Patents

Literature

56results about How to "Guaranteed oil supply" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

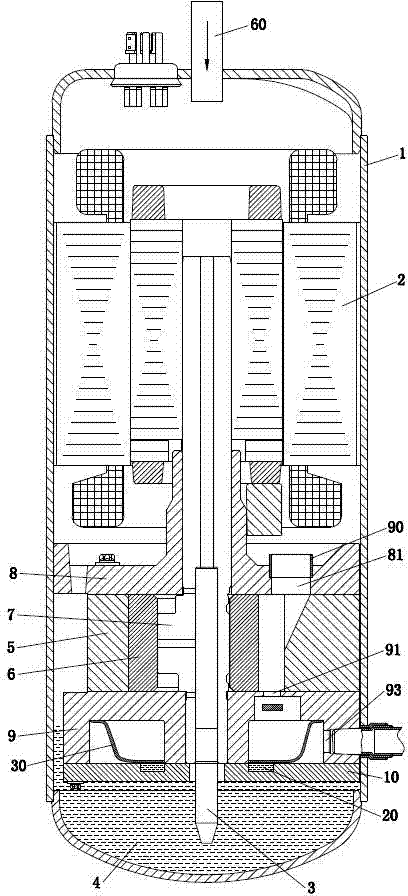

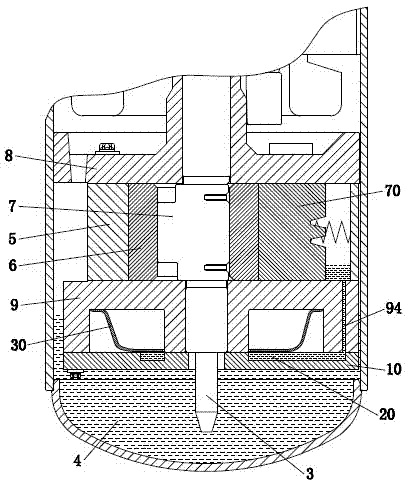

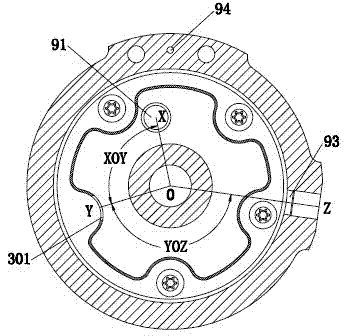

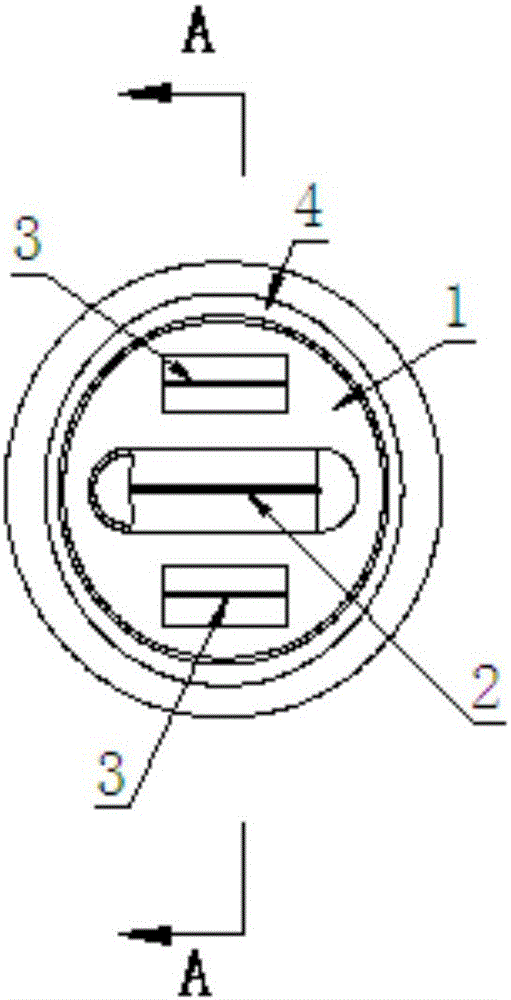

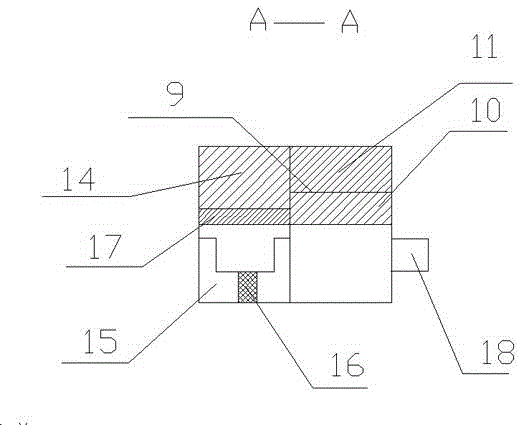

Rotating compressor of low pressure structure in shell

ActiveCN102878082AGuaranteed oil supplyAchieve separationRotary/oscillating piston pump componentsLiquid fuel engine componentsEngineeringPiston

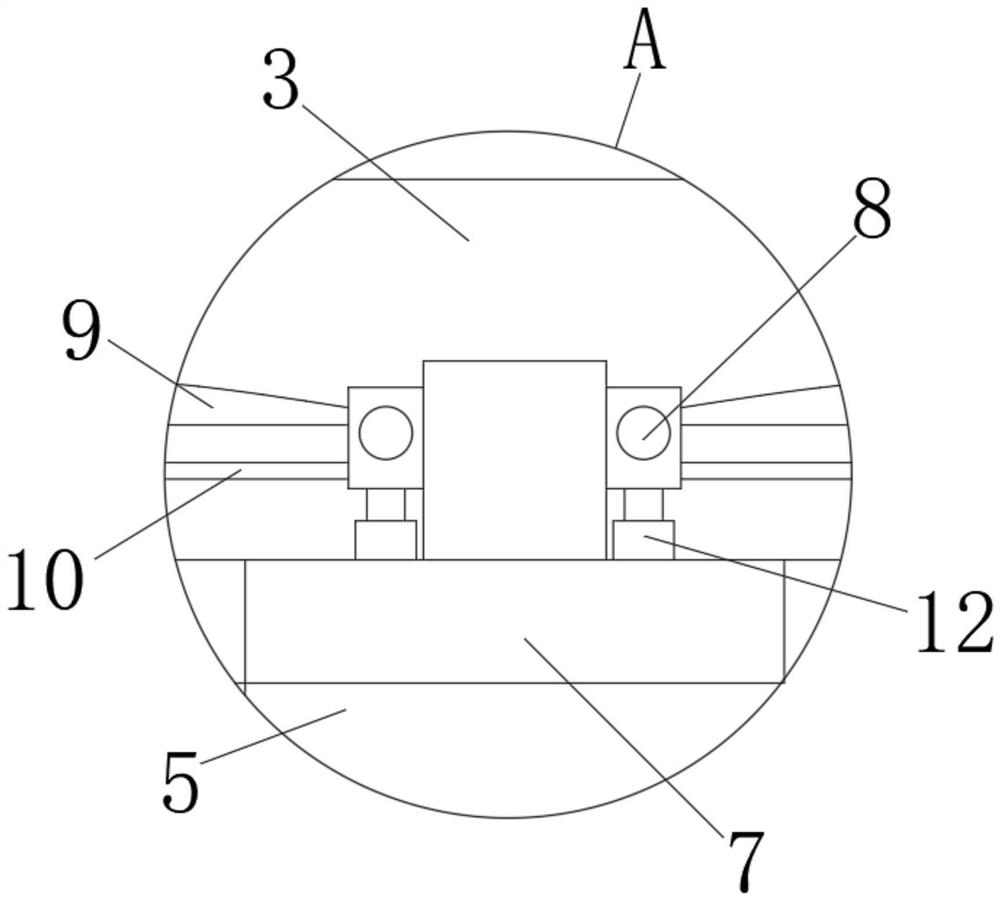

The invention belongs to the technical field of piston type rotating compressors, and discloses a rotating compressor of a low pressure structure in a shell. The invention is characterized in that a cover board (10) is arranged below a lower bearing (9), a closed cavity is arranged between the lower bearing (9) and the cover board (10), a second oil pond (20) is arranged in the cavity, and an air outlet (91) is communicated with an exhaust hole (93) through the cavity; and the lower bearing (9) is provided with an oil supply hole (94) of a backpressure cavity communicated with the second oil pond (20) and a cylinder (5). According to the invention, through the cover board and an oil supply path of the backpressure cavity in the lower bearing, the oil supply of the backpressure cavity is effectively ensured, and the rotating compressor has the advantages of simple structure, good manufacturability, low actual application difficulty, safety and reliability.

Owner:GUANGDONG MEIZHI COMPRESSOR

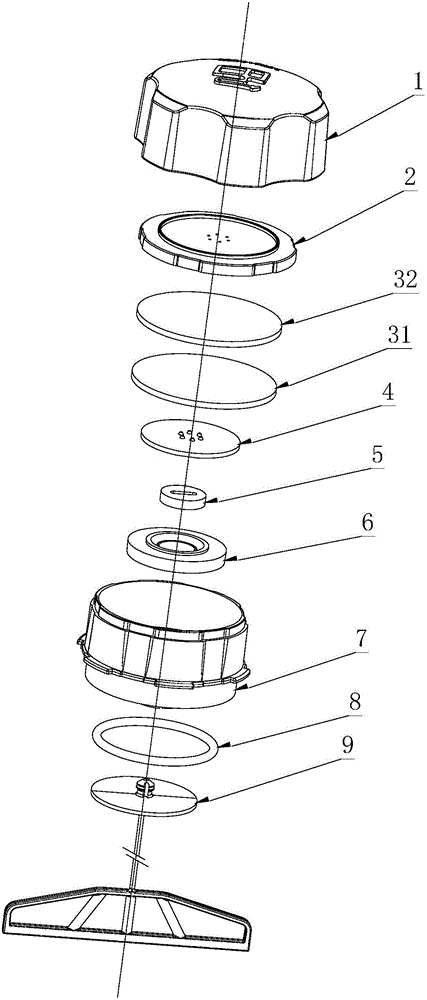

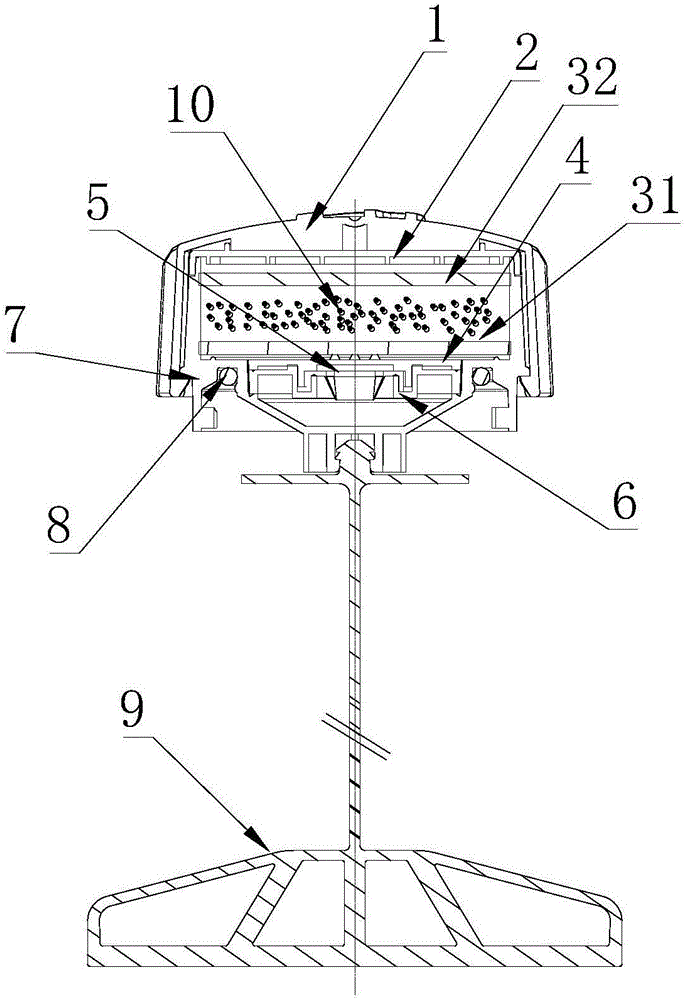

Breathing valve, oil tank cover and oil tank

ActiveCN105805373AAvoid breakage damageEasy to useClosuresCheck valvesAtmospheric pressureBreathing process

The invention relates to a breathing valve, an oil tank cover and an oil tank. The breathing valve for the oil tank cover comprises a valve body. A one-way air inlet part and a one-way exhaust part are arranged on the valve body. When the pressure in the oil tank and outside pressure are balanced, the oil tank is closed, volatile gas in the oil tank cannot be exhausted out, and the environment is protected. When negative pressure is formed in the oil tank, outside air is led into the oil tank through the one-way air inlet part, and balance of the air pressure of the oil tank is ensured. When the pressure in the oil tank is increased, gas in the oil tank is exhausted to the outside through the one-way exhaust part, when the oil tank is inclined or inverted, it is ensured that oil in the oil tank cannot flow out through the breathing valve, and therefore the use safety of the oil tank is ensured.

Owner:CHONGQING BAIKE DINGYU TECH CO LTD

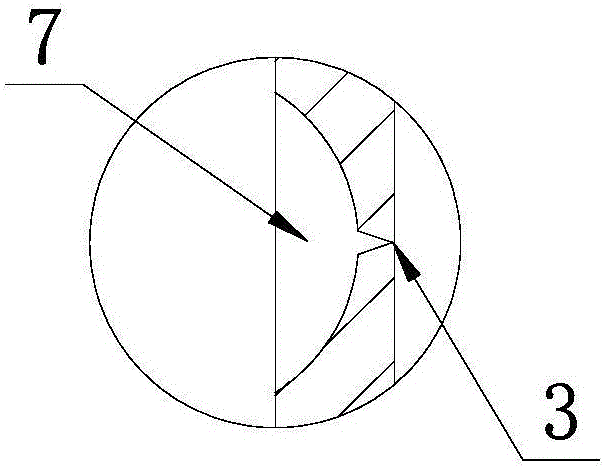

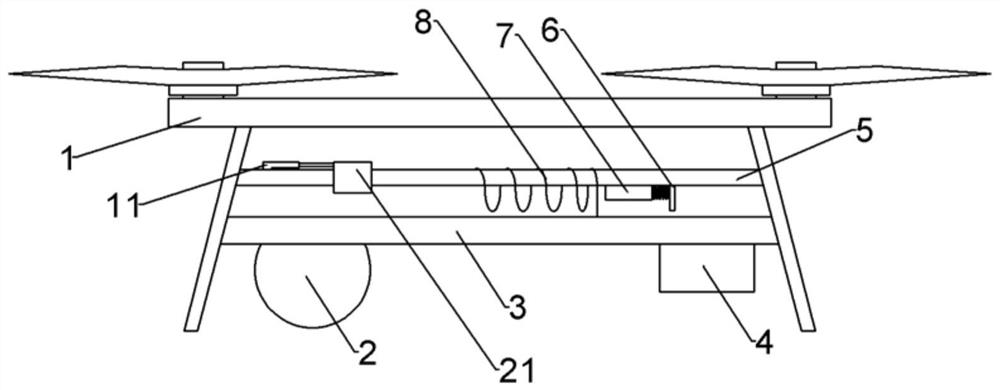

Surveying and mapping unmanned aerial vehicle capable of automatically adjusting balance

ActiveCN109720552AReduce loadSurveying and mapping work went wellAircraft stabilisation by gravity apparatusAircraftsFuel tankSurveyor

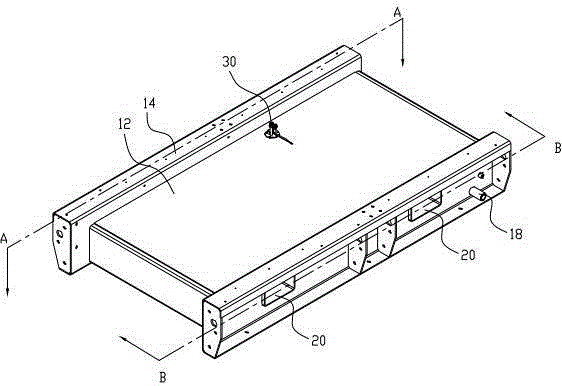

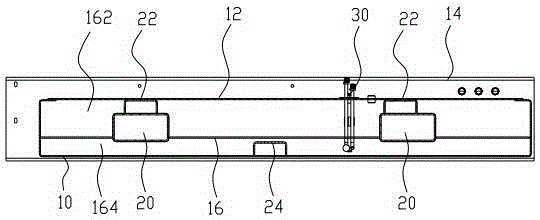

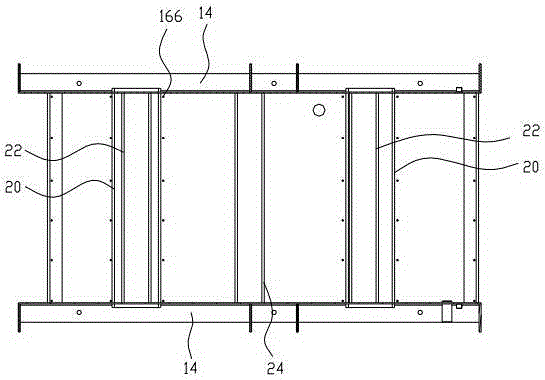

The invention relates to the technical field of surveying and mapping unmanned aerial vehicle equipment. In order to solve a problem that surveying and mapping works of an existing surveying and mapping unmanned aerial vehicle cannot be normally carried out in the using process because centre-of-gravity shift is caused by reducing of the fuel quantity in a fuel tank to generate unbalance, the invention provides a surveying and mapping unmanned aerial vehicle capable of automatically adjusting balance. The surveying and mapping unmanned aerial vehicle capable of automatically adjusting the balance comprises a body mounted with a camera; the body comprises a fuel system for providing a fuel system; the fuel system comprises the fuel tank, wherein the body further comprises a mounting seat; the camera is mounted at one end of the mounting seat; the fuel tank is positioned at the other end of the mounting seat; a mounting cross rod is also arranged on the body; a battery module is slidingly connected to the mounting cross rod; a lead is connected between the battery module and the camera; a spiral section is arranged on the lead; the spiral section externally sleeves one end, close tothe fuel tank, of the mounting cross rod; an iron patch is arranged on one side, facing towards the spiral section, of the battery module; an iron slide block is slidingly connected to the mounting cross rod through an elastic piece; and the slide block is inserted into the spiral section after sliding far away from the fuel tank.

