Patents

Literature

222results about "Lubricating system" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

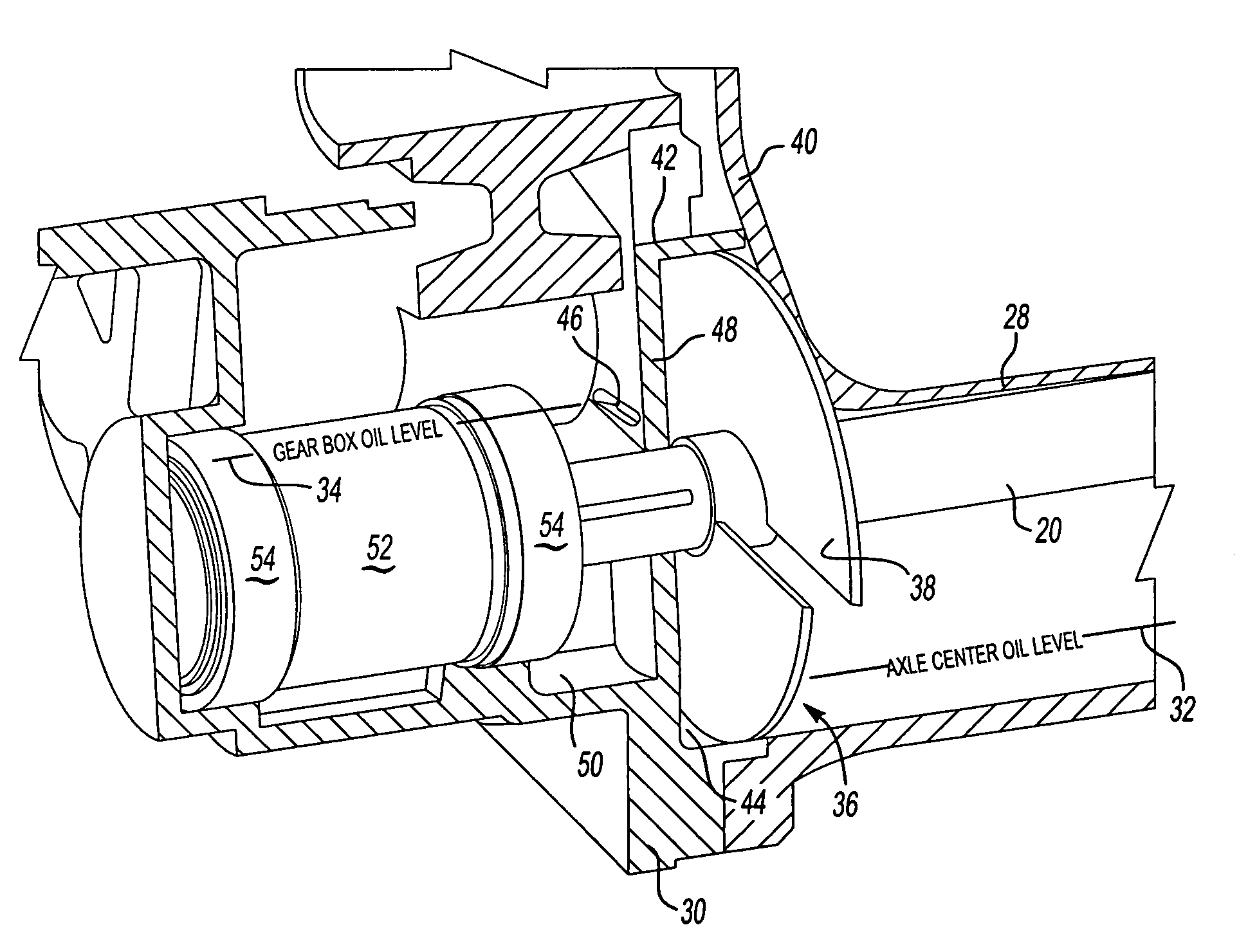

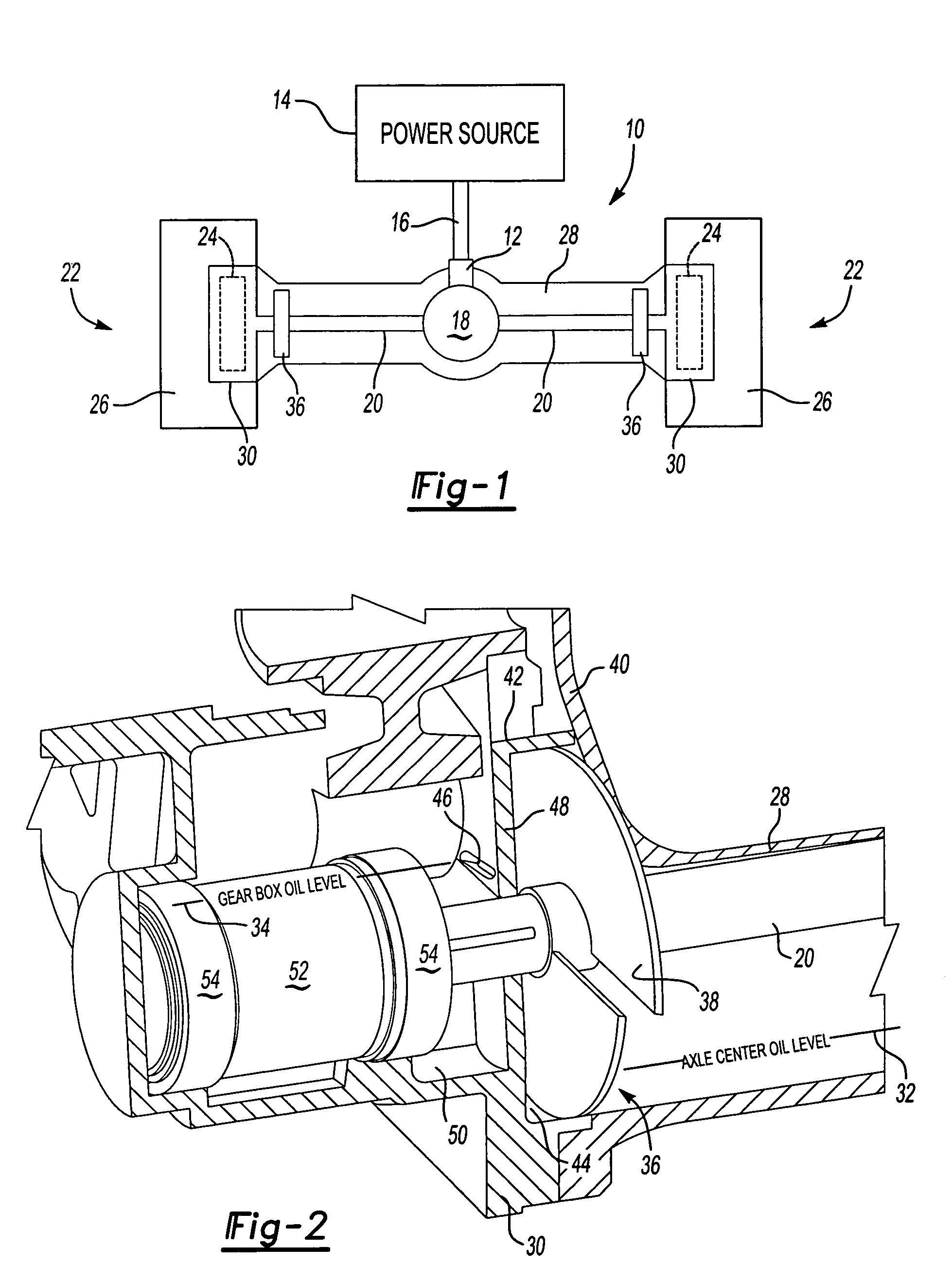

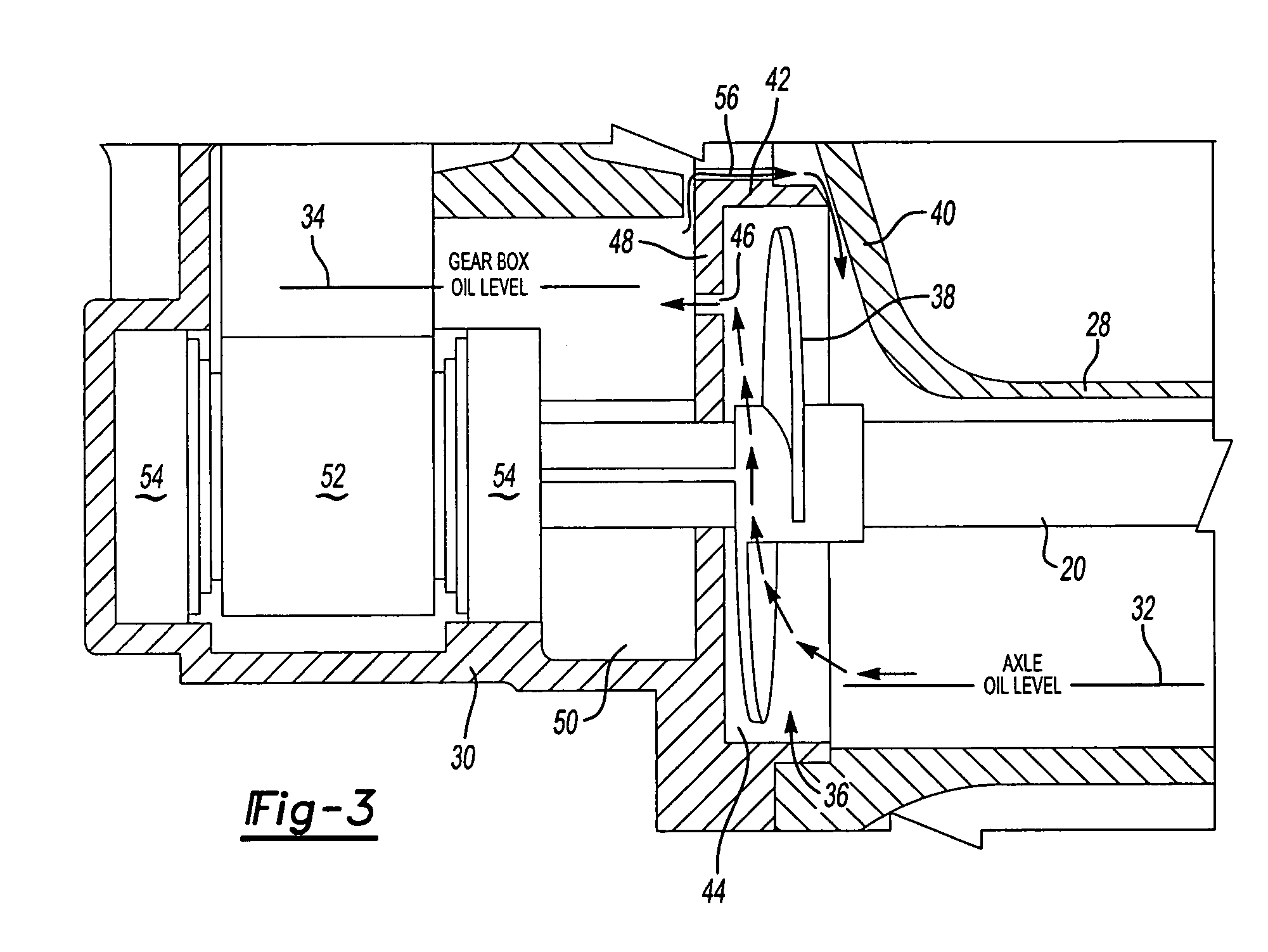

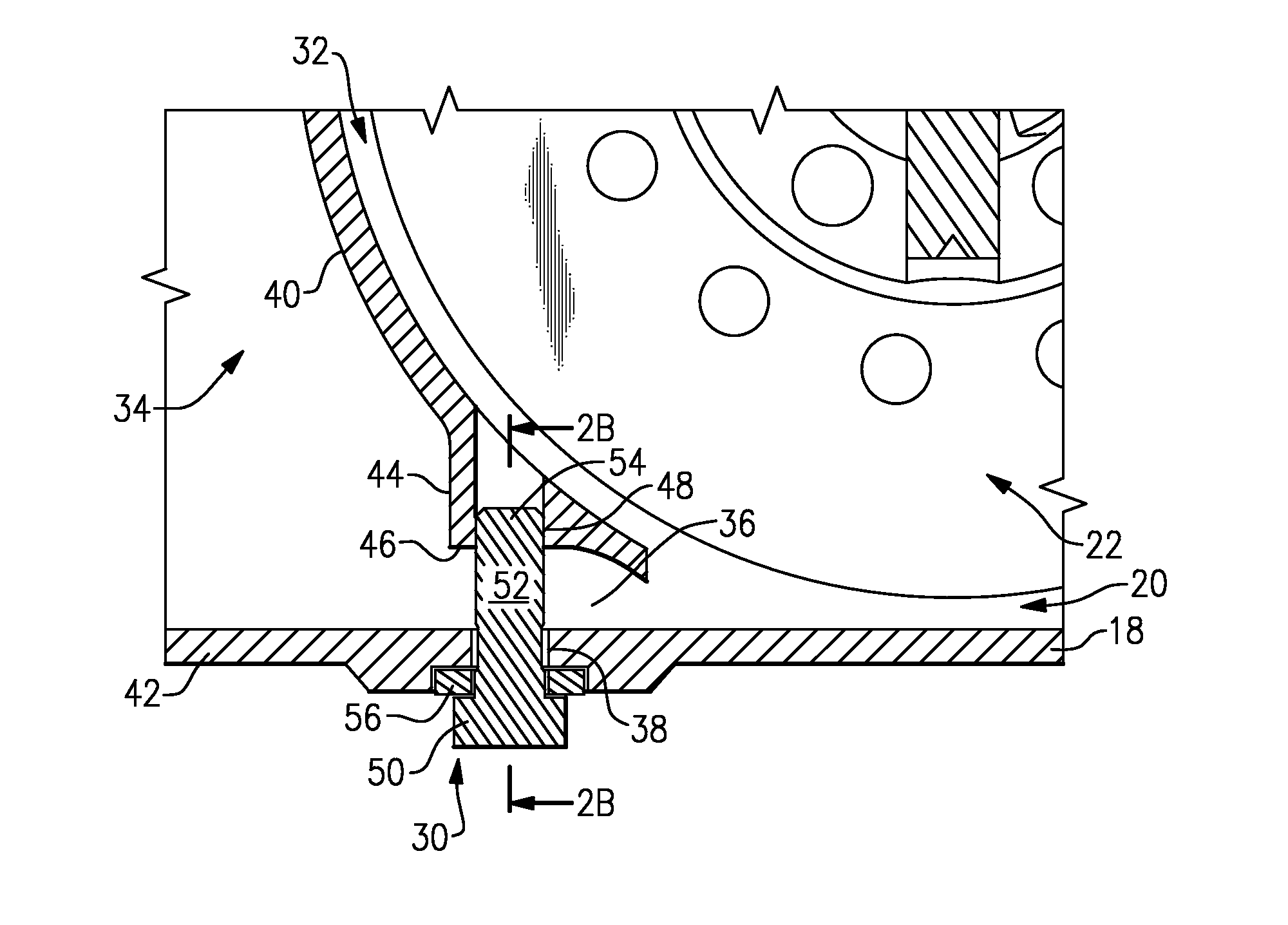

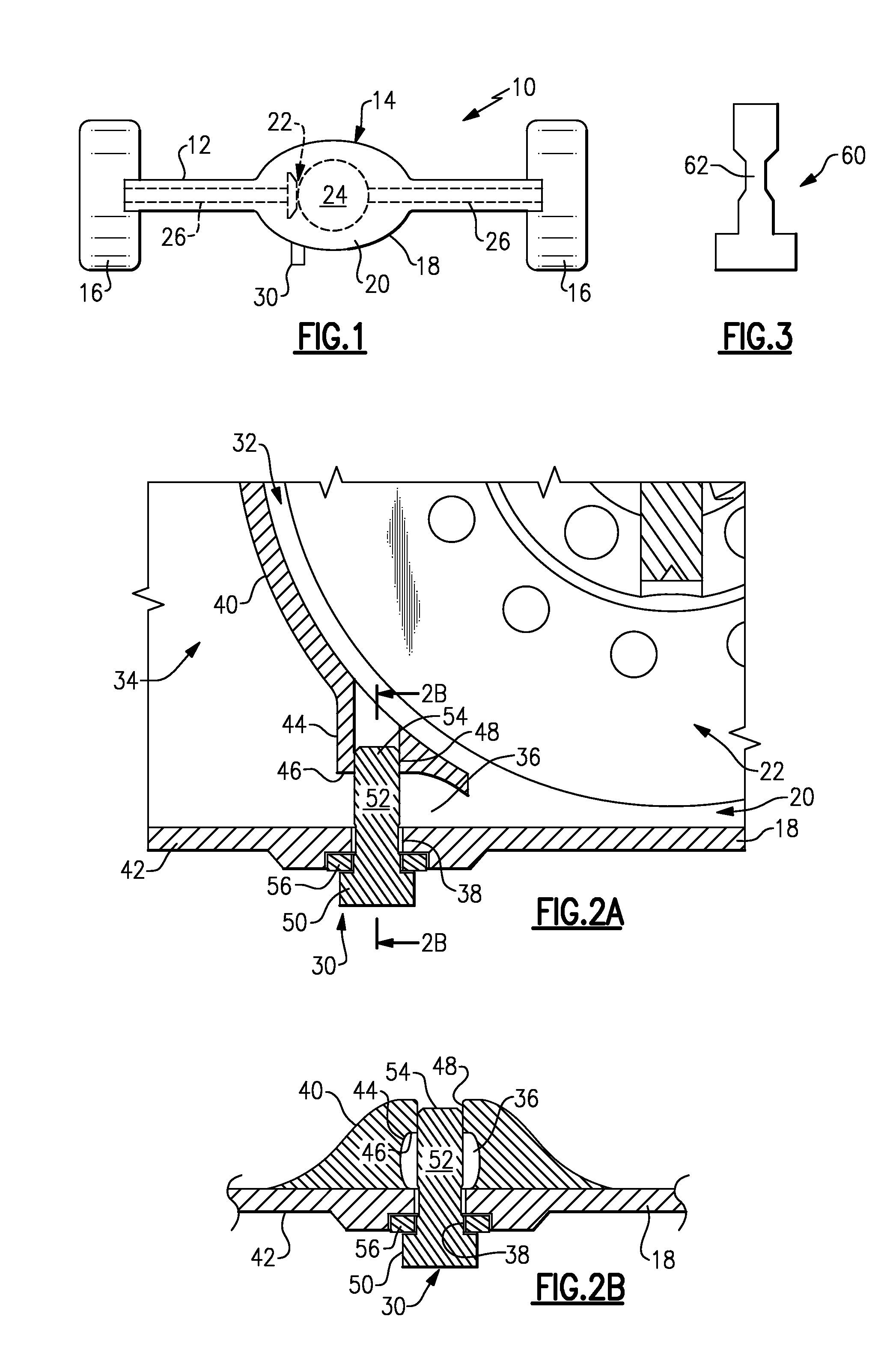

Dual level oil impeller for drive axle assembly

InactiveUS6991574B2Reduce the amount requiredFully lubricatedDrip or splash lubricationGear lubrication/coolingImpellerTransaxle

