Patents

Literature

34results about How to "Reduce oil discharge" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

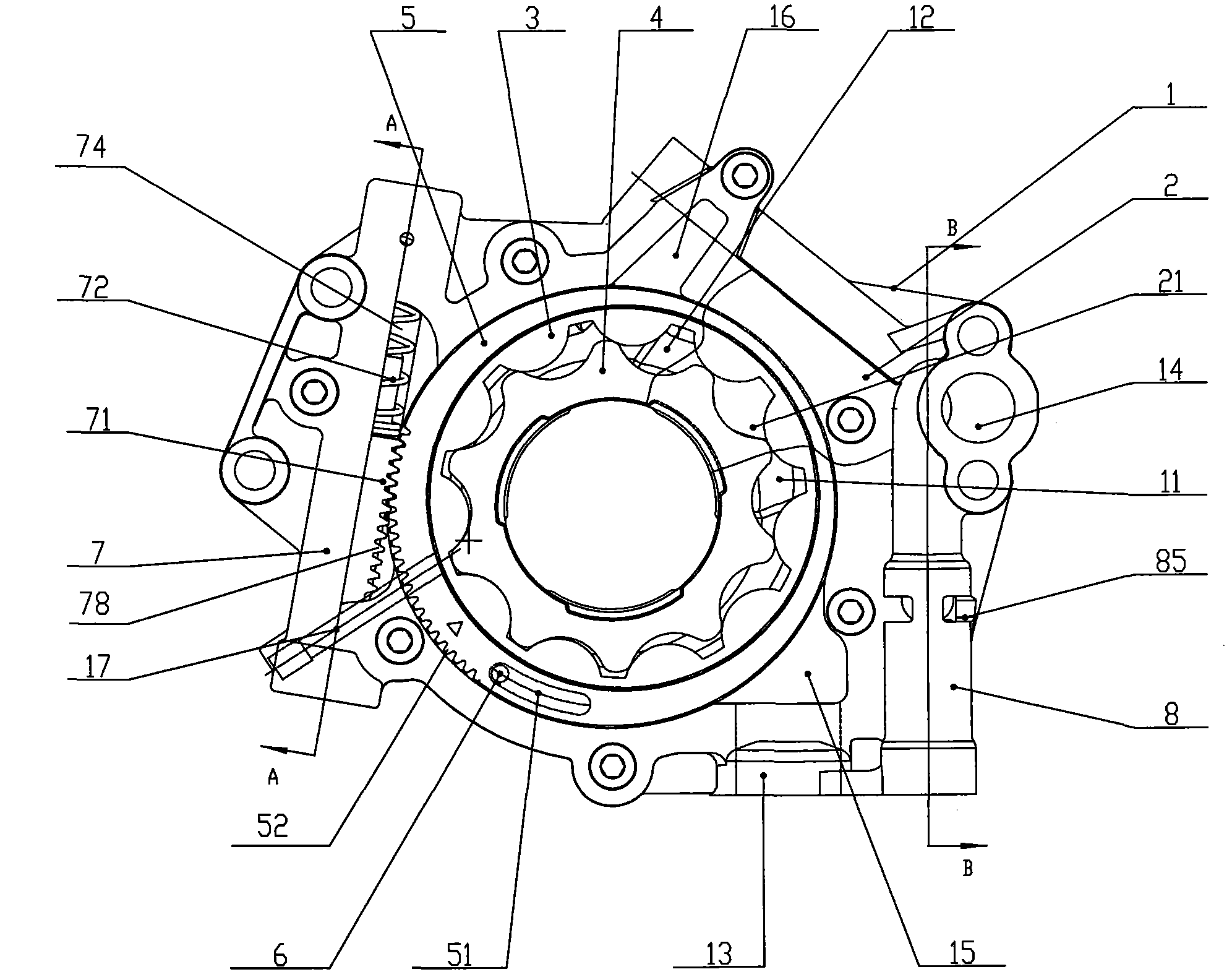

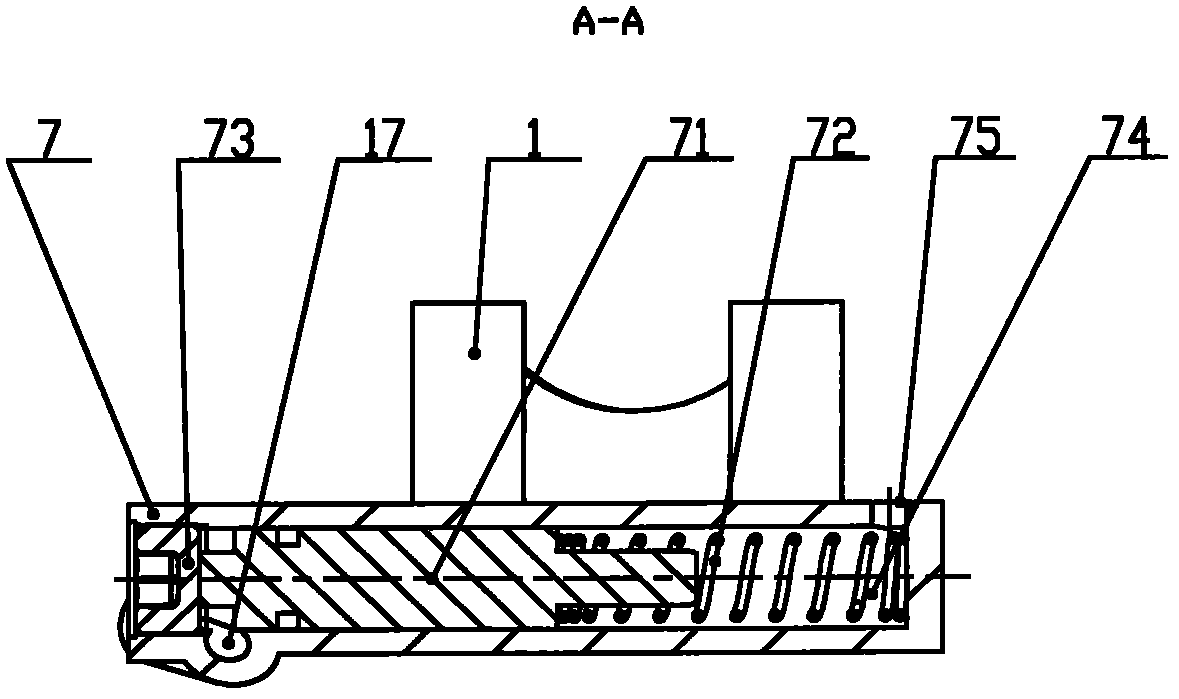

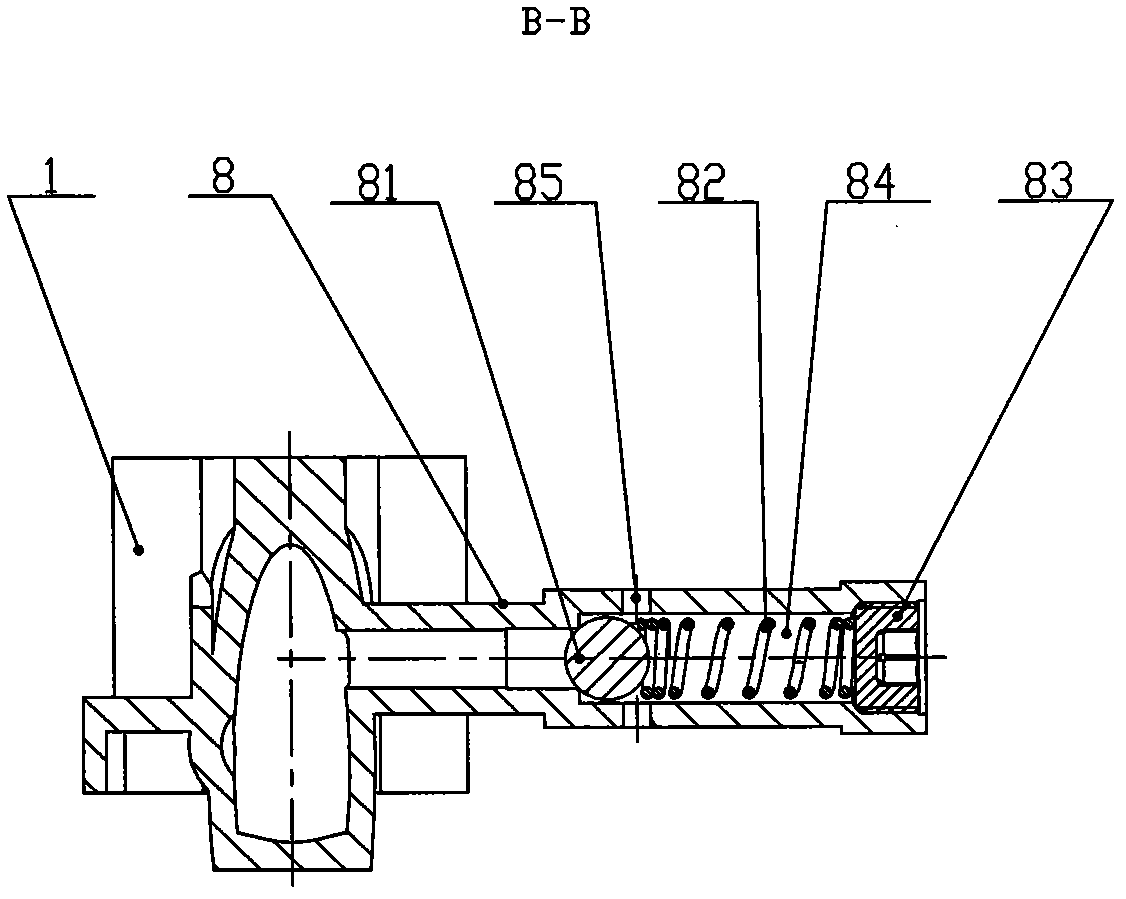

Eccentrically-adjusted variable rotor oil pump

The invention discloses an eccentrically-adjusted variable rotor oil pump. The oil pump consists of a pump body, a pump cover, an outer rotor, an inner rotor, an external tooth eccentric ring, a stop pin, a rack valve component and a safety valve component, wherein the pump body is provided with a rack valve hole for installation of the rack valve component, a safety valve hole for installation of the safety valve component and a limiting stop pin; the rack valve component is arranged in the rack valve hole; the safety valve component is arranged in the safety valve hole; the external tooth eccentric ring is arranged in an external tooth eccentric ring installation hole on the pump body; a limiting arc-shaped groove on the external tooth eccentric ring is aligned with the limiting stop pin on the pump body; the limiting stop pin is inserted into the limiting arc-shaped groove; and an external tooth of the external tooth eccentric ring is aligned with a rack which is arranged on a valve core of the rack valve in the rack valve hole, and is meshed with the rack on the valve core of the rack valve. After being matched with each other, the inner rotor and the outer rotor are arranged in rotor holes of the external tooth eccentric ring at the same time, and then the pump cover is covered on the pump body at a rotor position.