Owner:CHONGQING VOCATIONAL INST OF ENG

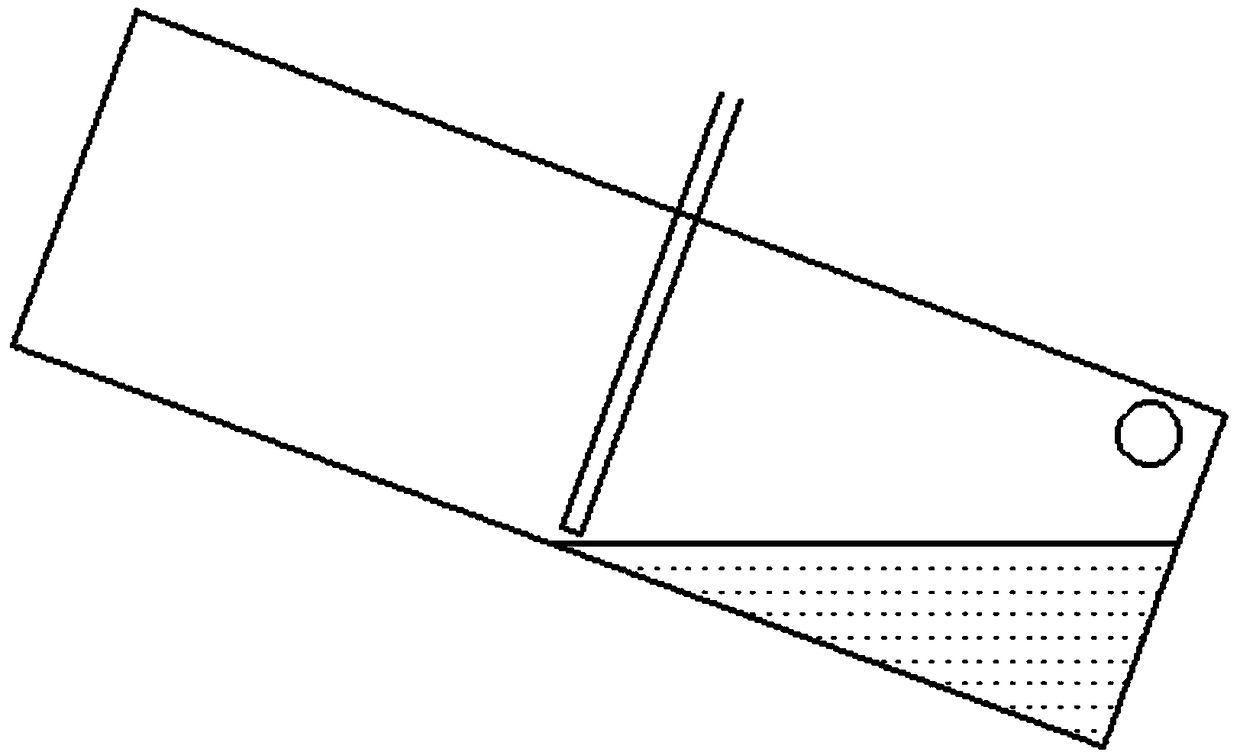

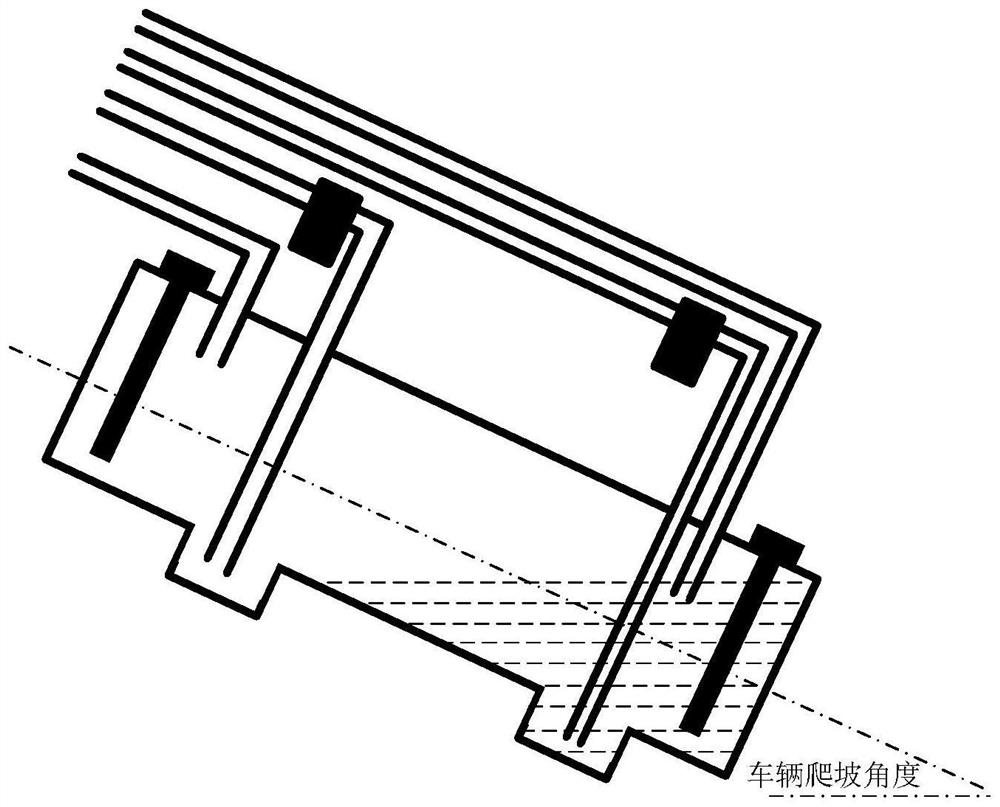

Fuel-tank of motor vehicle

PendingCN108891255AReduced risk of oil failureGuaranteed fuel supplyUnderstructuresFuel supplyShortest distanceFuel tank

A motor vehicle fuel tank It belongs to the field of fuel tank, comprises a tank body and an oil suction pipe, A partition plate is arranged inside the tank body to divide the tank body into a crude oil tank and an oil suction tank, The filling port is located in the crude oil tank, As that space length of the oil suction tank is small than the space length of the crude oil tank, the suction pipeextends into the suction tank to suck fuel, As that oil is supply by extending the oil suction pipe into the oil suction tank with small space length, The risk that the original suction pipe can not suck oil due to the excessively long original tank body can be reduced, and since the liquid level change of the suction tank with the smaller space length is far smaller than that of the original tankwith the larger space length when the whole tank is inclined, the fuel supply can be ensured when the suction pipe can face the gradient of the shorter distance.

Owner:高密市中科容器厂

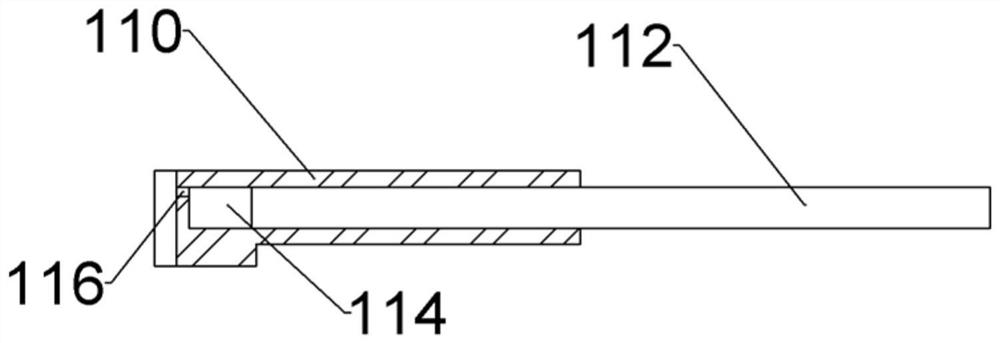

Automatic adaptation-connection device for oil-conveying pipeline

InactiveCN105275905AEasy to operateReduce work intensityServomotor componentsFluid-pressure actuator componentsProcess engineeringOil supply

Disclosed is an automatic adaptation-connection device for an oil-conveying pipeline. The automatic adaptation-connection device comprises the oil-conveying pipeline and an adaptation-connection device; the oil-conveying pipeline is a professional marine oil-conveying pipeline; the oil-conveying pipeline is connected with an inlet-outlet valve; separated oil-conveying pipes are connected to form the oil-conveying pipeline; sealing devices are arranged between the separated oil-conveying pipes; the oil-conveying pipeline is connected with the adaptation-connection device which is a hydraulic control adaptation-connection device; the inside of the oil-conveying pipeline is connected with a hydraulic pump; hydraulic remote-controlled valves are additionally arranged in the positions of an inlet and outlet of the hydraulic pump, and the inlet and outlet are in series connection. The hydraulic remote-controlled valves in an oil supply system of a refueling ship are used for control, so that operation by the crew is simple; the inlet and outlet are in series connection so that other pump ways can be automatically prepared for standby application when any pump breaks down, and normal oil supply for client ships is guaranteed; in consideration of the situation that during hydraulic control, hydraulic oil is extremely prone to be affected by temperature, a temperature control device and a viscosity testing device are arranged in a control pipeline so that viscosity of the hydraulic oil can be controlled whenever possible.

