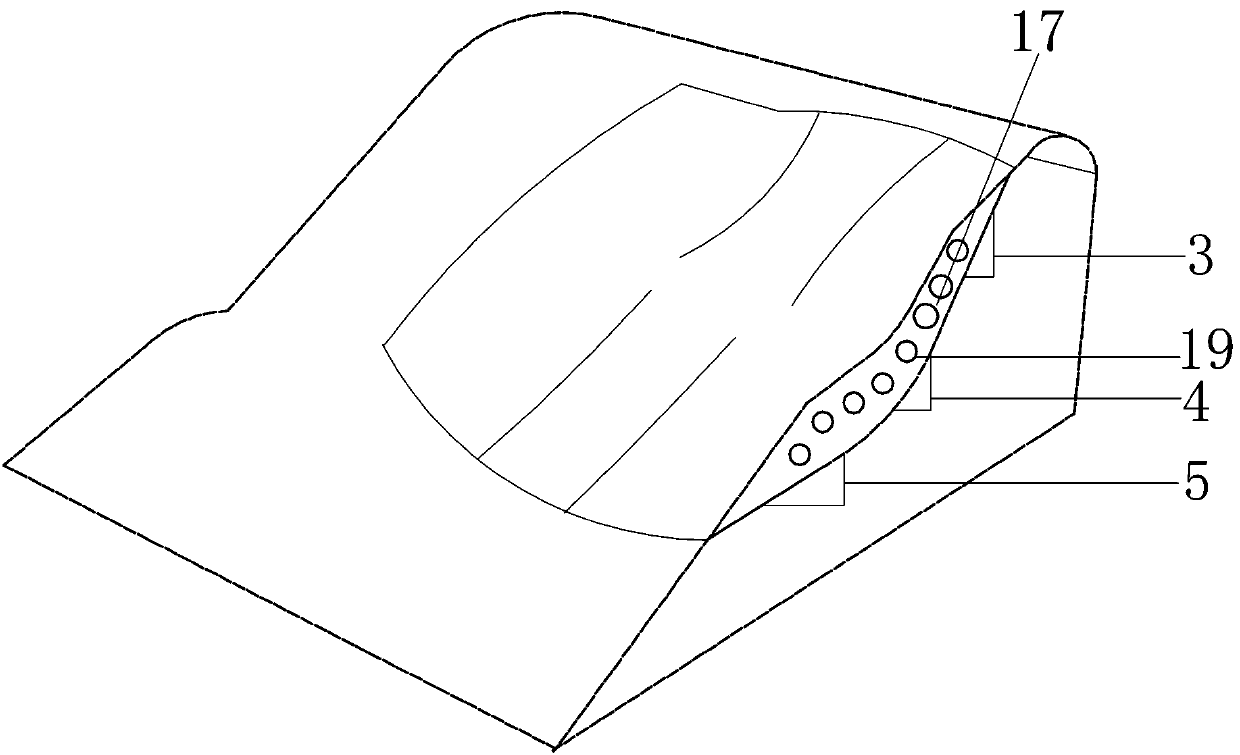

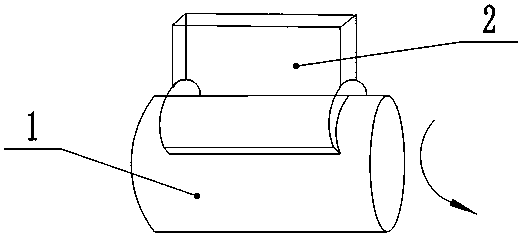

A sealing system, an industrial robot with a sealing system, and a method for providing a sealing surface

InactiveCN103946350AHigh affinityReduce frictionEngine sealsBase-materialsLubricant substanceEngineering

The invention describes asealing system comprising a rotary sealing surface (3) on a rotary shaft (1) and a rotary shaft lip seal (5), of which the rotary sealing surface has a surface coating layer (9) of a solid lubricant substance. The invention further comprises an industrial robot having several axes of rotation, comprising a manipulator with drive units for rotating robot parts according to the axes of rotation of the robot, and at least one of said drive units having a rotary shaft (1) provided with sucha sealing system. In addition, the invention comprises a method for providing a rotary sealing surface (3) on a rotary shaft (1), comprising coating the intended sealing surface of the rotary shaft with a surface coating layer (9) of a solid lubricant substance.

Owner:ABB RES LTD

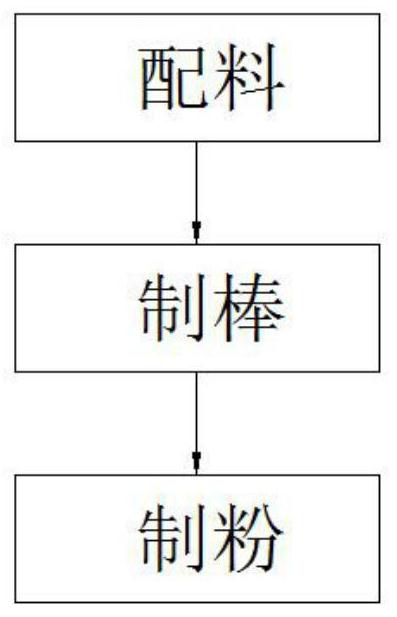

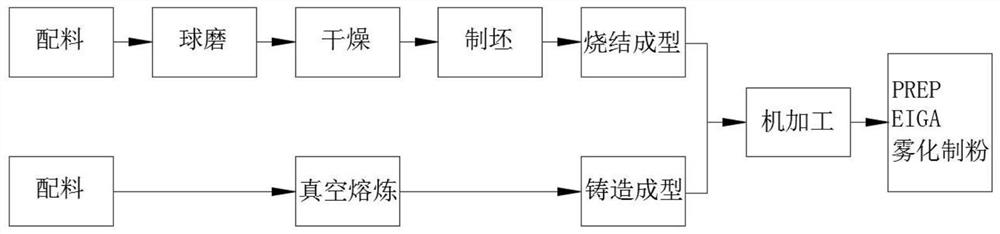

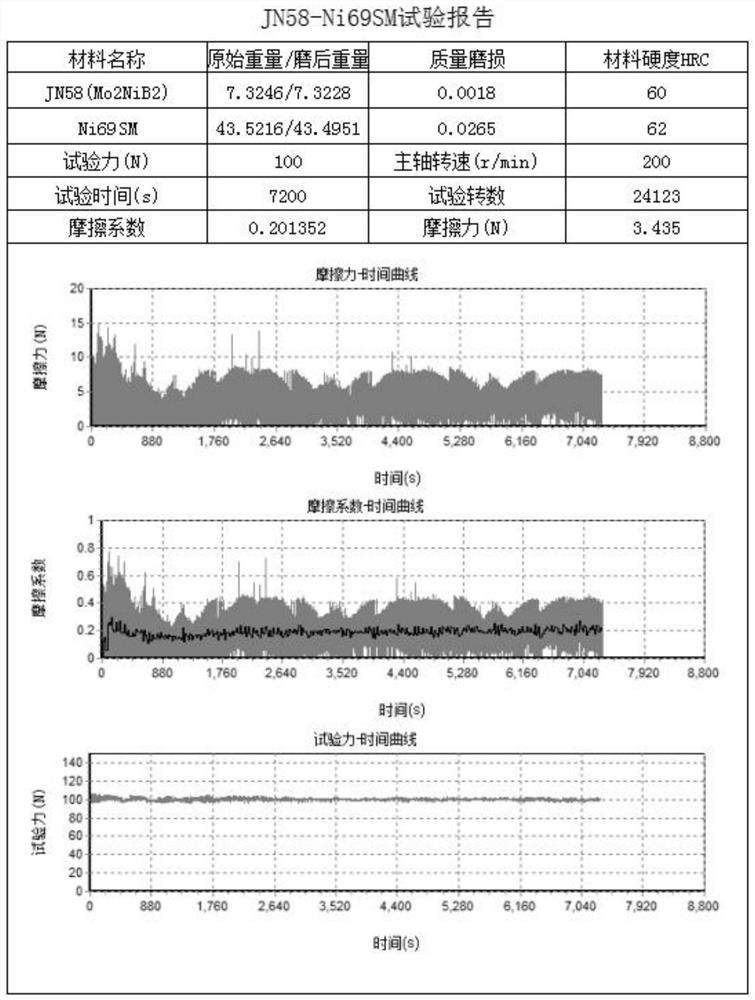

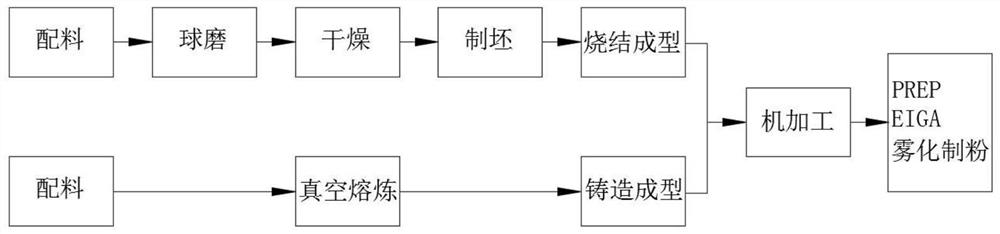

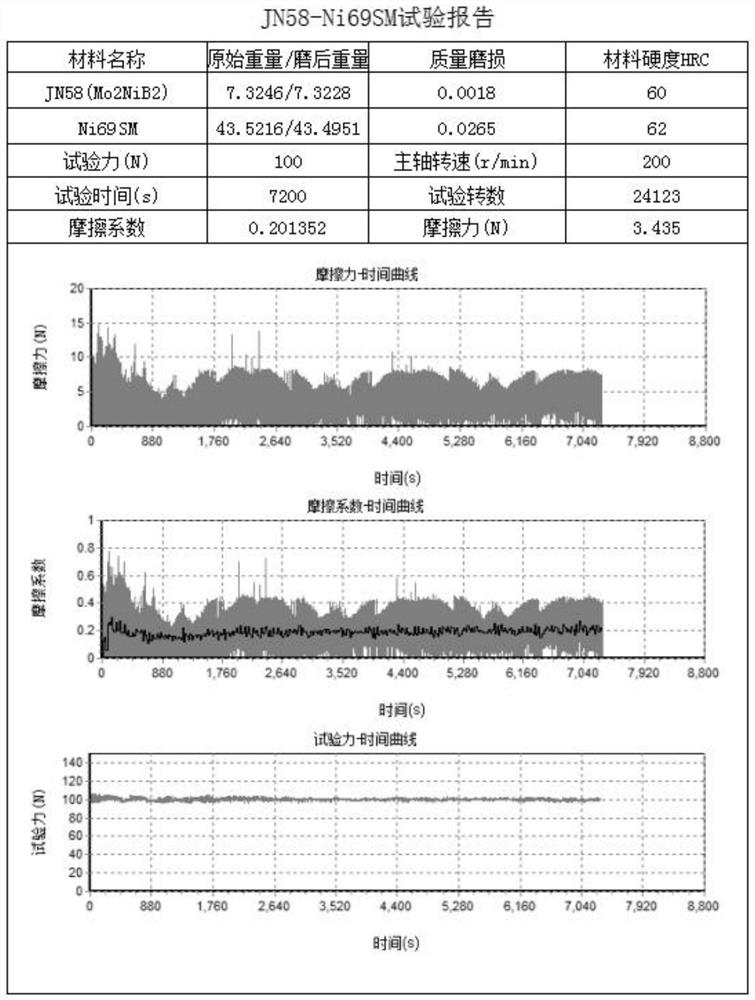

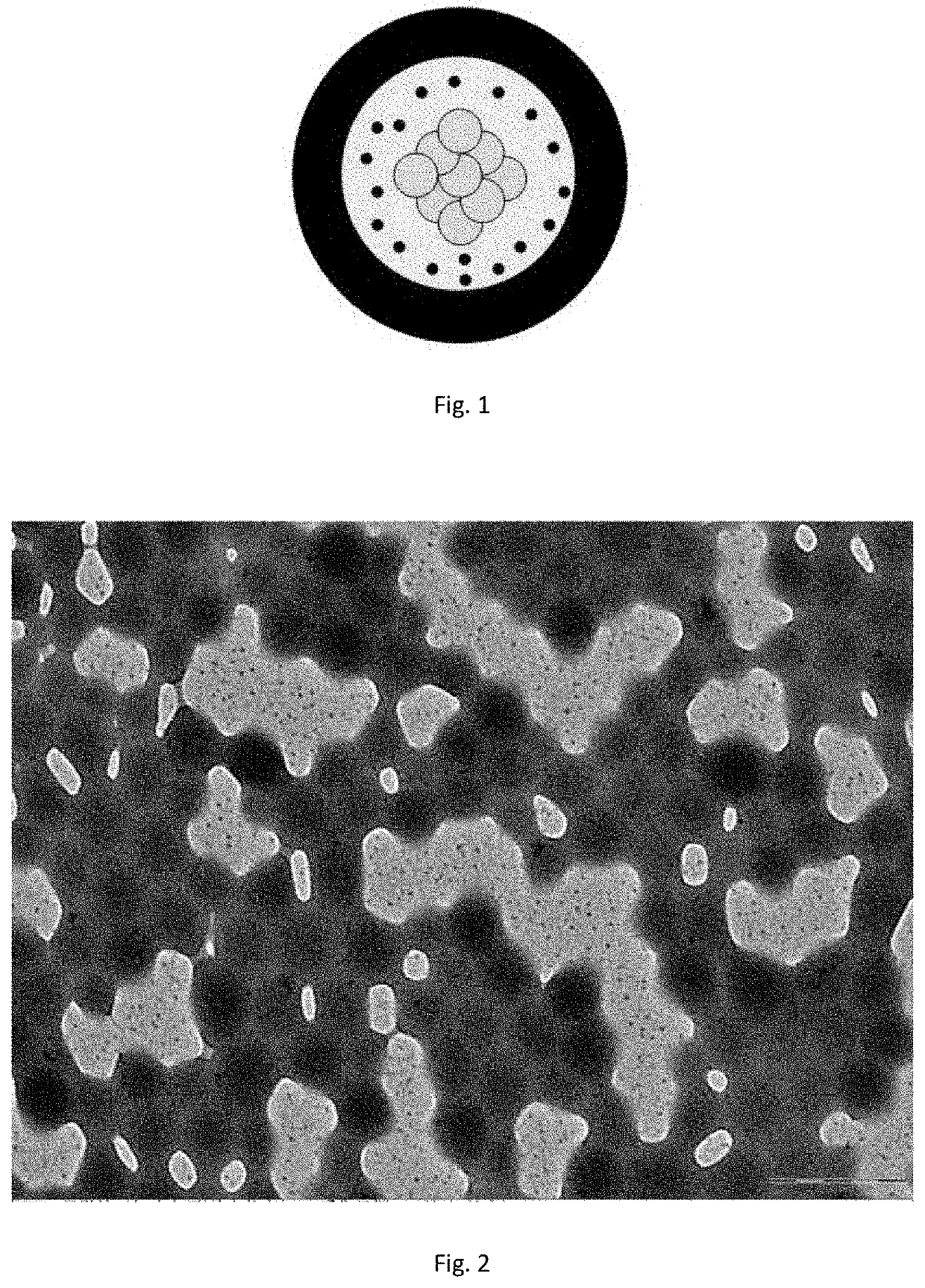

Ternary boride Mo2NiB2 alloy powder for 3D printing and production process of ternary boride Mo2NiB2 alloy powder for 3D printing

The invention discloses ternary boride Mo2NiB2 alloy powder for 3D printing and a production process of the ternary boride Mo2NiB2 alloy powder for the 3D printing. The ternary boride Mo2NiB2 alloy powder comprises the following elements of, in percentage by weight, 3.3%-7% of B, 25%-70% of Mo, 3%-15% of Cr, 0.2%-2% of C, 0.5%-5% of V, 1%-3% of Nb, 0.5%-8% of W, 0.1%-0.8% of Ce, 1%-5% of Mn, 0.1%-1% of Ta, 0.1%-1% of Ti, and the balance Ni. Ternary boride Mo2NiB2 alloy coating products and 3D printing parts with complex structures prepared from the 3D printing ternary boride alloy powder provided by the invention has the advantages of high melting point, high hardness, high wear resistance and high corrosion resistance, self-lubricating substances such as molybdenum dioxide can be generated during friction, the friction coefficient is small, the wear resistance of a material can be greatly improved, the service life is long, the application prospect is wide, and the alloy powder and the process can be applied to various wear-resistant and corrosion-resistant professional fields.