Owner:HUNAN OIL PUMP

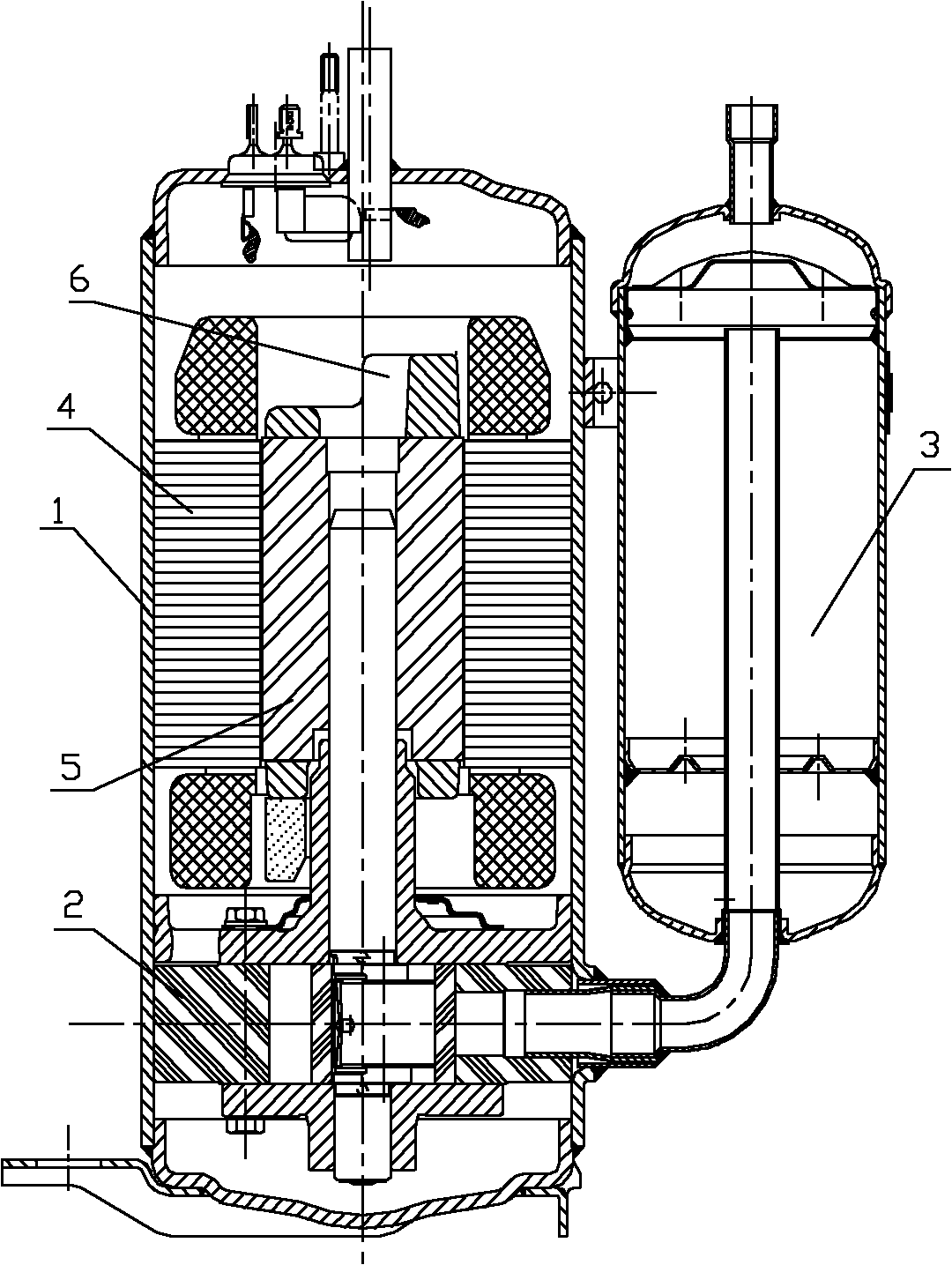

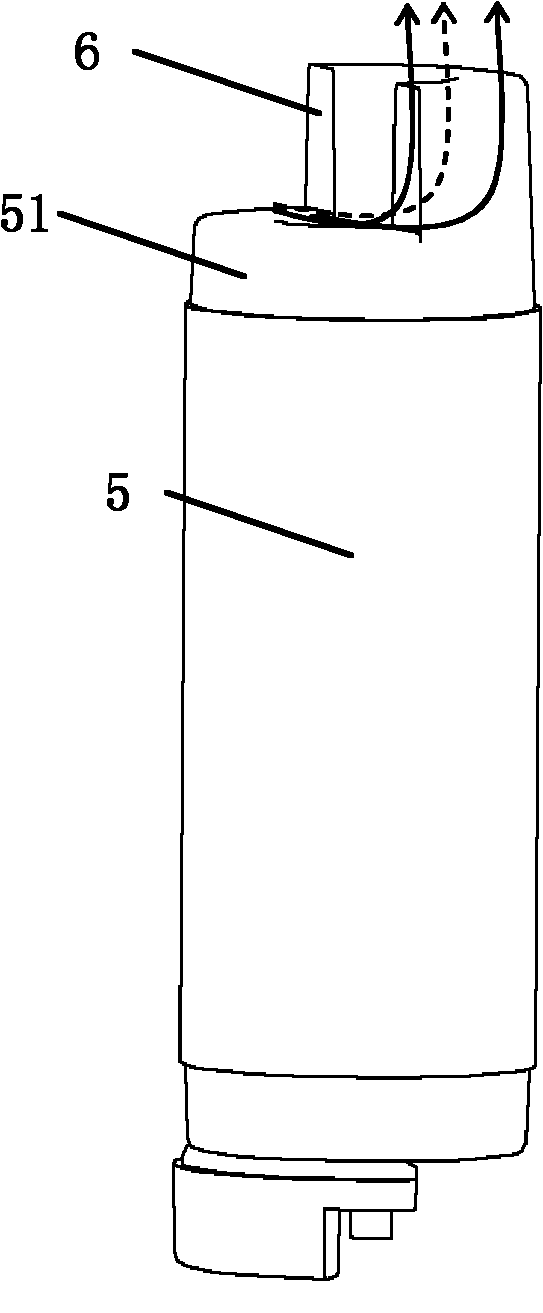

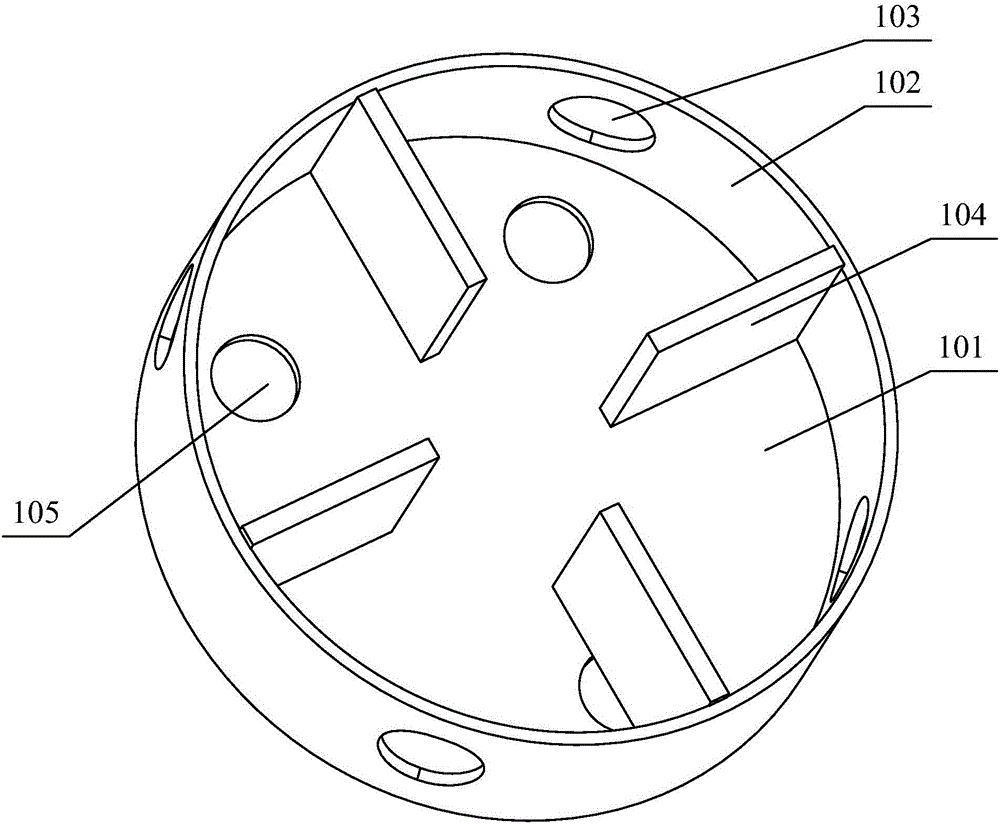

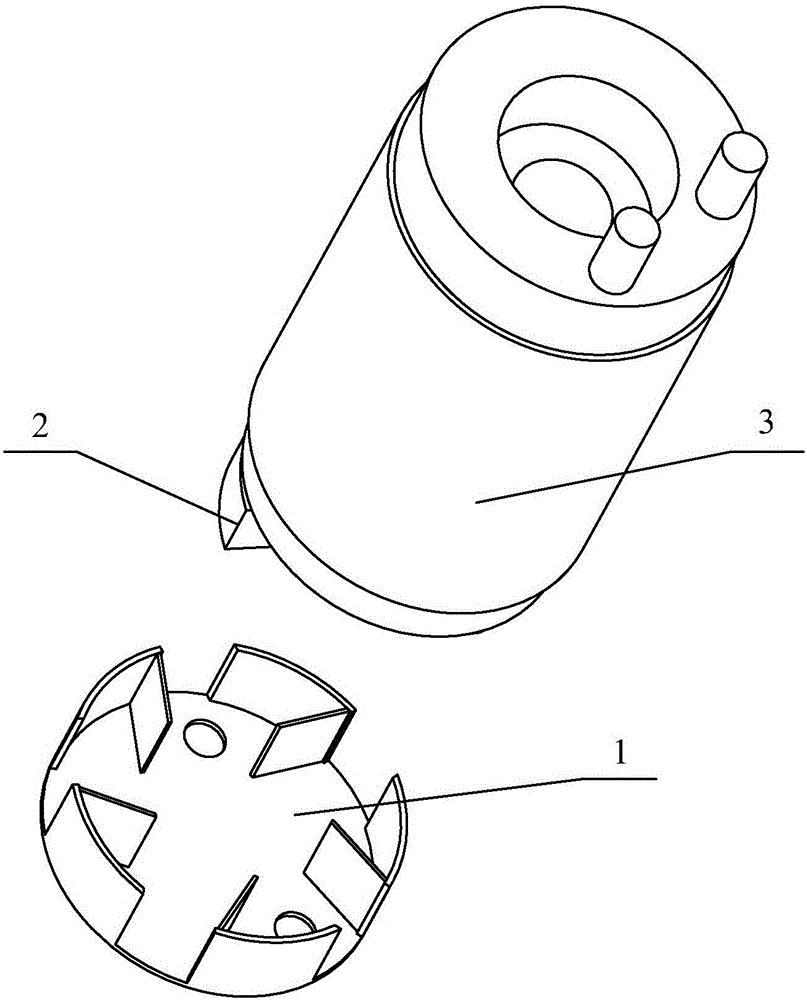

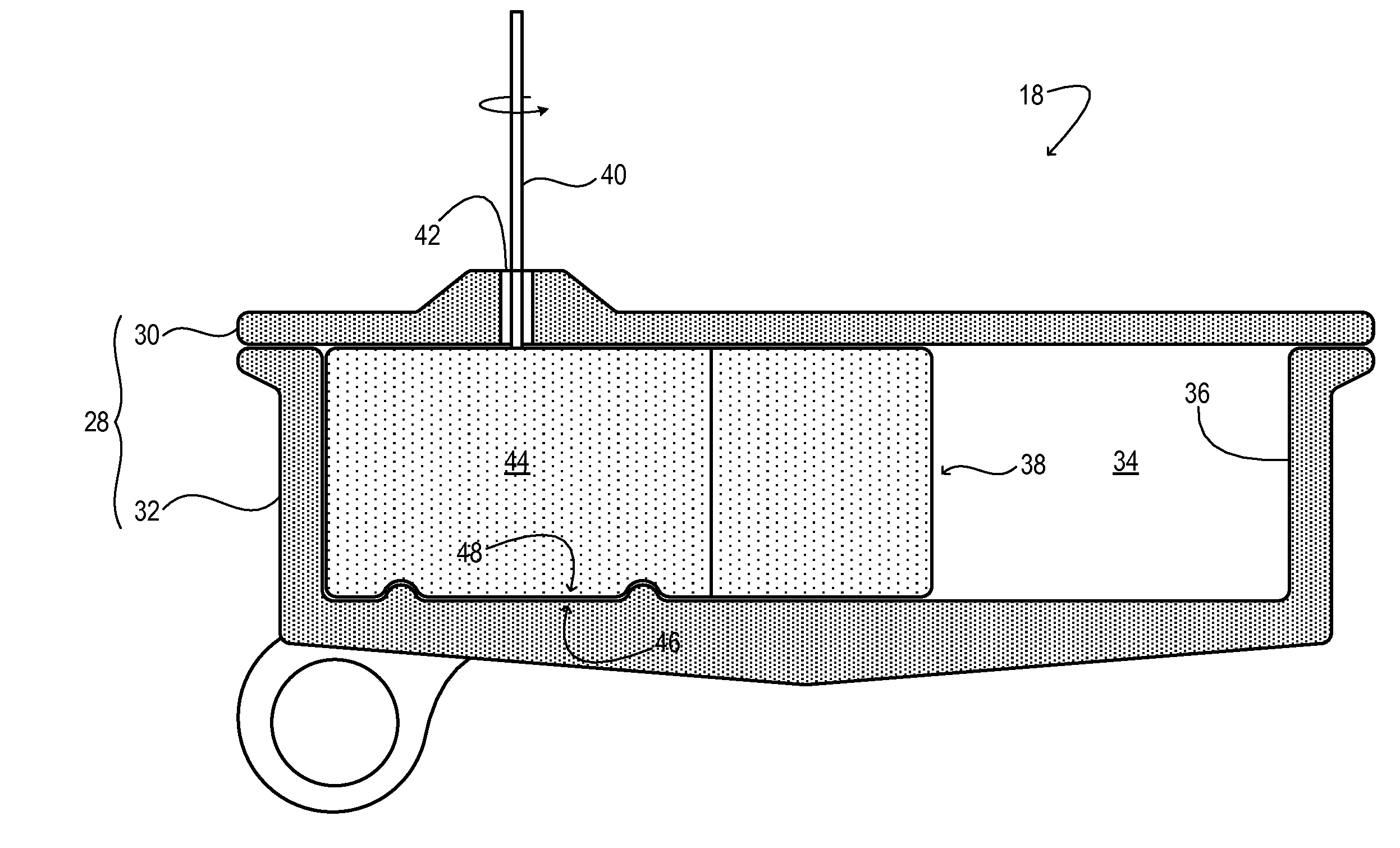

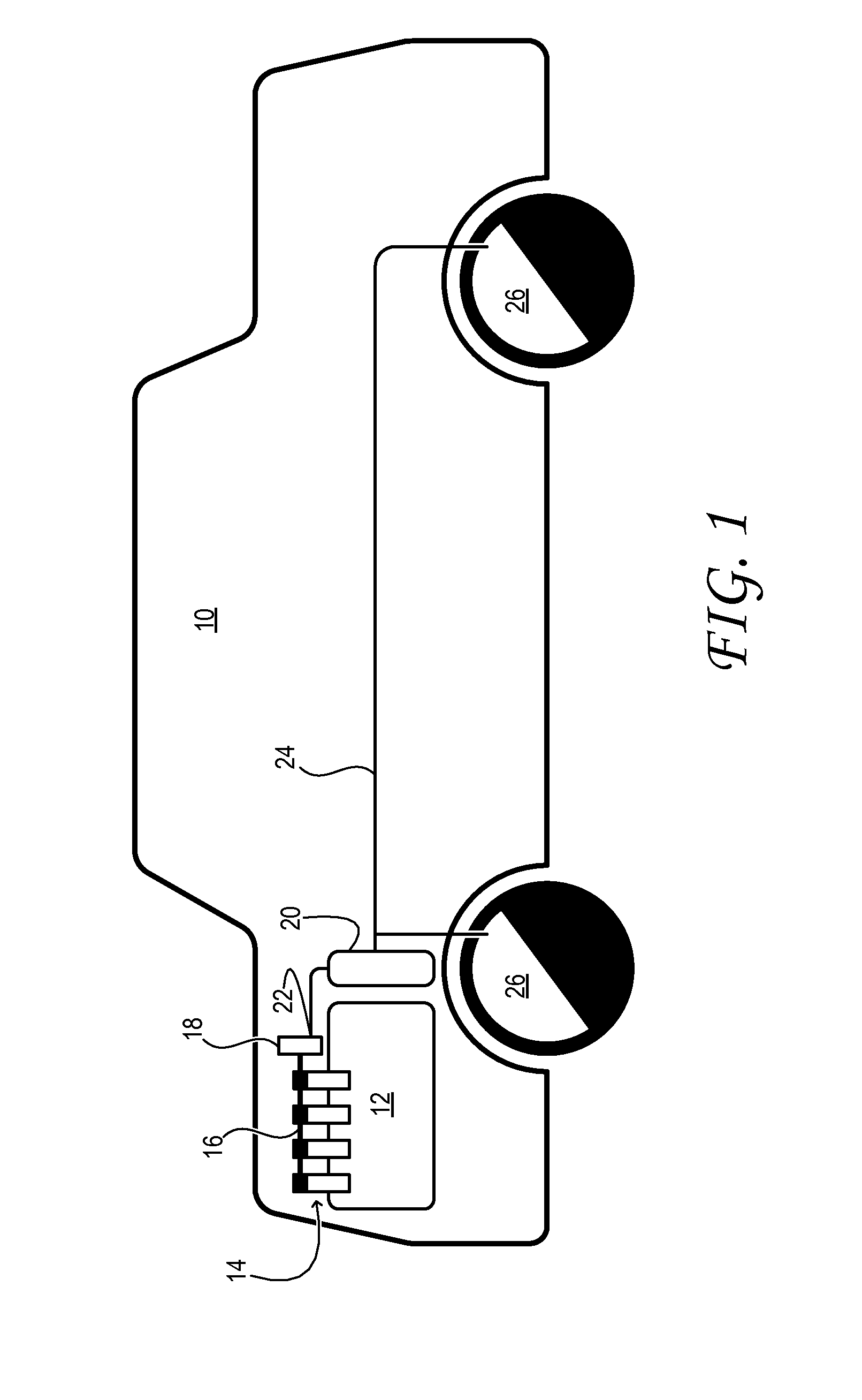

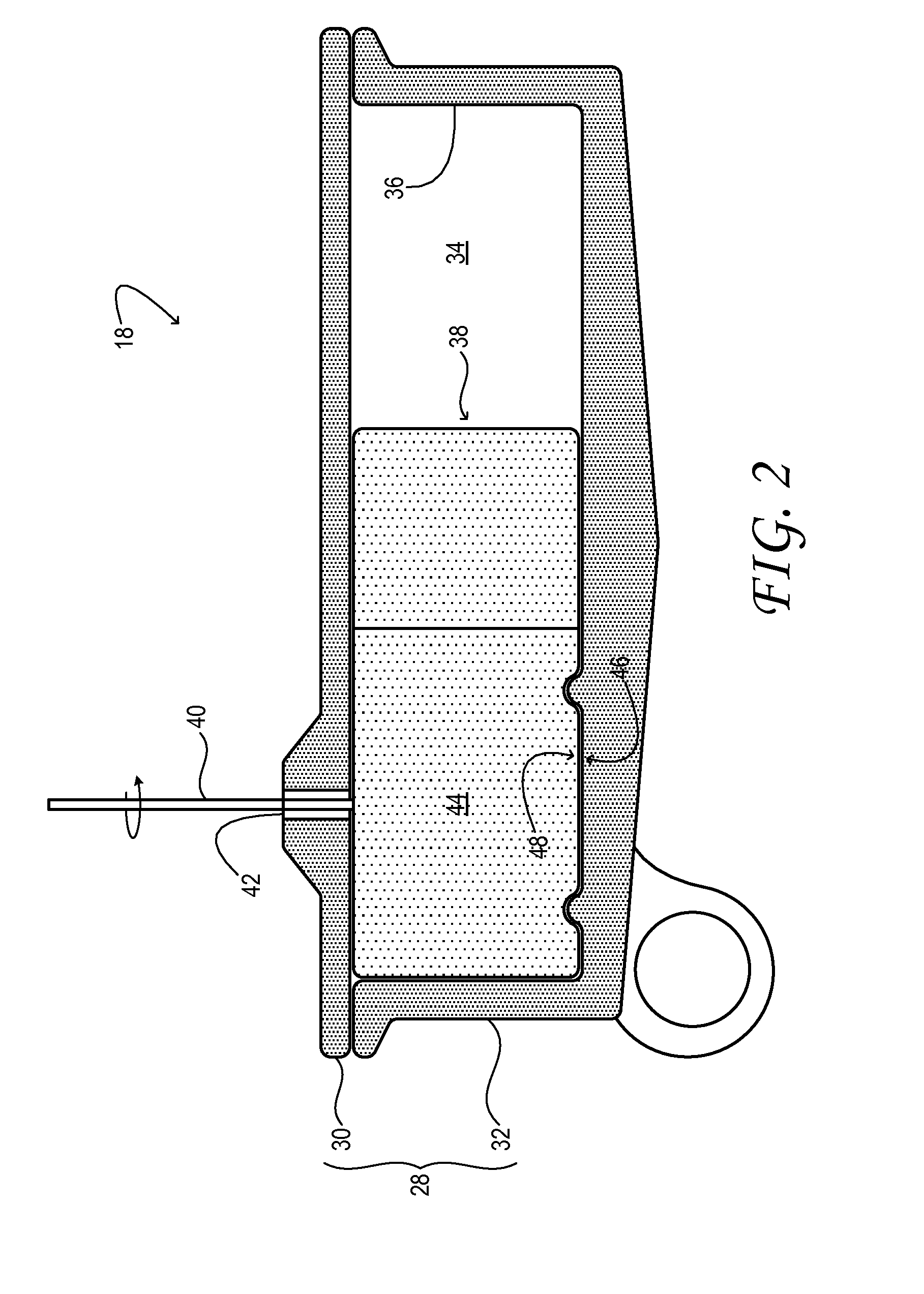

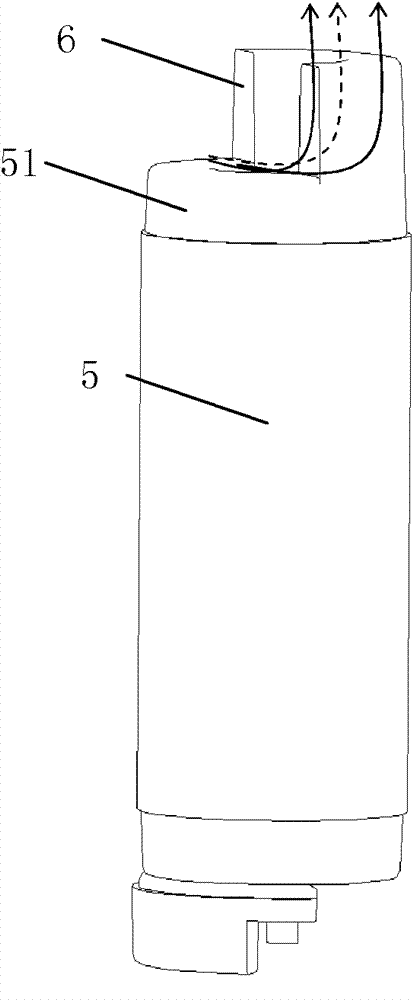

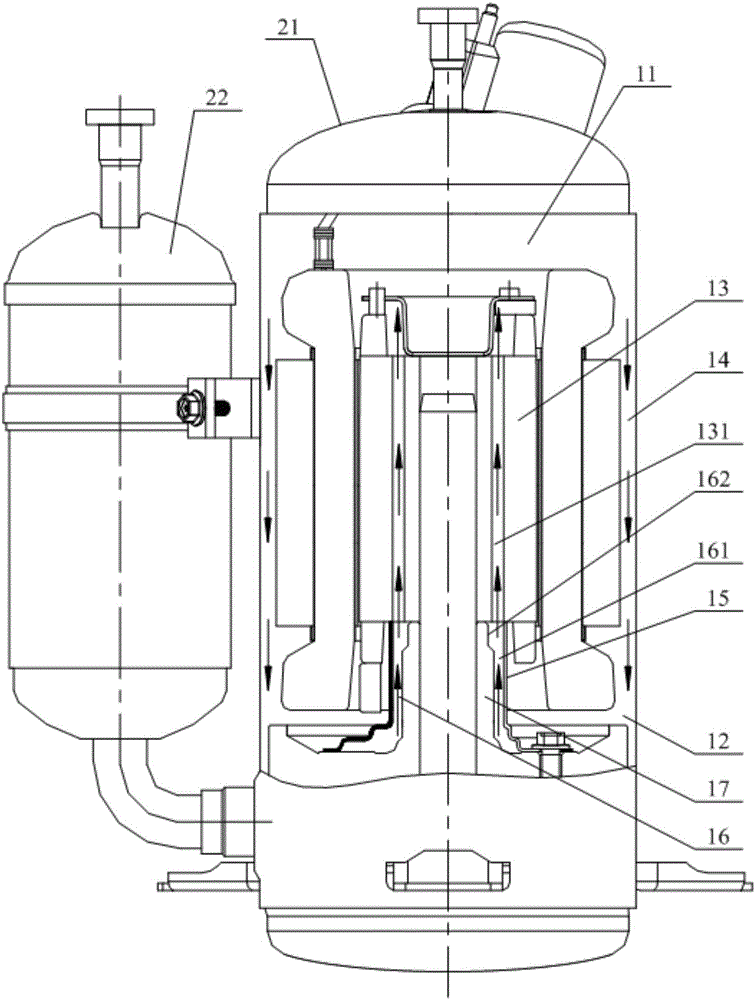

Oil-gas separated-type balancing block

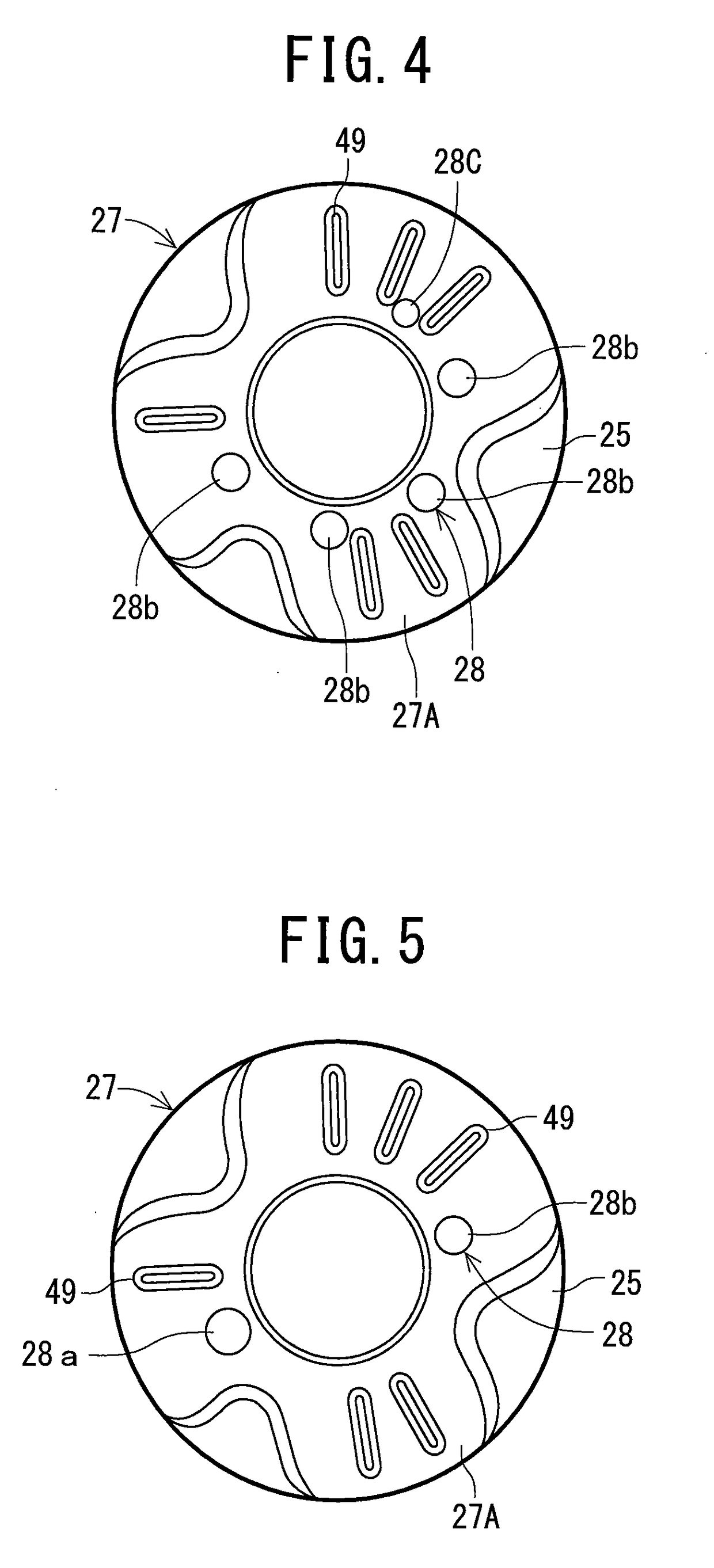

ActiveCN102162454AReduce oil dischargeExtended service lifeRotary/oscillating piston pump componentsLiquid fuel engine componentsEngineeringMechanical engineering

The invention discloses an oil-gas separated-type balancing block which is internally provided with a channel, wherein the channel penetrates through two end surfaces of the balancing block and is communicated with the outer side wall of the balancing block. By adopting a compressor equipped with the balancing block provided by the invention can separate refrigerating machine oil from gas refrigerant in the operation process, thus the oil discharge amount of the compressor is reduced, not only can the amount of refrigerating machine oil in the shell of the compressor be ensured, the service life and dependance of the compressor are improved, but also the heat transfer effect and energy efficiency of an air conditioner can be improved.

Owner:PANASONIC WANBAO GUANGZHOU COMPRESSOR

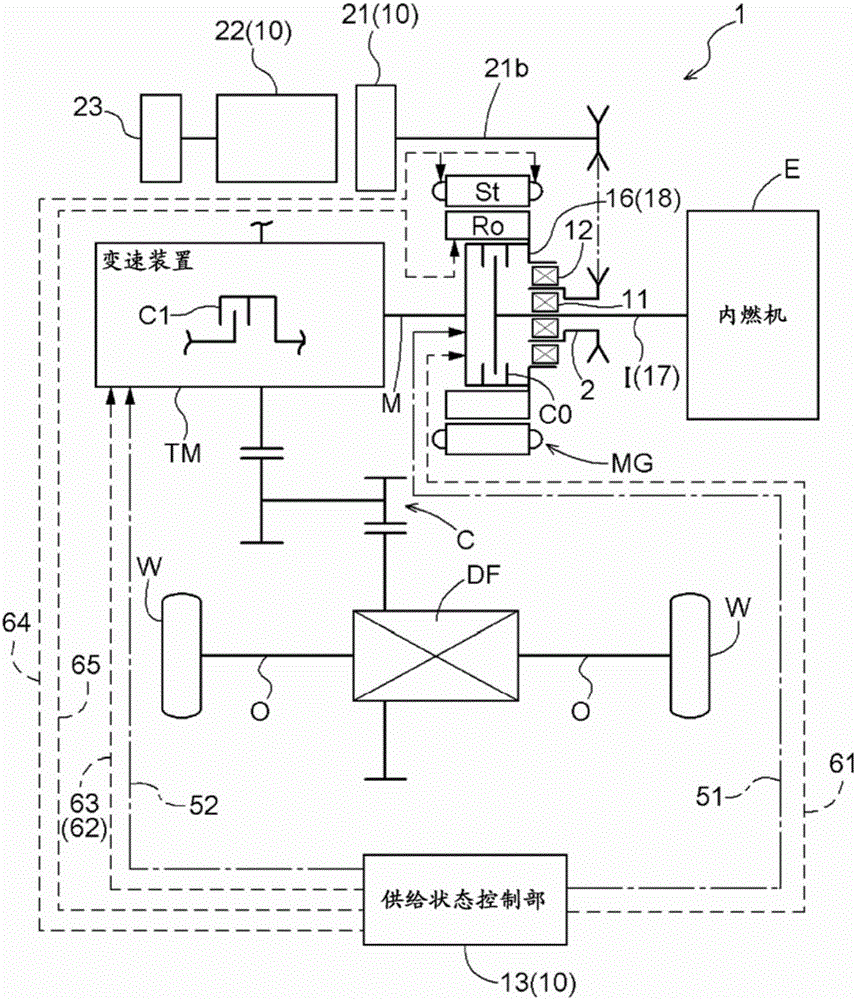

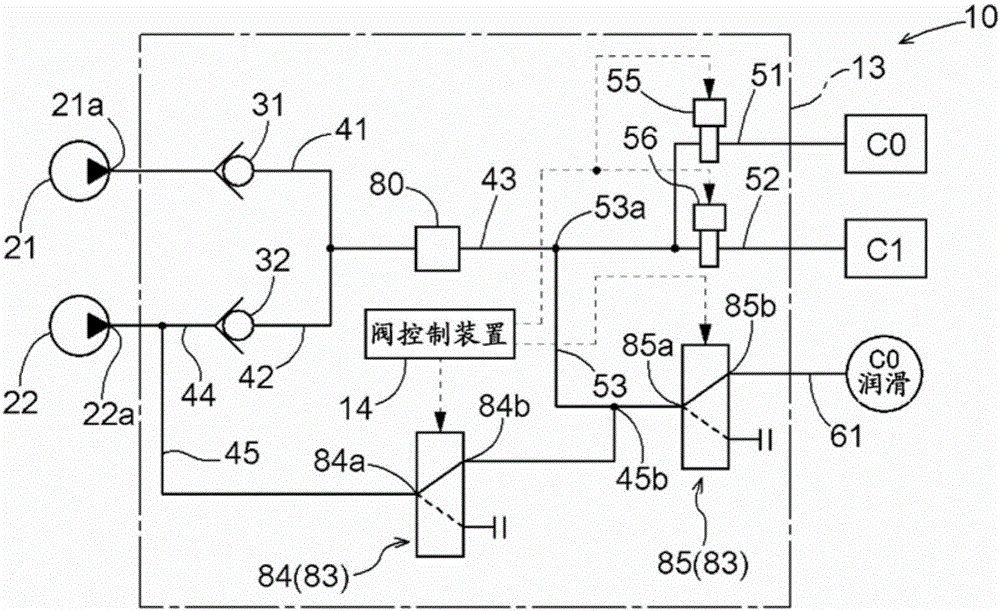

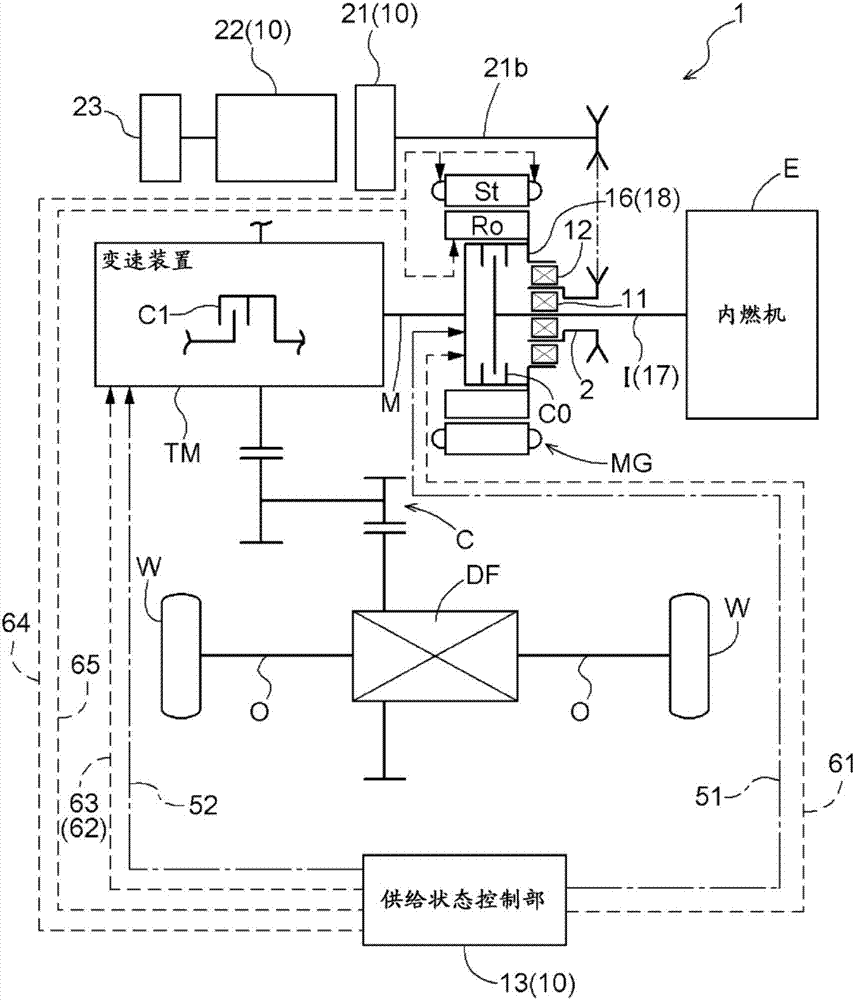

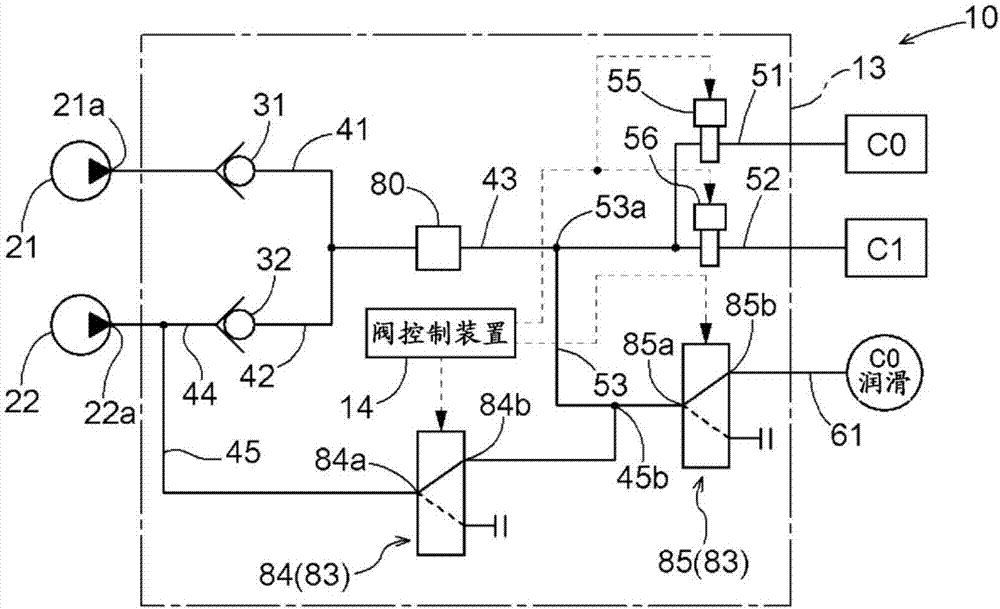

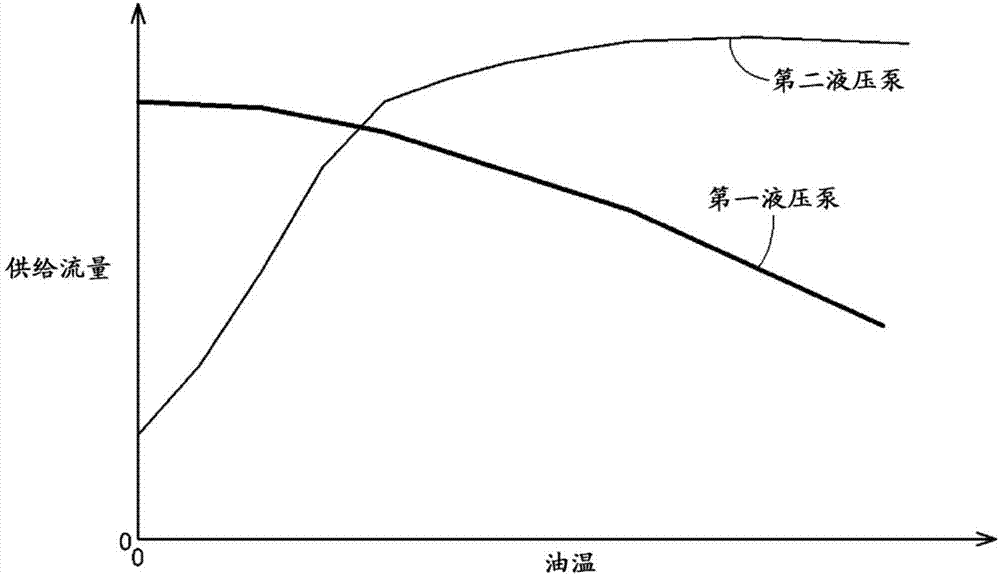

Oil supply device

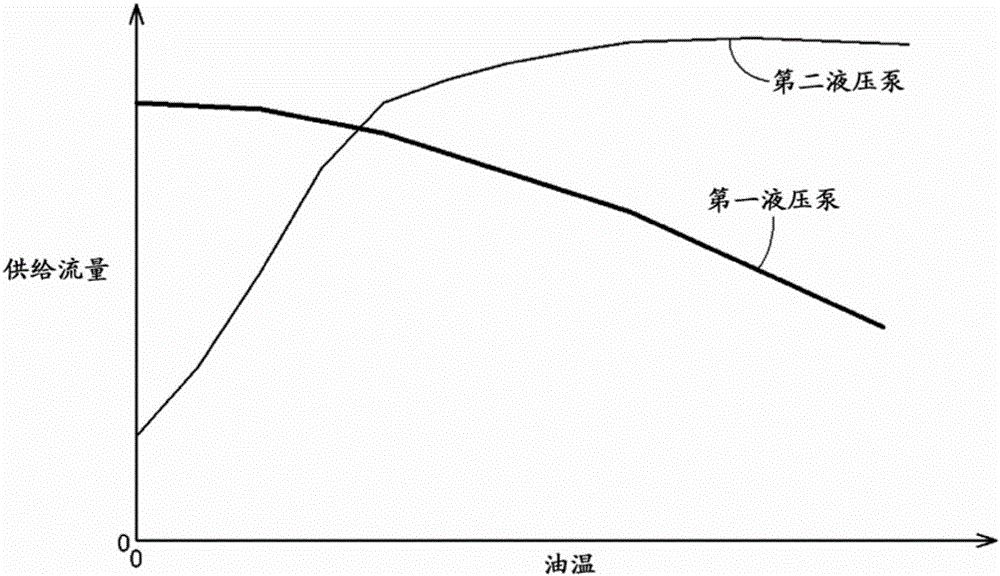

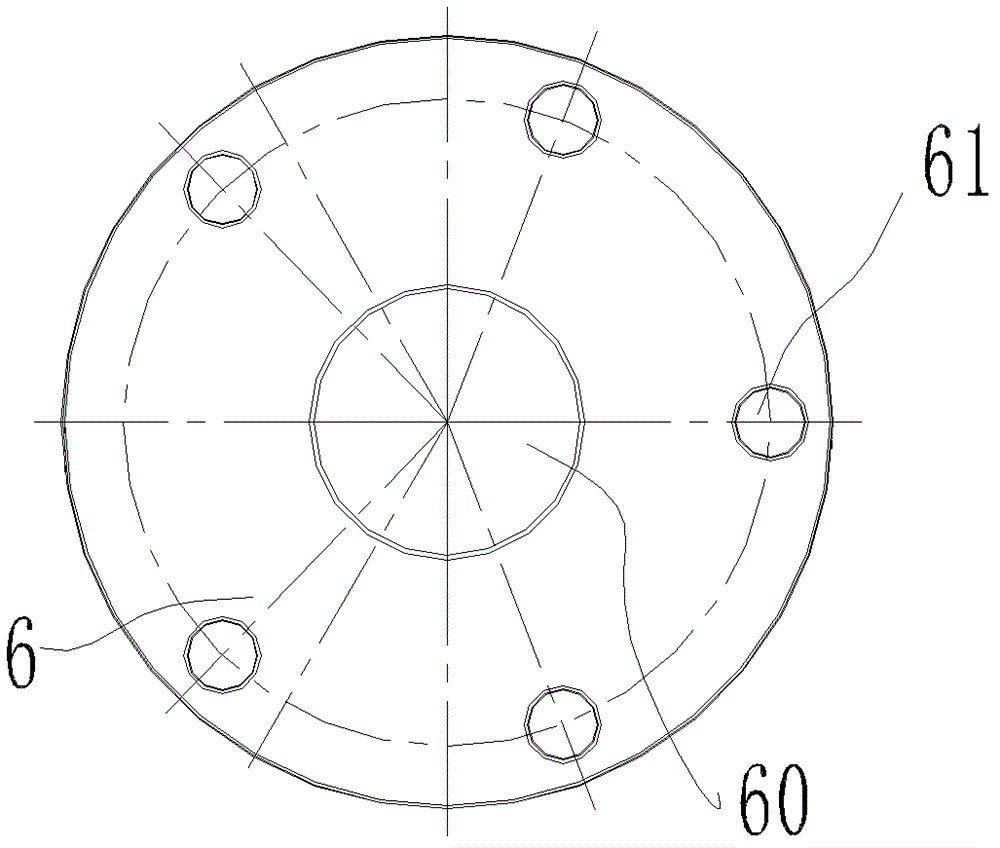

InactiveCN105026233AReduce oil dischargeMiniaturizationHybrid vehiclesSpeed controllerHydraulic pumpInternal combustion engine

There is desired an oil supply device that can supply an appropriate amount of oil to a vehicle drive device, while suppressing an increase in size of a hydraulic pump, in the case where torque of an internal combustion engine is transferred to wheels with an engagement device controlled to a slipping engagement state. An oil supply device 10 includes a first hydraulic pump 21, a second hydraulic pump 22 driven by a dedicated drive force source 23, a lubrication oil passage 61 for lubricating engagement devices C0 and C1, a first engagement oil passage 51 for controlling the state of engagement of the decoupling engagement device C0, and a second engagement oil passage 52 for controlling the state of engagement of the shifting engagement device C1. In the case where the engagement devices C0 and C1 are controlled to a slipping engagement state, the supply state control section 10 establishes a state in which oil discharged from the first hydraulic pump 21 is supplied to the first engagement oil passage 51 and the second engagement oil passage 52, and in which at least oil discharged from the second hydraulic pump 22 is supplied to the lubrication oil passage 61.