Owner:ARVINMERITOR TECH

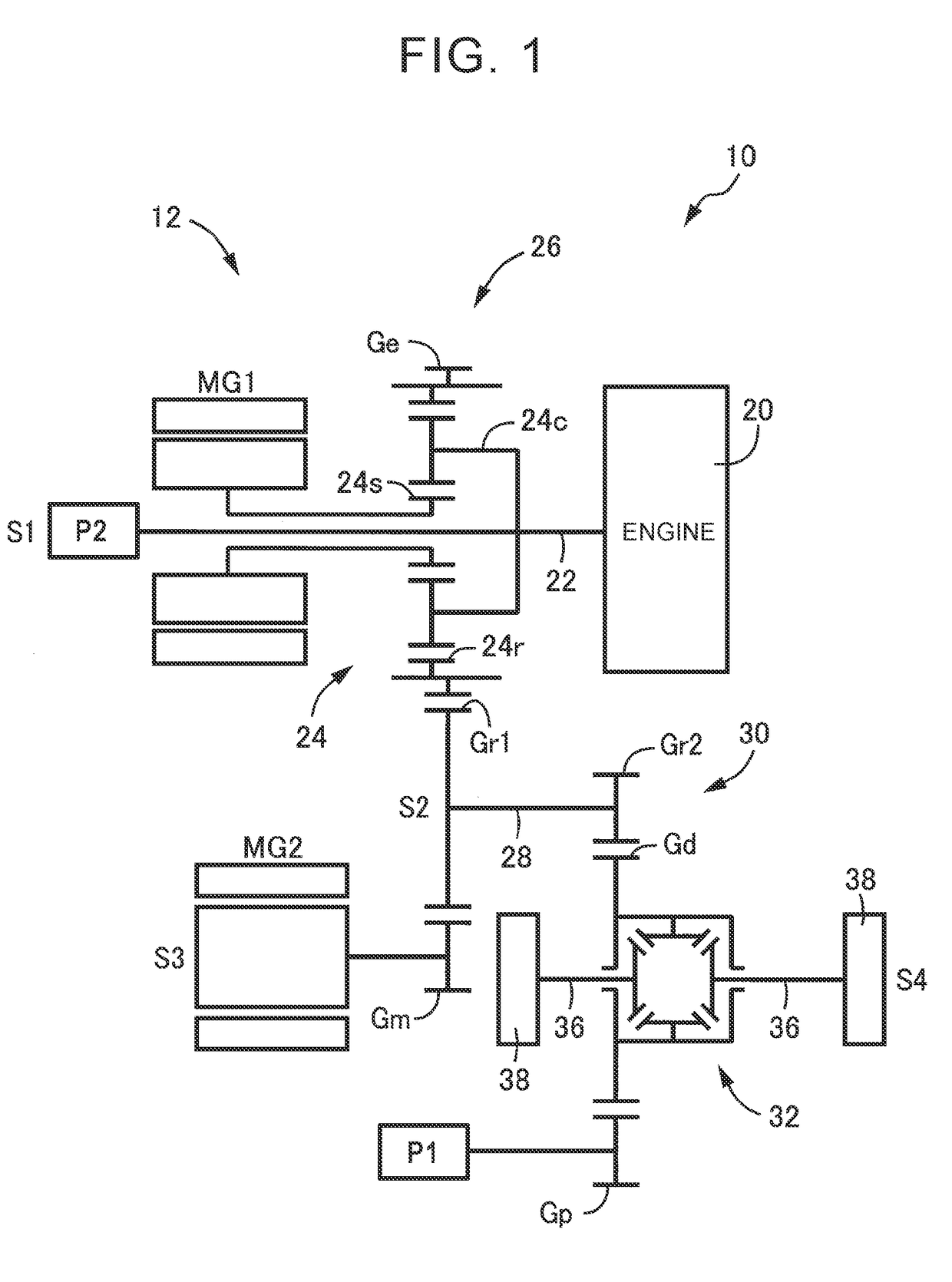

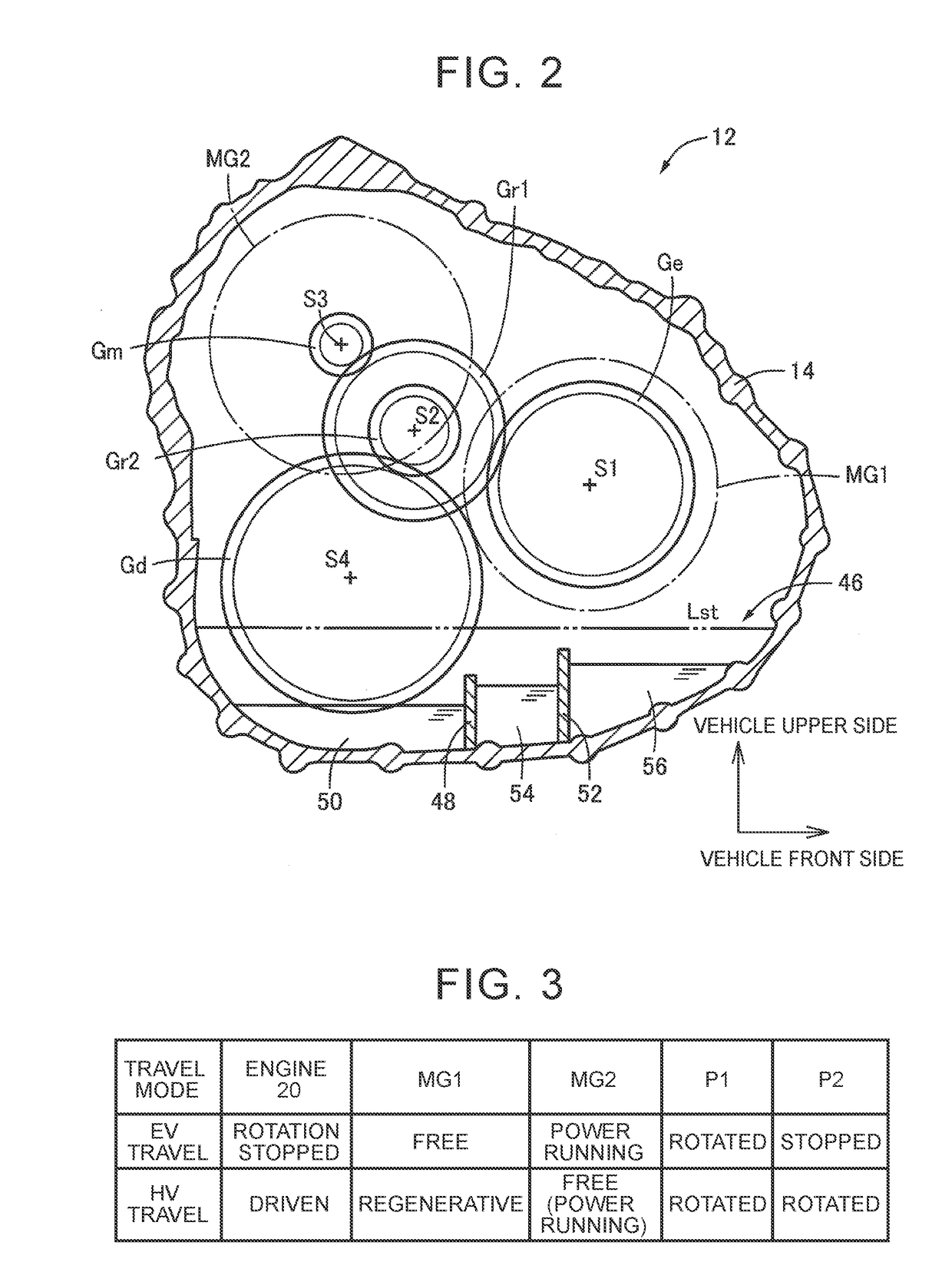

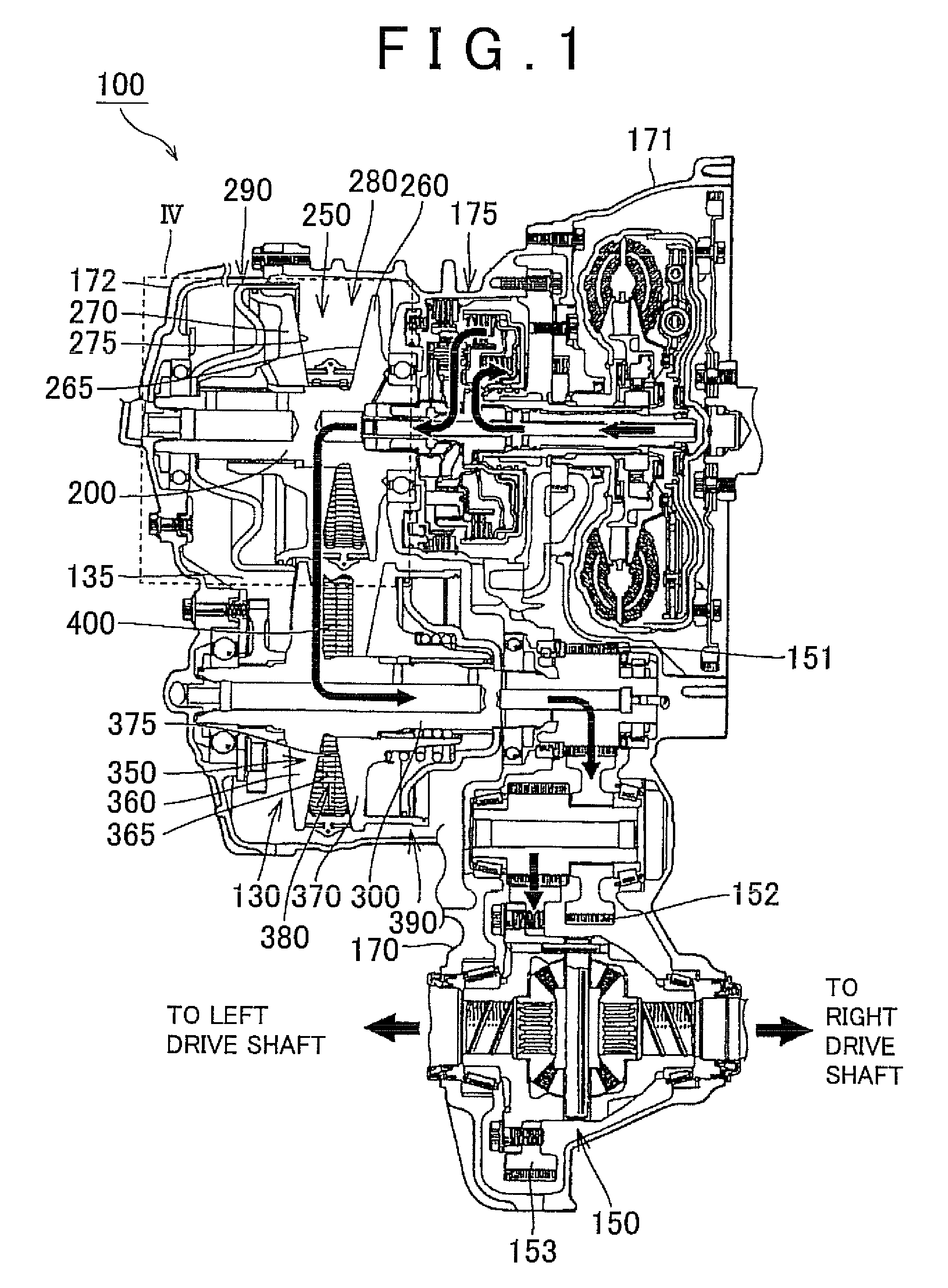

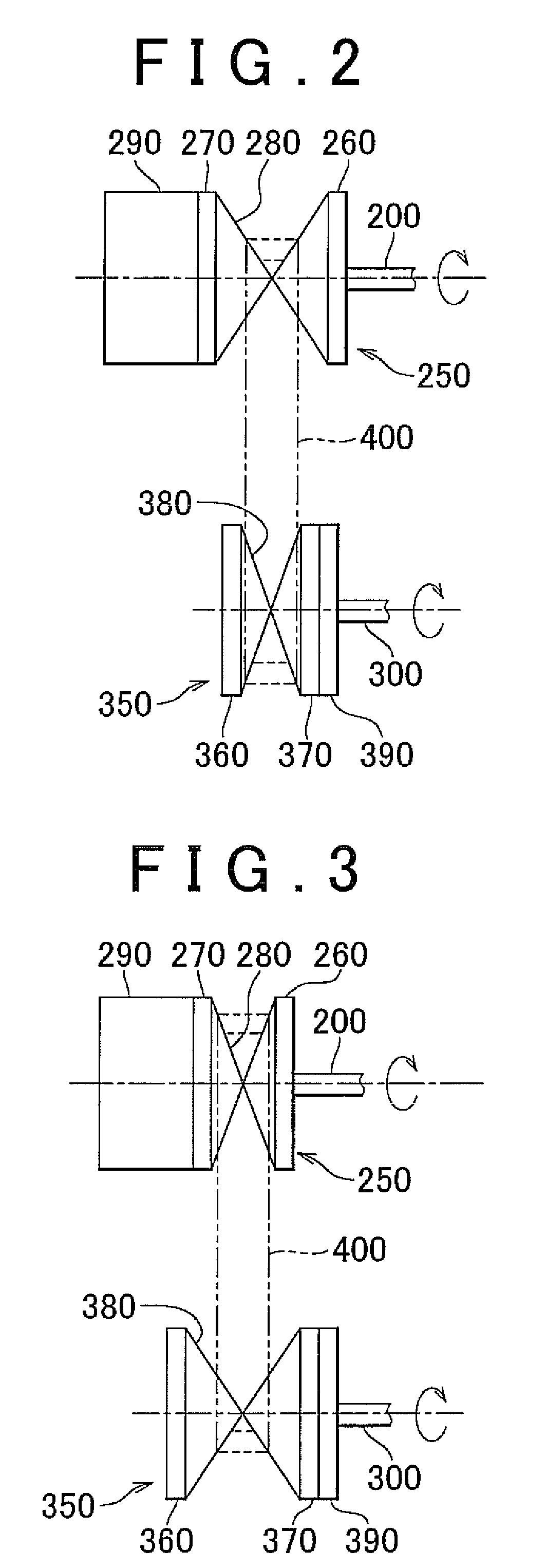

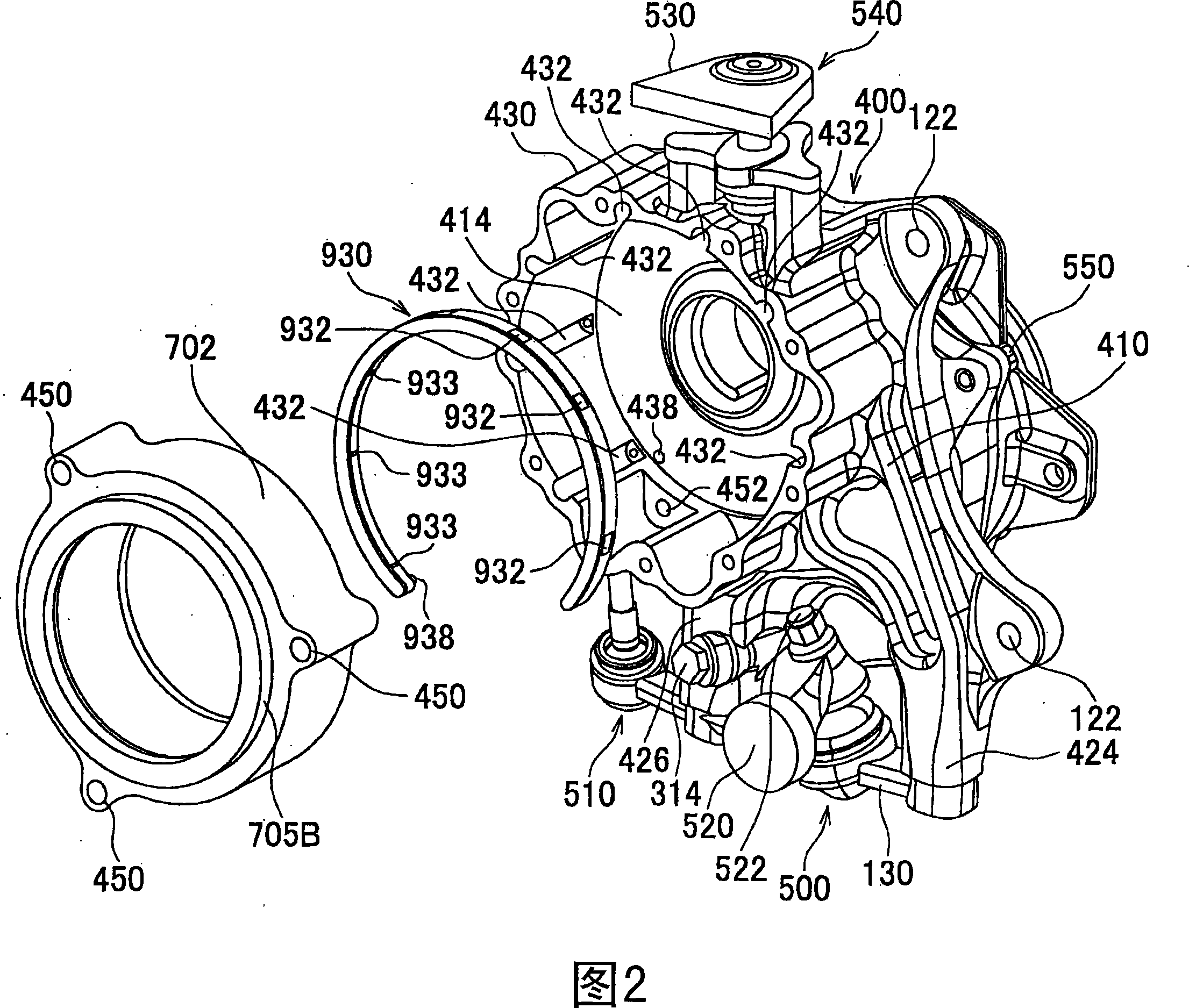

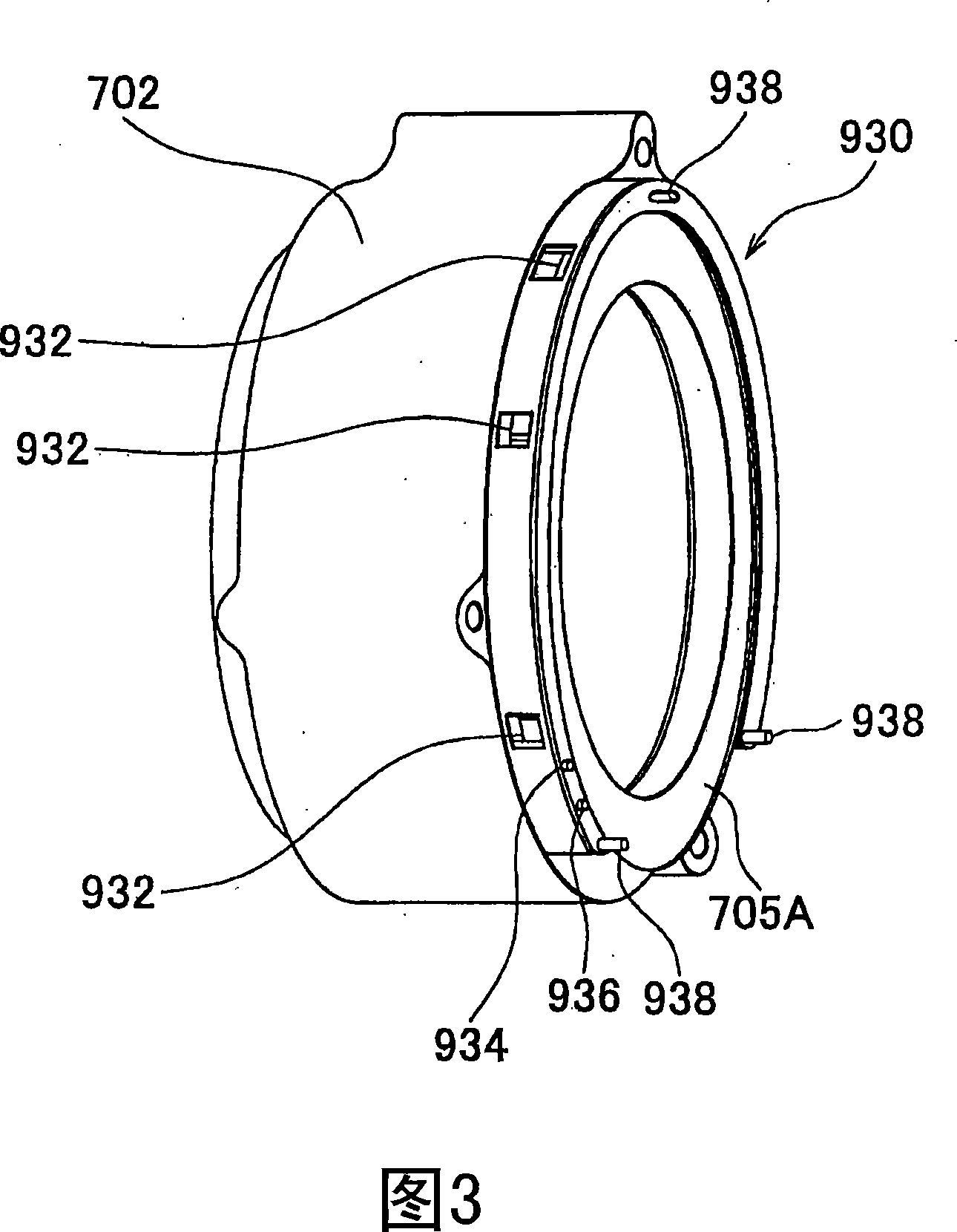

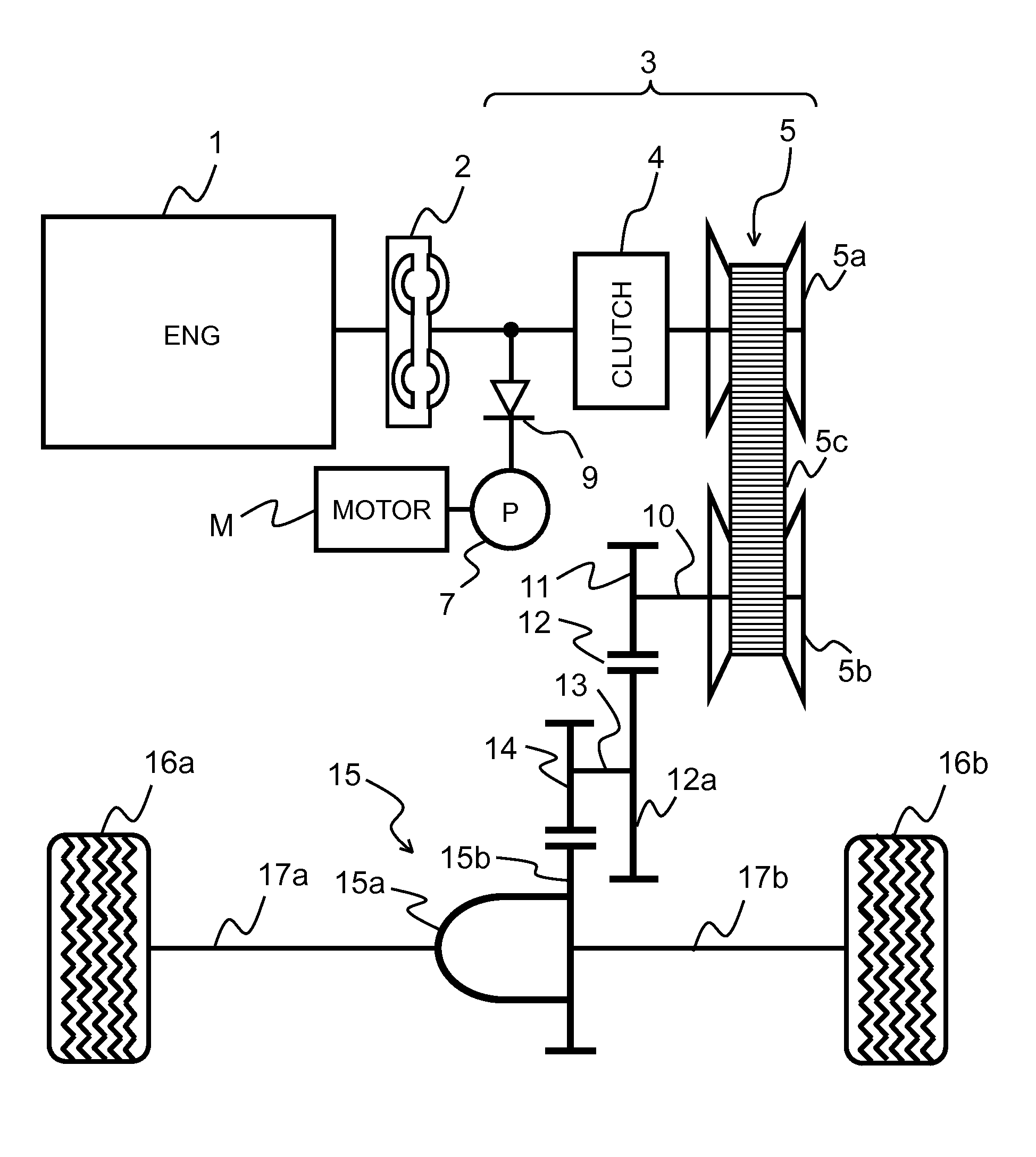

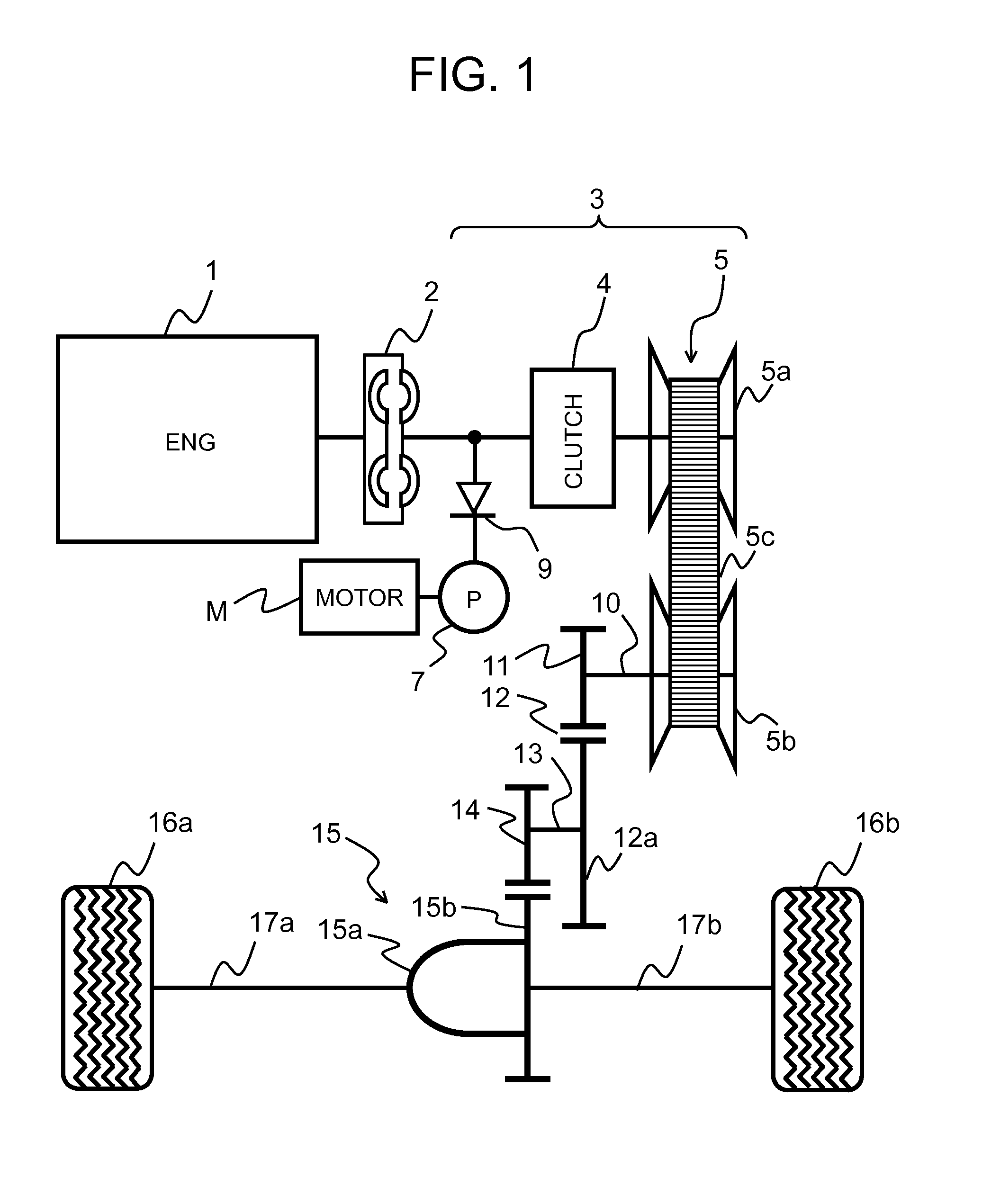

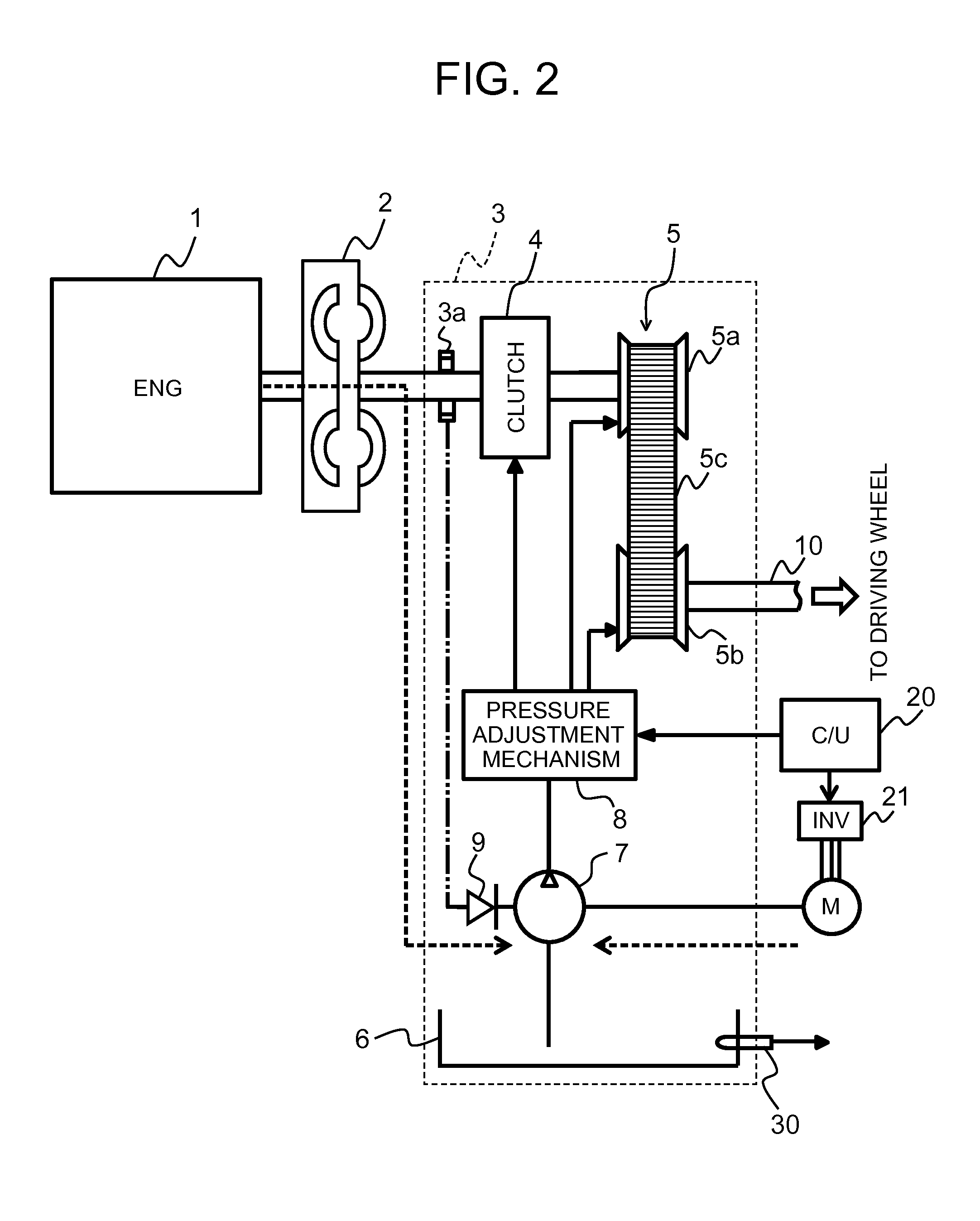

Lubricating Device of Power Transmission Device for Vehicle

ActiveUS20170219085A1Lower oil levelReduce energy lossGas pressure propulsion mountingGear lubrication/coolingPower transmissionOil storage

During the travel of a vehicle, the oil level of lubricating oil is lowered due to the suction by at least a first oil pump and the scraping-up by the rotation of a differential ring gear and so on. In particular, until the oil level becomes equal to or lower than an upper end of a first partition wall, the oil level is lowered due to both the suction by the first oil pump and the scraping-up by the rotation of the differential ring gear and so on, and therefore, a region, that is immersed in the lubricating oil, of the differential device rapidly becomes smaller. Since a suction port of the first oil pump is disposed in a second oil storage portion, the oil level in the second oil storage portion during the travel of the vehicle can be adjusted independently of that in a first oil storage portion.

Owner:TOYOTA JIDOSHA KK

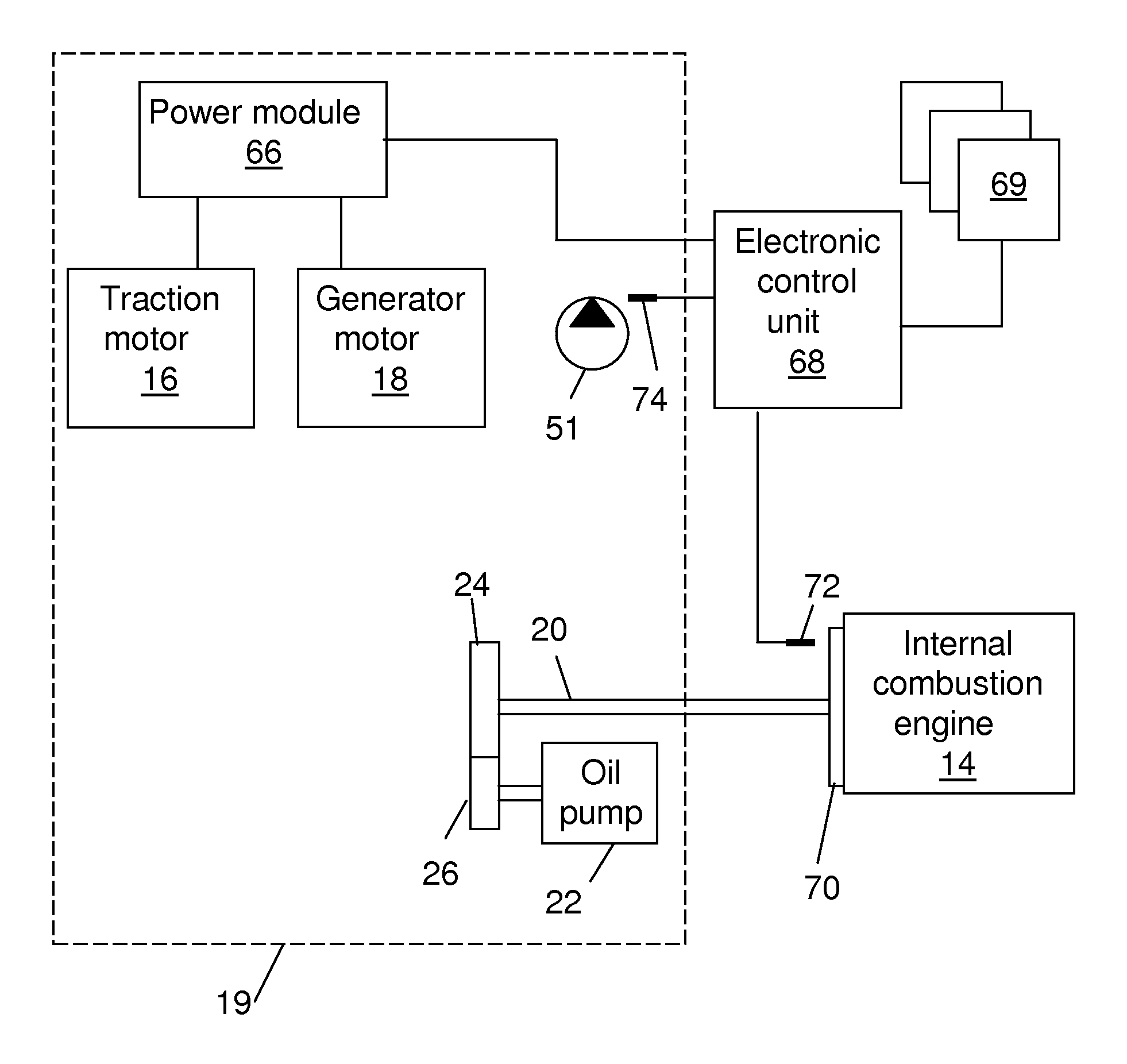

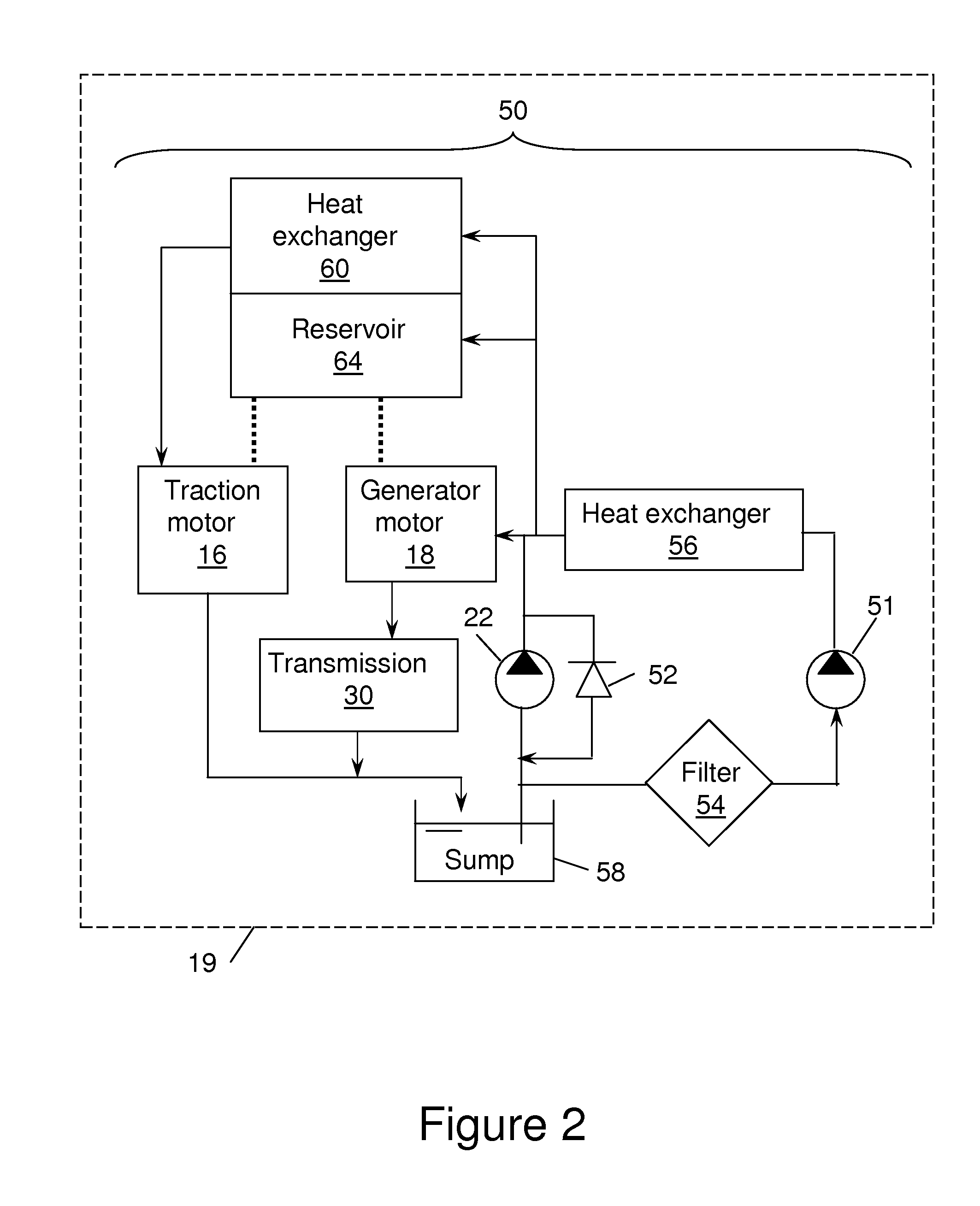

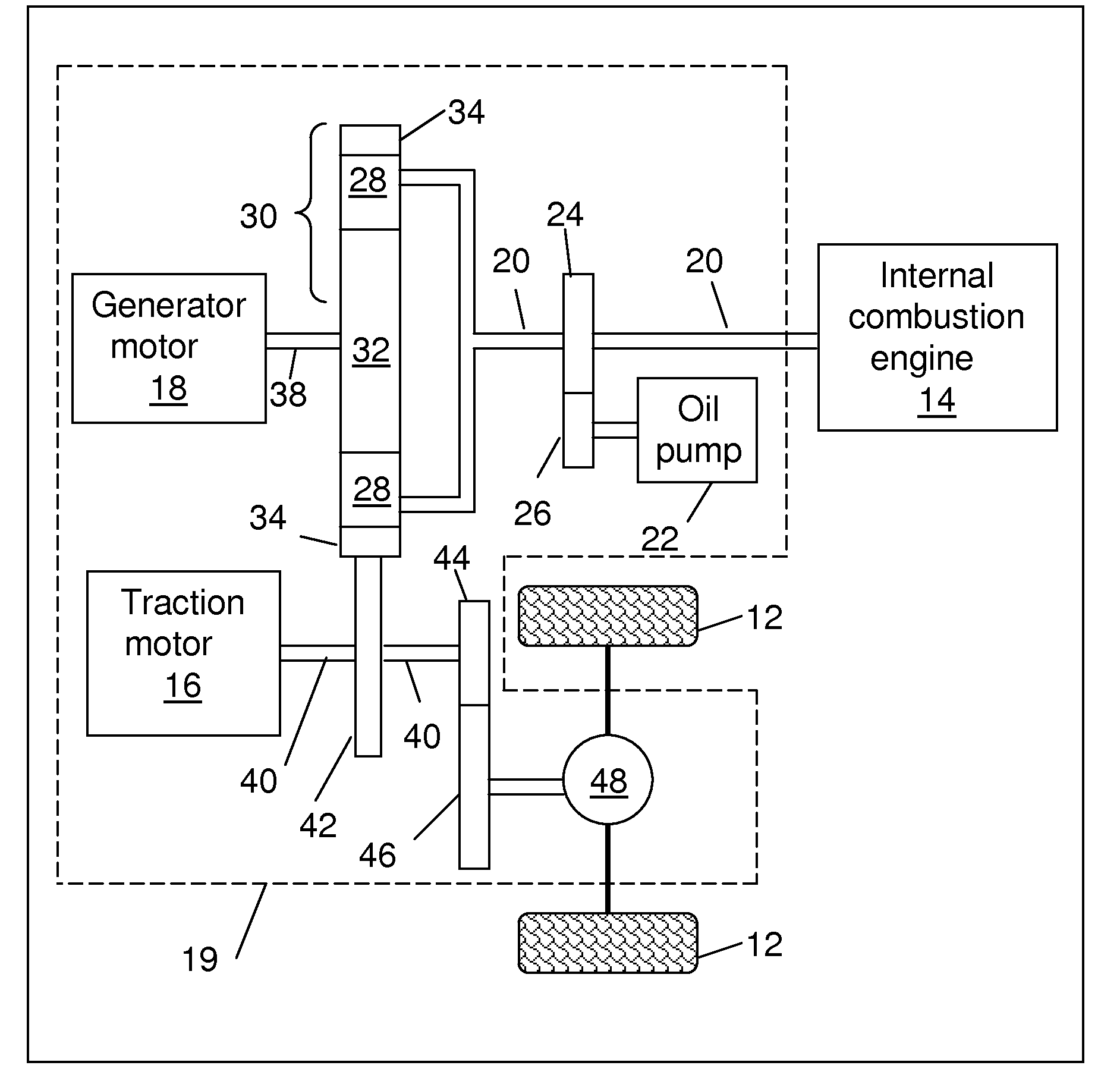

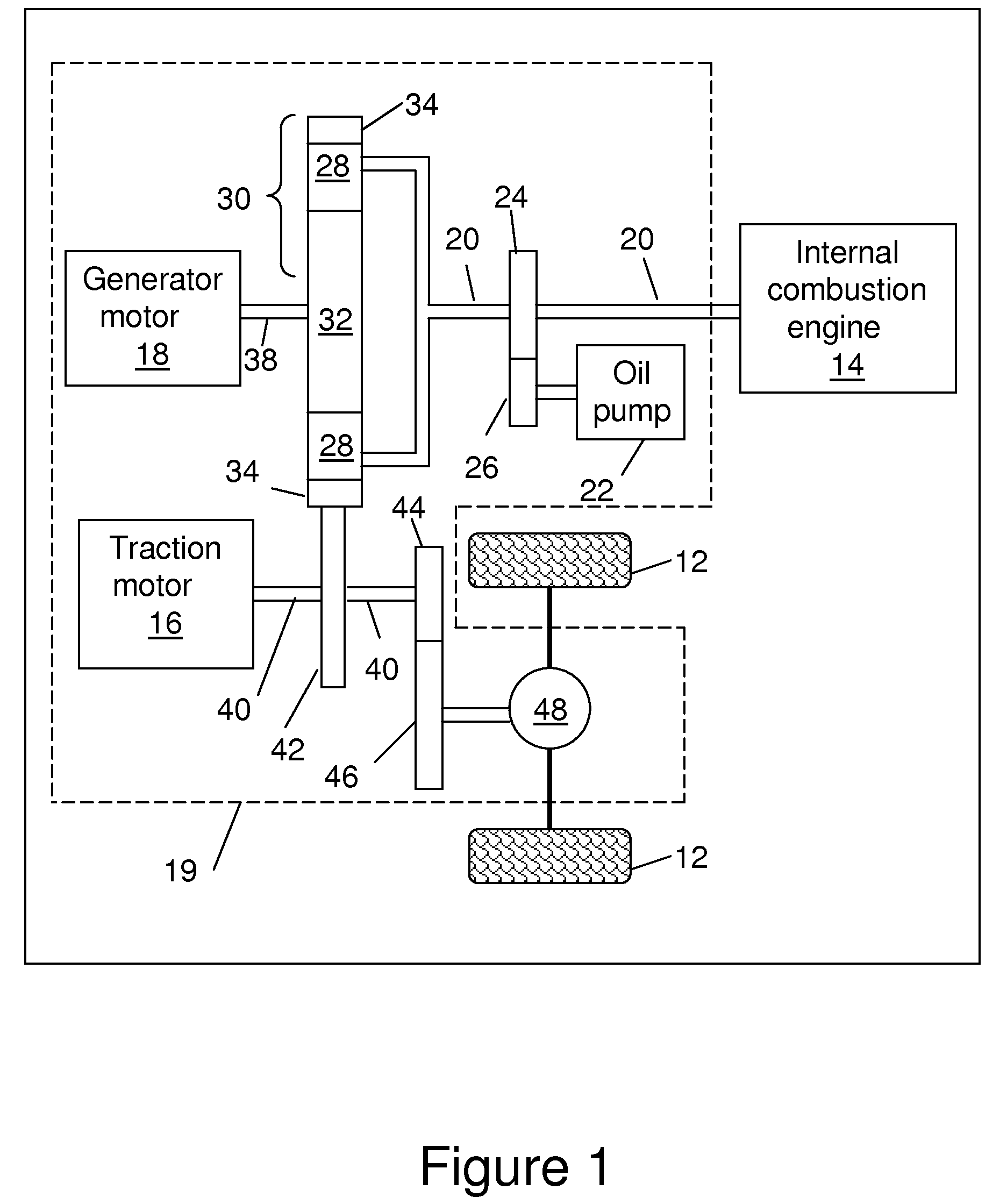

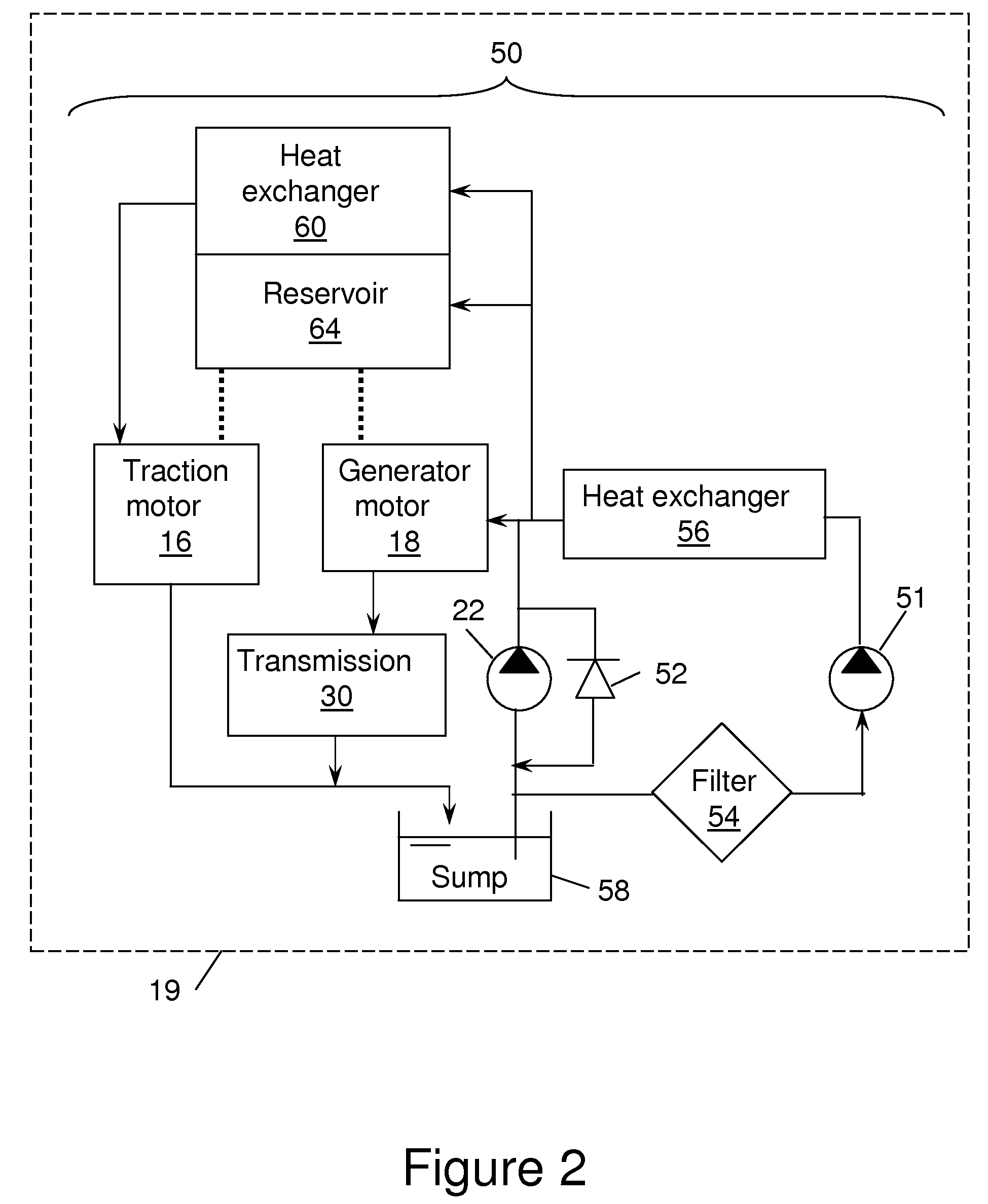

System and method to provide lubrication for a plug-in hybrid

In hybrid electric vehicles having increased battery storage capacity and plug-in capability, electric-only operation of significant duration is available. To supplement lubrication for the electric and mechanical components provided in a fluid circuit by an engine-driven mechanical pump, an electric pump is provided in parallel to the mechanical pump. When the electric pump is operating, a diagnostic can be performed to determine system integrity. According to one embodiment, an actual quantity provide to the circuit is determined; an expected quantity is estimated; and a fault is determined when the actual and expected quantities differ by more than a predetermined amount. The fault may indicate a leak or plug in the fluid circuit or a failure of a component in the fluid circuit.