Owner:YANGZHOU KEJIN SHIPYARD

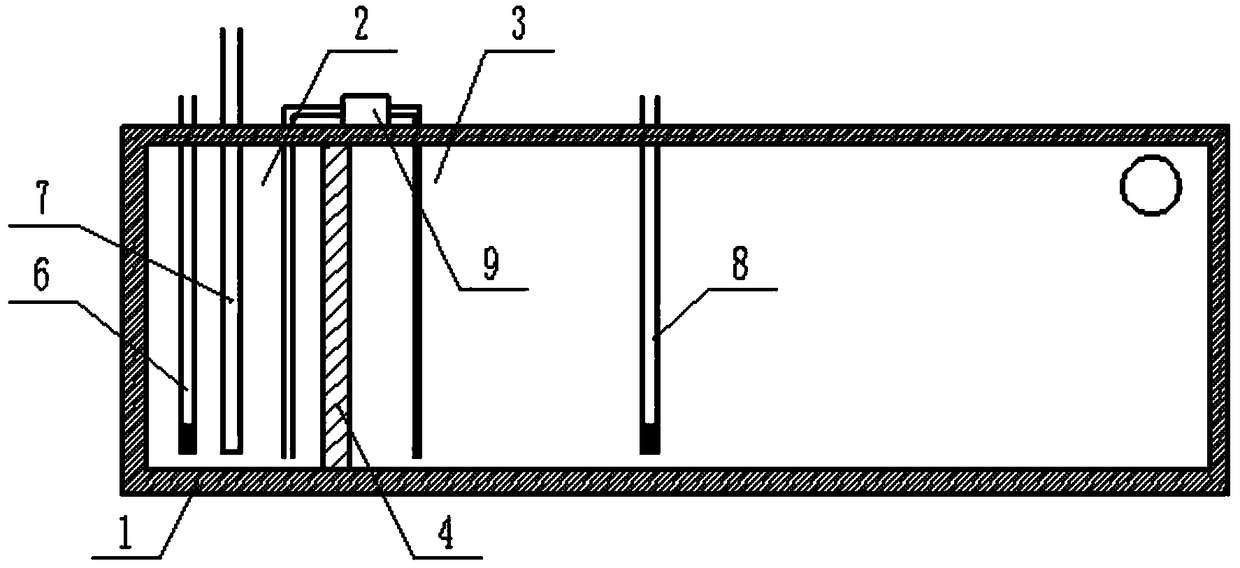

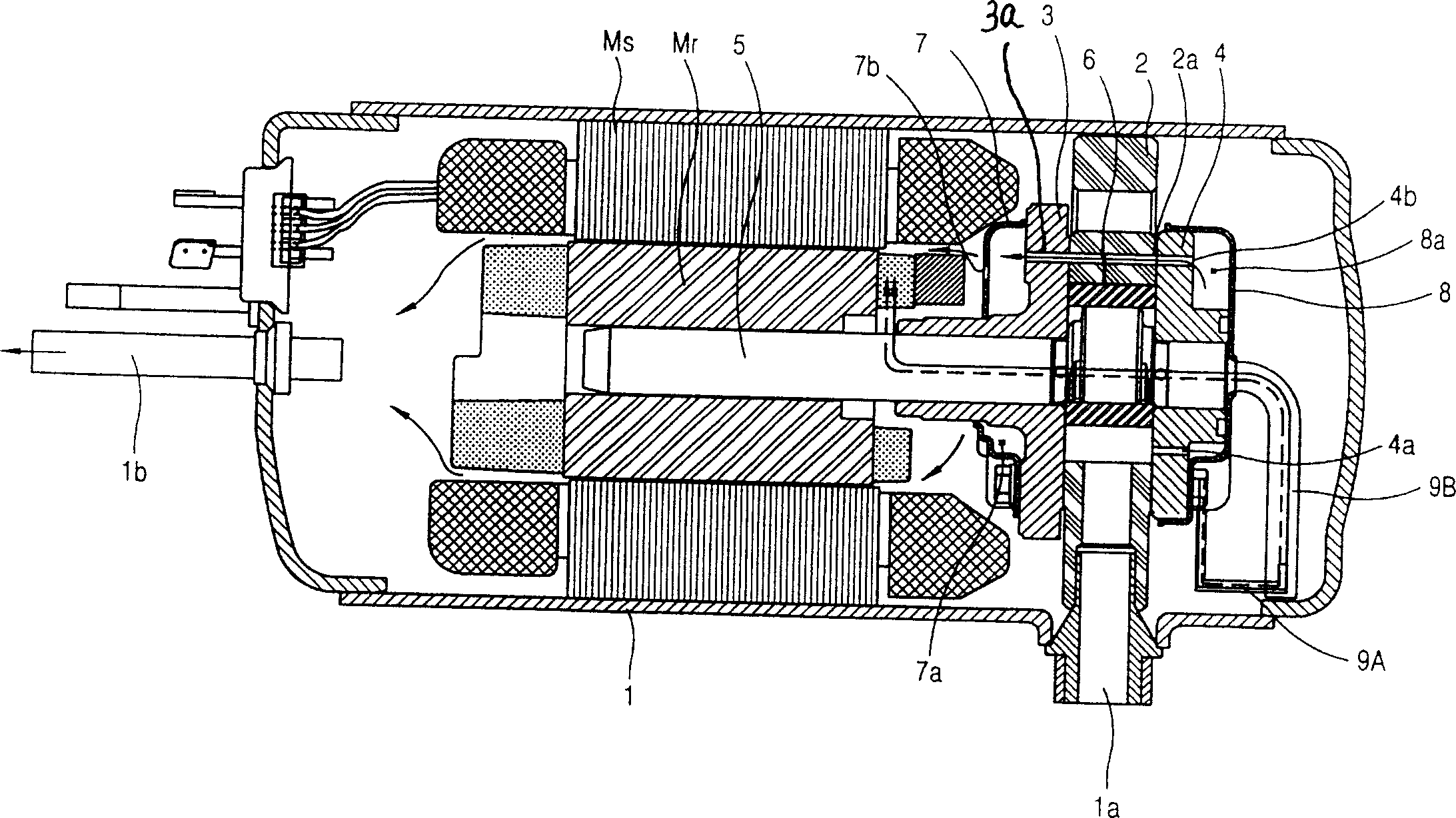

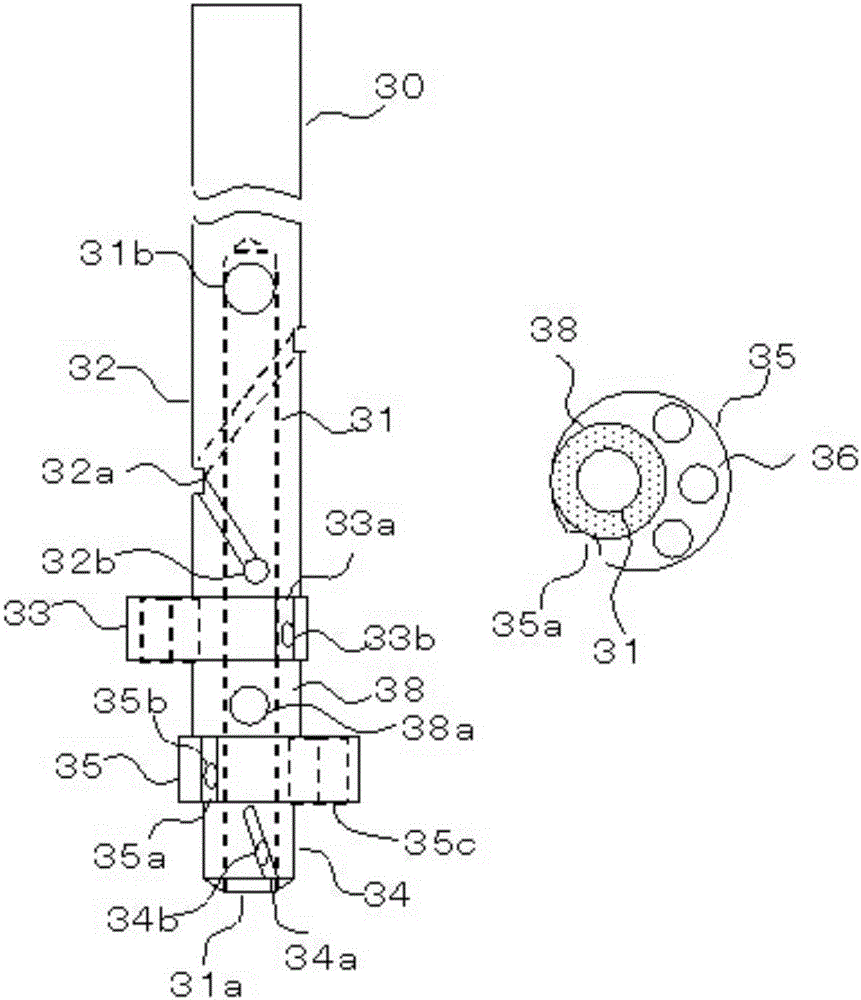

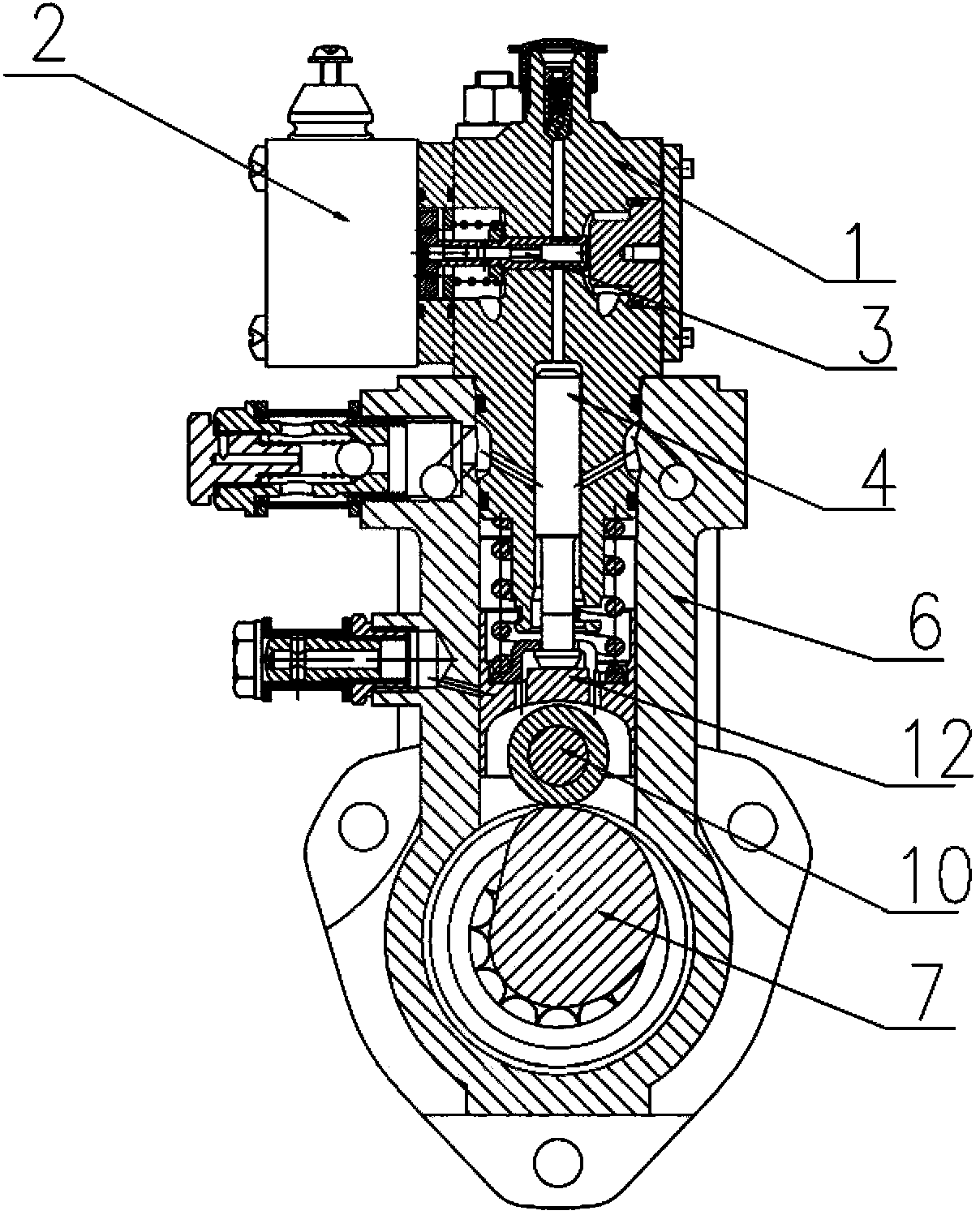

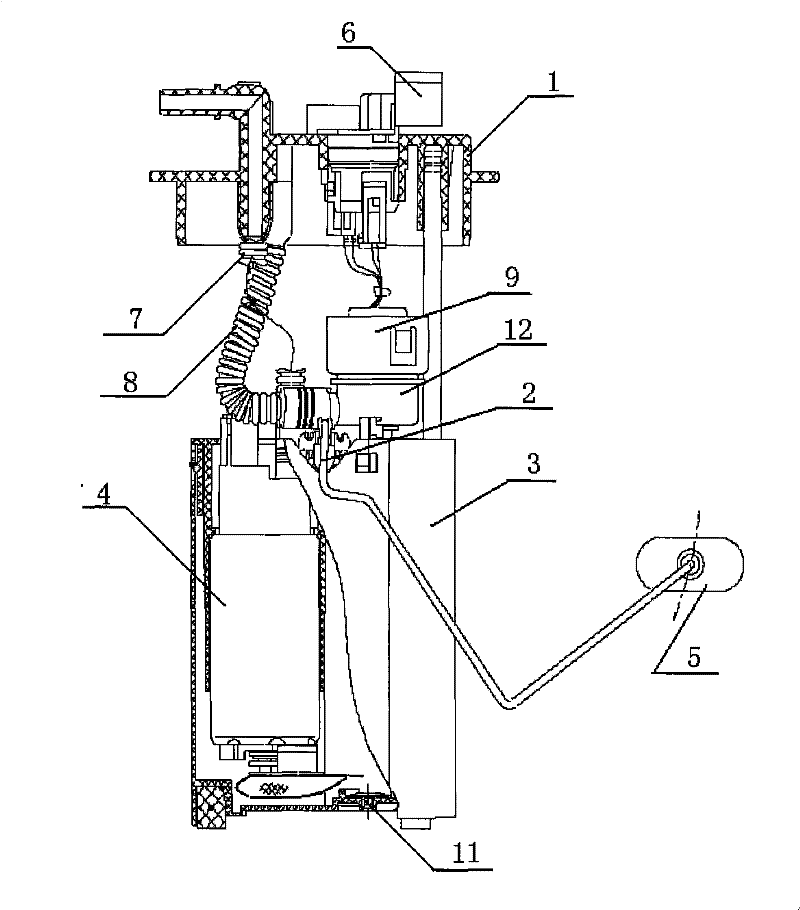

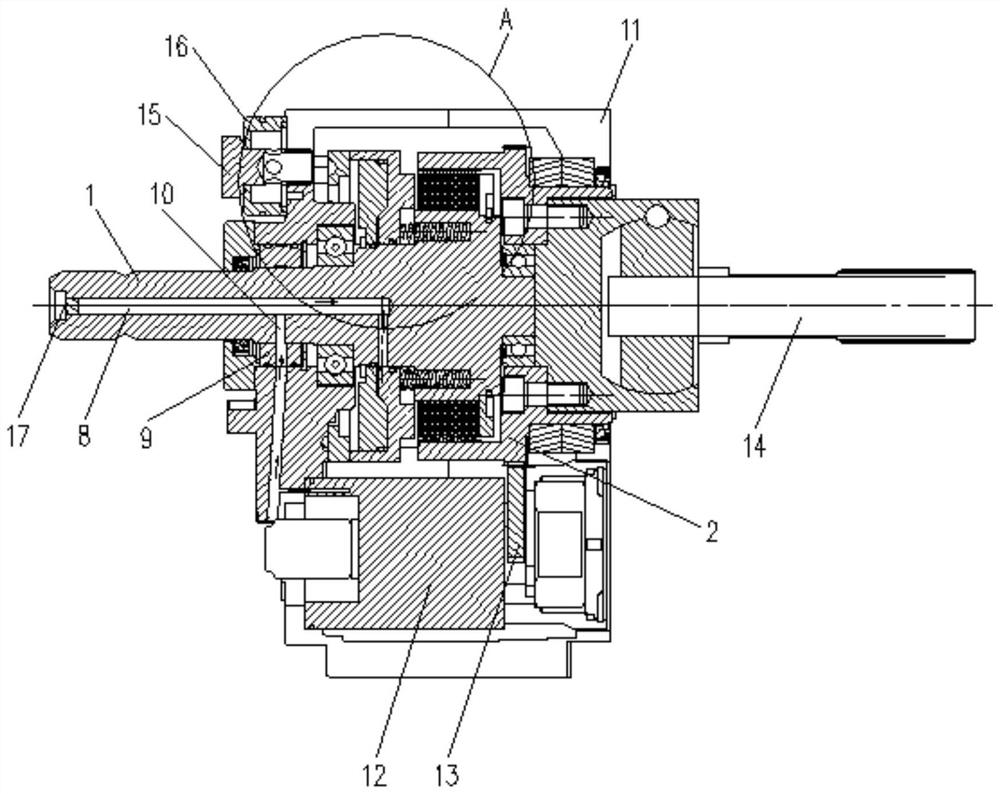

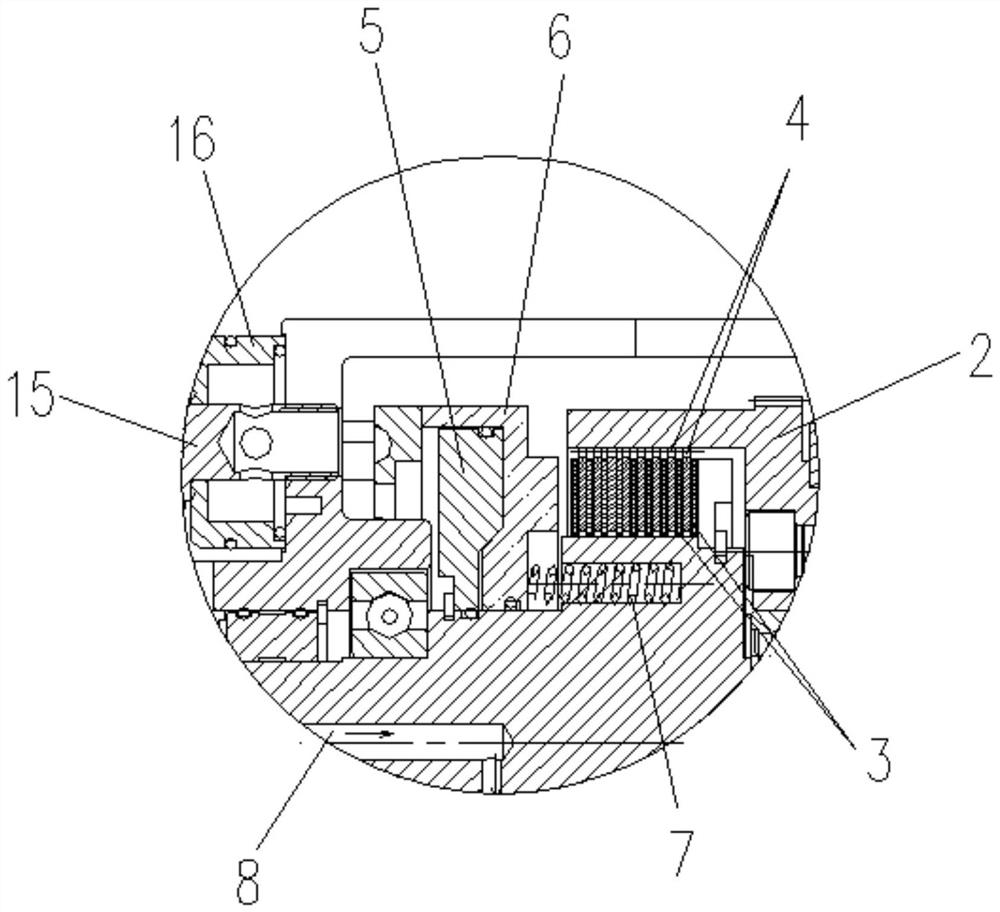

Oil supply device for horizontal compressor

InactiveCN1566697AImprove reliabilityGuaranteed oil supplyRotary piston pumpsRotary piston liquid enginesDifferential pressureOil supply

The invention is about a oil supply device of horizontal compressor, comprising a sealed container with suction pipe and output pipe, in the sealed container, a rotating shaft is arranged connecting the electric mechanism on one end and a compressing mechanism on the other end, one end of the rotating shaft is connected to the oil way, the other end is s immersed in the oil in the sealed container arranged on one side of the compressing mechanism, between the electric mechanism and the compressing mechanism, a differential pressure separating plate is arranged, and on the differential pressure separating plate, and oil hole is arranged, on the cylinder, an oil through hole is arranged, on the electric mechanism, a output tank is arranged, and on outside of the compressing mechanism, an oil cover connected to at least one oil guiding pipe is mounted. The invention improved the lubricating condition and simplified the part structure.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

Carbon tank fuel tank cap assembly

InactiveCN106523215ANot easy to spillGuaranteed oil supplyGas treatmentNon-fuel substance addition to fuelFilling materialsFuel tank

The invention relates to a carbon tank fuel tank cap assembly. The carbon tank fuel tank cap assembly comprises an outer cap and an inner cap. A cavity with an upper end opening is formed in the inner cap, the outer cap is arranged above the inner cap, and the upper end opening of the cavity is covered by the outer cap; a lower vent cap is arranged in the cavity, and the cavity is divided into a filling cavity and a volume cavity by the lower vent cap; the filling cavity is located above the volume cavity, the filling cavity is filled with absorption filling materials, and through holes are formed in the middle of the lower vent cap; a breathing valve used for being automatically opened when the air pressure of the filling cavity and the air pressure of the volume cavity are unbalanced is arranged on the through holes, a first air vent hole is formed in the bottom surface of the volume cavity, and a second air vent hole is formed in the bottom surface of the filling cavity; and an outward discharge channel used for fuel gas volatilizing in a fuel tank is formed by the first air vent hole, the breathing valve and the second air vent hole in sequence. According to the carbon tank fuel tank cap assembly, fuel gas and fuel are not prone to overflowing while the air pressure balance in the fuel tank with a fuel tank cap is guaranteed since the gas discharge channel is automatically opened by the breathing valve when inner and outer air pressure of the fuel tank is unbalanced, and air can also smoothly enter the fuel tank, so that normal fuel supply is guaranteed.