Owner:AISIN AW CO LTD

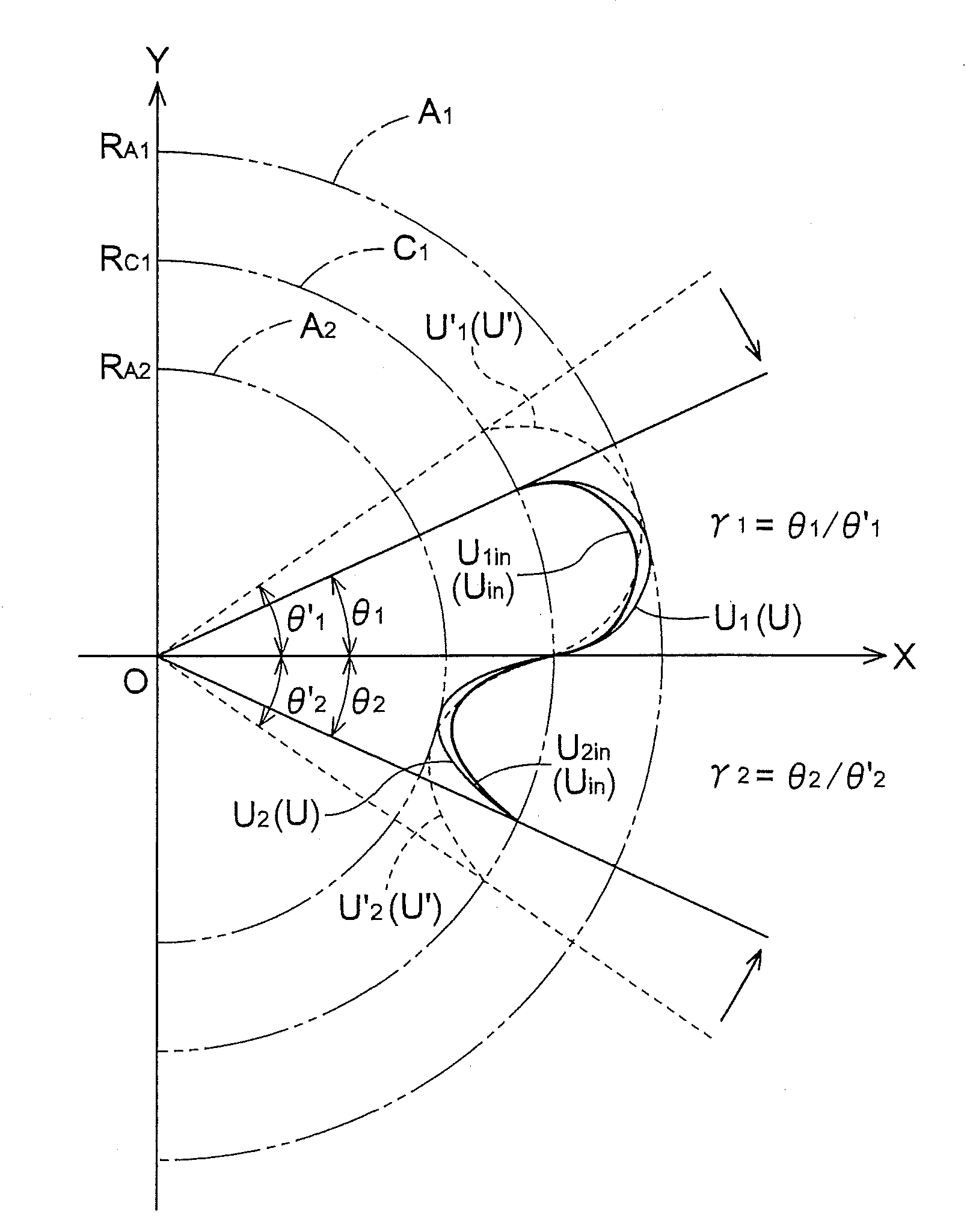

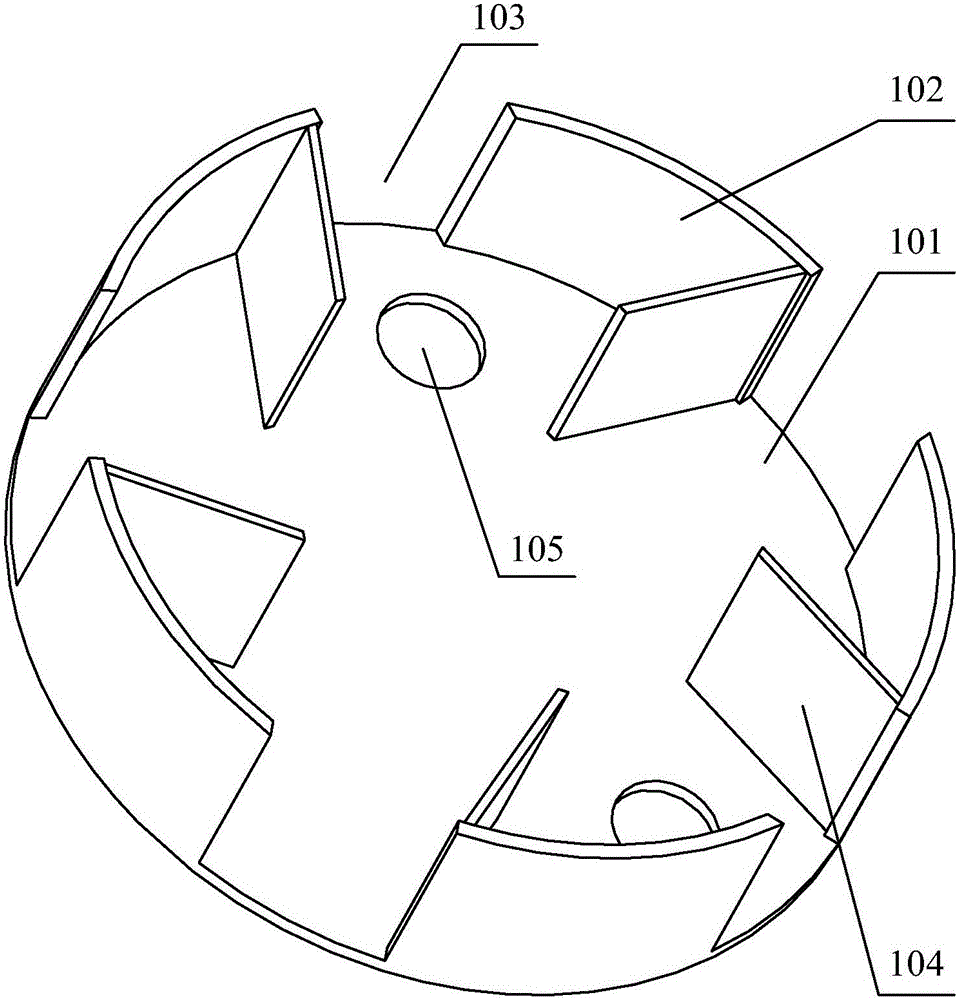

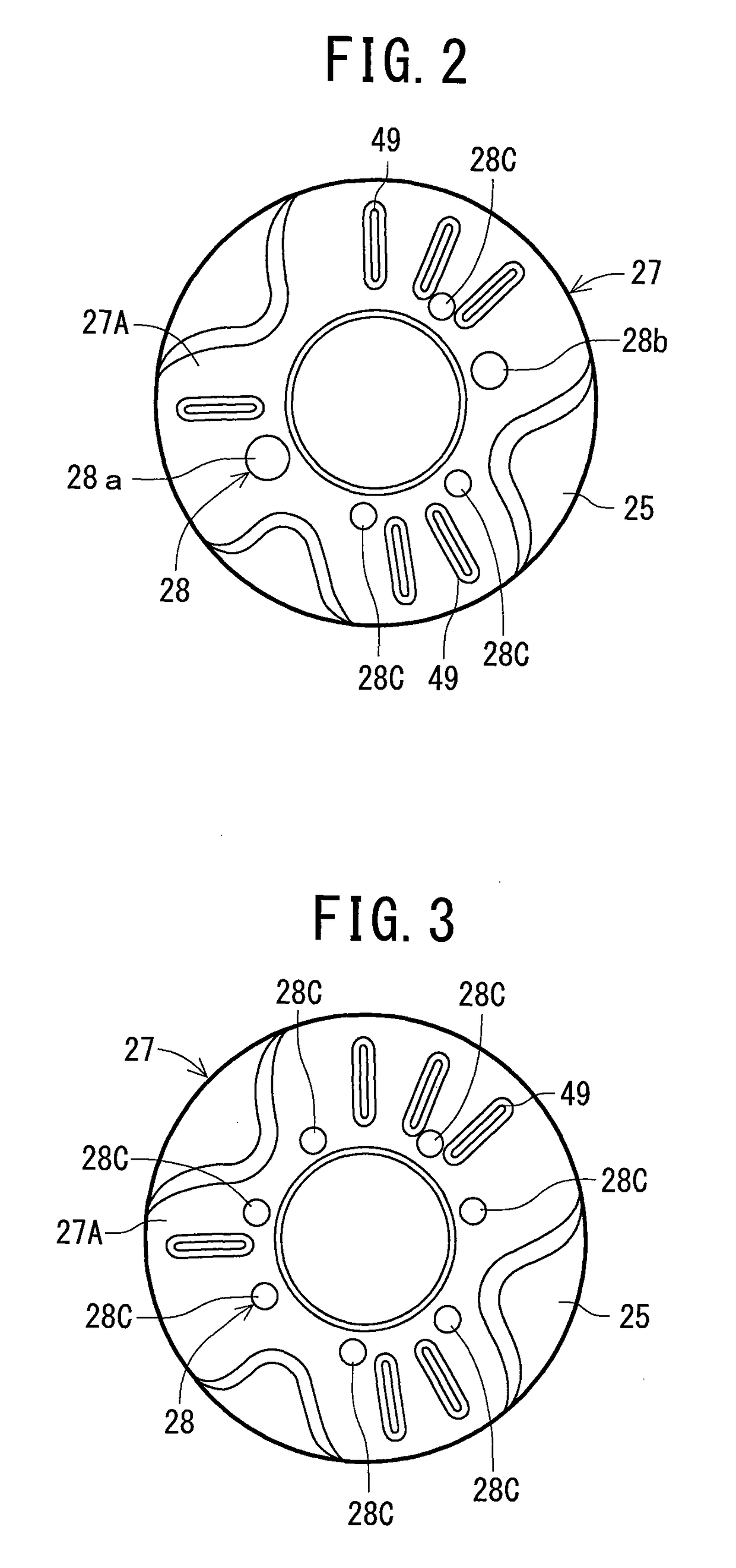

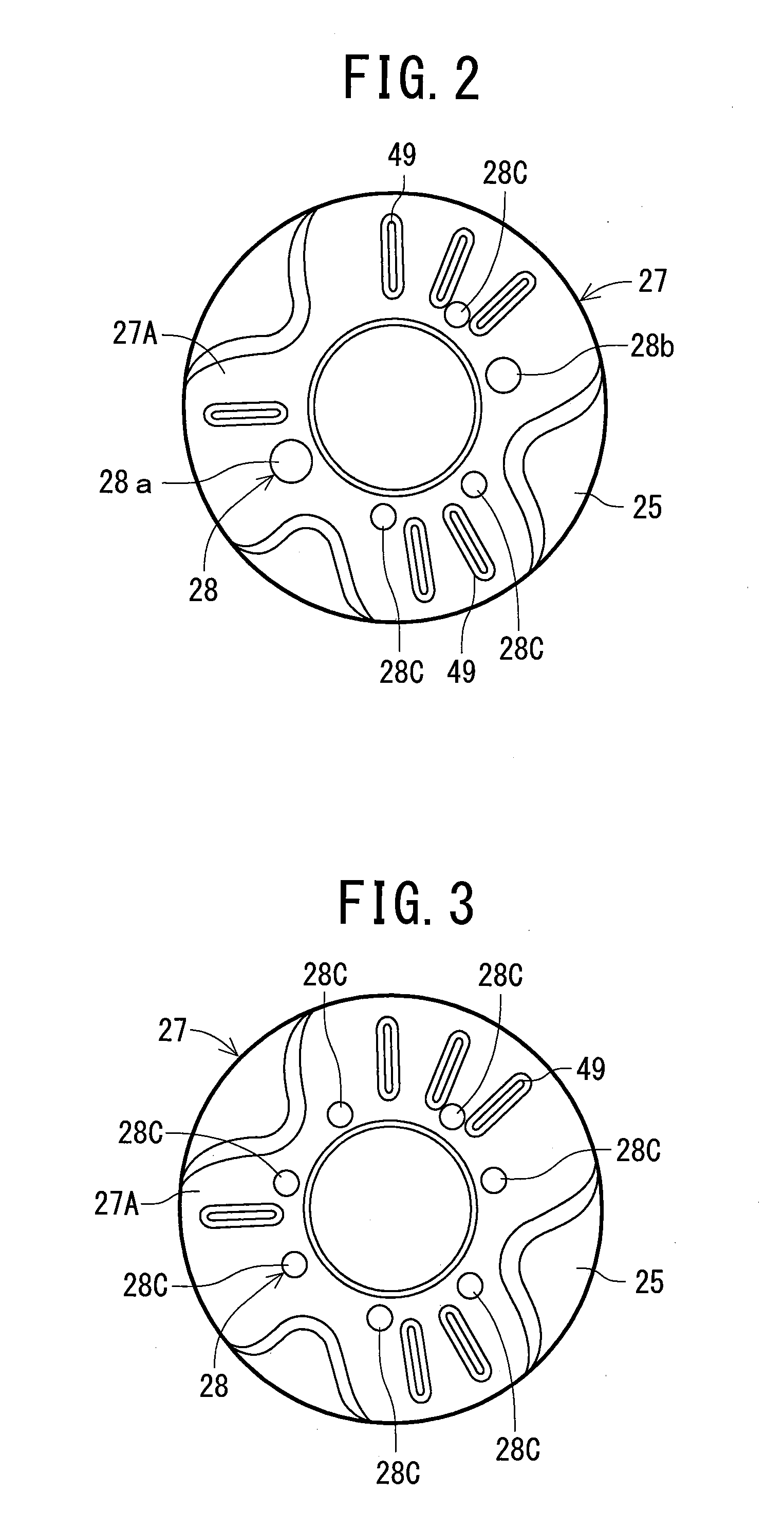

Oil pump rotor

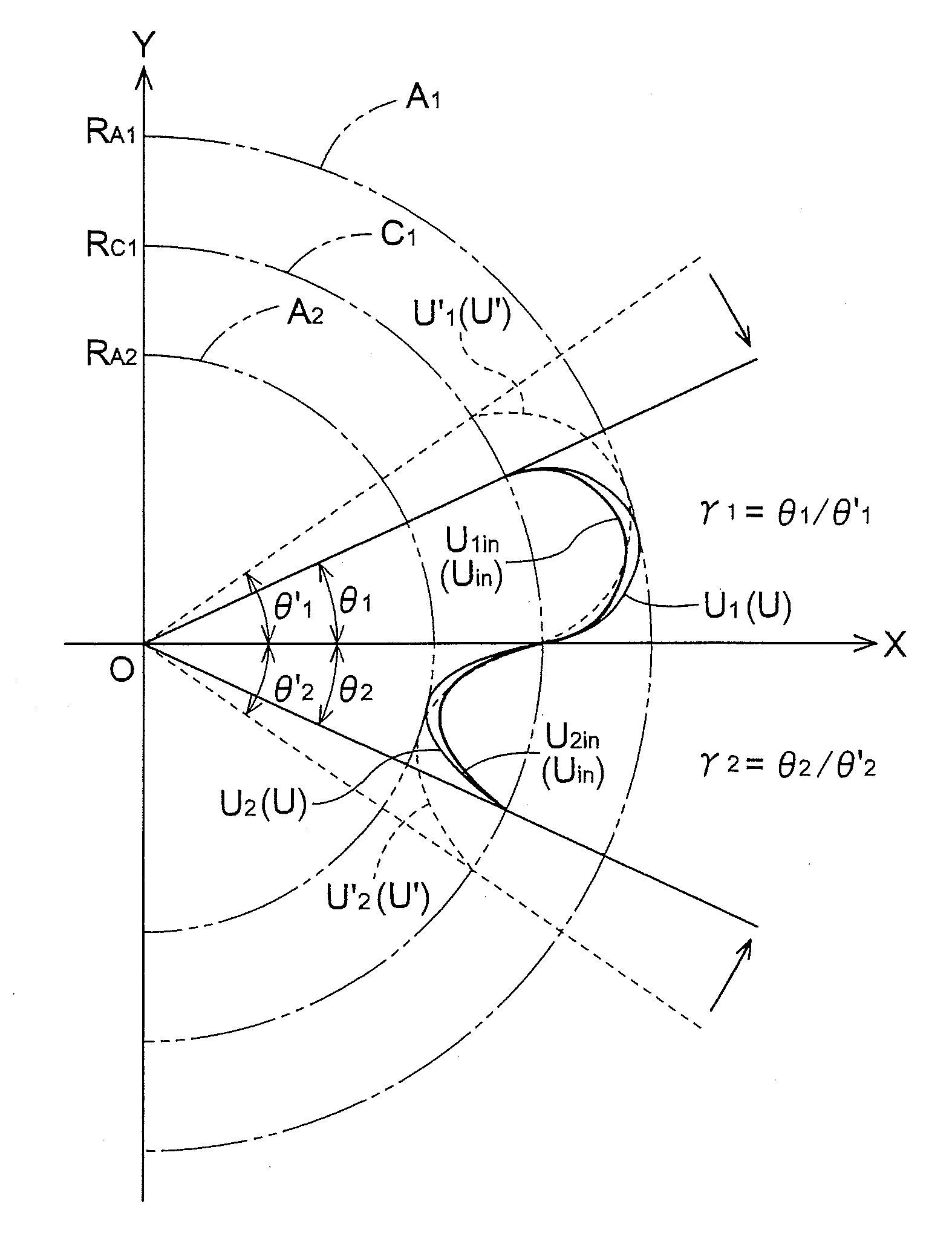

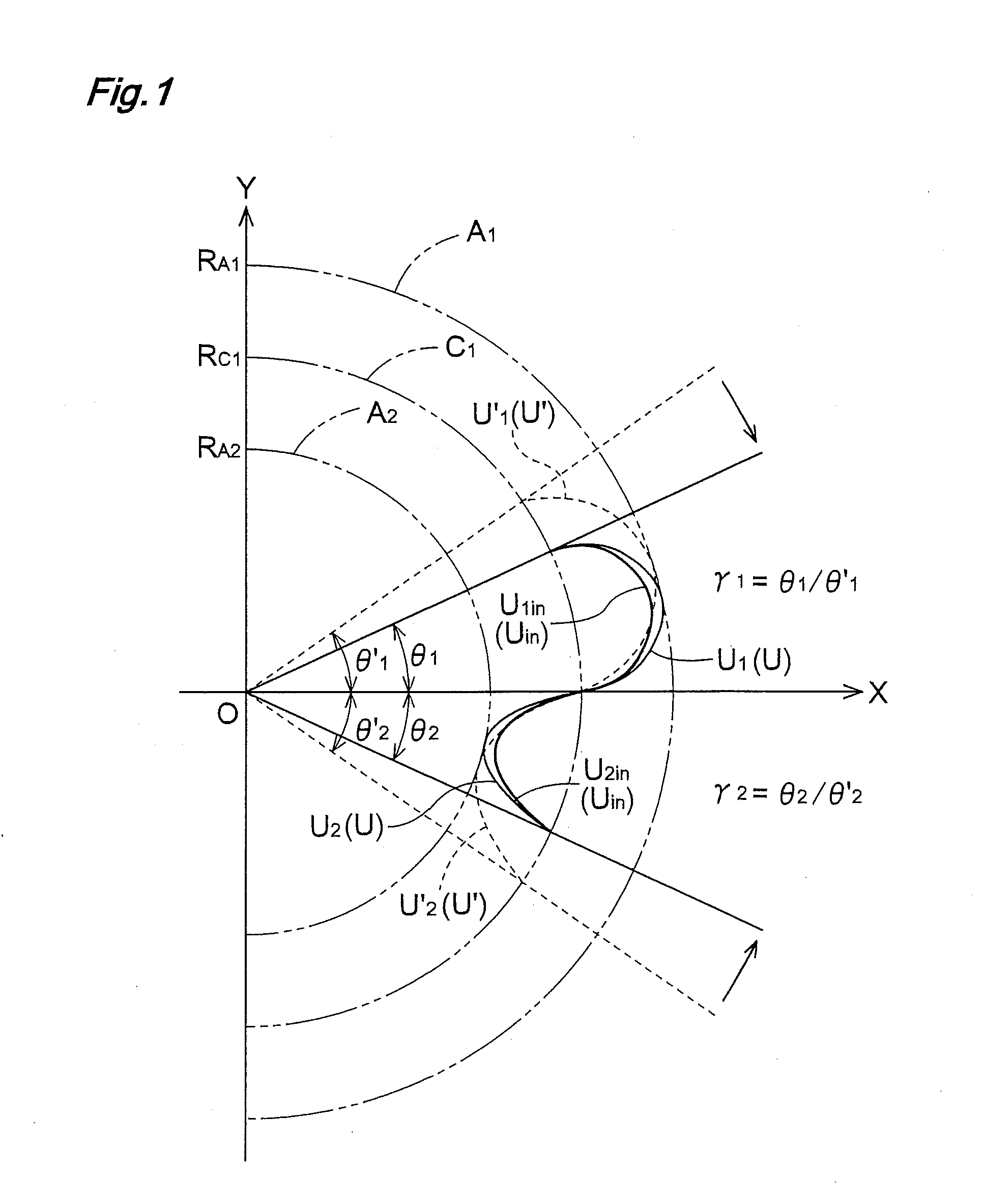

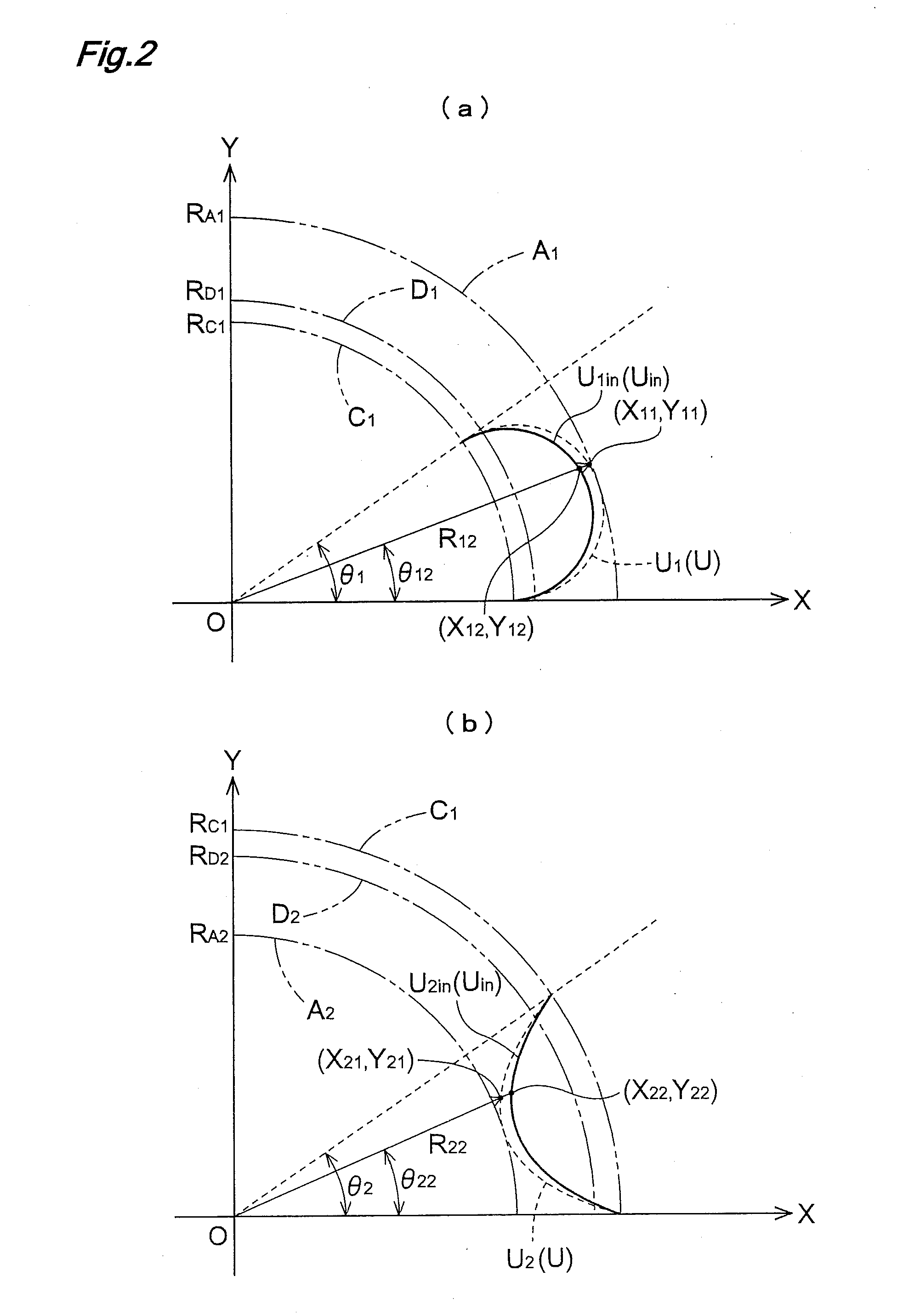

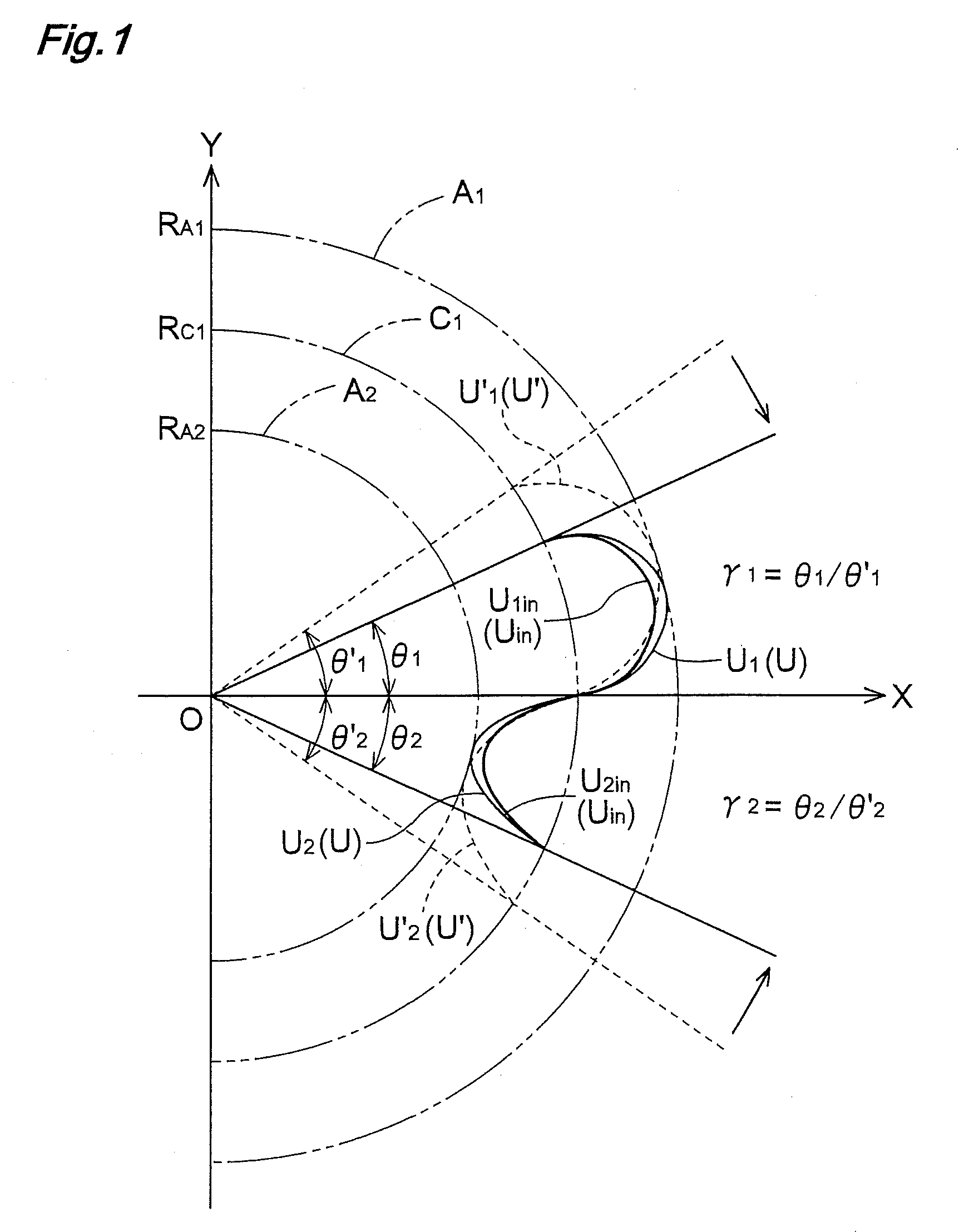

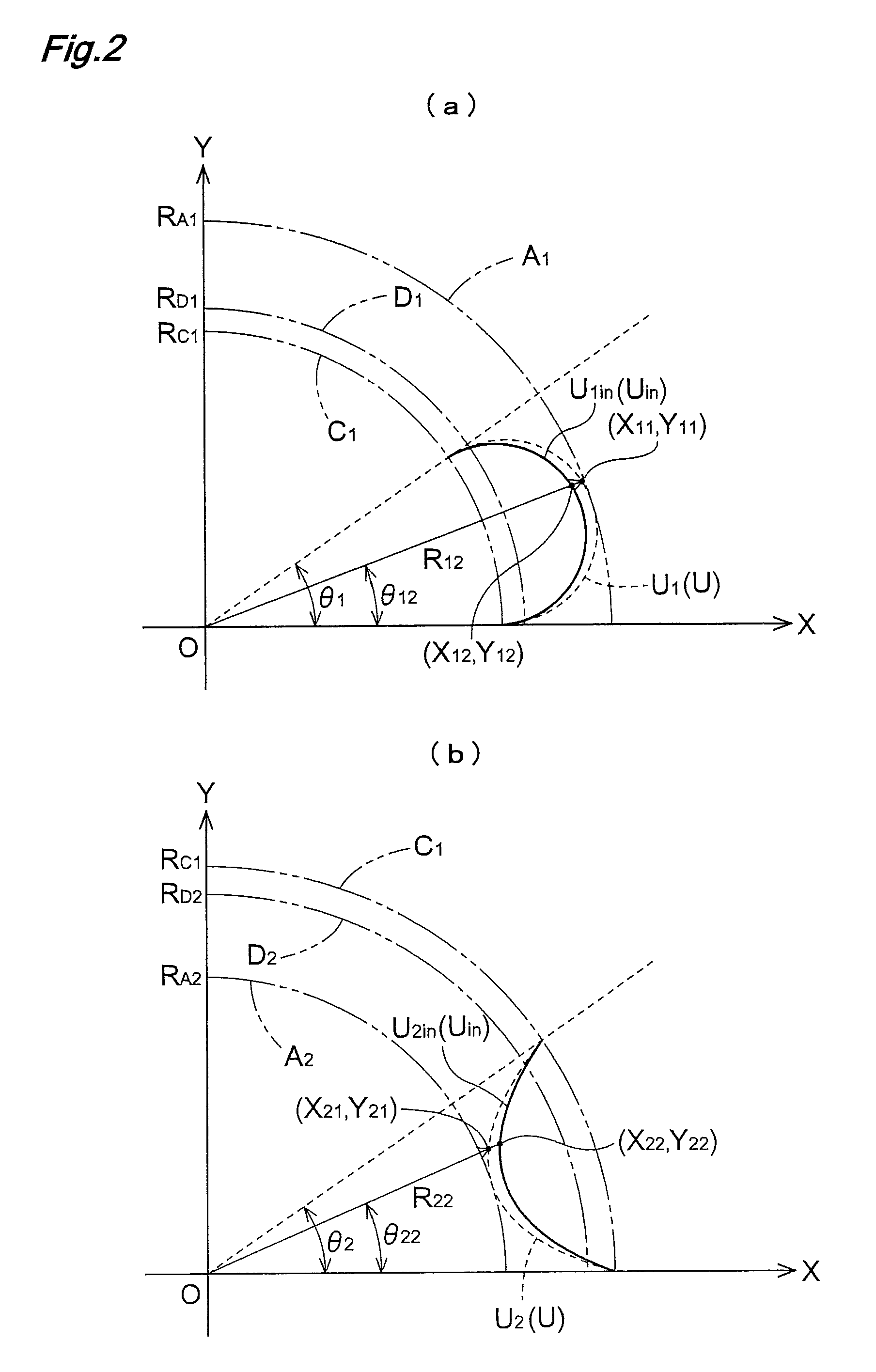

ActiveUS20100129253A1Easy to shapeIncreasing rotor sizeEngine of arcuate-engagement typeOscillating piston enginesMechanical engineering

An oil pump rotor includes an inner rotor formed with n (n: a natural number) external teeth, and an outer rotor formed with n+1 internal teeth which are in meshing engagement with each of the external teeth. And the oil pump rotor is used in an oil pump that includes a casing having a suction port for drawing in fluid and a discharge port for discharging fluid and conveys the fluid by drawing in and discharging the fluid due to changes in volumes of cells formed between surfaces of the internal teeth and surfaces of the external teeth during rotations of the rotors under meshing engagement therebetween. And the tooth profile of the external teeth of the inner rotor is formed by a deformation in the circumferential direction and a deformation in the radial direction applied to a profile defined by a mathematical curve with the deformation in the circumferential direction is applied while maintaining the distance between the radius (RA1) of an addendum circle (A1) and the radius (RA2) of the tooth groove circle (A2).

Owner:AISIN SEIKI KK

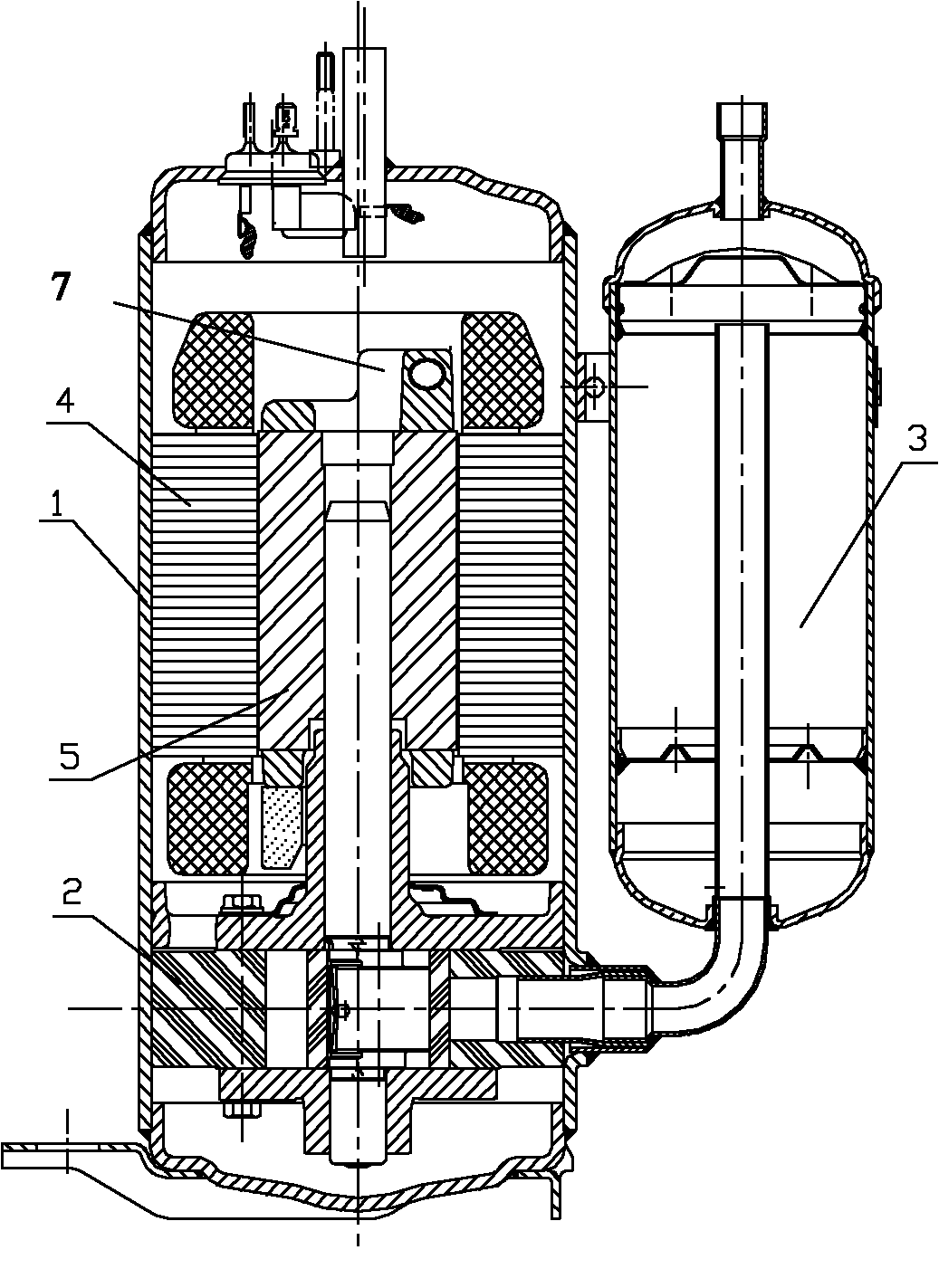

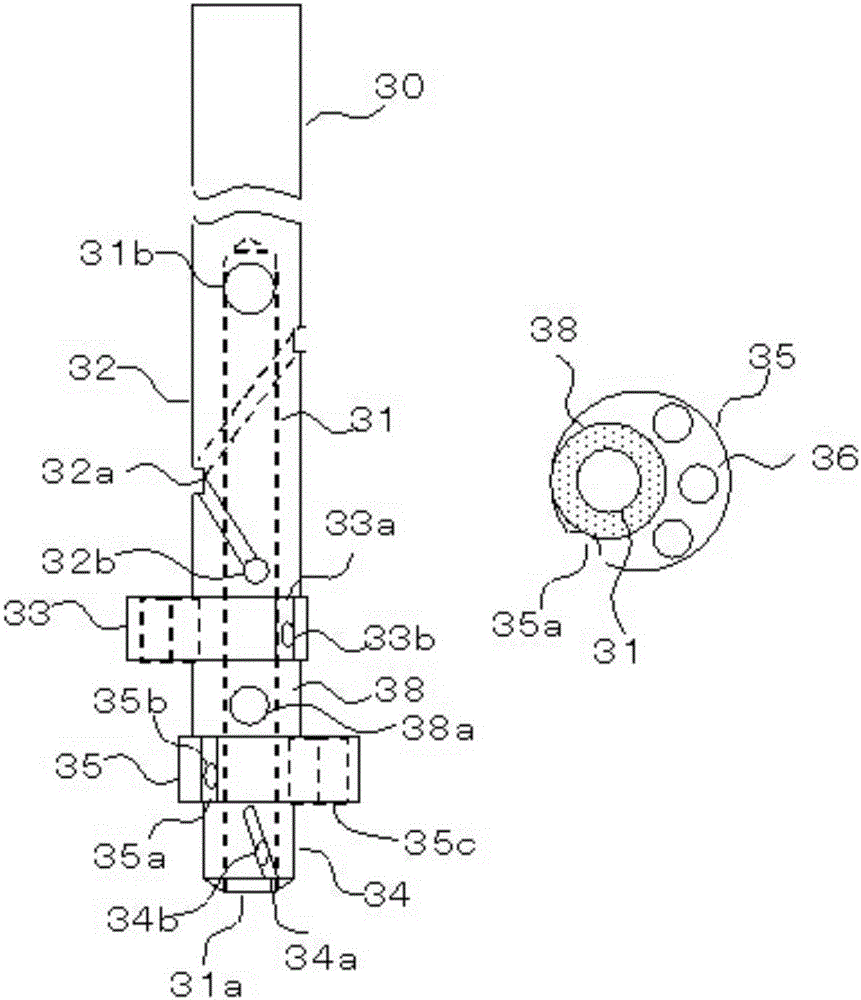

Rotation compressor and refrigerating cycle device with same

ActiveCN106089710AReduce oil dischargeNo need to increase oil seal volumeCompressorCompression machines with non-reversible cycleCrankshaftPiston

The invention discloses a rotation compressor and a refrigerating cycle device with the rotation compressor. An electric motor and a compression mechanism portion are contained in a sealed shell of the rotation compressor. A suction pipe is arranged on the shell. An oil storage tank storing lubricating oil is arranged at the bottom of the shell. The compression mechanism portion comprises an air cylinder, a piston, a slide sheet, a crankshaft and bearings. The air cylinder is provided with a compression cavity. Refrigerant gas, containing oil, discharged from the compression cavity at least flows through a gas passageway arranged between the crankshaft and the bearings to be discharged into the shell. According to the rotation compressor, the oil discharge amount of the compressor is lowered, and on the basis that oil supply to the compression mechanism portion is sufficient, the seal oil amount of the compressor does not need to be increased.

Owner:GUANGDONG MEIZHI COMPRESSOR +1

Oil pump rotor

ActiveUS8360762B2Increasing rotor sizeReduce noiseEngine of arcuate-engagement typeOscillating piston enginesEngineeringMechanical engineering

An oil pump rotor includes an inner rotor formed with n (n: a natural number) external teeth, and an outer rotor formed with n+1 internal teeth which are in meshing engagement with each of the external teeth. And the oil pump rotor is used in an oil pump that includes a casing having a suction port for drawing in fluid and a discharge port for discharging fluid and conveys the fluid by drawing in and discharging the fluid due to changes in volumes of cells formed between surfaces of the internal teeth and surfaces of the external teeth during rotations of the rotors under meshing engagement therebetween. And the tooth profile of the external teeth of the inner rotor is formed by a deformation in the circumferential direction and a deformation in the radial direction applied to a profile defined by a mathematical curve with the deformation in the circumferential direction is applied while maintaining the distance between the radius (RA1) of an addendum circle (A1) and the radius (RA2) of the tooth groove circle (A2).