Owner:FORD GLOBAL TECH LLC

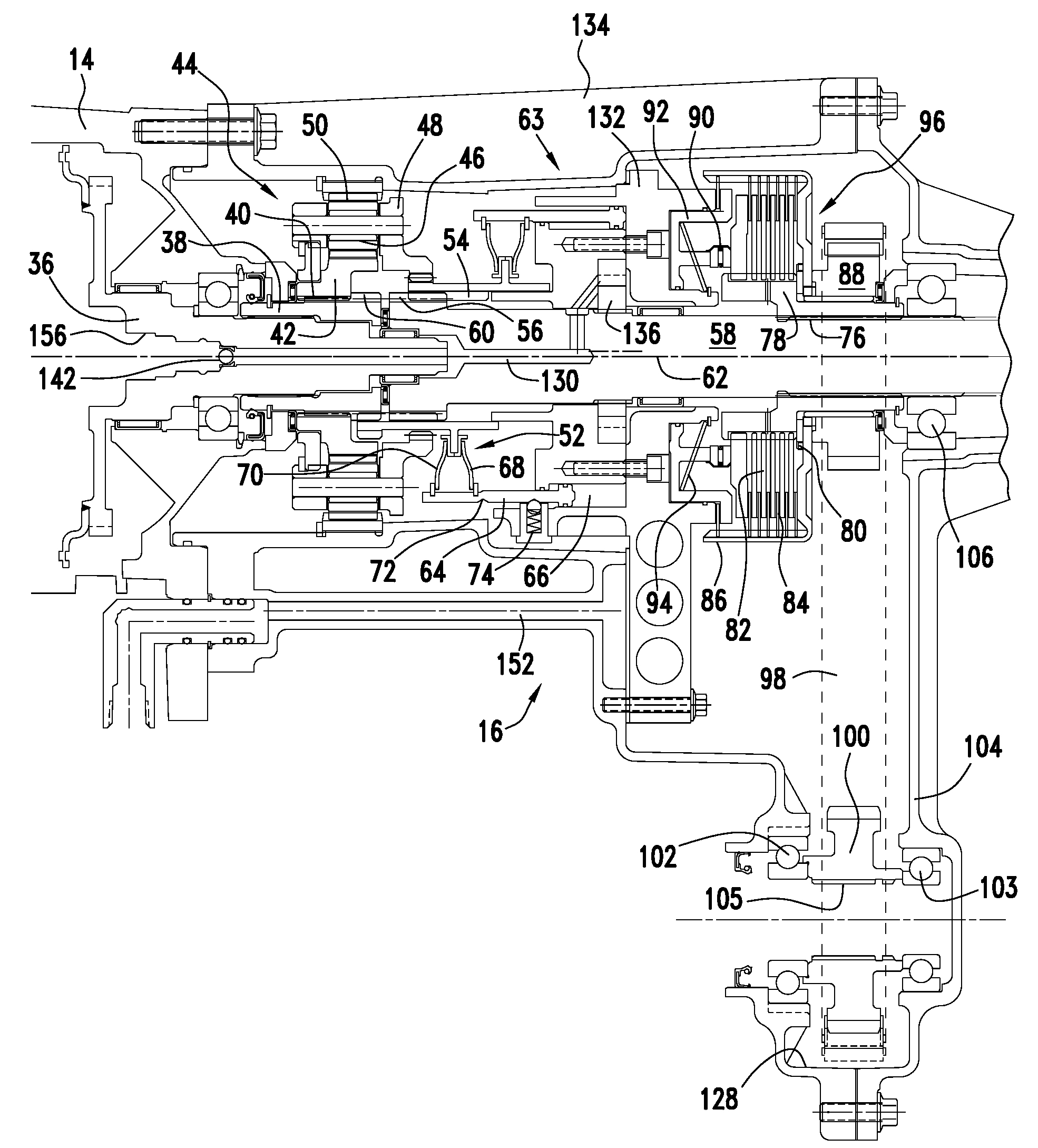

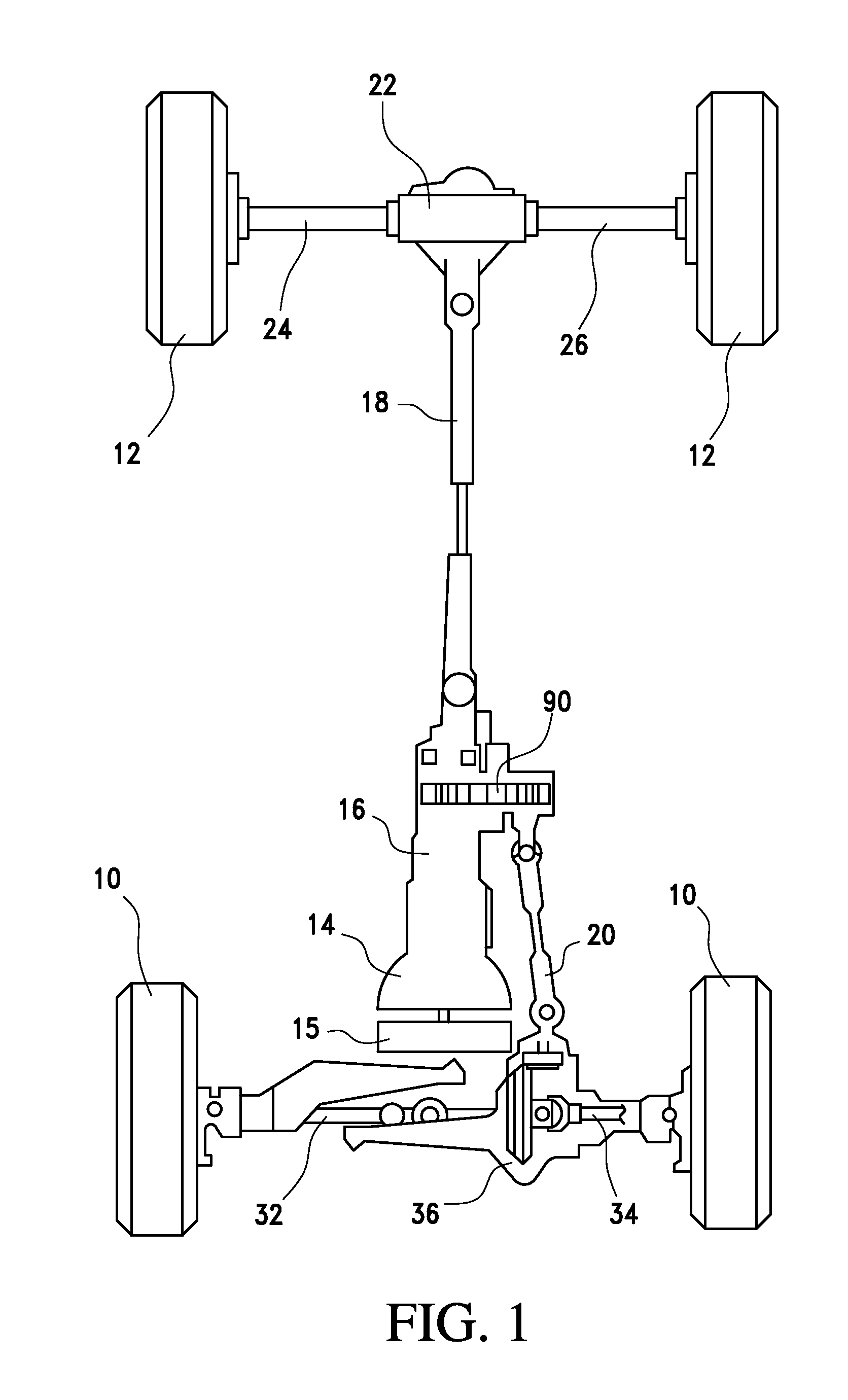

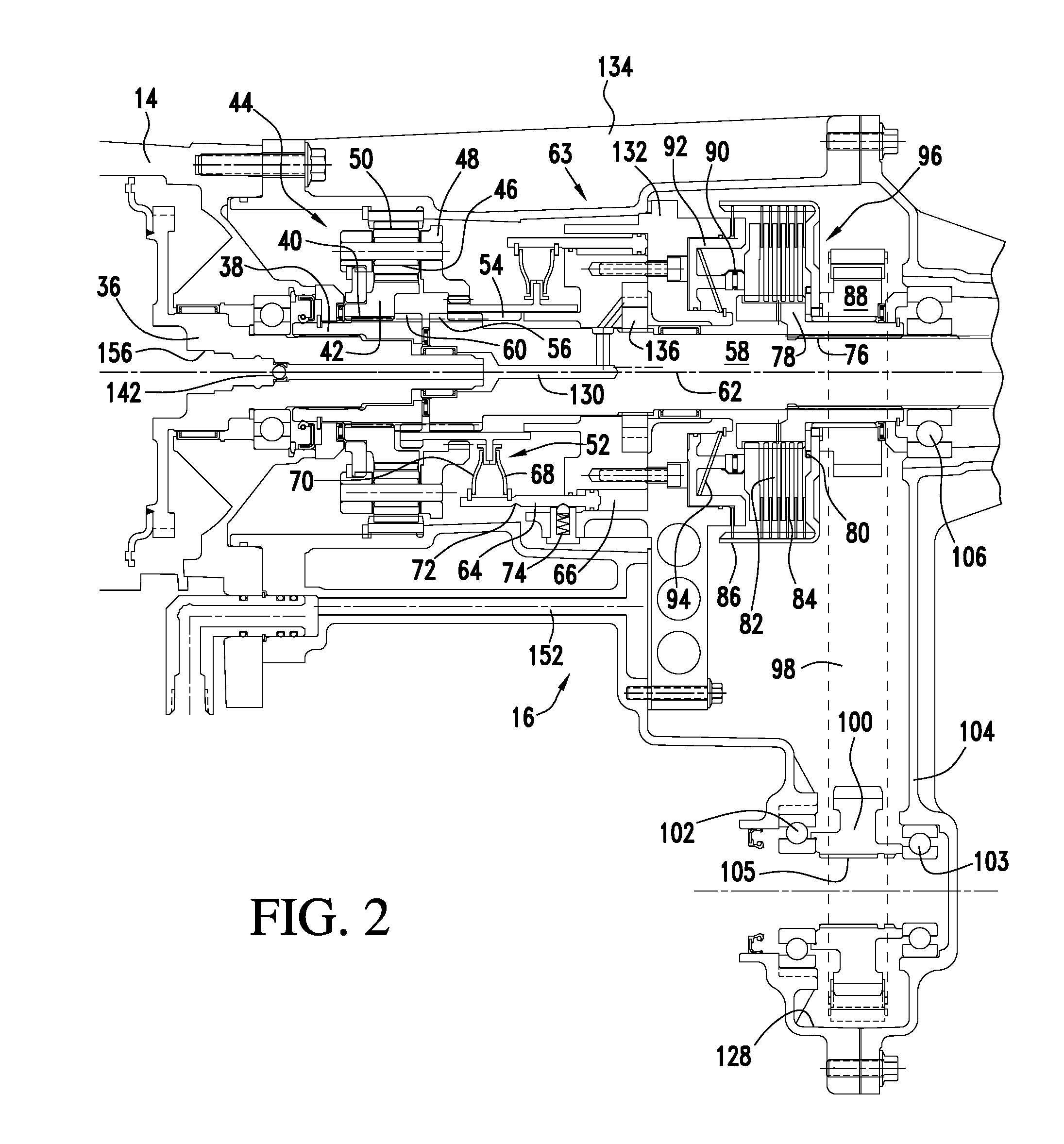

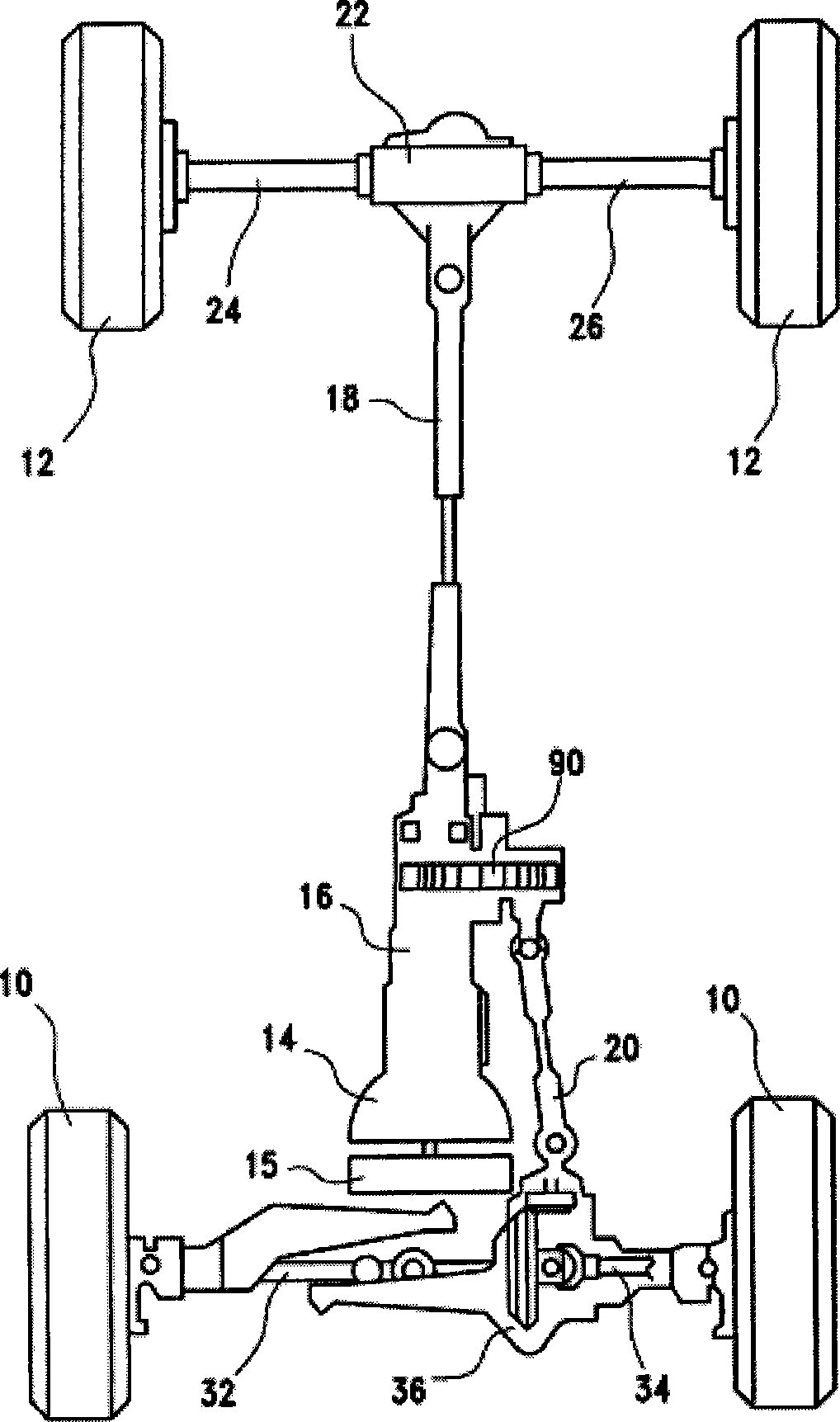

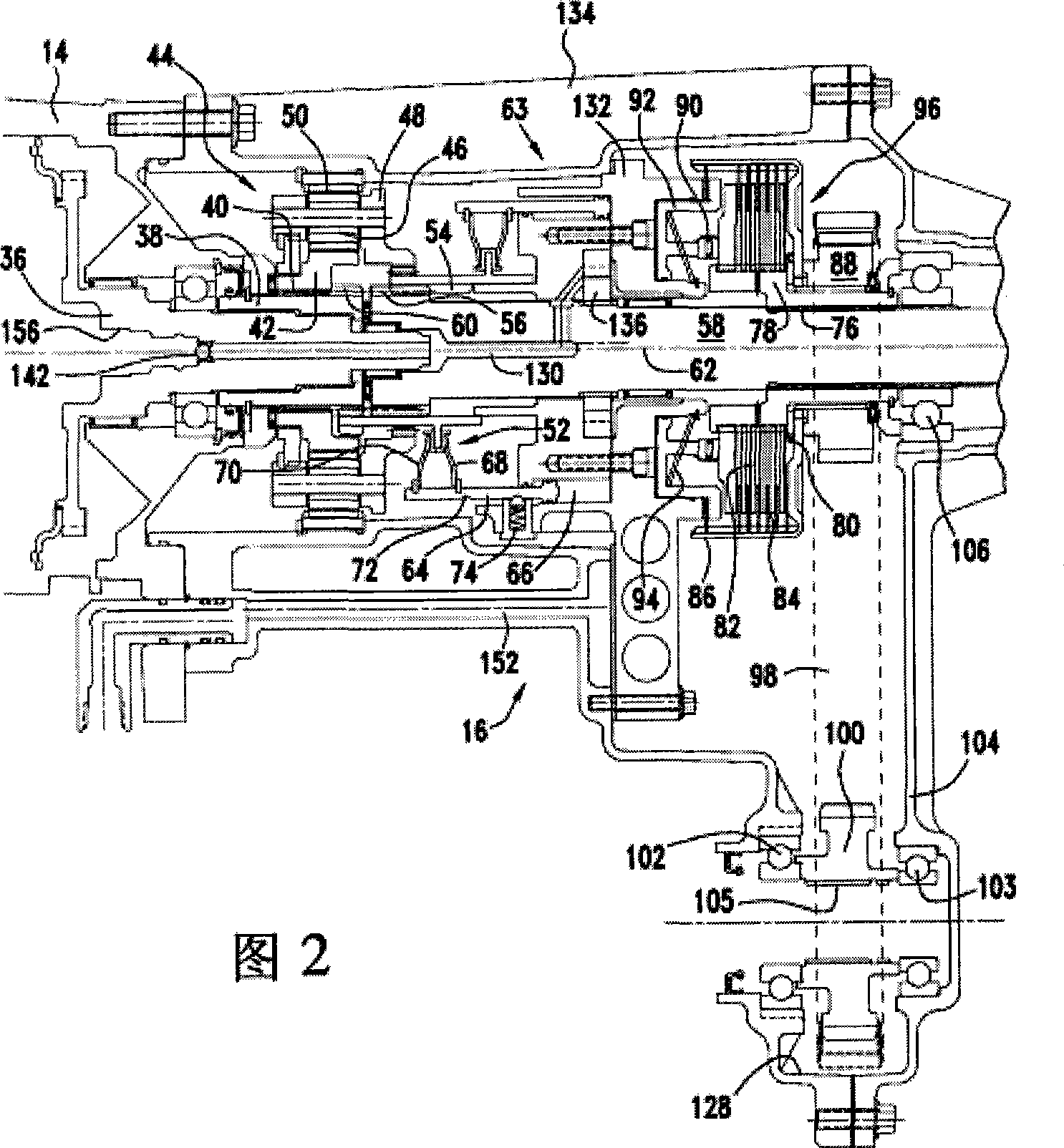

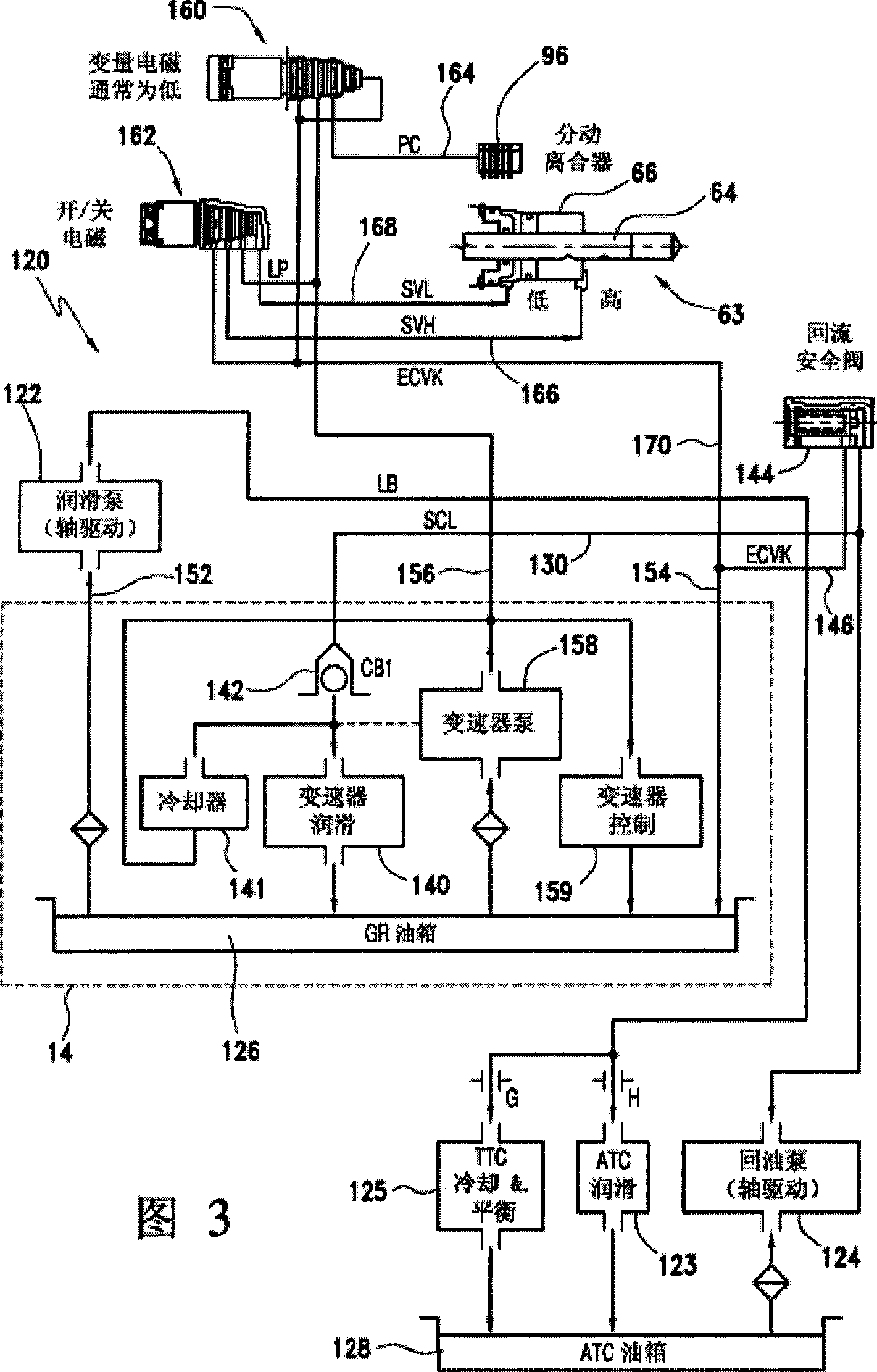

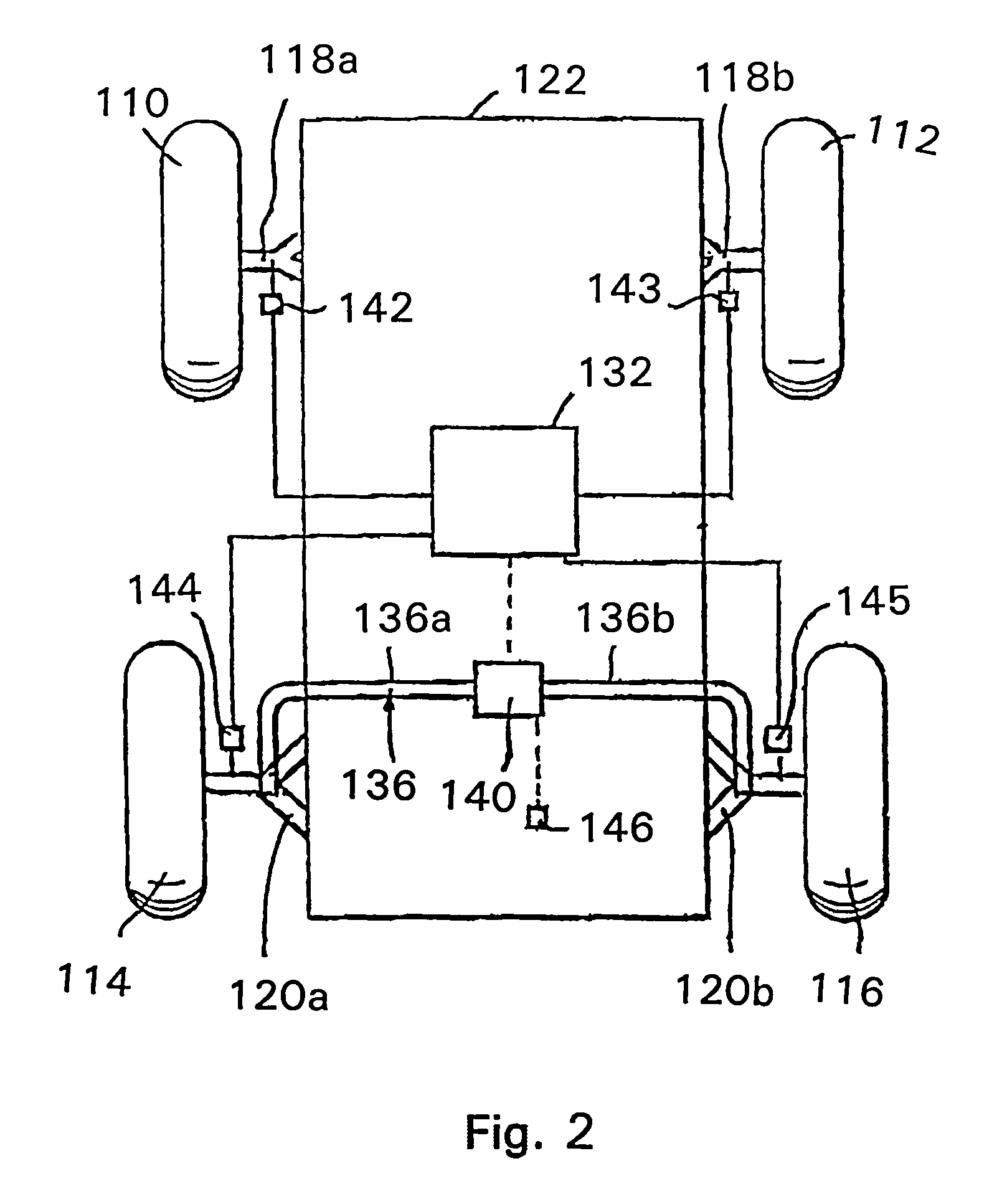

Transfer Case for a Motor Vehicle Powertrain

InactiveUS20090143182A1Drag efficiency reductionFuel efficiency reductionGear lubrication/coolingLubrication pressure controlTransfer caseDrivetrain

A motor vehicle powertrain includes a multiple speed transmission including a first lube circuit that supplies hydraulic lubricant to components of the transmission, a first oil sump, and a first pump driveably connected to an engine for supplying oil at a first pressure to the lube circuit, a transfer case including a first output, a second oil sump located in the transfer case, a second pump located in the transfer case and driveably connected to the first output, and a check valve for alternately opening and closing a connection between the first pump and the lube circuit and for opening and closing a connection between the second pump and the lube circuit in response to differential pressure between an outlet of the first pump and an outlet of the second pump.