Owner:CHONGQING BAIKE DINGYU TECH CO LTD

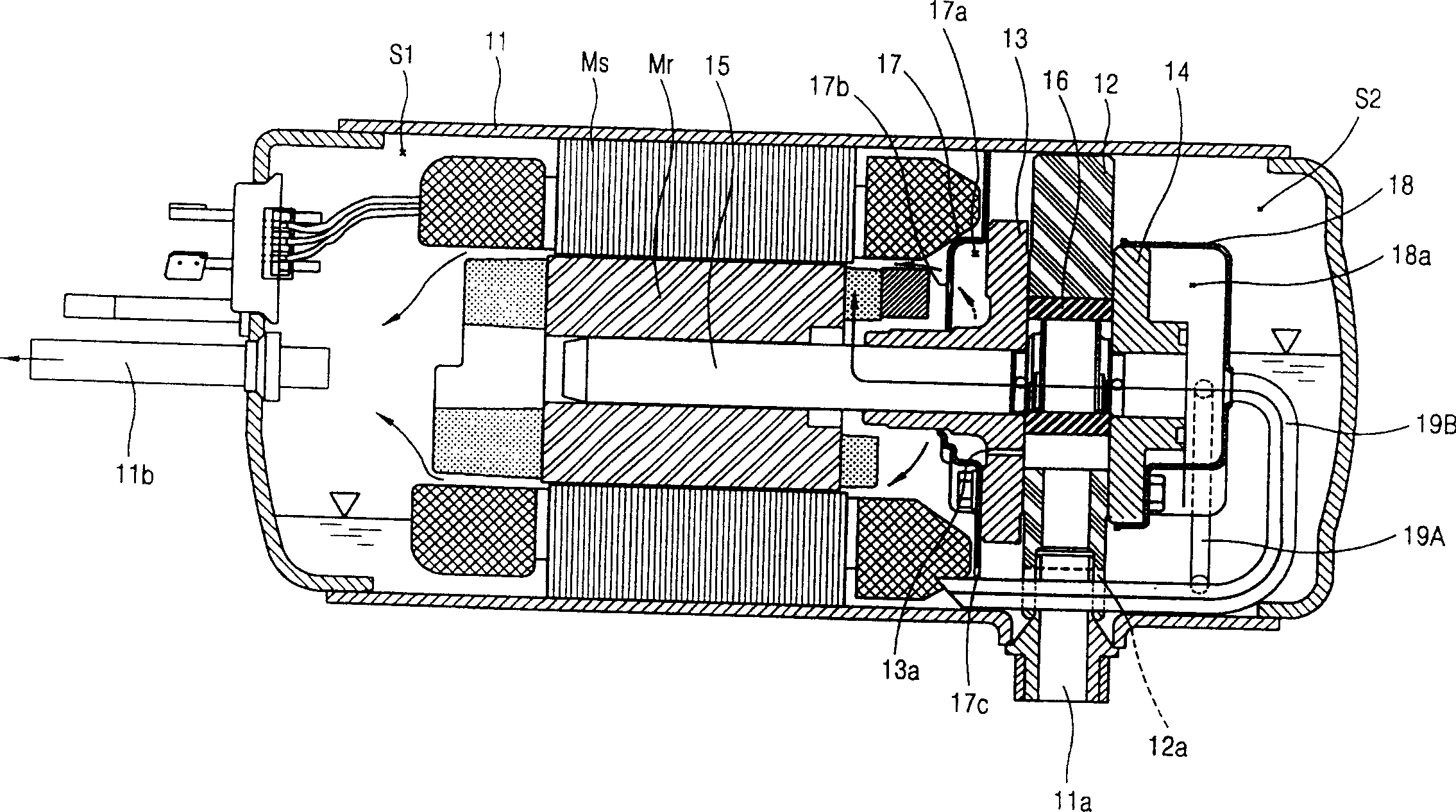

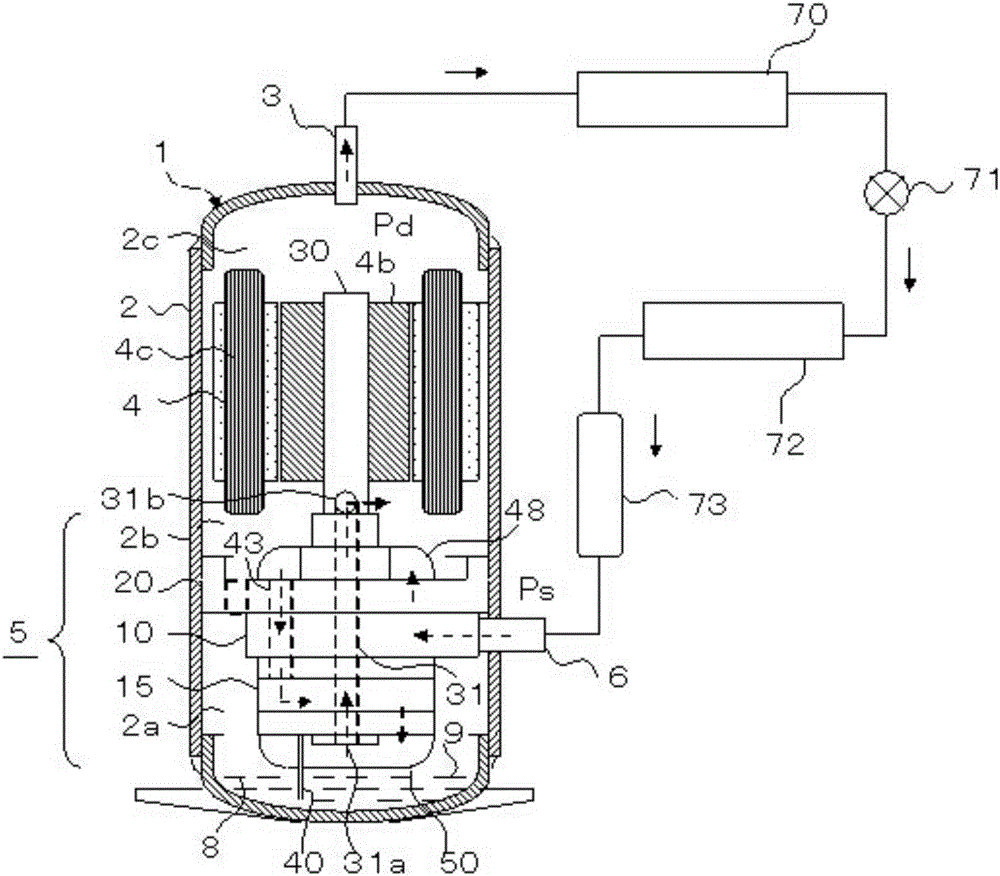

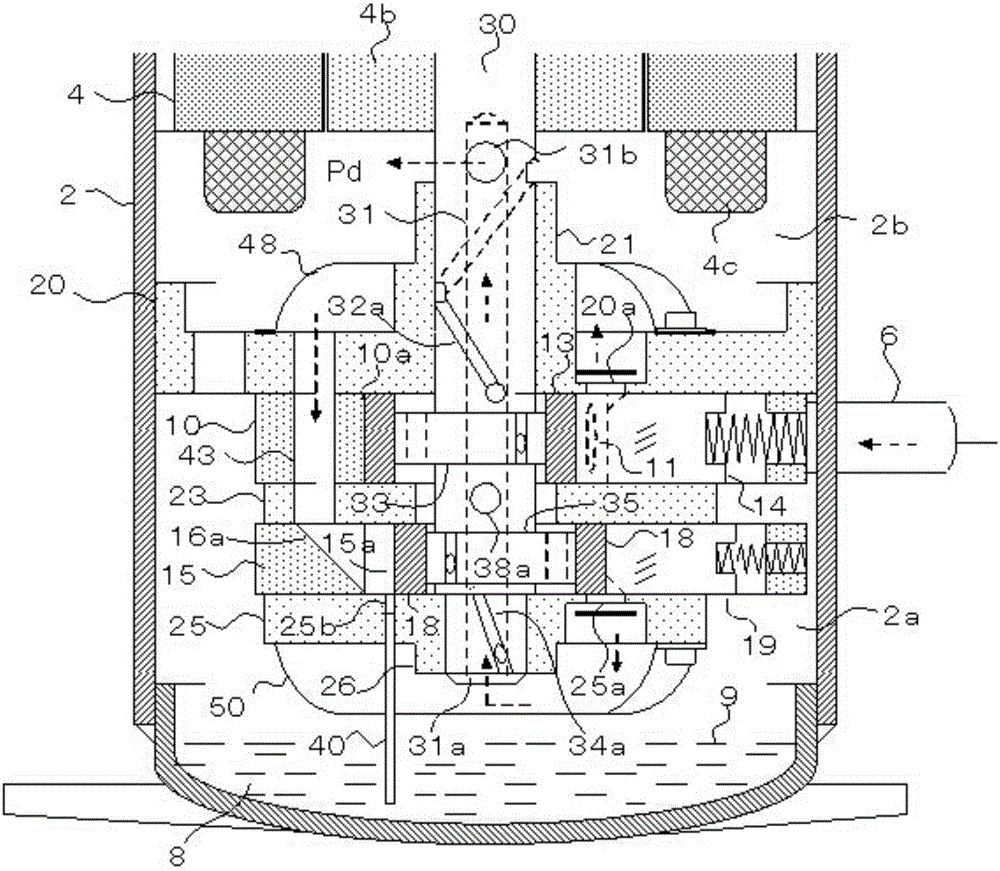

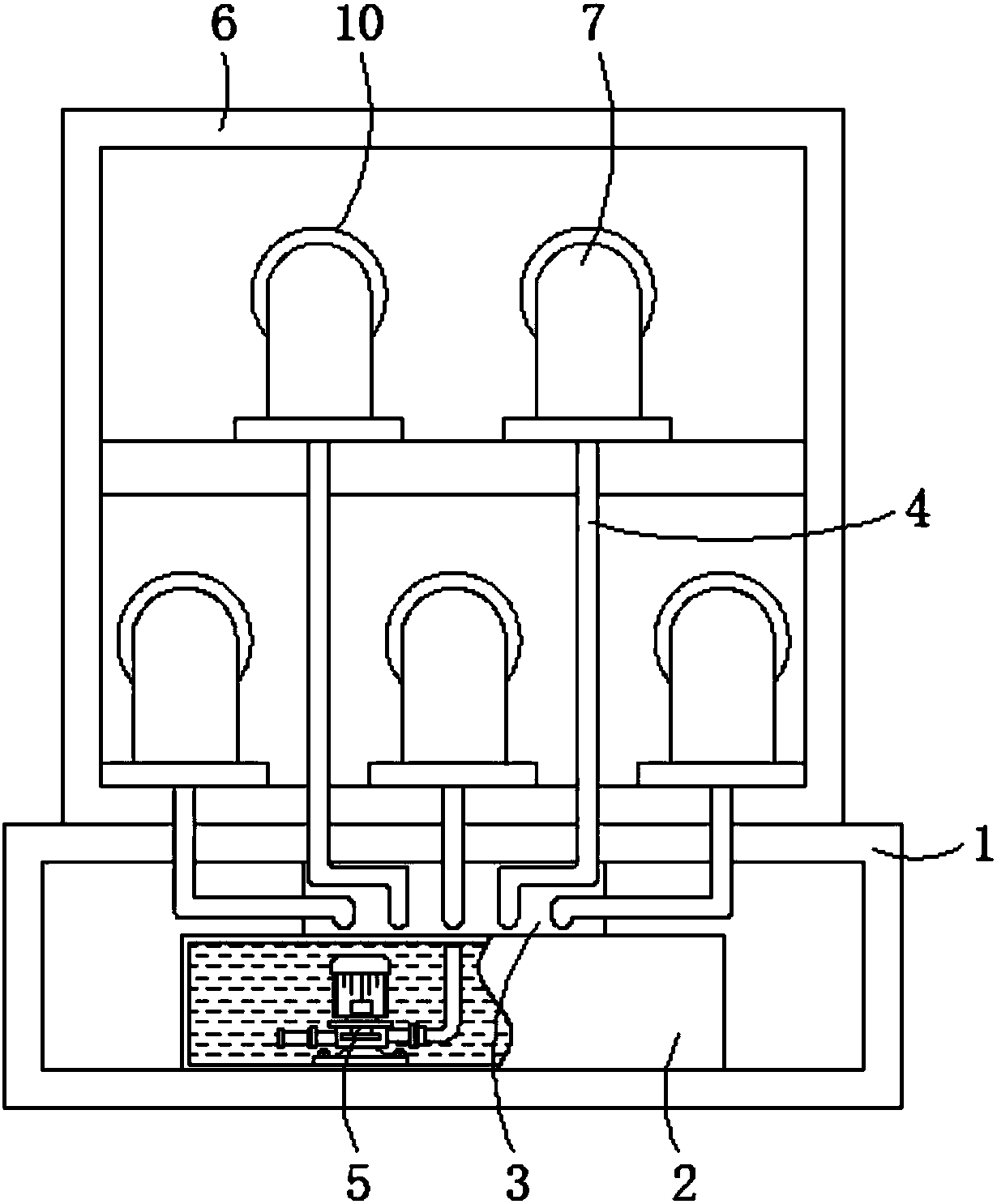

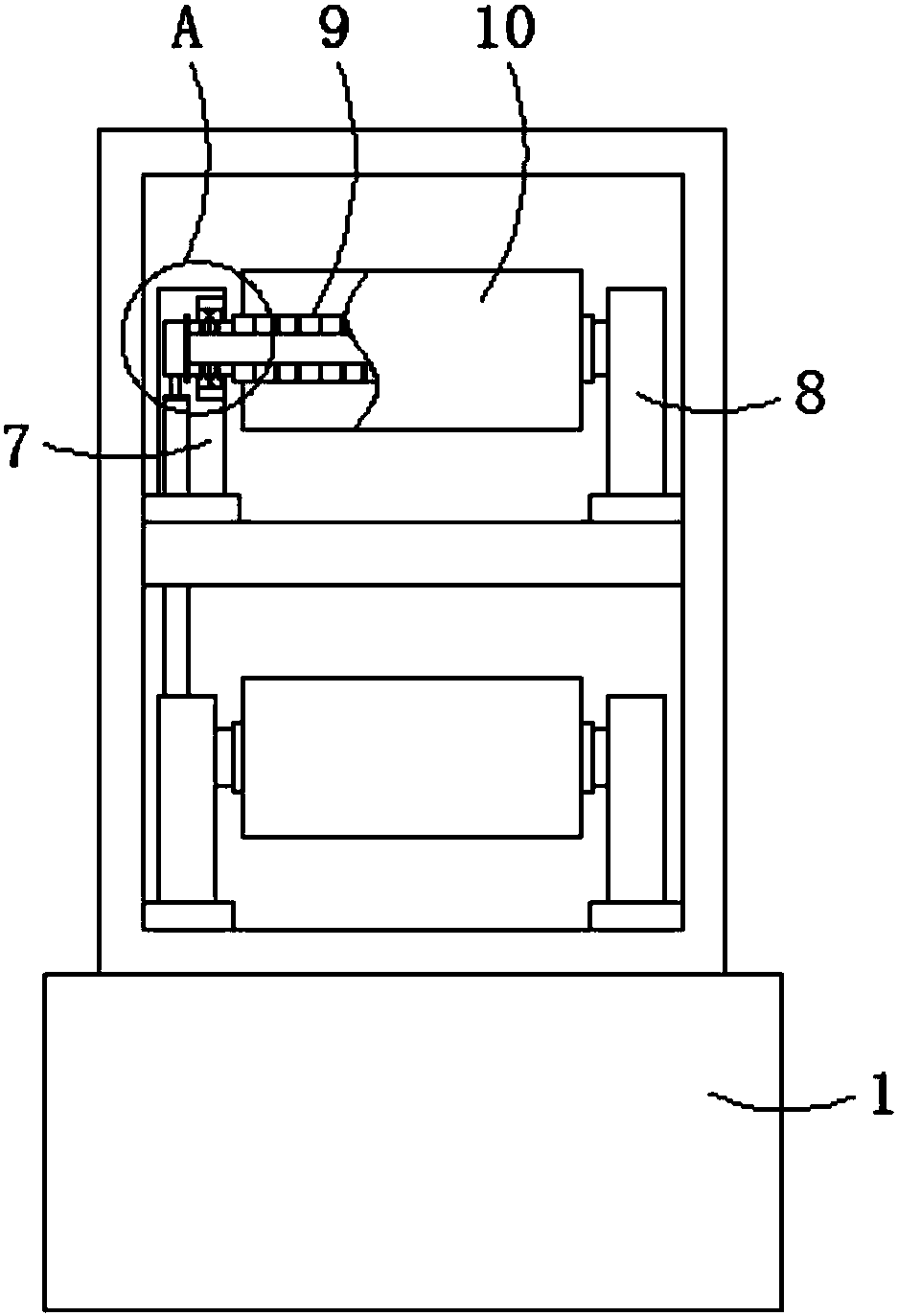

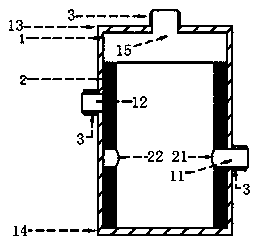

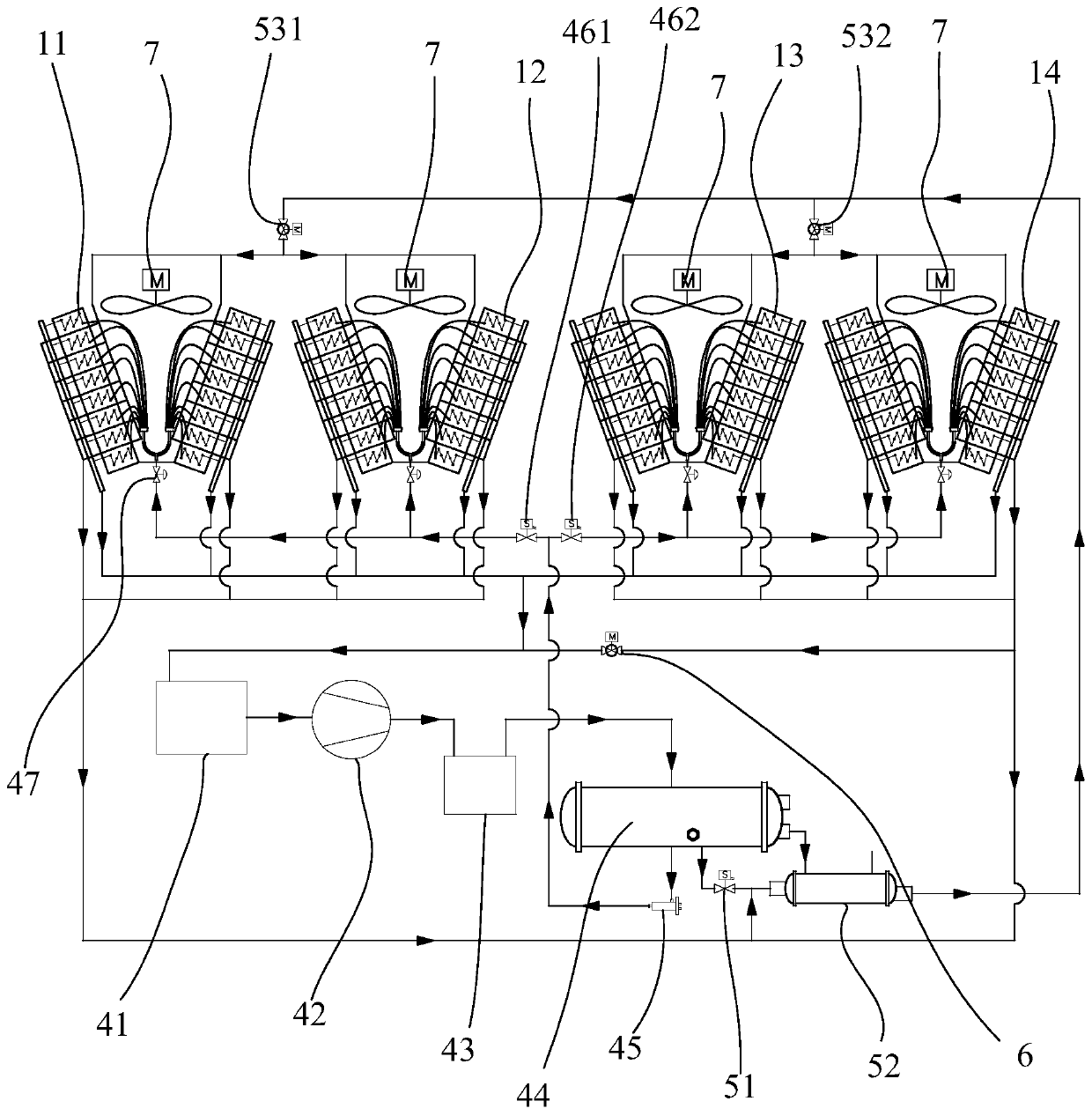

Multi-stage compression type rotary compressor and refrigerating circulating device provided with same

InactiveCN106382227AReduce oil dischargeGuaranteed oil seal volumeRotary/oscillating piston combinations for elastic fluidsCompression machines with non-reversible cycleEngineeringCrankshaft

The invention discloses a multi-stage compression type rotary compressor and a refrigerating circulating device provided with the same. An electric motor and a multi-stage compression type compression mechanism part are accommodated in a sealed housing of the multi-stage compression type rotary compressor; the compression mechanism part comprises at least two air cylinders, a crankshaft, a bearing and a lubricating path; each air cylinder is equipped with a compression cavity; an eccentric revolving piston is arranged in each compression cavity; the crankshaft is used for driving all the pistons to rotate; the bearing is in sliding fit with the crankshaft; and oil-containing refrigerant gas discharged from one compression cavity passes through the lubricating path which is arranged along the revolving axis of the crankshaft to at least lubricate a sliding fit gap part between the crankshaft and the bearing. According to the embodiment of the invention, the multi-stage compression type rotary compressor can effectively lubricate the crankshaft to reduce oil discharge amount of the compressor, so that liquid level of the lubricating oil in an oil storage slot is not greatly reduced.

