Rotation and lubrication system for automobile control arm

A technology of automobile control arm and lubrication system, which is applied in the direction of lubrication system, vehicle parts, cantilever installed on the pivot, etc. It can solve the problems of small specific pressure, poor bearing capacity and low service life of steel bushings, and achieve the elimination of The torsion angle is small, which solves the problem of poor bearing capacity and improves the effect of bearing load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

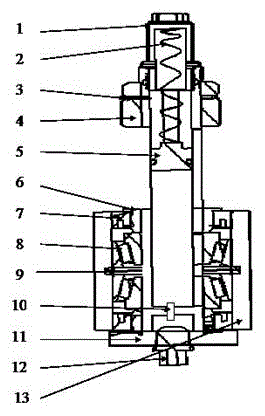

[0020] see figure 1 , The invention discloses an automobile control arm rotation and lubricating system. As shown in the figure: it includes a control arm 13. The control arm 13 cooperates with a pair of back-to-back single-row cone bearings 8. A pin shaft 10 passes through the middle of the single-row cone bearings 8 and is tightened with nuts 4; the pin shaft 10 is closed at both ends. , the inner cavity is divided into two sections by the piston assembly 5, a section of the inner cavity passing through the single-row cone bearing 8 is filled with a lubricating substance (such as: lithium-based grease), and a spring 2 is set in the other section of the inner cavity. When the control arm 13 is in motion, the lubricating substance is consumed, the spring 2 continues to bounce back against the piston assembly 5 and moves downward, and the lubricating substance in the cavity of the pin shaft 10 enters the cavity of the single-row tapered bearing 8 from the hole of the pin shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com