Owner:FORD GLOBAL TECH LLC

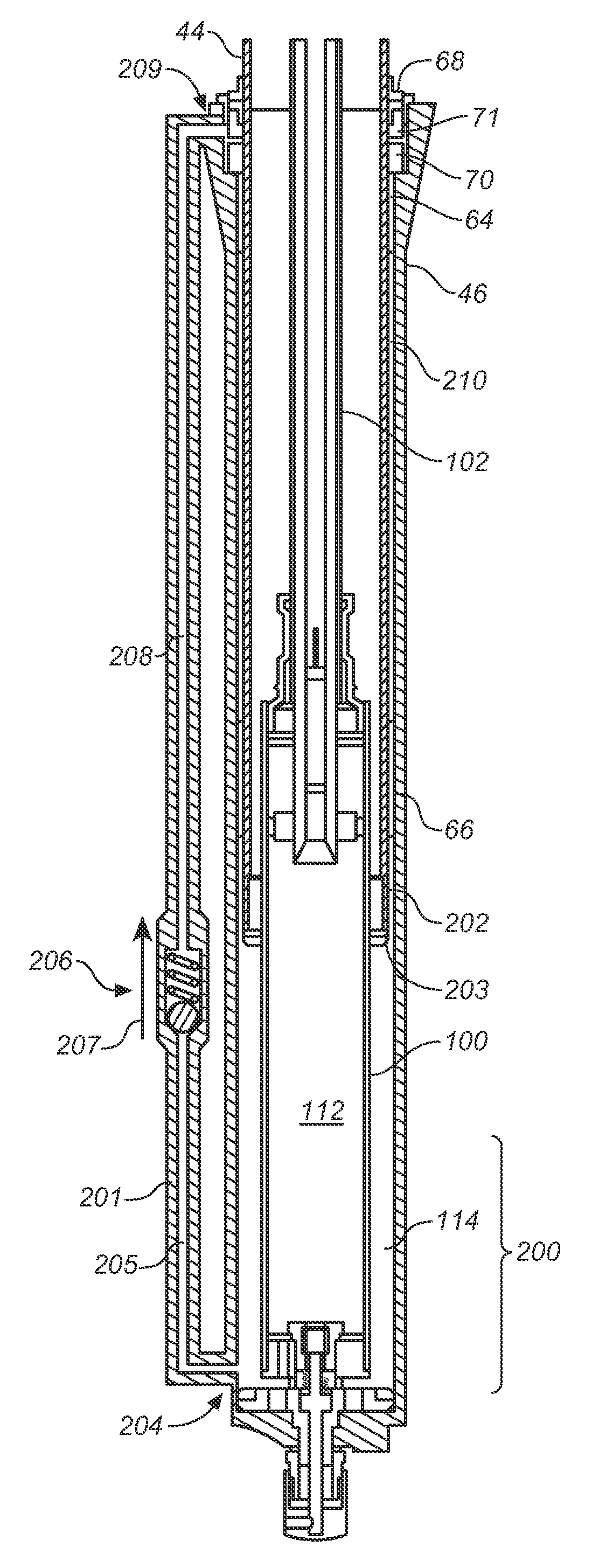

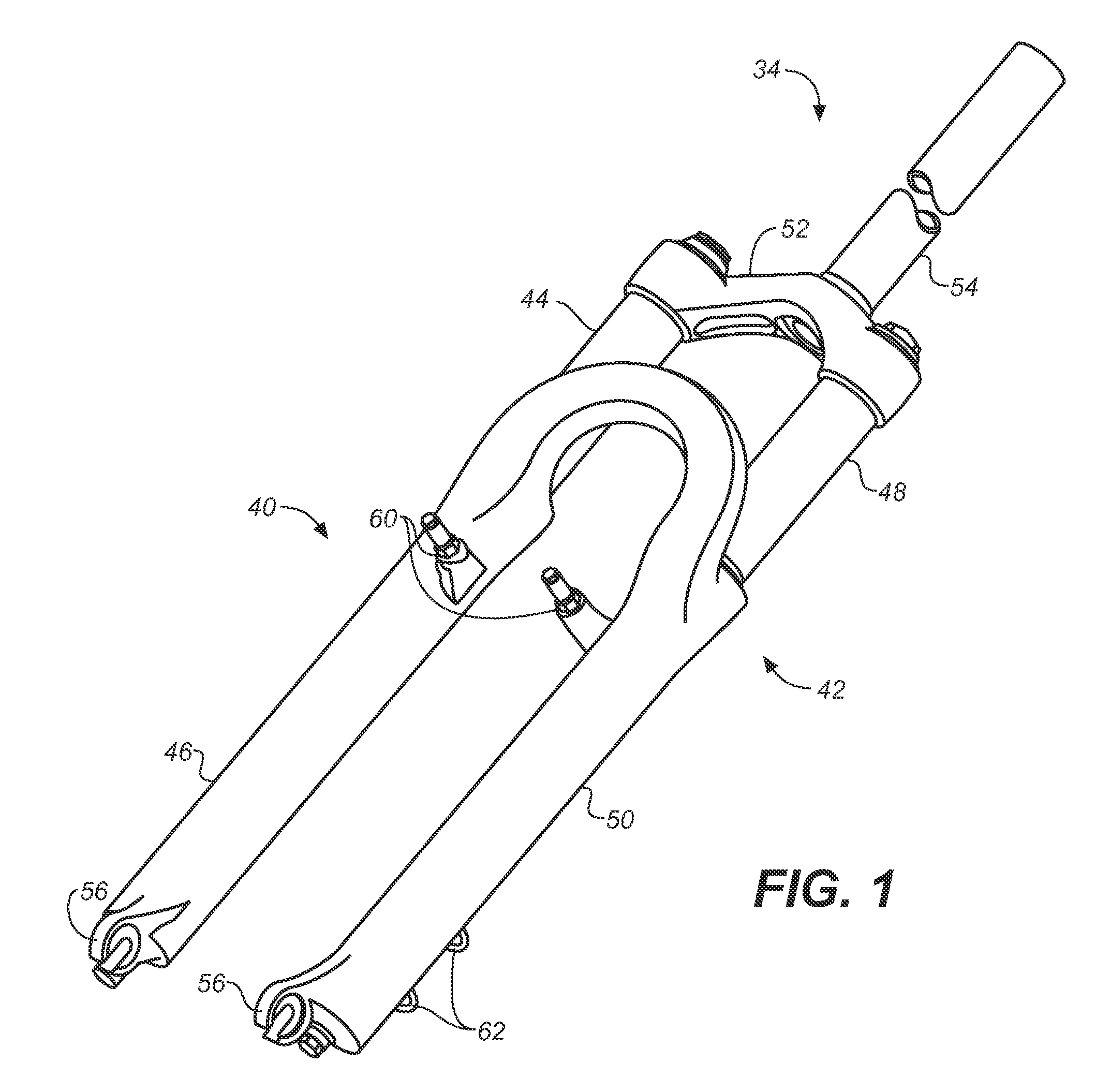

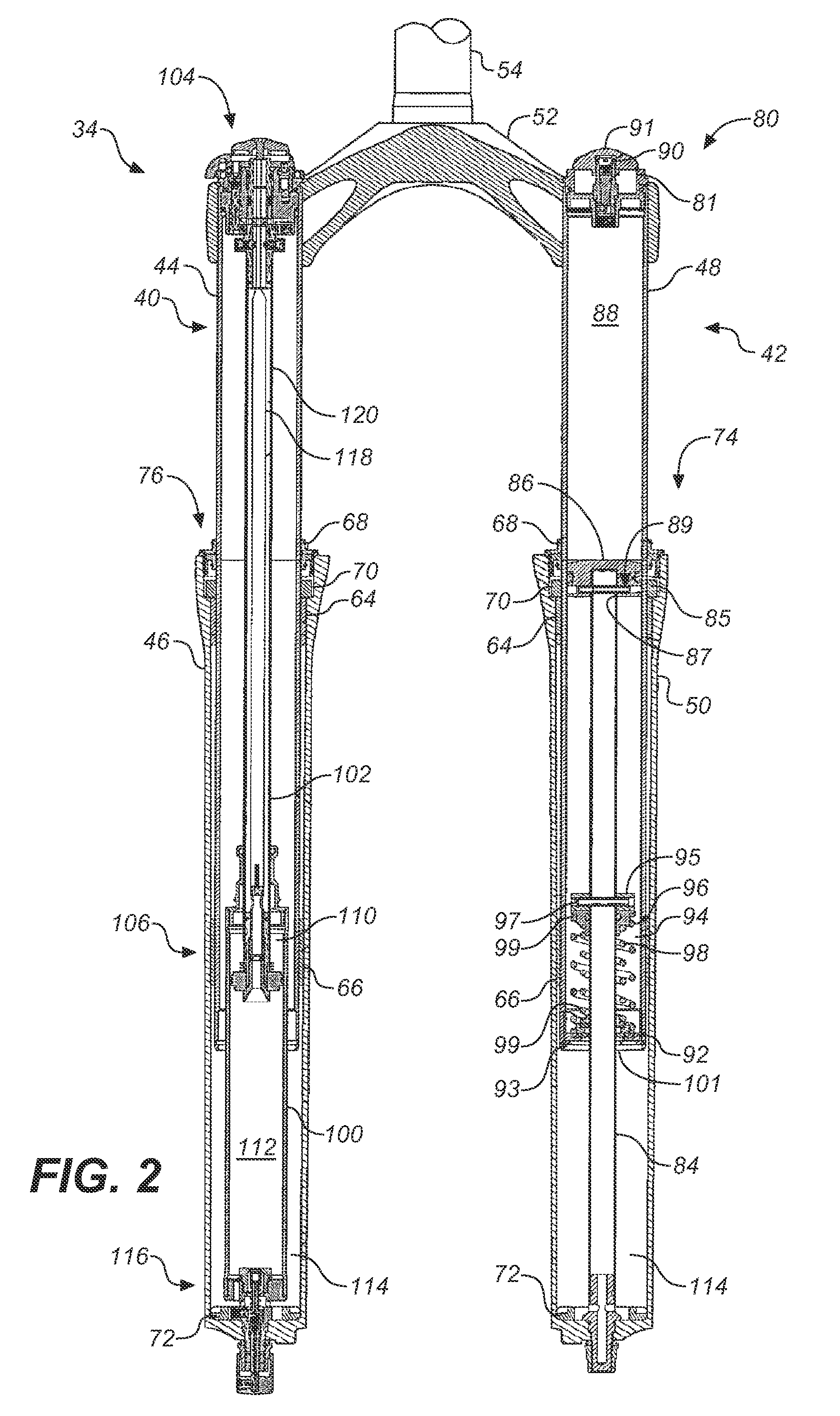

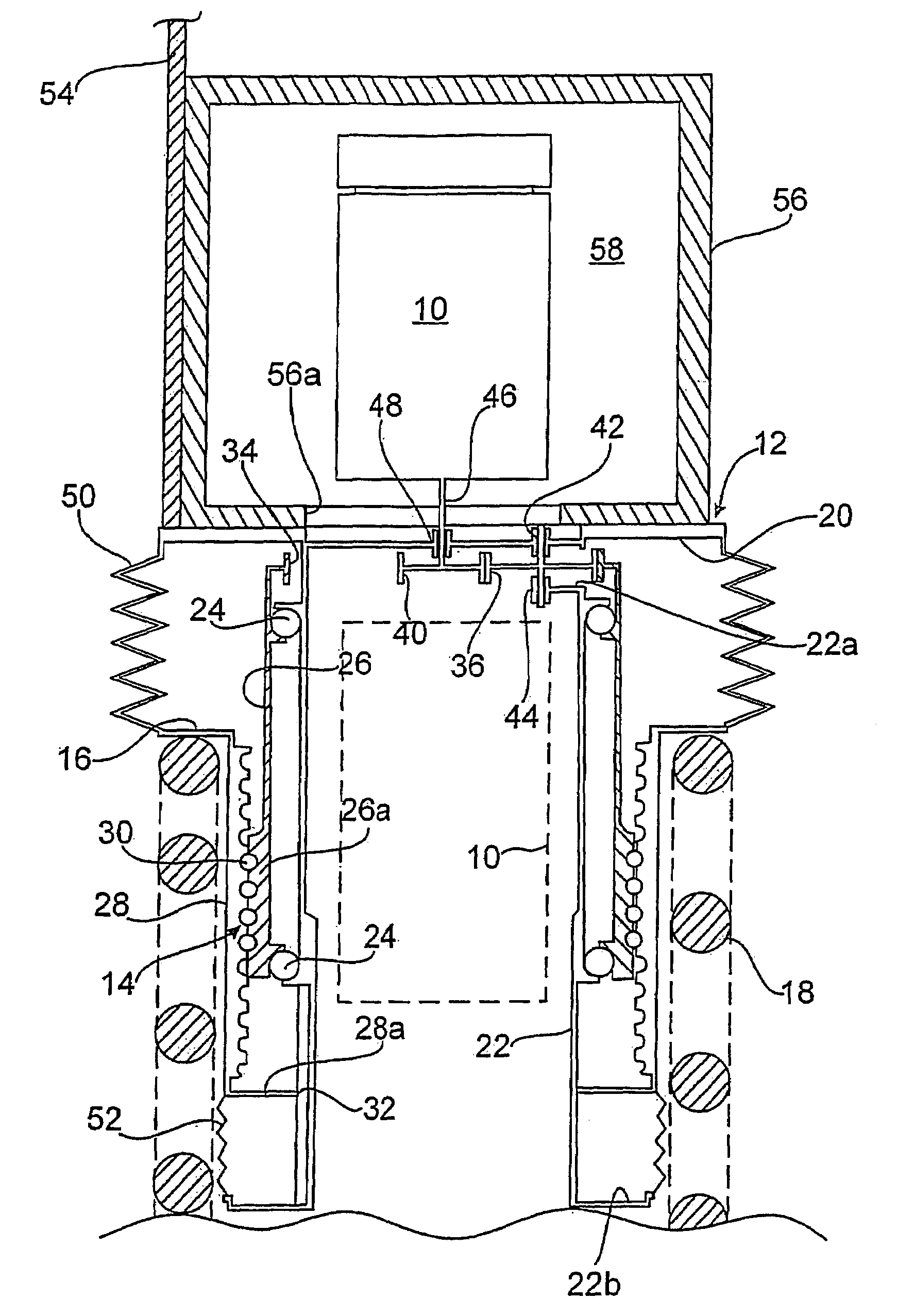

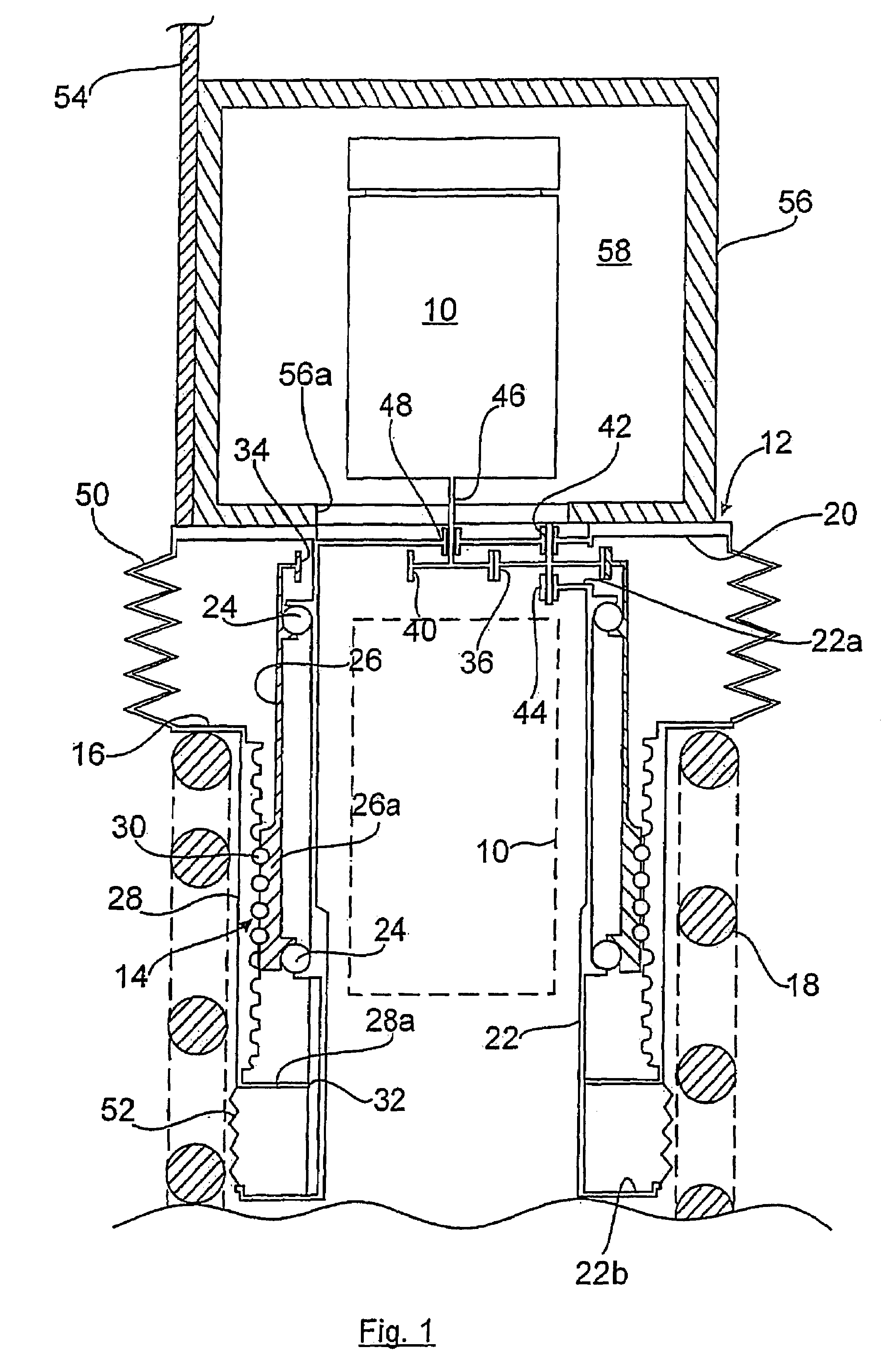

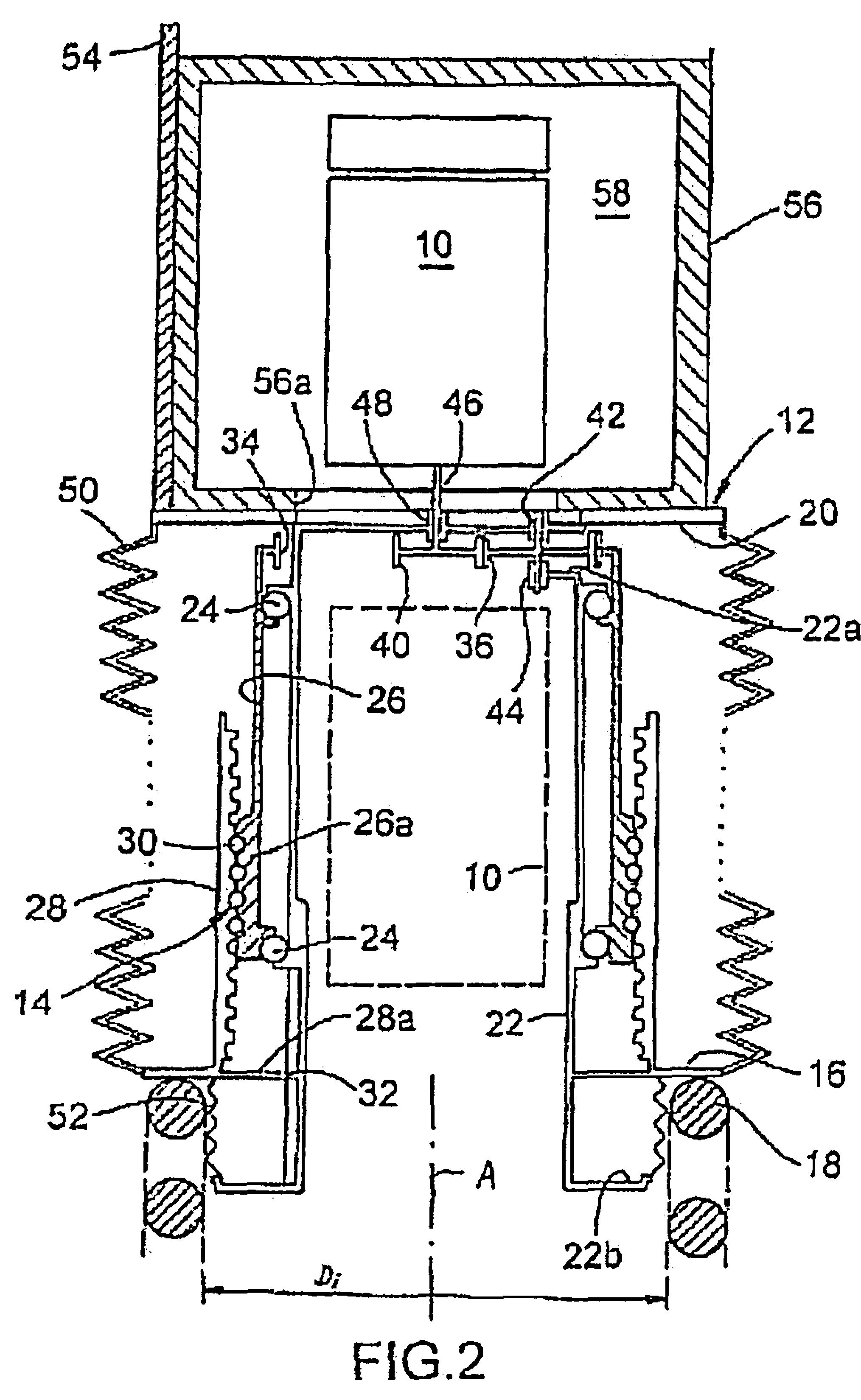

Methods and apparatus for lubricating suspension components

Owner:FOX FACTORY

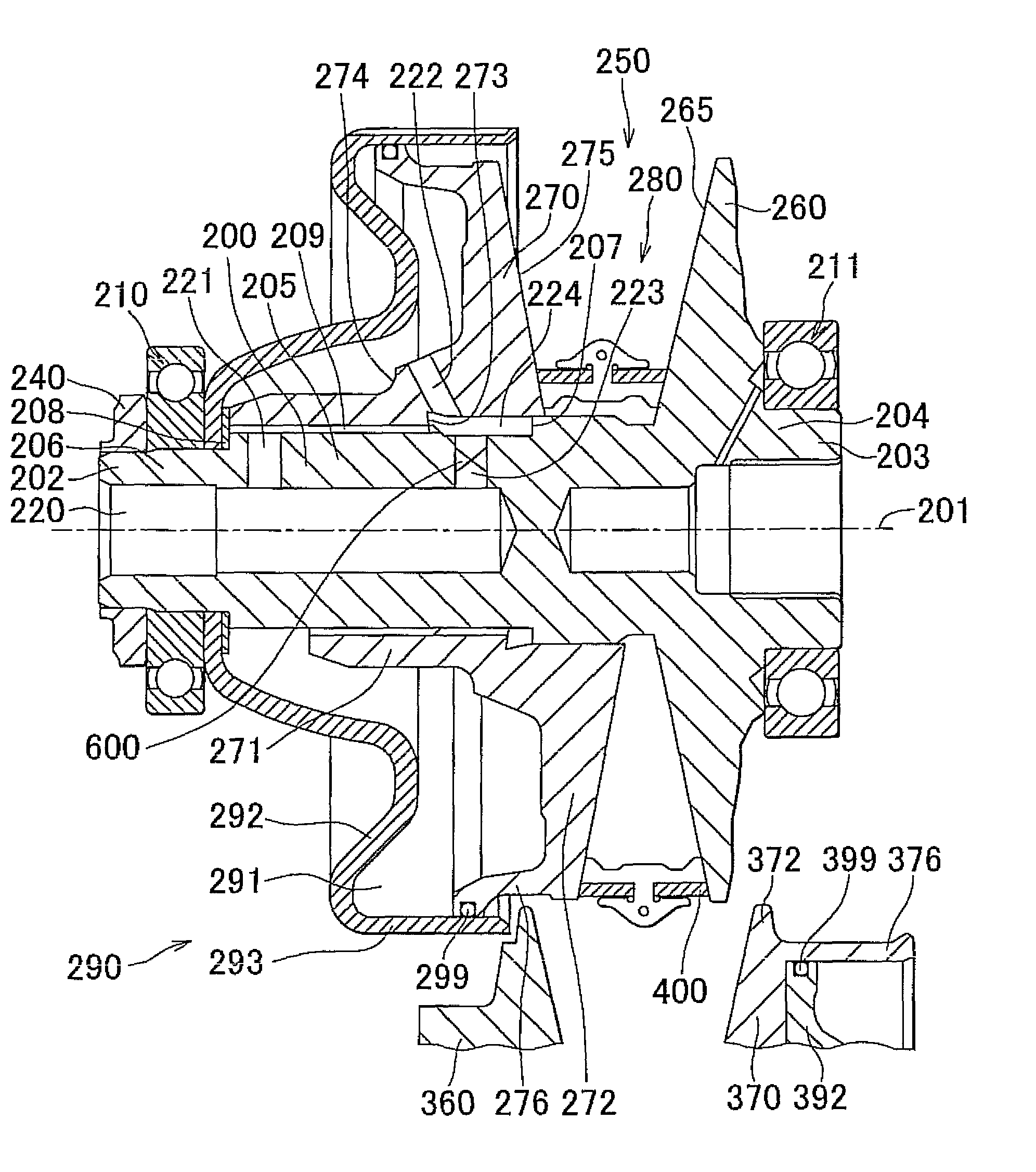

Continuously variable transmission

ActiveUS8100791B2Precise positioningReduce internal pressureProportioning devicesPortable liftingPulleyPetroleum engineering

Owner:TOYOTA JIDOSHA KK

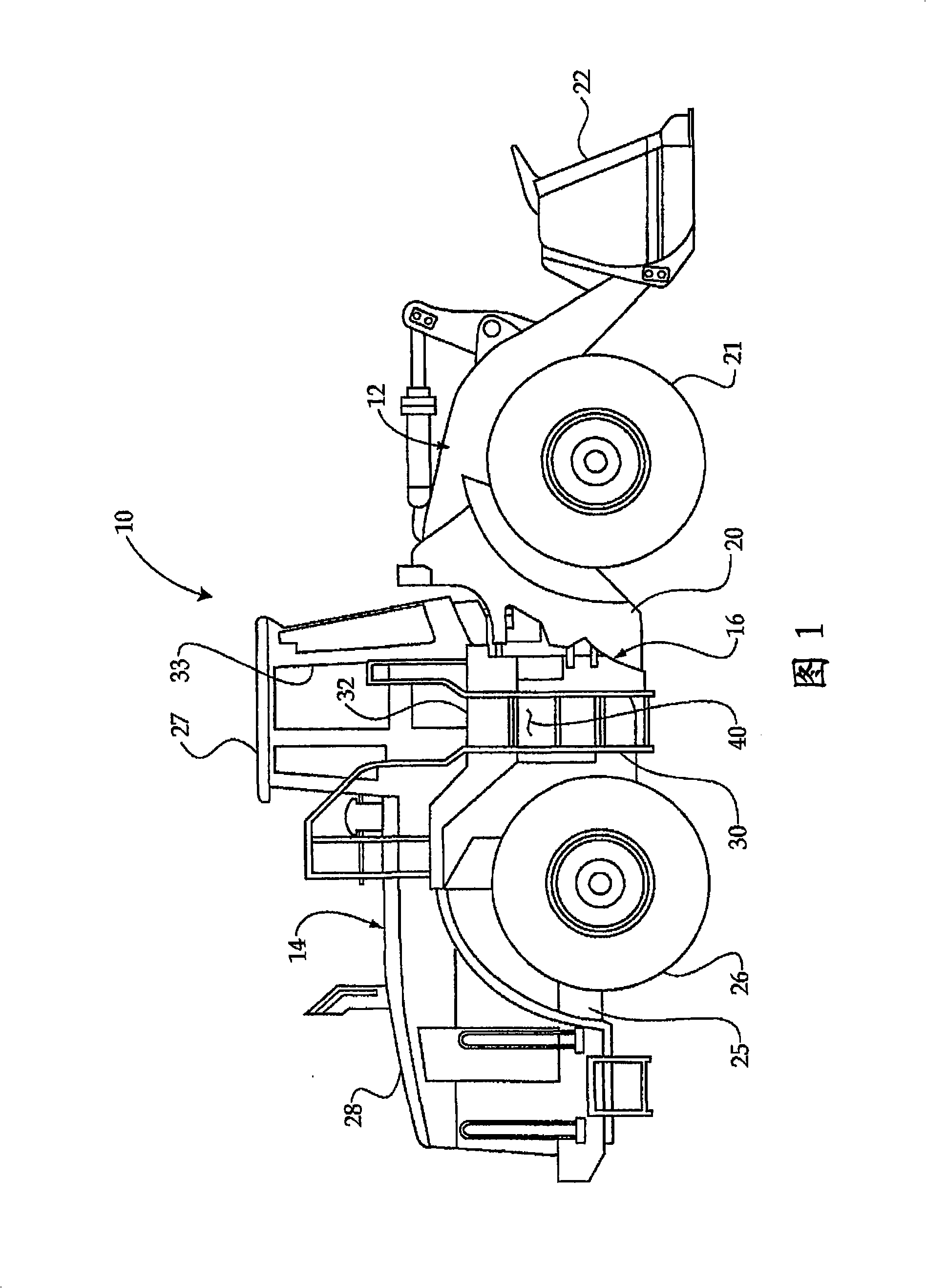

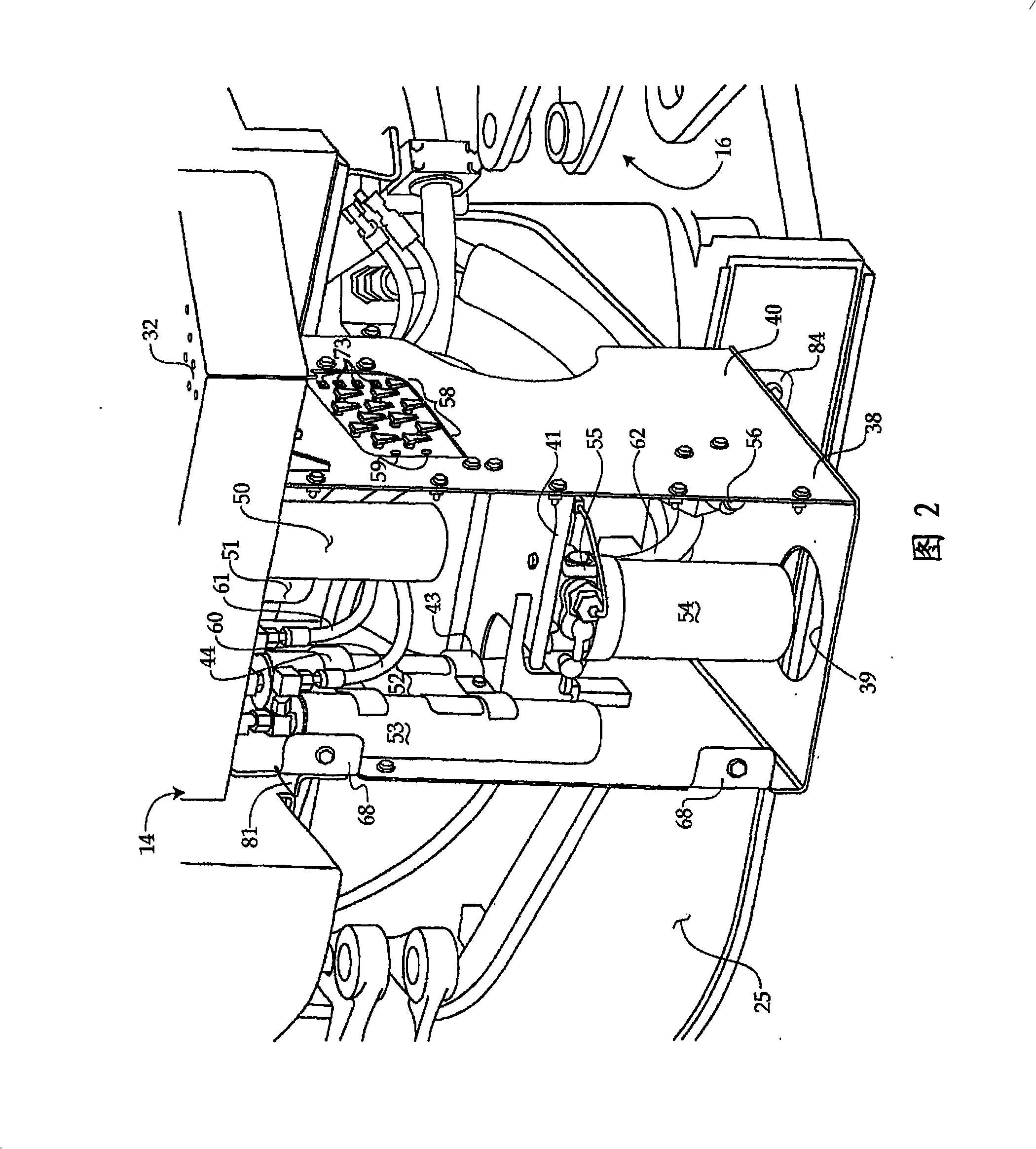

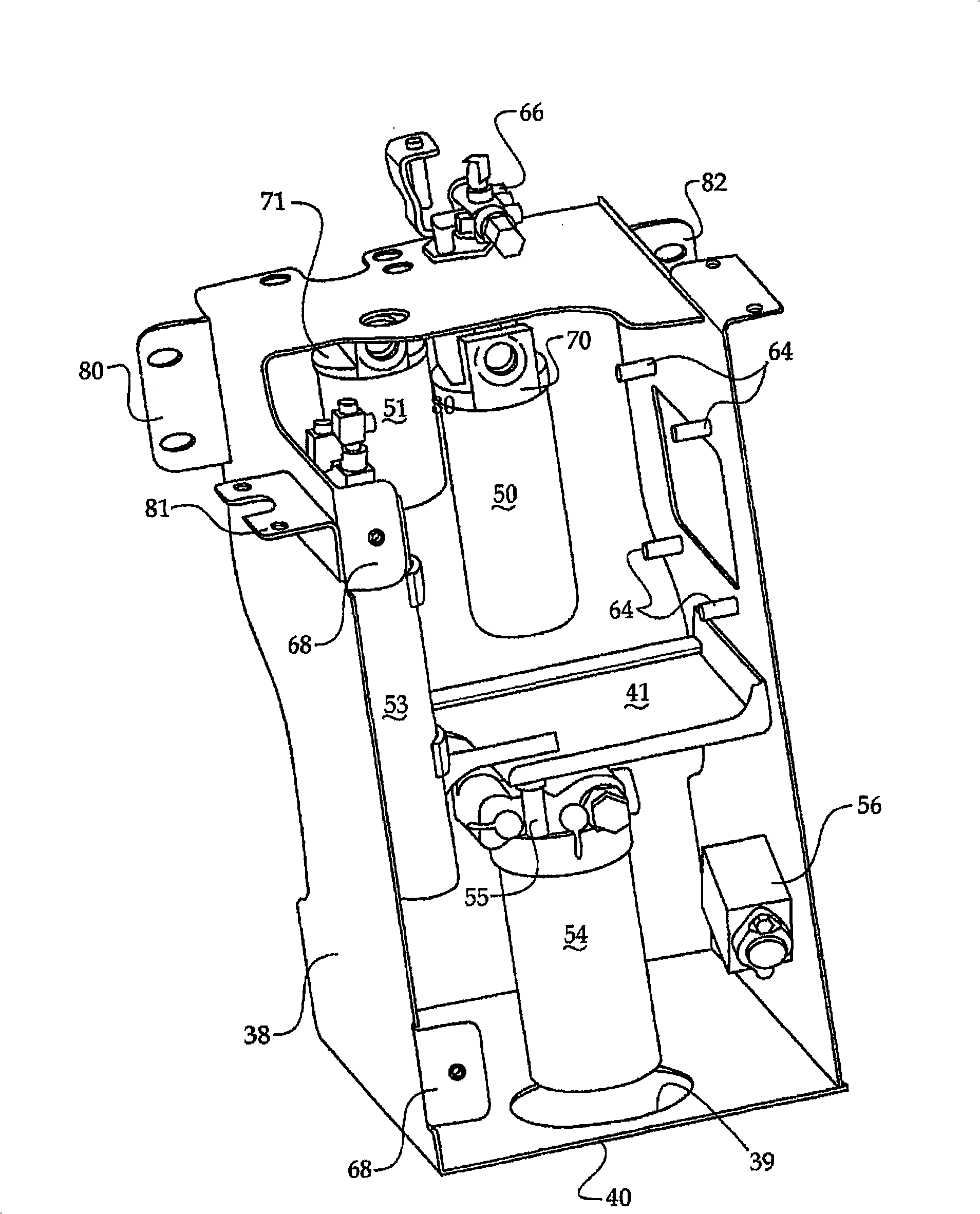

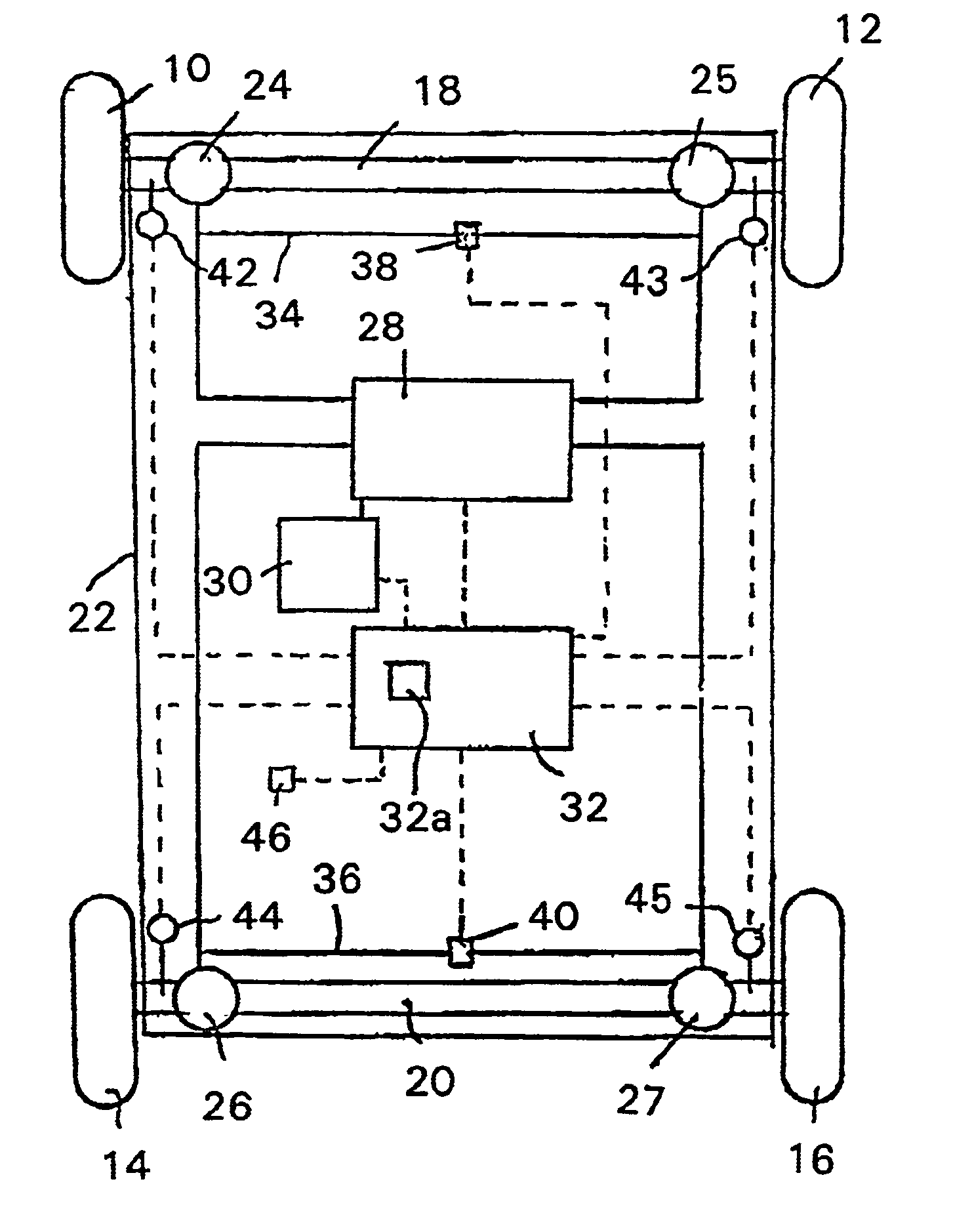

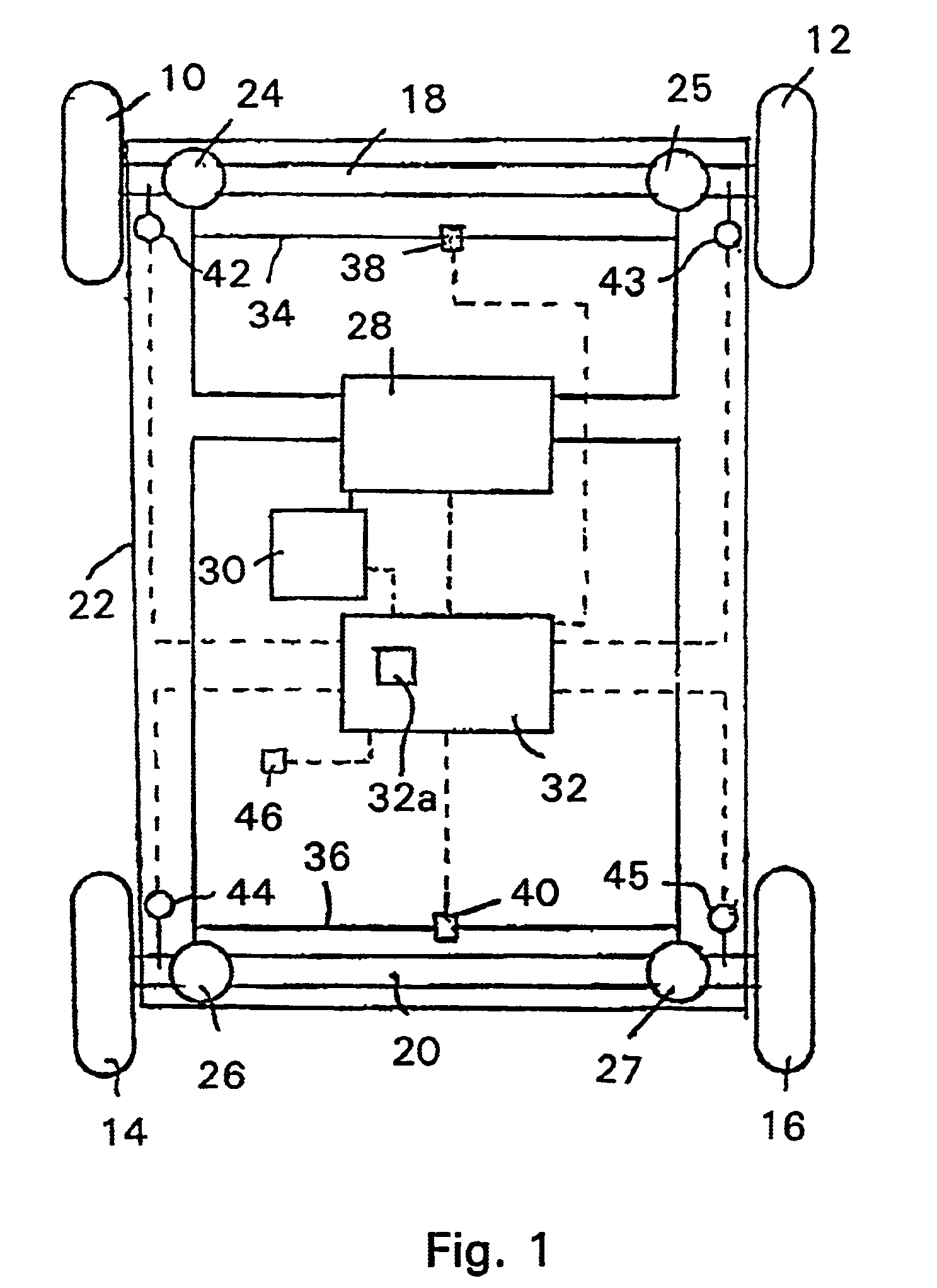

Work machine with electrical and hydraulic service centers

InactiveCN101356323ASoil-shifting machines/dredgersSuperstructure subunitsHydraulic fluidRolling chassis

An articulated work machine (10), such as a wheel loader, includes many regularly serviced hydraulic points, such as a hydraulic fluid filter (50), a case drain filter (51), a transmission fluid filter (54) and brake accumulators (52, 53) that are grouped and mounted in a common service center subassembly (40), which may be preassembled and then later attached to the chassis when the machine (10) is being built. Likewise, an electrical service center subassembly (140) might include a battery box (144), relays and an emergency shutoff switch (150) that can be preassembled and attached to the machine chassis as a unit at the time that the work machine (10) is being built. The respective hydraulic and electrical service centers (40, 140) are attached to the work machine chassis underneath cab access steps (32, 132) on opposite sides of the machine (10). This strategy allows for a potential reduction in cost during the work machine (10) manufacture, and also better facilitates servicing of the hydraulic and / or electrical service points at an easily accessible and common location(s).

Owner:CATERPILLAR INC

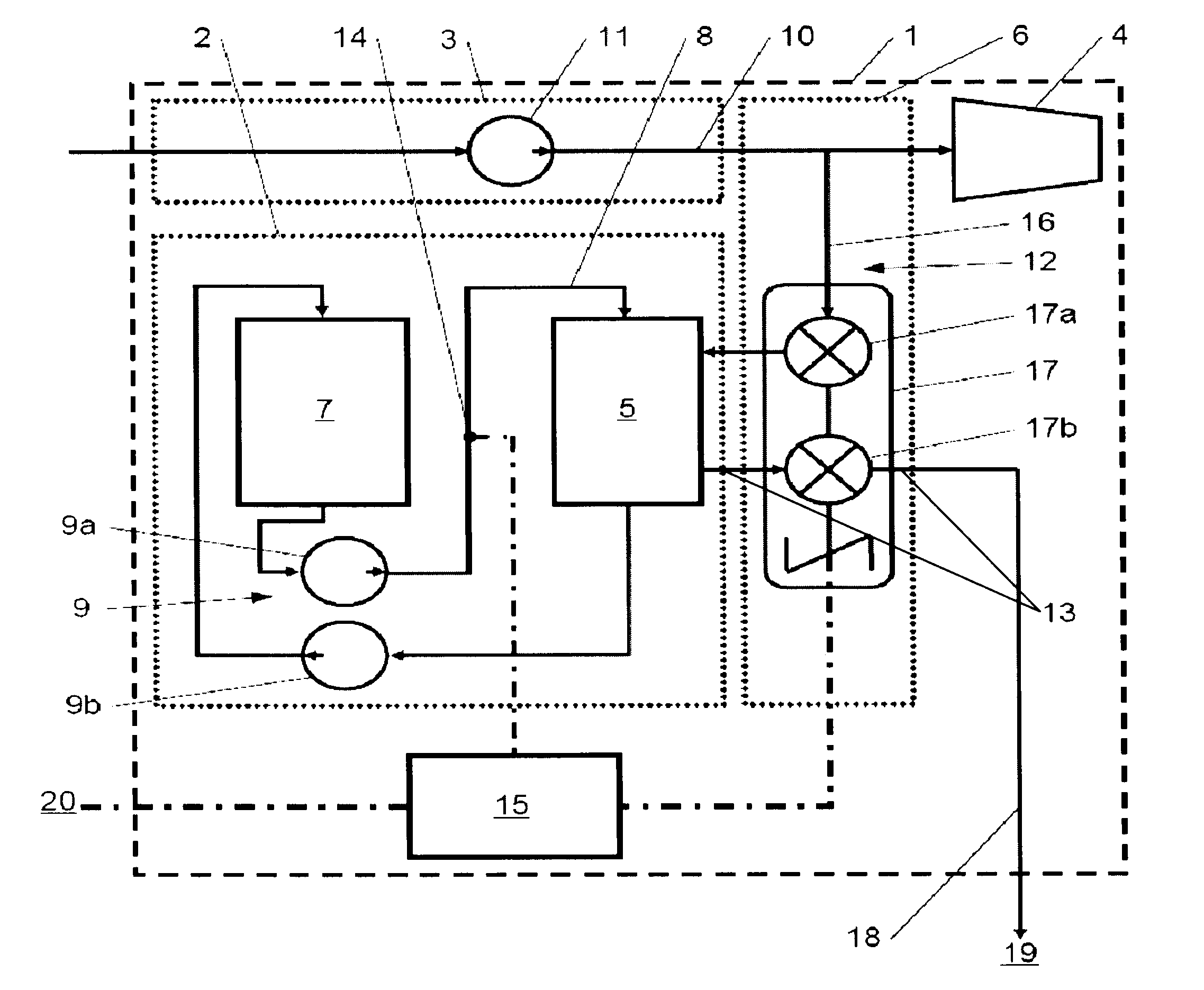

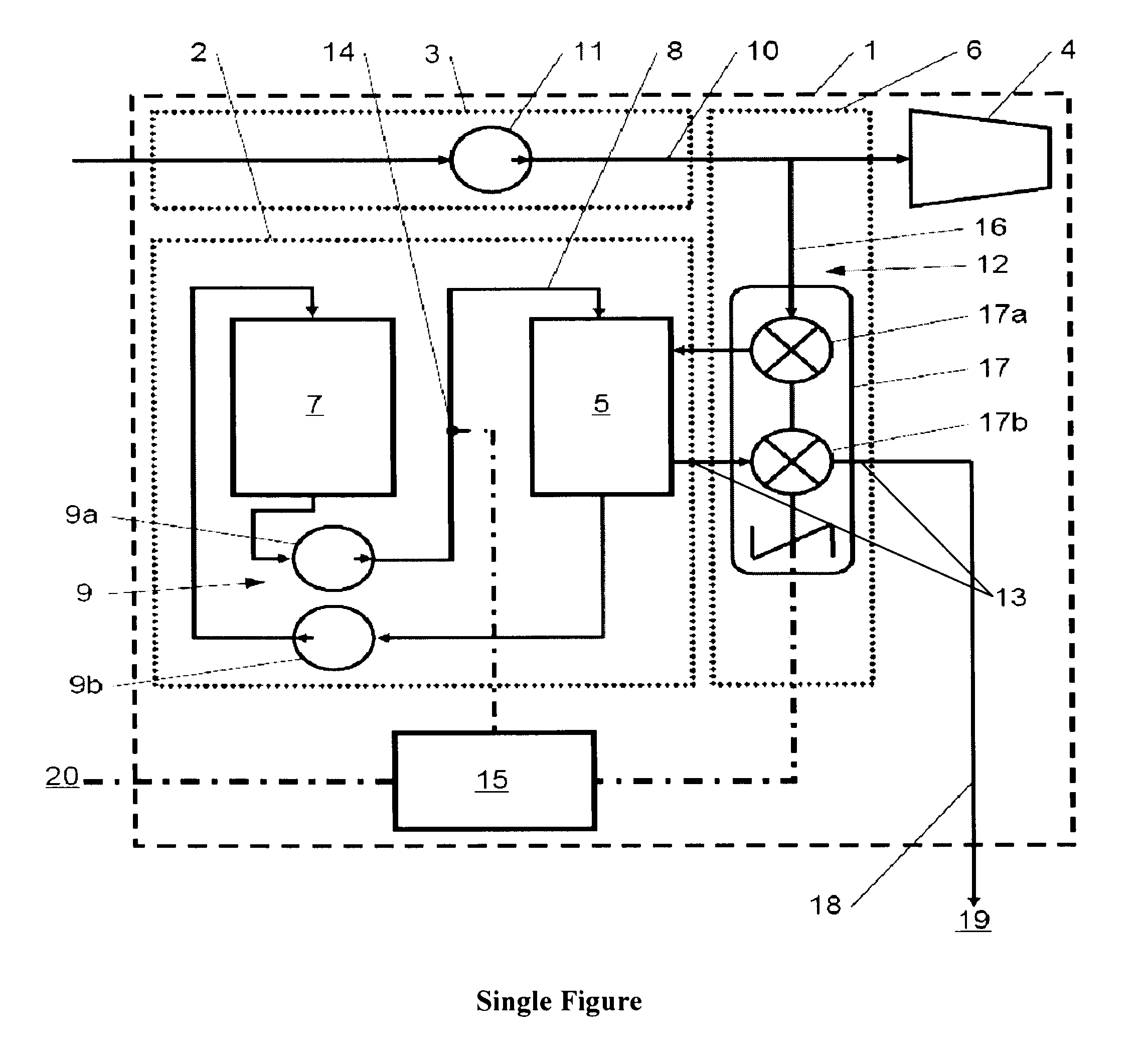

Device and method of standby lubrification for an engine

ActiveUS20080196974A1Minimal weight penaltyEasy to adaptAnalogue computers for vehiclesCrankshaftsLubricationAutomotive engineering

The invention relates to a standby lubrication method for an engine 1 in the event of the failure of a main lubrication system 2 of this engine 1, in which said failure is detected and, in response to the detection of this failure, at least one portion of a fuel fluid of the engine 1 is tapped off to lubricate at least one element of the engine 1. The invention also relates to a standby lubrication device 6 for an engine 1 comprising a main lubrication system 2, said standby lubrication device 6 comprising means for detecting a failure of the main lubrication system 2, means 12 for tapping off at least a portion of a fuel fluid of the engine 1 in order to direct it to at least one element of the engine 1 intended to be lubricated, and control means 15 capable of being connected to said tapping and detection means 12, in order to carry out the standby lubrication method.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

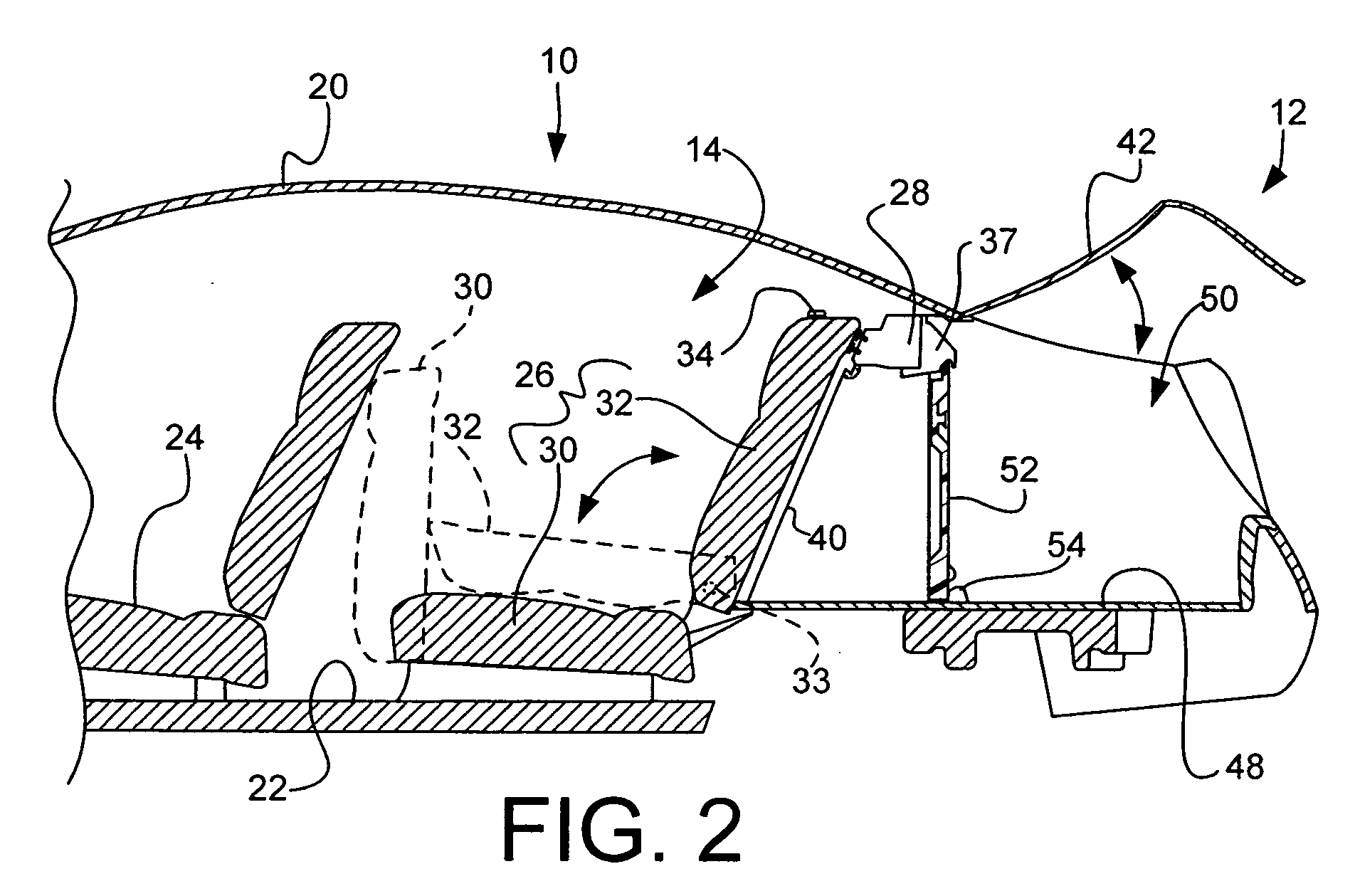

Vehicle compartment divider

InactiveUS20060170236A1Improve versatilityIncrease storage capacityPassenger spaceVehicle arrangementsEmbedded systemHolding room

A vehicle compartment structure includes a vehicle storage compartment defining a storage area with a floor. A rigid compartment divider is pivotally coupled to the floor of the storage compartment between a first substantially horizontal storage position and a second substantially vertical dividing position. In the horizontal storage position, the storage area is substantially unobstructed by the rigid compartment divider. In the second substantially vertical dividing position, the compartment divider divides the storage compartment into two separate spaces.