Owner:AISIN SEIKI KK

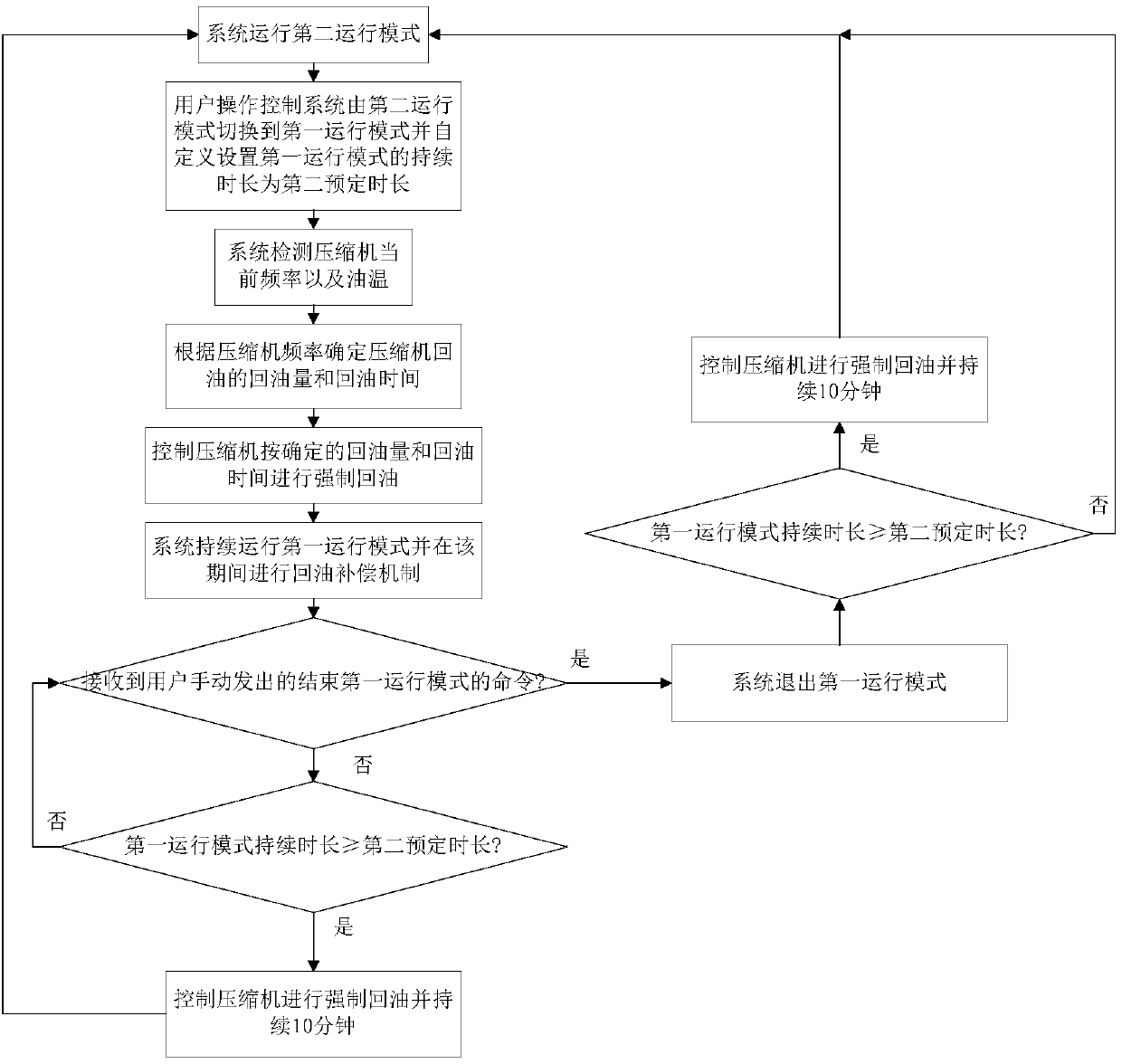

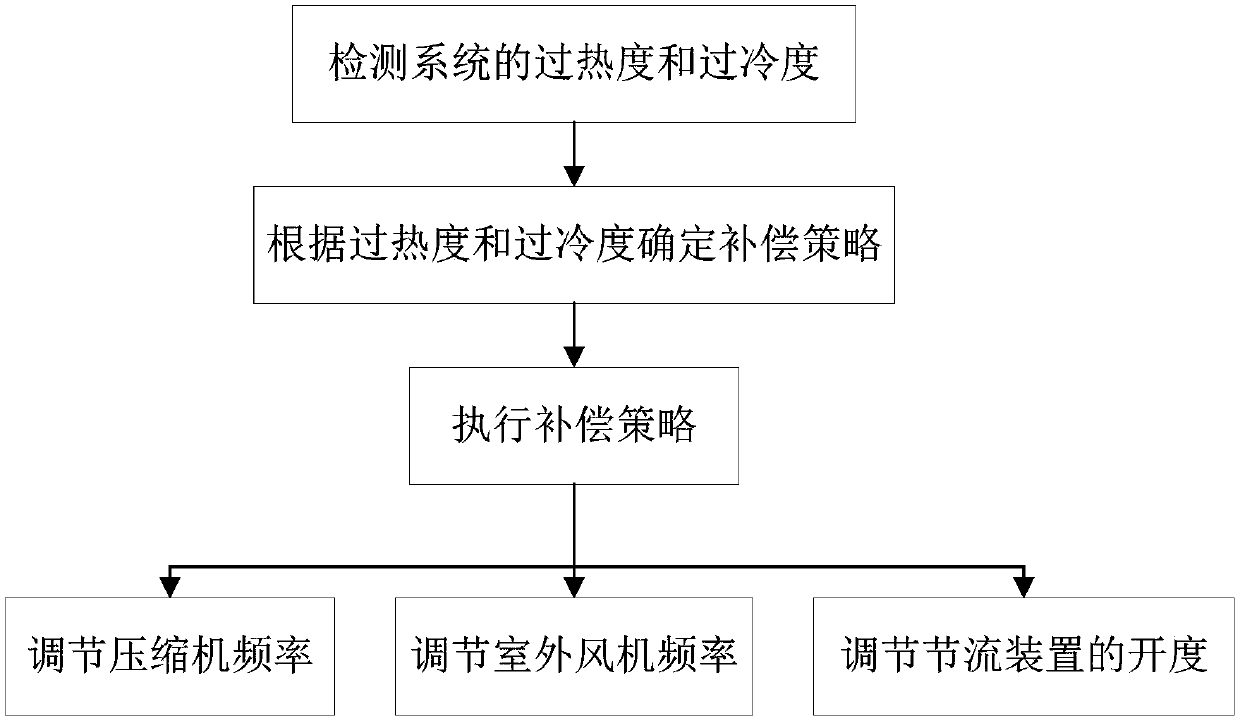

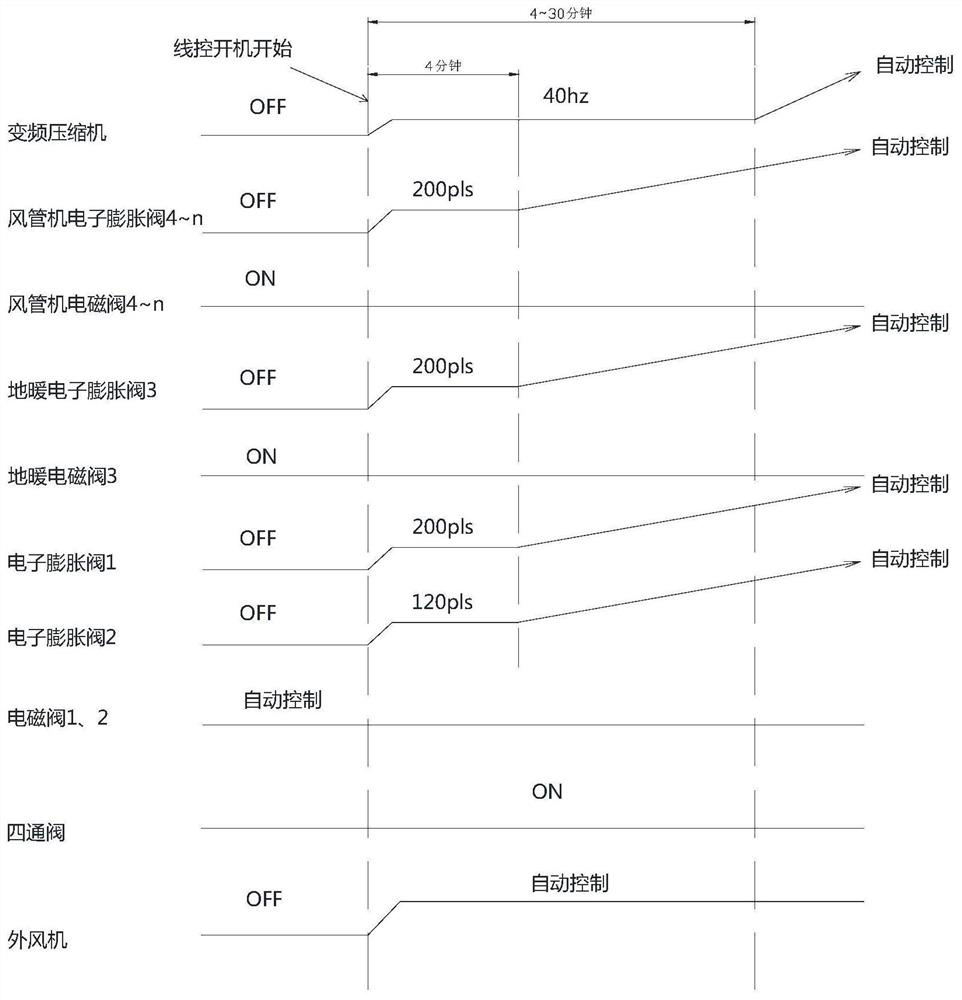

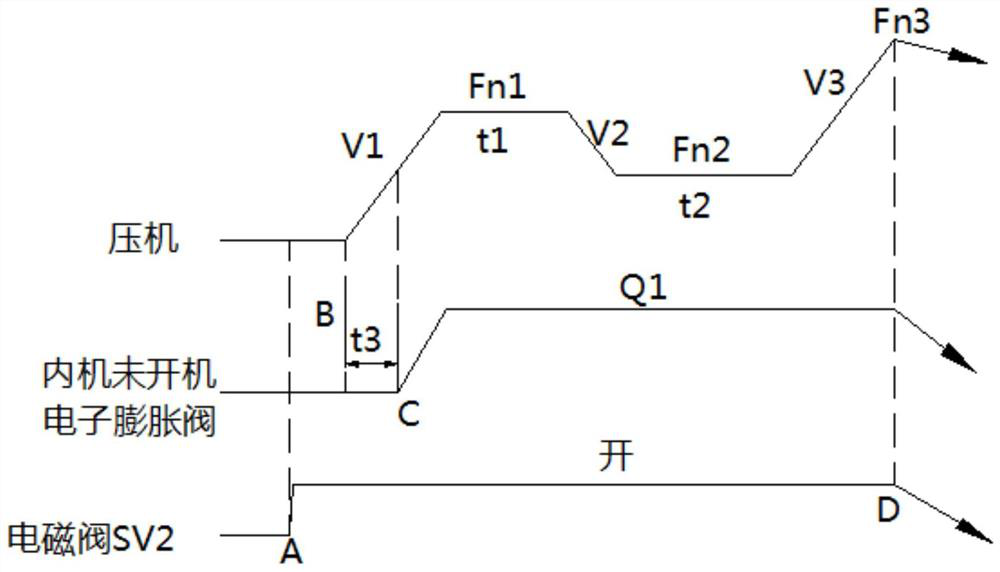

Control method for refrigerant circulation system

ActiveCN110360777AReduce oil dischargeGuaranteed comfortCompressorRefrigeration safety arrangementUser needsEngineering

The invention discloses a control method for a refrigerant circulation system. The control method comprises the following steps of adjusting the running parameters of the refrigerant circulation system according to the superheating degree and / or supercooling degree of the refrigerant circulation system in a first running mode, so that the oil discharge amount of the compressor in the period of thefirst running mode is reduced. In the control method for the refrigerant circulation system, the refrigerant circulation system has the first running mode of not carrying out oil return of the compressor, and in the running mode, the frequency of the compressor, the frequency of an outdoor fan, the opening degree of a throttle device, and other running parameters can be adjusted according to thesuperheating degree and / or supercooling degree of an indoor heat exchanger, so that the oil discharge amount of the compressor is reduced, and then carried oil at an indoor side is increased, and a reliable running oil amount for the compressor in the period of the running mode is ensured; and when a user needs to keep a quiet environment, a running module can be switched over to the first runningmode, so that the use comfort of the user is ensured.

Owner:GREE ELECTRIC APPLIANCES INC

Oil baffle plate, compressor rotor assembly, compressor and air conditioner

InactiveCN106015007AHigh rotational strengthEasy to separateRotary/oscillating piston pump componentsLiquid fuel engine componentsPetroleum engineeringGas separation

An oil baffle disclosed in an embodiment of the present invention includes an oil baffle body, the surface of the oil baffle body facing the rotor is an oil-gas separation surface, and an oil-gas separation surface arranged on the oil baffle body side guide vanes. For the oil baffle provided by the present invention, when the oil baffle rotates together with the rotor, the guide vanes located on the oil-air separation surface of the oil baffle body will rotate together with the oil baffle body, because the turbulence caused by the rotation of the guide vanes The function enhances the rotation strength of the refrigerant flow field and assists the gas circulation, thereby enhancing the separation effect of the oil-gas mixture, reducing the oil discharge of the compressor, and improving the overall performance of the compressor. The invention also discloses a compressor rotor assembly, a compressor and an air conditioner.

Owner:ZHUHAI LANDA COMPRESSOR +1

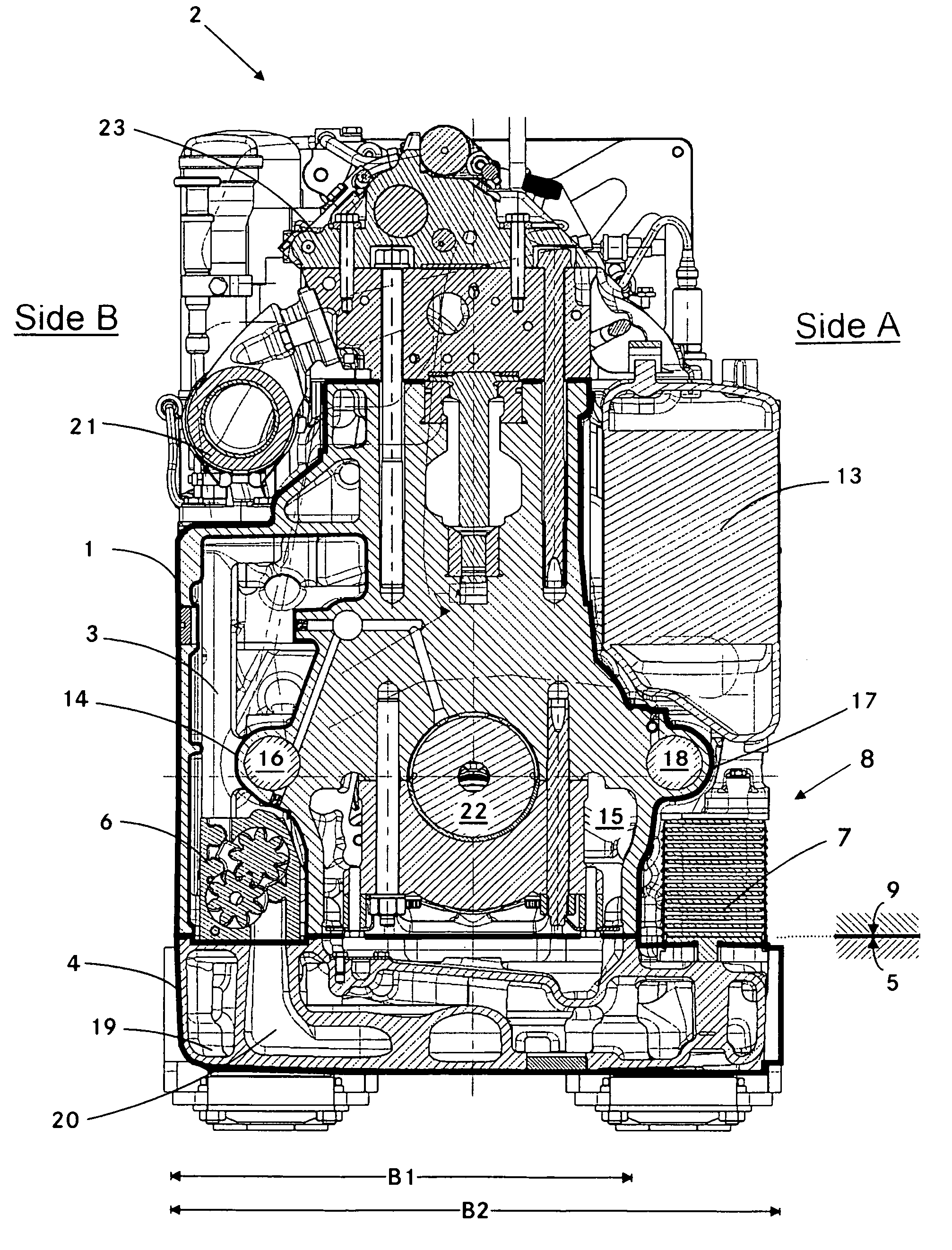

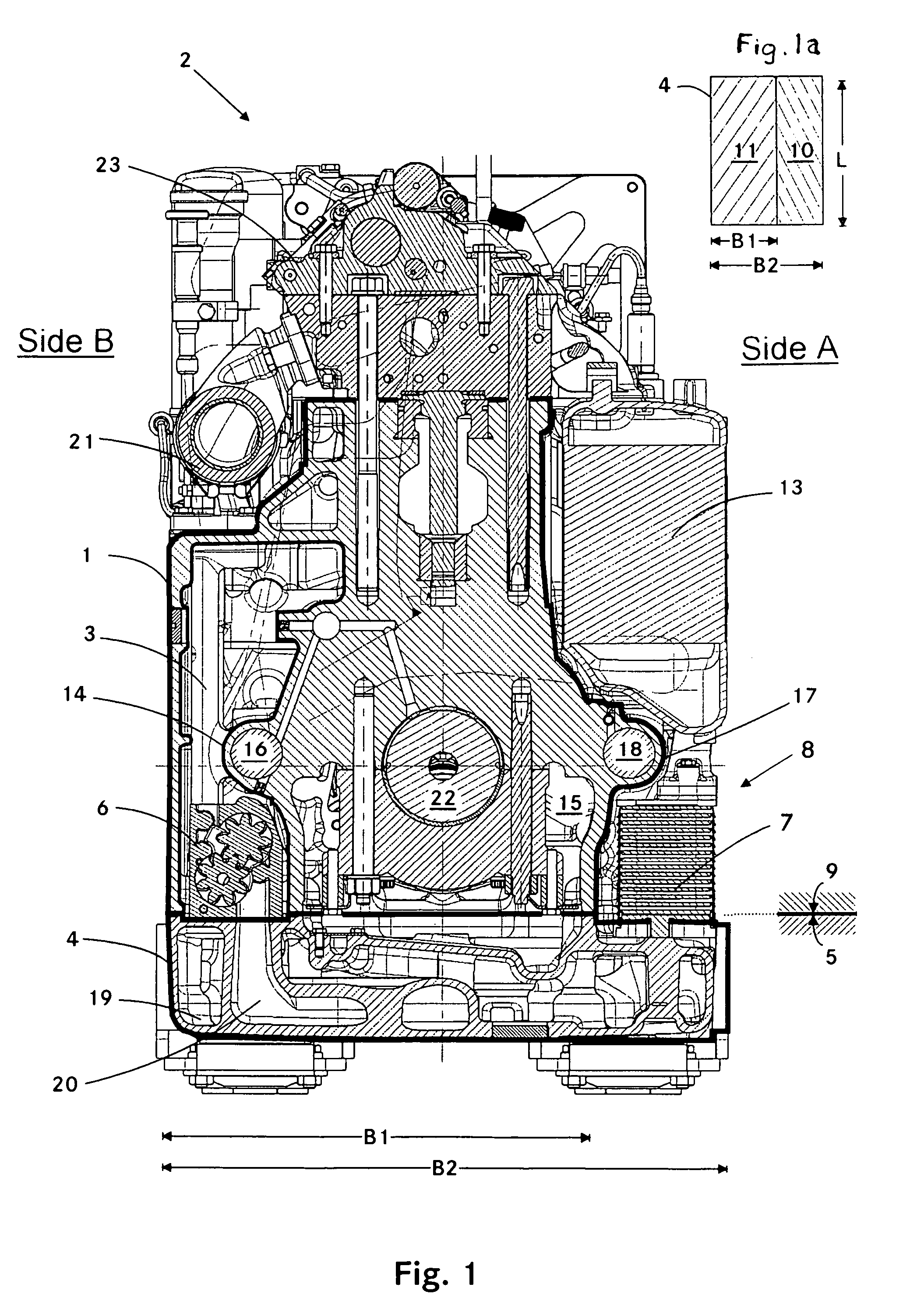

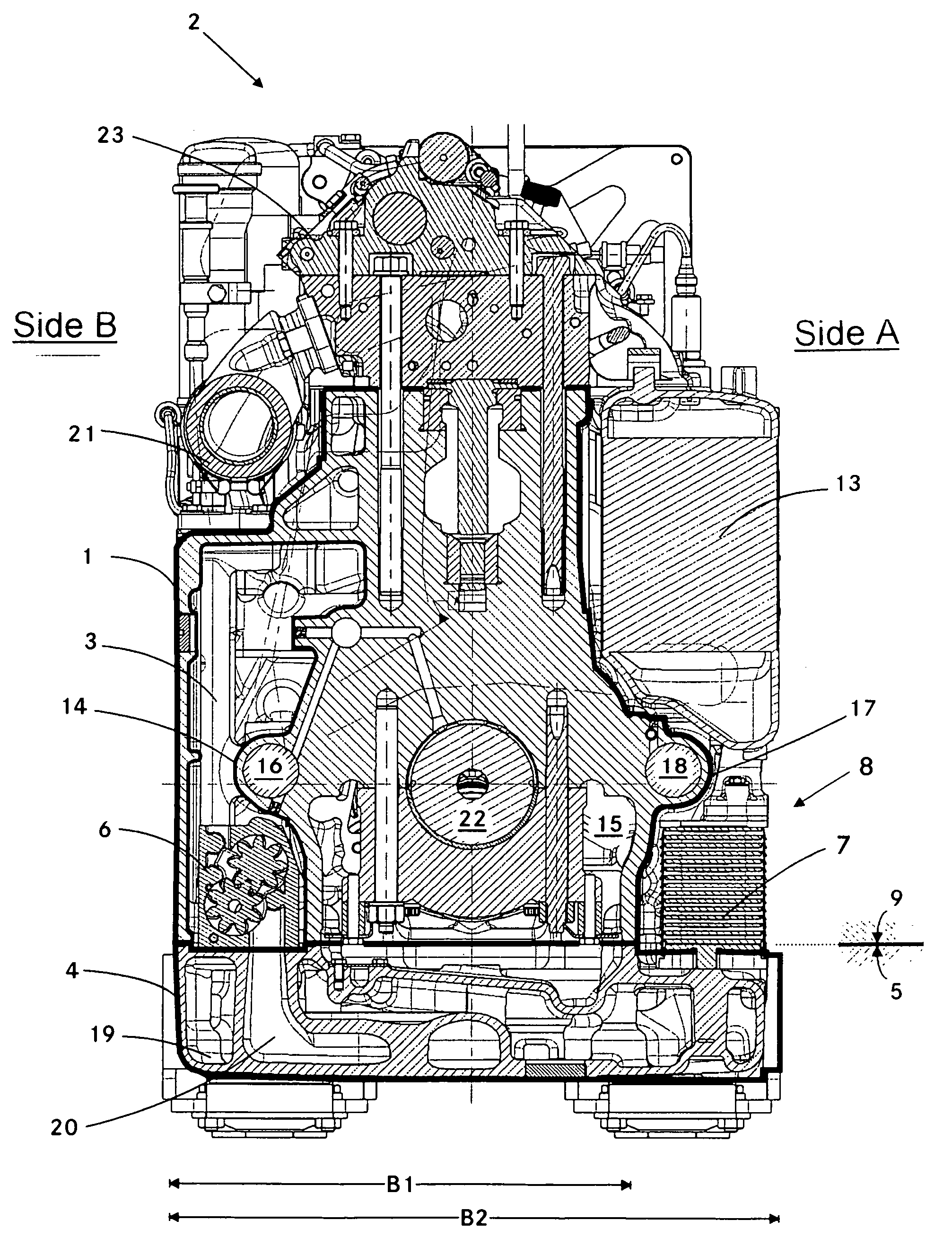

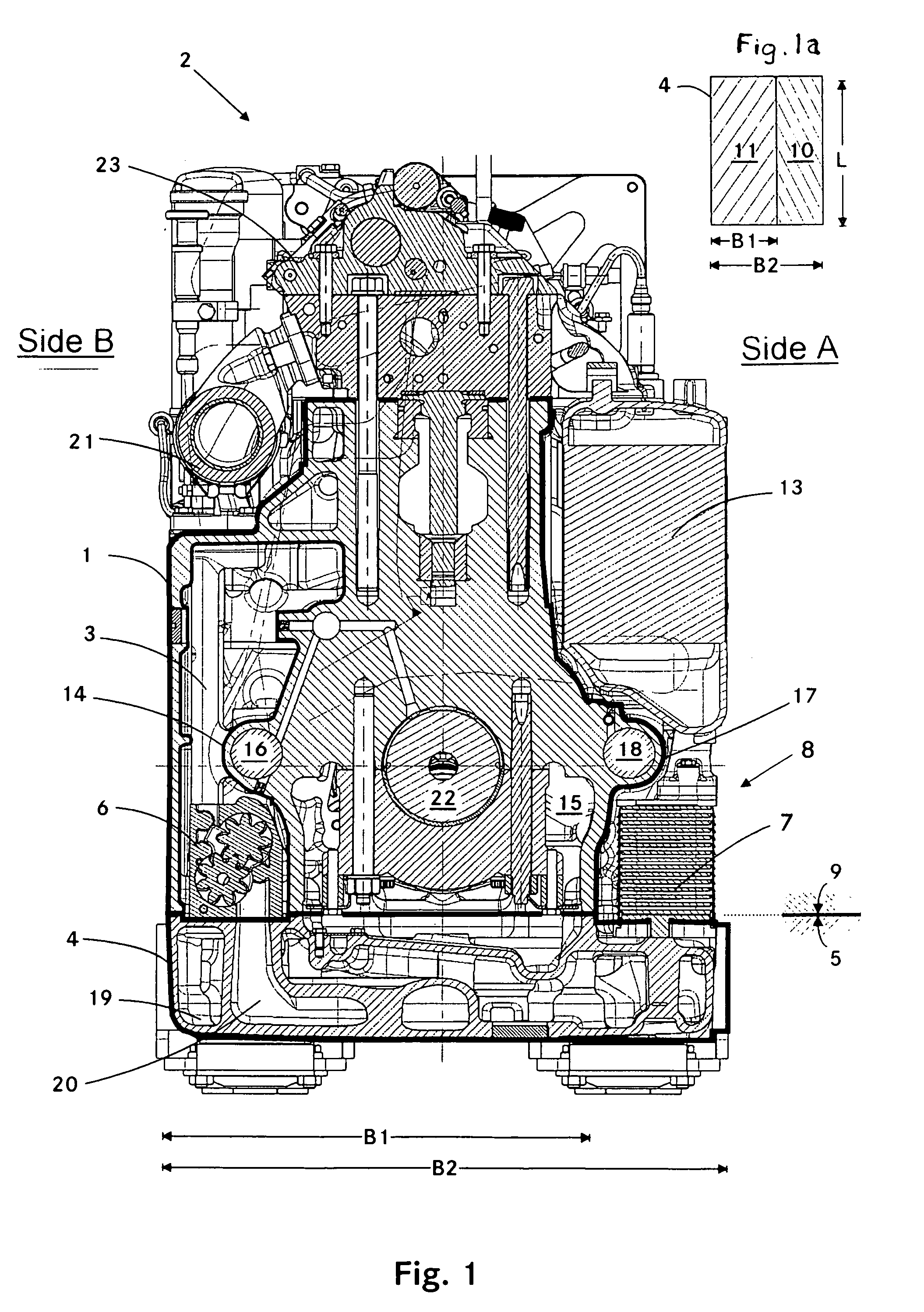

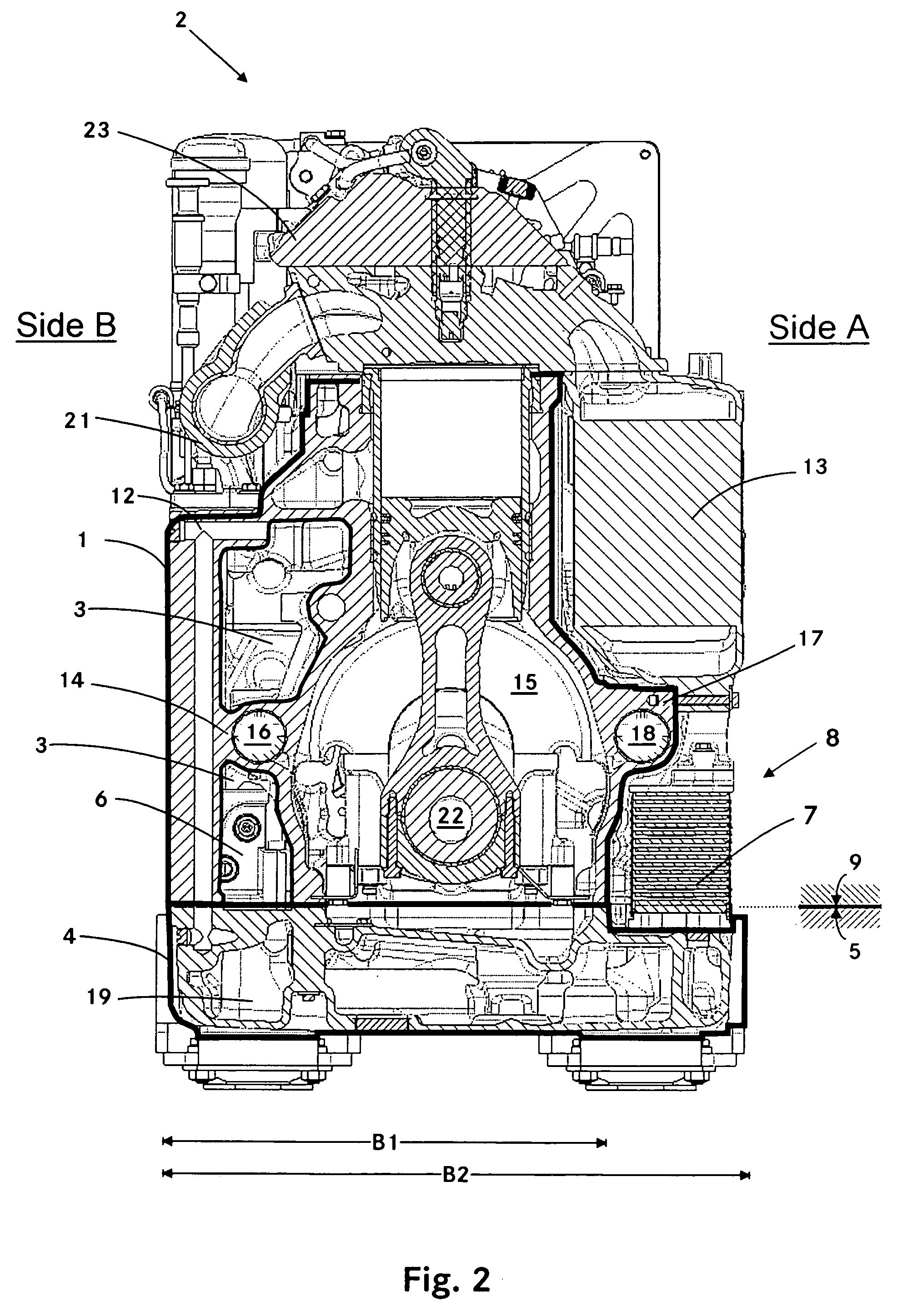

Crankcase with bottom plate

ActiveUS7267093B2Inhibition releaseOperational securityCasingsLubrication of auxillariesEngineeringDry sump

In a crankcase for an internal combustion engine, including a lubricant chamber for the collection of lubricant, and a bottom plate for providing dry sump lubrication closing the crankcase and being sealingly joined to the bottom end of the crankcase, wherein the crankcase includes auxiliary equipment comprising pumps for pumping lubricant into the lubricant chamber and from the lubricant chamber to various lubrication points, the bottom plate has a width exceeding the width of the crankcase so that it forms a section which is disposed outside the crankcase and auxiliary equipment is disposed on this section outside the crankcase.