Owner:GUANGDONG MEIZHI COMPRESSOR +1

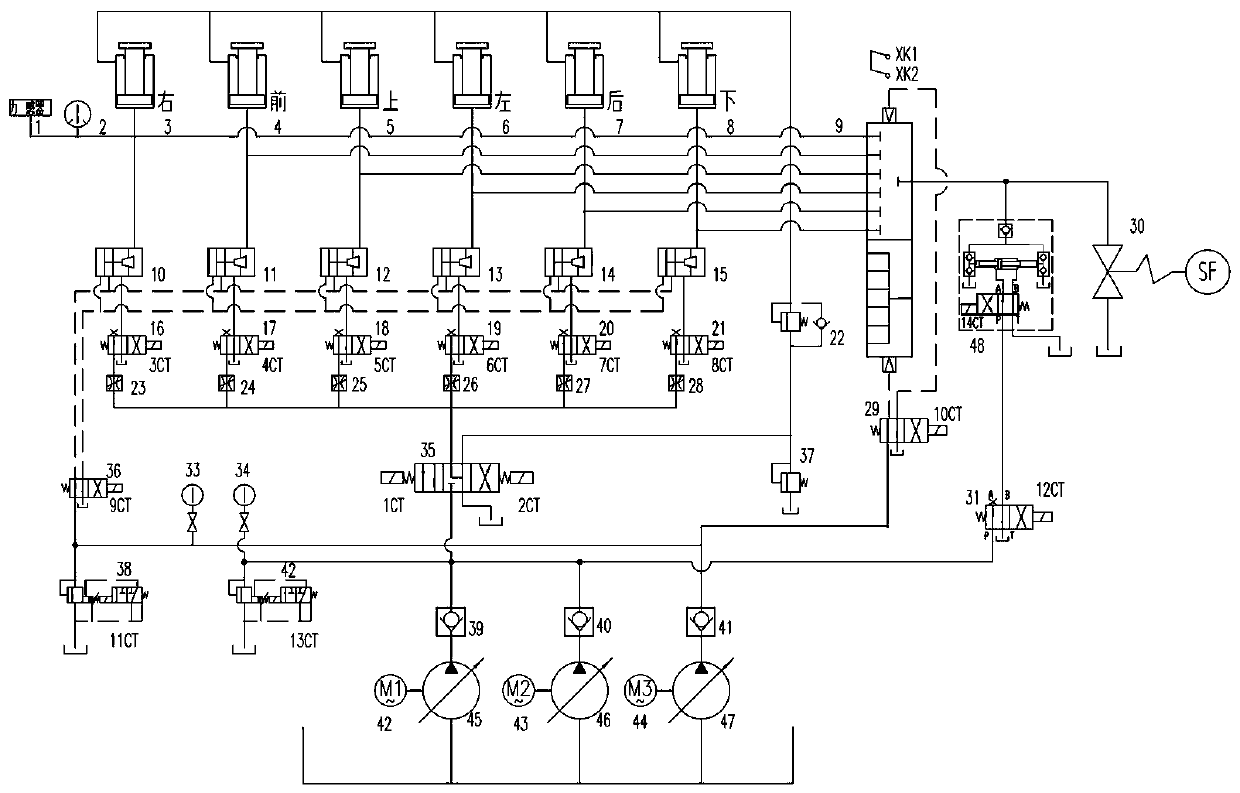

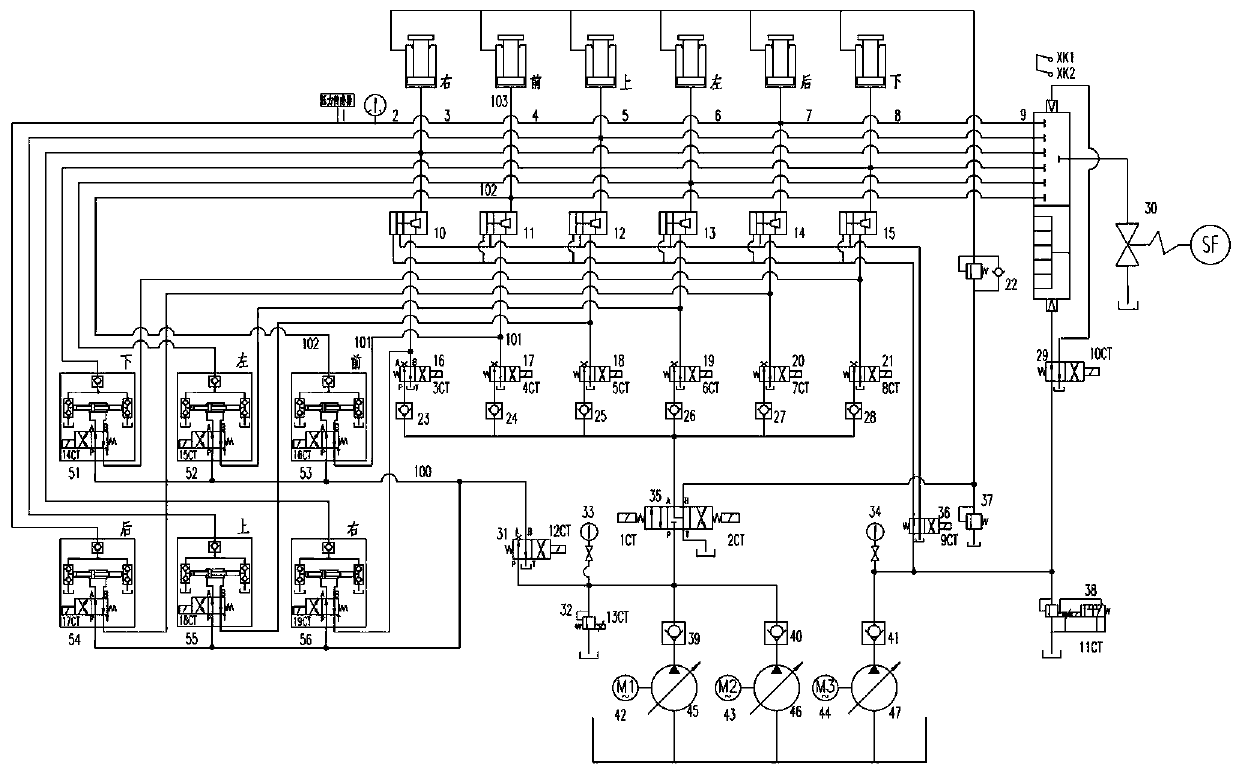

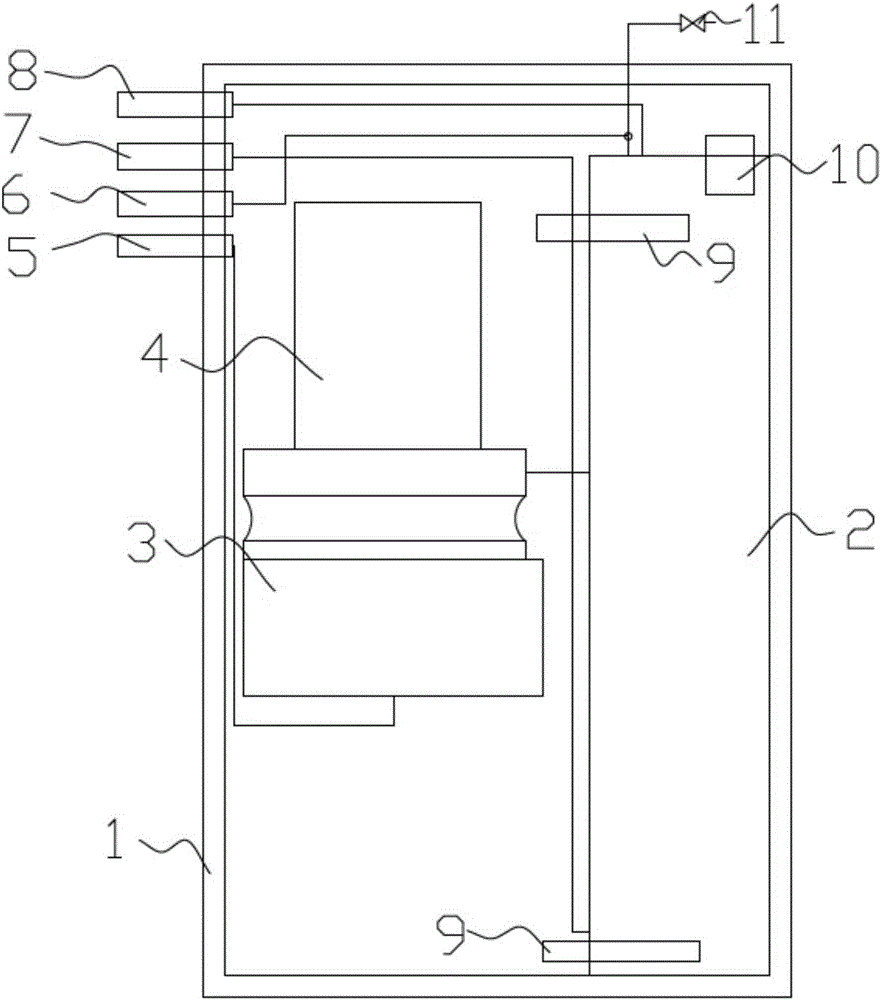

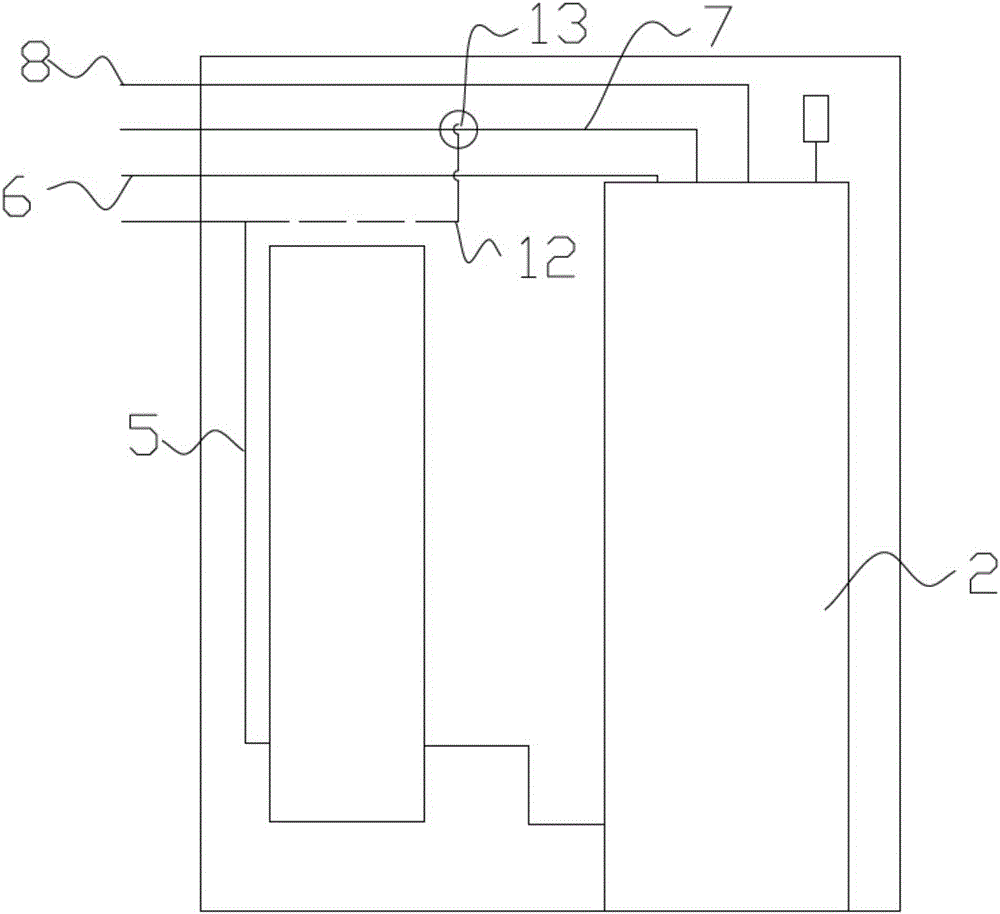

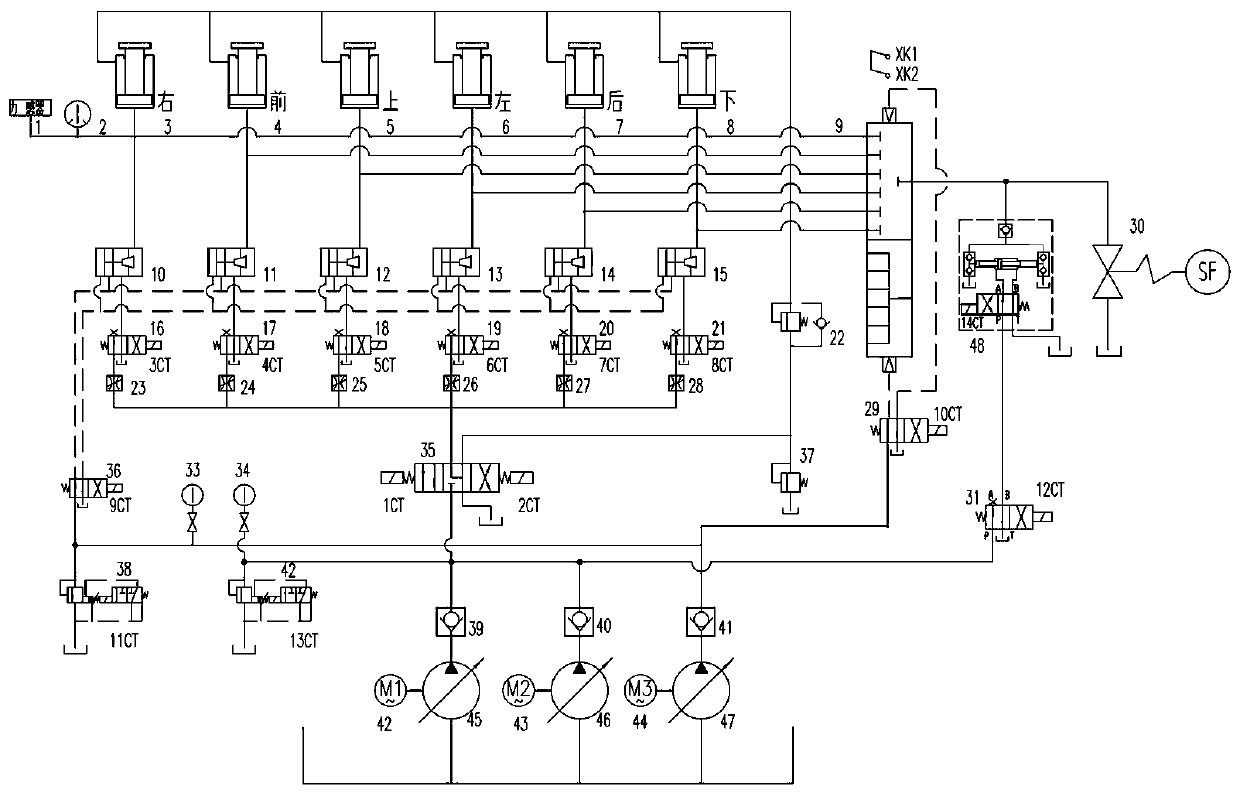

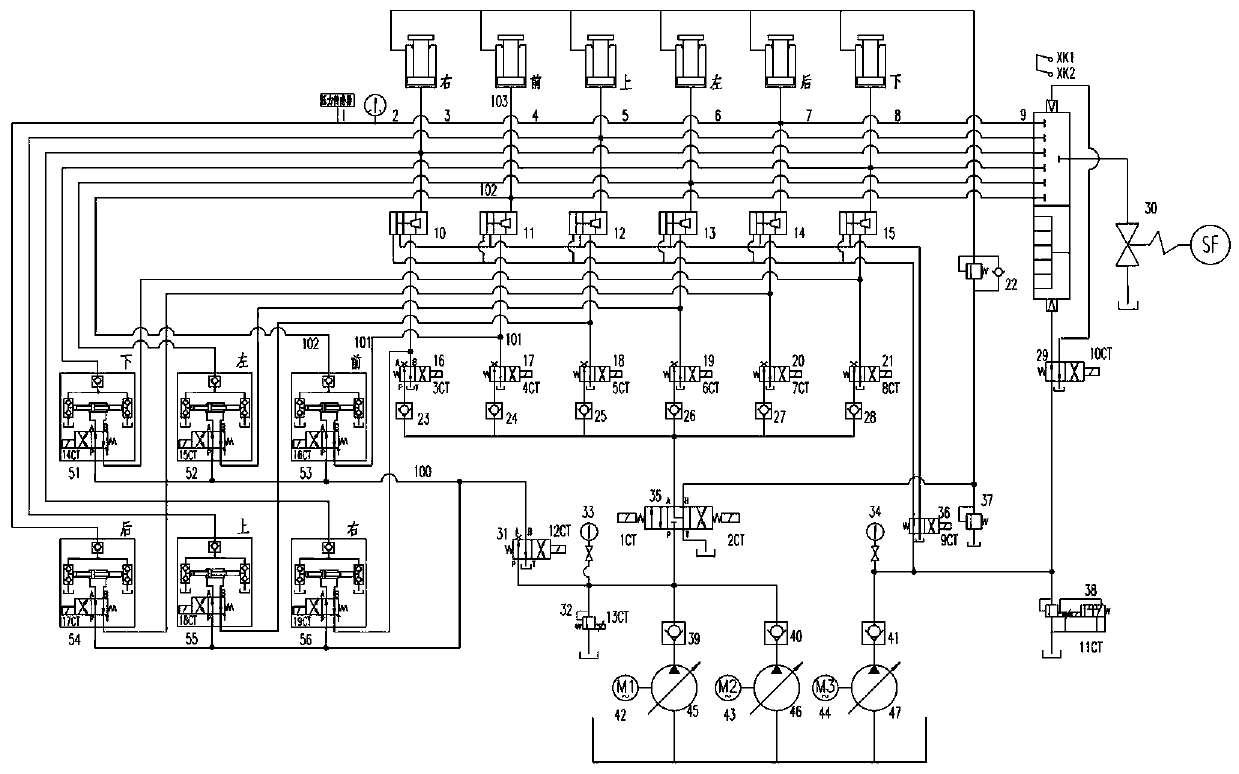

Synchronous control system for hydraulic oil cylinder of hexahedral jacking machine

ActiveCN110864021AHigh flexibilityGuaranteed accuracyServomotorsServometer circuitsHydraulic ramControl system

The invention discloses a synchronous control system for a hydraulic oil cylinder of a hexahedral jacking machine. The synchronous control system comprises single-cylinder oil supply pipelines and reciprocating superchargers, which are in one-to-one correspondence to working oil cylinders, wherein ultrahigh-pressure hydraulic-control one-way valves are arranged on the single-cylinder oil supply pipelines; single-cylinder one-way valves are arranged on oil inlets of the single-cylinder oil supply pipelines; high-pressure plunger piston oil discharge holes of the six reciprocating superchargersare connected to outlets of the ultrahigh-pressure one-way valves after being connected in parallel, solenoid valve T ports of the six reciprocating superchargers are connected to the inlets of the ultrahigh-pressure hydraulic-control one-way valves in parallel, and low-pressure piston exhausted oil of the reciprocating superchargers flows out from the solenoid valve T ports of the reciprocating superchargers, and is pressed into the inlets of the ultrahigh-pressure hydraulic-control one-way valves after being accessed in parallel. The synchronous control system can guarantee synchronous displacement control precision of six-cylinder equal-volume oil supply, and enables synchronous control precision to reach 0.1mm-0.2mm; and moreover, the reciprocating superchargers can be taken as an ultrahigh-pressure oil source for loading oil pressure of a working oil cylinder to working pressure being 120 MPa. The synchronous control system can realize precisely controlling six-cylinder synchronous displacement in a liquid filling process and an ultrahigh-pressure process.