Owner:NISSAN MOTOR CO LTD

Transfer case for a motor vehicle powertrain

InactiveCN101445055AReduce resistanceCancel noiseClutchesGear lubrication/coolingMobile vehicleTransfer case

A motor vehicle powertrain includes a multiple speed transmission including a first lube circuit that supplies hydraulic lubricant to components of the transmission, a first oil sump, and a first pump driveably connected to an engine for supplying oil at a first pressure to the lube circuit, a transfer case including a first output, a second oil sump located in the transfer case, a second pump located in the transfer case and driveably connected to the first output, and a check valve for alternately opening and closing a connection between the first pump and the lube circuit and for opening and closing a connection between the second pump and the lube circuit in response to differential pressure between an outlet of the first pump and an outlet of the second pump.

Owner:FORD GLOBAL TECH LLC

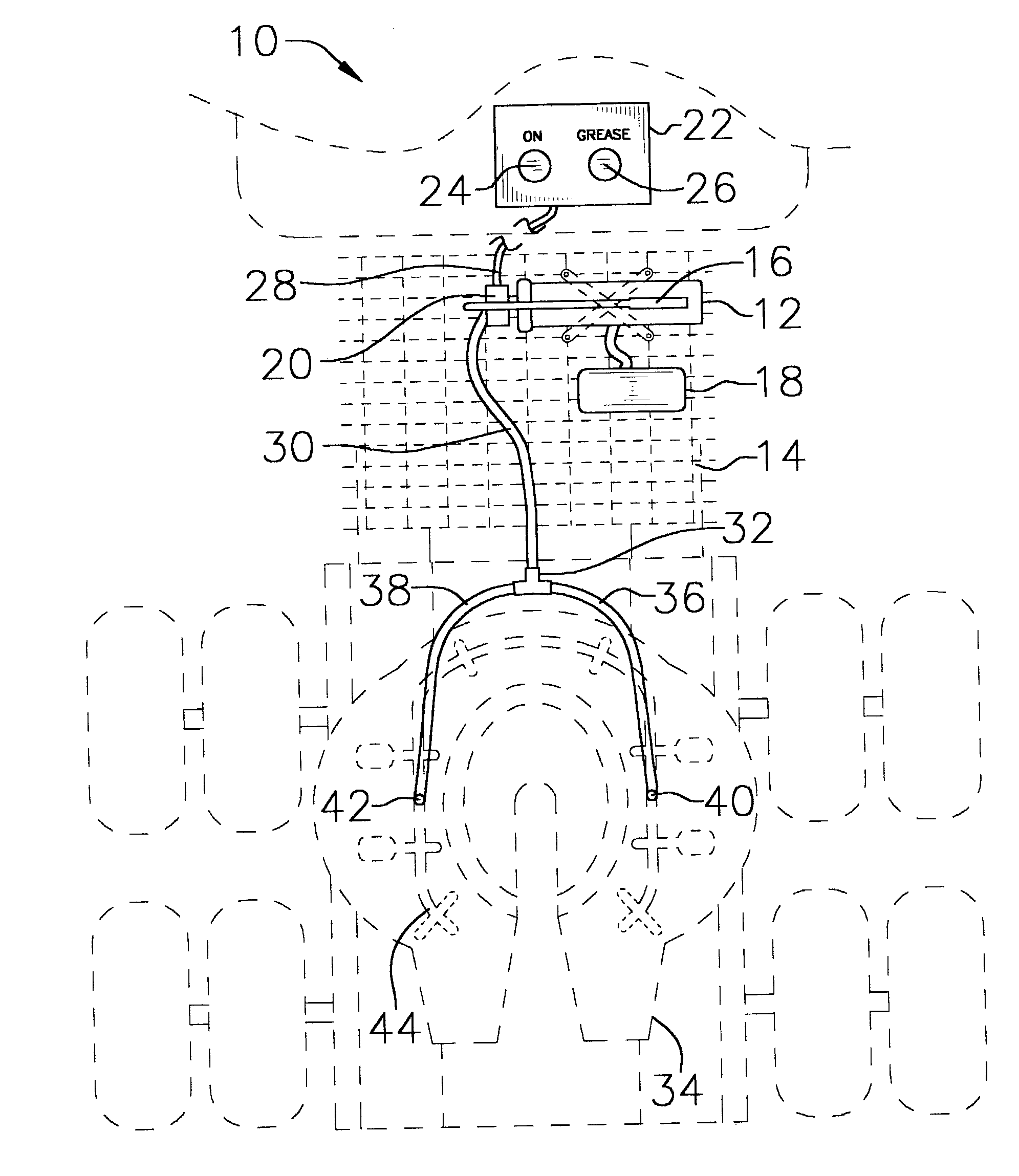

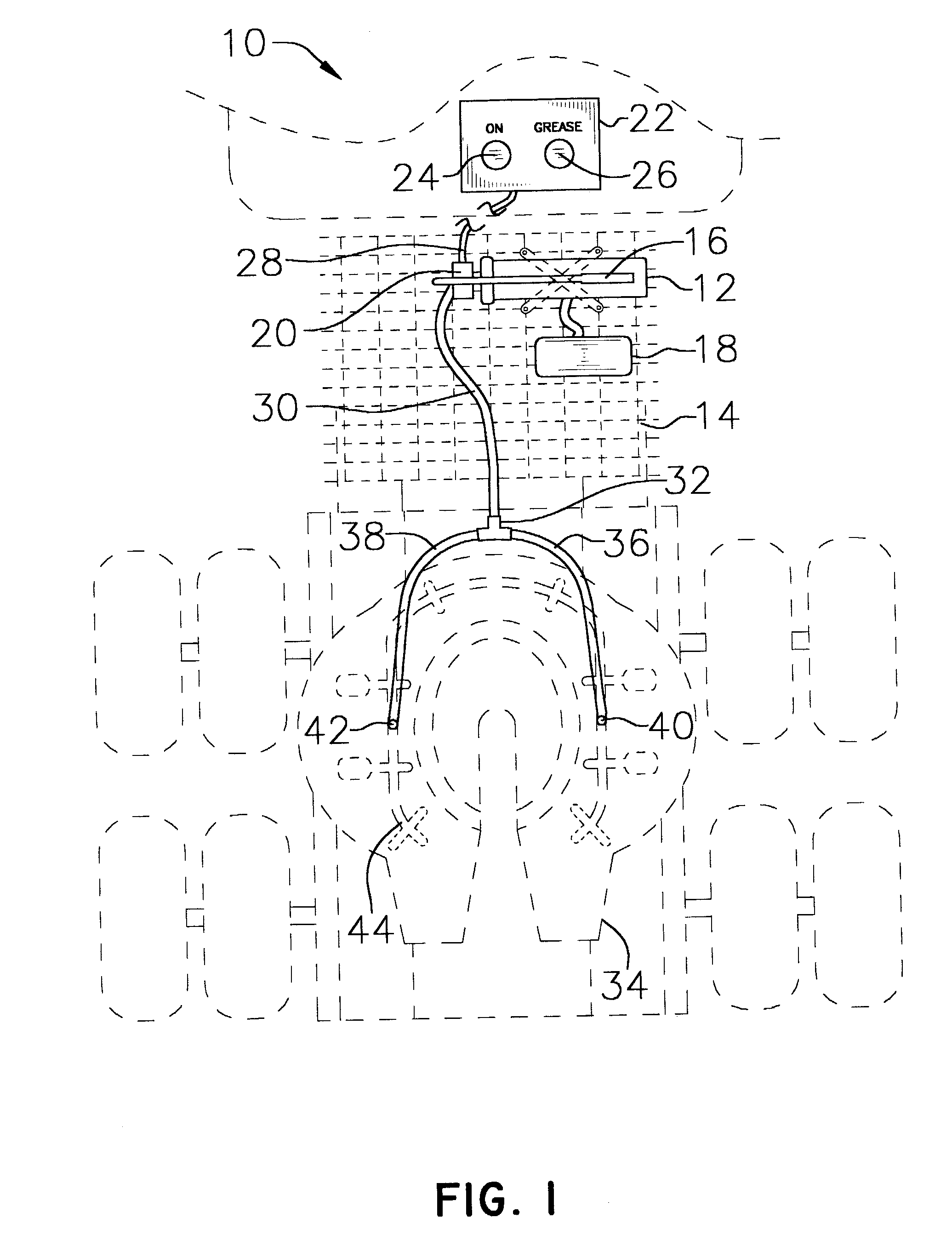

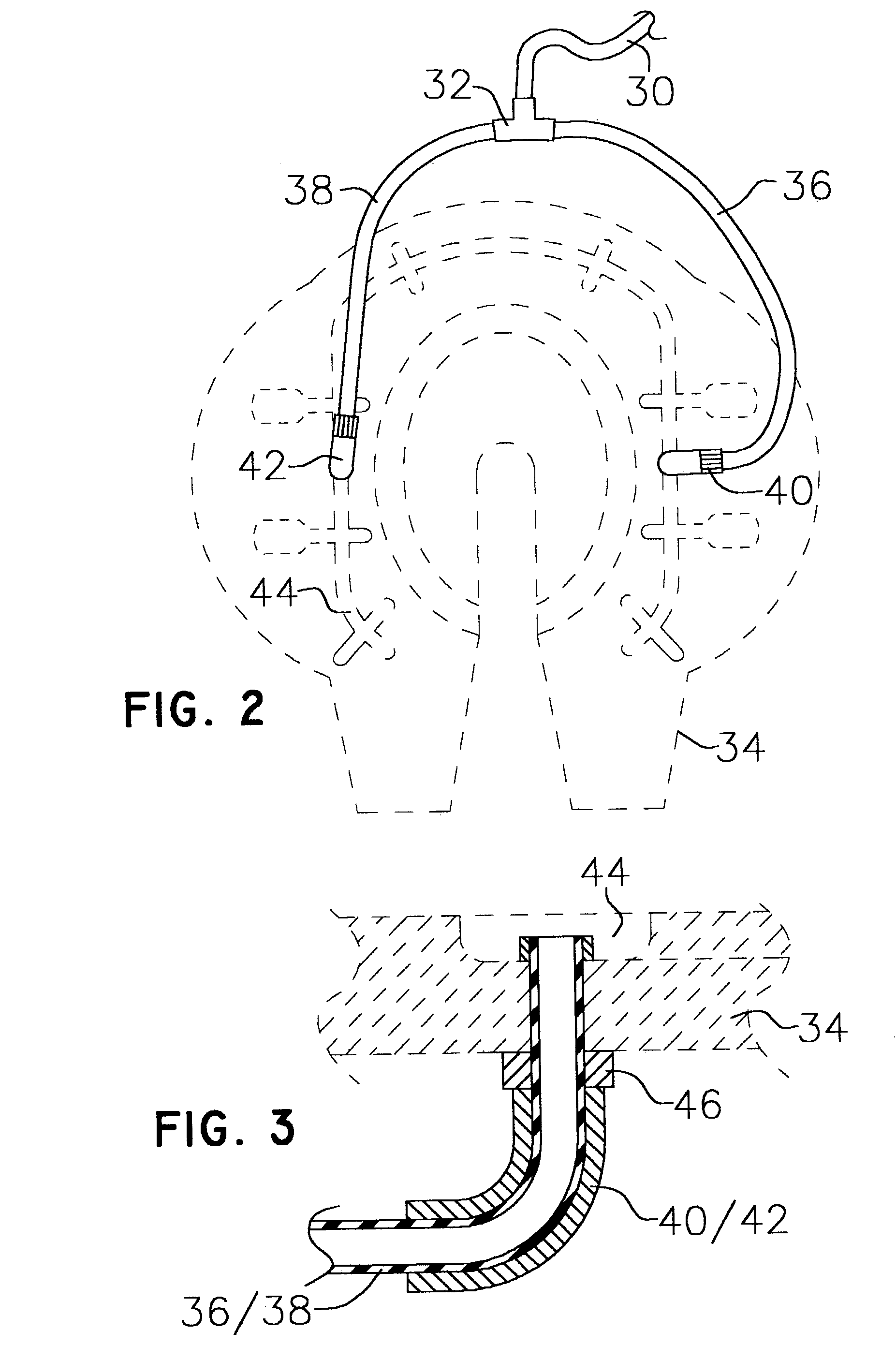

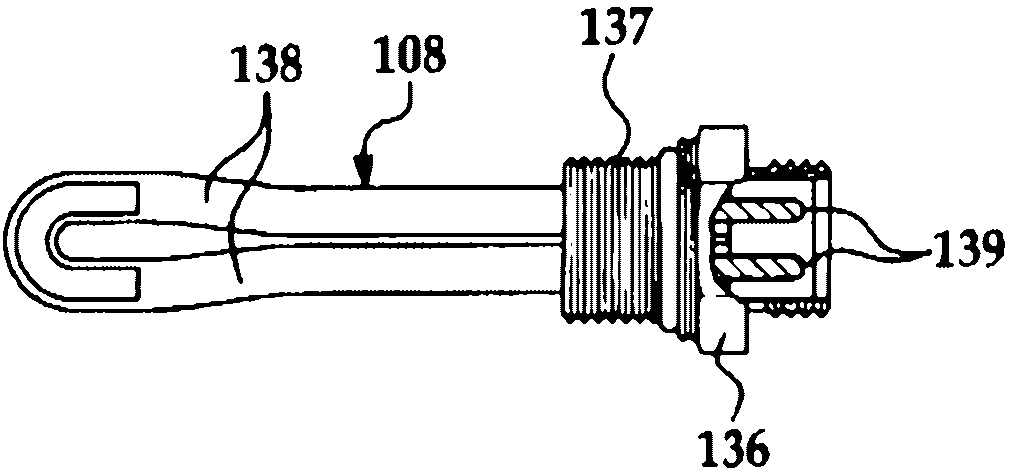

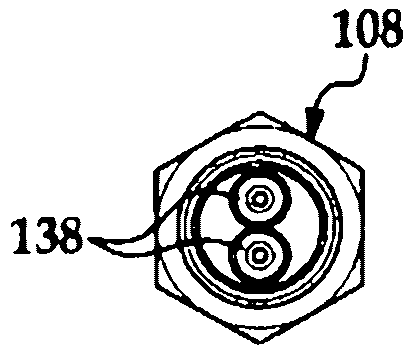

Fifth wheel lubrication system

InactiveUS6874599B1Easy and efficient to manufactureLower sales priceManual lubricationMachines/enginesEngineeringAir compressor

A fifth wheel lubricating system for greasing the interface between the upper and lower fifth wheel plates while the trailer is couple to the tractor. The system supplies grease form a cartridge that is coupled to a solenoid activated grease valve and controlled by means of an electrical controller mounted in the cab or on the catwalk of the fifth wheel tractor. The grease gun is operated pneumatically from an onboard air compressor or can be manually operated by means of a hand pump lever built into the grease gun. A primary grease hose carries grease from the grease valve to a grease distribution hub, where it is distributed to two or more distribution hoses that connect to the bottom side of the tractor mounted lower fifth wheel plate. The grease is forced up through holes in the lower fifth wheel plate, into grease slots on the top side of the lower plate. In operation, the driver can push a button on the controller and force a desired amount of grease into the grease slots located at the interface between the upper and lower fifth wheel plates, thereby providing a more convenient, cleaner, and more efficient means of lubricating a fifth wheel.

Owner:RISKEDAL BRAD A

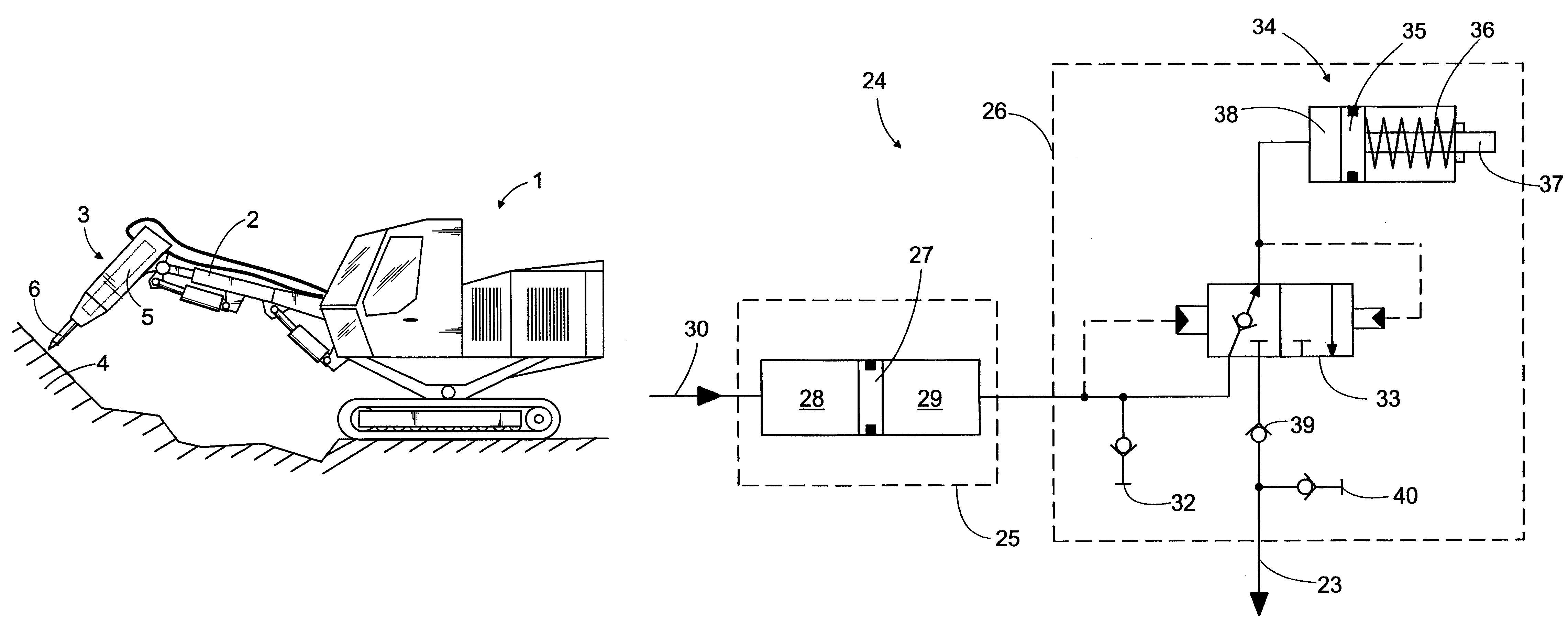

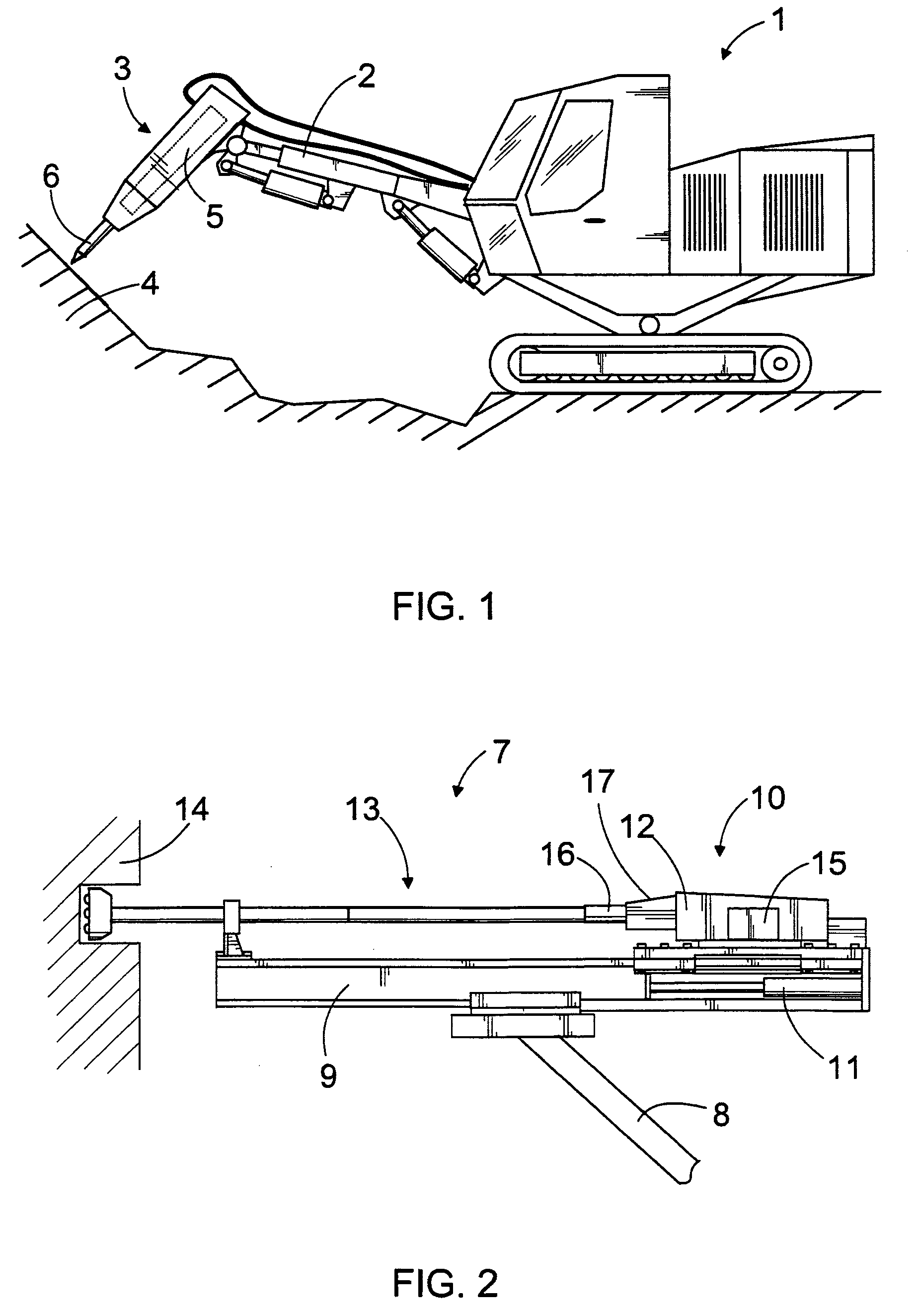

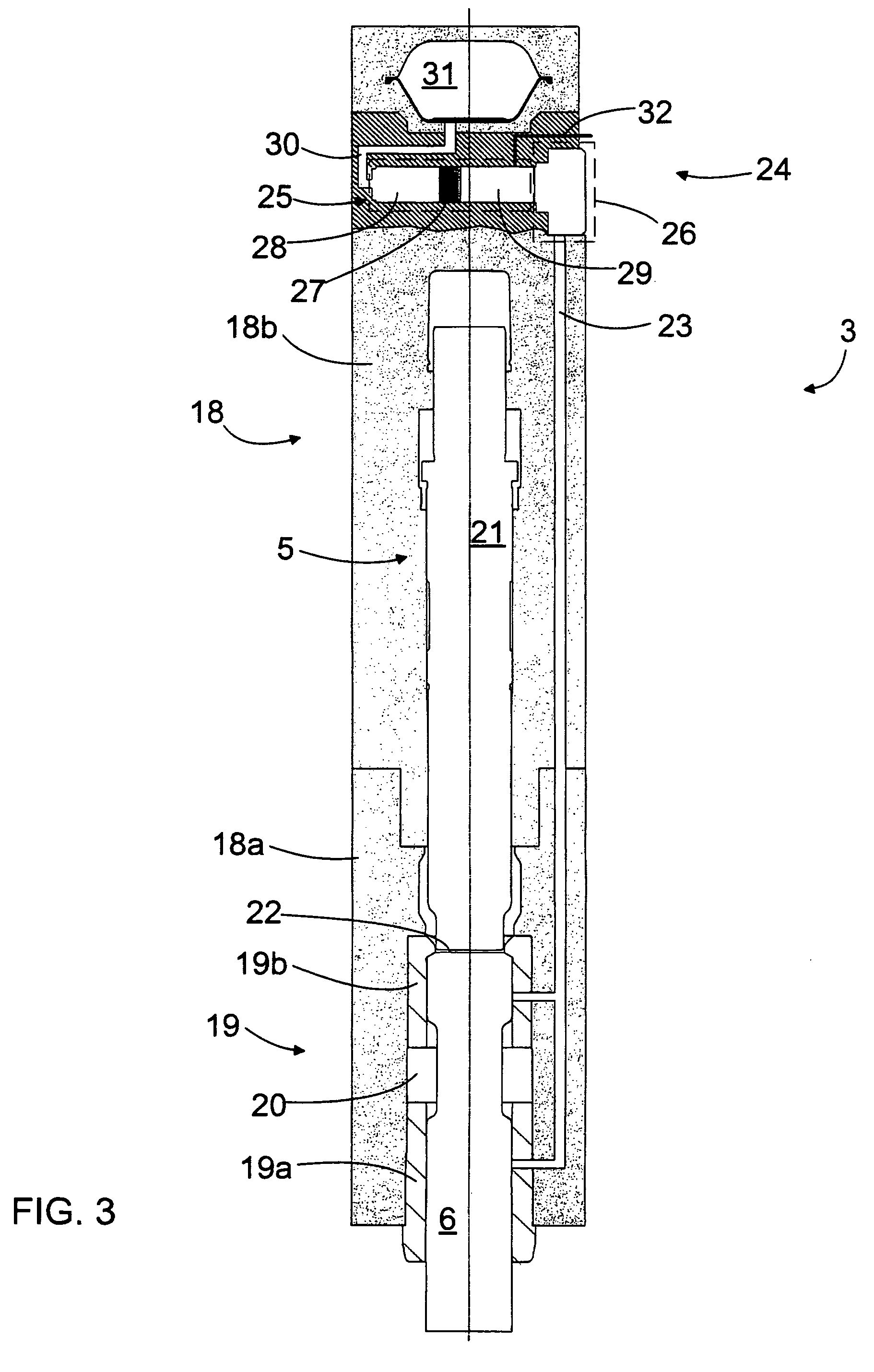

Rock breaking machine and lubricating method

InactiveUS7694748B2Effective lubricationProlong lifeSoil-shifting machines/dredgersPortable power-driven toolsEngineeringLubricant