Owner:ROLLS ROYCE SOLUTIONS GMBH

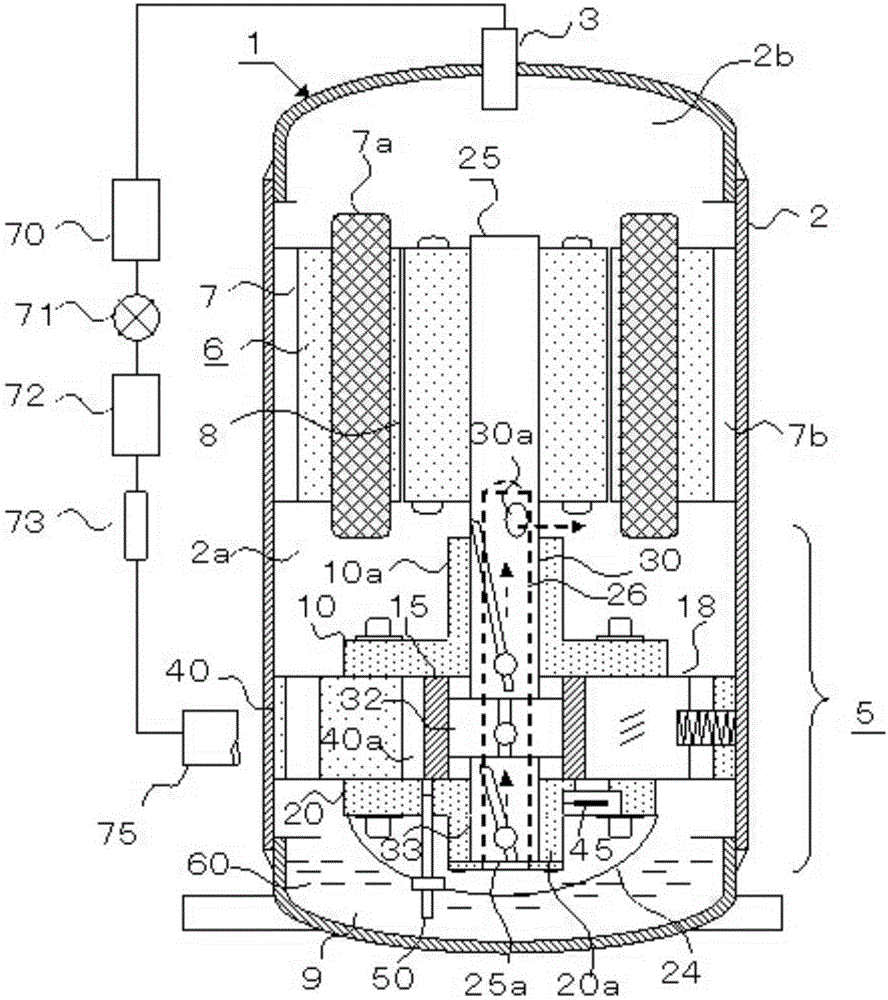

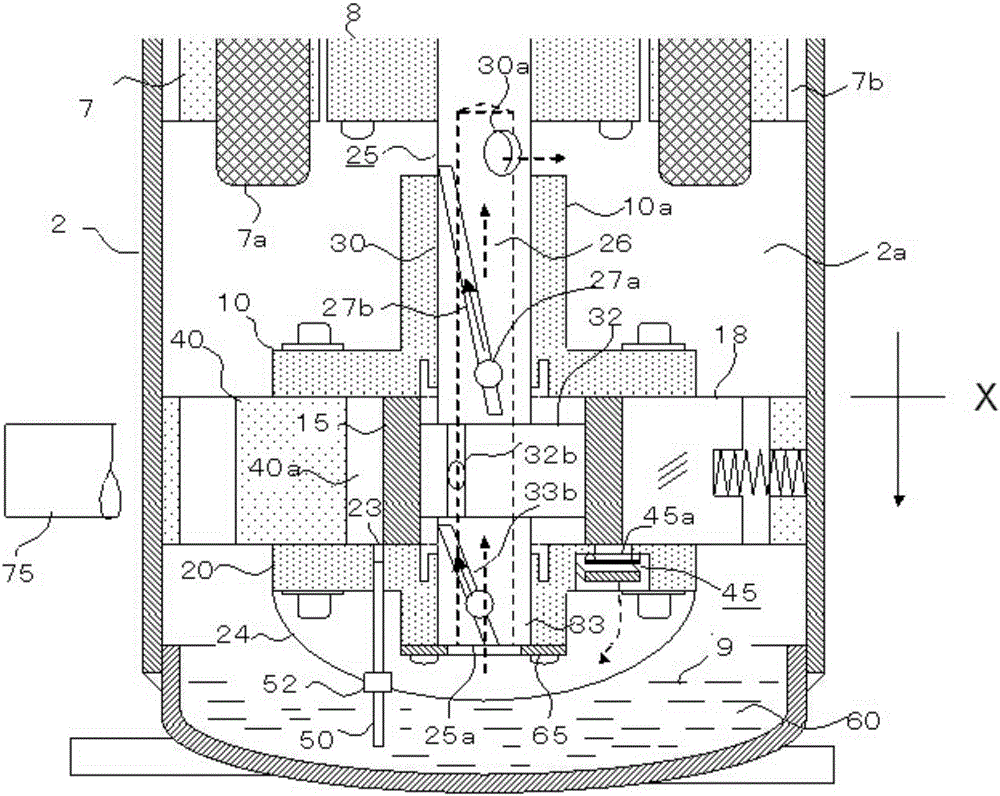

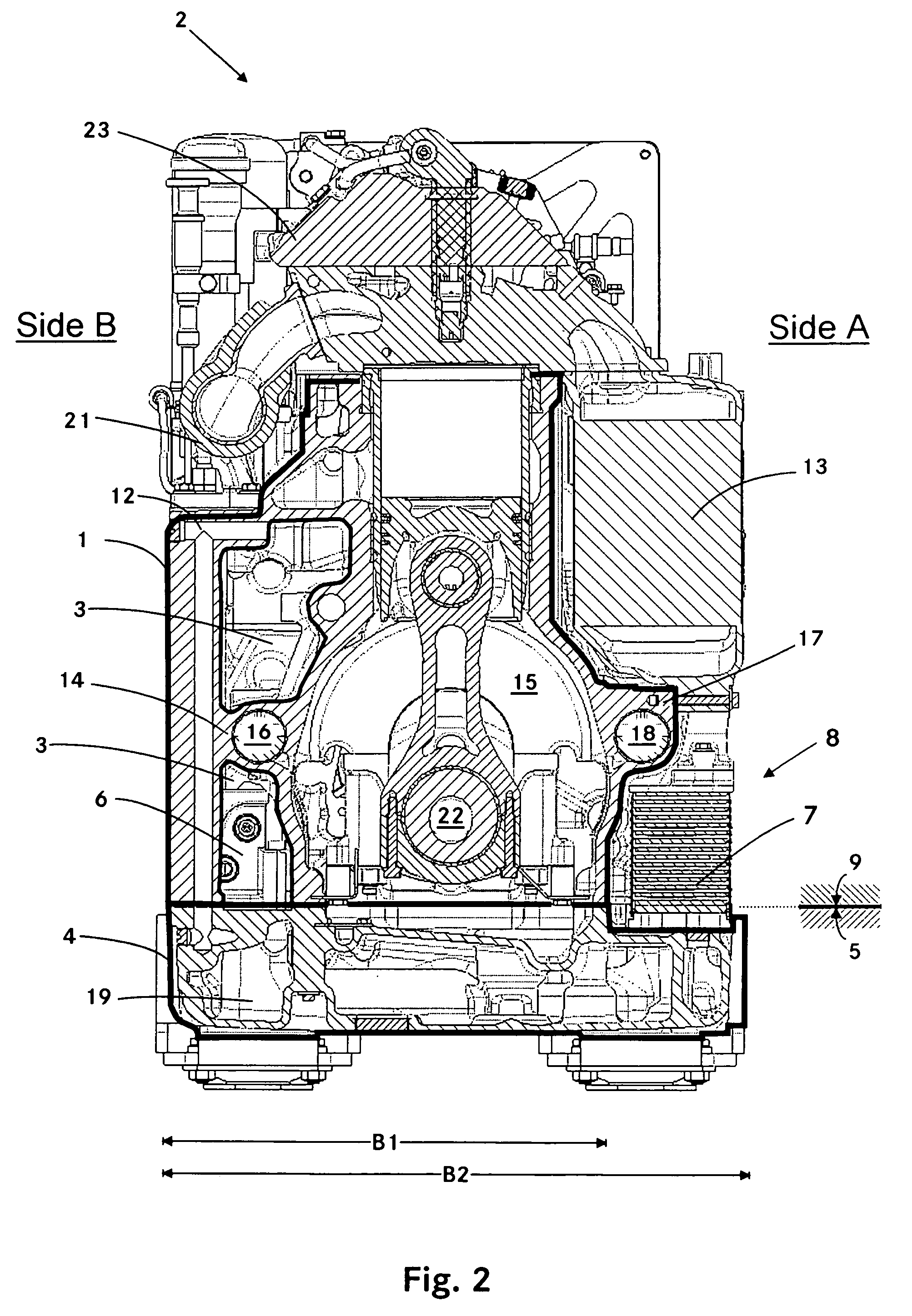

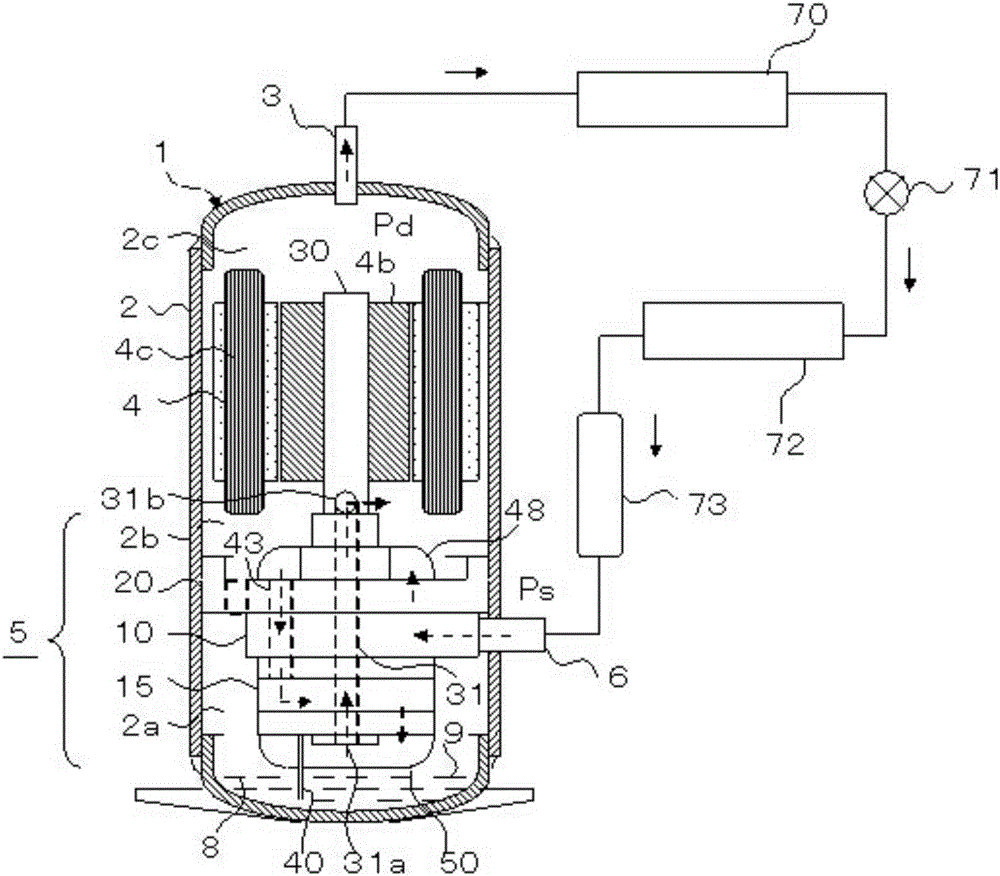

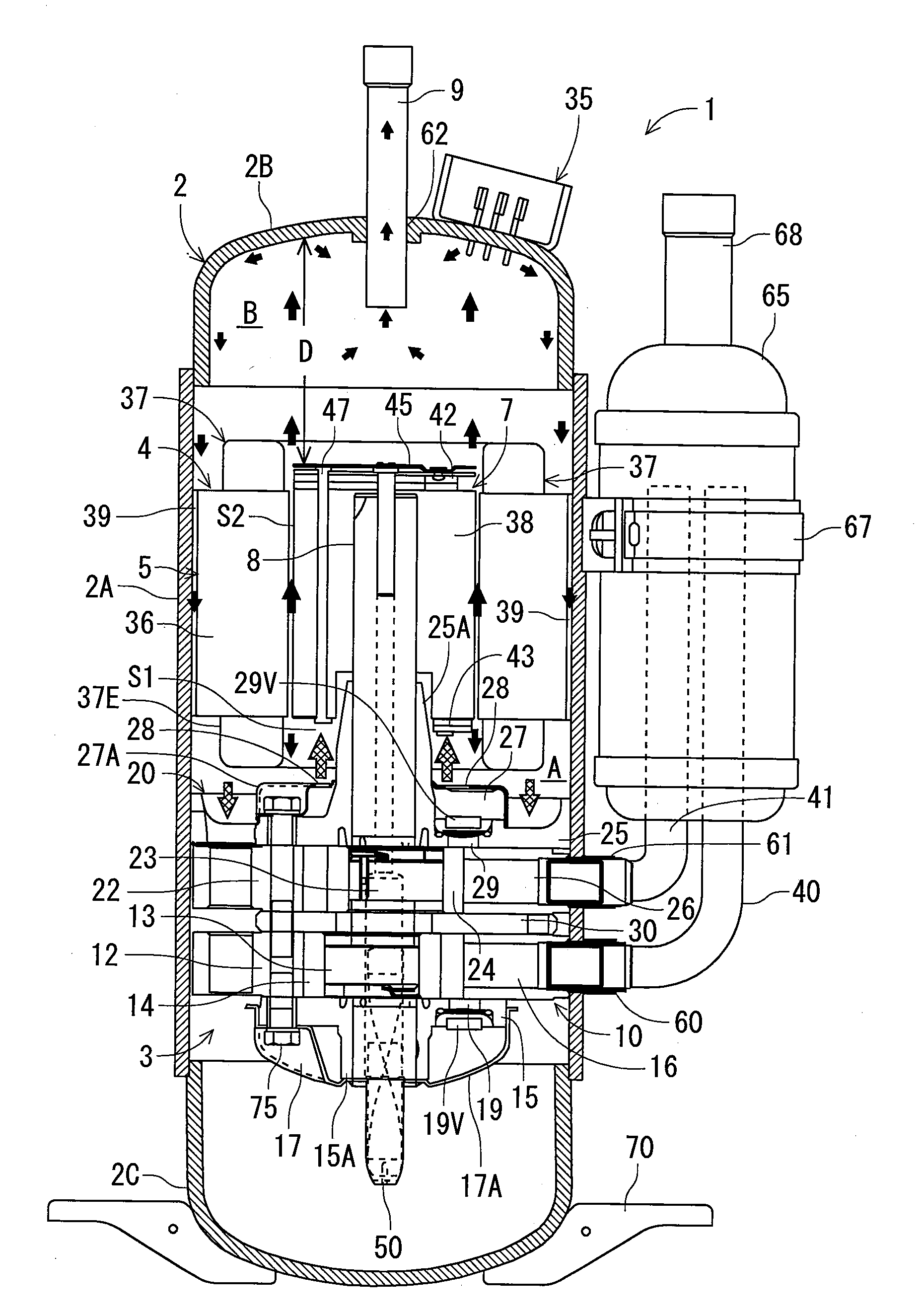

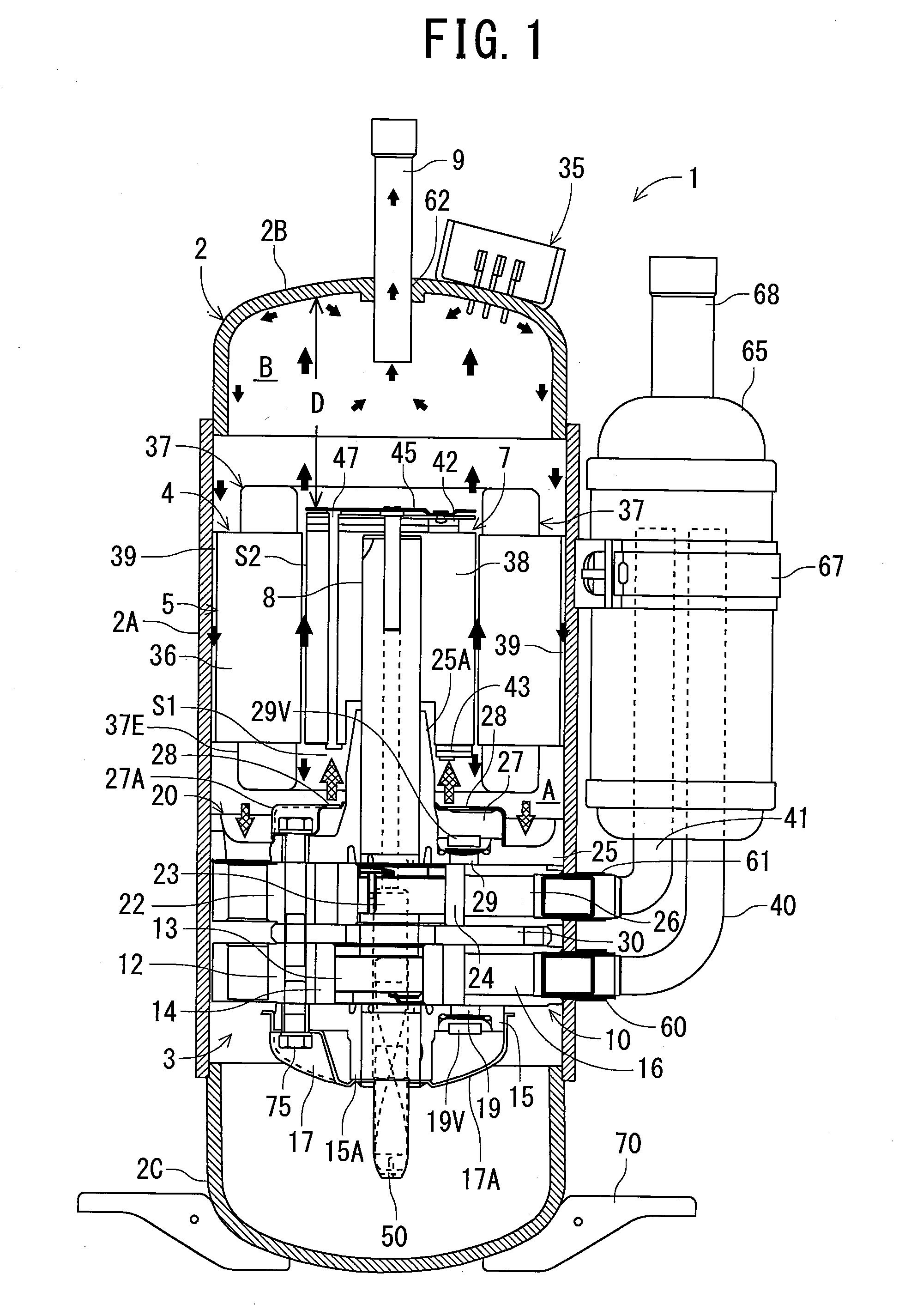

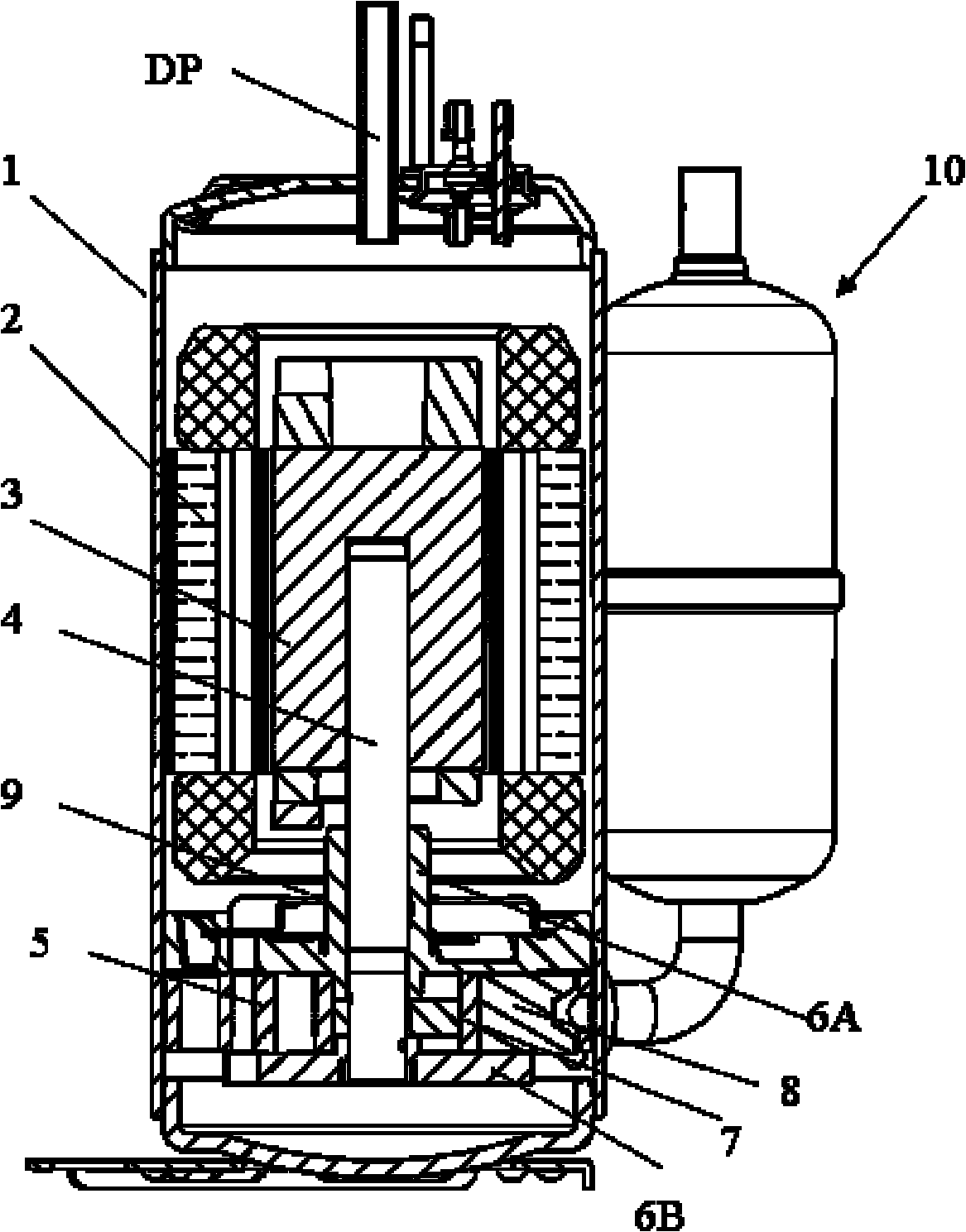

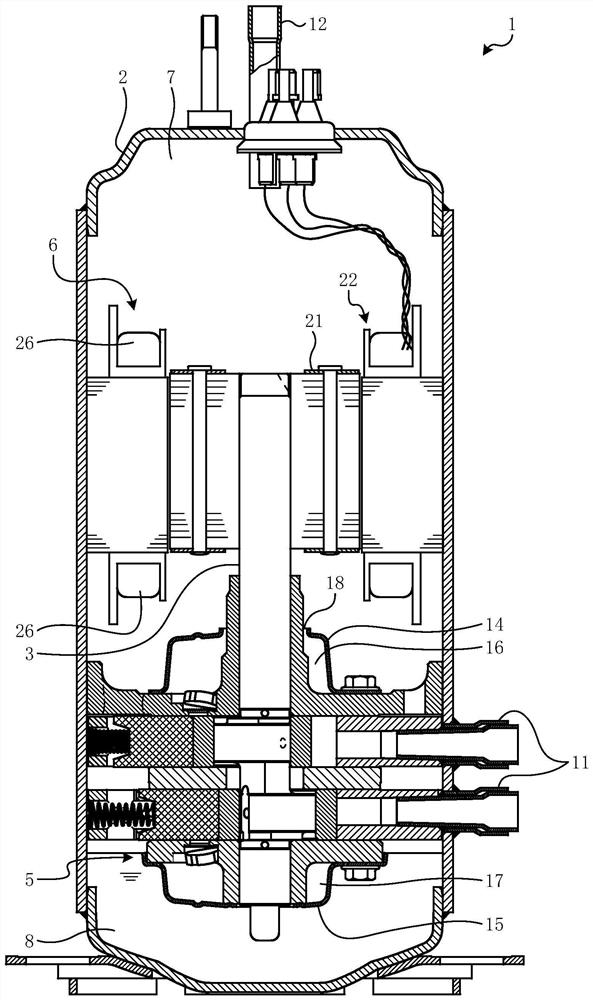

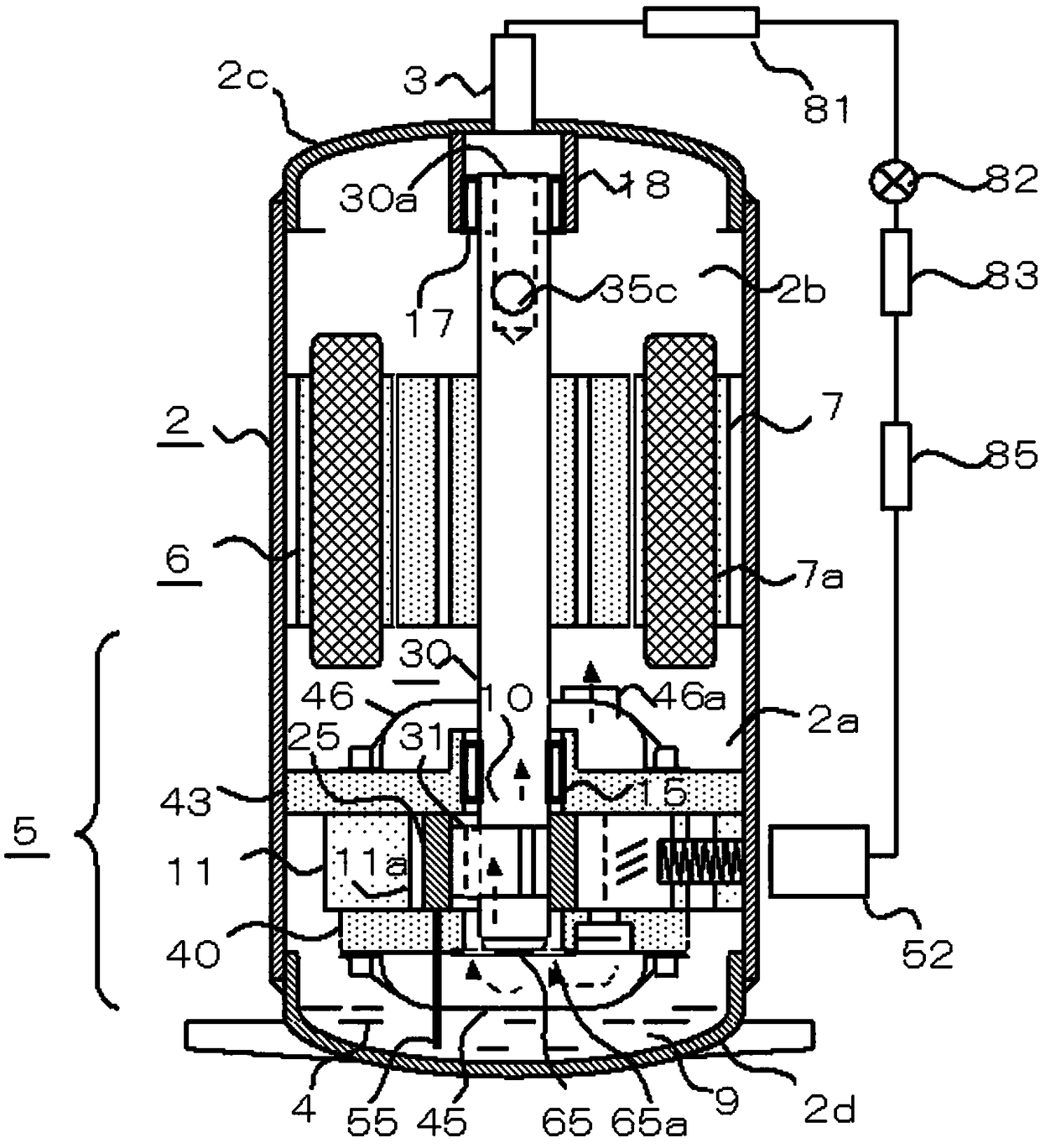

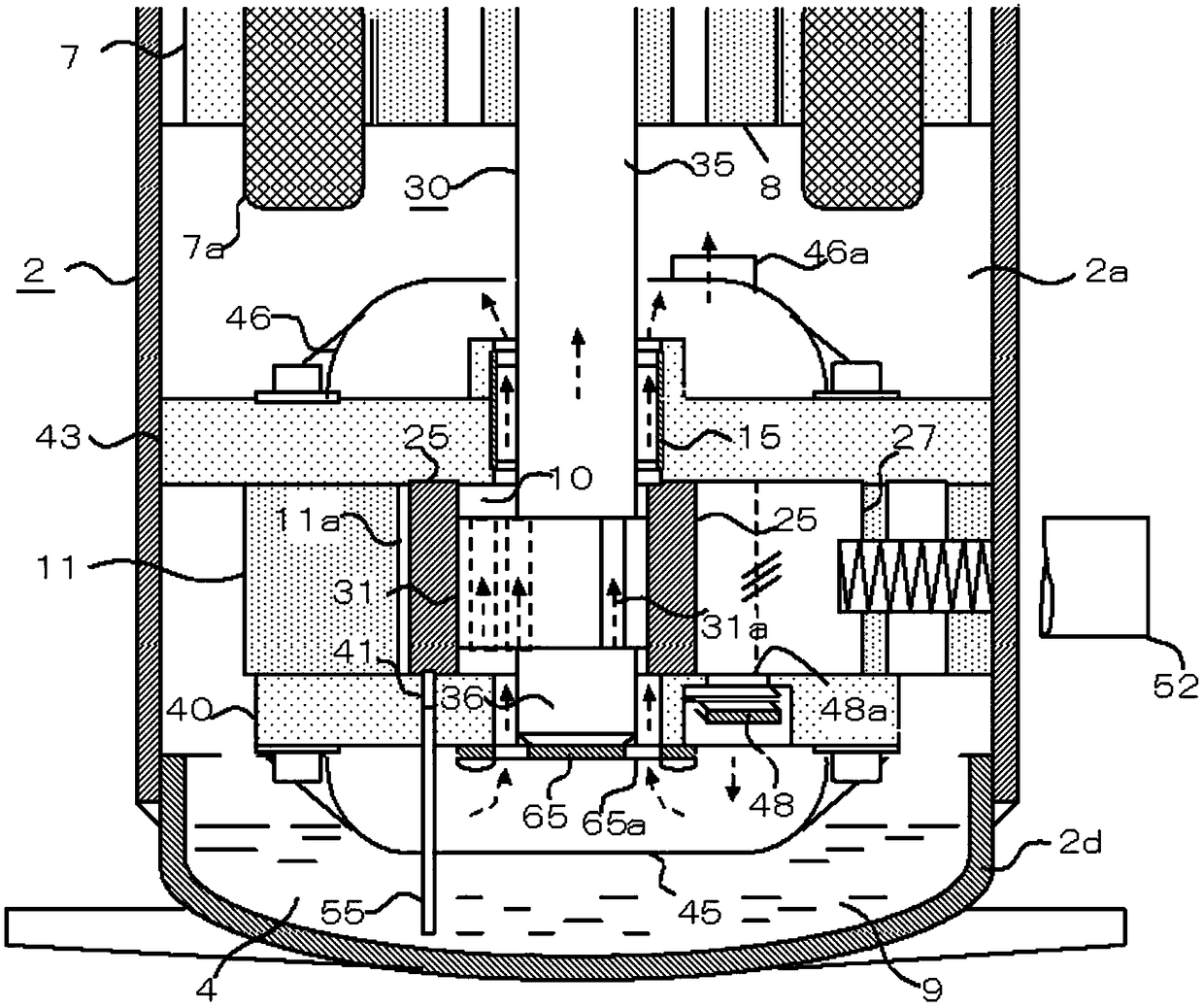

Sealed type rotary compressor

ActiveUS8469679B2Easy to separateEfficient executionRotary/oscillating piston combinations for elastic fluidsPositive displacement pump componentsOil separationRefrigerant

An object of the present invention is to promote oil separation in a sealed container, thereby decreasing the amount of oil discharged to the outside of a compressor. The compressor comprises discharge hole provided at position facing the end surface of a rotor and through which a compressed refrigerant from first and second rotary compression elements is discharged into the sealed container; and a refrigerant flow path which is extended from a space surrounded with a coil end of a stator projecting from the end surface of the rotor to a rotary compression mechanism side to a space of an air gap between the rotor and the stator, to guide the compressed refrigerant discharged through the discharge hole to an electromotive element opposite to the rotary compression mechanism side. The outlet of this refrigerant flow path opposite to the rotary compression mechanism side faces the inner wall surface of the sealed container, and the volume of a space between the inner wall surface of the sealed container and the electromotive element is 1.5 times or more and 15 times or less that of a space between the rotary compression element and the electromotive element.

