Multi-stage compression type rotary compressor and refrigerating circulating device provided with same

A rotary compressor and compression technology, applied in the field of refrigeration cycle devices and multi-stage compression rotary compressors, can solve problems such as increased costs, worrying environmental problems, and increased refrigerant encapsulation, so as to avoid wear failures and ensure reliable operation. , the effect of reducing oil discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

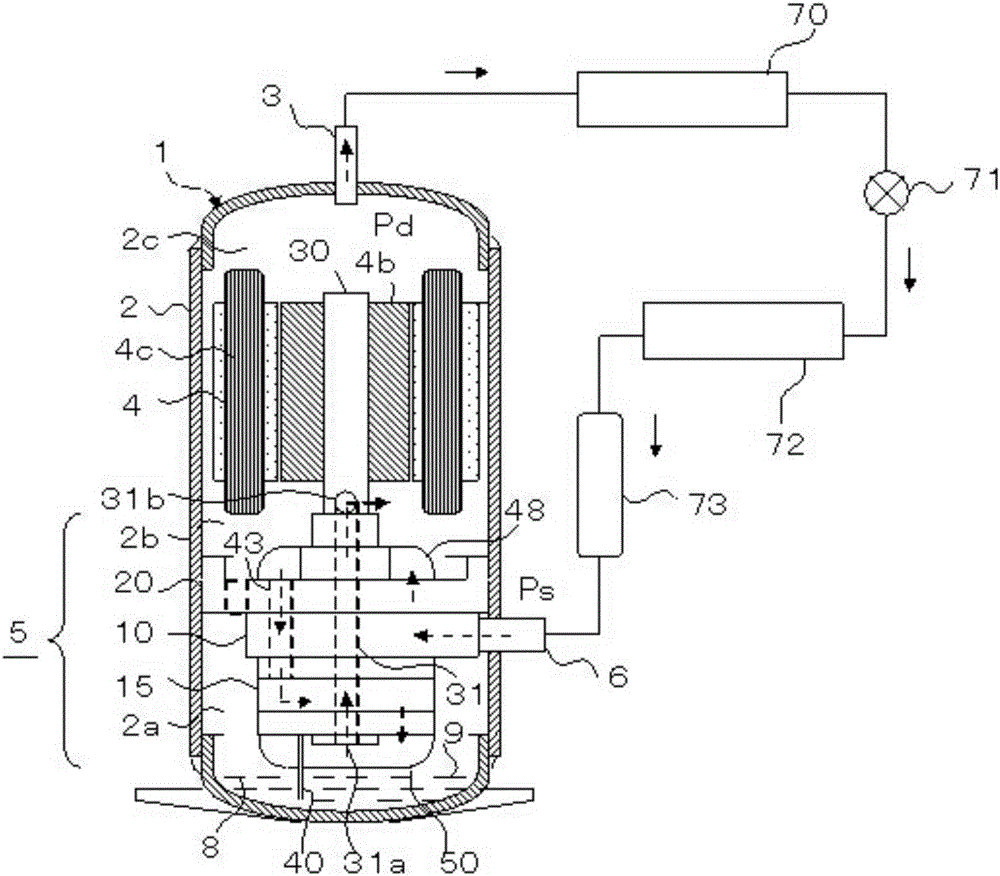

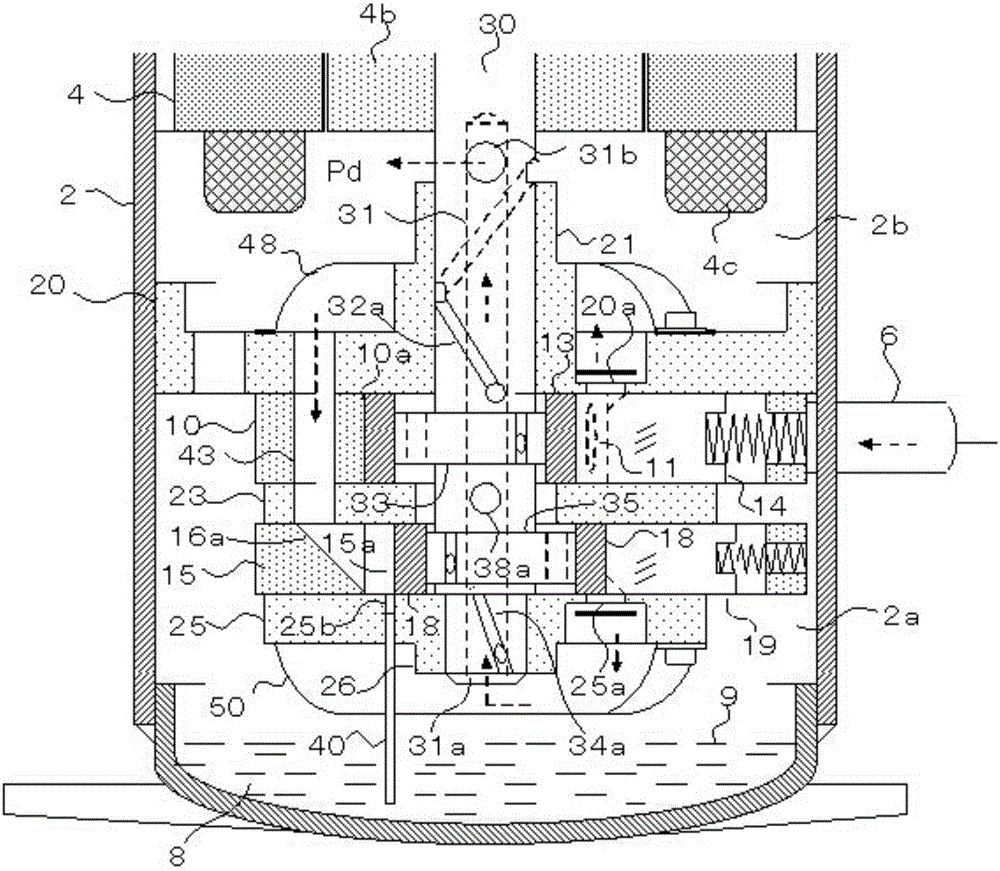

[0051] figure 1 The illustrated two-stage compression rotary compressor 1 includes an inverter-type electric motor 4 (hereinafter referred to as motor 4 ) fixed to the inner peripheral wall of a hermetic casing 2 and a compression mechanism 5 driven by a rotor 4 b. The housing 2 is divided into three chambers by the first end plate 20 of the compression mechanism part 5 and the motor 4 , a compression mechanism cavity 2 a , a motor lower cavity 2 b and a motor upper cavity 2 c. The oil sump 8 at the bottom of the compression mechanism chamber 2a has lubricating oil 9 (hereinafter simply referred to as oil 9).