Owner:SANDVIK MINING & CONSTR OY

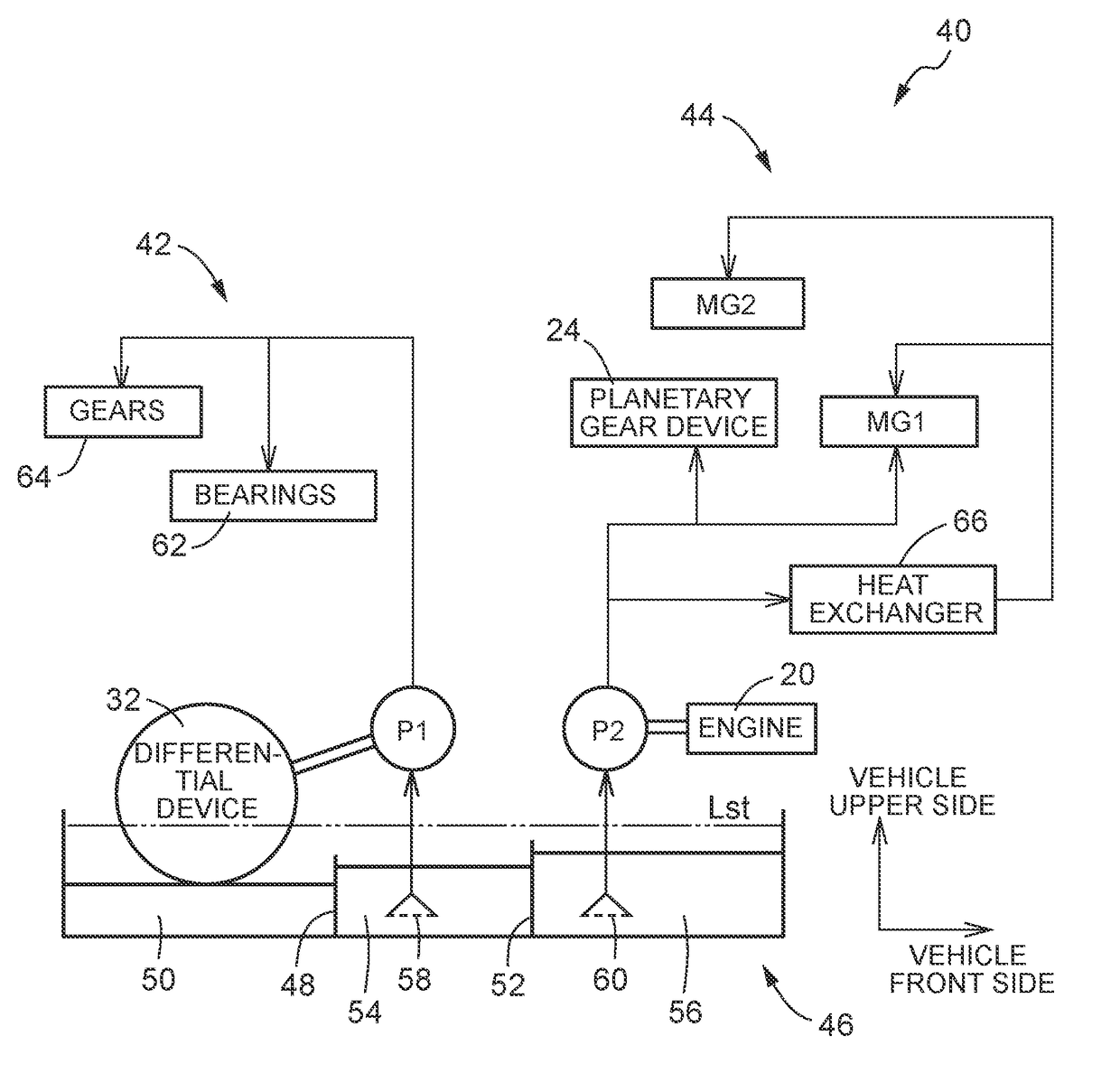

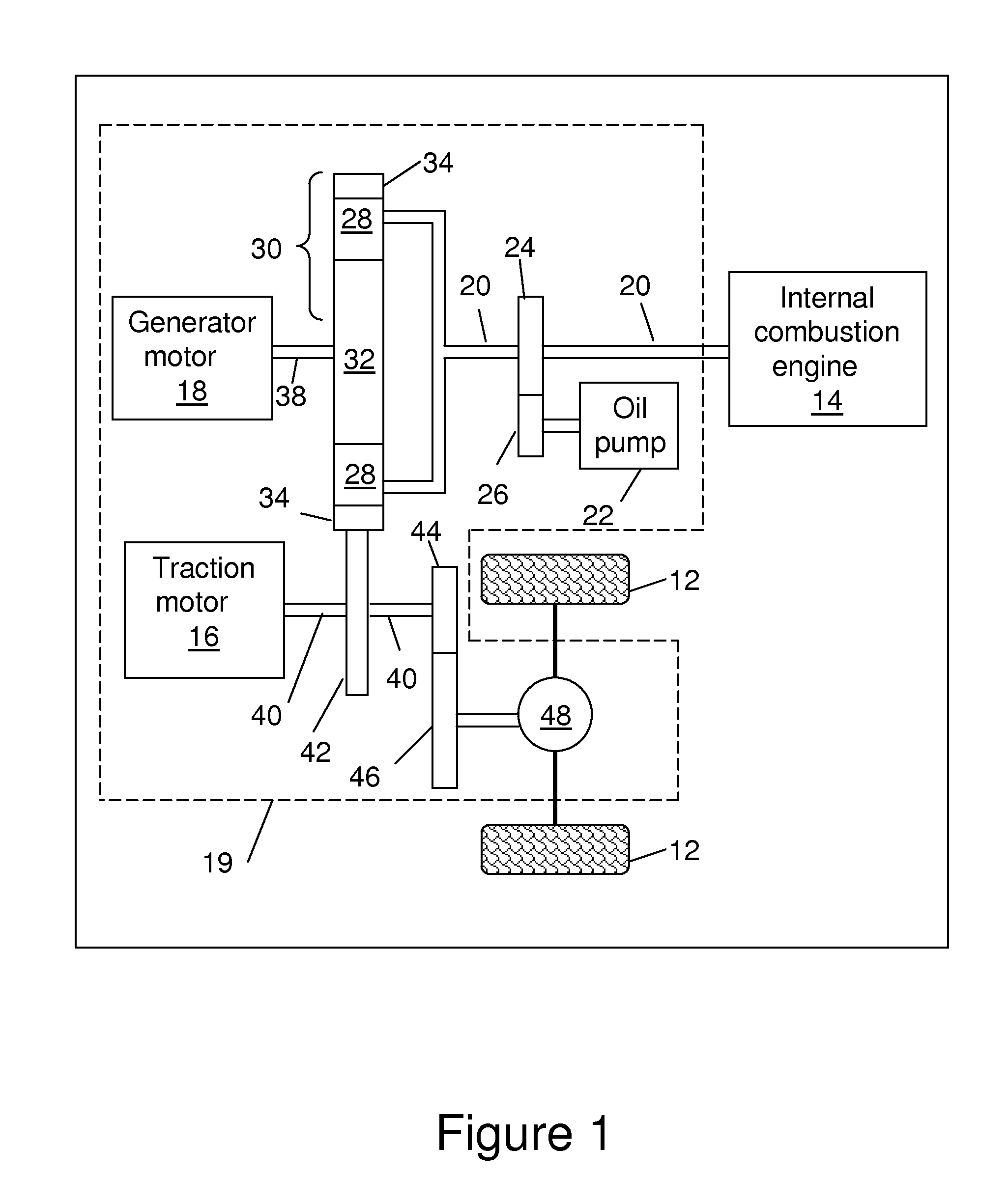

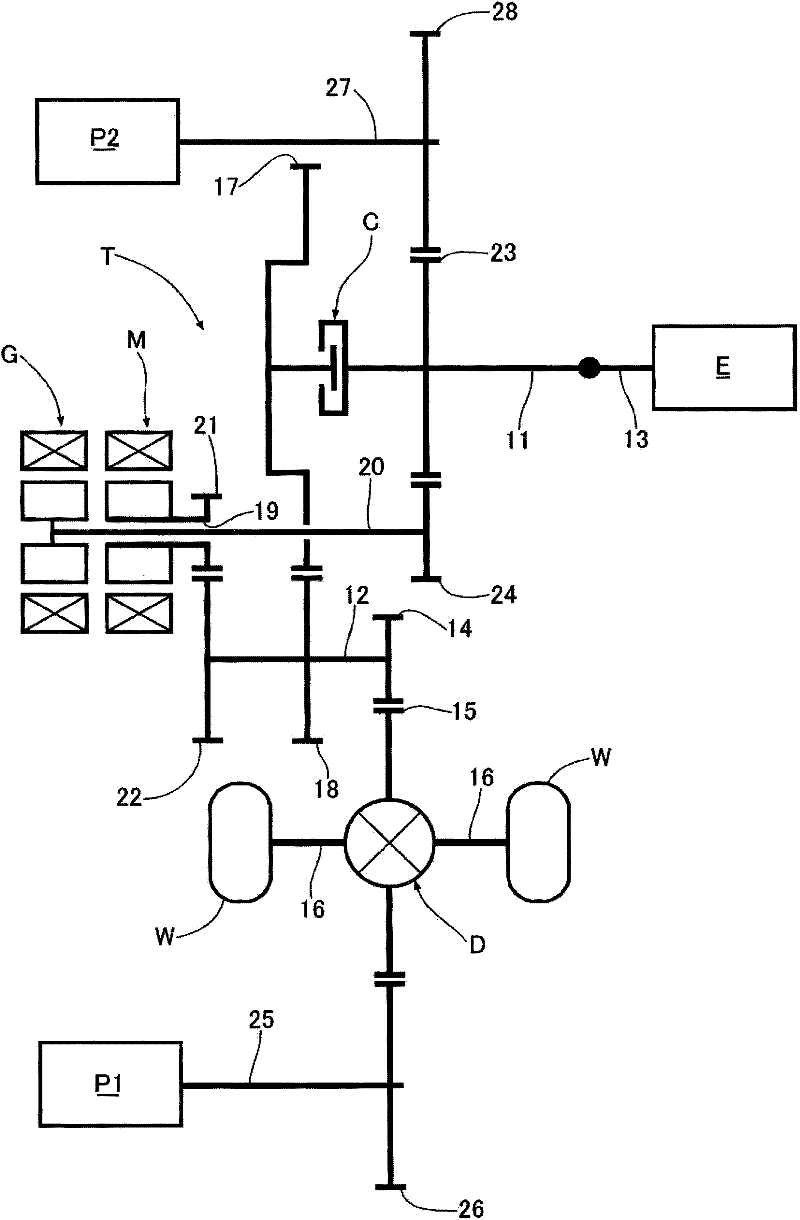

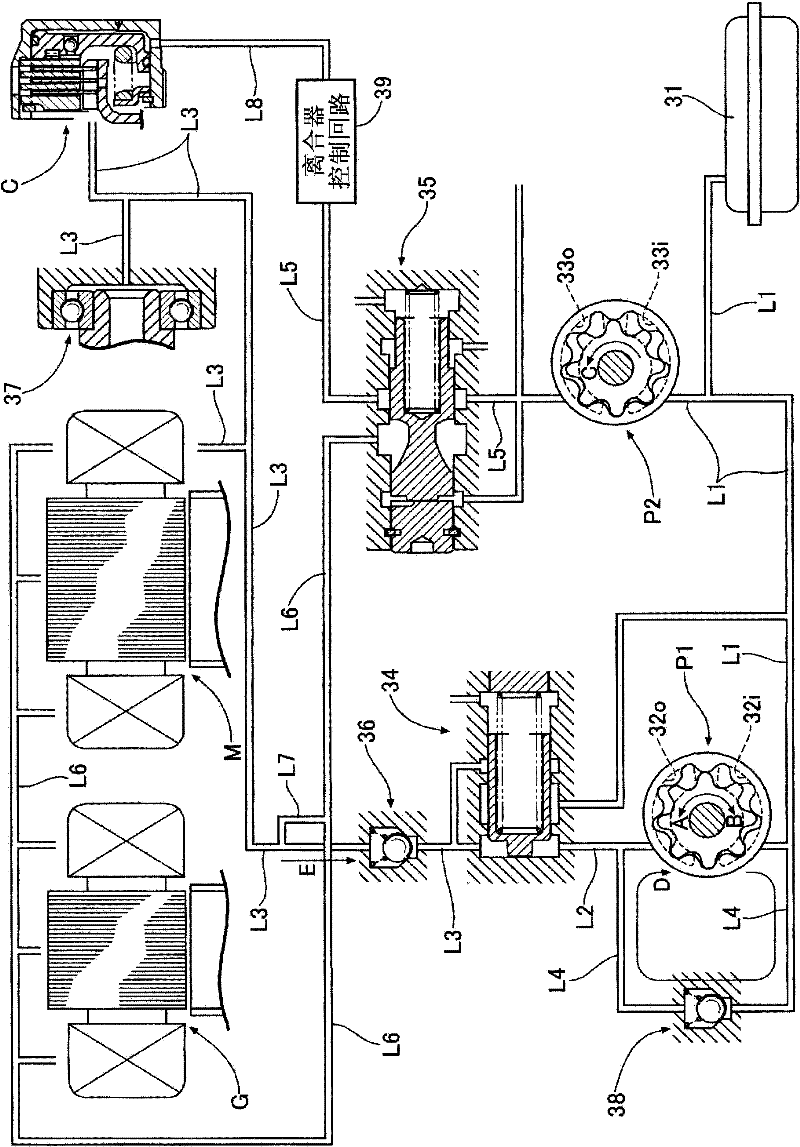

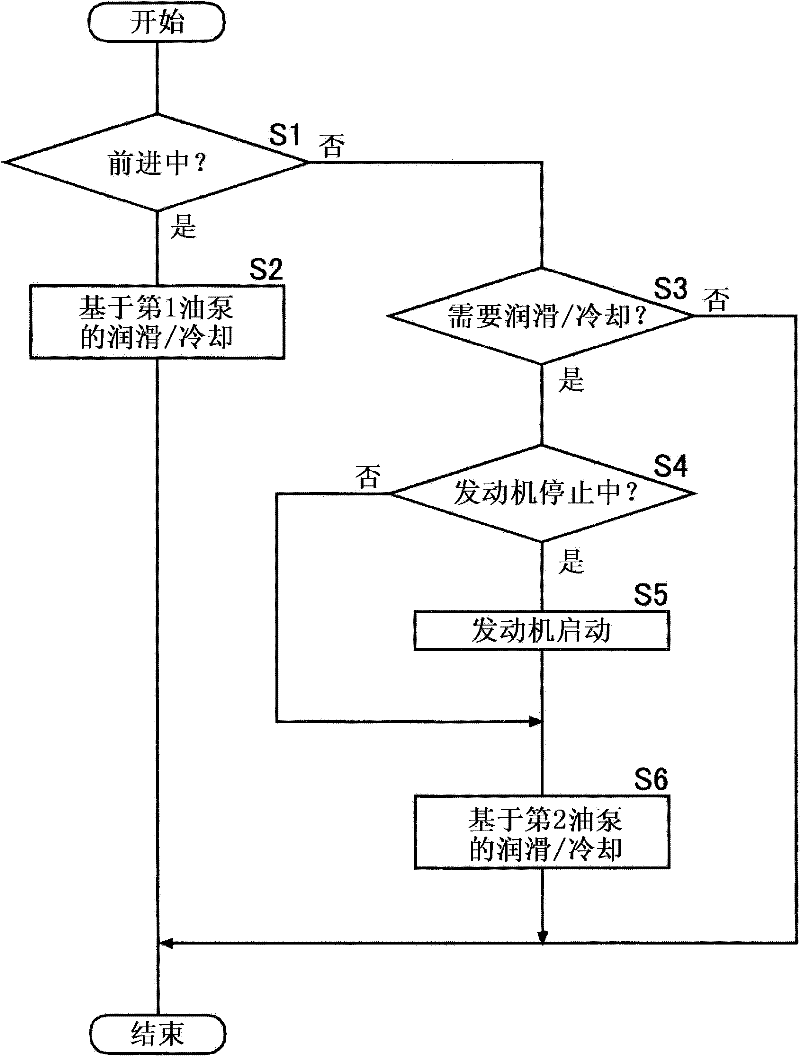

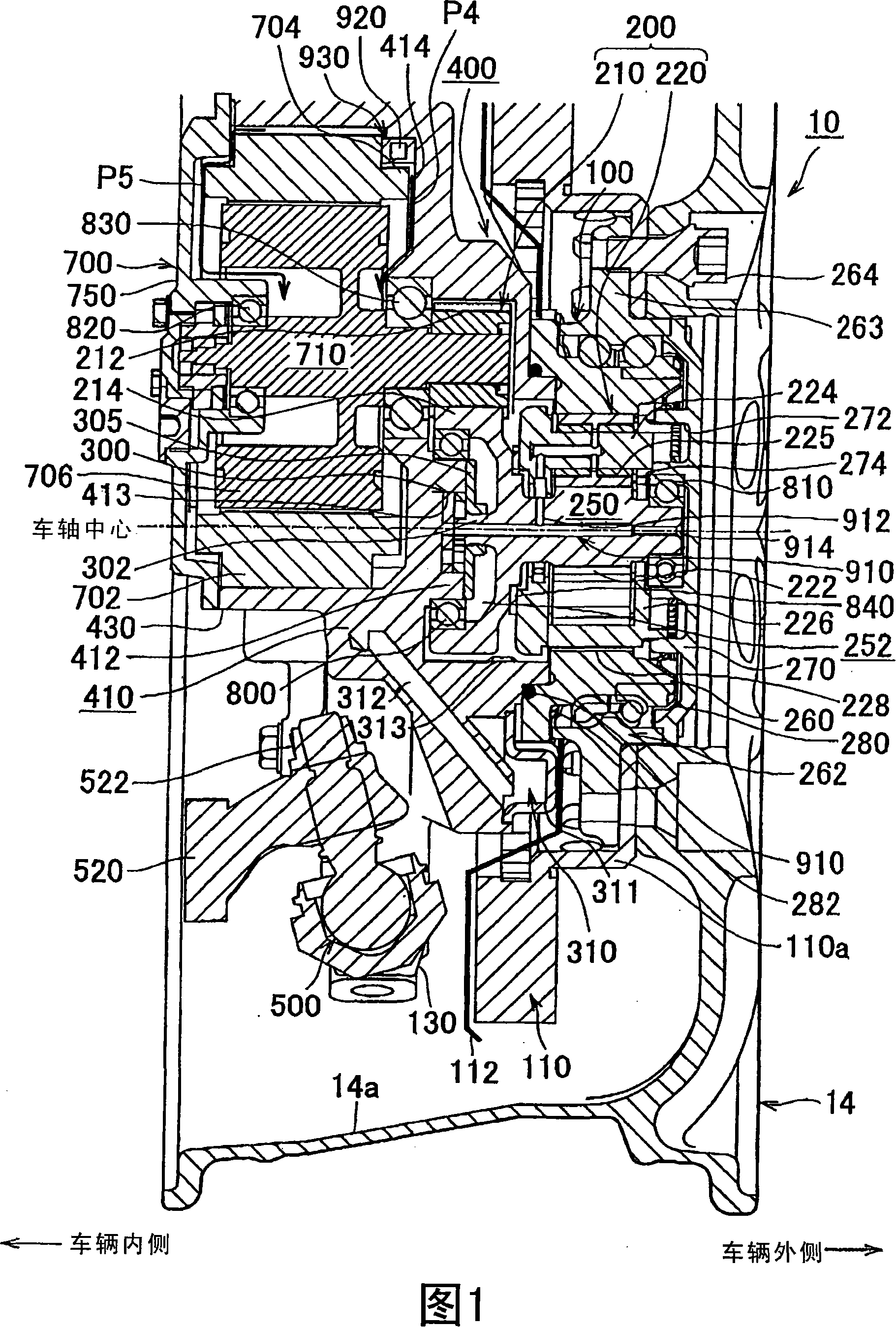

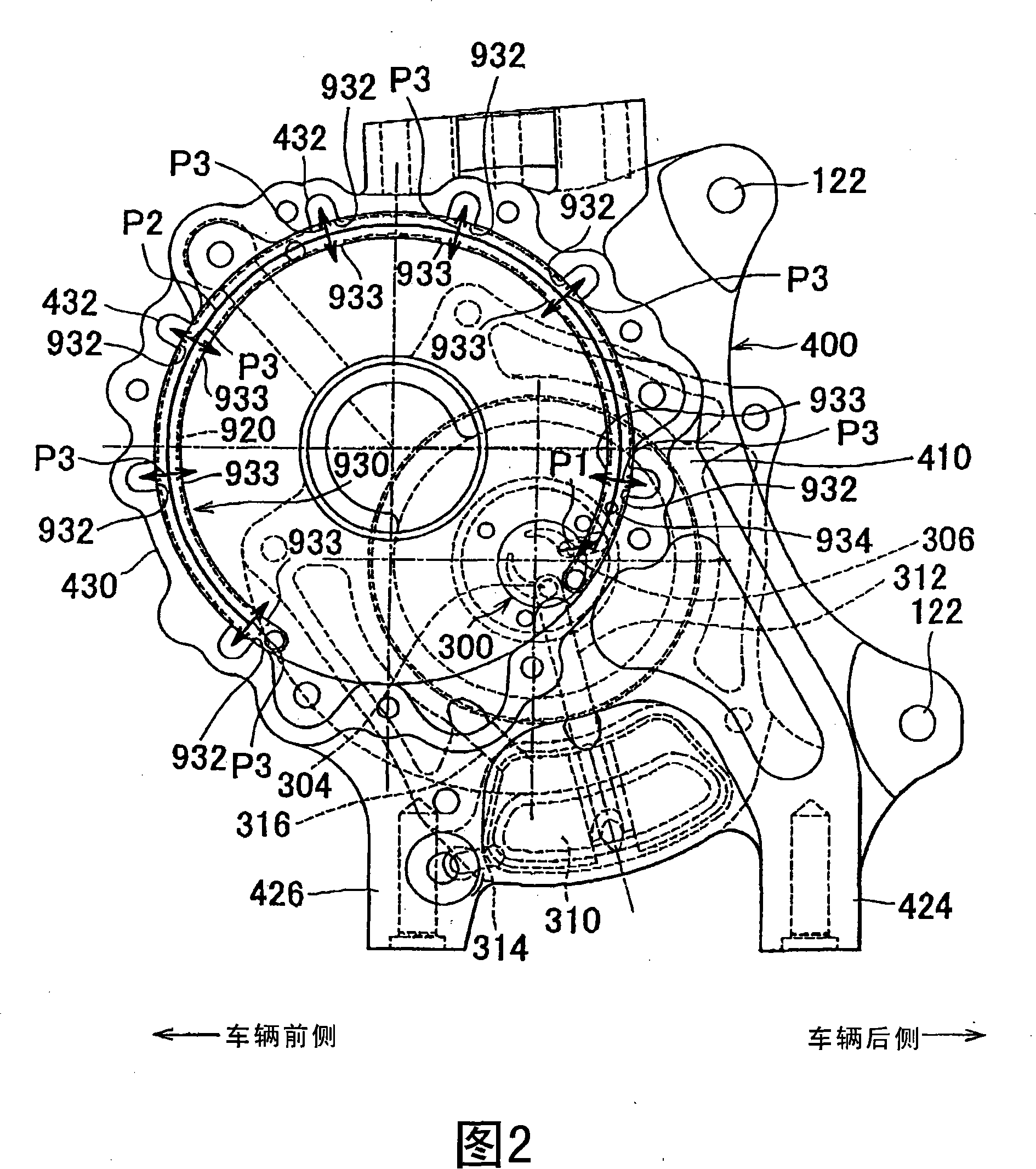

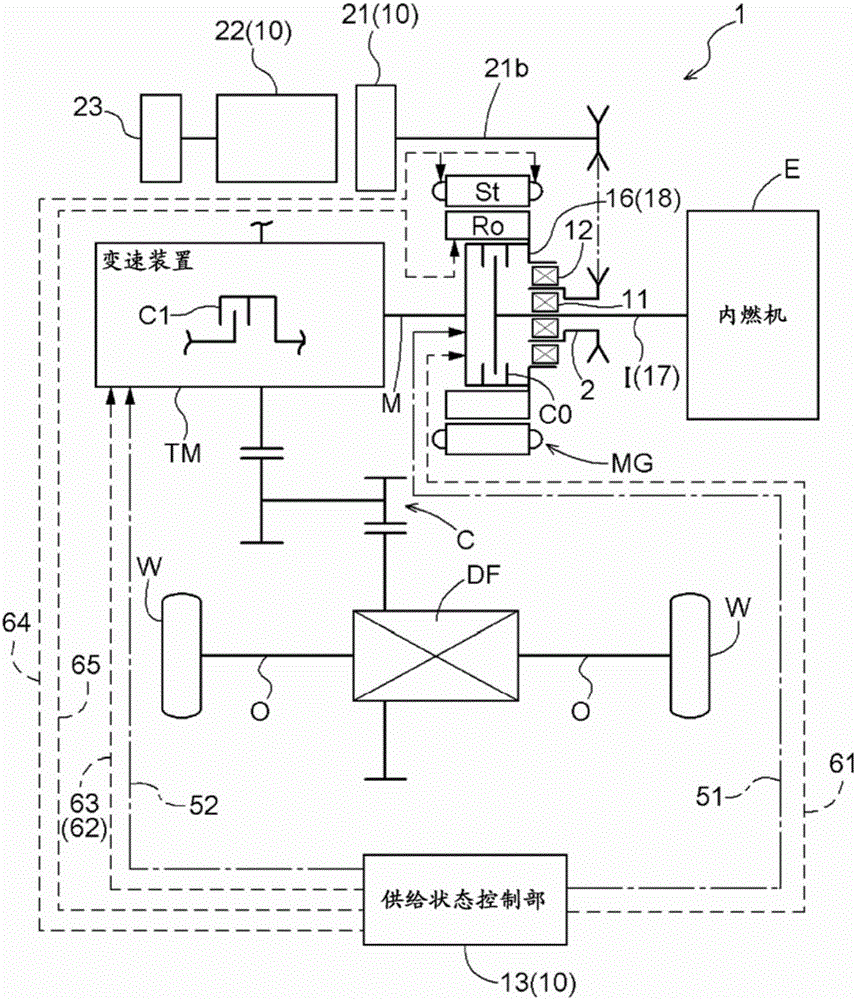

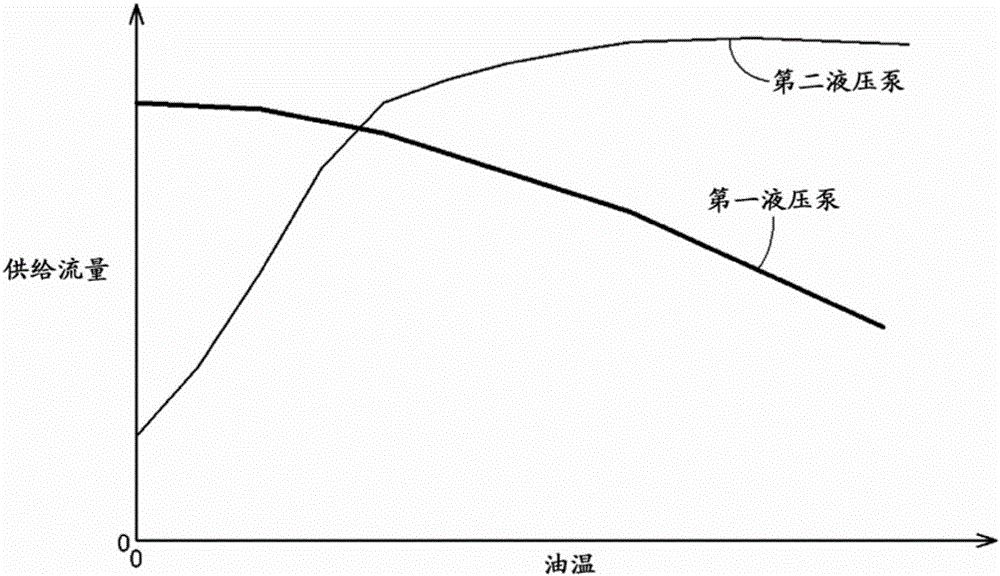

Hybrid electrical vehicle

ActiveCN102463940AIncrease pump outputGuaranteed cooling effectHybrid vehiclesGas pressure propulsion mountingHybrid electrical vehicleHybrid vehicle

The invention provides a hybrid electrical vehicle which helps to effectively lubricating\cooling the lubricating\cooling portion or the motor of a hybrid electrical vehicle. The hybrid electrical vehicle is connected with wheels (W), and when the vehicle is running, the pumping output of a first petrol pump (P1) is increased along with the increase of the speed of the vehicle, that is, along with the increase of heat output of the lubricating\cooling portion, the motor (M) and the like, such that enough needed petrol can be automatically provided to the lubricating\cooling portion for guarantee of cooling performance. In addition, when the vehicle stops and the first petrol pump (P1) stops, if a second petrol pump (P2) is driven via an engine (E), petrol can be provided to the motor (M), the lubricating\cooling portion and the like without barrier under a high-temperature state. Moreover, lubricating\cooling oil channels extended from the first petrol pump and the second petrol pump are mutually communicated, such that even if one of the two petrol pumps stops running, all lubricating\cooling portions can be cooled, and the air is not liable to be absorbed into a lubricating\cooling oil channel that is communicated with a petrol pump on a stopping side.

Owner:HONDA MOTOR CO LTD

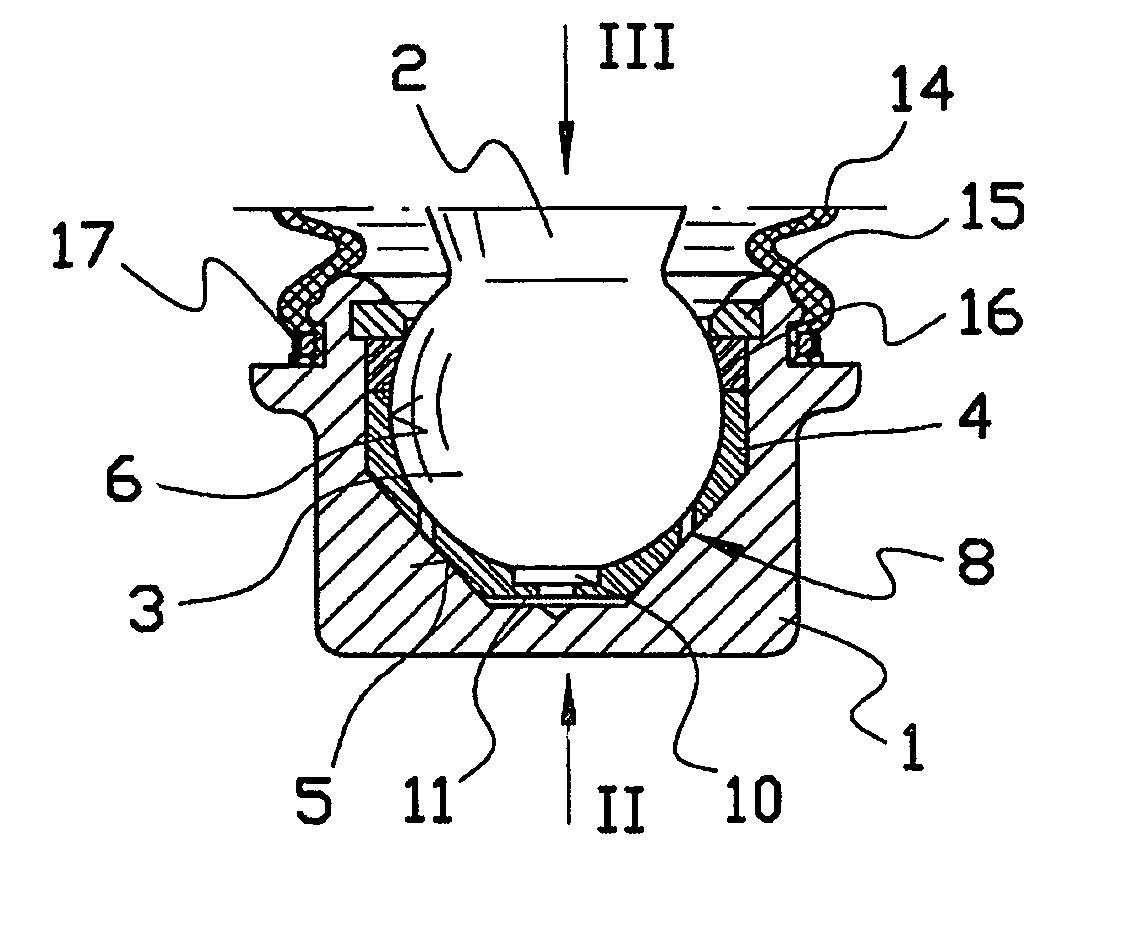

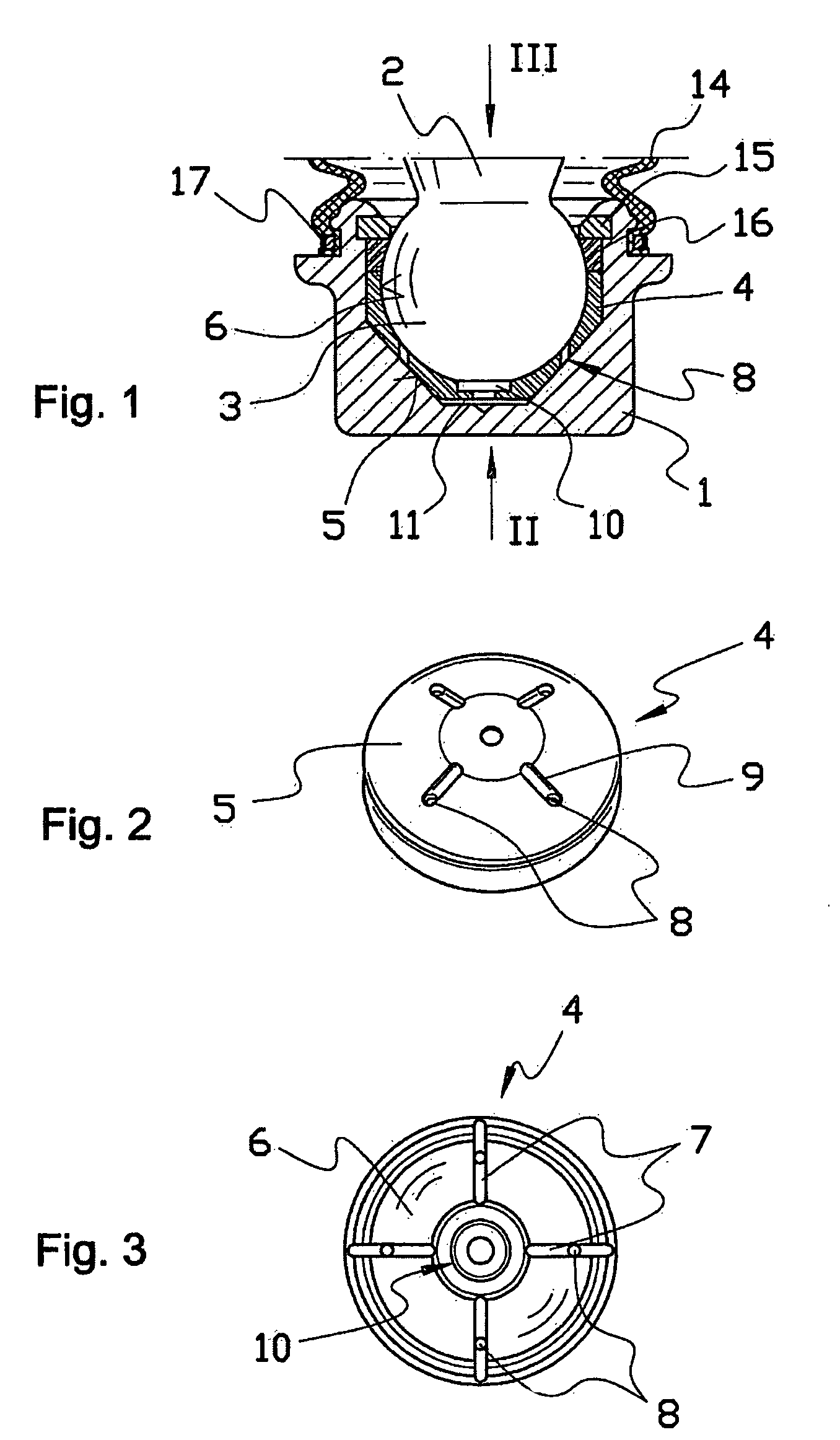

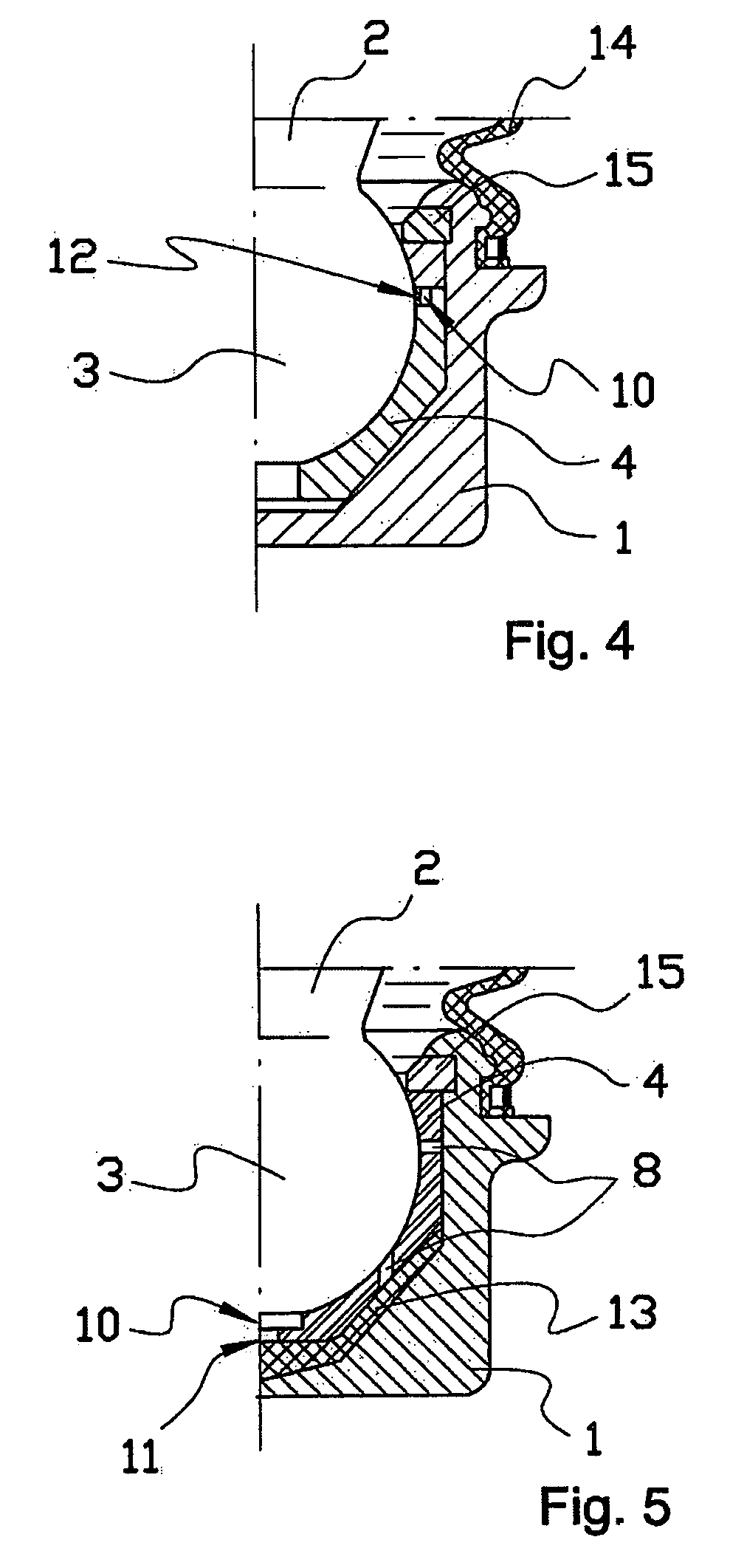

Articulated unit and method for lubricating an articulated unit

ActiveUS8678656B2Simple structureReduce manufacturing costRolling contact bearingsCouplings for rigid shaftsEngineeringLubricant

An articulated unit for a motor vehicle with a housing (1) and a link pin (2) supported in the housing (1), and a bearing shell (4) disposed between the housing (1) and a bearing section (3) of the link pin (2), with the bearing shell (4) supported with its outer surface (5) at least in sections in the housing (1) and having on its inner surface (6) facing the bearing section (3) of the link pin (2) recesses (7) for a lubricant. The bearing shell (4) has at least one opening (8) which extends through the bearing shell (4) from the inner surface (6) to the outer surface (5) and forms a flow channel. A method for lubricating an articulated unit is presented, wherein the bearing shell (4) having elastic compliance produces during the relative movement of the link pin (2) in the housing (1) a pumping action, which enables distribution of the lubricant via the lubricant channel system.

Owner:ZF FRIEDRICHSHAFEN AG

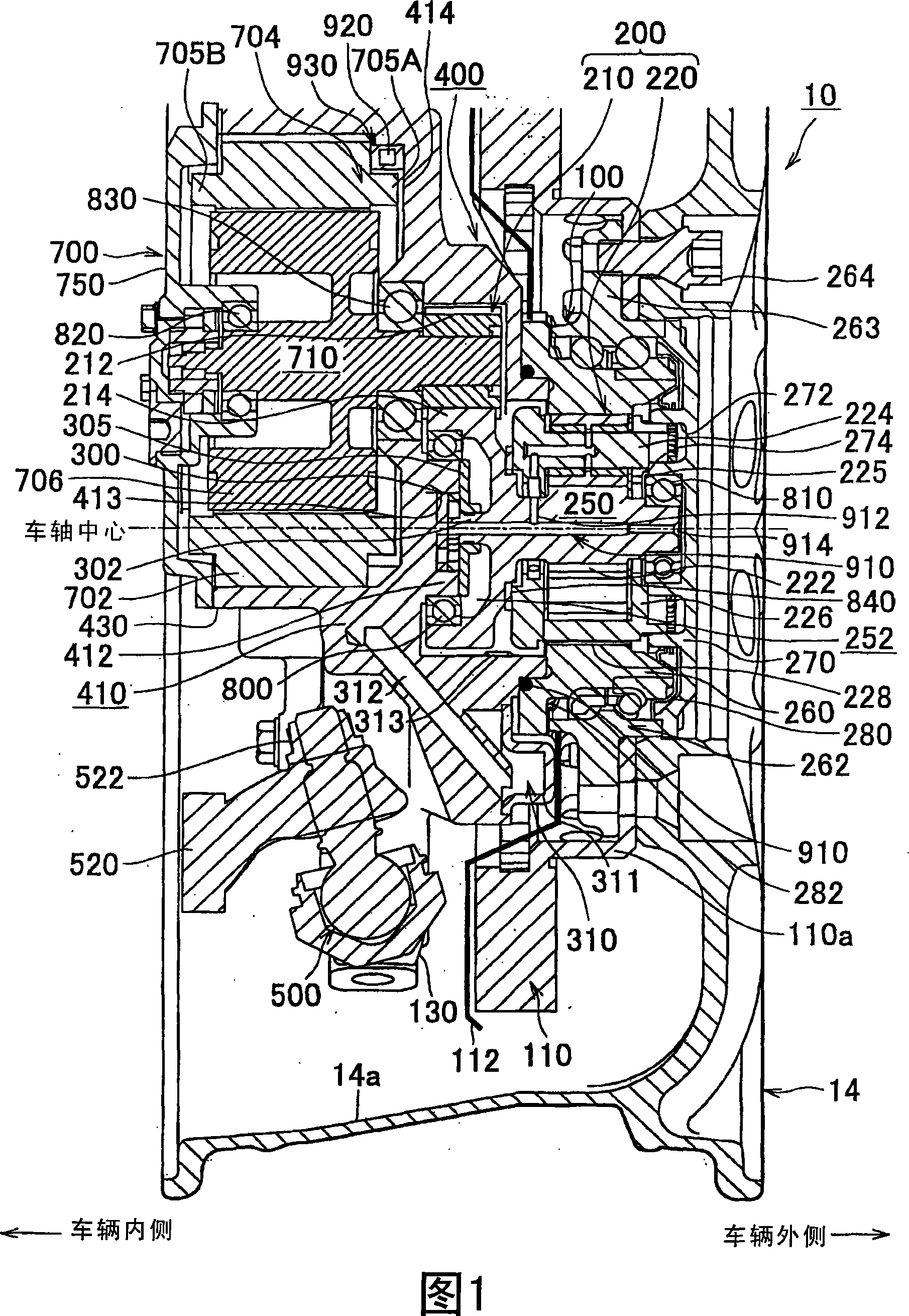

Wheel assembly with in-wheel motor

ActiveCN101121393AEasy supplyDoes not affect durabilityElectric devicesGear lubrication/coolingGear wheel

Owner:TOYOTA JIDOSHA KK

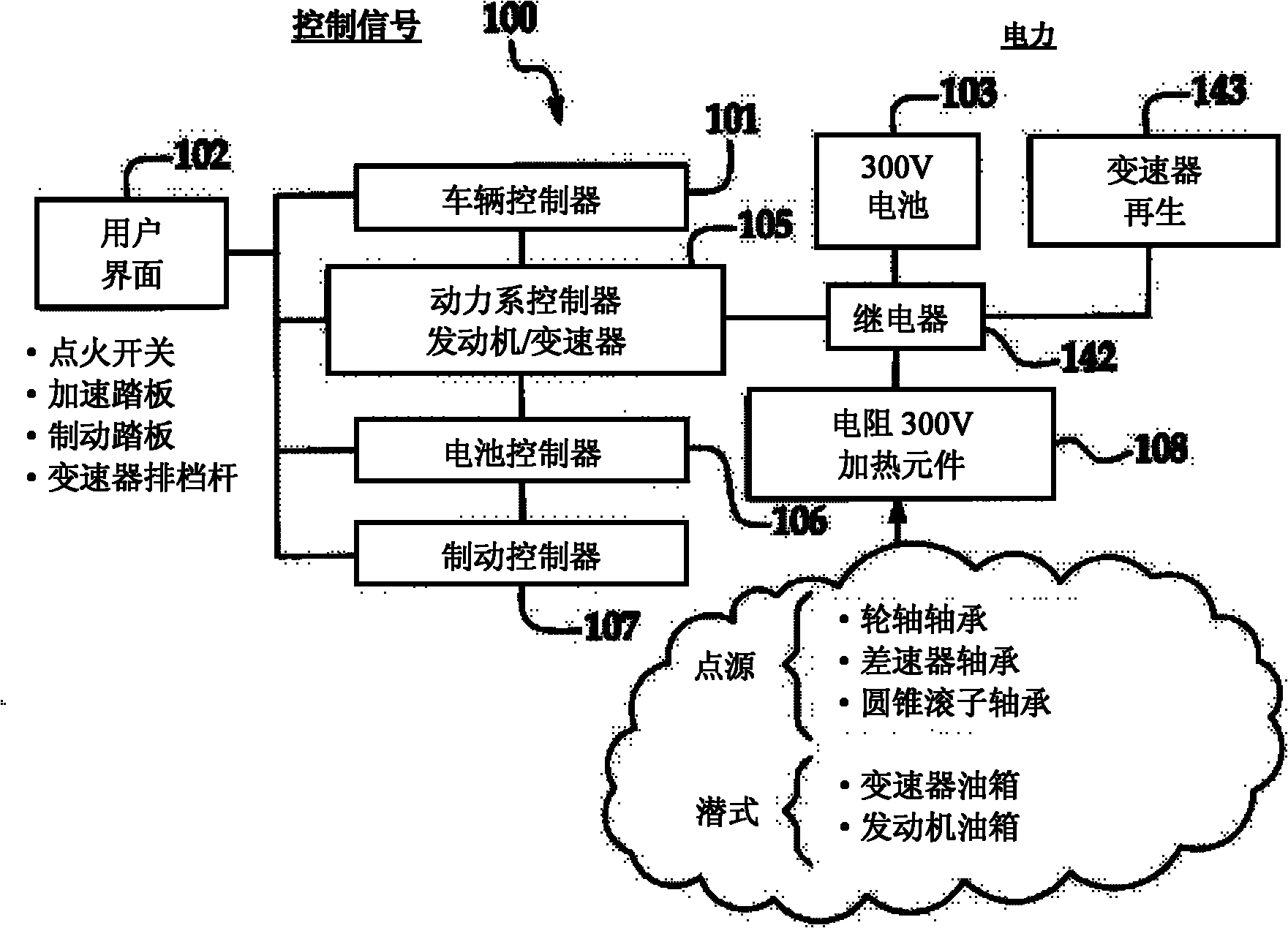

Powertrain driveline warm-up system and method

A powertrain / driveline warm-up system includes a vehicle controller, an electrical power source interfacing with the vehicle controller, at least one heater interfacing with the vehicle controller and at least a portion of a vehicle powertrain provided in thermal contact with the at least one heater.

Owner:FORD GLOBAL TECH LLC

Vehicle suspensions

InactiveUS7040632B2Reduce resistanceAdjustable resistanceVehicle cleaning apparatusLoading/unloading vehicle arrangmentTerrainEastern Interconnection

A vehicle air suspension system includes a control unit 32 which is arranged to produce a running measure of the level of cross articulation of the two axles 18, 20 and, if it exceeds a certain level indicating that the vehicle is on rough terrain, to open respective interconnections 34, 36 between the suspension units 24 on opposite ends of each axle so as to reduce the resistance to that articulation. The interconnections are arranged to close when the vehicle speed increases so as to provide roll control.