Owner:ZHENGZHOU RES INST FOR ABRASIVES & GRINDING CO LTD

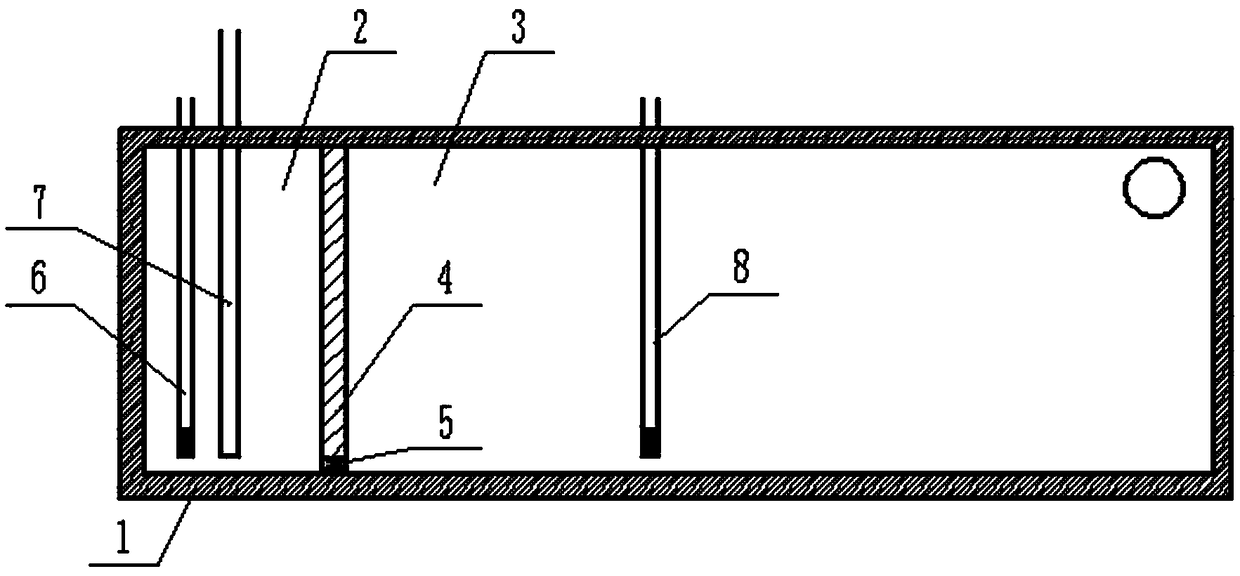

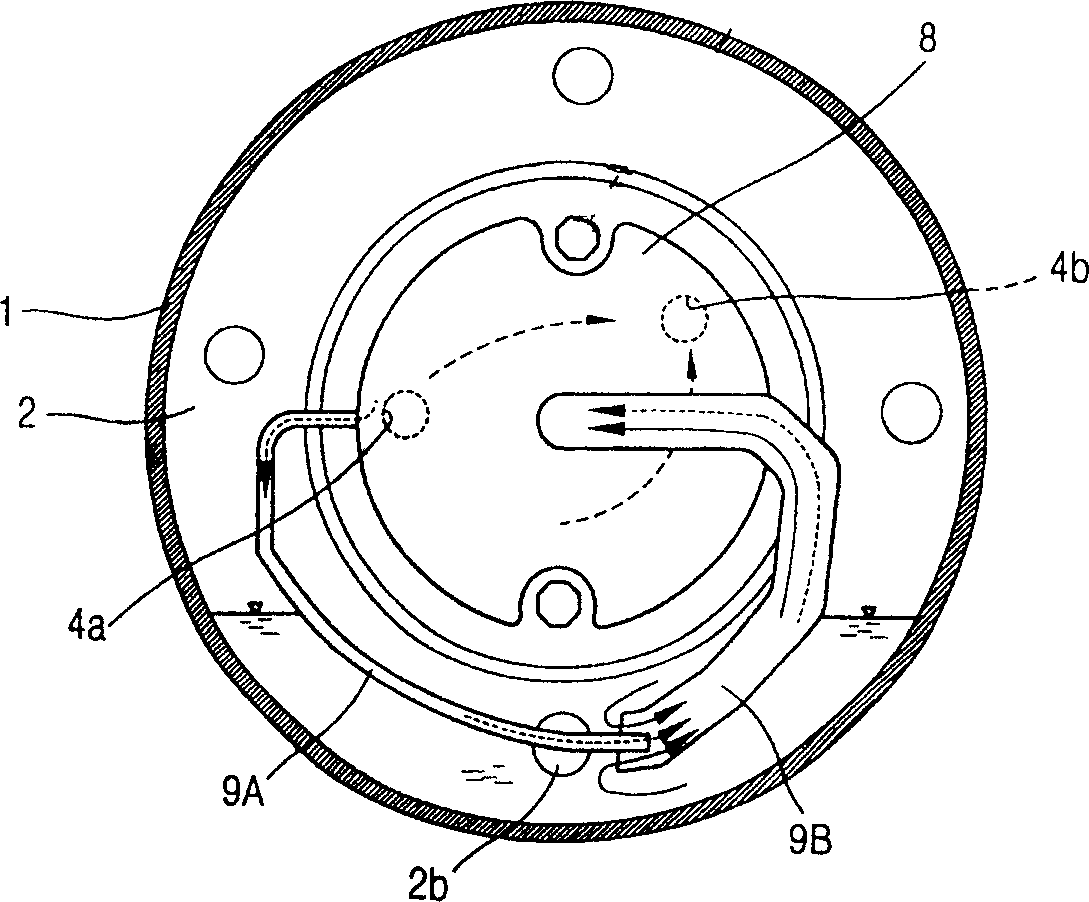

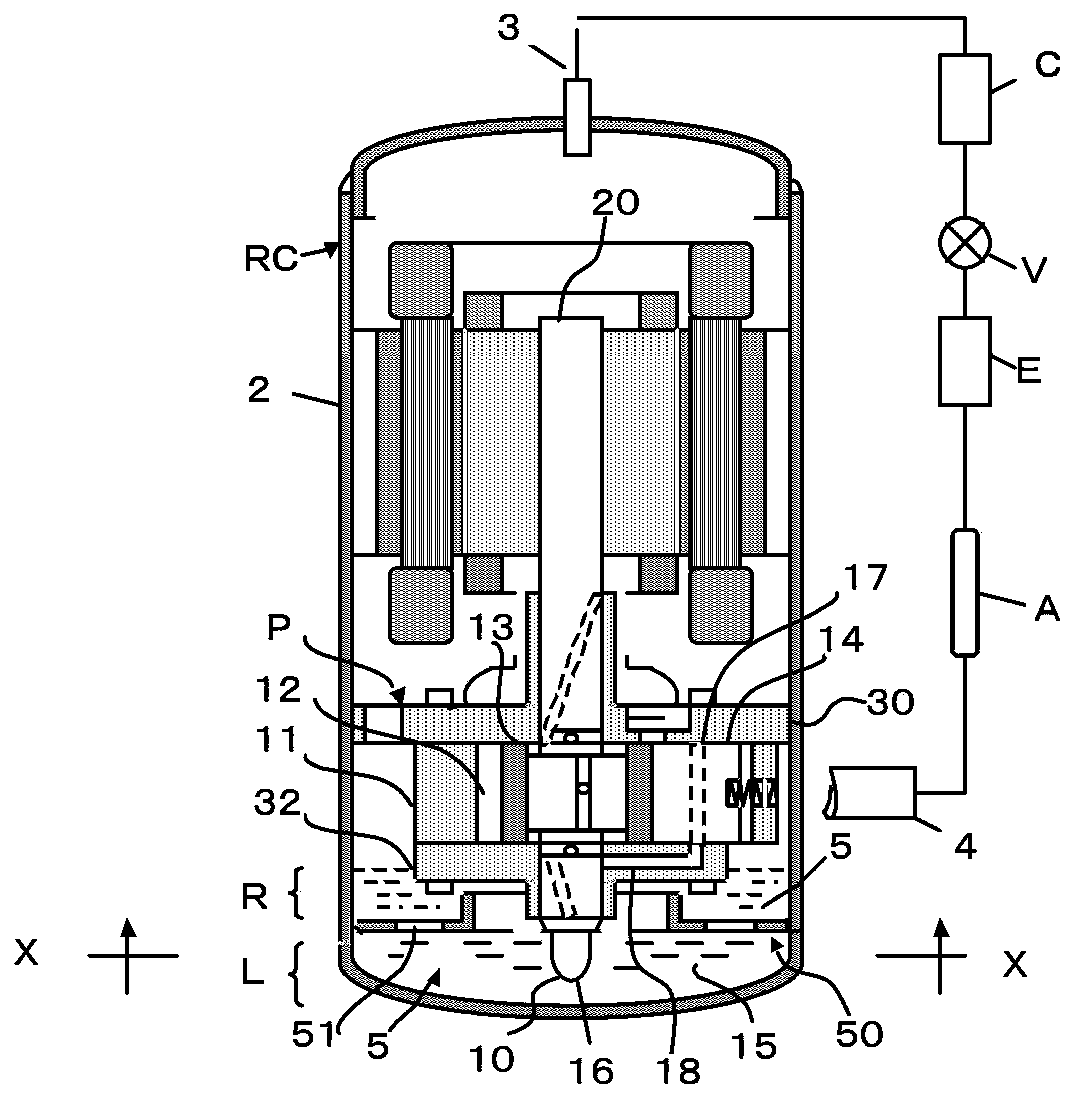

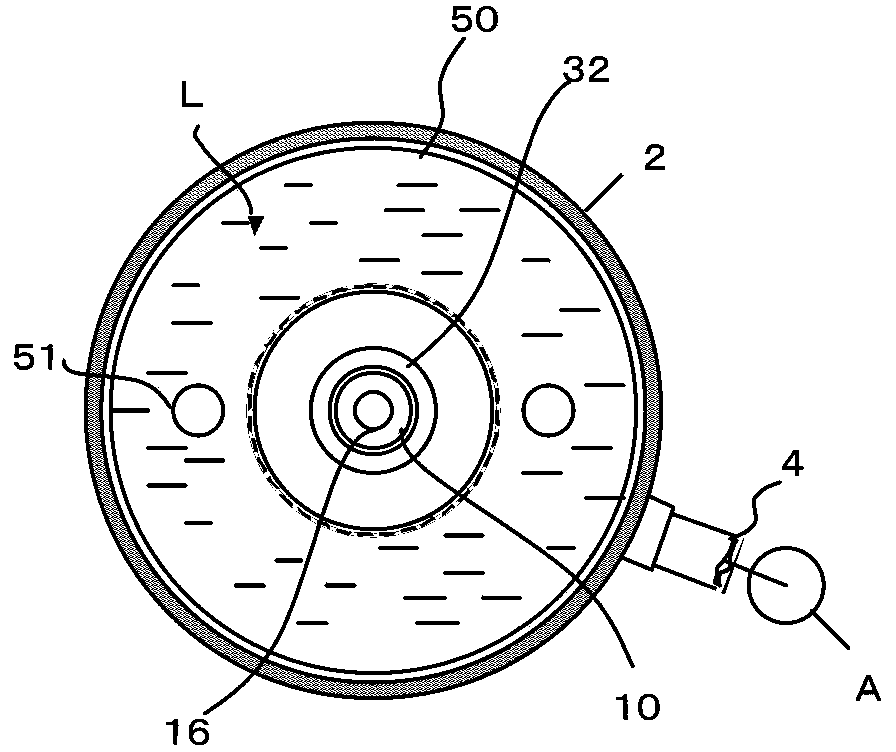

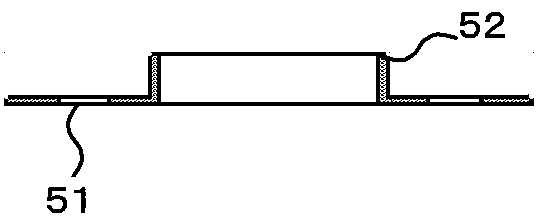

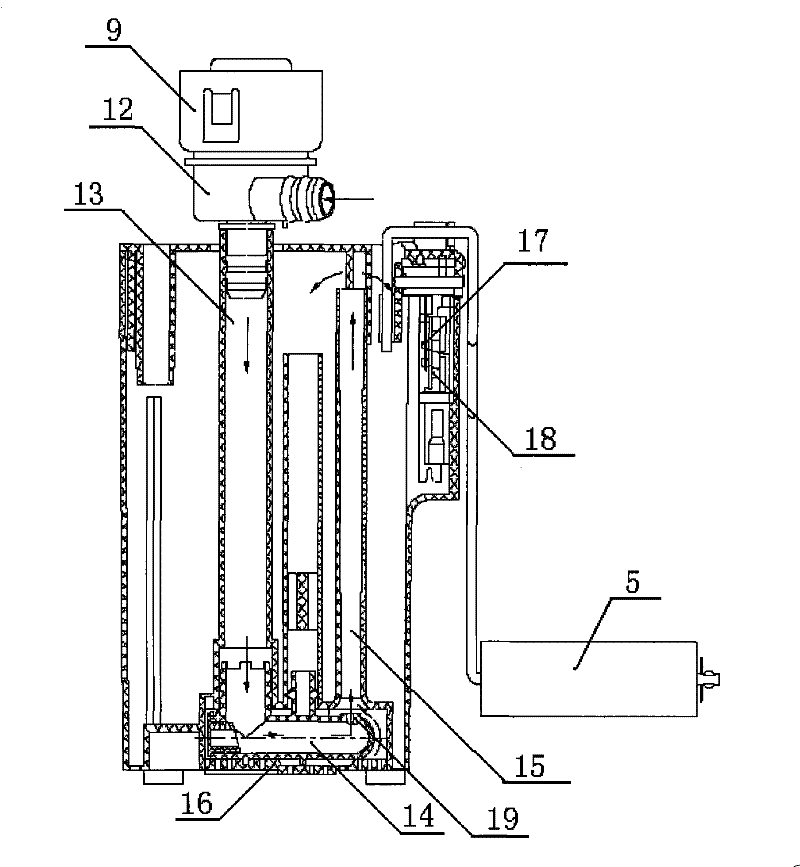

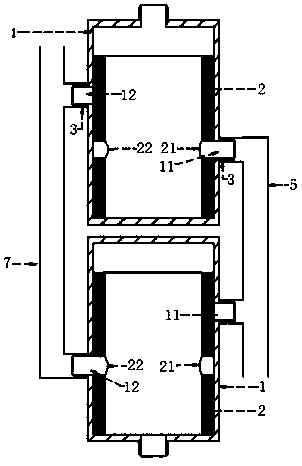

Rotary compressor

InactiveCN103388582AAvoid Reliability LossAvoid dischargeRotary/oscillating piston pump componentsLiquid fuel engine componentsPistonMain bearing

The invention relates to a rotary compressor comprising a compressing mechanism and a motor arranged in a housing. An oil storage chamber is arranged on the bottom of the housing. Oil is stored in the oil storage chamber. A separation plate dividing the oil storage chamber into an upper part and a lower part is arranged in the oil storage chamber. The compressing mechanism is provided with an oil feeding mechanism. The oil feeding mechanism comprises an oil absorption pipe. An opening of the oil absorption pipe is between the separation plate and the bottom of the housing. A refrigerant and refrigerant oil with condensation proportion higher than that of the refrigerant are sealed in the housing. The compressing mechanism comprises a gas cylinder, a piston performing eccentric rotation in a compressing chamber of the gas cylinder, a slide sheet performing synchronous reciprocating rotation with the piston, an eccentric crank used for driving the piston, and a main bearing and an auxiliary bearing supporting the eccentric crank. The oil feeding mechanism is arranged on the lower end of the eccentric crank. The oil absorption pipe is inserted into a central hole of the eccentric crank. An oil absorption hole is arranged on the lower end of the oil absorption pipe. The compressor provided by the invention has the characteristics of simple and reasonable structure, flexible operation, good lubricating effect, wide application range, and the like.