Owner:广东博杰特新材料科技有限公司

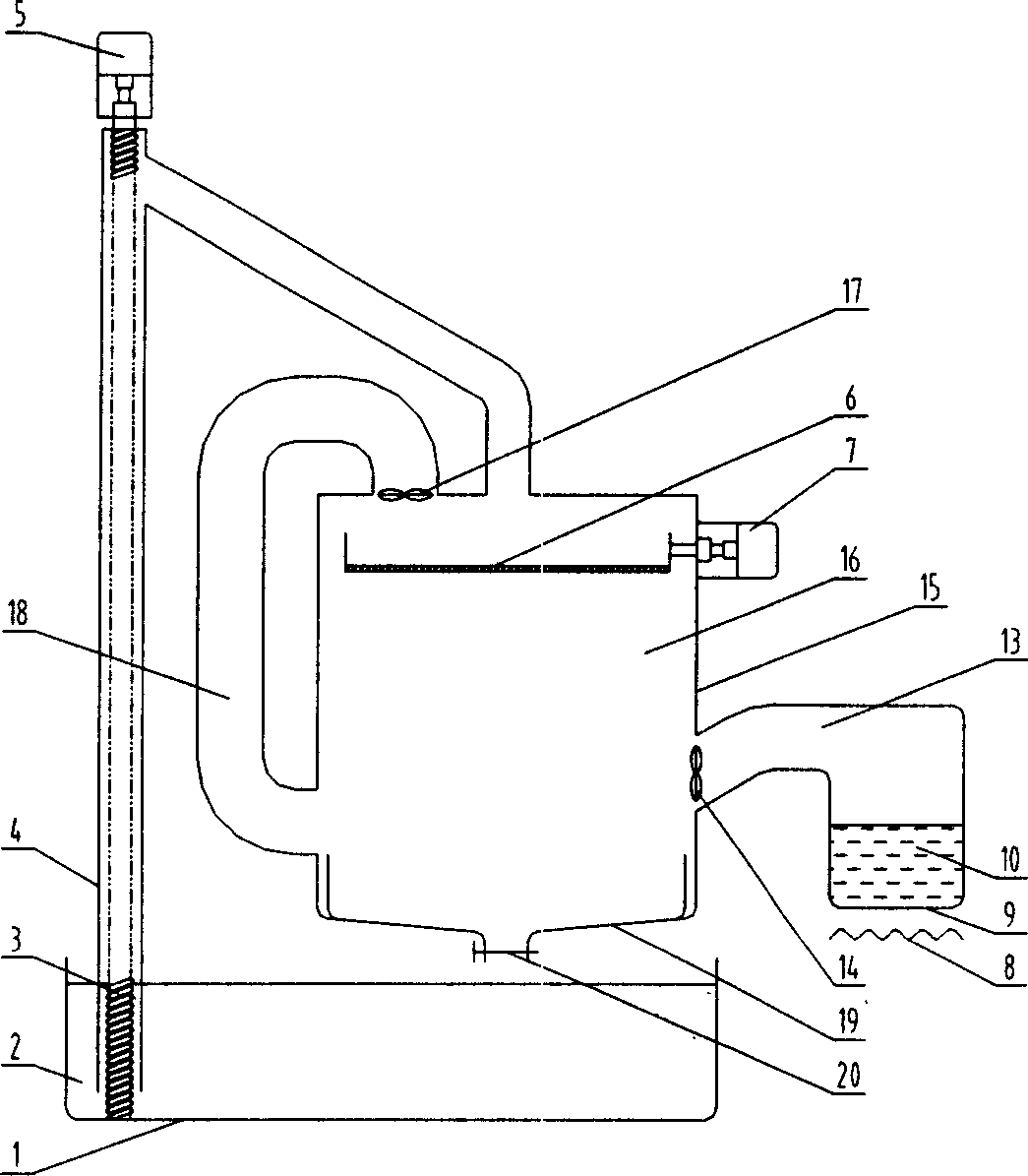

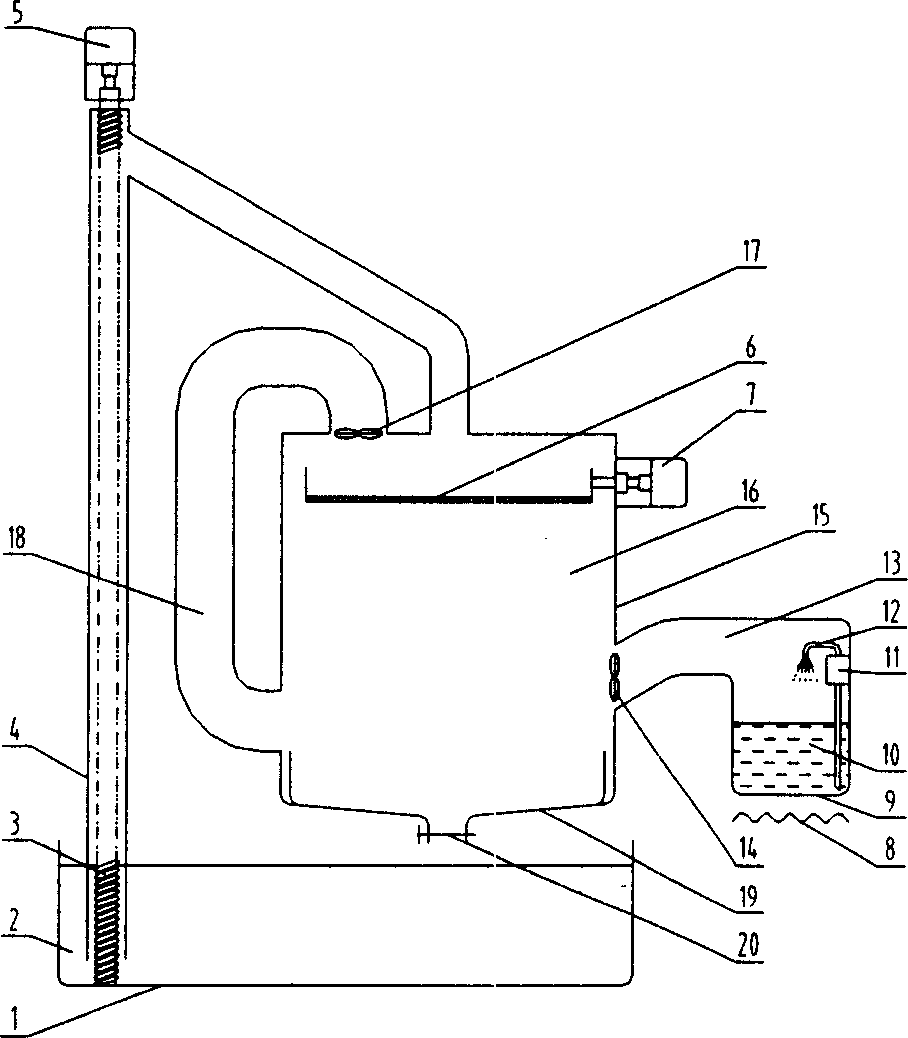

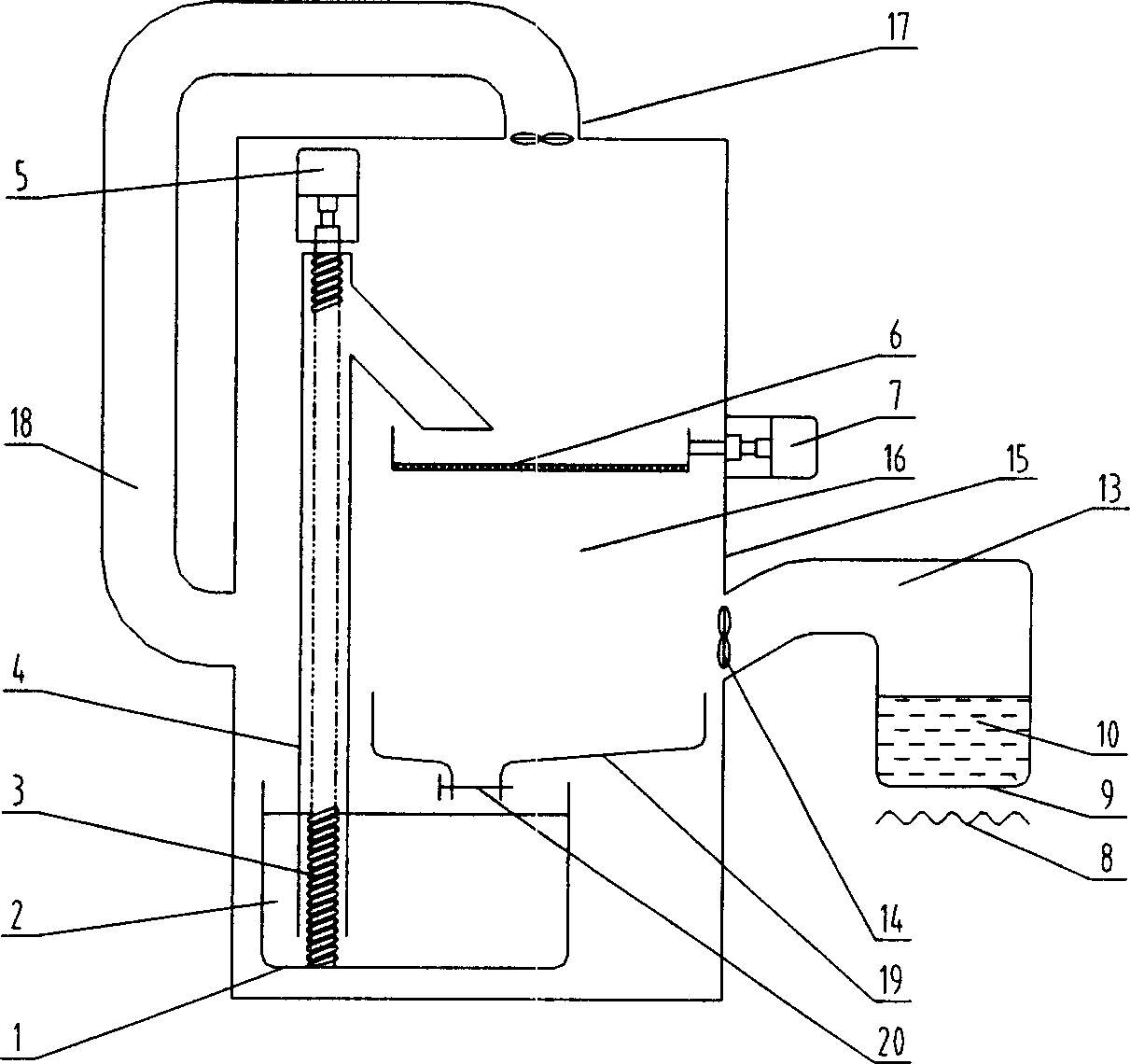

Method for uniform distribution of greasing substance on solid surface, apparatus and application thereof

InactiveCN1603029AEfficient use ofReduce consumptionLiquid surface applicatorsCoatingsHigh volume manufacturingEngineering

The invention supplies a method which is used to make the lubricating substance be uniformly distributed at the surface of the solid. It includes the following steps that firstly the lubricating substance is transformed to the gaseous state by physical mode to form gaseous state lubricating substance environment. Then the surface of the solid which needs to lubricate is set in the environment to make the gaseous state lubricating substance be coagulated at it. An installation which can realize the above method is that it includes powder lifting gearing, operating room, lubricating substance boil-off component. The powder lifting gearing is set in the outside or inner of the operating room; the lubricating substance boil-off component is connected to the under part of the operating room by pipeline. The invention can be used in the lubricating process of the powder solid surface or powder compacting tool set wall. It can form uniform thin lubricating layer at the surface of the solid and control its thickness, effectively utilize the lubricant. Its advantages are that the operation process is simple; the cost is low; it suits to volume produce, and is easy to popularize.