Owner:JAGUAR LAND ROVER LTD

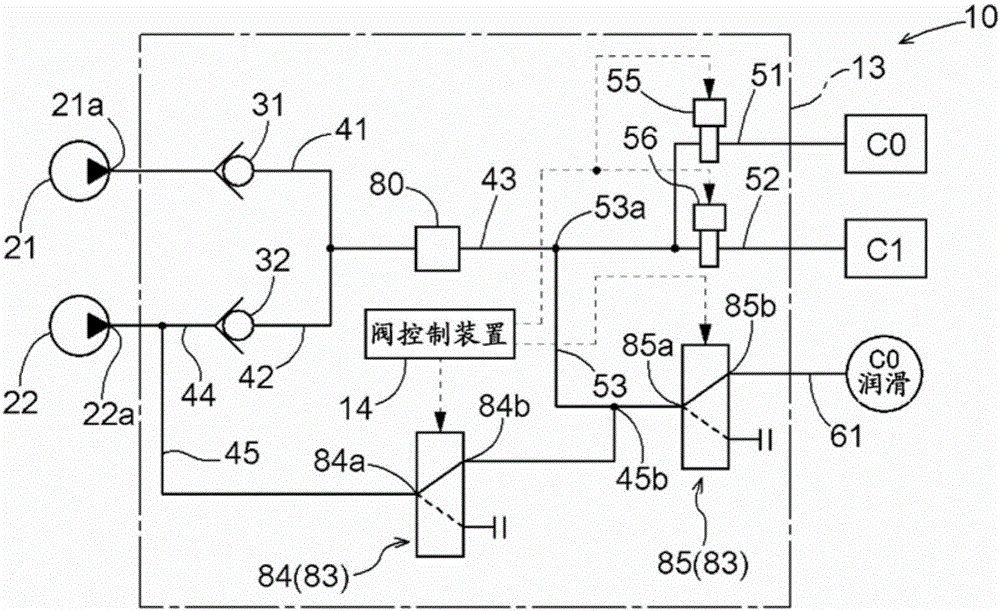

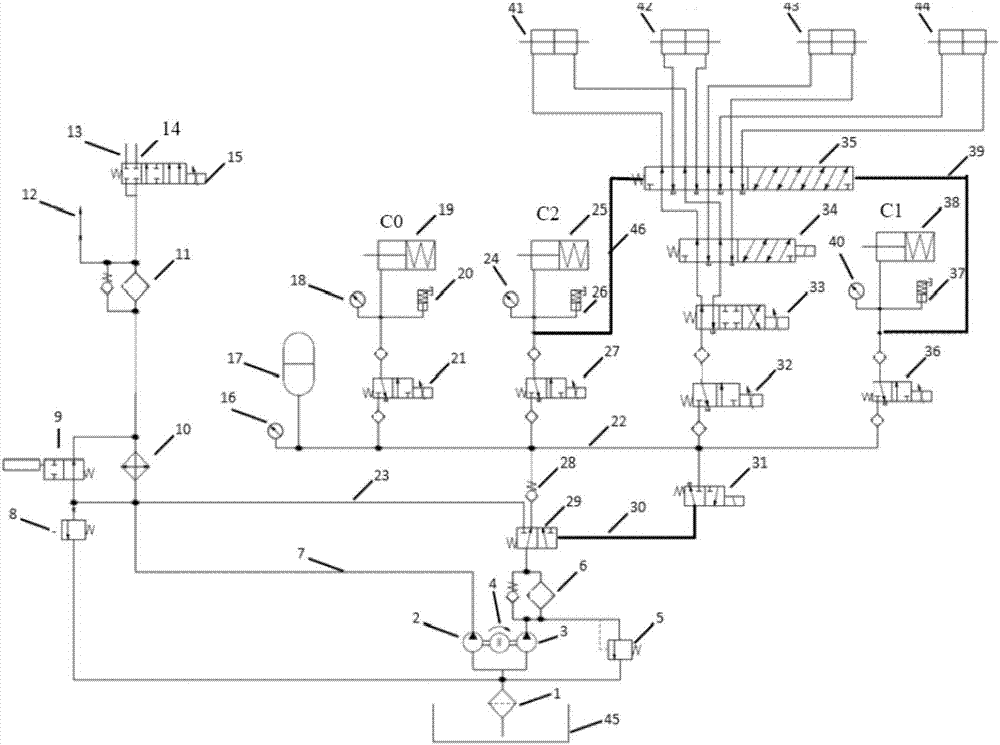

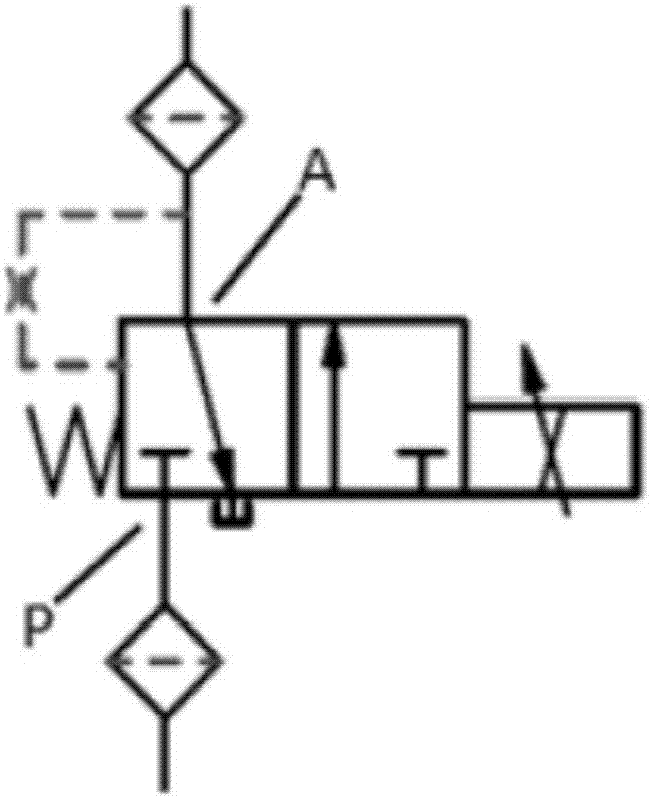

Oil supply device

InactiveCN105026233AReduce oil dischargeMiniaturizationHybrid vehiclesSpeed controllerHydraulic pumpInternal combustion engine

There is desired an oil supply device that can supply an appropriate amount of oil to a vehicle drive device, while suppressing an increase in size of a hydraulic pump, in the case where torque of an internal combustion engine is transferred to wheels with an engagement device controlled to a slipping engagement state. An oil supply device 10 includes a first hydraulic pump 21, a second hydraulic pump 22 driven by a dedicated drive force source 23, a lubrication oil passage 61 for lubricating engagement devices C0 and C1, a first engagement oil passage 51 for controlling the state of engagement of the decoupling engagement device C0, and a second engagement oil passage 52 for controlling the state of engagement of the shifting engagement device C1. In the case where the engagement devices C0 and C1 are controlled to a slipping engagement state, the supply state control section 10 establishes a state in which oil discharged from the first hydraulic pump 21 is supplied to the first engagement oil passage 51 and the second engagement oil passage 52, and in which at least oil discharged from the second hydraulic pump 22 is supplied to the lubrication oil passage 61.

Owner:AISIN AW CO LTD

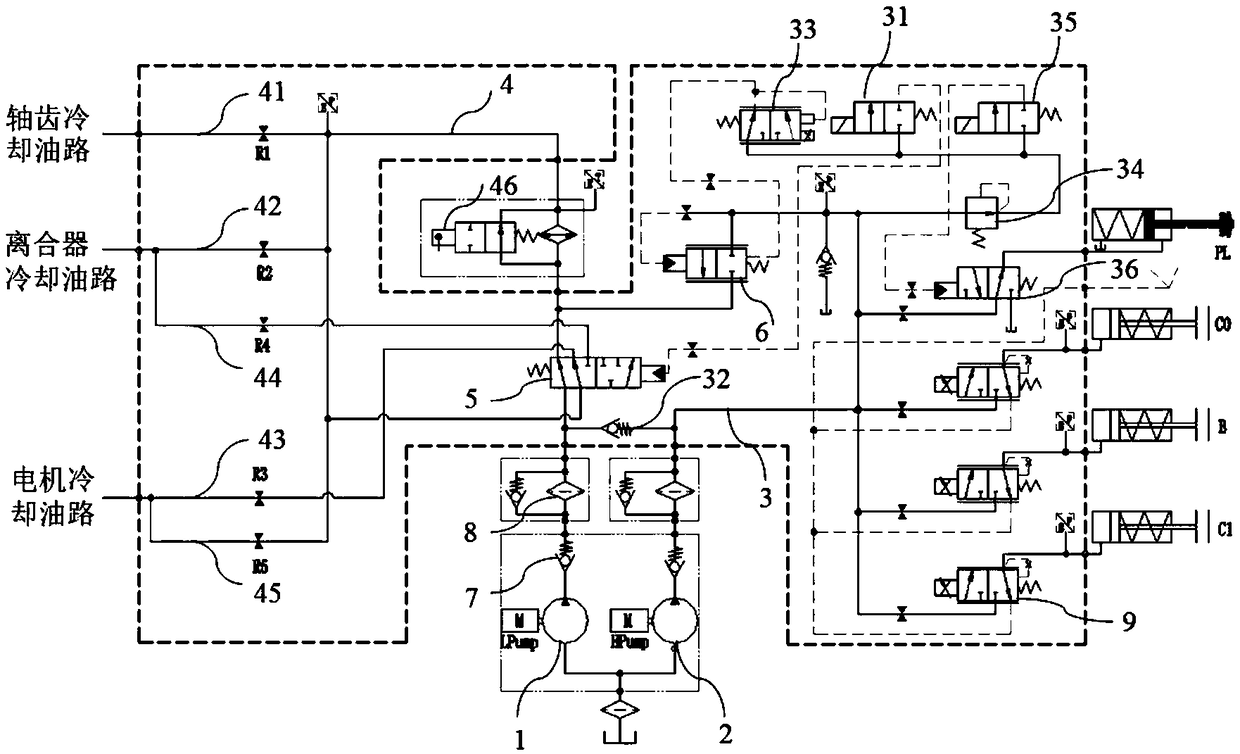

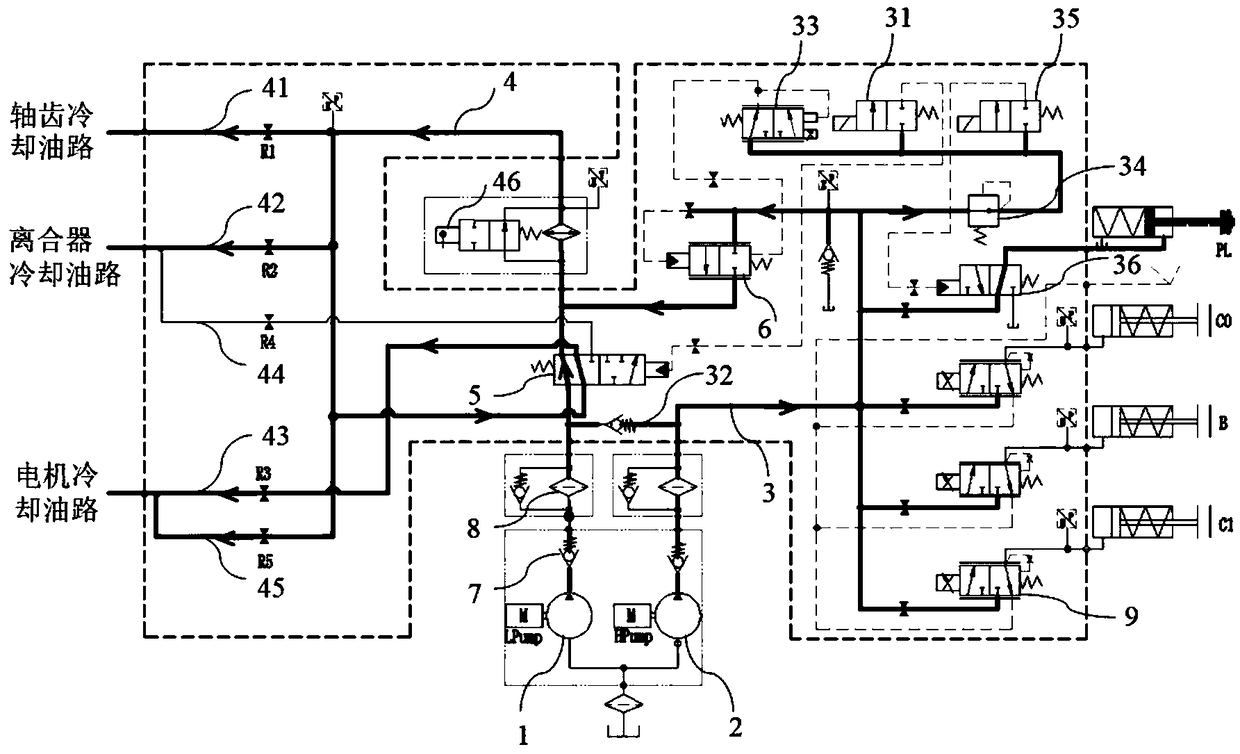

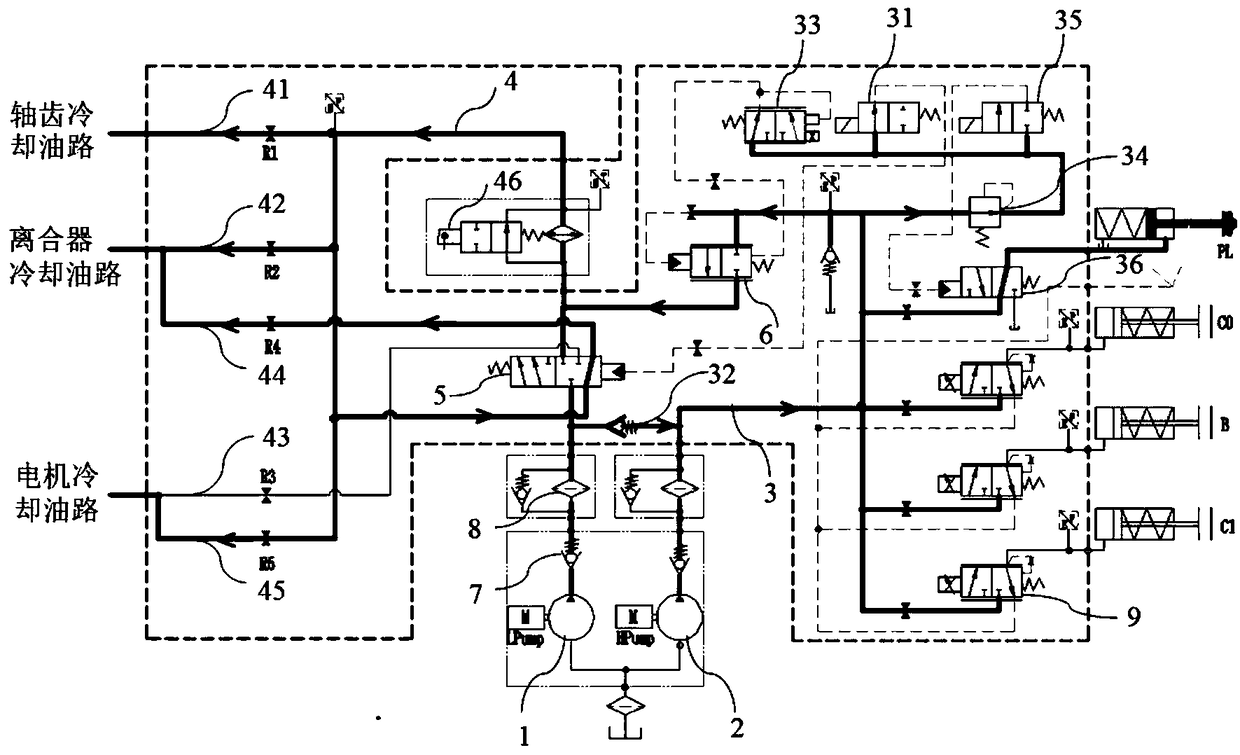

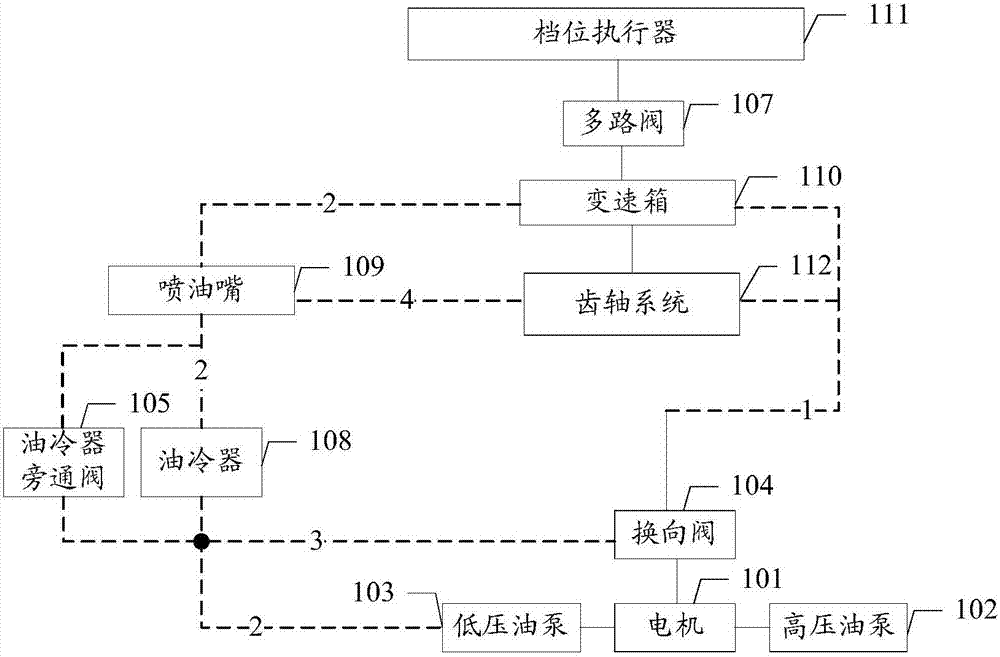

Hydraulic control system of hybrid power vehicle and control method thereof

PendingCN109282028AEnsure efficiencyEnsure power performanceGearing controlLubricating systemHydraulic pumpPressure reduction

The invention relates to the field of hybrid power vehicle control and particularly discloses a hydraulic control system of a hybrid power vehicle and a control method of the hydraulic control systemof the hybrid power vehicle. The hydraulic control system of the hybrid power vehicle comprises a main oil channel, a cooling lubricating oil channel, a reversing valve, a first oil hydraulic pump, asecond oil hydraulic pump communicating with the main oil channel, a pressure adjusting valve connected between the main oil channel and the cooling lubricating oil channel and a first control valve used for controlling the reversing valve to switch the valve position. The reversing valve is located at the first valve position when a clutch or a brake does not need uniting, so that the first oilhydraulic pump is made to communicate with the cooling lubricating oil channel. The reversing valve is located at the second valve position when the clutch or the brake needs uniting, the first oil hydraulic pump and the second oil hydraulic pump are made to be coupled to provide hydraulic oil flow for the main oil channel, and remaining flow is conveyed to the cooling lubricating oil channel. Thehydraulic control system of the hybrid power vehicle reasonably matches the cooling lubricating flow with the hydraulic oil flow of the main oil channel, pressure reduction during uniting of the clutch is avoided, the parts are prevented from being worn and scorched, and the overall efficiency and power performance of the vehicle are ensured beneficially.

Owner:GUANGZHOU AUTOMOBILE GROUP CO LTD

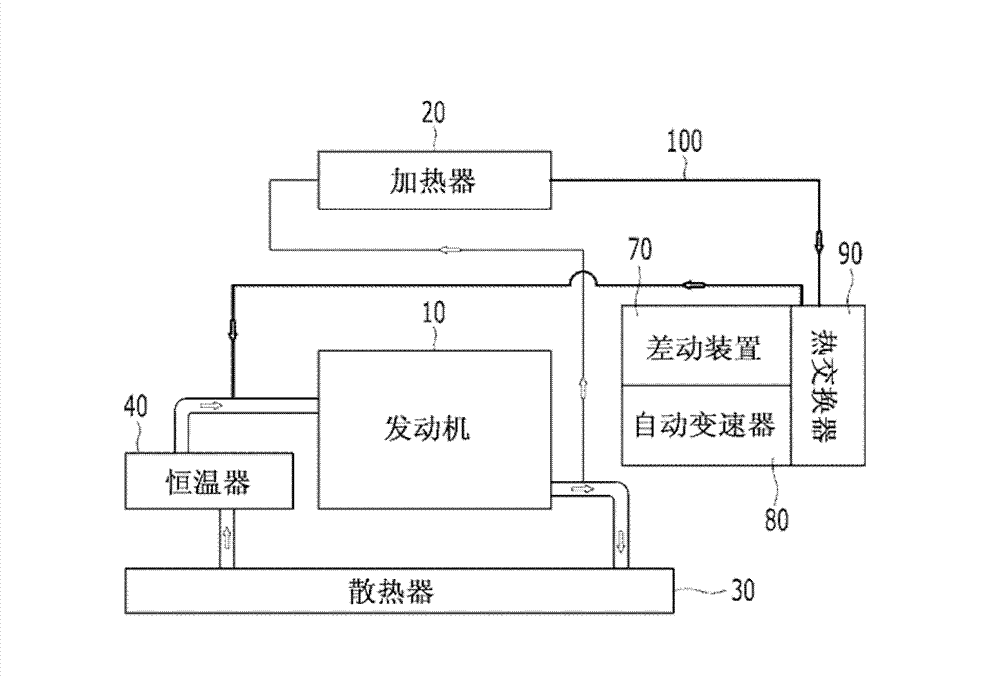

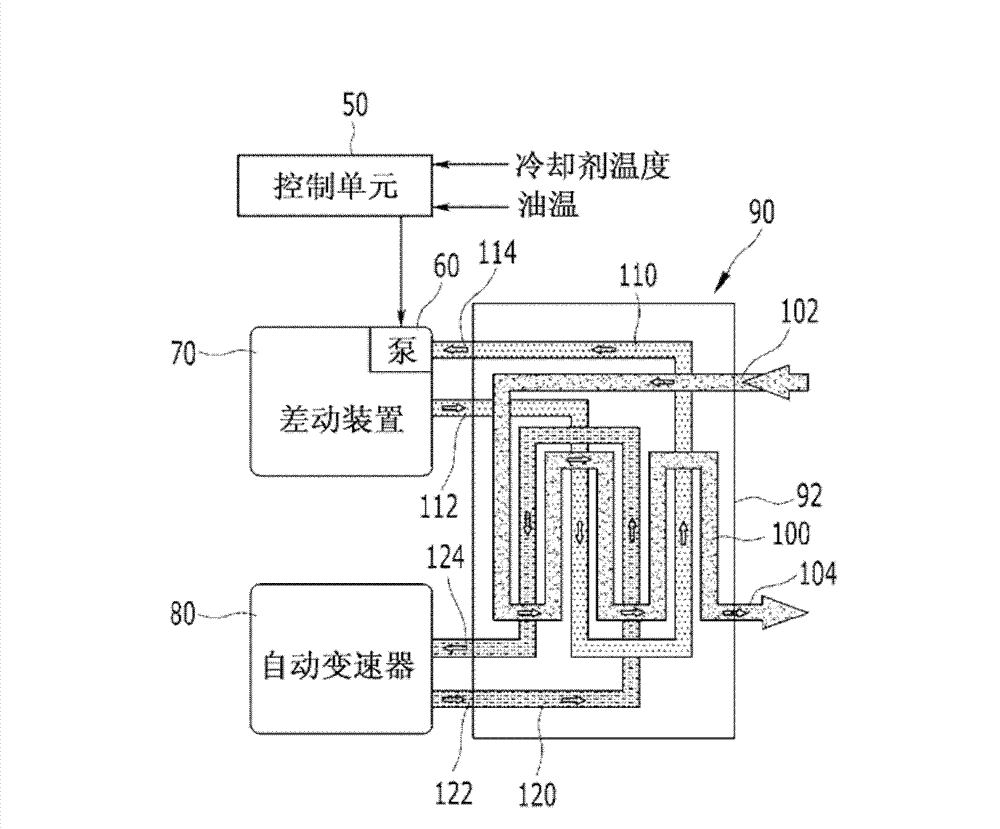

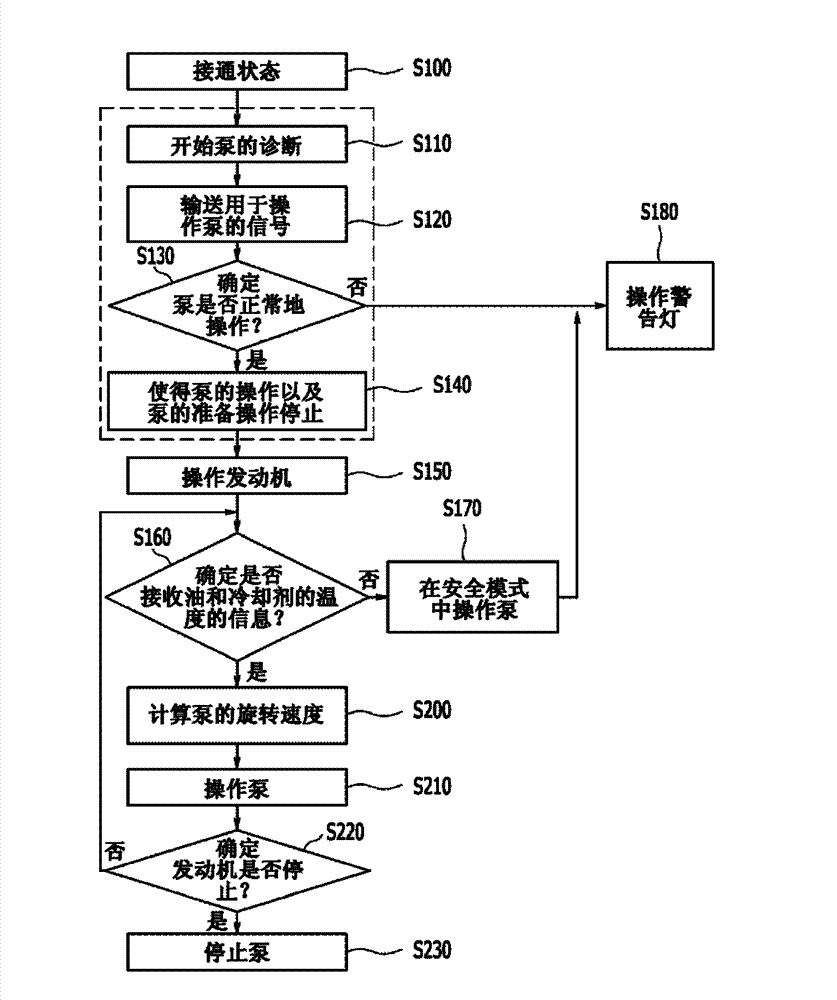

Heat exchanging system for vehicle and control method thereof

A heat exchange system for a vehicle may include a heat exchanger to transfer heat among a coolant, an automatic transmission oil, and / or a gear oil, an engine fluidly connected to the heat exchanger and adapted to deliver / receive the coolant, an automatic transmission fluidly connected to the heat exchanger and adapted to deliver / receive the automatic transmission oil, a differential apparatus fluidly connected to the heat exchanger and adapted to deliver / receive the gear oil, a pump adapted to pump the gear oil, and a control unit adapted to control the pump. A control method is also provided.

Owner:HYUNDAI MOTOR CO LTD

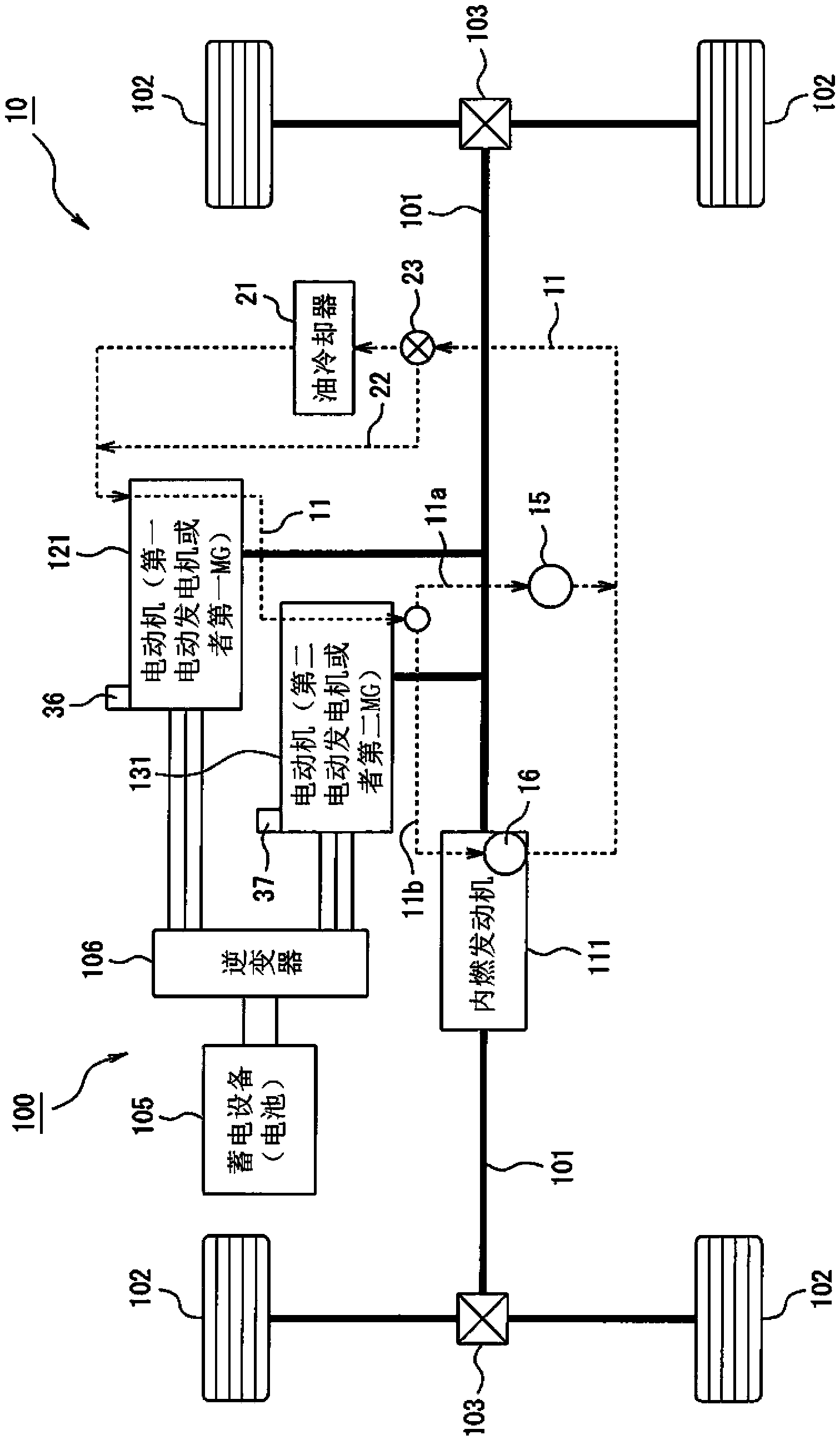

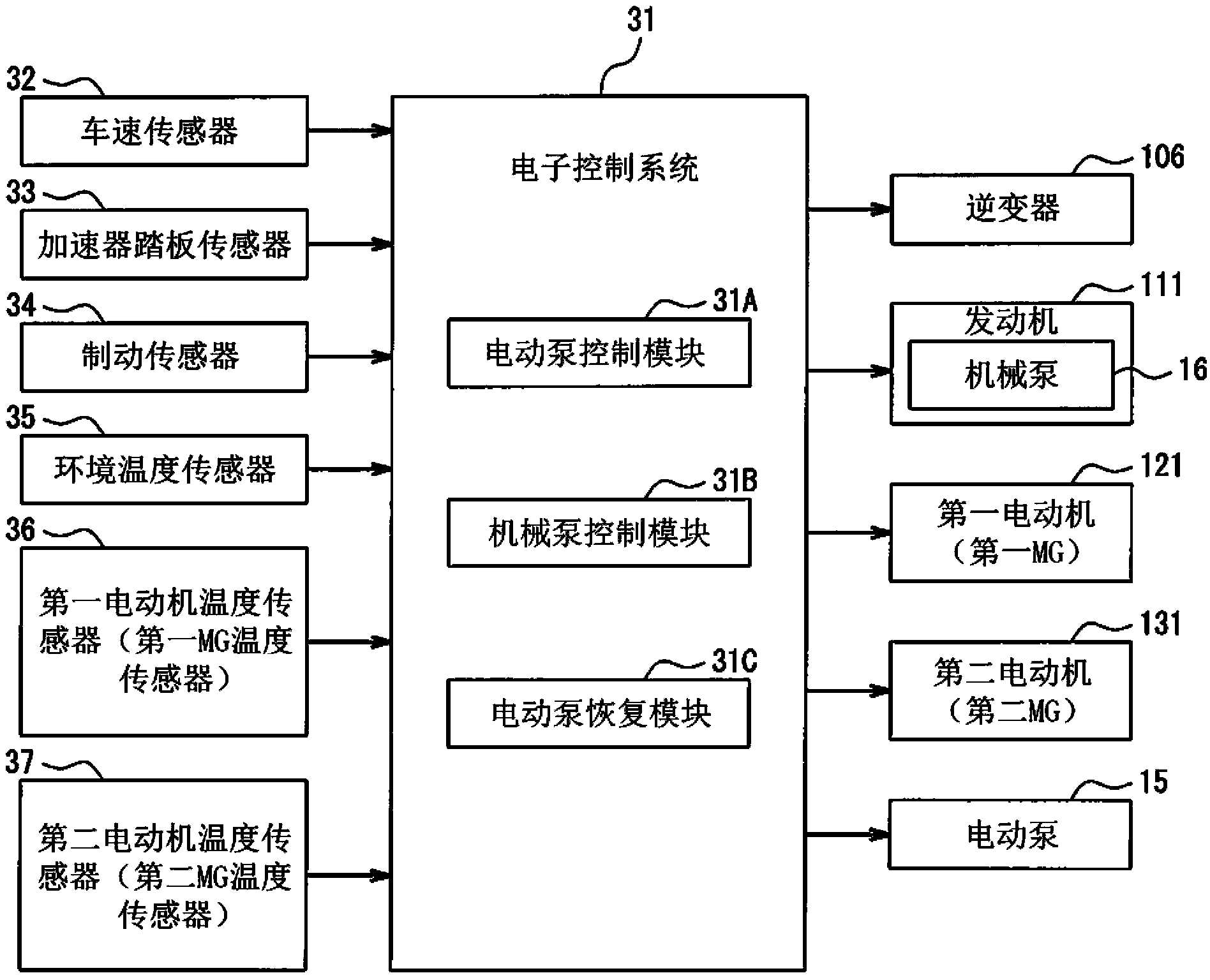

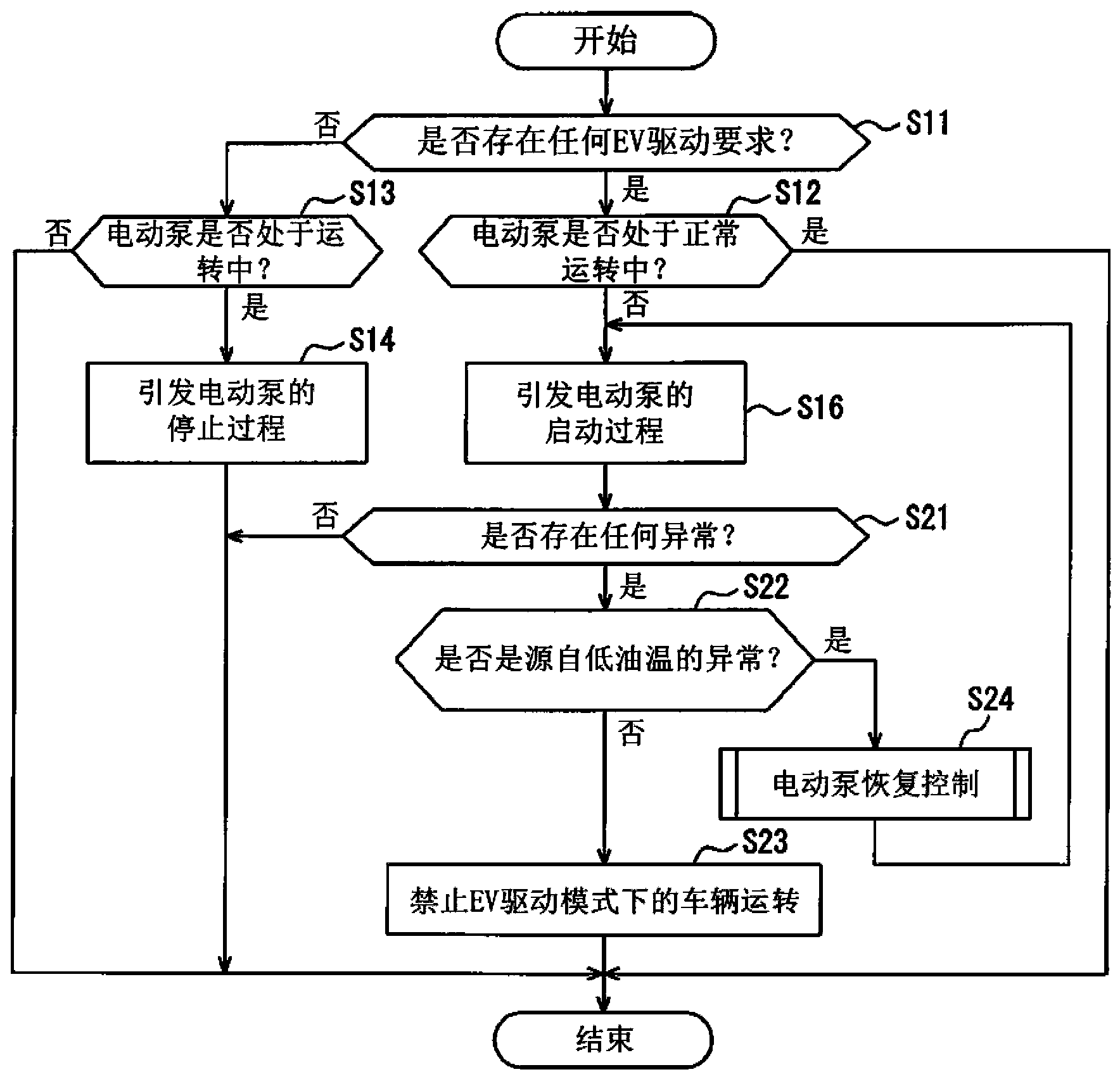

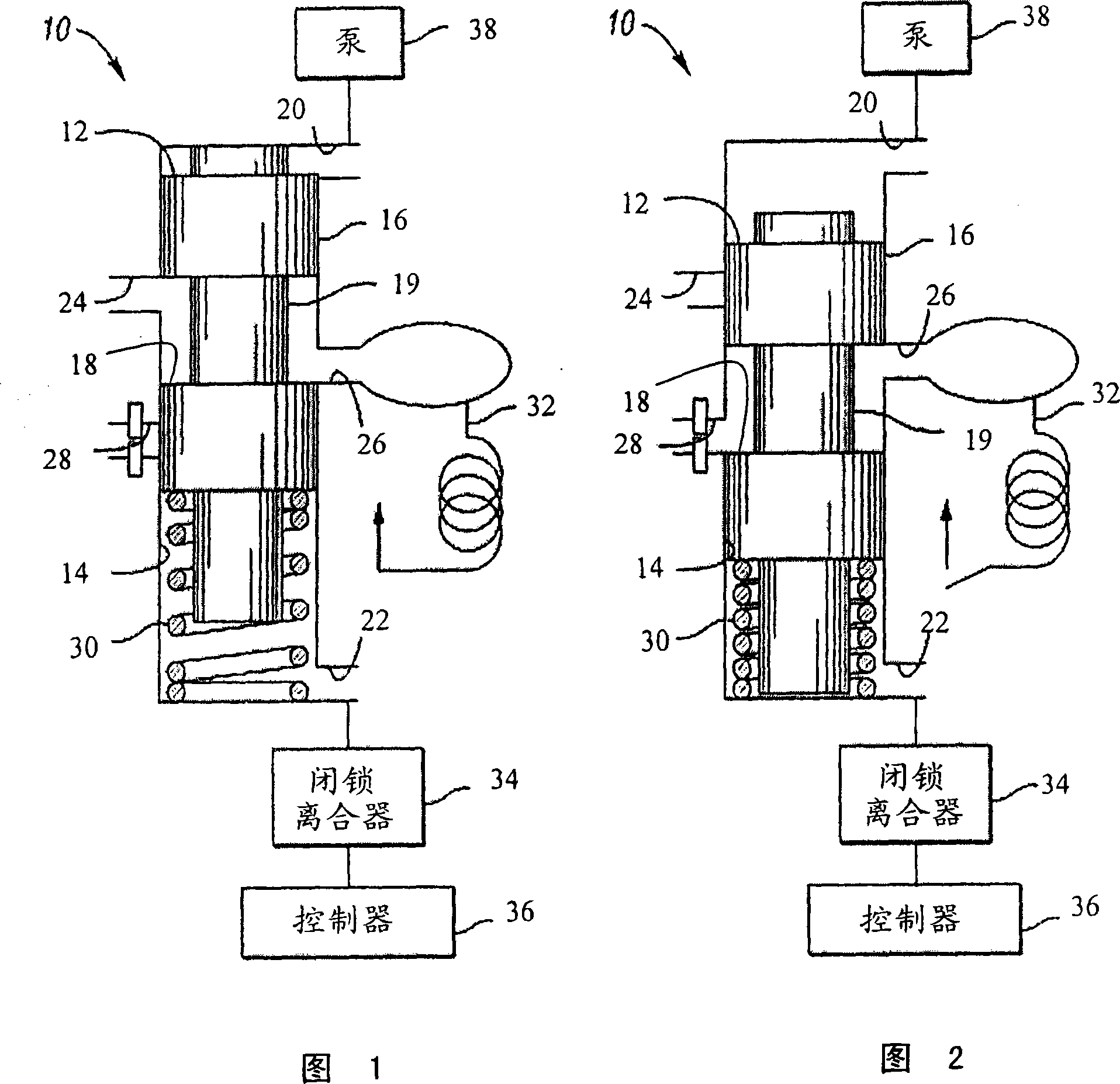

Oil circulation system for electric motor in a hybrid electric vehicle

ActiveCN103448638AEfficient rotationEnsure adequate lubricationPump controlLubricating systemExternal combustion engineInternal combustion engine

An oil circulation system for electric motors in a hybrid electric vehicle having, as a power source, an internal combustion engine is disclosed. Provision is made to start oil circulation under high reliability even though an electric pump cannot circulate lubricant oil through the electric motors due to increased viscosity at low temperatures. The oil circulation system includes the electric pump in fluid communication with an oil flow path for the electric motors;a mechanical pump, in fluid communication with the oil flow path, operable on driving power of the engine;and a controller for control of operation of the electric pump and that of the mechanical pump. The controller utilizes operation of the mechanical pump upon detection of abnormality in operation of the electric pump derived from viscosity of the lubricant oil in order to recover the electric pump.