[0052] The low-pressure gas drawn in from the intake pipe 6 is compressed in the first cylinder 10 to become an intermediate-pressure gas, and is discharged to the sealed first muffler 48 . The intermediate-pressure gas is sucked into the second cylinder 15 through the communication hole 43 , becomes high-pressure gas, and is discharged to the second muffler 50 . As w...

Embodiment 2

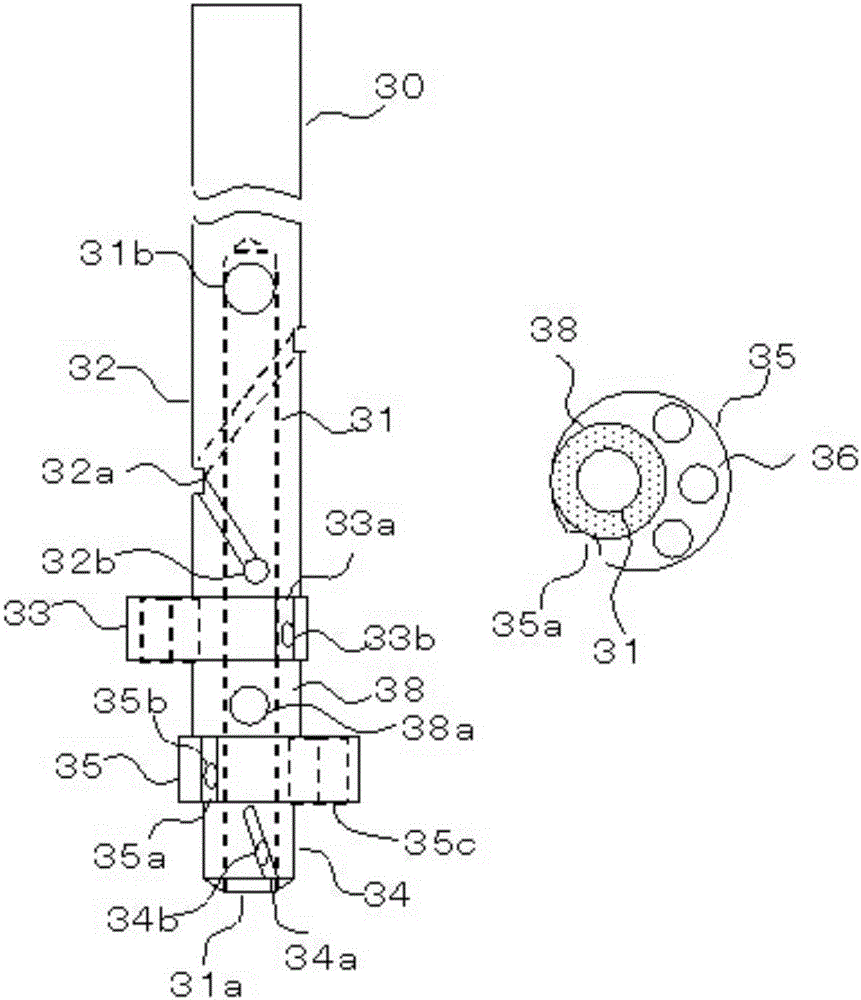

[0082] Image 6 It is a two-stage compression rotary compressor 1 and a refrigeration cycle diagram connected to the compressor. The low-pressure gas sucked in from the intake pipe 6 is compressed in the first cylinder 10 to become an intermediate-pressure oil-containing refrigerant gas, and is discharged to the first muffler 51 . Next, the intermediate-pressure oil-containing refrigerant gas passes through the through hole 36 of the crankshaft 30 to lubricate the sliding parts, then flows from the shaft end hole 31c to the rotating rotor disc 52, and then diffuses toward the motor coil 4c. In other words, the intermediate-pressure oil-containing refrigerant gas is discharged from the first muffler 51 to the motor upper chamber 2c. Therefore, the internal pressure of the casing 2 corresponds to the pressure of the oil-containing refrigerant gas, and is an intermediate pressure.

[0083] The oil-containing refrigerant gas in the upper chamber 2c of the motor passes through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com