Owner:SOUTH CHINA UNIV OF TECH

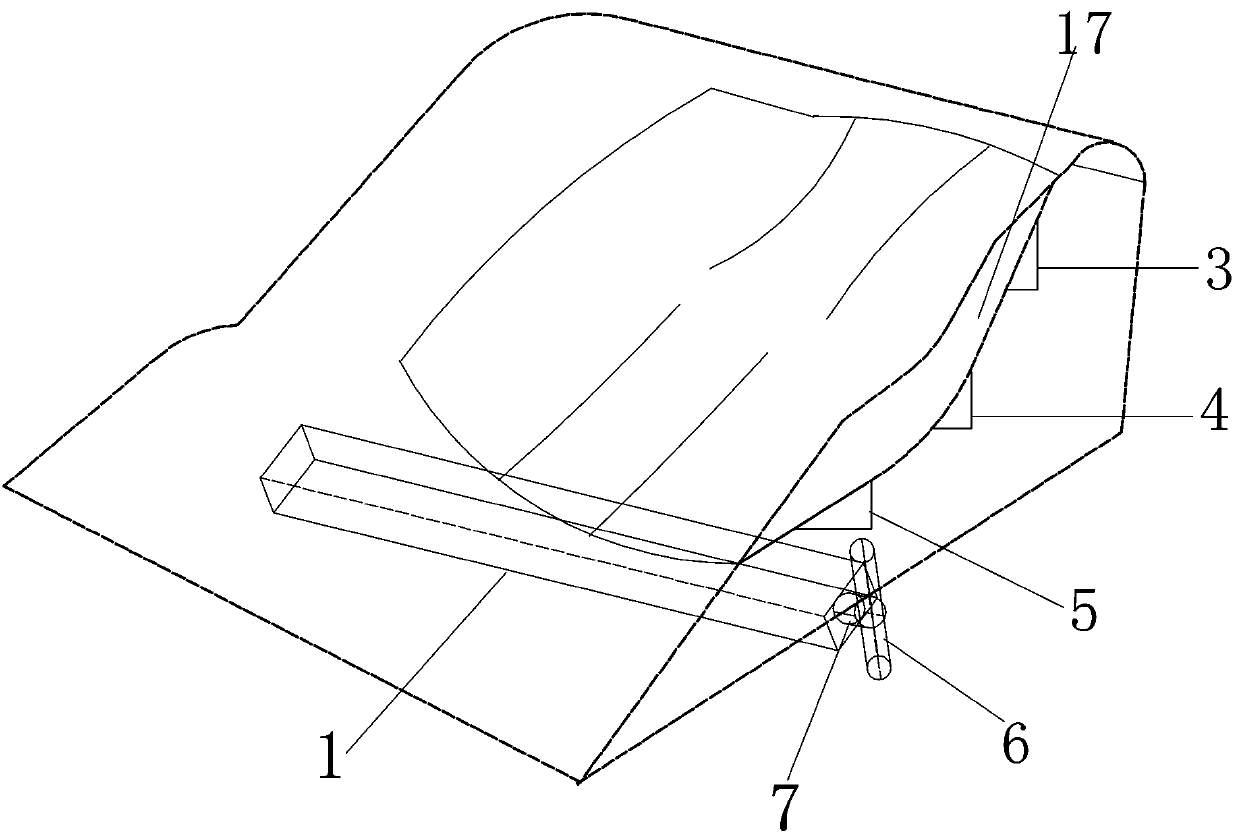

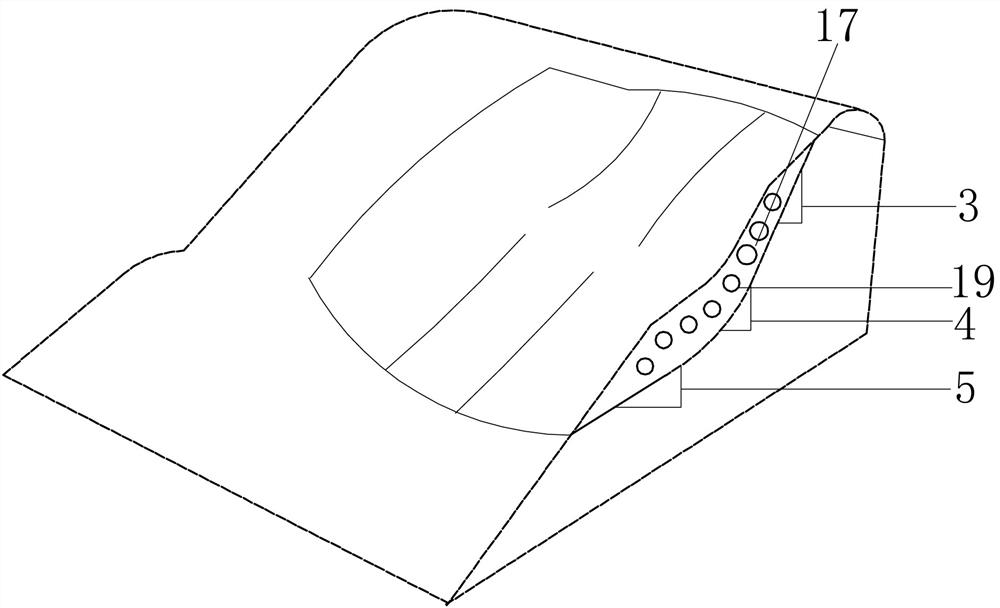

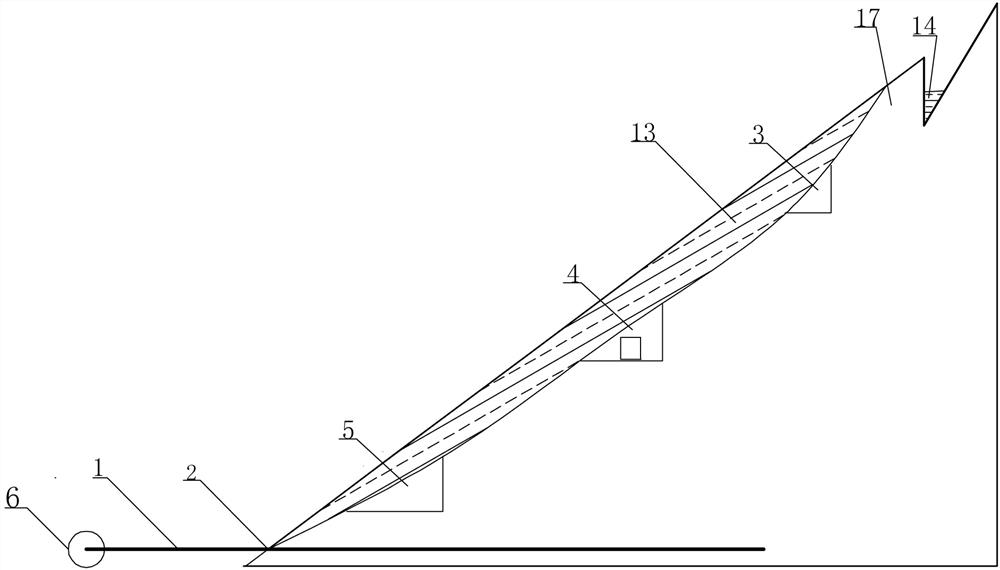

Device and method for actively promoting landslide collapse

ActiveCN111074914AGuarantee the safety of lifeGuarantee property securityBlastingExcavationsLubricant substanceLandslide

The invention provides a device and a method for actively promoting landslide collapse. The method comprises the steps that a loosening agent is sprayed to a to-be-slide mass to loosen the soil texture of the mass, hinges provided with self-expansion bag bodies are placed at the positions of slide blocking keys, and extensible double-layer floral tubes are arranged in the horizontal direction of alandslide belt; each bag body is of a double-layer structure, wherein an expanding agent or gas is placed in the inner layer, and the outer layer is filled with lubricating substances; and repeated expansion is conducted, so that a gap is generated between the to-be-landslide mass and a landslide bed, the pressure in the bag bodies is increased, and the lubricating substances enter the landslidebelt. Meanwhile, magnetic fluid mixed with the lubricating substances is arranged at the position of a backup pull fracture belt, the magnetic fluid is guided in a graded mode to be fully distributedon the landslide belt, and the landslide mass is promoted to slide away from the landslide bed through the combined effect. The problems that manpower and material resources are wasted, and normal operation of traffic transportation and construction operation is affected due to long-term monitoring of the to-be-landslide mass are solved. The device and the method have the advantages that feasibility is high, manpower and material resources are saved, and personnel injuries are reduced.

Owner:CHINA THREE GORGES UNIV

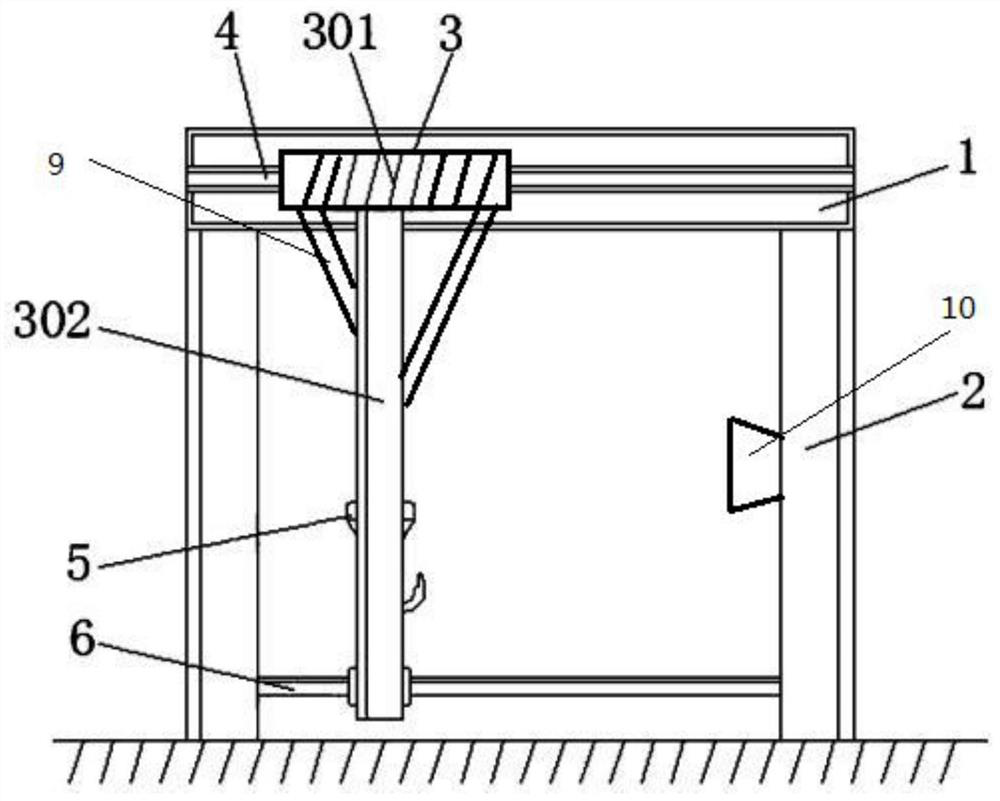

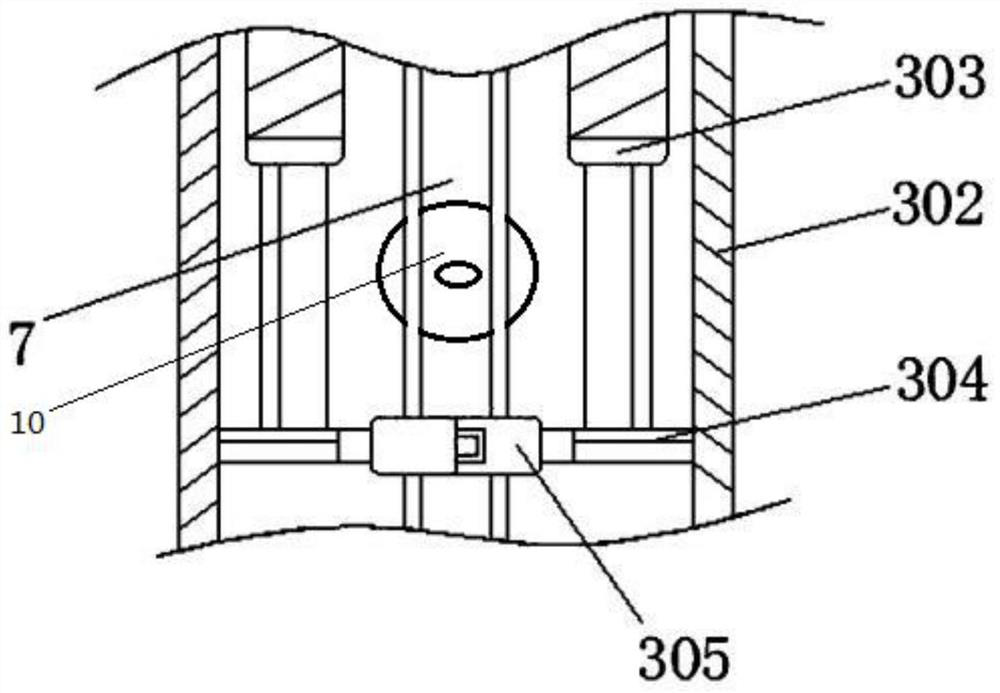

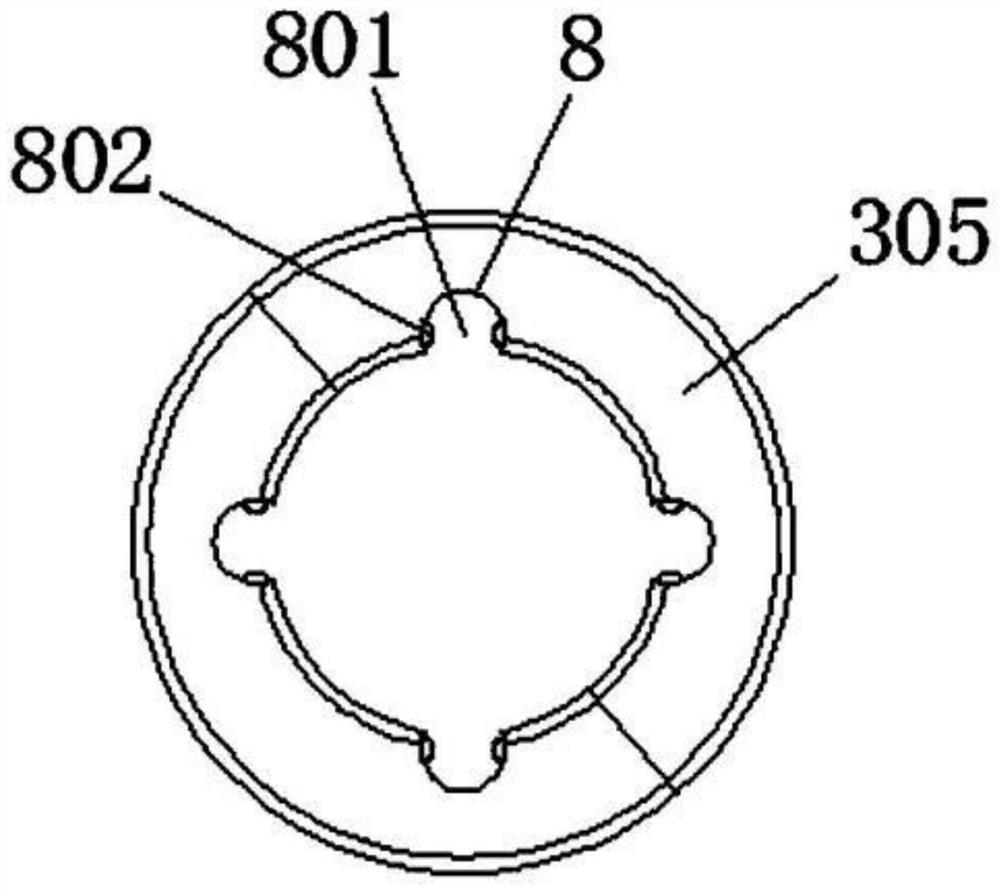

Hoisting machinery safety protection device with lighting effect

InactiveCN114436122AIncreased riskNot easy to looseLoad-engaging elementsLubricant substanceMechanical equipment

The hoisting machinery safety protection device with the lighting effect comprises a hoisting machinery body, supporting rods are arranged on the two sides of the bottom of the hoisting machinery body, a lighting lamp is installed on the surface of the supporting rod on one side, a sliding groove is formed in the front face of the hoisting machinery body, and a protection mechanism is arranged on the outer side of the hoisting machinery body. The protection mechanism is fixedly connected with one end of the reinforcing beam, and the other end of the reinforcing beam is fixedly connected to the outer side face of the connecting rod. When hoisting mechanical equipment conducts hoisting work, through the effect of the protruding blocks which are symmetrical about the central axis of the reserved groove, synchronous fixing operation can be conducted when cylindrical lubricating substances are placed in the reserved groove; the lubricating substances are not prone to loosening, when the steel wire rope is limited by the limiting ring, the friction operation between the lubricating substances and the outer wall of the steel wire rope is facilitated, the lubricating work on the steel wire rope is assisted to be completed, the lighting effect is provided by the lighting lamp, and the stabilizing effect is provided by the reinforcing beam.