Owner:SUZUKI MOTOR CORP

Height adjustment device for motor vehicles

InactiveUS7874561B2Large gearing coverageReduced space requirementsVehicle cleaning apparatusLoading/unloading vehicle arrangmentDrive motorEngineering

Owner:AUDI AG

System and method to provide lubrication for a plug-in hybrid

In hybrid electric vehicles having increased battery storage capacity and plug-in capability, electric-only operation of significant duration is available. To supplement lubrication for the electric and mechanical components provided in a fluid circuit by an engine-driven mechanical pump, an electric pump is provided in parallel to the mechanical pump. When the electric pump is operating, a diagnostic can be performed to determine system integrity. According to one embodiment, an actual quantity provide to the circuit is determined; an expected quantity is estimated; and a fault is determined when the actual and expected quantities differ by more than a predetermined amount. The fault may indicate a leak or plug in the fluid circuit or a failure of a component in the fluid circuit.

Owner:FORD GLOBAL TECH LLC

In-wheel motor and wheel assembly with this in-wheel motor

A motor has a stator core, a coil, a rotor, and a motor case in which the stator core, the coil, and the rotor are housed. The motor is also provided with a fluid carrying member that is arranged around a coil end of the coil in the motor case and has an inlet hole that is communicated with a fluid supply source and a distribution hole that is communicated with a space inside the motor case.

Owner:TOYOTA JIDOSHA KK

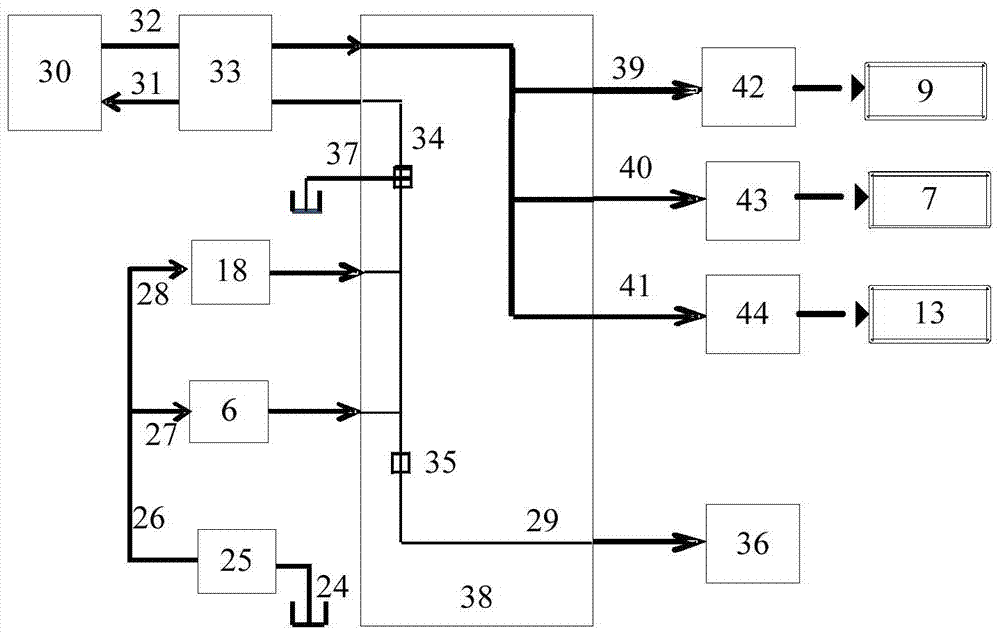

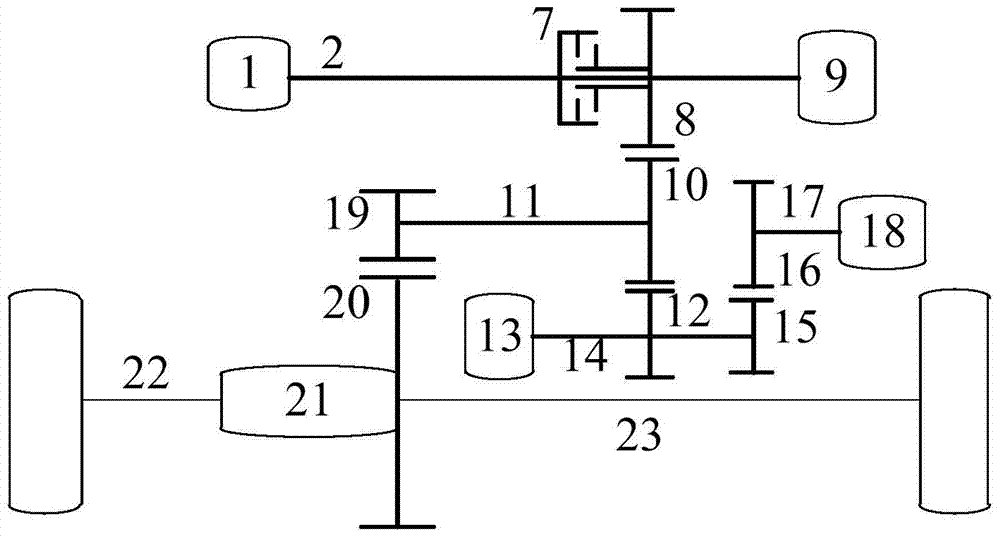

Hybrid electric vehicle coupling mechanism cooling and lubricating device and control method thereof

ActiveCN106956586AReduce weightMeet cooling and lubrication requirementsHybrid vehiclesLubricating systemElectric machineryDrive motor

The invention relates to the field of automobiles and discloses a hybrid electric vehicle coupling mechanism cooling and lubricating device and a control method thereof. The control method comprises the following steps a working mode of a coupling mechanism are received; when the coupling mechanism is in a pure-electric mode, an electric pump does not work, a drive motor drives a mechanical pump to operate so as to conduct cooling and lubricating on the drive motor; and when the coupling mechanism is in a stroke increasing mode or a hybrid power mode, the electric pump operates to conduct cooling and lubricating on a generator and a clutch, and meanwhile, the drive motor drives the mechanical pump to operate so as to conduct cooling and lubricating on the drive motor. The hybrid electric vehicle coupling mechanism cooling and lubricating device integrates cooling and lubricating of the coupling mechanism, spatial size of a system and the weight of system components can be reduced, the system adopts the mechanical pump and the electric pump as power sources of lubricating and cooling of oil liquid, switching can be conducted according to the working modes of the coupling mechanism, development cost is reduced, and control difficulty is lowered.

Owner:GUANGZHOU AUTOMOBILE GROUP CO LTD

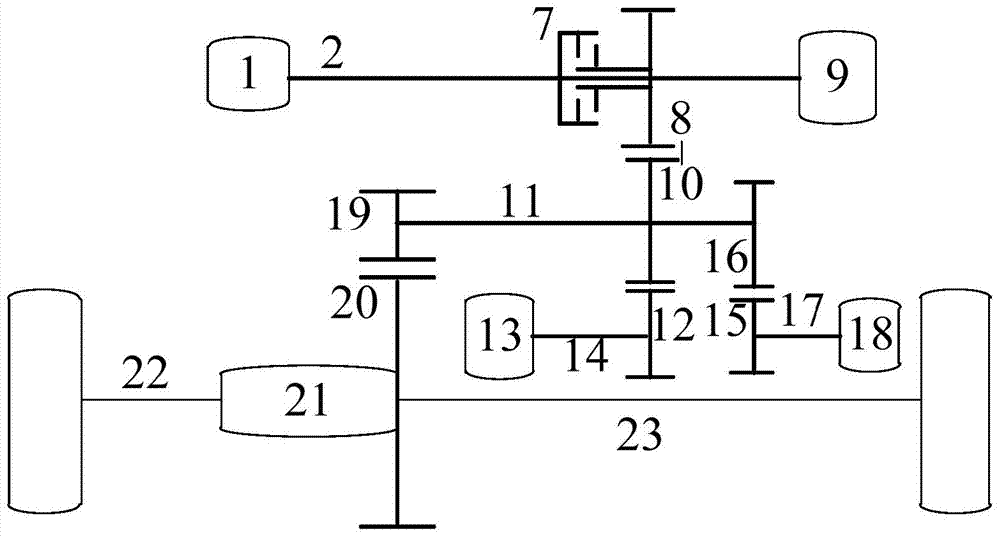

Power system and vehicle

ActiveCN107303856AImprove efficiencyReduce the required powerGear lubrication/coolingLubricating systemHigh pressureEnergy consumption

The invention discloses a power system and a vehicle. The power system comprises a transmission case, a motor, a high-pressure oil pump, a low-pressure oil pump and a reversing valve, wherein the high-pressure oil pump is coupled to the motor and is used for providing a high-pressure oil-way with low-pressure oil; the high-pressure oil-way is used for driving the transmission case; the low-pressure oil pump is coupled to the motor and is provided for providing a low-pressure oil-way with low-pressure oil; the low-pressure oil-way is used for lubricating the transmission case; the reversing valve is used for switching the flow direction of high-pressure oil output from the high-pressure oil pump and the high-pressure oil flows to the high-pressure oil-way or the low-pressure oil-way, wherein the pressure intensity of the low-pressure oil is lower than that of the high-pressure oil; and the high-pressure oil pump is connected with the high-pressure oil-way through the reversing valve. According to the power system and the vehicle, the cost and the energy consumption of the power system are reduced.

Owner:SAIC MOTOR

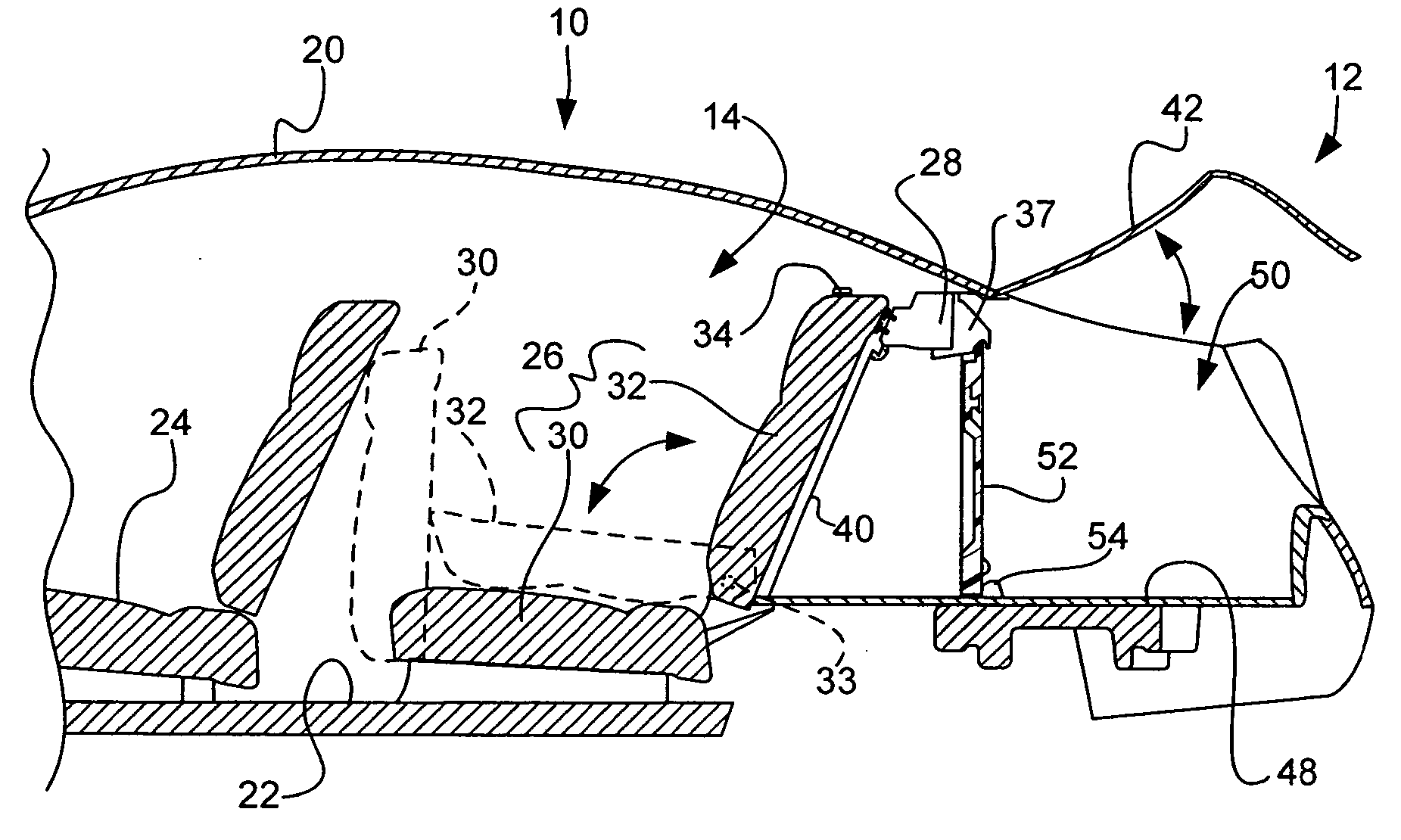

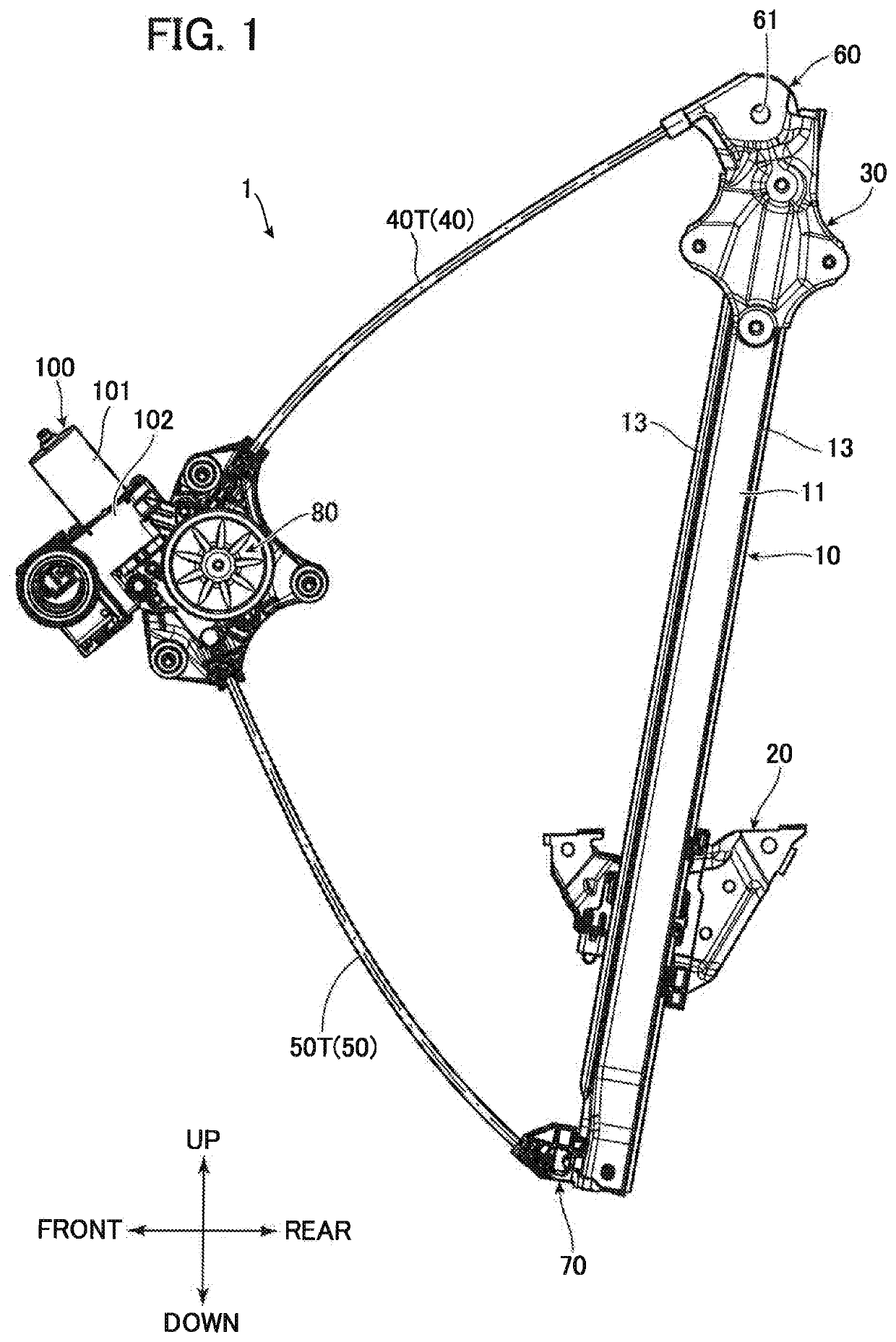

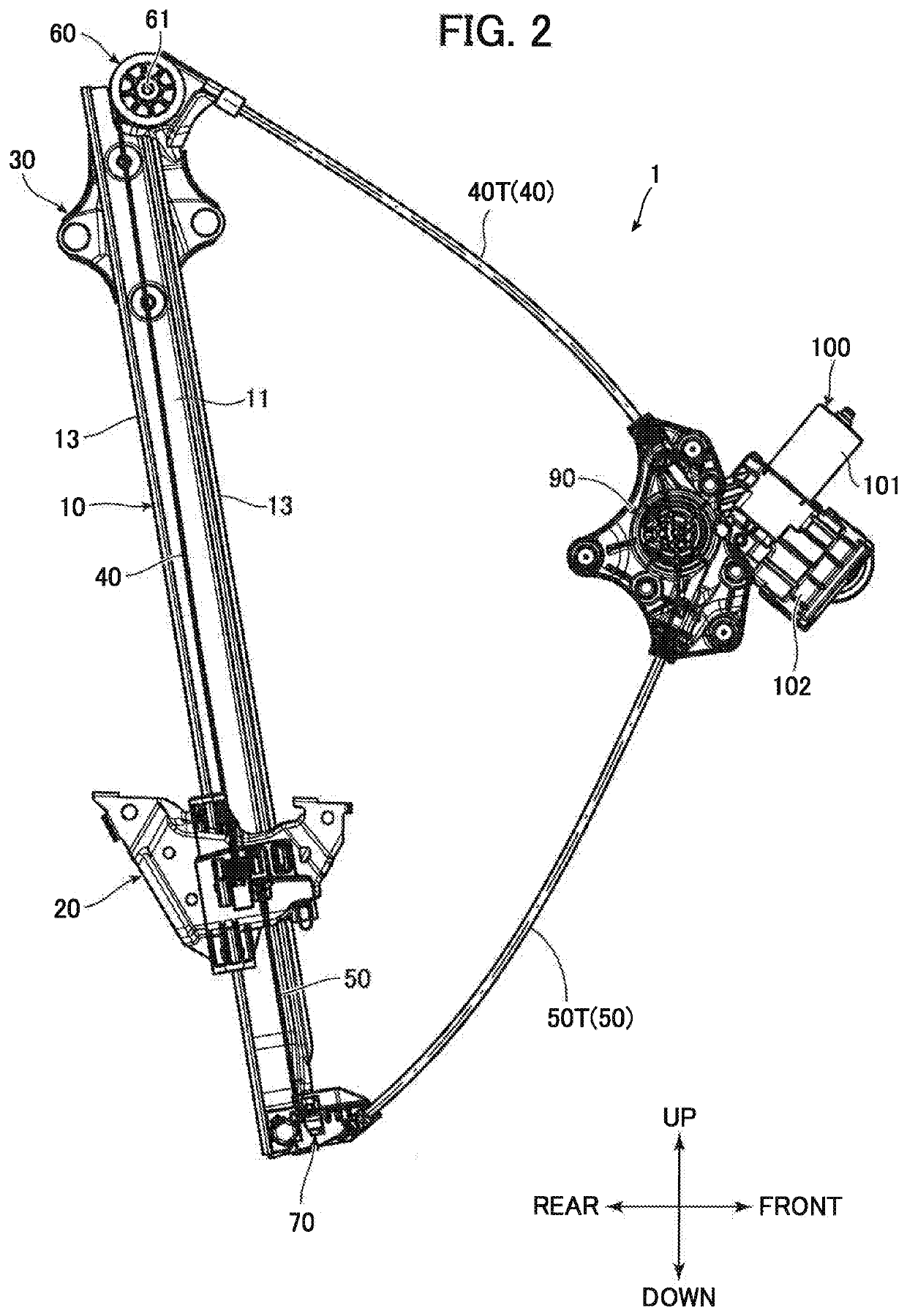

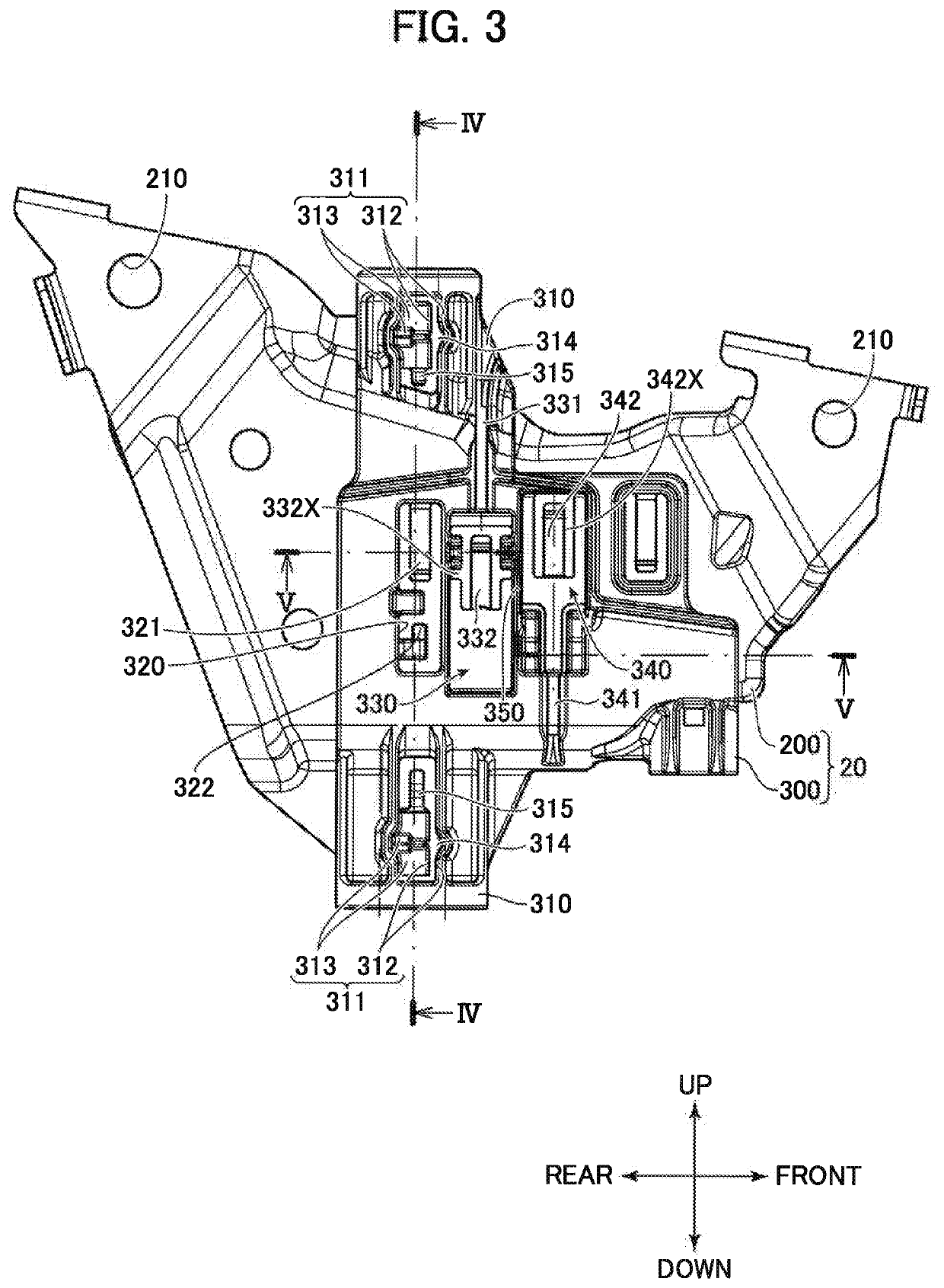

Window regulator and method of assembling the same

To provide a window regulator and a method of assembling the same, capable of easily applying grease to a main wall portion of a guide rail, the window regulator includes: a guide rail extending in an operation direction of a window glass; and a slider installed to the window glass and guided along the operation direction on the guide rail, wherein the guide rail has a main wall portion extending in a front-rear direction, and the slider has a main body portion facing the main wall portion of the guide rail abuttably from a vehicle width direction, and a grease application portion configured to apply grease along the operation direction on the main wall portion of the guide rail.

Owner:AISIN CORP

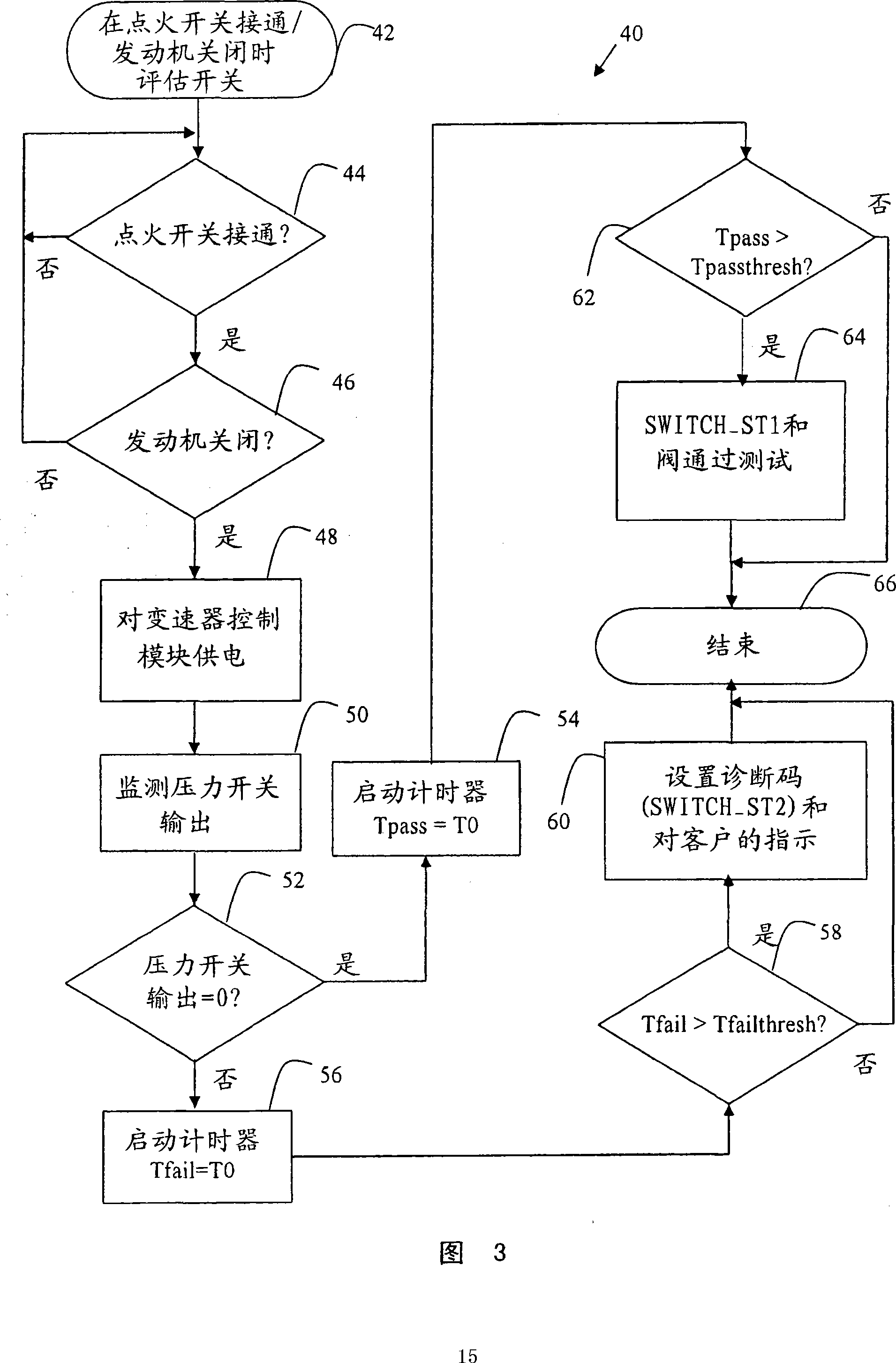

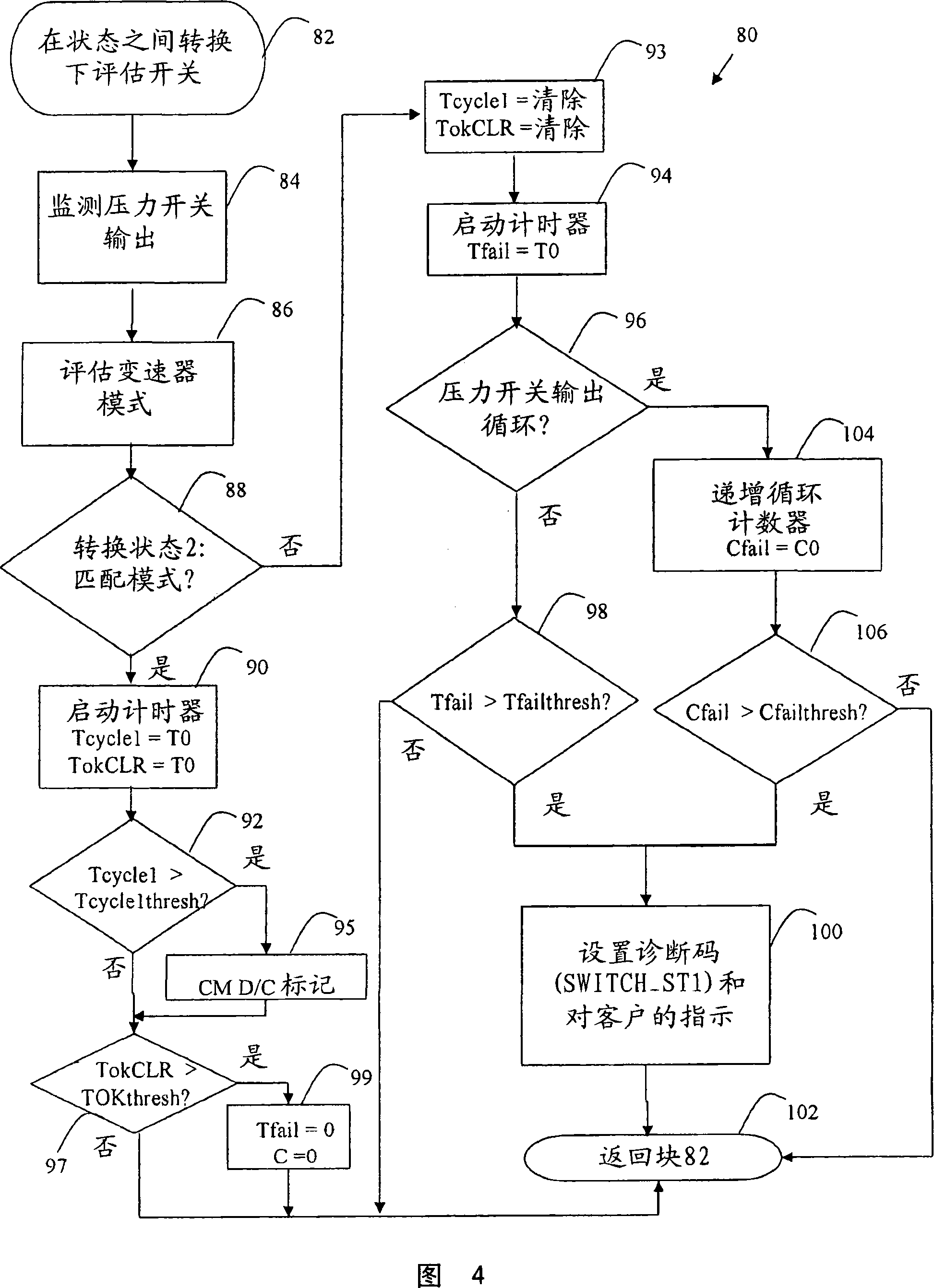

Method for controlling a filter maintenance indicator

ActiveCN101149107AGear lubrication/coolingStructural/machines measurementRecording durationDriver/operator

A method for determining the condition of a transmission fluid filter and controlling an operator indicator to alert the operator that the fluid filter requires replacement is disclosed. The method includes monitoring a fluid pressure switch, determining an operating mode of the transmission, determining whether the operating mode of the transmission is changing, activating a timer if the operating mode is changing, recording the time, comparing the time to a predefined time threshold, determining whether the recorded time is greater than the predefined threshold, and activating the operator indicator to indicate that the fluid filter requires replacement if the recorded time is greater than the predefined threshold.

Owner:ALLISON TRANSMISSION INC

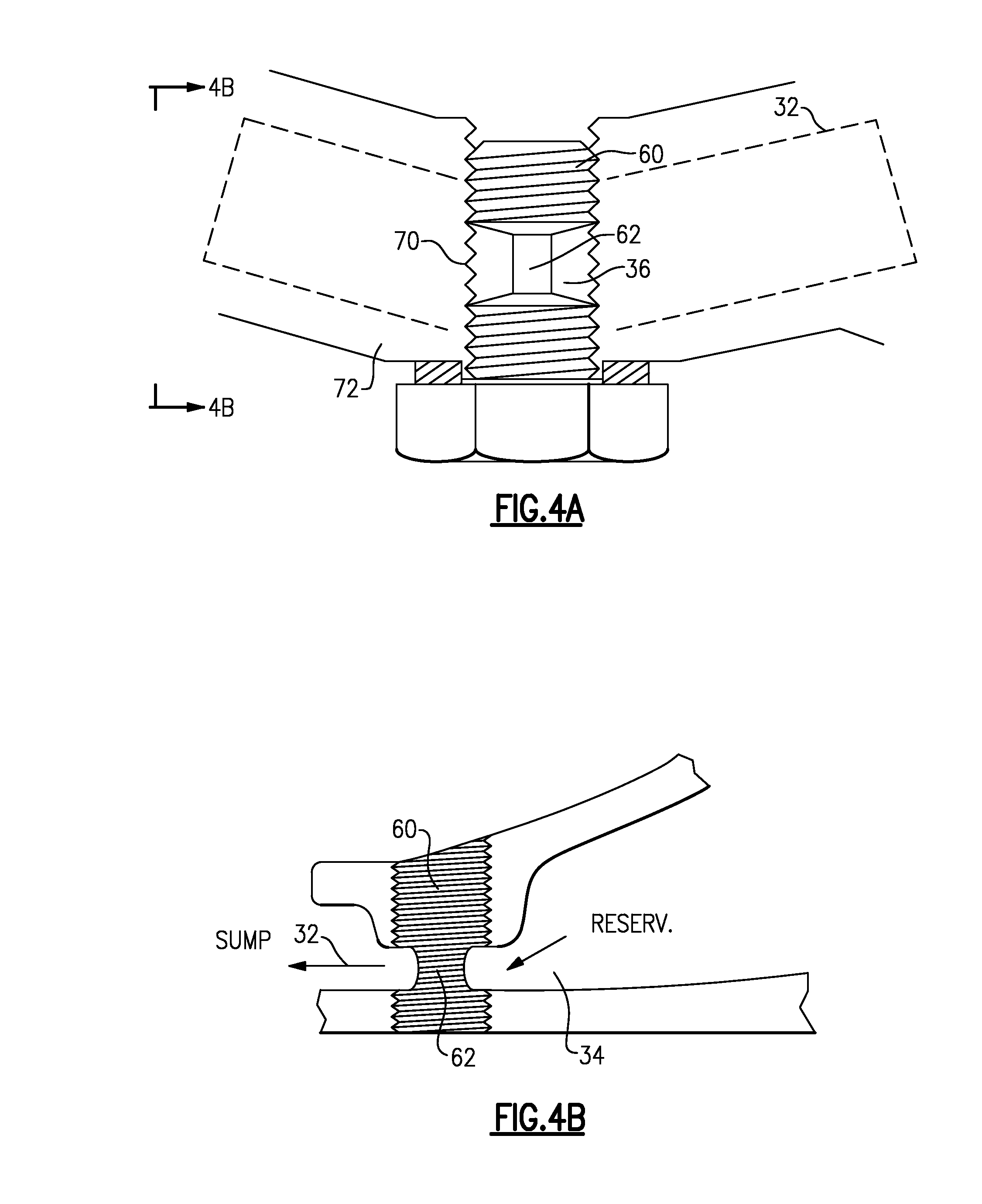

Drain plug for carrier assembly

A drain plug for a carrier assembly is used to control fluid flow from a reservoir to a sump. The carrier assembly includes a carrier housing with an internal cavity that houses a gear assembly. The sump is located within the internal cavity to lubricate the gear assembly. The reservoir is separated from the sump by a channel. The drain plug is attached to the carrier housing, and extends into the channel, to provide a fluid flow restriction between the reservoir and the sump.

Owner:ARVINMERITOR TECH

Oil Supply Device

ActiveUS20160025207A1Simple configurationReduce the number of partsDigital data processing detailsGear lubrication/coolingIdle reductionAutomatic transmission

The present invention relates to an oil supply device for use in an automatic transmission mounted on a vehicle, and is applied to a vehicle in which an idle reduction control or the like is performed. The oil supply device includes an oil pump which is driven by a driving motor of a vehicle and a motor separate from the driving motor, and an engagement and disengagement element which transmits a driving force of the driving motor to the oil pump, and the oil pump is driven by the motor without using a drive system of the driving motor.

Owner:HITACHI ASTEMO LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com