Owner:SANYO ELECTRIC CO LTD

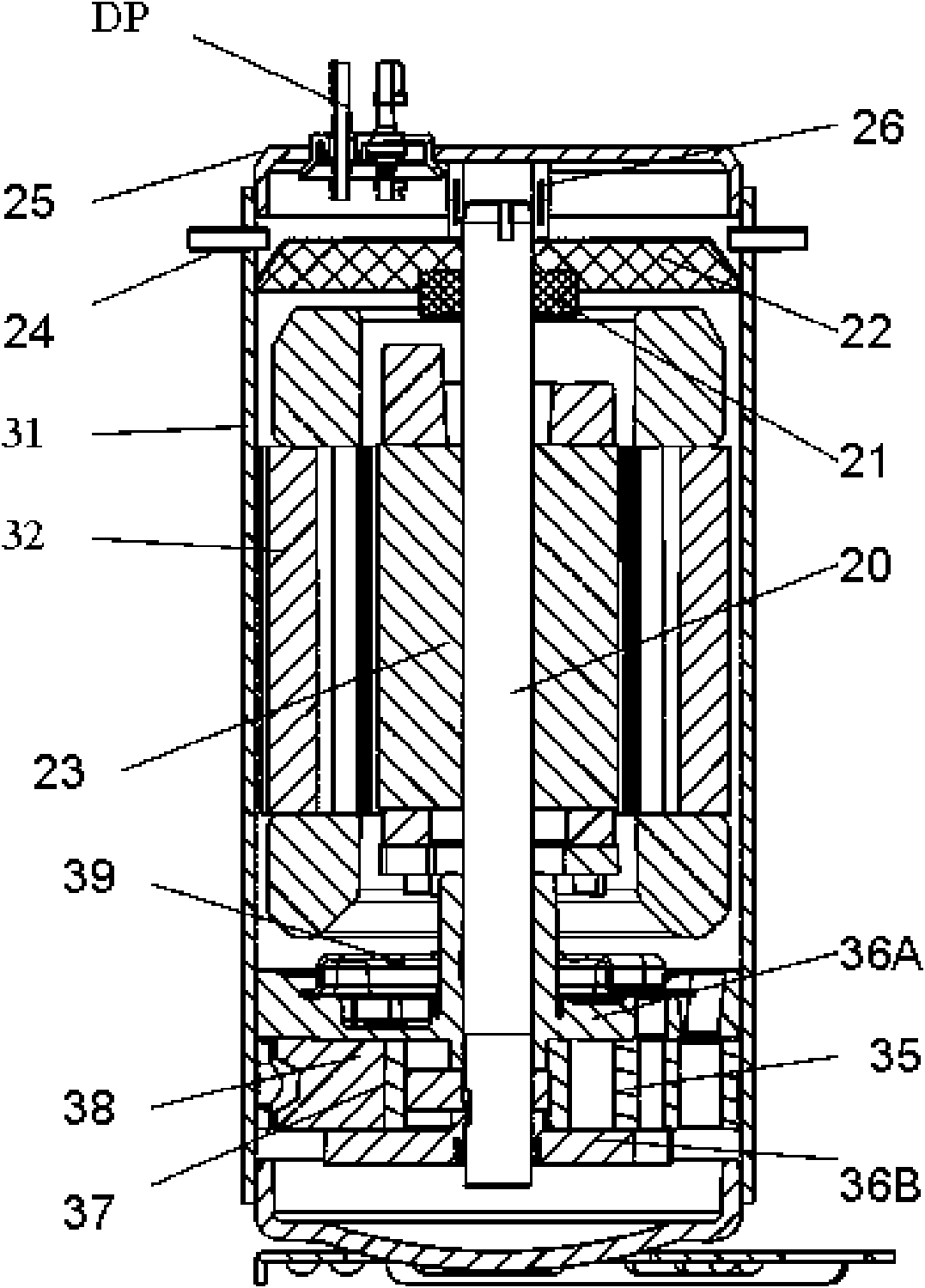

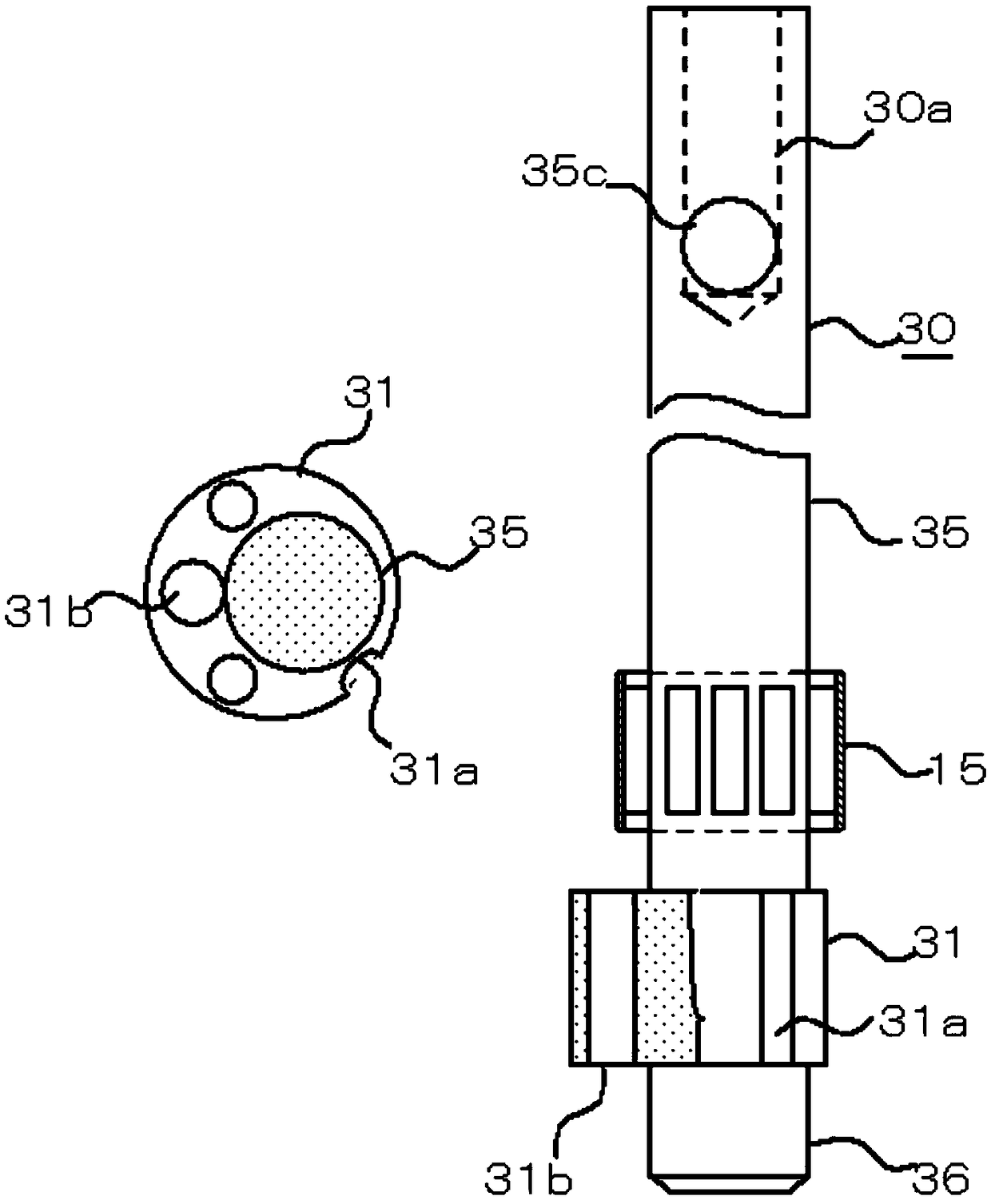

Multi-stage compression type rotary compressor and refrigerating circulating device provided with same

InactiveCN106382227AReduce oil dischargeGuaranteed oil seal volumeRotary/oscillating piston combinations for elastic fluidsCompression machines with non-reversible cycleEngineeringCrankshaft

The invention discloses a multi-stage compression type rotary compressor and a refrigerating circulating device provided with the same. An electric motor and a multi-stage compression type compression mechanism part are accommodated in a sealed housing of the multi-stage compression type rotary compressor; the compression mechanism part comprises at least two air cylinders, a crankshaft, a bearing and a lubricating path; each air cylinder is equipped with a compression cavity; an eccentric revolving piston is arranged in each compression cavity; the crankshaft is used for driving all the pistons to rotate; the bearing is in sliding fit with the crankshaft; and oil-containing refrigerant gas discharged from one compression cavity passes through the lubricating path which is arranged along the revolving axis of the crankshaft to at least lubricate a sliding fit gap part between the crankshaft and the bearing. According to the embodiment of the invention, the multi-stage compression type rotary compressor can effectively lubricate the crankshaft to reduce oil discharge amount of the compressor, so that liquid level of the lubricating oil in an oil storage slot is not greatly reduced.

Owner:GUANGDONG MEIZHI COMPRESSOR +1

Sealed type rotary compressor

InactiveUS20100215524A1Efficient executionReduce oil dischargeRotary/oscillating piston combinations for elastic fluidsRotary piston pumpsOil separationEngineering

An object of the present invention is to promote oil separation in a sealed container, thereby decreasing the amount of oil discharged to the outside of a compressor. The compressor comprises discharge hole provided at positions facing the end surface of a rotor and through which a compressed refrigerant from first and second rotary compression elements is discharged into the sealed container; and a refrigerant flow path which is extended from a space surrounded with a coil end of a stator projecting from the end surface of the rotor to a rotary compression mechanism side to a space of an air gap between the rotor and the stator, to guide the compressed refrigerant discharged through the discharge hole to an electromotive element opposite to the rotary compression mechanism side, and the outlet of this refrigerant flow path opposite to the rotary compression mechanism side faces the inner wall surface of the sealed container.

Owner:SANYO ELECTRIC CO LTD

Crankcase with bottom plate

ActiveUS20070000471A1Inhibition releaseOperational securityCasingsLubrication of auxillariesEngineeringCrankshaft

In a crankcase for an internal combustion engine, including a lubricant chamber for the collection of lubricant, and a bottom plate for providing dry sump lubrication closing the crankcase and being sealingly joined to the bottom end of the crankcase, wherein the crankcase includes auxiliary equipment comprising pumps for pumping lubricant into the lubricant chamber and from the lubricant chamber to various lubrication points, the bottom plate has a width exceeding the width of the crankcase so that it forms a section which is disposed outside the crankcase and auxiliary equipment is disposed on this section outside the crankcase.

Owner:ROLLS ROYCE SOLUTIONS GMBH

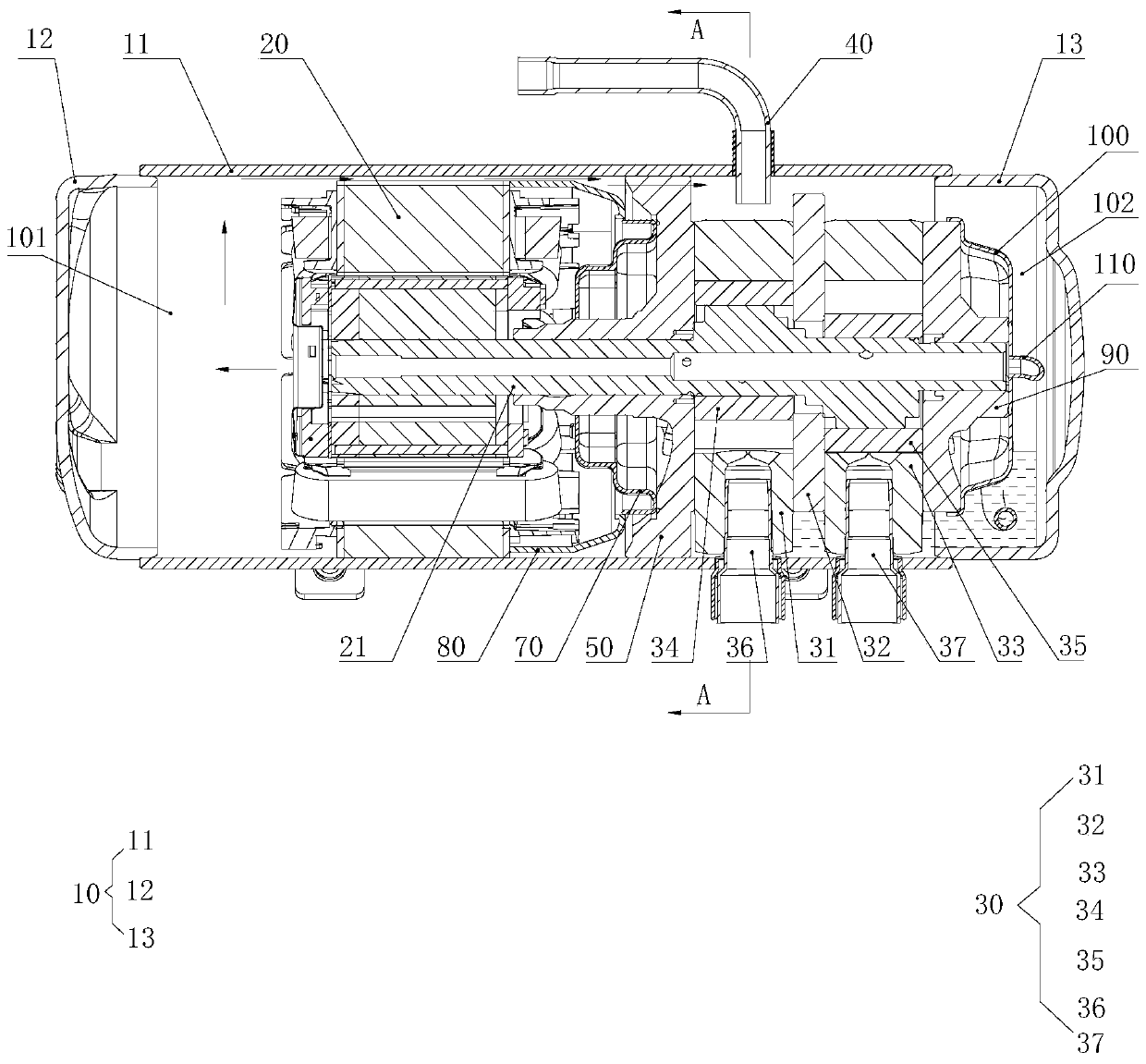

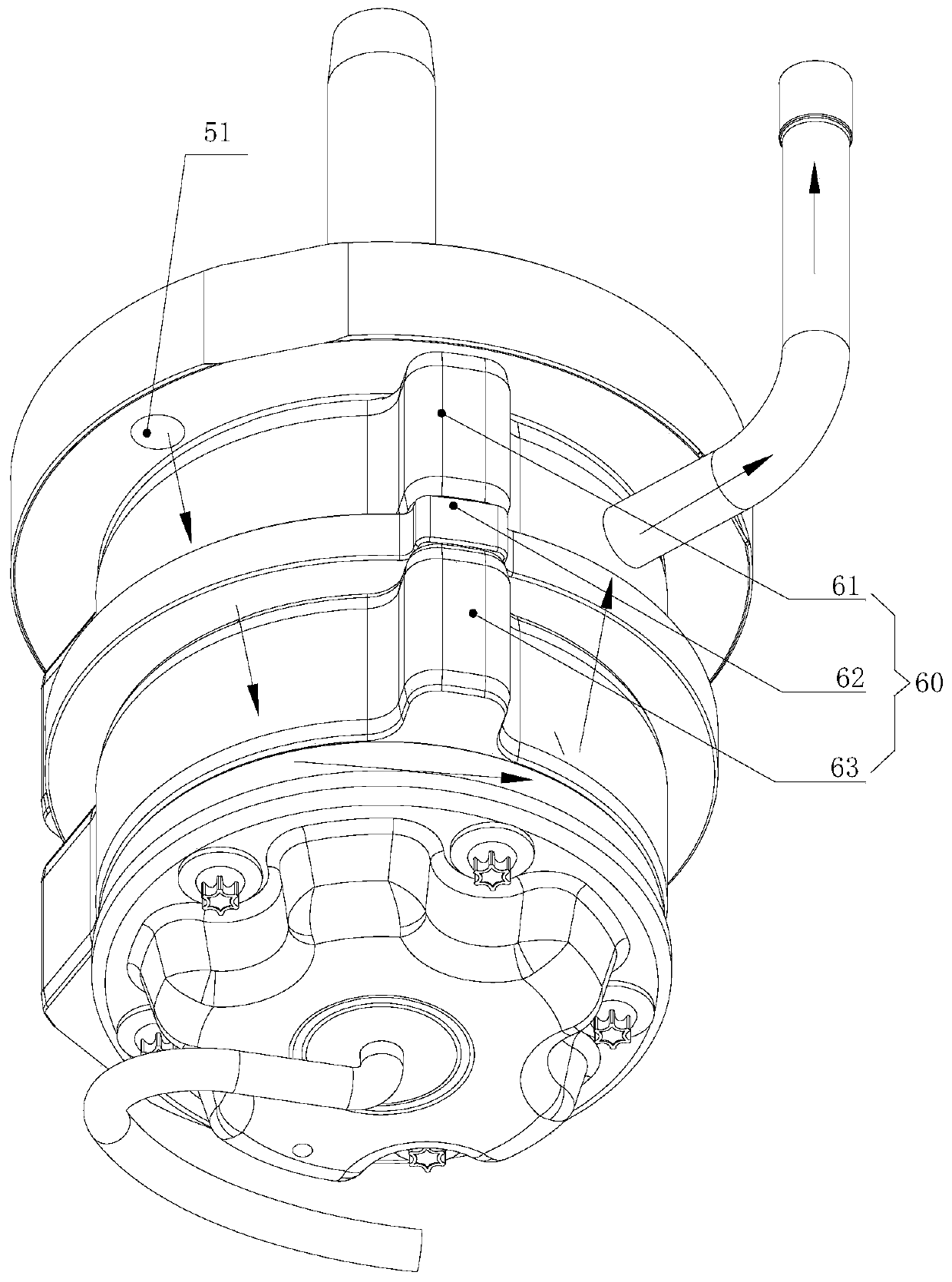

Horizontal compressor and heat exchange working system

ActiveCN110748485AReduce oil dischargeImprove use reliabilityRotary/oscillating piston combinations for elastic fluidsRotary/oscillating piston pump componentsElectric machineryEngineering

The invention provides a horizontal compressor, which comprises a shell, a drive motor, a compression mechanism, an exhaust pipe and a main bearing, wherein the outer peripheral wall of the main bearing is connected with the inner peripheral wall of the shell and divides the inner cavity of the shell into a first internal cavity and a second internal cavity, the drive motor is arranged in the first internal cavity, and the compression mechanism is arranged in the second internal cavity; an exhaust port of the compression mechanism communicates with the first internal cavity, a first through hole is formed in the main bearing, the first through hole communicates with the first internal cavity and the second internal cavity, and the exhaust pipe is inserted from the outside of the shell andcommunicates with the second internal cavity; the outer peripheral wall of the compression mechanism is convexly provided with a drainage structure matching with the inner peripheral wall of the shell, the drainage structure is located between the first through hole and the exhaust pipe along a circumferential direction of the compression mechanism, and an end, away from the main bearing, of the drainage structure is spaced from the inner end wall of the shell. A heat exchange working system comprises the horizontal compressor. The horizontal compressor provided by the invention prolongs the flow path of an oil-gas mixture and improves the oil-gas separation effect.

Owner:GUANGDONG MEIZHI COMPRESSOR

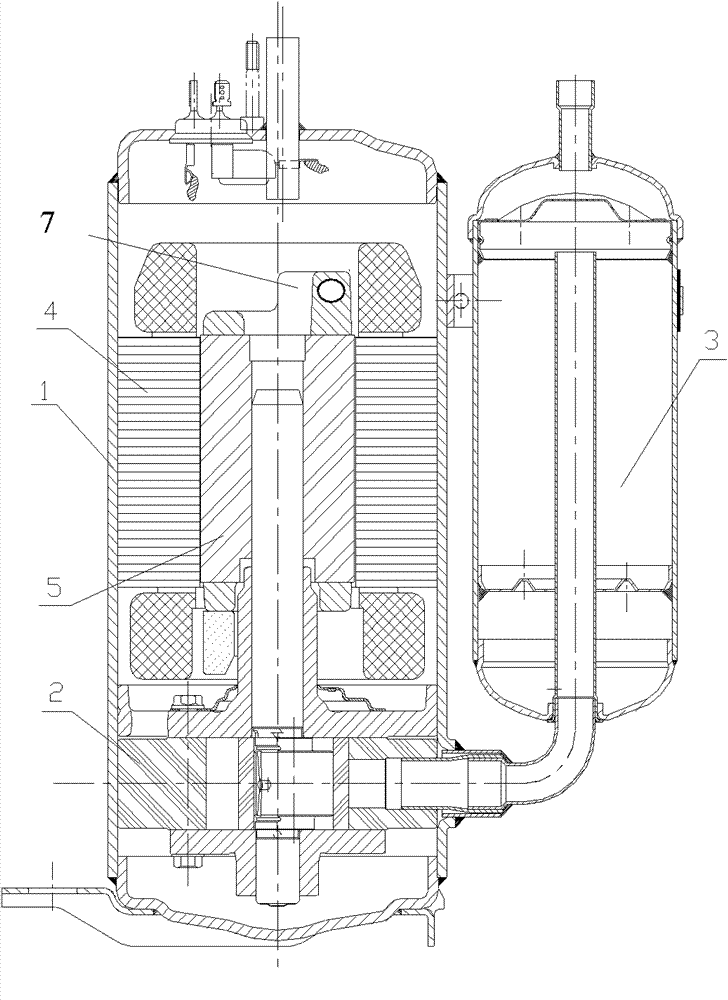

Rotary compressor

InactiveCN101988503AReduce oil dischargeRotary piston pumpsRotary piston liquid enginesMotor driveEngineering

The invention discloses a rotary compressor, which comprises a crankshaft of the compressor, a compressing structure part, an upper bearing, a lower bearing and a motor driving part, wherein the crankshaft of the compressor is arranged in a casing and is provided with an eccentric part, the compressing structure part is used for compressing coolant gas, the upper bearing and the lower bearing are respectively arranged at the upper side and the lower side of the compressing structure part, the motor driving part is used for driving the compressing structure part, the upper part of the casing is provided with an upper cover, the crankshaft upwards extends, the upper end of the crankshaft is arranged in a bearing arranged under the upper cover, a cylindrical gas-liquid separator is arranged on the crankshaft arranged between the bearing and a rotor, the diameter of the gas-liquid separator is smaller than that of the rotor, at least one exhaust opening is arranged on the outer peripheral surface of the upper part of the casing, and a filter screen is arranged between the exhaust opening and the gas-liquid separator. The rotary compressor of the invention separates small oil drops carried in gaseous coolants through the gas-liquid separator and the filter screen, and reduces the oil outlet quantity of the compressor.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

Vacuum pump with rotor-stator positioning to provide non-return

InactiveUS20140241928A1Low differential pressureReduce oil dischargeOscillating piston enginesSealing arrangement for pumpsStatorVacuum pump

A rotary-vane vacuum pump comprises a stator and a vaned rotor, the stator partly defining an outlet chamber and including an outlet passage opening to the outlet chamber. The rotor is rotatably sealed to the stator; it has a sealing area to block the outlet passage, and, an unsealing area alignable with the outlet passage by rotation of the rotor to periodically unblock the outlet passage. The disclosed pump offers reduced resistance to lubricant oil discharge from the outlet passage, which results in lower differential pressure between inlet and outlet chambers at the end of the pumping cycle.

Owner:FORD GLOBAL TECH LLC

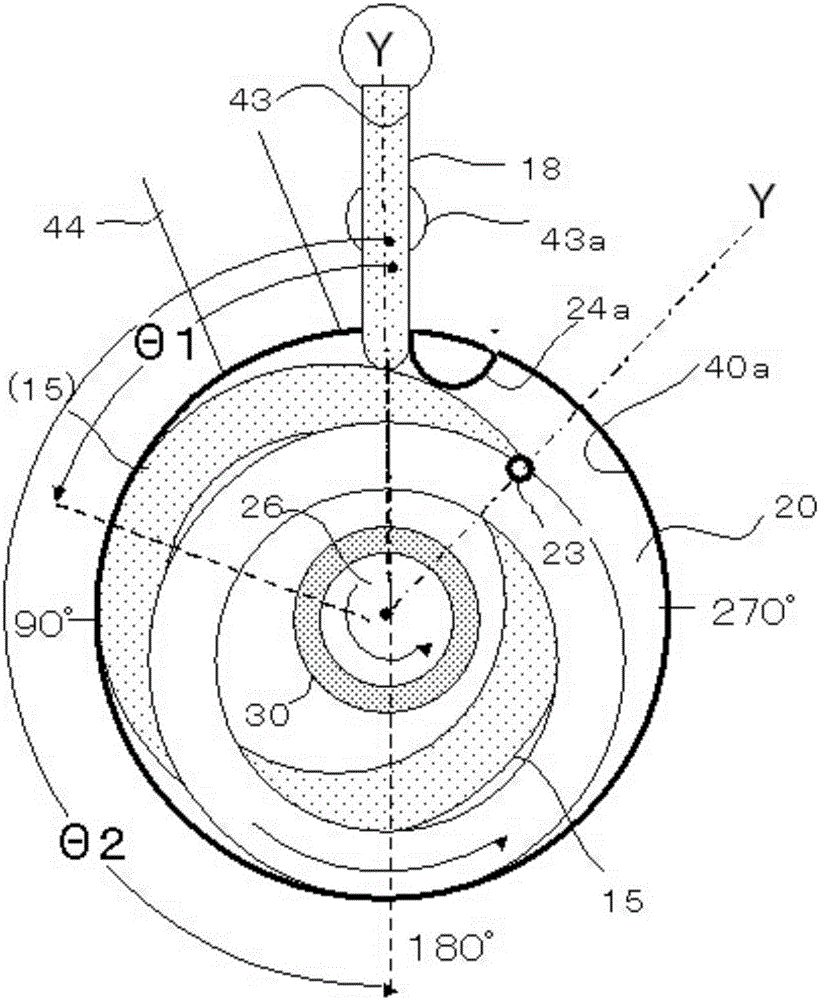

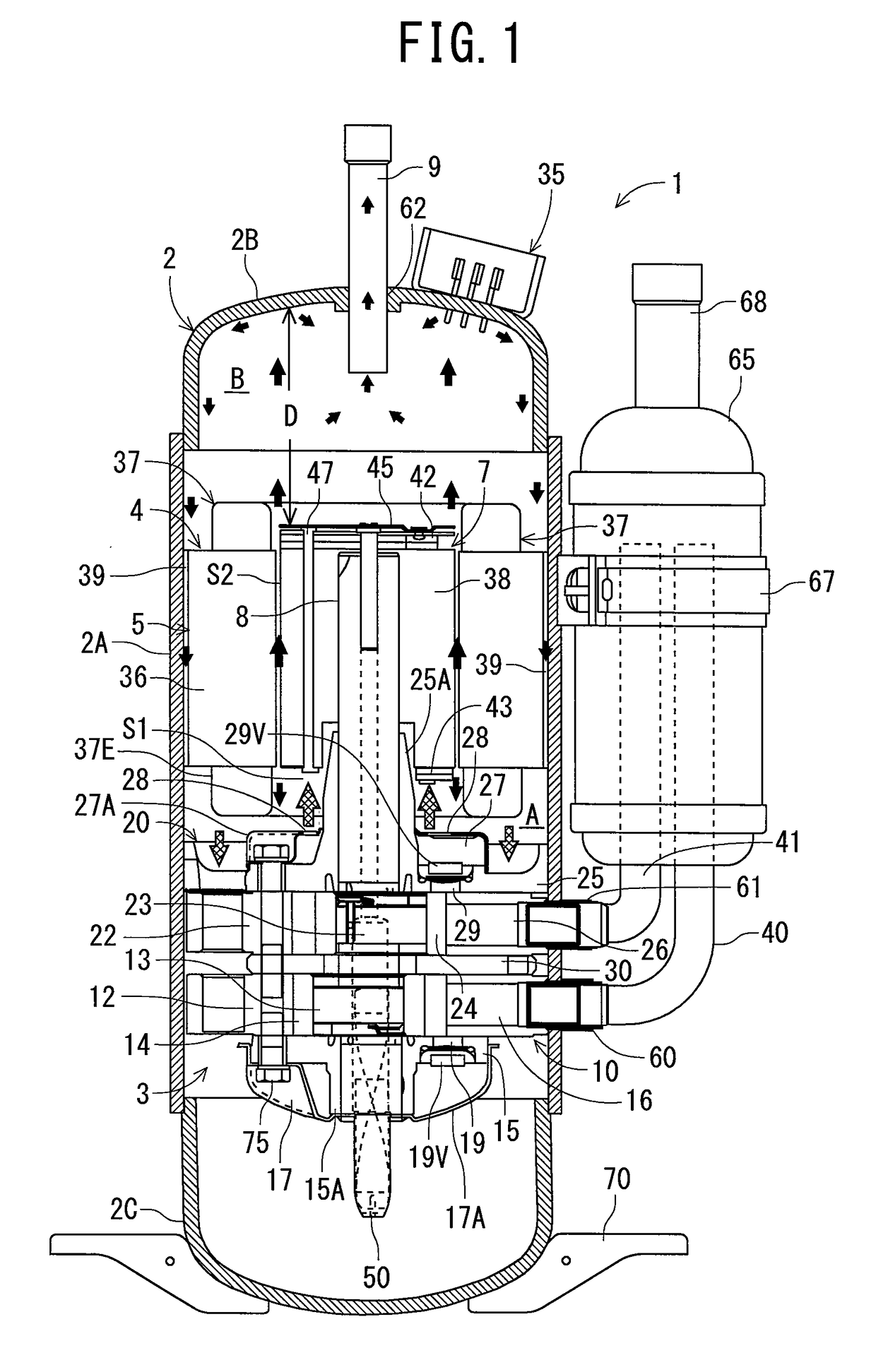

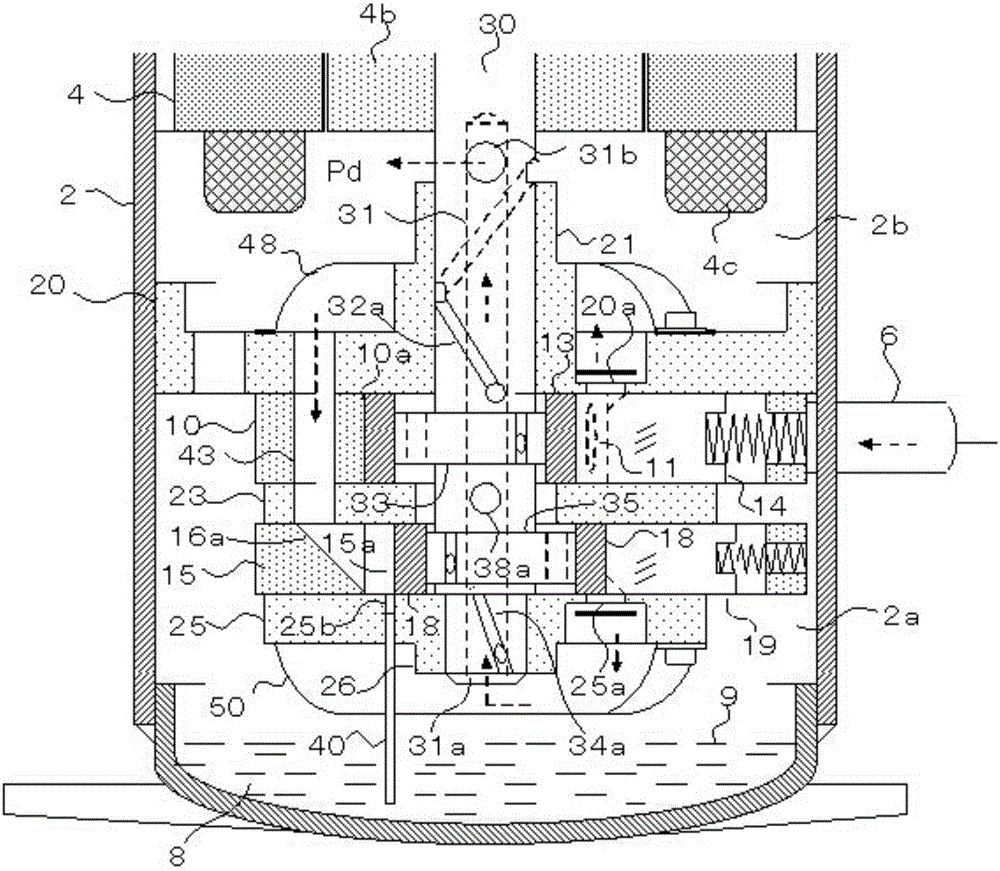

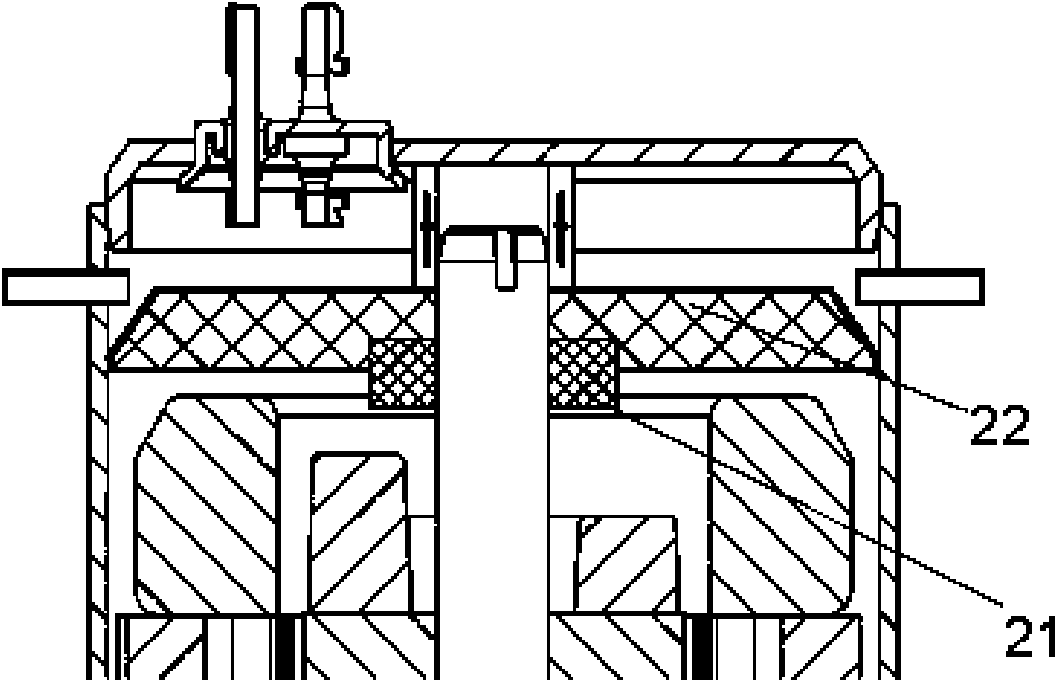

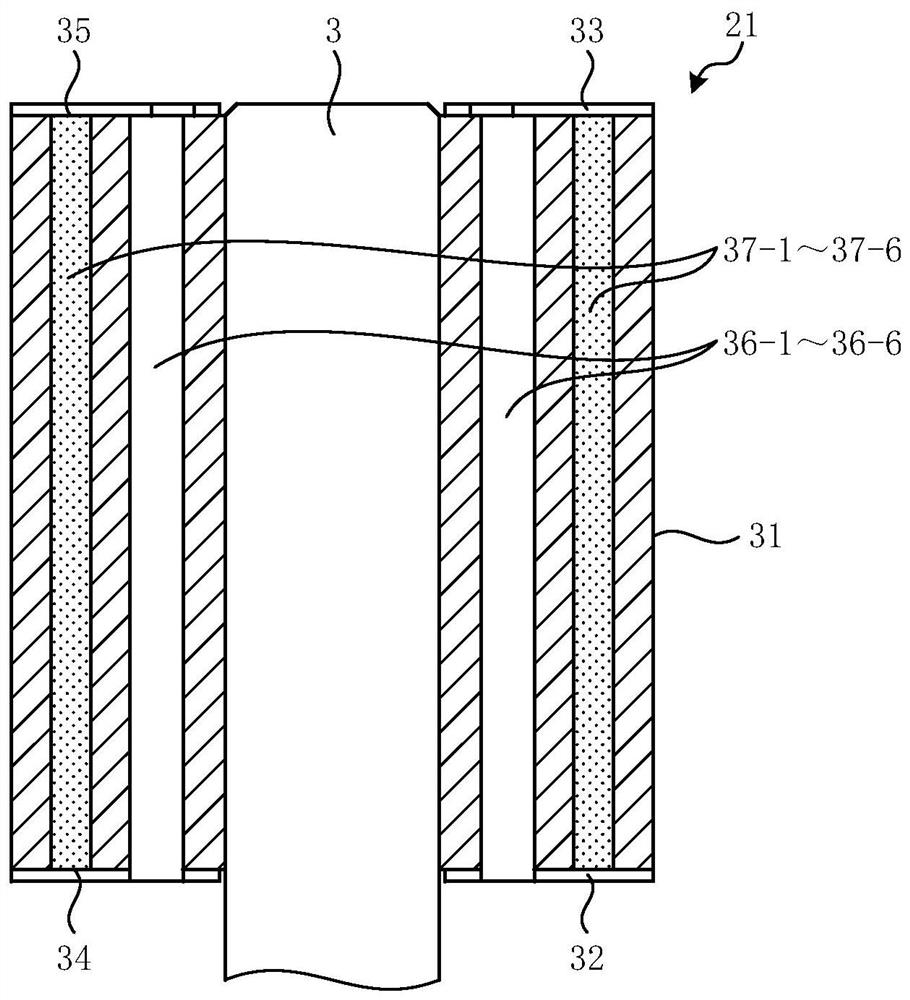

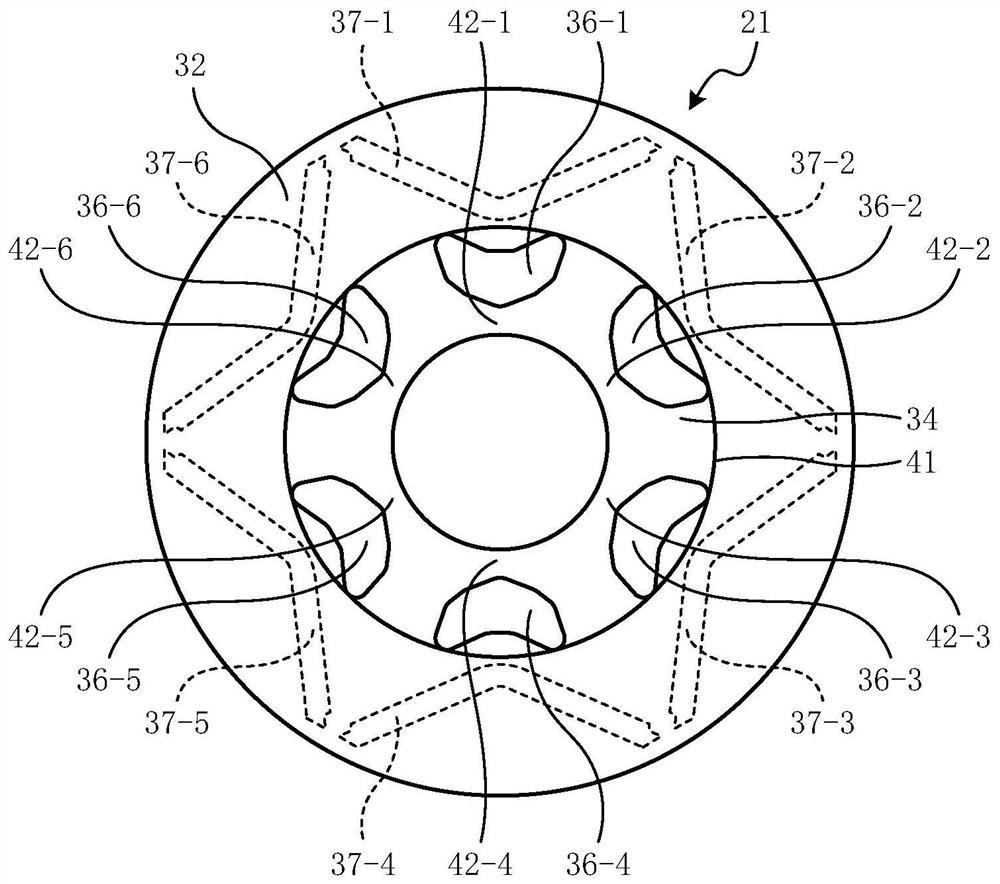

Compressor

ActiveCN111836967ASuppress flow path resistanceReduce oil dischargeCompressorMagnetic circuit rotating partsPhysicsRefrigerant

A rotor that provides a rotating power to a compressor unit for compressing a refrigerant comprises: a rotor core having formed through-holes (36-1 to 36-6) that have cross sections with a plurality of crotches in a direction away from a rotating axis and through which the refrigerant passes; a first end plate covering a first end surface on which one end of both end portions of the through-holes(36-1 to 36-6) in the rotor core that is on the side closer to the compressor unit is formed; and an upper rotor end plate (33) covering a lower rotor end surface (34) on which the other end of the plurality of holes in the rotor core is formed. The first end plate has formed a first opening portion providing communication between the through-holes (36-1 to 36-6) and an inner space. The upper rotor end plate (33) has formed an upper opening portion (43) providing communication between the through-holes (36-1 to 36-6) and the inner space. The upper rotor end plate (33) has formed protruding portions (44-1 to 44-6 and 45-1 to 45-6) covering each of tip-end portions (36-11 to 36-62) at the ends of each of the crotches of the through-holes (36-1 to 36-6).