Owner:湖北宝鑫桥梁工程有限公司

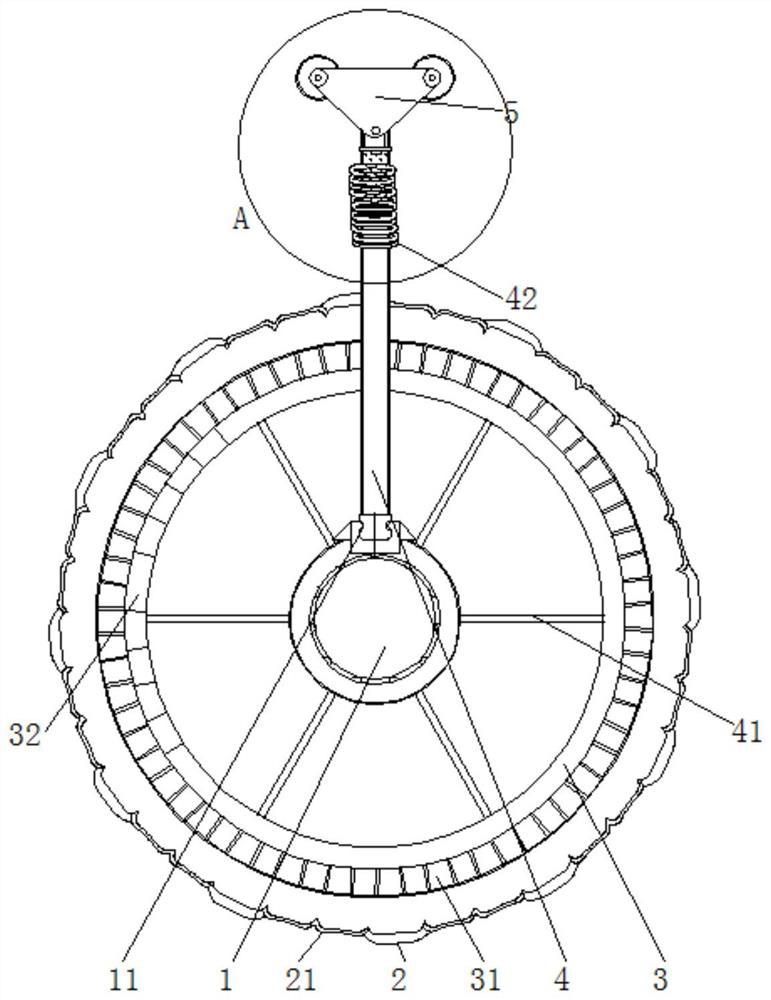

Axle self-lubricating device for balance car

ActiveCN109334842BExtended service lifeGuaranteed lubrication supplyCycle equipmentsAxle unitsLubricant substanceEngineering

The purpose of the self-lubricating device for the axle of the self-balancing car is to solve the problems that the lubricating oil in the existing self-balancing car can easily lead to the imbalance of the balance function during artificial maintenance, the shell with high integrity is difficult to disassemble, there is no independent lubrication system, and the problems of serious friction and wear. Functionalized graphene polymers are installed at the hub module and the linkage block to ensure good lubrication of the friction parts during long-term operation, and use the collision impact force between the balance car and the ground to make the lubricating matter in the oil tank pass through to prevent leakage The head quantity is delivered to the lower bearing, which ensures the lubrication supply of the balance car, and does not need to buy additional lubricating items, so as to achieve the function of self-lubricating inside the balance car, and the lubricating substances are supplied between the moving parts at any time by themselves, and it also avoids due to lubrication. It has an independent and complete self-lubricating system, which also avoids structural damage caused by maintenance and disassembly, and greatly increases the service life of the self-balancing vehicle.

Owner:浙江永美科技股份有限公司

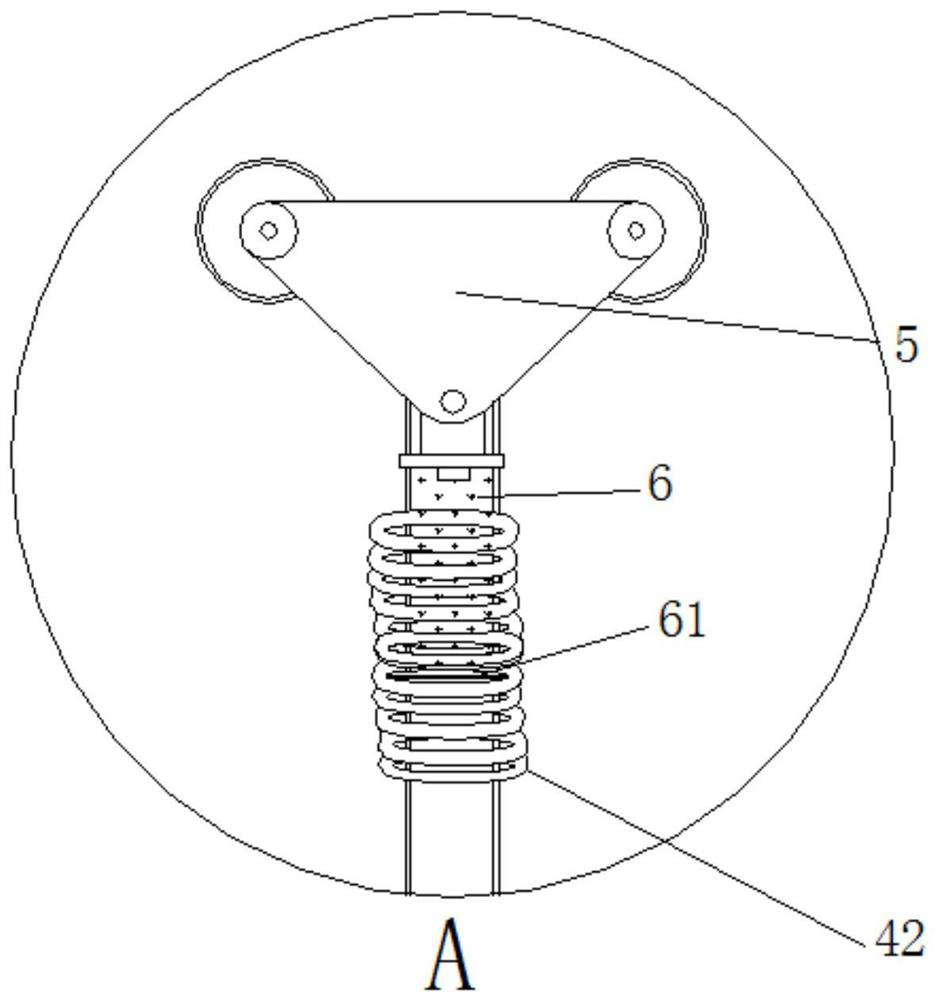

Suspension apparatus of screw conveyer

InactiveCN103101733AAvoid crackingAvoid breaking and crackingPackagingRotational axisLubricant substance

The invention discloses a suspension apparatus of a screw conveyer. The suspension apparatus of the screw conveyer comprises a connecting flange shaft which is used for connecting two rotating shafts and a bearing seat which is arranged on the connecting flange shaft. A bearing is arranged between the connecting flange shaft and the bearing. Each rotating shaft is further provided with two glands. The two glands are respectively arranged on two sides of the bearing seat. A seal component is arranged between each gland and each rotating shaft. The seal component comprises a hair felt ring and an oil seal. The hair felt ring and the oil seal are arranged in sequence from inside to outside. The oil seal is a J-shaped frameless rubber oil seal. The suspension apparatus of the screw conveyer is capable of preventing dust from entering into the bearing seat and preventing lubrication materials in the bearing seat from leaking outwards, guarantees a good lubrication state in the bearing seat, avoids bearing abrasion, fissures producing and breaking, is long in service lift, is free from frequent production halts, overhauling and exchanging and increases production efficiency.

Owner:宋炜赓

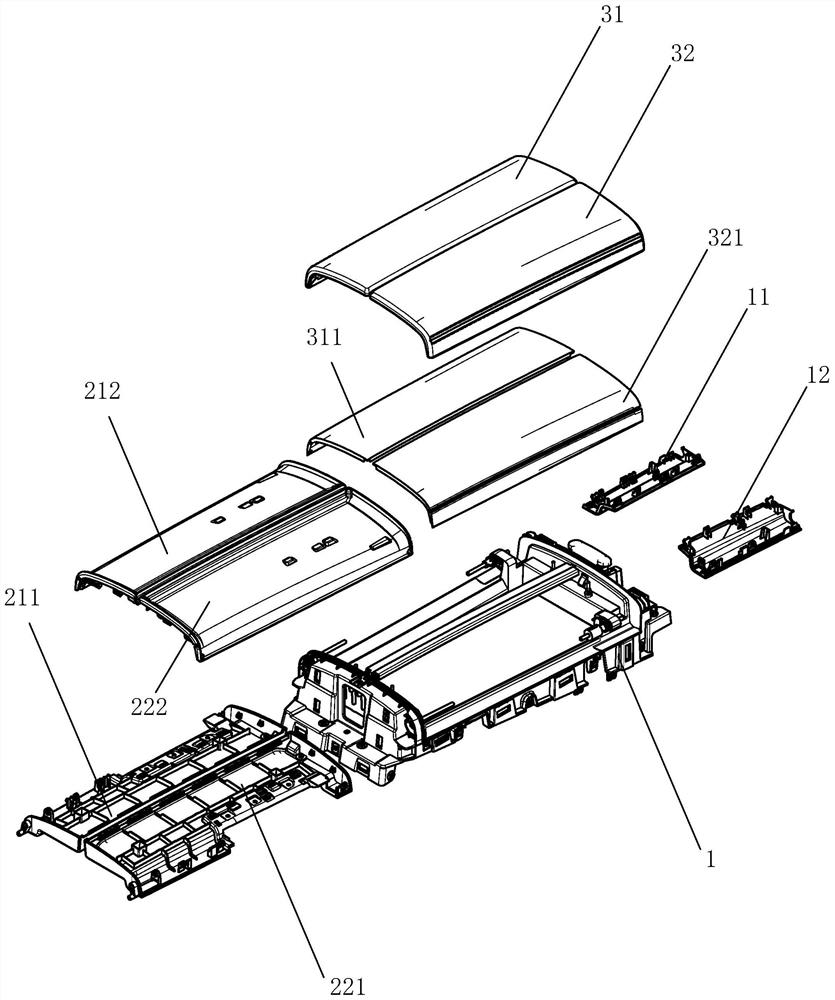

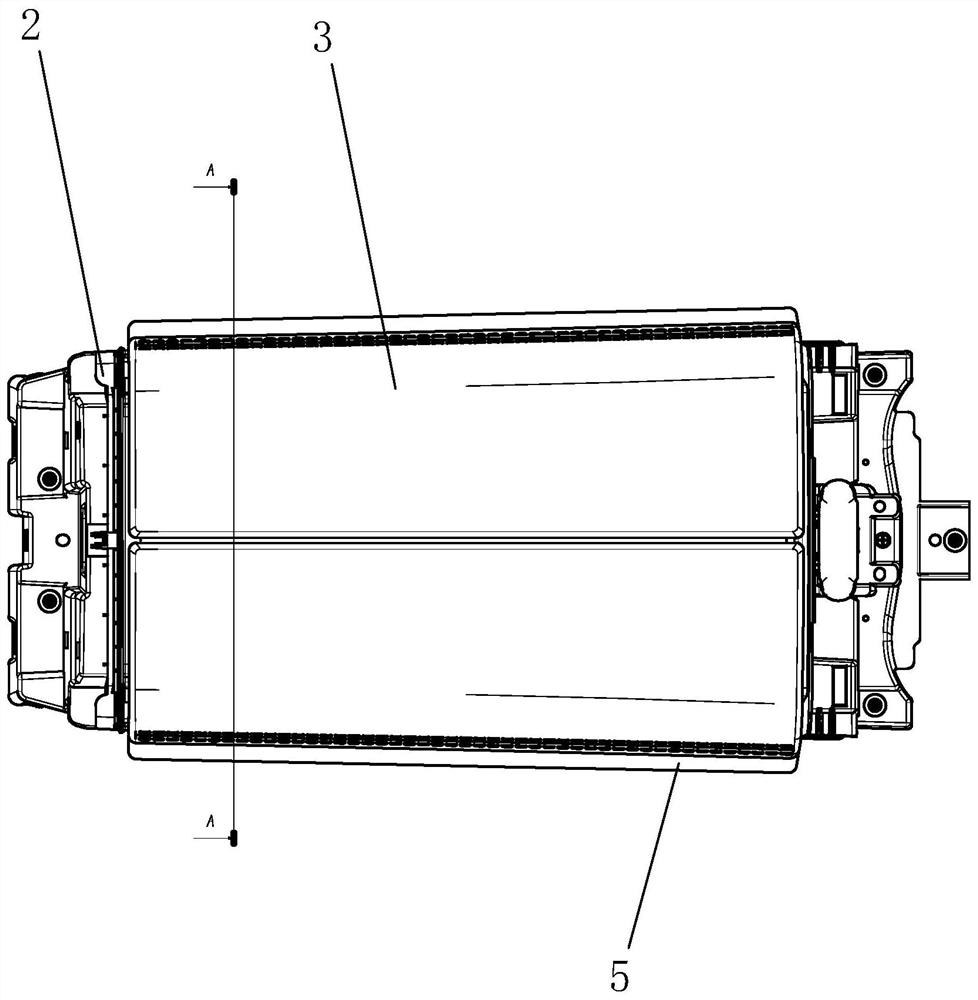

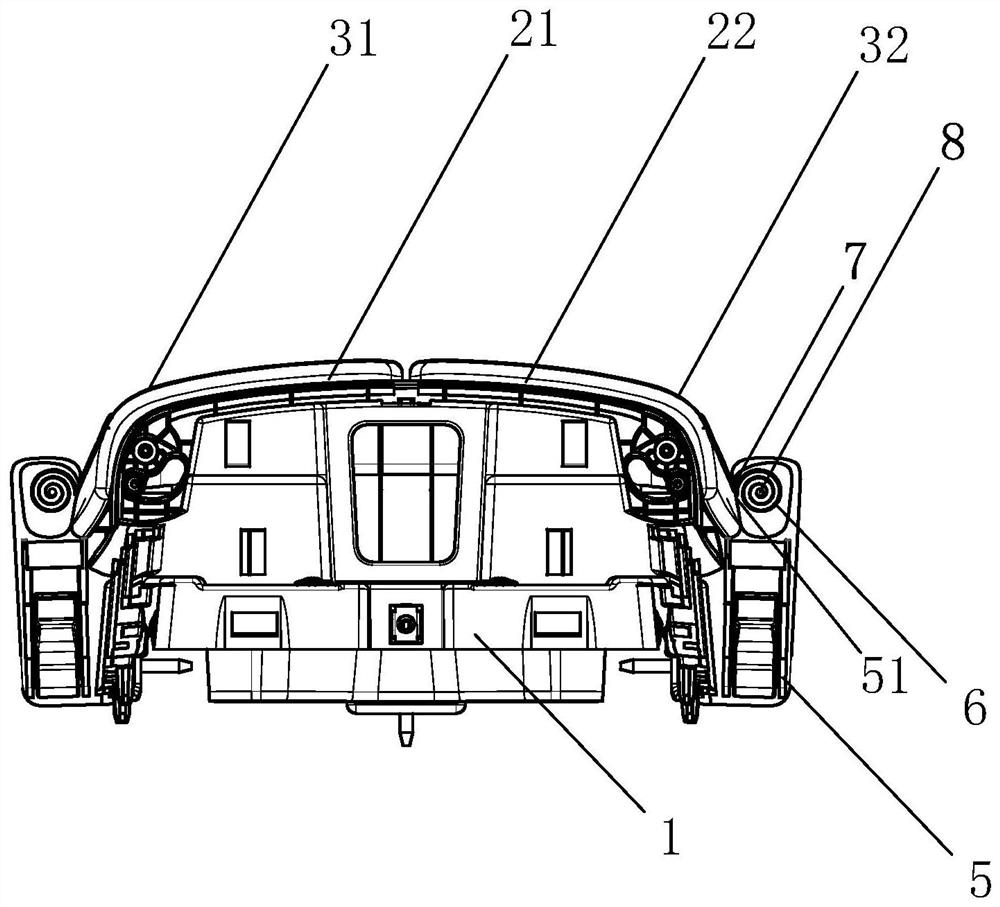

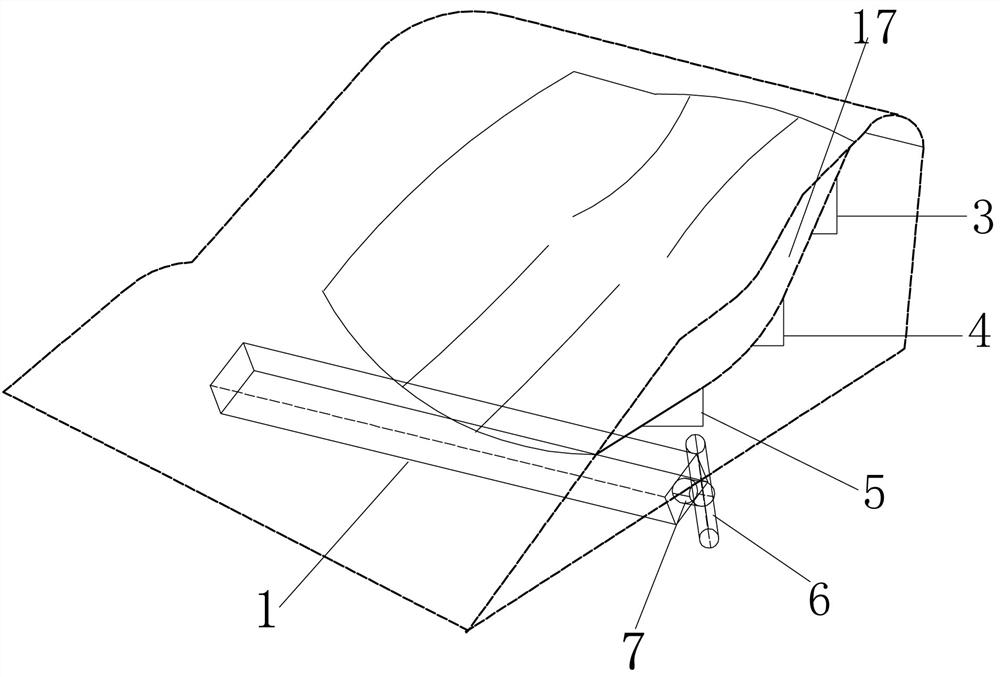

Coated split handrail

ActiveCN113276746AGood lookingGuaranteed purityArm restsSuperstructure subunitsLubricant substanceCosmetic appearance

The invention discloses a coated split handrail which comprises a handrail framework, a split cover plate assembly is arranged on the handrail framework, a skin layer is arranged on the cover plate assembly in a coating mode, containing grooves are formed in the corners of the cover plate assembly, and the corners of the skin layer are arranged in the containing grooves in a clamped mode. Accumulated wrinkles at the corners of the skin are arranged through the containing grooves formed in the corners of the cover plate assembly, the appearance effect of the corners of the skin layer covering the automobile armrest is effectively improved, in the sliding process of a left cover plate and a right cover plate, a skin lubricating part can conduct attached lubrication on the skin layer of the cover plate assembly, the skin layer is in contact with lubricating substances to be maintained and nursed, and the time of wrinkling and loosening of the skin surface is delayed.