Owner:GUANGDONG MEIZHI COMPRESSOR

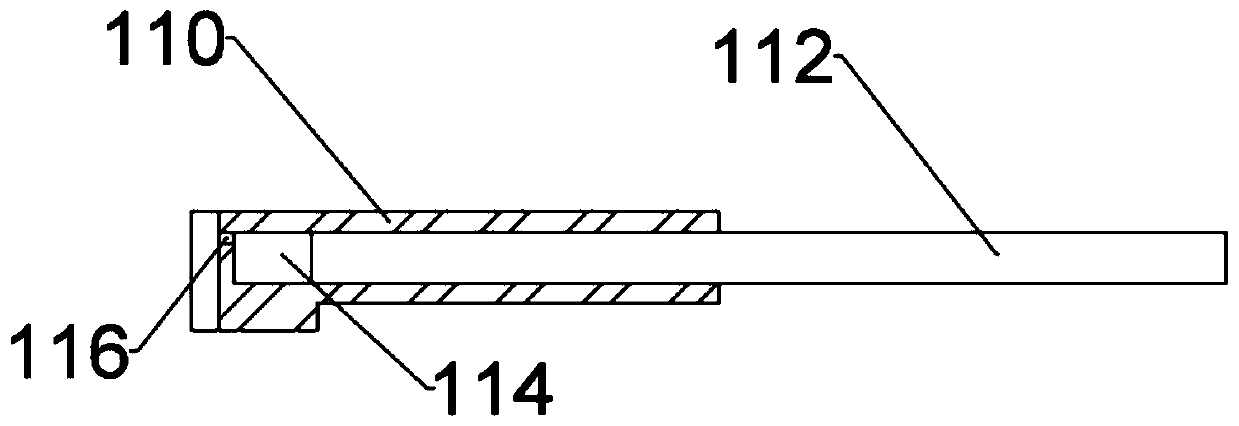

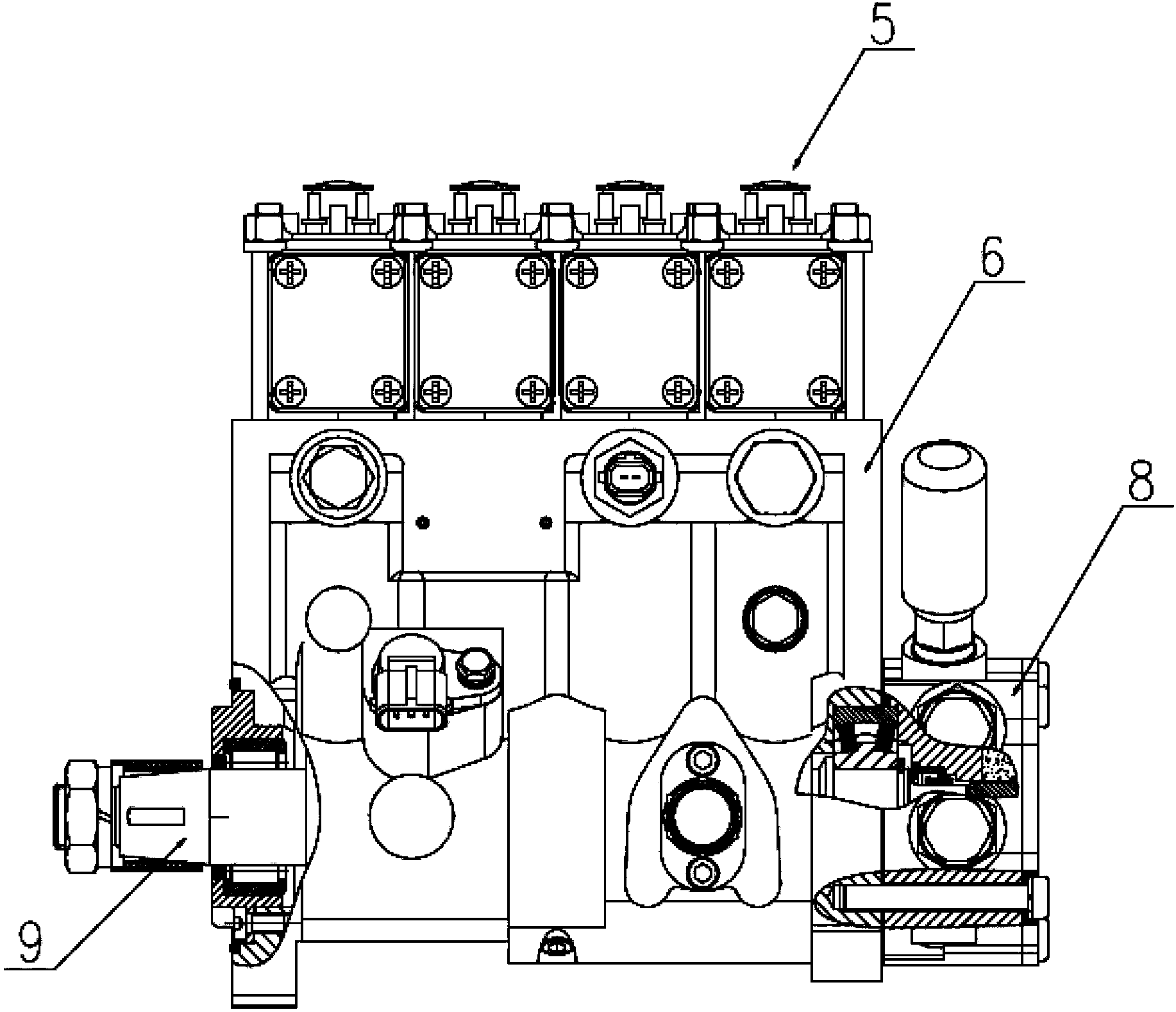

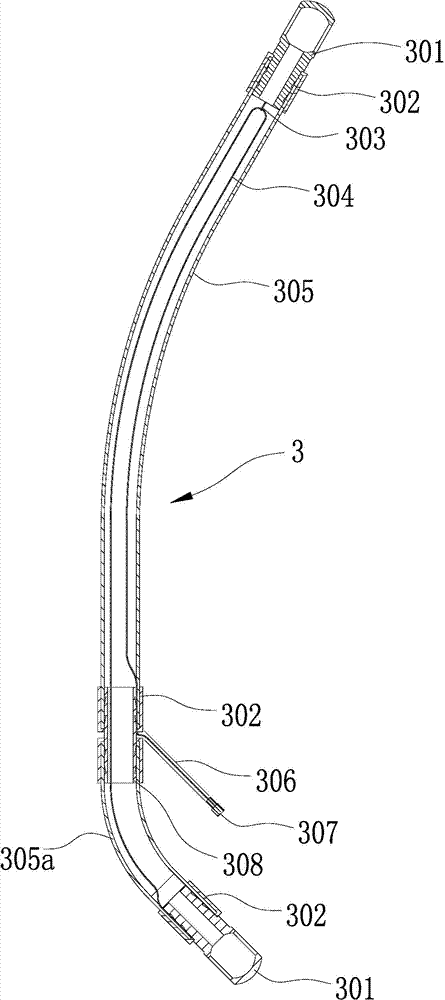

Electronic unit composite pump for light-vehicle diesels

ActiveCN103410643AGuaranteed working lengthReduce weightFuel injection apparatusMachines/enginesCamEngineering

The invention relates to the technical field of vehicle engine manufacturing, in particular to an electronic unit composite pump for light-vehicle diesels. The electronic unit composite pump for light-vehicle diesels comprises a composite pump body, an oil conveying pump, a camshaft, a plurality of electronic unit pumps, tappet body assemblies corresponding to the electronic unit pumps and a cam, and is characterized in that the electronic unit pumps are installed on the composite pump body and comprise unit pump bodies, a plunger, control valve elements and electromagnets installed on one sides of the unit pump bodies, the oil conveying pump is installed on one side of the composite pump body, the tappet body assemblies are arranged between the cam and the plunger and comprise tappets, rolling wheels and rolling wheel pins, and U-shaped cavities are formed in the ends where the tappets make contact with the rolling wheels, wherein the plunger and the control valve elements are arranged in the unit pump bodies. The electronic unit composite pump for light-vehicle diesels has the advantages of being more compact in structure and capable of acquiring higher working speed so as to be matched with the high-speed diesels.

Owner:龙口龙泵柴油喷射高科有限公司

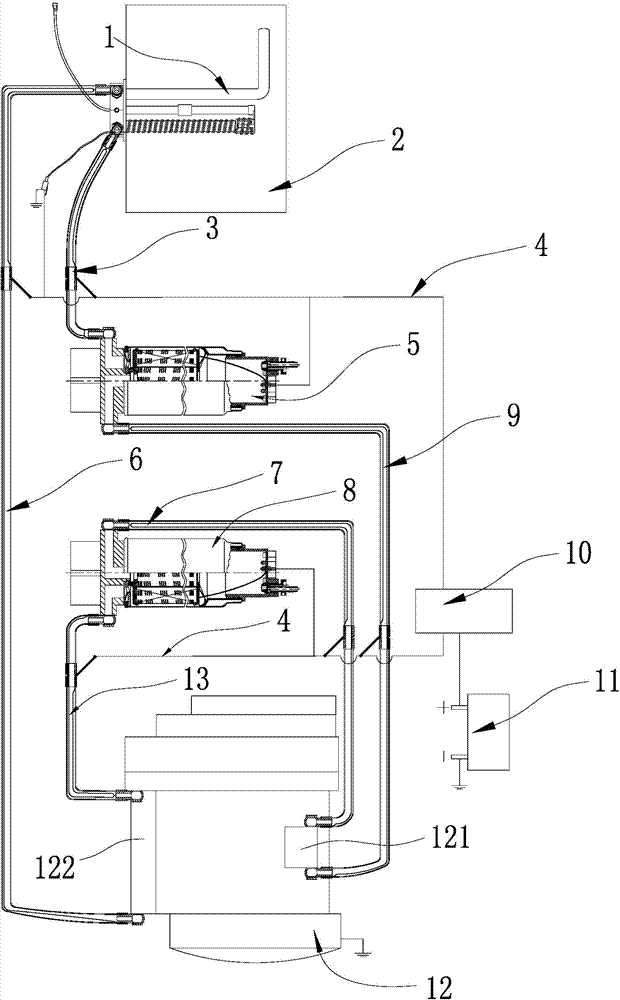

An electric fuel pump assembly

ActiveCN101865057BReduce the chance of leaksAvoid life-shortening situationsMachines/enginesLiquid fuel feedersLevel sensorFuel tank

The invention provides an electric fuel pump assembly, including a bottom barrel, an electric fuel pump, an oil level sensor, an oil outlet pipeline, and an oil return pipeline; the electric fuel pump is arranged in the bottom barrel; the bottom of the bottom barrel is provided with a one-way oil inlet valve; the oil outlet pipeline is connected to the oil outlet of the electric fuel pump; the top of the electric fuel pump assembly is provided with an upper cover that matches the fuel tank port, and the oil outlet of the oil outlet pipeline and the oil inlet of the oil return pipeline are set on the upper cover of the fuel tank port ;The oil return pipeline is connected with a pressure regulating valve; the oil level sensor is fixed on the inner shell of the bottom barrel; the upper cover of the fuel tank port is provided with a combined junction box, and the wiring of the oil level sensor and the electric fuel pump are connected to the combined junction box through connectors middle. The invention centrally arranges the pressure regulating valve and the oil level sensor, and also has the oil storage function, has a compact structure, is convenient for installation and maintenance, saves costs, and reduces the probability of fuel leakage.

Owner:SDZ AUTO PARTS

Automatic oiling device used in filament sizing machine

InactiveCN108426158ASame split velocityGuaranteed oil supplyProportioning devicesTextile treatmentFuel tankSizing

The invention discloses an automatic oiling device for a filament sizing machine, which comprises a base, wherein an oil tank is arranged in the base; a flow equalizer is arranged on the top end of the oil tank; a filter plate, a sealing partition and a main flow pipe are arranged in the flow equalizer; the main flow pipe penetrates through the filter plate and the sealing partition and one end ofthe main flow pipe is provided with a spray head. The filter plate is arranged above the sealing partition. A sealing ball valve is arranged on one side of the main flow pipe. According to the invention, a flow equalizer, a filter plate, a sealing partition, a sealing ball valve and a flow divider pipe are arranged. The lubricating oil in the oil tank is led into the flow equalizer by an oil pumpduring operation. The lubricating oil is filtered by the filter plate in the flow equalizer. The filtered lubricating oil flows into a uniform flow cavity formed between the filter plate and the sealing partition. A sealing ball valve is arranged on the sealing partition. The more the content of the lubricating oil in the uniform flow cavity is, the greater the pressure of the sealing ball in thesealing ball valve is.