Owner:FUJITSU GENERAL LTD

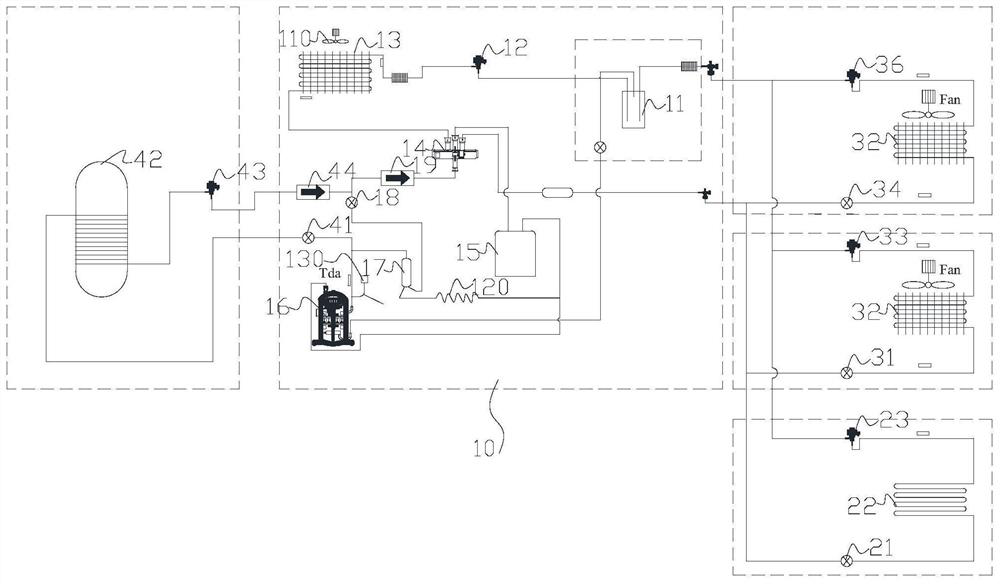

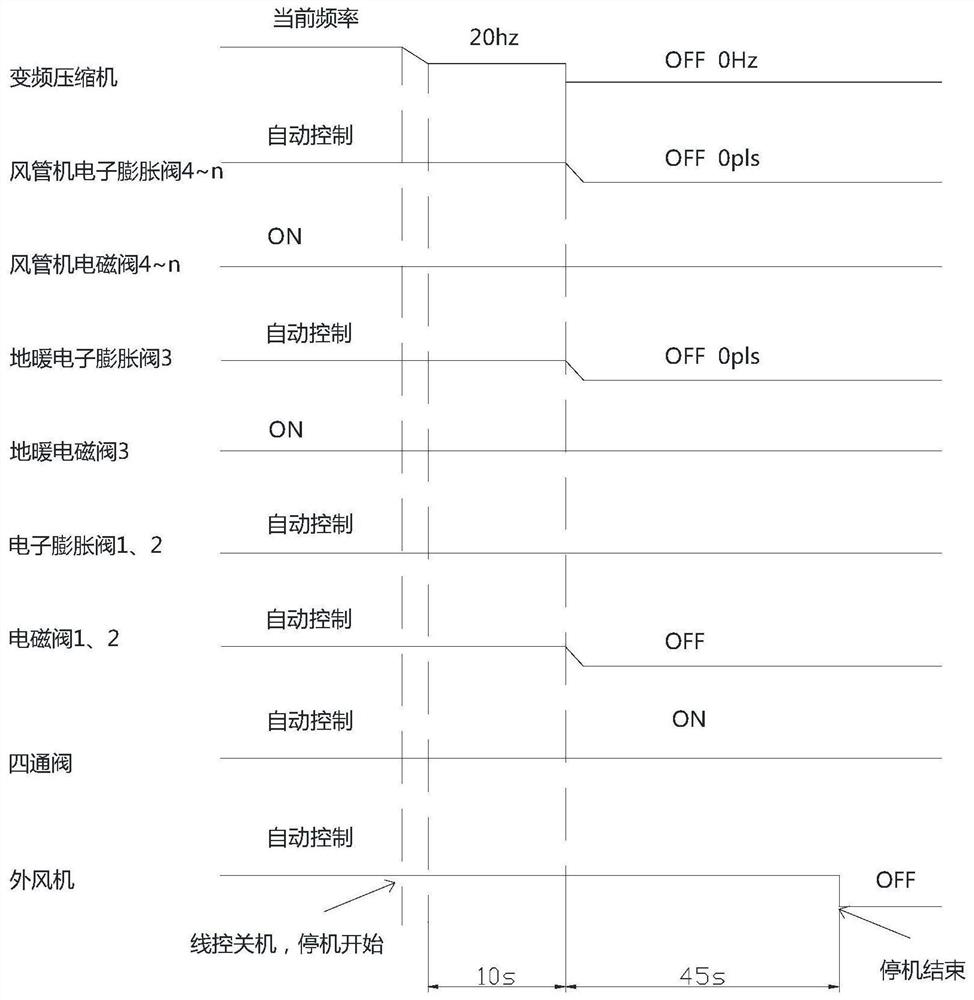

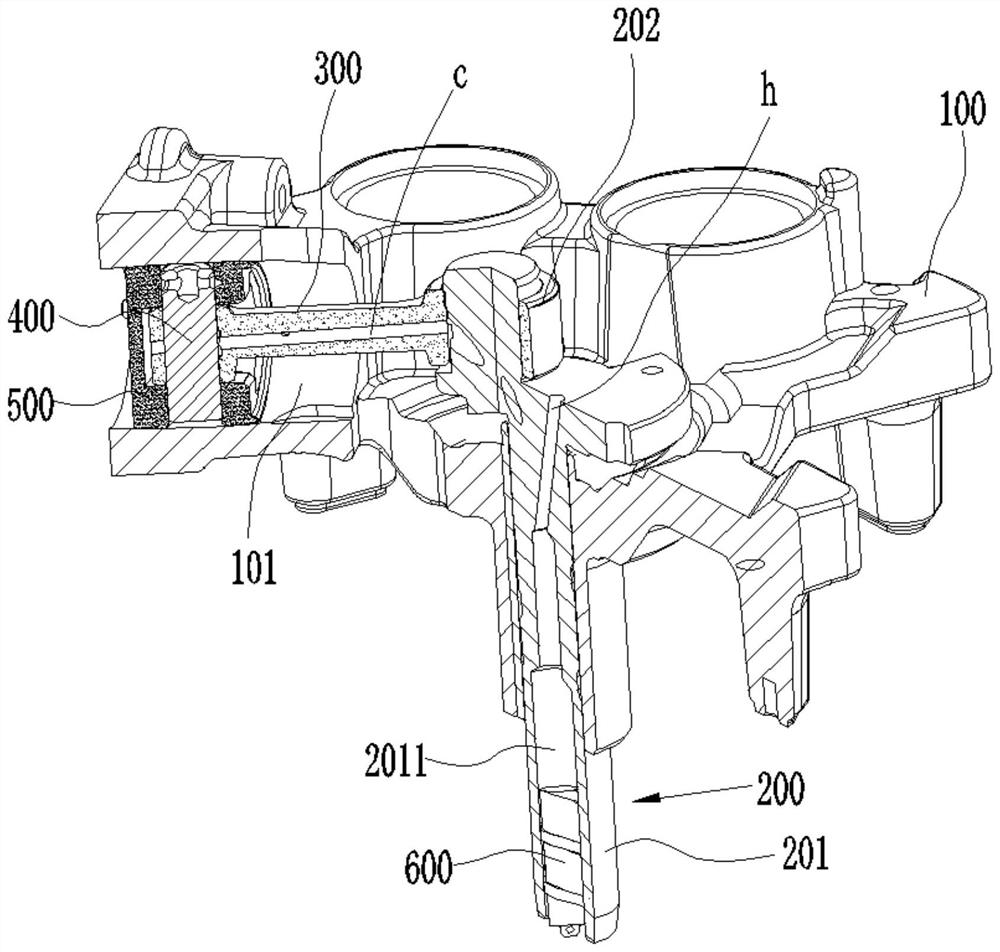

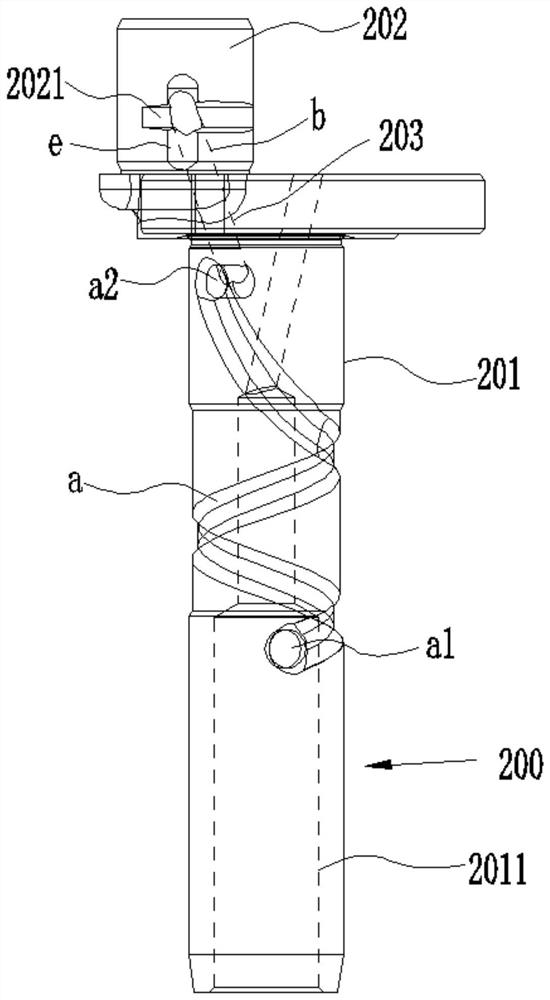

Control method for improving oil shortage of compressor during starting of water-free floor heating unit and triple co-generation system

ActiveCN113669784ACausing oil shortageReduce oil dischargeCompressorHeating fuelOil separationEngineering

The invention relates to a control method for improving oil shortage of a compressor during starting of a water-free floor heating unit and a triple co-generation system thereof. The triple co-generation system comprises a heat pump external unit and a water-free floor heating unit used for indoor heating. The external unit comprises the compressor, an outdoor heat exchanger, an outdoor fan and a first electronic expansion valve. The exhaust end of the compressor is connected with an oil separator in series. An oil return capillary pipe is arranged on a refrigerant pipeline, bypassing the oil separator to the air inlet end of the compressor. A first electromagnetic valve and a first one-way valve are sequentially arranged on the refrigerant outlet side of the oil separator. A second electromagnetic valve used for controlling on-off of a refrigerant is arranged on the refrigerant inlet side of the water-free floor heating unit, and a second electronic expansion valve is arranged on the refrigerant outlet side of the water-free floor heating unit. According to the control method, when the external unit receives a water-free floor heating shutdown command, most of the refrigerant in the system is stored in the floor heating capillary pipe, and the problem of a large amount of liquid return during starting is solved; and when the external unit receives a water-free floor heating starting command, the unit is controlled to be softly started to operate, and oil discharge of the compressor is reduced.

Owner:ZHEJIANG ZHONGGUANG ELECTRIC CO LTD

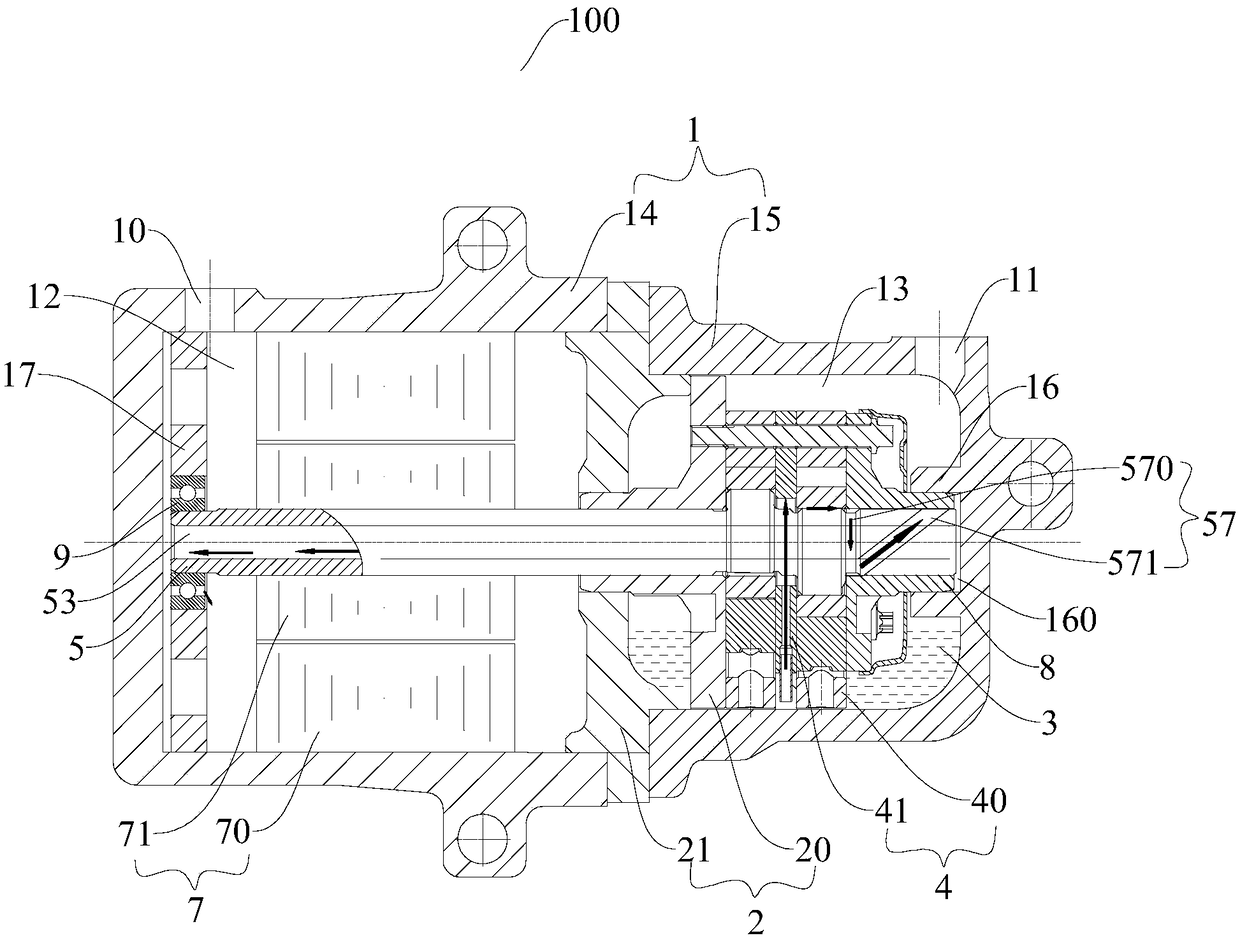

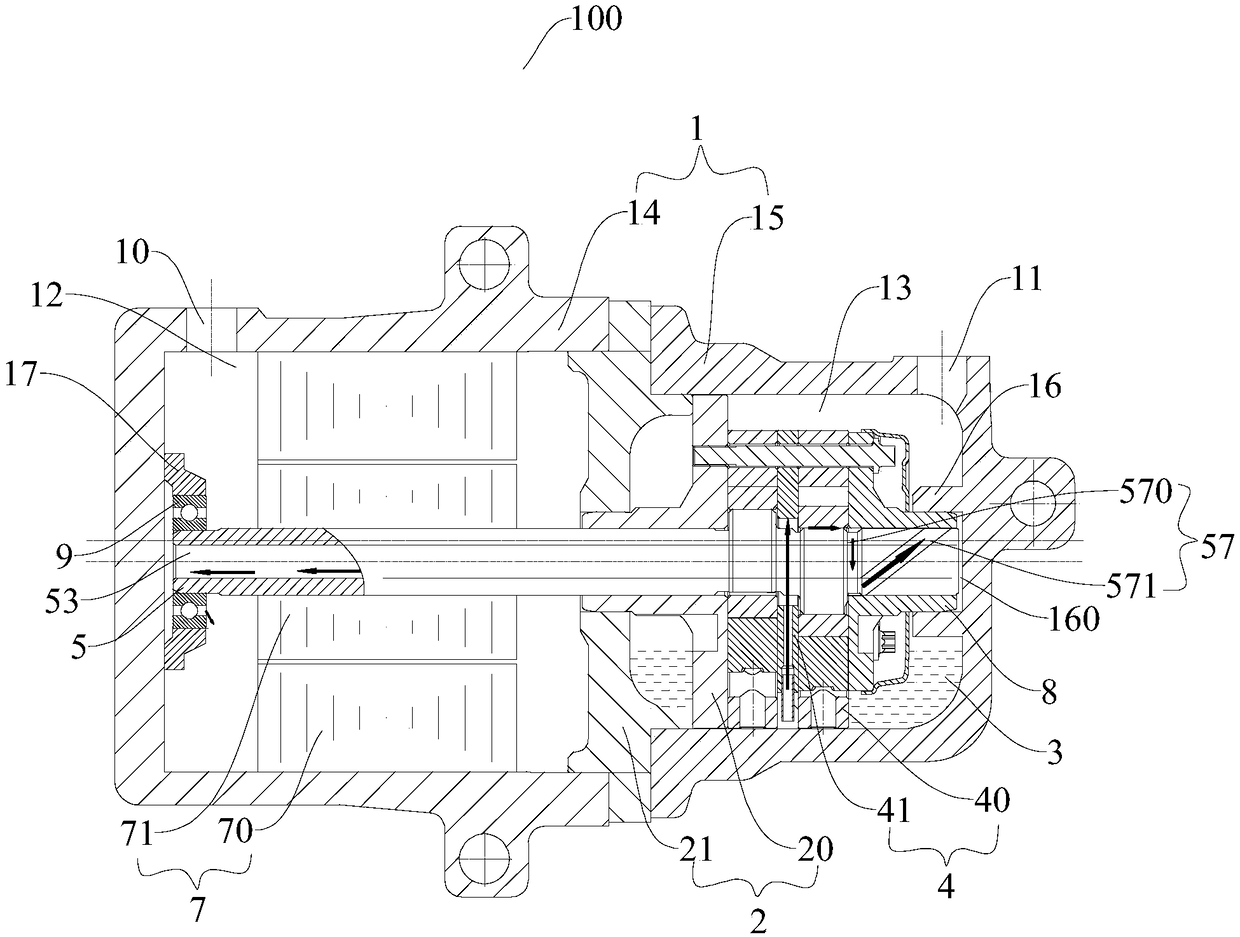

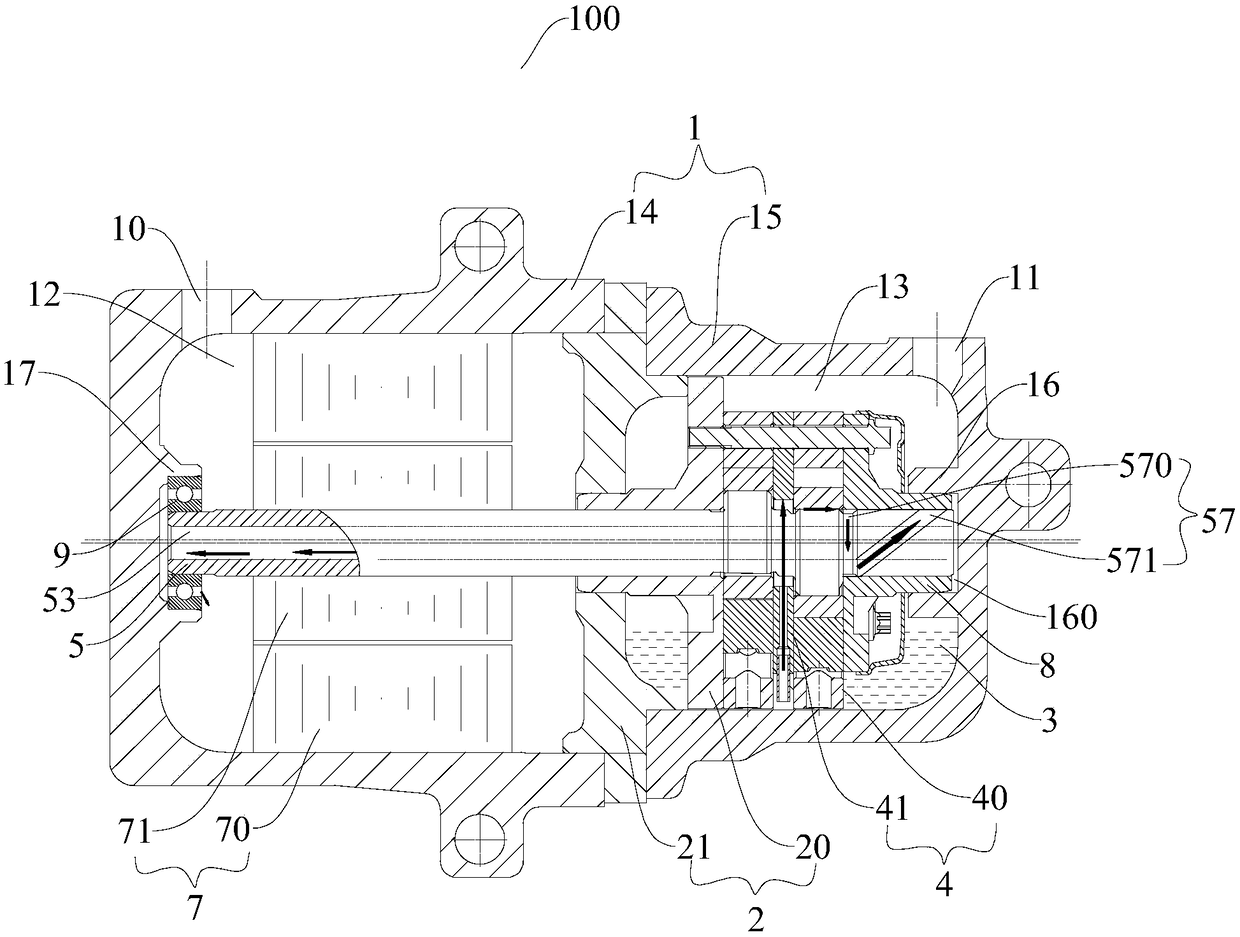

Compressor and vehicle with same

ActiveCN106704198BReduce noiseGuaranteed operational reliabilityRotary/oscillating piston pump componentsLiquid fuel engine componentsEngineeringHigh pressure

The invention discloses a compressor and a vehicle provided with same. The compressor comprises a housing, a separating assembly, an air cylinder assembly, a secondary bearing, a crankshaft and a rolling bearing, wherein a gas suction hole and a gas exhaust hole are formed in the housing; the separating assembly is arranged on the housing for internally separating the housing into a low-pressure cavity and a high-pressure cavity; the separating assembly comprises a primary bearing; the air cylinder assembly is arranged in the high-pressure cavity; the air cylinder assembly comprises two air cylinders and a middle separating plate; a first oil path channel which communicates with an oil tank is arranged in the middle separating plate; a central shaft hole is formed in the crankshaft; an inlet end of the central shaft hole communicates with the first oil path channel; a lubricating path is arranged among the crankshaft, the primary bearing and the secondary bearing; one end of the lubricating path communicates with the low-pressure cavity; the other end of the lubricating path communicates with the first oil path channel; the rolling bearing is arranged on the inner wall of the housing; and an outlet end of the central shaft is positioned in the rolling bearing. According to the embodiment of the invention, the compressor ensures supply continuity of lubricating oil.

Owner:GUANGDONG MEIZHI COMPRESSOR

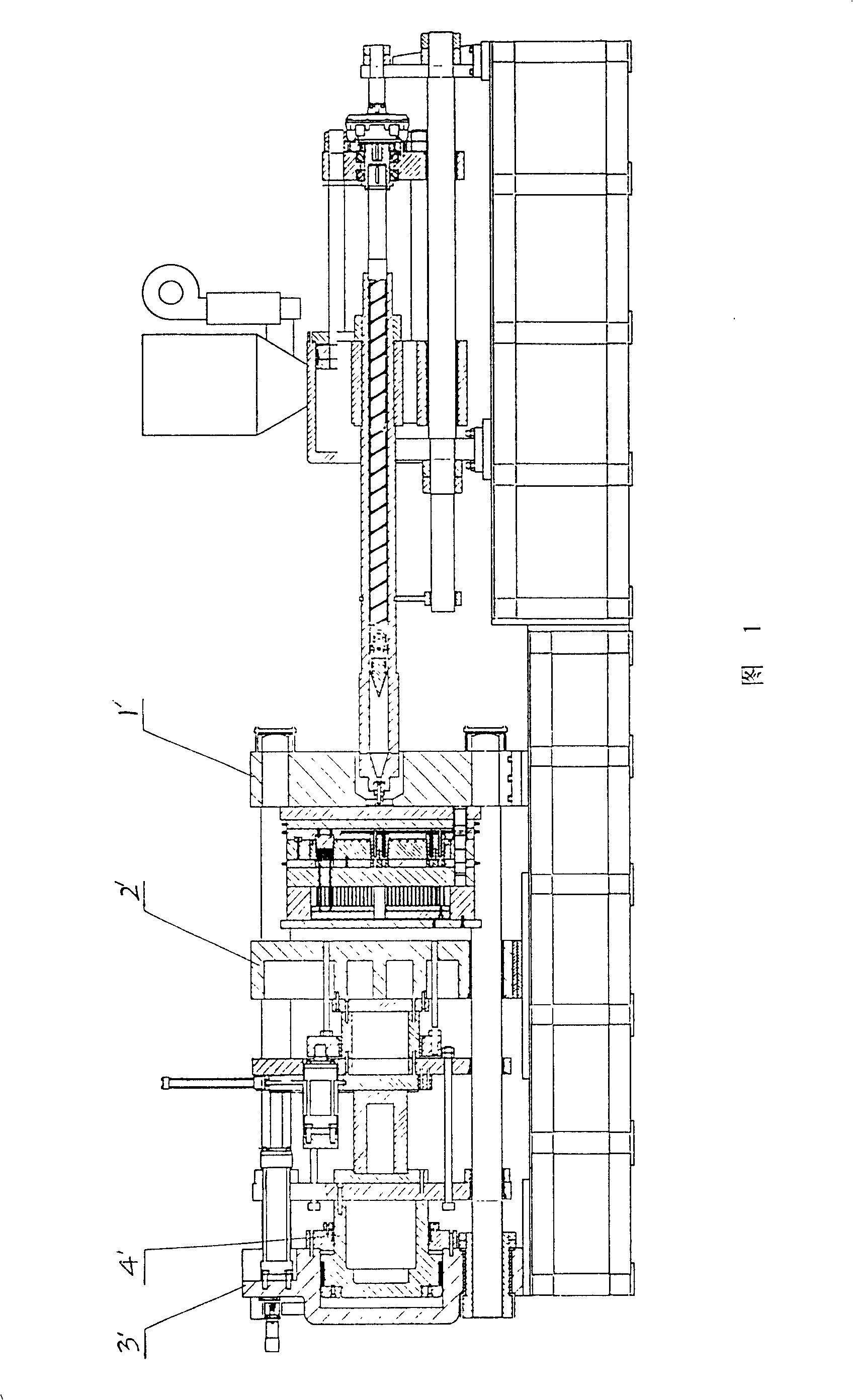

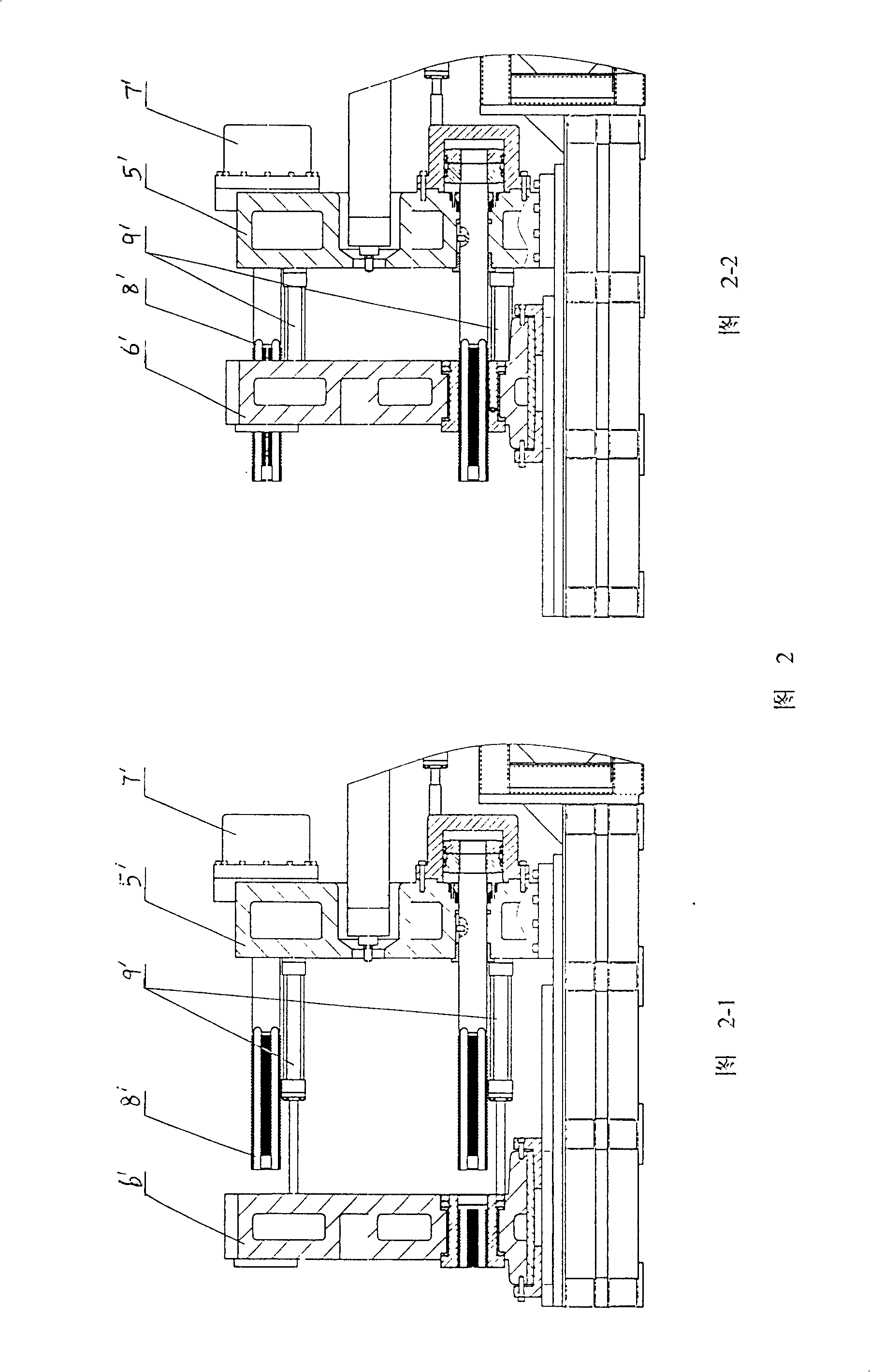

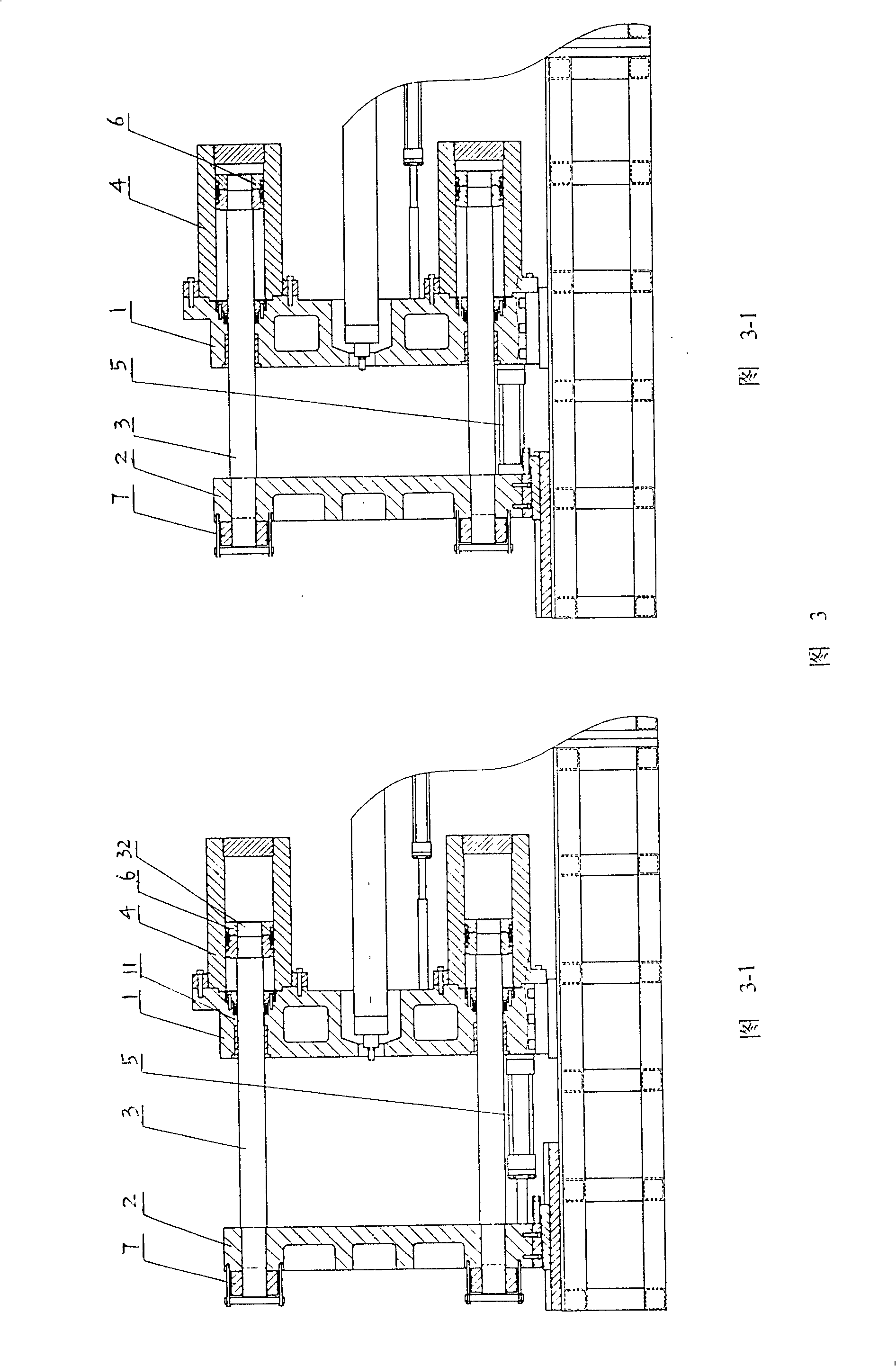

Biplate lock mould structure injection moulding machine and its manufacturing method

An injection moulding machine with dual-plate mould-locking structure features that its mould-locking pull rod is permanently connected to slide template via locking nut and the other end of said pull rod is integrated with the piston in mould-locking cylinder, so whole assembly can only move left and right. The diameter and length of piston tail are increased, so it can run outside the cylinder to decrease the amount of oil sucked and discharged by mould-locking cylinder. Its advantages are high strength and mould-locking speed, low cost and low energy consumption.