Owner:ZHEJIANG LEAPMOTOR TECH CO LTD

A device and method for actively promoting landslide collapse

ActiveCN111074914BGuarantee the safety of lifeGuarantee property securityBlastingExcavationsLubricant substanceLandslide

The invention provides a device and a method for actively promoting landslide collapse. The method comprises the steps that a loosening agent is sprayed to a to-be-slide mass to loosen the soil texture of the mass, hinges provided with self-expansion bag bodies are placed at the positions of slide blocking keys, and extensible double-layer floral tubes are arranged in the horizontal direction of alandslide belt; each bag body is of a double-layer structure, wherein an expanding agent or gas is placed in the inner layer, and the outer layer is filled with lubricating substances; and repeated expansion is conducted, so that a gap is generated between the to-be-landslide mass and a landslide bed, the pressure in the bag bodies is increased, and the lubricating substances enter the landslidebelt. Meanwhile, magnetic fluid mixed with the lubricating substances is arranged at the position of a backup pull fracture belt, the magnetic fluid is guided in a graded mode to be fully distributedon the landslide belt, and the landslide mass is promoted to slide away from the landslide bed through the combined effect. The problems that manpower and material resources are wasted, and normal operation of traffic transportation and construction operation is affected due to long-term monitoring of the to-be-landslide mass are solved. The device and the method have the advantages that feasibility is high, manpower and material resources are saved, and personnel injuries are reduced.

Owner:CHINA THREE GORGES UNIV

Sealing System, An Industrial Robot With A Sealing System, And Method For Providing A Sealing Surface

InactiveUS20140234064A1Environmentally friendlyReduce frictionEngine sealsBase-materialsLubricant substanceEngineering

A sealing system including a rotary sealing surface on a rotary shaft and a rotary shaft lip seal, of which the rotary sealing surface has a surface coating layer of a solid lubricant substance. The invention further includes an industrial robot having several axes of rotation, including a manipulator with drive units for rotating robot parts according to the axes of rotation of the robot, and at least one of the drive units having a rotary shaft provided with such a sealing system. In addition, the invention includes a method for providing a rotary sealing surface on a rotary shaft, including coating the intended sealing surface of the rotary shaft with a surface coating layer of a solid lubricant substance.

Owner:ABB RES LTD

3d printed ternary boride mo 2 nib 2 Alloy powder and its production process

The invention discloses a 3D printing ternary boride Mo 2 NiB 2 Alloy powder and its production process, its element content percentage is: B3.3~7%, Mo25~70%, Cr3~15%, C0.2~2%, V0.5~5%, Nb1~3%, W0.5-8%, Ce0.1-0.8%, Mn1-5%, Ta0.1-1%, Ti0.1-1%, Ni balance. Using the 3D printing ternary boride alloy powder provided by the invention to prepare the ternary boride Mo 2 NiB 2 Alloy-coated products and 3D printed parts with complex structures have the advantages of high melting point, high hardness, high wear resistance and high corrosion resistance, and can produce self-lubricating substances such as molybdenum dioxide during friction, and the friction coefficient is small. The wear resistance of the material can be greatly improved, the service life is long, the application prospect is broad, and it can be applied to various professional fields of wear resistance and corrosion resistance.

Owner:广东博杰特新材料科技有限公司

Fireproof glue solution matrix and preparation method thereof and fireproof glue solution and preparation method thereof

InactiveUS20210002527A1High viscosityOvercome problemsNon-macromolecular adhesive additivesConstructions elementsPolymer scienceLubricant substance

Owner:CHINA BUILDING MATERIALS ACAD

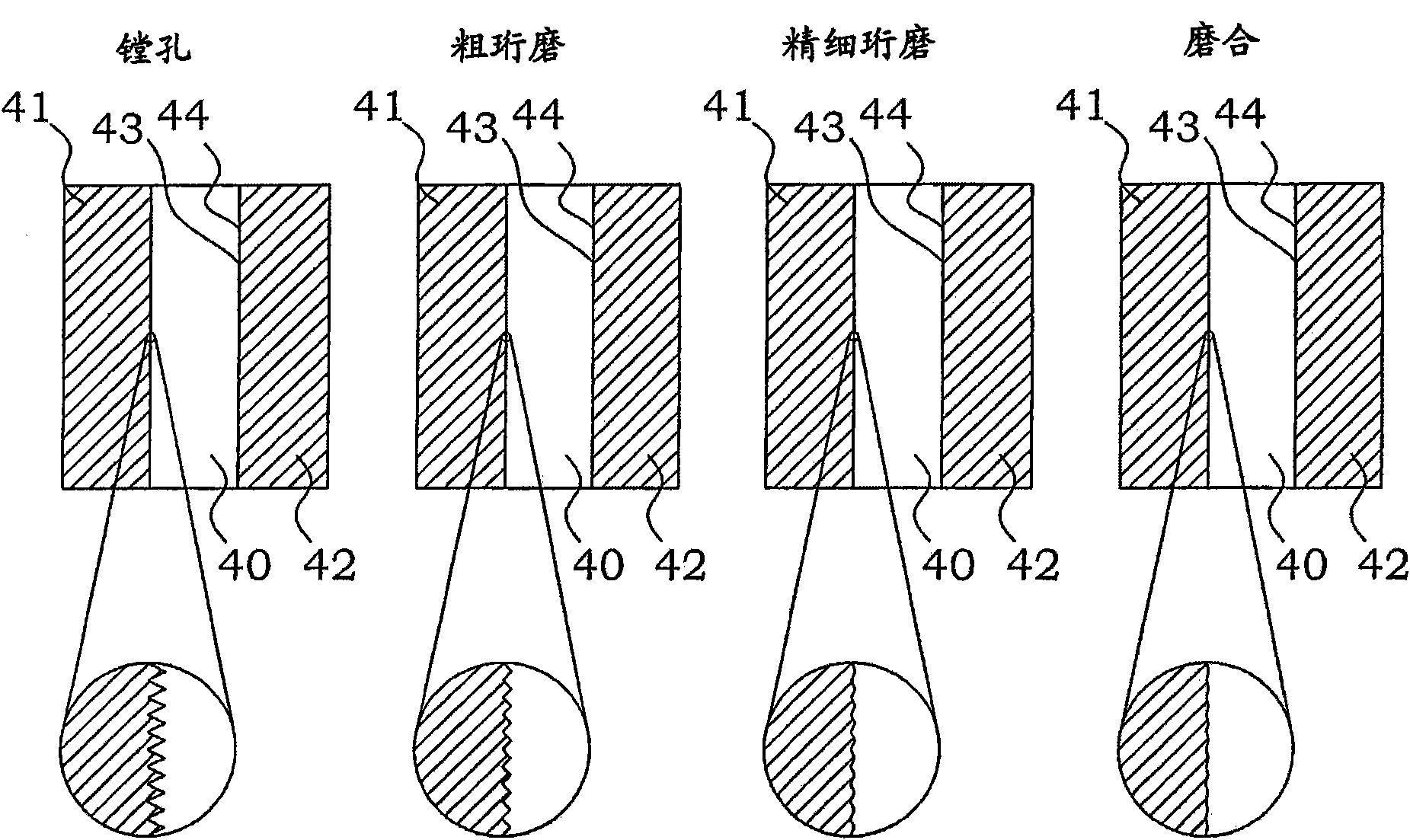

A method for preparing a high-hardness, smooth, corrosion-resistant surface of ferrous metals

ActiveCN110774061BHigh surface hardnessImprove corrosion resistanceSeat surface grinding machinesSurface finishLubricant substance

This patent discloses a method for preparing a high-hardness, smooth, and corrosion-resistant surface of ferrous metals. The metal sample to be treated is made into a friction pair. The material of the pair is the same as that of the metal sample to be processed and the hardness is similar. The initial surface roughness of the two pairs is Ra ≤1.6um, and lubricated by lubricating substances, which are lubricating oil, grease and emulsion containing serpentine, attapulgite, kaolinite, montmorillonite and other minerals, using splash lubrication and forced lubrication. The contact form of the friction pair includes surface-to-surface contact and line-to-surface contact. The friction form includes sliding friction and rolling friction. The cumulative friction movement time is not less than 72 hours. This process method is relatively simple, and one process section can realize "improving surface hardness, The comprehensive goal of "smoothness and corrosion resistance" has a certain promotion value.

Owner:中建材科创新技术研究院(山东)有限公司

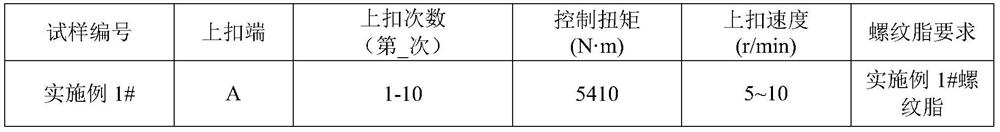

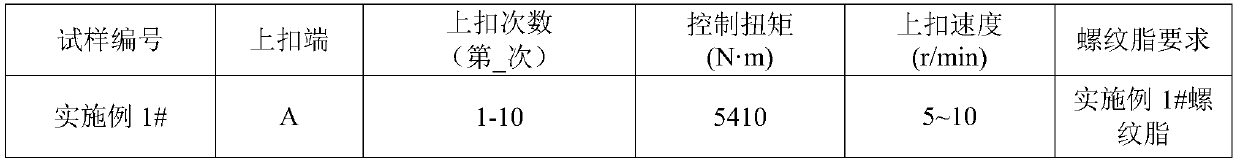

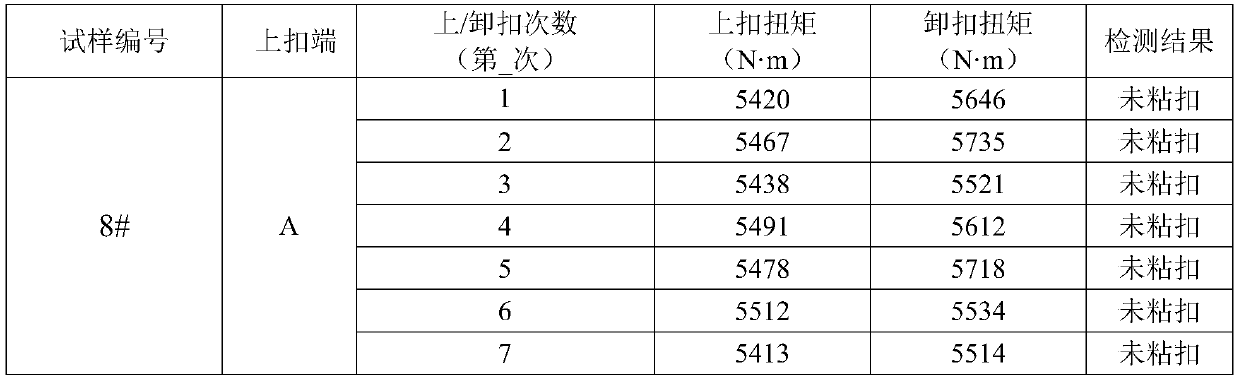

Anti-galling thread grease and method of using the same

ActiveCN111575089BConvenient coatingImprove the lubrication effectNon-macromolecular adhesive additivesEpoxy resin adhesivesVulcanizationLubricant substance

The invention discloses an anti-galling thread grease, which includes component A, component B and component C, and the mass ratio of the three components is A:B:C=(0.8-1.1):(1.6-2.2): (3.6-4.2); in terms of mass percentage, component A includes 30%-50% of polyamide curing agent, 50%-70% of n-hexane; component B includes 47%-60% of epoxy resin, and 5% of nickel powder ~15%, tungsten disulfide powder 30%~40%, silicon nitride 1%~4%, fumed silica 1%~3%; component C includes titanium base grease 30%~50%, microcrystalline graphite 3%~7%, silicon carbide whisker 7%~13%, graphite powder 15%~23%, PTFE powder 13%~18%, nickel titanium alloy 1%~4%, zinc powder 10%~15% %. When using, first apply component B to the thread surface, and then apply component A to the thread surface painted by component B, the two will undergo a chemical curing reaction, forming a layer of lubricating coating on the thread surface. The coating has the advantage of strong surface adhesion, and then a layer of oil-based grease lubricating substance is applied on the surface of the lubricating coating to play the role of the oil-based grease lubricating material to physically block the thread leakage gap and spread it on the thread surface. The advantages.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Preparation method of ferrous metal with high hard, smooth and corrosion-resistant surface

ActiveCN110774061AHigh surface hardnessImprove corrosion resistanceSeat surface grinding machinesLubricant substanceLubrication

The invention discloses a preparation method of ferrous metal with a high hard, smooth and corrosion-resistant surface. The preparation method includes the following steps that a metal sample to be treated is made into friction pairs, materials of the friction pairs are the same as those of the metal sample to be treated and hardness is similar, initial surface smoothness Ra of the two pairs is less than or equal to 1.6[mu]m, lubricating materials are used for lubricating,include lubricating oil, grease, and emulsion which contain serpentine, attapulgite, kaolinite, montmorillonite and other minerals, and methods of splash lubrication and forced lubrication are adopted. Contact forms of the friction pairs include surface-to-surface contact and line-to-surface contact, friction forms include sliding friction and rolling friction, accumulated friction movement time is not less than 72 hours, the process method is relatively simple, and one process section can achieve a comprehensive goalof "improving the surface hardness, smoothness and corrosion resistance", and has a certain promotion value.

Owner:中建材科创新技术研究院(山东)有限公司

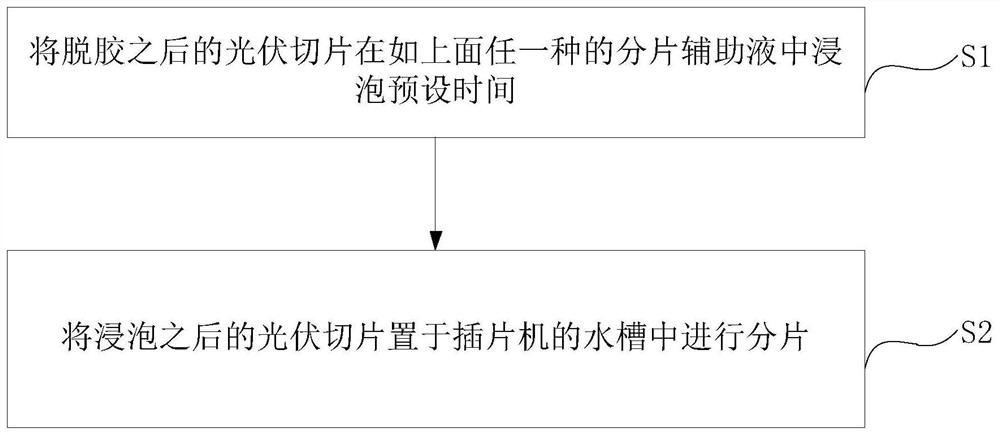

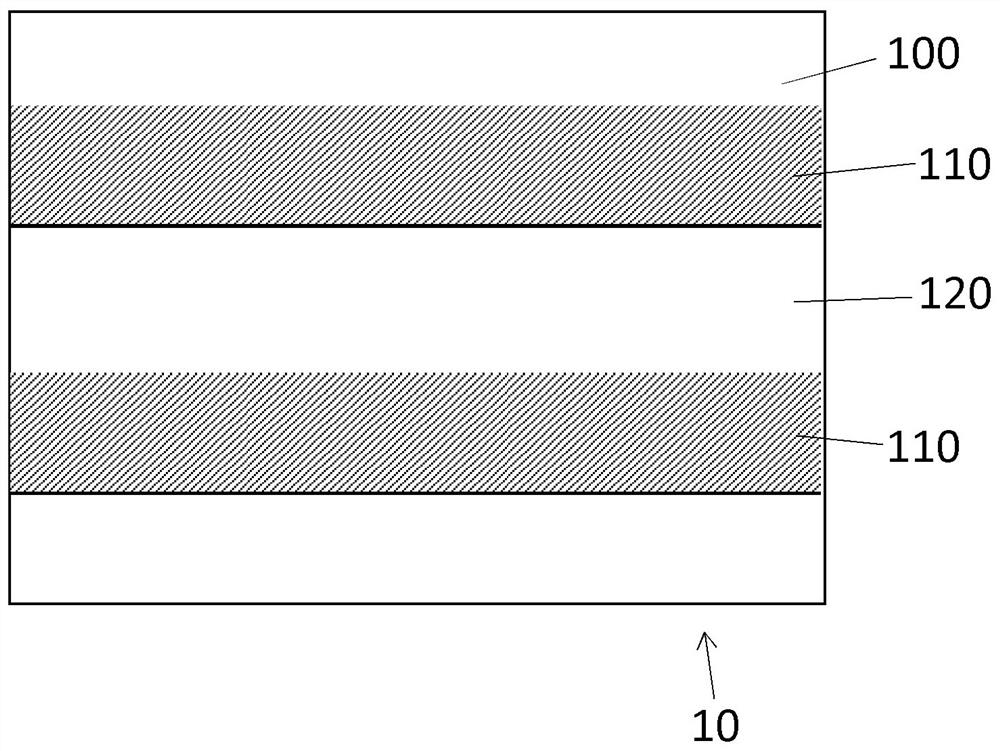

Slicing auxiliary liquid and slicing method for photovoltaic slices

ActiveCN109262869BIncrease buoyancyImprove separabilityFine working devicesLubricant substanceMaterials science

The invention discloses photovoltaic slice separation auxiliary liquid which comprises bubble formation substances and surface lubrication substances. The bubble formation substances are dissolved inwater, the weight ratio of the bubble formation substances ranges from 2% to 15%, the weight ratio of the surface lubrication substances ranges from 0.1% to 2%, the bubble formation substances are attached to the surfaces of photovoltaic slices and decompose bubbles, the surface lubrication substances are used for fixing the bubbles decomposed by the bubble formation substances to the surfaces ofthe photovoltaic slices to form lubrication films containing gas, the buoyancy force of the photovoltaic slices in water can be improved, the separable characteristic of the photovoltaic slices can beimproved, the proportion of slice adhesion and slice connection is decreased, running smoothness of a slice inserter is improved, and the probability of slice breakage and edge damage is reduced. Theinvention further discloses a photovoltaic slice separation method which includes the steps: soaking the degummed photovoltaic slices in the separation auxiliary liquid for preset time; placing the soaked photovoltaic slices into a water tank of the slice inserter and separating the slices.