Owner:SUNNEX METAL PROD SHEN ZHEN

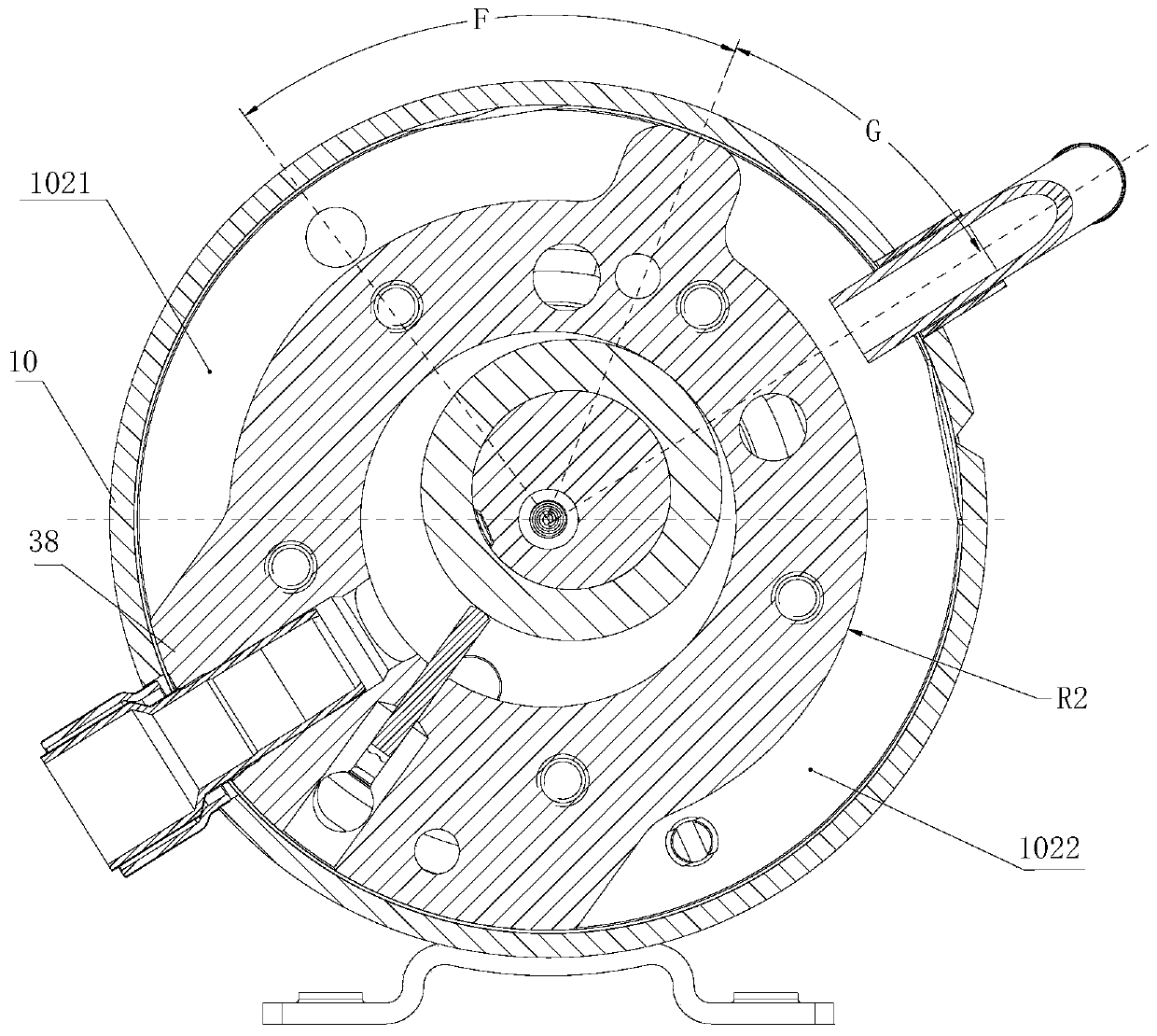

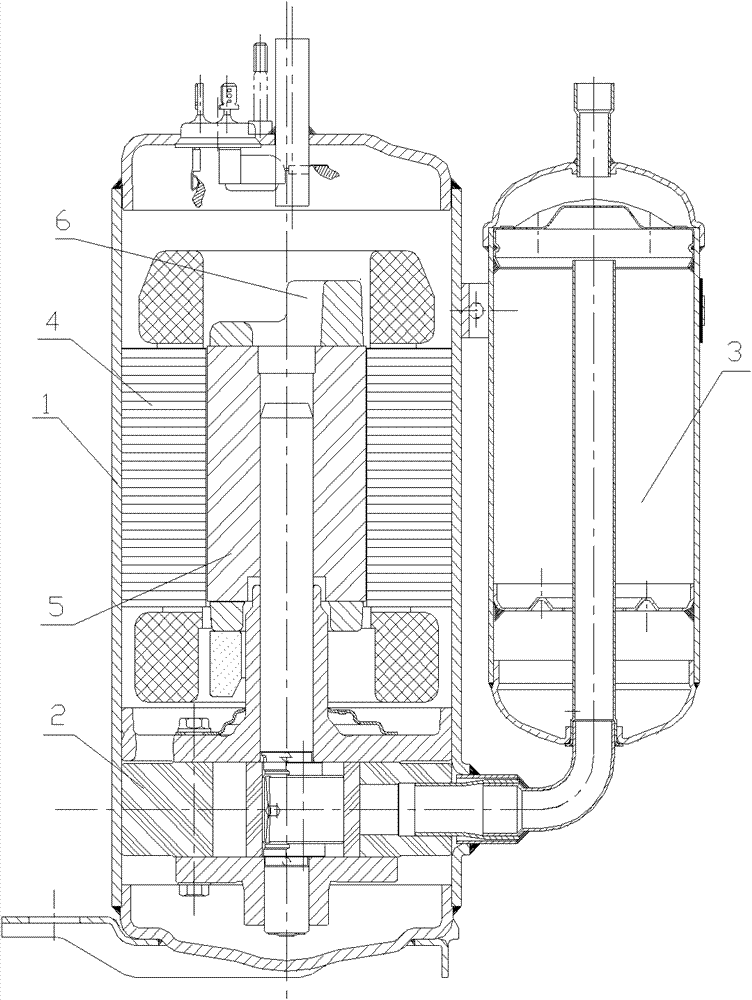

Oil-gas separated-type balancing block

ActiveCN102162454BReduce oil dischargeExtended service lifeRotary/oscillating piston pump componentsLiquid fuel engine componentsEngineeringMechanical engineering

The invention discloses an oil-gas separated-type balancing block which is internally provided with a channel, wherein the channel penetrates through two end surfaces of the balancing block and is communicated with the outer side wall of the balancing block. By adopting a compressor equipped with the balancing block provided by the invention can separate refrigerating machine oil from gas refrigerant in the operation process, thus the oil discharge amount of the compressor is reduced, not only can the amount of refrigerating machine oil in the shell of the compressor be ensured, the service life and dependance of the compressor are improved, but also the heat transfer effect and energy efficiency of an air conditioner can be improved.

Owner:PANASONIC WANBAO GUANGZHOU COMPRESSOR

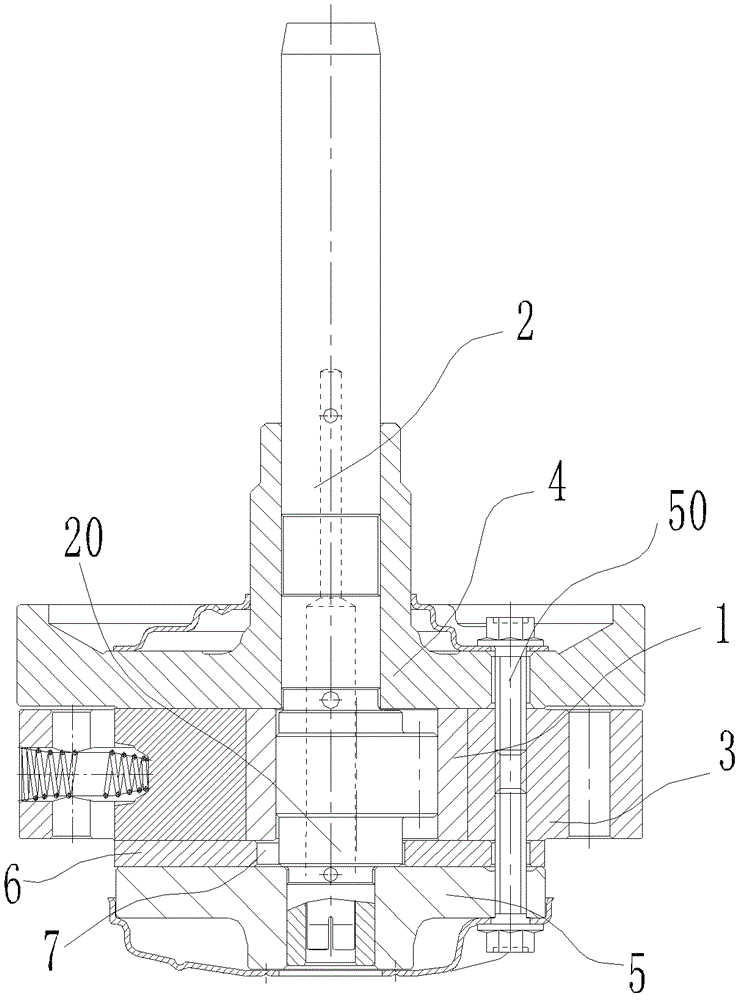

A rotary compressor with an oil storage chamber pump body

ActiveCN102588290BImprove reliabilityImprove stand-alone performanceRotary/oscillating piston pump componentsLiquid fuel engine componentsEngineeringCrankshaft

The invention provides a rotary compressor of a pump body with an oil storage cavity. The rotary compressor comprises a roller, a crankshaft, a cylinder, an upper flange and a lower flange, wherein the roller is arranged on the crankshaft and is matched with the cylinder in an eccentric mode; a thrust surface extension part is extended on a thrust surface at the lower end of the crankshaft along the axial direction; a clapboard matched with the thrust surface extension part is arranged between the cylinder and the lower flange; the oil storage cavity which makes the compressor conveniently lubricated and prevents redundant refrigerant oil from being discharged or extruded out of an exhaust port of the pump body is enclosed at the matched position among the lower flange, a short shaft of the crankshaft and the clapboard; a friction working surface of the thrust surface at the lower end of the crankshaft is matched with an upper end surface of the lower flange; and a friction working surface of the roller is matched with the clapboard.

Owner:GREE ELECTRIC APPLIANCES INC +1

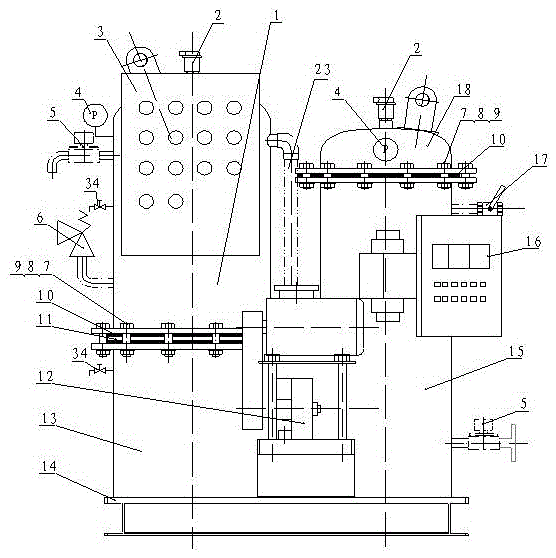

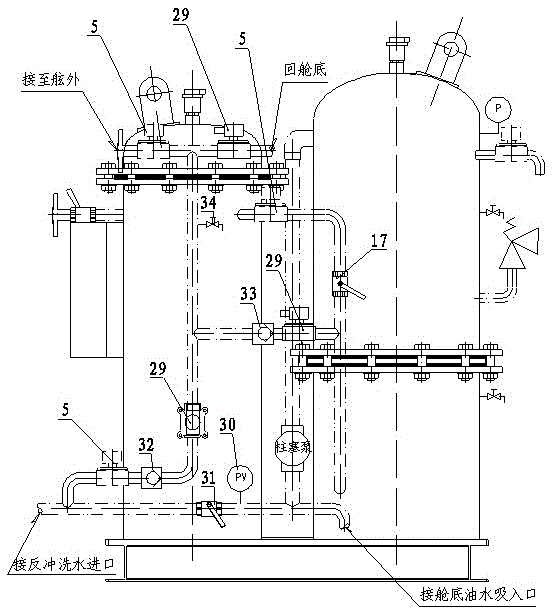

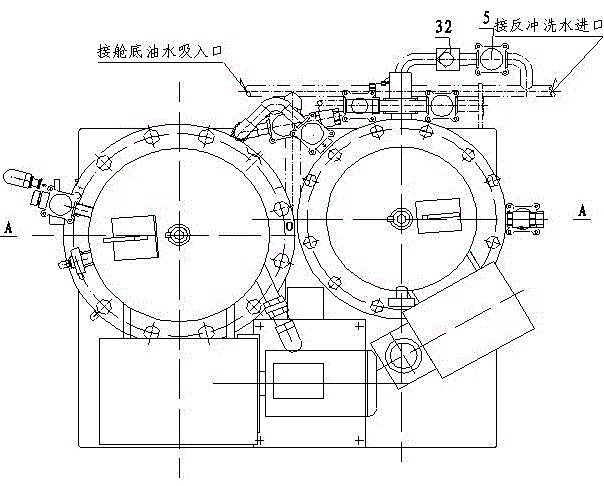

Marine oil water separator

InactiveCN103933755BEasy maintenanceEasy to manageNon-miscible liquid separationOily water separatorElectrical control

The invention relates to an oil-water separator for a ship. The oil-water separator is characterized by comprising a primary filter, a secondary filter, a fine filter, an electric control box, an electric plunger pump set for the ship, a base and a 15ppm cabin bottom water alarm device, wherein the primary filter and the secondary filter are connected one above the other through a bolt and are arranged in parallel on the base together with the electric plunger pump set for the ship and the fine filter; one end of the electric plunger pump set for the ship is communicated with the outside through an oil pipe, and the other end of the electric plunger pump set for the ship is communicated to the primary filter through an oil pipe; the insides of the primary filter and the secondary filter are communicated with each other; two oil pipelines are led out of the secondary filter; one pipeline is communicated with the outside, and the other pipeline is communicated with the fine filter; an oil pipe is led out of the fine filter and communicated with the outside, and an electromagnetic valve is arranged at a corresponding position on the oil pipe; the electromagnetic valve, the electric control box and the 15ppm cabin bottom water alarm device form a loop. The separator has the characteristics of high automatic degree, low oil drainage amount, compact structure, convenience in installation, easiness in maintenance and management, and the like.

Owner:GUANGXI YANYAN MACHINERY MFG CO LTD

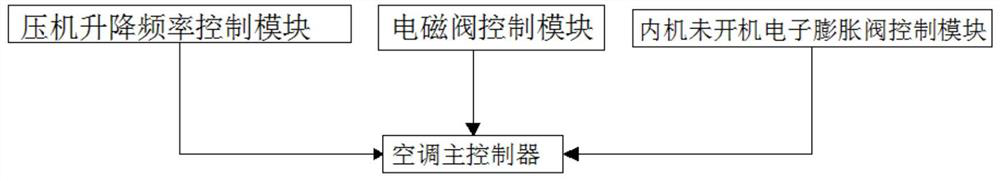

Oil return control method, system, air conditioner and computer readable storage medium

ActiveCN111271901BRealize oil return control methodReduce oil dischargeCompressorRefrigeration safety arrangementSolenoid valveProcess engineering

The present invention provides an oil return control method, system, air conditioner and computer-readable storage medium, the method includes the step: S1, when the outdoor ambient temperature package detects that the temperature is <T for 30 seconds continuously, T is taken as -15°C ~0°C, when some indoor units start, the outdoor unit receives the indoor unit start command, and the solenoid valve SV2 starts immediately; S2, after the power-on self-check, the compressor rises to Fn1 at the frequency increase rate V1, and maintains at the frequency Fn1 for t1 seconds, Then reduce the frequency at the ramp-up rate of V2 and maintain it for t2 seconds according to Fn2, then increase the ramp-up rate to Fn3 at the ramp-up rate of V3, and then perform automatic operation according to the normal startup platform; After the signal, after t3 seconds, the opening is adjusted to the number of Q1 steps; S4, after the start-up of the air conditioner is completed, the compressor, the solenoid valve SV2 and the electronic expansion valve of the internal unit are not turned on, and the electronic expansion valve is normally adjusted. The oil return control method of the present invention, The system, the air conditioner and the computer-readable storage medium can realize rapid oil return in the low-temperature start-up stage.

Owner:NINGBO AUX ELECTRIC

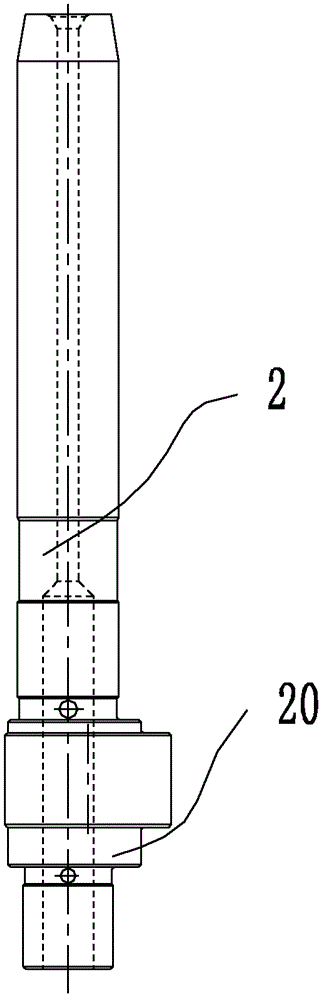

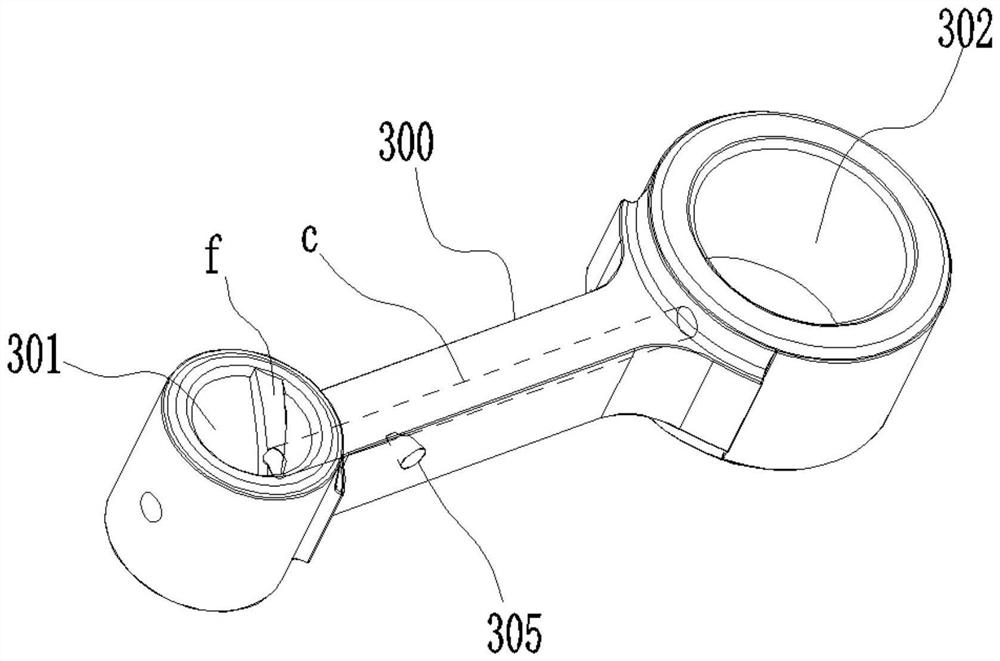

Compressor crankshaft connecting rod oil supply mechanism and compressor

ActiveCN113565739AOptimize oiling pathIncrease high frequency cooling capacityPositive displacement pump componentsPositive-displacement liquid enginesControl theoryCrankshaft

The invention discloses a compressor crankshaft connecting rod oil supply mechanism and a compressor, and belongs to the technical field of compressors. The problems that in the prior art, oil discharge is increased when a compressor operates under the working conditions of high rotating speed and high load, and formation of a friction pair oil film is not facilitated are solved. The compressor crankshaft connecting rod oil supply mechanism comprises a machine base with an air cylinder hole and a shaft hole; a crankshaft, wherein a long shaft of the crankshaft is rotationally arranged on the shaft hole of the machine base; a connecting rod, wherein a pin shaft hole and a crankshaft hole are formed in the two ends of the connecting rod respectively, and a short shaft of the crankshaft is rotationally connected with the crankshaft hole; and a piston, wherein the piston is movably arranged in the air cylinder hole, a pin shaft is fixedly arranged on the piston, and the pin shaft is rotationally connected with the pin shaft hole. A first matching surface between the long shaft and the shaft hole is provided with a first oil duct with an oil supply inlet and an oil supply outlet. The oil discharge quantity is reduced, oil discharge atomization is improved, the oil quantity in circulating air suction is reduced, and the high-frequency refrigerating capacity of the compressor is improved.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

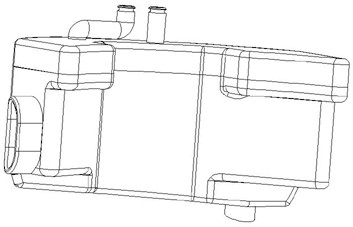

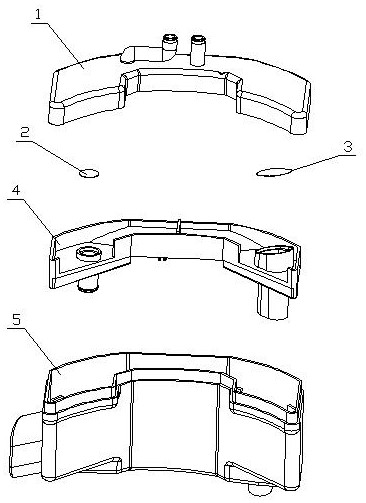

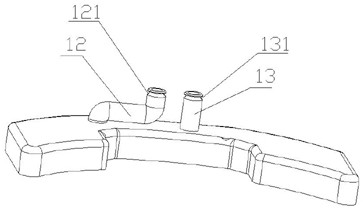

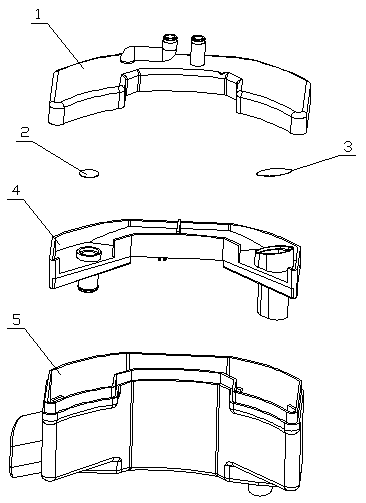

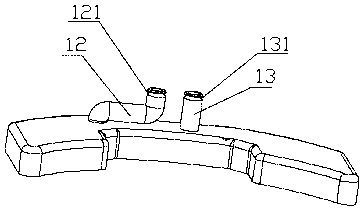

A suction muffler applied to a compressor

ActiveCN110425107BReduce noiseReduce inspiratory pulsationPositive displacement pump componentsPositive-displacement liquid enginesEngineeringMuffler

The invention discloses a suction muffler applied to a compressor, comprising an upper cover (1), a middle partition (4) and a casing (5); the top of the upper cover (1) is provided with an air outlet pipe ( 12) and outlet pipe 2 (13), the bottom of the upper cover (1) is provided with installation groove 1 (14), and the inner middle is provided with installation groove 2 (15); the inside of the middle partition (4) is provided with a separation plate One (42), the bottom is provided with the installation groove three (410); the top of the housing (5) is provided with the installation notch (57), and the inside is provided with the separation plate two (56); the middle partition (4 ) is set in the housing (5), and the installation groove three (410) is matched with the separation plate two (56); the upper cover (1) is set on the middle partition (4) and the top of the housing (5), Groove one (14) cooperates with installation notch (57), and installation groove two (15) cooperates with separation plate one (42). The invention can improve gas transmission efficiency and reduce oil discharge, so it has broad market prospects.

Owner:CHANGHONG HUAYI COMPRESSOR CO LTD

Oil supply device

ActiveCN107415674AReduce oil dischargeMiniaturizationHybrid vehiclesSpeed controllerHydraulic pumpInternal combustion engine

There is desired an oil supply device that can supply an appropriate amount of oil to a vehicle drive device, while suppressing an increase in size of a hydraulic pump, in the case where torque of an internal combustion engine is transferred to wheels with an engagement device controlled to a slipping engagement state. An oil supply device (10) is provided with: a first hydraulic pump (21); a second hydraulic pump (22) driven by a dedicated drive-power source (23); a lubricating oil passage (61) for lubricating engagement devices (C0, C1); a first engagement oil passage (51) for controlling an engagement state of a release engagement device (C0); and a second engagement oil passage (52) for controlling an engagement state of a gear-shift engagement device (C1). In cases when the engagement devices are controlled so as to be in a slip engagement state, a supply state controller sets a state in which oil discharged from the first hydraulic pump is supplied to the first engagement oil passage and the second engagement oil passage, and oil discharged from the second hydraulic pump is supplied to the lubricating oil passage.

Owner:AISIN AW CO LTD

Compressor and motor assembly thereof

InactiveCN106100187AEnsure oil lubrication effectReduce oil dischargeMagnetic circuit rotating partsPiston pumpsMain channelLubrication

The invention discloses a motor assembly, which comprises an upper cavity and a lower cavity, a rotor is arranged between the upper cavity and the lower cavity, and an air flow passage connecting the upper cavity and the lower cavity is provided on the inner side of the rotor , a main channel is also connected between the upper chamber and the lower chamber. During assembly and operation, due to the adoption of a double-channel structure consisting of an airflow channel and a main channel, the gas discharged from the pump body of the compressor passes directly into the upper chamber through the airflow channel in whole or in part from the lower chamber, and is refrigerated. The refrigerating oil brought to the upper cavity by the agent can quickly return to the lower cavity and the oil pool through the main channel, thus effectively avoiding the accumulation of the refrigerating oil in the upper cavity due to the influence of the air flow during the return process of the refrigerating oil, and effectively ensuring the oil retention of related components. The effect of liquid lubrication, and the oil discharge of the compressor is reduced accordingly. The invention also discloses a compressor using the motor assembly.

Owner:ZHUHAI LANDA COMPRESSOR +1

Rotary compressor and refrigeration cycle device having same

ActiveCN106194735BReduce oil dischargeAvoid wear failuresRotary/oscillating piston combinations for elastic fluidsRotary piston pumpsReciprocating motionSlip sheet

The invention discloses a rotary compressor and a refrigeration circulating device with the same. An electric motor and a compressing mechanism part are contained in a sealed shell of the rotary compressor. The shell is provided with an air suction pipe, and lubricating oil is stored at the bottom of the shell. The compressing mechanism part comprises a cylinder, a piston, a slip sheet, a crankshaft, a first rolling bearing and an end plate. A compressing cavity is formed in the cylinder. The piston is arranged in the compressing cavity in an eccentric rotation mode. The slip sheet is arranged on the cylinder in a reciprocating motion mode. An eccentric shaft of the crankshaft is externally sleeved with the piston to drive the piston to rotate in an eccentric mode. The crankshaft is matched with the first rolling bearing. The end plate is arranged on the cylinder to support the crankshaft. Oil-containing refrigerant gas exhausted from the compressing cavity at least needs to lubricate the first rolling bearing. According to the rotary compressor, the oil discharge amount of the compressor is reduced, and the phenomenon that the liquid level of lubricating oil in an oil storage tank drops dramatically can be avoided.

Owner:GUANGDONG MEIZHI COMPRESSOR +1

Air suction silencer applied to compressor

ActiveCN110425107AReduce noiseReduce inspiratory pulsationPositive displacement pump componentsPositive-displacement liquid enginesMufflerPhysics

The invention discloses an air suction silencer applied to a compressor. An upper cover (1), a middle partition plate (4) and a shell (5) are included. A first air outlet pipe (12) and a second air outlet pipe (13) are arranged on the top of the upper cover (1). A first installing groove (14) is formed in the bottom of the upper cover (1), and a second installing groove (15) is formed in the middle inside. A first separation plate (42) is arranged in the middle partition plate (4), and a third installing groove (410) is formed in the bottom. An installing seam allowance (57) is arranged on thetop of the shell (5), and the interior is provided with a second separation plate (56). The middle partition plate (4) is arranged in the shell (5), and the third installing groove (410) is matched with the second separation plate (56). The upper cover (1) is arranged on the tops of the middle partition plate (4) and the shell (5), the first installing groove (14) is matched with the installing seam allowance (57), and the second installing groove (15) and the first separation plate (42) are matched. By means of the air suction silencer, the air conveying efficiency can be improved, oil emission is reduced, and therefore wide market prospects are achieved.

Owner:CHANGHONG HUAYI COMPRESSOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com