Owner:JINKO SOLAR CO LTD +1

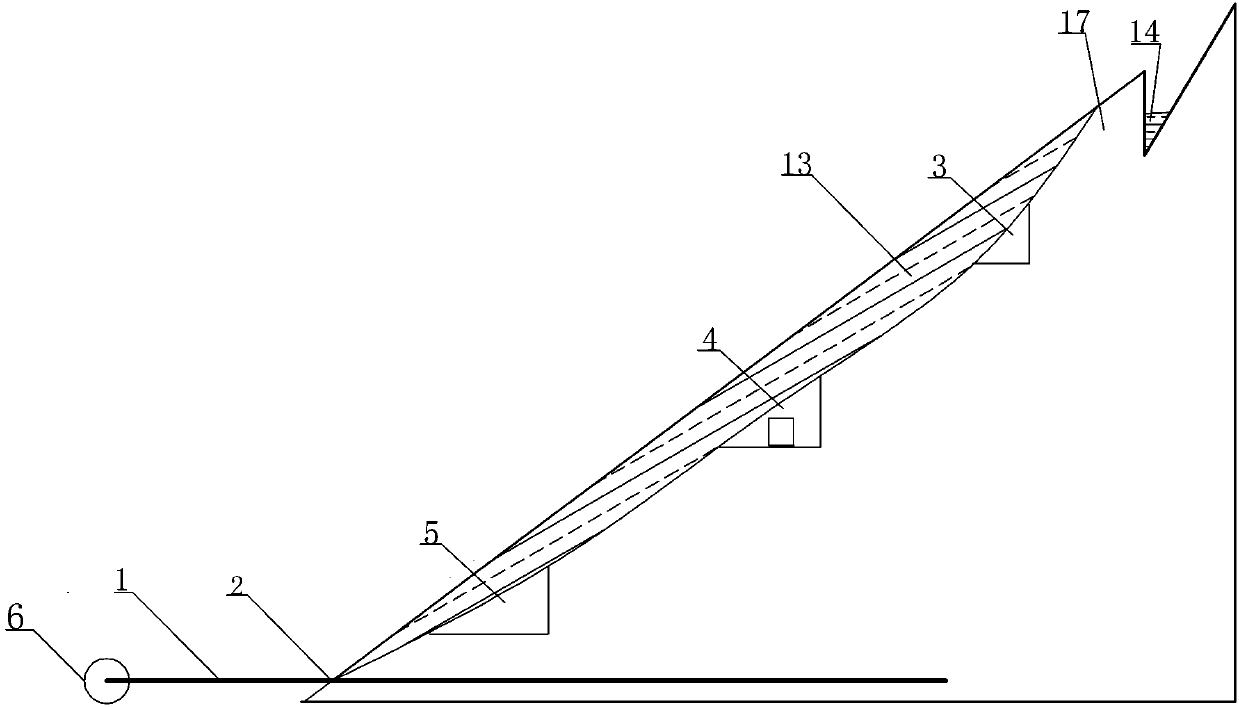

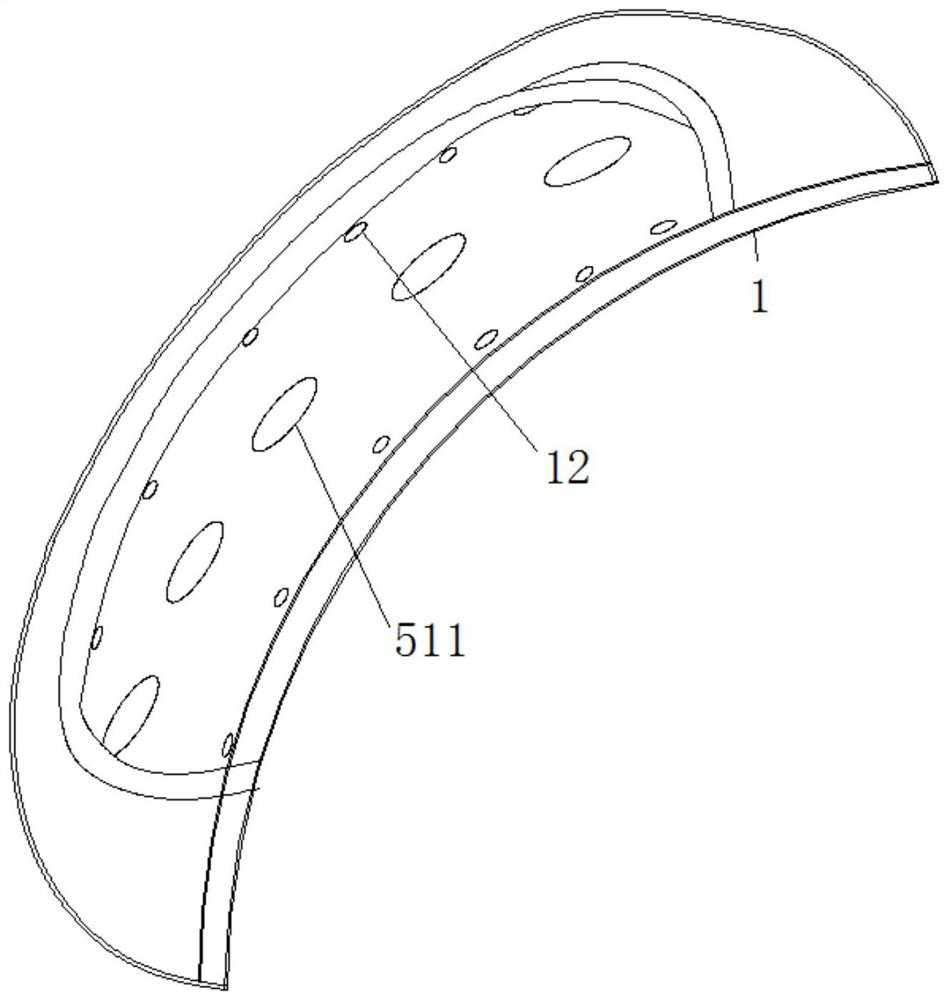

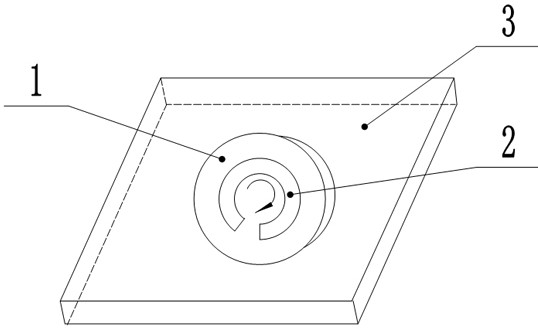

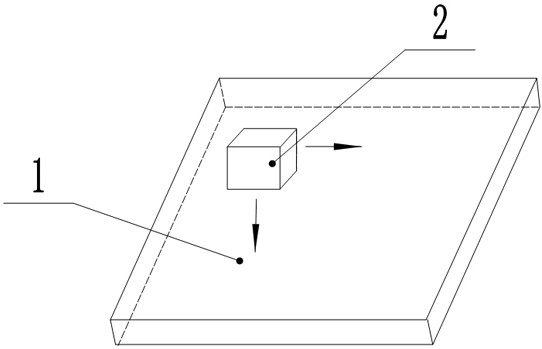

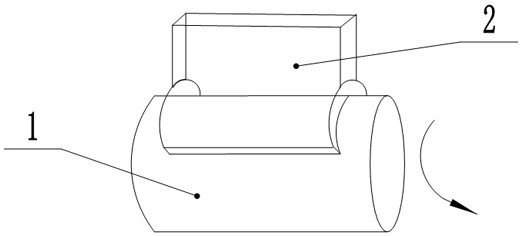

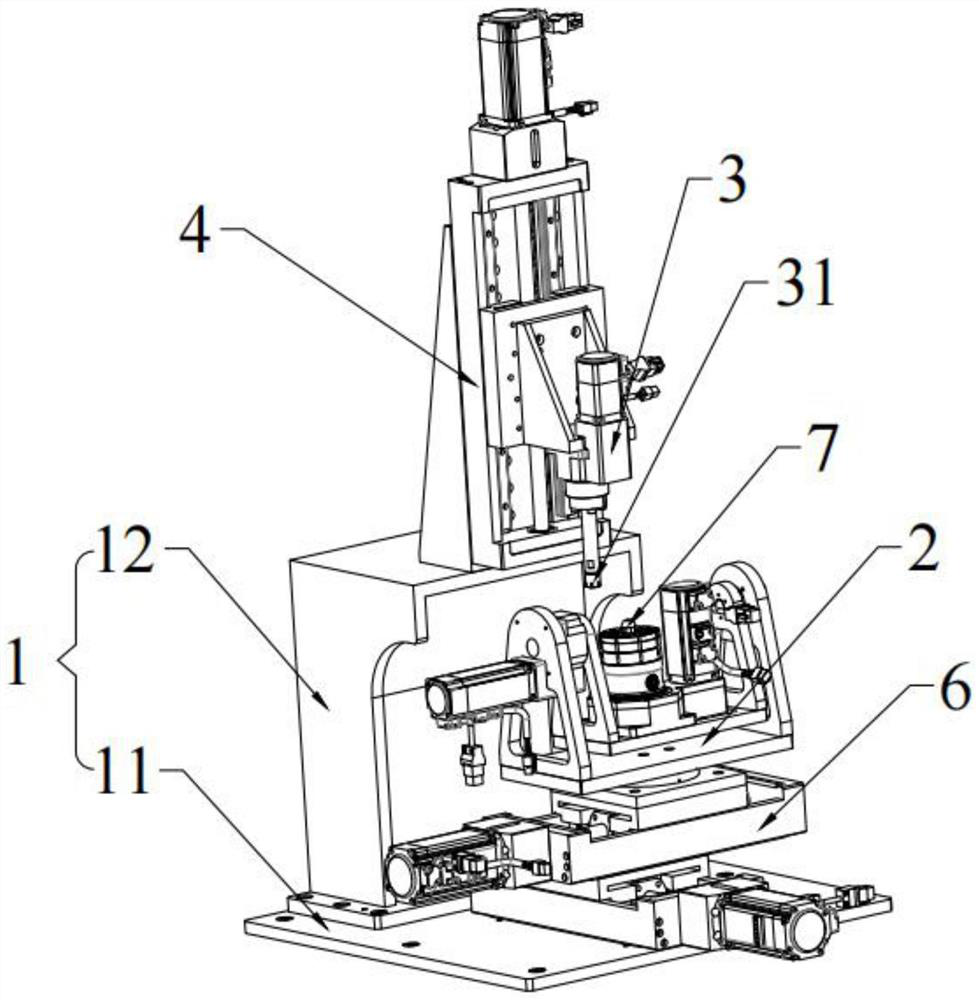

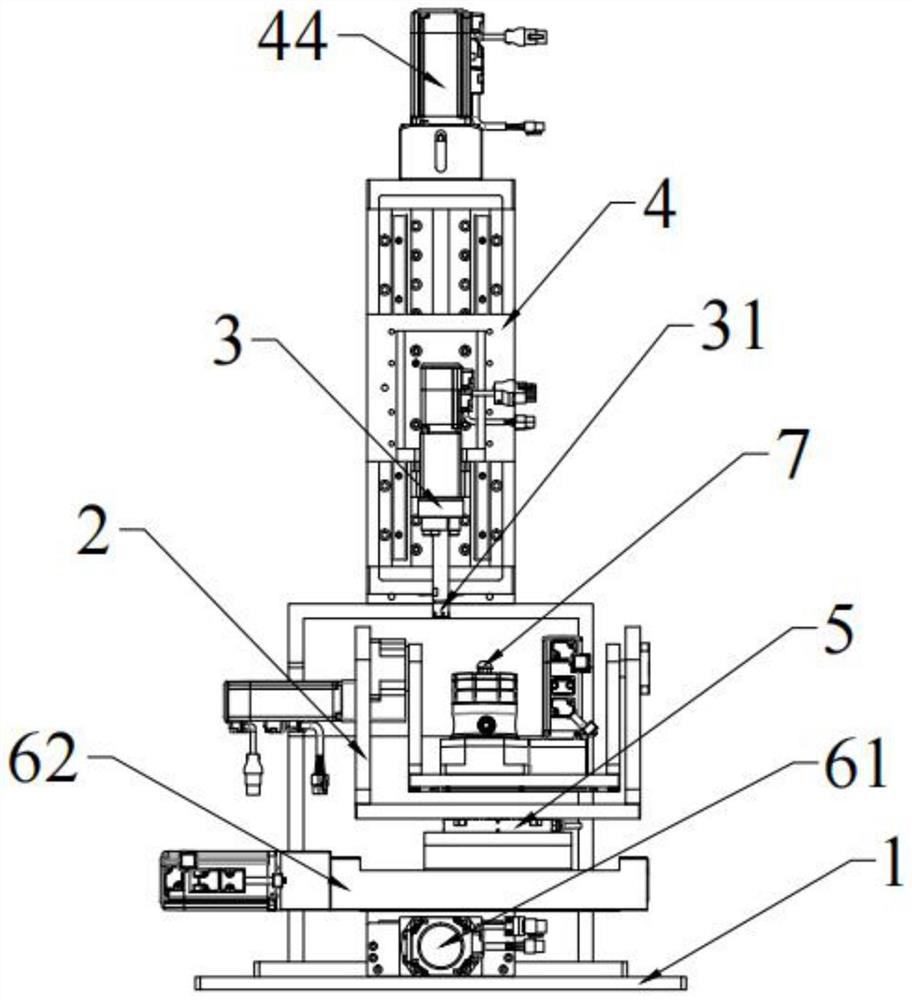

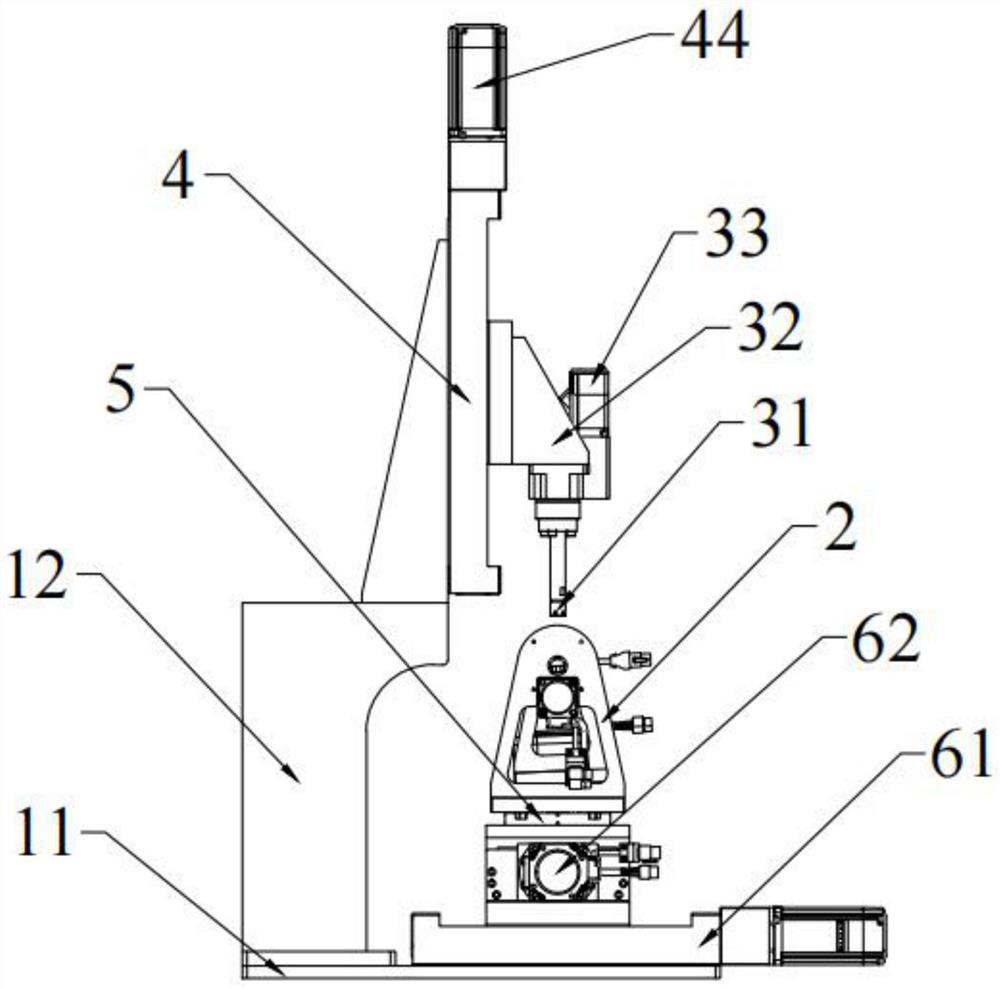

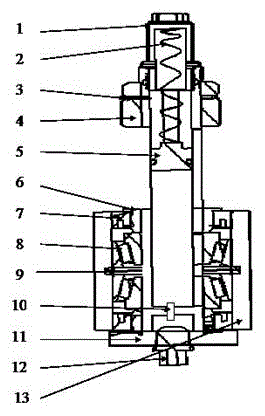

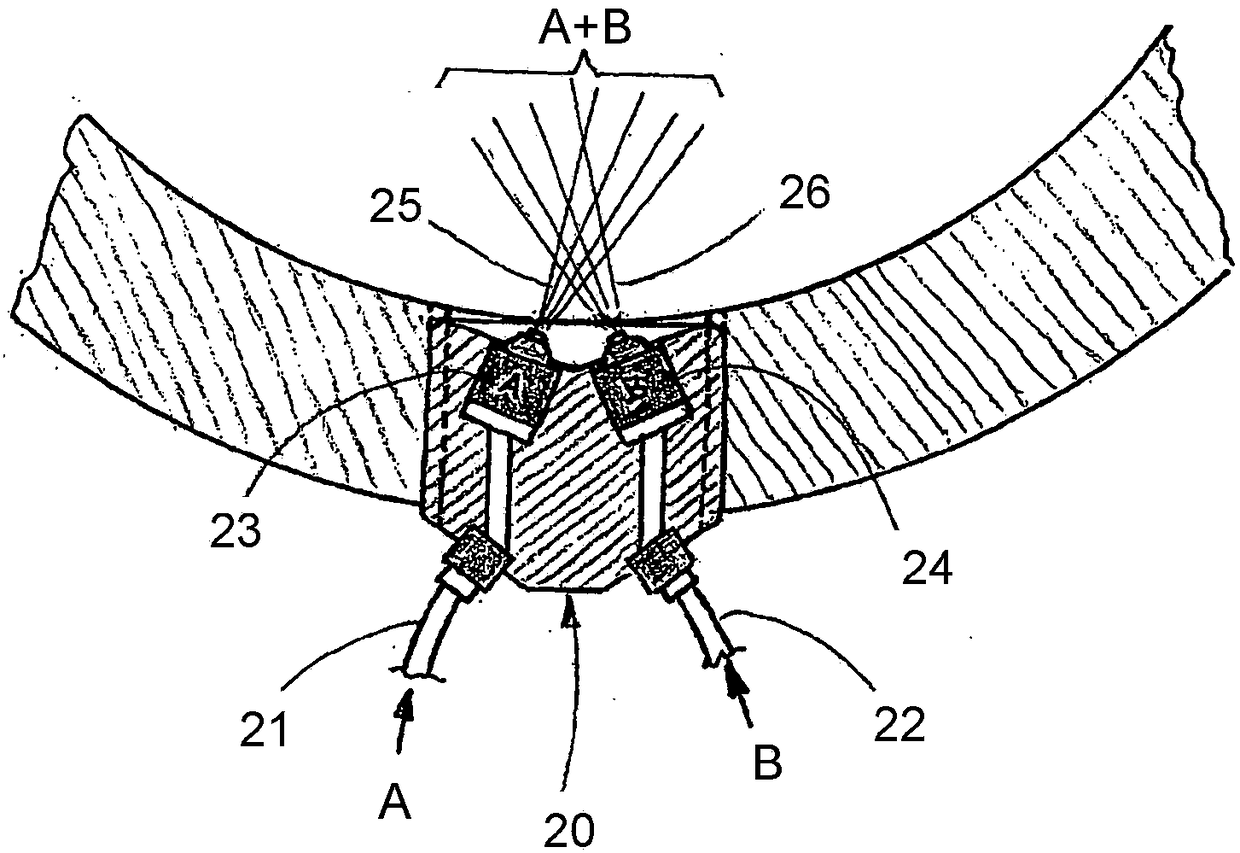

Spherical bearing boundary lubricating layer coating system

ActiveCN114733697AFully rubbedSmear all overLiquid surface applicatorsCoatingsLubricant substanceSpherical bearing

The invention provides a spherical bearing boundary lubricating layer smearing system. The system comprises a rack; a driving mechanism; the driving mechanism is mounted on the rack; the spherical bearing is mounted on the driving mechanism; the driving mechanism is used for driving the spherical bearing to swing around a first axis direction and is also used for driving the spherical bearing to rotate around a second axis direction; the second axis direction is perpendicular to the first axis direction; the second axis direction is the axis direction of the spherical bearing; an applying mechanism; the smearing mechanism is mounted on the rack and is positioned above the driving mechanism; the inunction mechanism comprises an inunction head; and the smearing head is used for smearing lubricating substances on the surface of the spherical bearing. According to the automatic inunction system, an automatic inunction mode is adopted, the inunction process is not affected by human factors, the inunction system can conduct sufficient and comprehensive inunction on the spherical bearing, the phenomenon that inunction cannot be conducted comprehensively due to local inunction missing is avoided, and the quality of spherical bearing products is guaranteed advantageously.

Owner:NORTH CHINA INST OF AEROSPACE ENG +1

Wear-resistant material with thermal response and self-lubricating properties and preparation method thereof

Owner:WUHAN TEXTILE UNIV

Micromechanical component for containing a lubricant substance

Owner:ASSOC SUISSE POUR LA RECH HORLOGERE ASRH

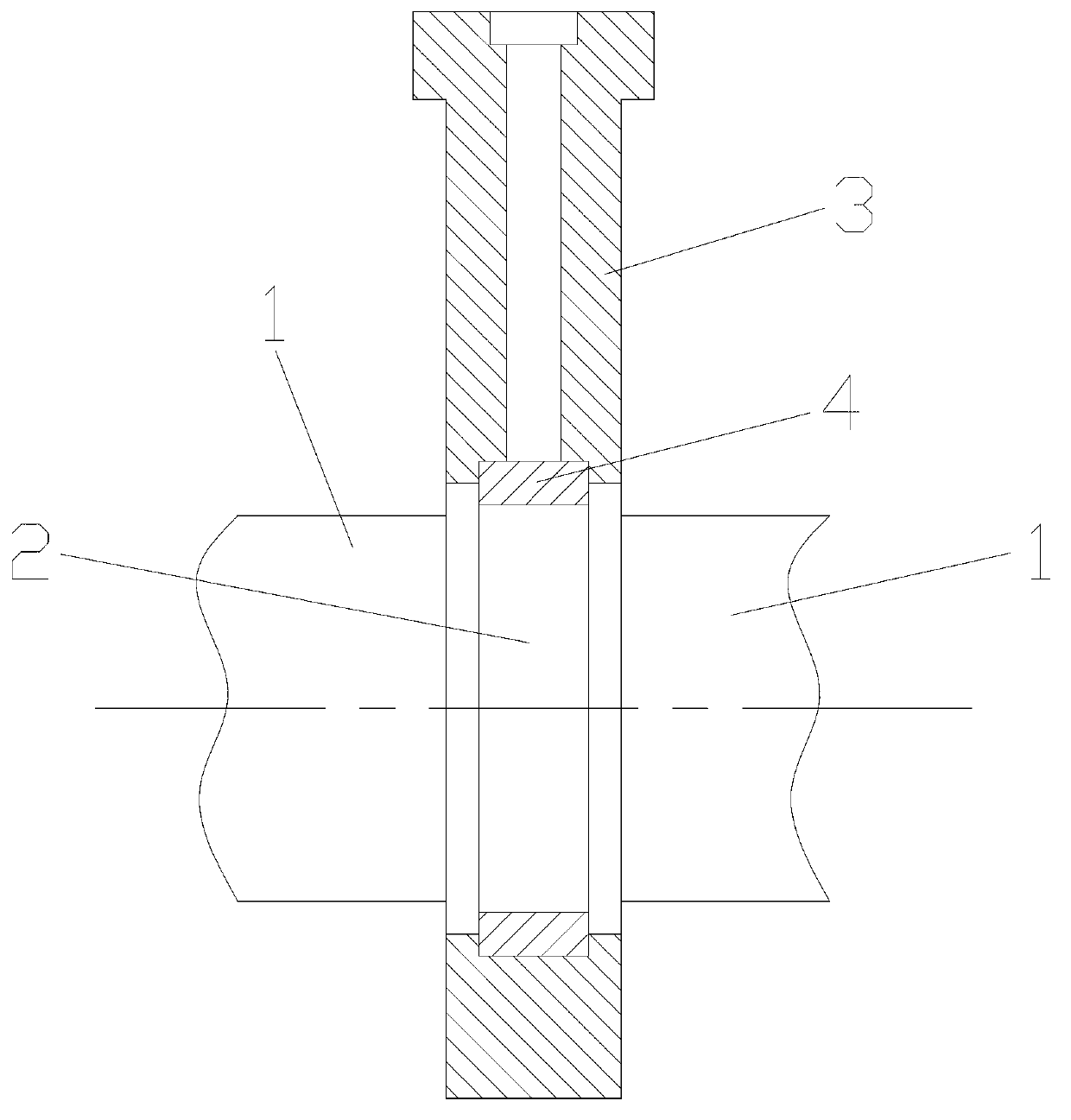

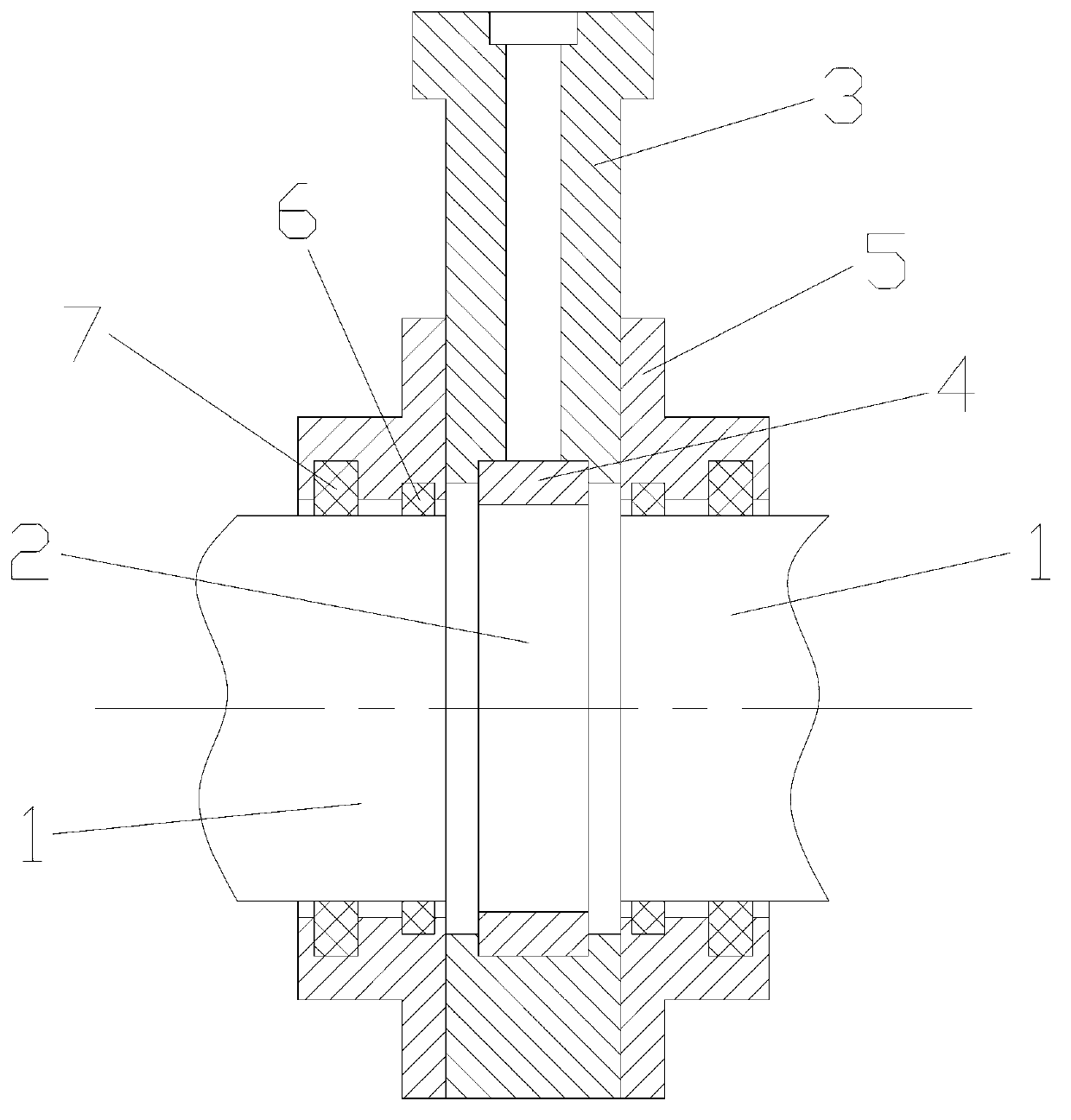

Rotation and lubrication system for automobile control arm

InactiveCN105128619ANo maintenanceImprove carrying capacityLubricating systemPivoted suspension armsLubricant substanceControl arm

The invention relates to a rotation and lubrication system for an automobile control arm. The rotation and lubrication system comprises the control arm. The control arm is matched with a pair of bearings, and a pin shaft penetrates through the portion between the bearings and is tensioned through a nut. The two ends of the pin shaft are closed, an inner cavity of the pin shaft is partitioned into two sections through a piston assembly, one section, penetrating through the bearings, of the inner cavity is filled with lubricating matter, and the other section of the inner cavity is internally provided with a spring. When the control arm moves, the lubricating matter is consumed, the spring continuously rebounds to jack the piston assembly to move downwards, and the lubricating matter in the cavity of the pin shaft enters inner cavities of the bearings from a hole of the pin shaft for lubrication. The purposes that the bearing capacity of the control arm is enhanced, the system is maintained (the lubricating matter is automatically added) in a free-of-charge mode, and the service life of the system is prolonged can be achieved.

Owner:JIANGSU RUIJIANG VEHICLE SYST CO LTD

Anti-thread-gluing thread grease and using method thereof

ActiveCN111575089AConvenient coatingImprove the lubrication effectNon-macromolecular adhesive additivesEpoxy resin adhesivesPolymer scienceVulcanization

The invention discloses anti-thread-gluing thread grease which comprises a component A, a component B and a component C. The mass ratio of the component A to the component B to the component C is (0.8-1.1): (1.6-2.2): (3.6-4.2). The component A comprises the following components in percentage by mass: 30%-50% of a polyamide curing agent and 50%-70% of normal hexane; the component B comprises 47%-60% of epoxy resin, 5%-15% of nickel powder, 30%-40% of tungsten disulfide powder, 1%-4% of silicon nitride and 1%-3% of fumed silica; and the component C comprises 30%-50% of titanium-based lubricating grease, 3%-7% of microcrystalline graphite, 7%-13% of silicon carbide whiskers, 15%-23% of graphite powder, 13%-18% of polytetrafluoroethylene powder, 1%-4% of nickel-titanium alloy and 10%-15% of zinc powder. During use, the component B is firstly brushed on the surface of a thread, then the component A is brushed on the surface of the thread brushed by the component B, a lubricating coating isformed on the surface of the thread through a chemical curing reaction of the two components, the coating has the advantage of strong surface adhesion, and then a layer of oil-based grease lubricating substance is coated on the surface of the lubricating coating so that the advantages that the oil-based grease lubricating material physically blocks a thread leakage gap and spreads on the surfaceof the thread are exerted.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

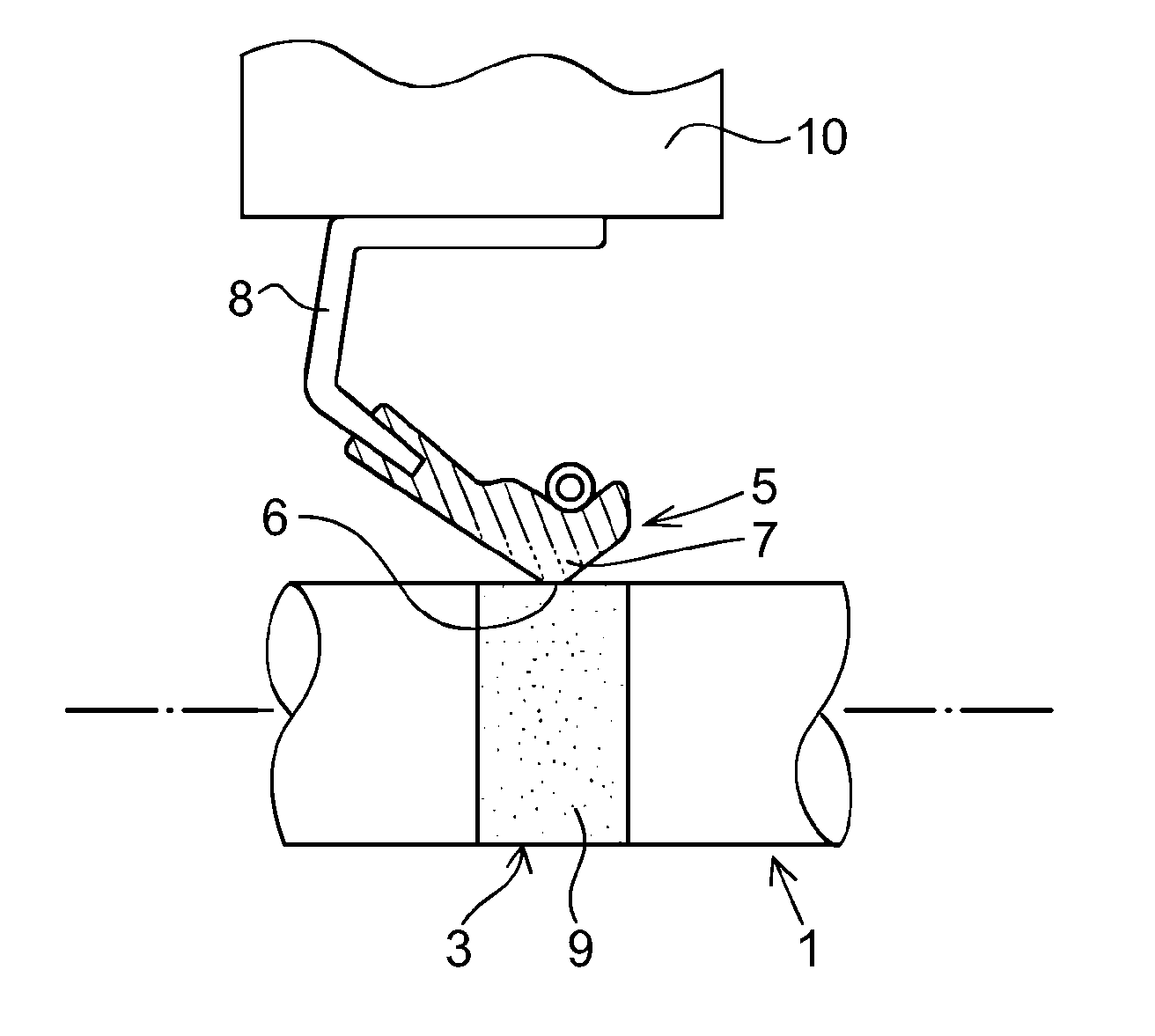

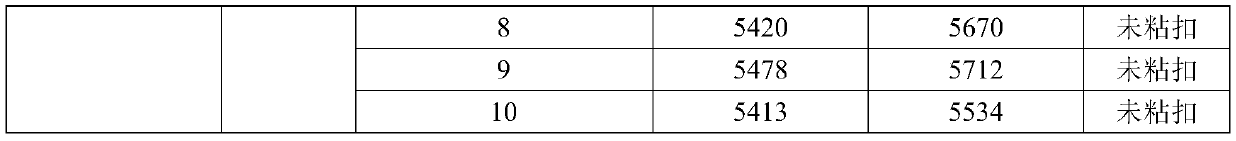

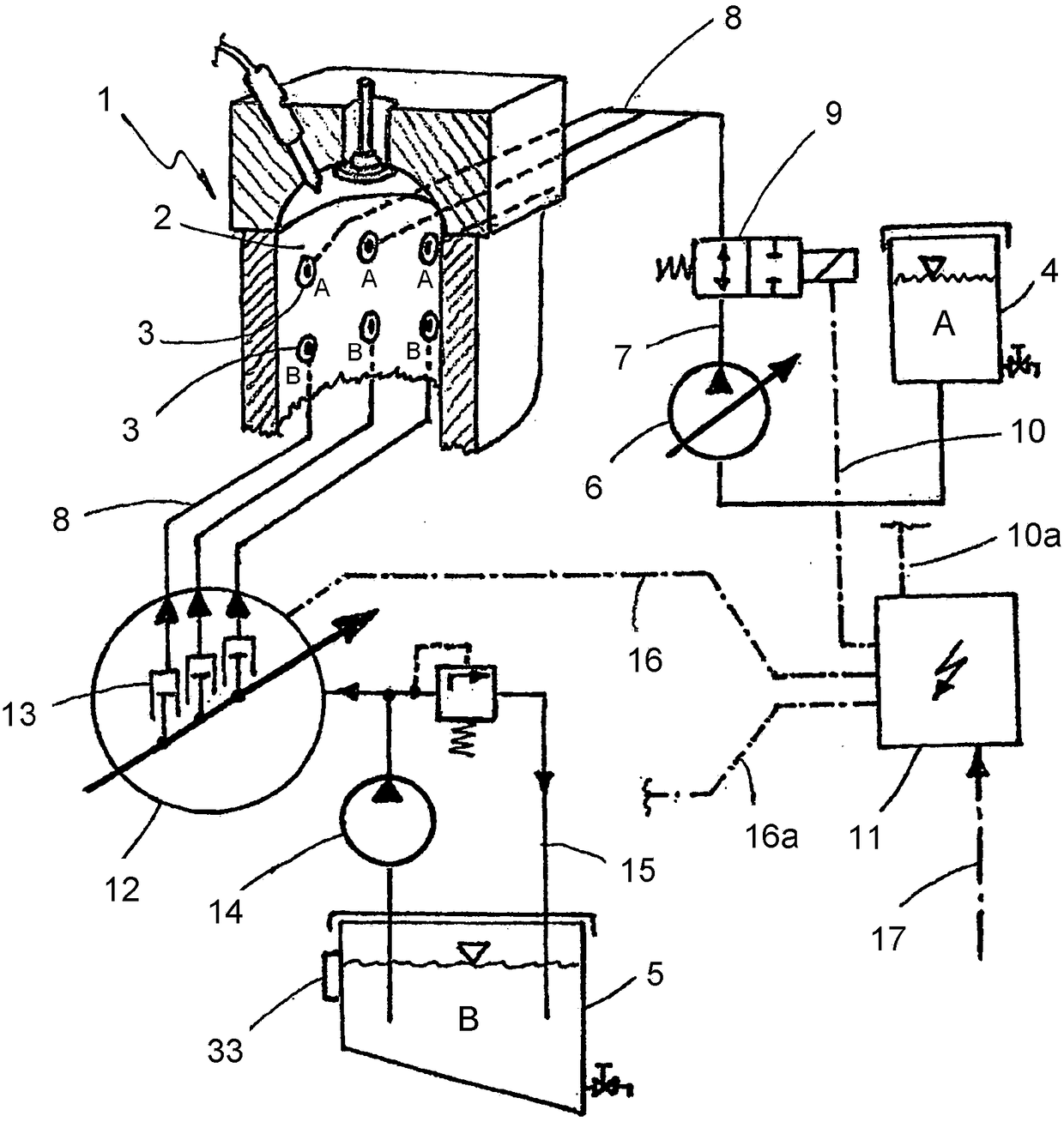

Method and apparatus for cylinder lubrication

ActiveCN105074145BNo overdoseMissingLubricant conduit arrangementsMachines/enginesLubricant substanceCombustion

The invention relates to the lubrication of the cylinders (1) of internal combustion engines that burn acid-generating fuels, wherein several lubricants having different neutralization capability are used. According to the invention an optimization of the lubrication and of the acid neutralization and thus high operational reliability and economic efficiency can be achieved in that at least one lubricant having a neutralization capability that does not exceed the neutralization requirement in any possible use case and at least one lubricant having an neutralization capability that is not less than the neutralization requirement in any possible use case are used and that the lubricants used are individually fed to the cylinder interior in metered amounts and are mixed in the cylinder interior.

Owner:MAN DIESEL & TURBO FILIAL AF MAN DIESEL & TURBO SE TYSKLAND

Machine-made sand concrete and preparation method thereof

The invention relates to concrete, in particular to machine-made sand concrete and a preparation method thereof. The concrete comprises the following materials in parts by weight: 320-330 parts of cement, 60-70 parts of mineral powder, 40-50 parts of fly ash, 710-730 parts of sand, 1050-1100 parts of gravel, 165-175 parts of water, 8-9 parts of an admixture and 100-110 parts of water absorption blocks. The admixture improves the flowability of the concrete and delays the hydration process, so that the concrete is not easy to bleed, and the workability is improved. The added water absorption blocks can be used as a lubricating substance of machine-made sand, and the water absorption blocks are not completely saturated at the moment and can continuously absorb bleeding water or redundant water in the concrete, so that the workability is further improved.

Owner:海南兆诚混凝土有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com