Owner:CHANGXING JUFENG SILK WEAVING FACTORY

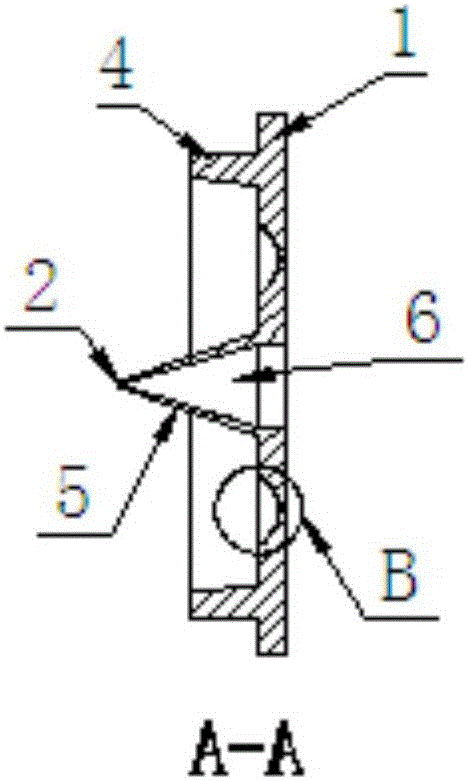

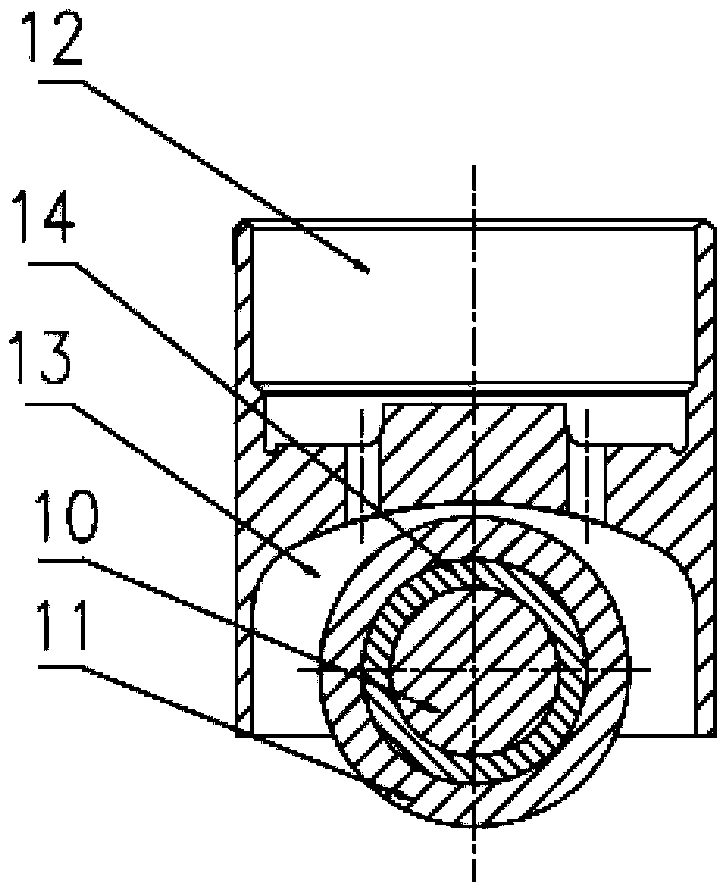

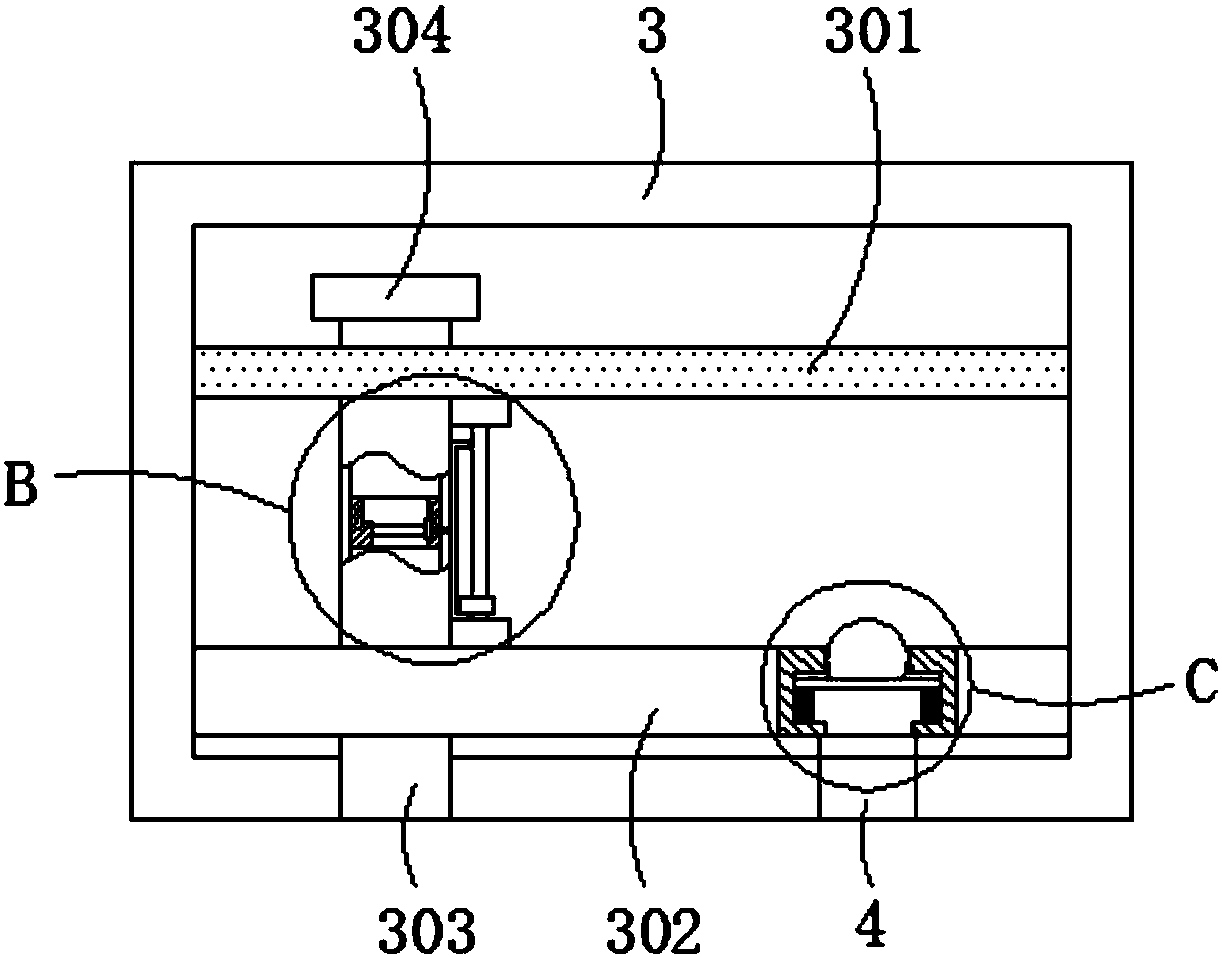

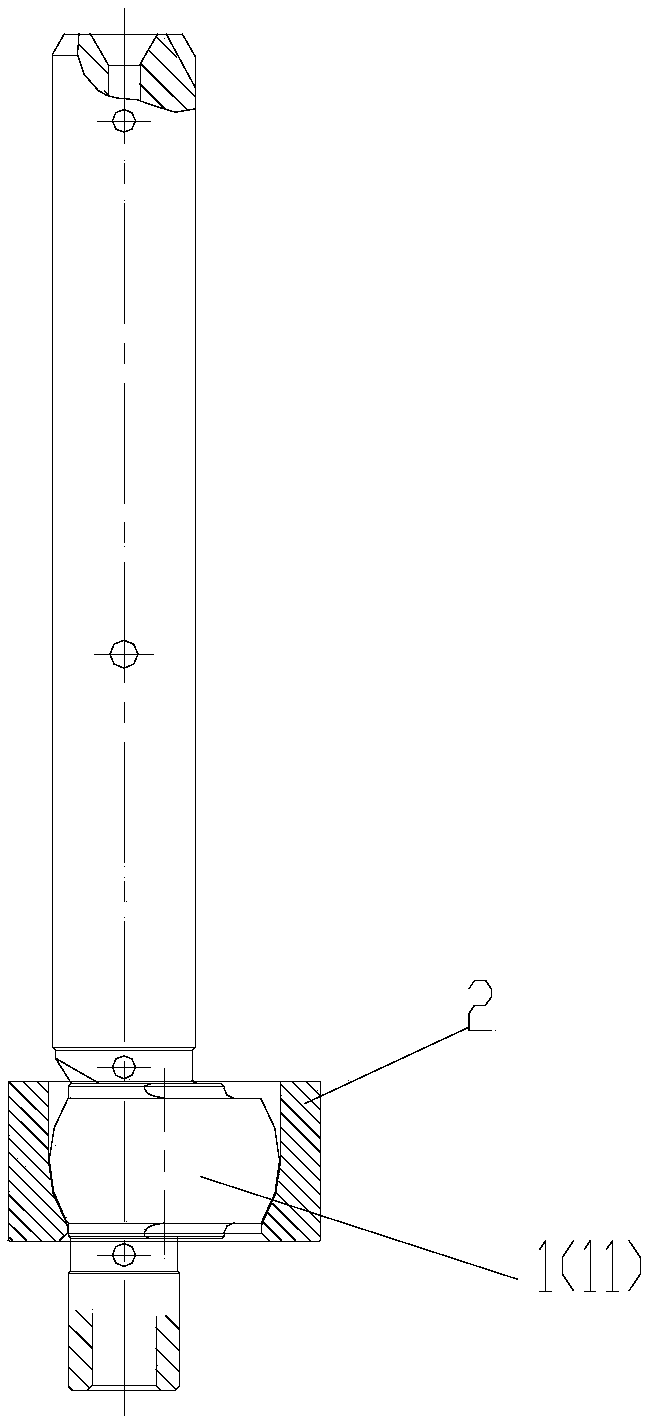

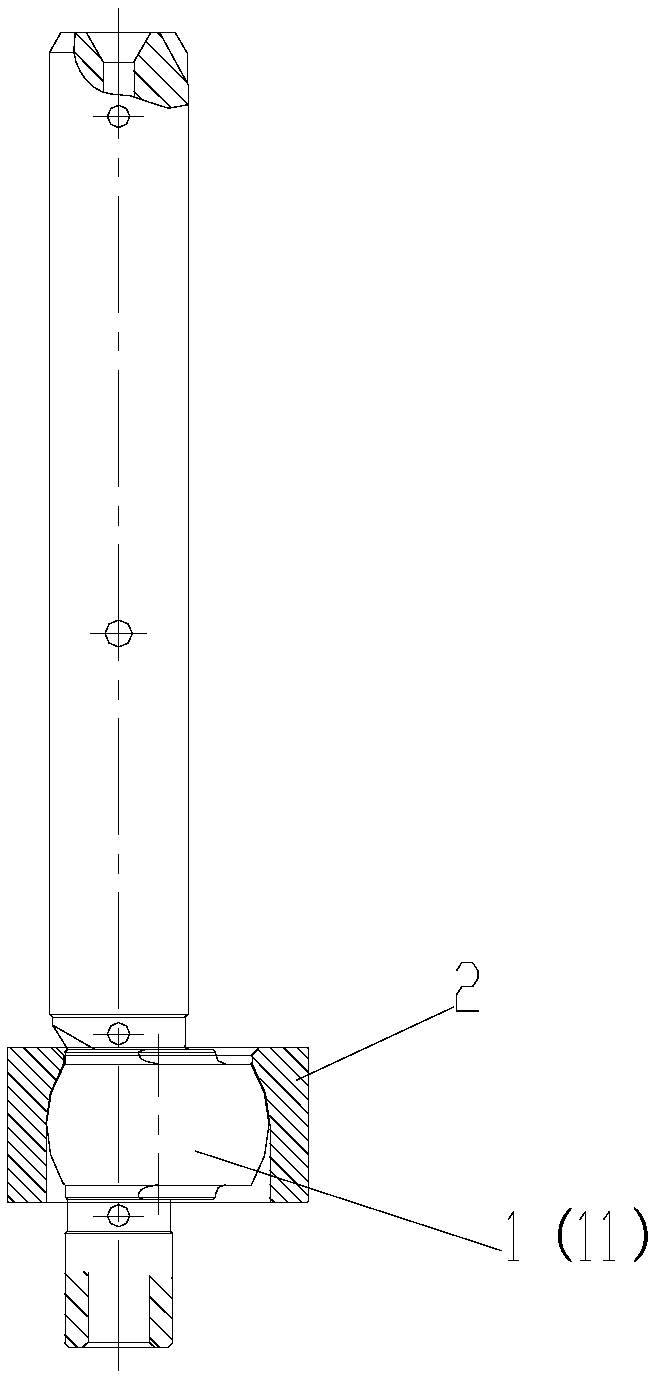

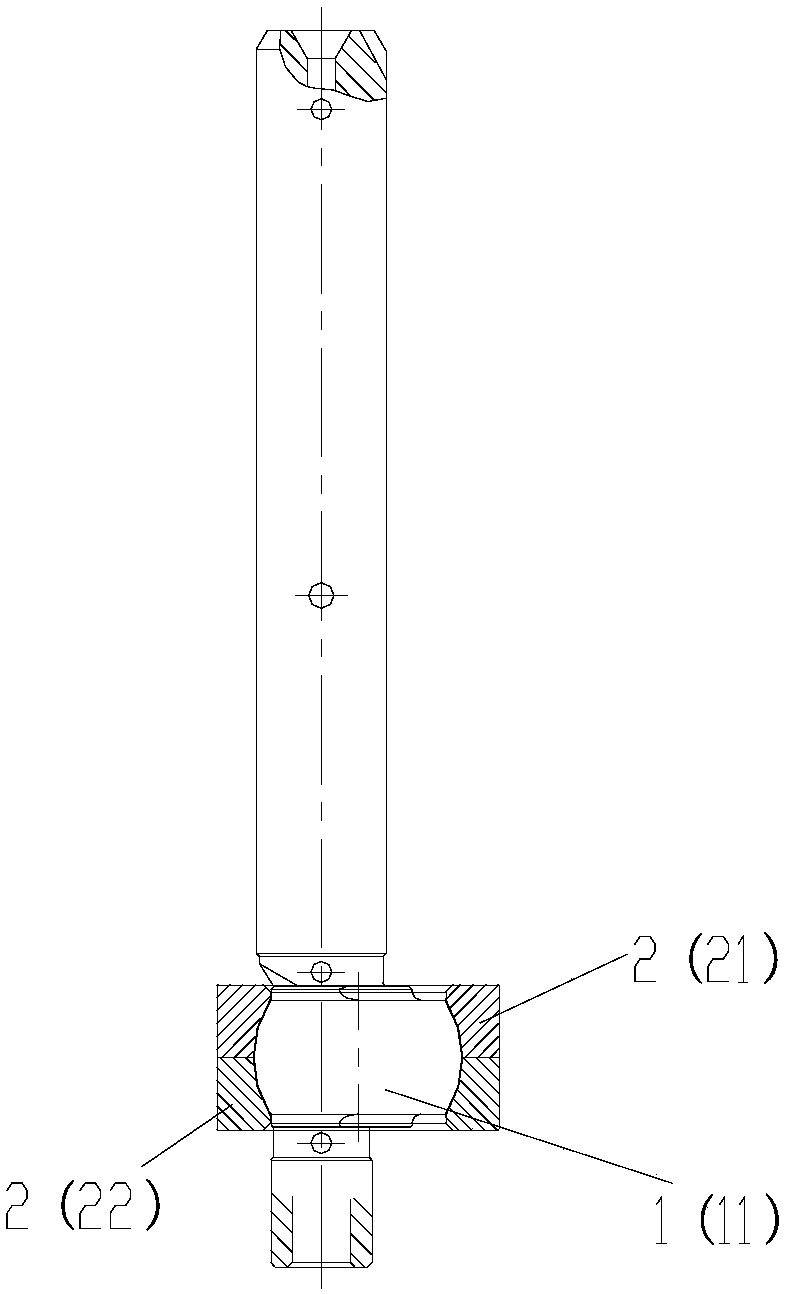

Crank shaft roller structure, compressor and air conditioner

InactiveCN108119368AReduce frictionImprove performanceRotary/oscillating piston pump componentsLiquid fuel engine componentsFriction reductionEngineering

The invention provides a crank shaft roller structure, a compressor and an air conditioner. The crank shaft roller structure comprises a crank shaft (1) and a roller (2), wherein the crank shaft (1) is provided with an eccentric part (11); the roller (2) sleeves the periphery of the eccentric part (11); the outer peripheral surface of the eccentric part (11) is a first spherical surface and the inner peripheral surface of the eccentric part (11) is a second spherical surface; the second spherical surface is adaptive to the first spherical surface, so that the roller (2) can be driven by the eccentric part (11) to rotate. By adopting the crank shaft roller structure provided by the invention, the contact between the crank shaft and the roller is space spherical contact, and the crank shaftand the roller are allowed to do space three-dimensional relative rotation, and coaxiality deviation and co-axis included angle of the crank shaft and the roller, caused by factors including an external force and the like, are automatically adjusted, and friction is reduced; friction, even insufficient power transmission, caused by the fact that the crank shaft and the roller are pressed by an external force and an internal force can be effectively reduced; the performance of the compressor is improved and the reliability is increased.

Owner:ZHUHAI LANDA COMPRESSOR +1

Oil tank, oil supply system and vehicle

PendingCN113623096ASolve the problem of flameoutAvoid stallingMachines/enginesLiquid fuel feedersFuel tankFuel oil

The invention discloses an oil tank, an oil supply system and a vehicle. The oil tank comprises an oil tank body, wherein an oil storage chamber is formed in the oil tank body; an oil supply pipe mounting hole, an oil return pipe mounting hole and an oil quantity sensor mounting hole which communicate with the oil storage chamber are formed in the oil tank body; a bulge part which communicates with the oil storage chamber is further arranged on the oil tank body; an oil collecting chamber which communicates with the oil storage chamber but does not intersect with the oil storage chamber is arranged in the bulge part; and the arrangement position of the oil collecting chamber corresponds to the arrangement position of the oil supply pipe mounting hole. The oil tank can load more fuel oil, and can prevent air from entering an oil supply pipeline due to oil liquid vibration to cause power fluctuation of an engine.

Owner:DONGFENG OFF ROAD VEHICLE CO LTD

Electric fuel pump assembly

ActiveCN101865057AReduce the chance of leaksAvoid life-shortening situationsMachines/enginesLiquid fuel feedersLevel sensorInlet valve

The invention provides an electric fuel pump assembly, which comprises a bottom barrel, an electric fuel pump, a fuel level sensor, a fuel outlet pipe and a fuel return pipe. The electric fuel pump is arranged in the bottom barrel; the bottom of the bottom barrel is provided with a one-way fuel inlet valve; the fuel outlet pipe is connected with the fuel outlet of the electric fuel pump; the top end of the electric fuel pump assembly is provided with an upper cover which is matched with a fuel tank port, and the fuel outlet of the fuel outlet pipe and the fuel inlet of the fuel return pipe are arranged on the upper cover of the fuel tank port; the fuel return pipe is connected with a pressure regulating valve; the fuel level sensor is fixed on the inner shell of the bottom barrel; and a combined wiring box is arranged on the upper cover of the fuel tank port, and the wire of the fuel level sensor and the wire of the electric fuel pump are connected into the combined wiring box through connector clips. The invention not only realizes the centralized arrangement of the pressure regulating valve and the fuel level sensor, but also has the function of fuel storage. Moreover, the invention has the advantages of compact structure and convenient installation and maintenance, saves the cost and reduces the chance of fuel leakage.

Owner:SDZ AUTO PARTS

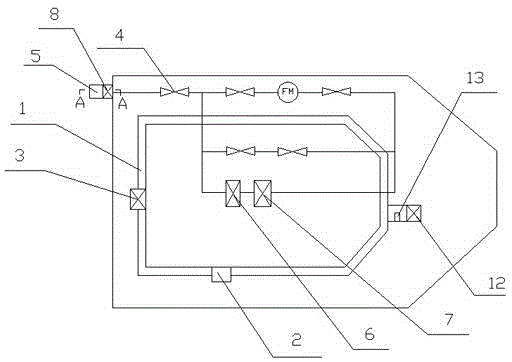

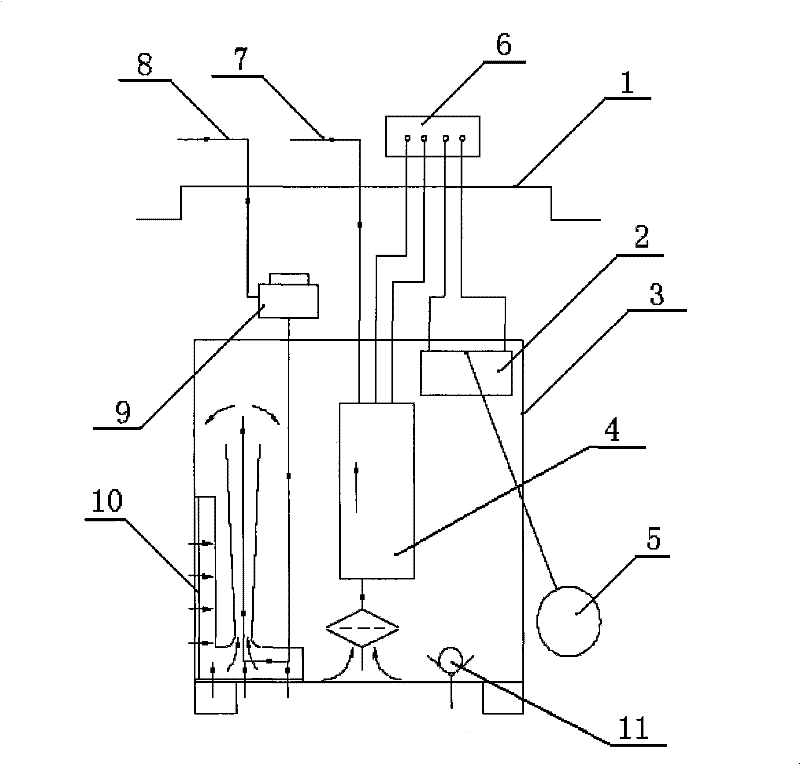

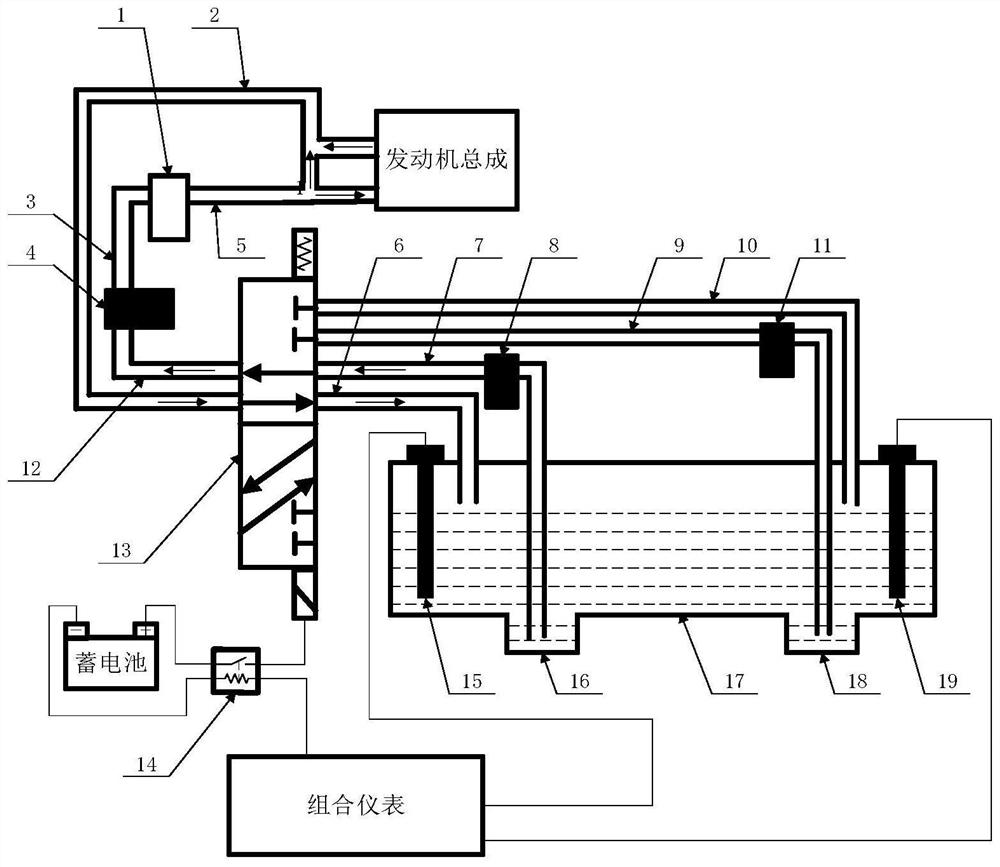

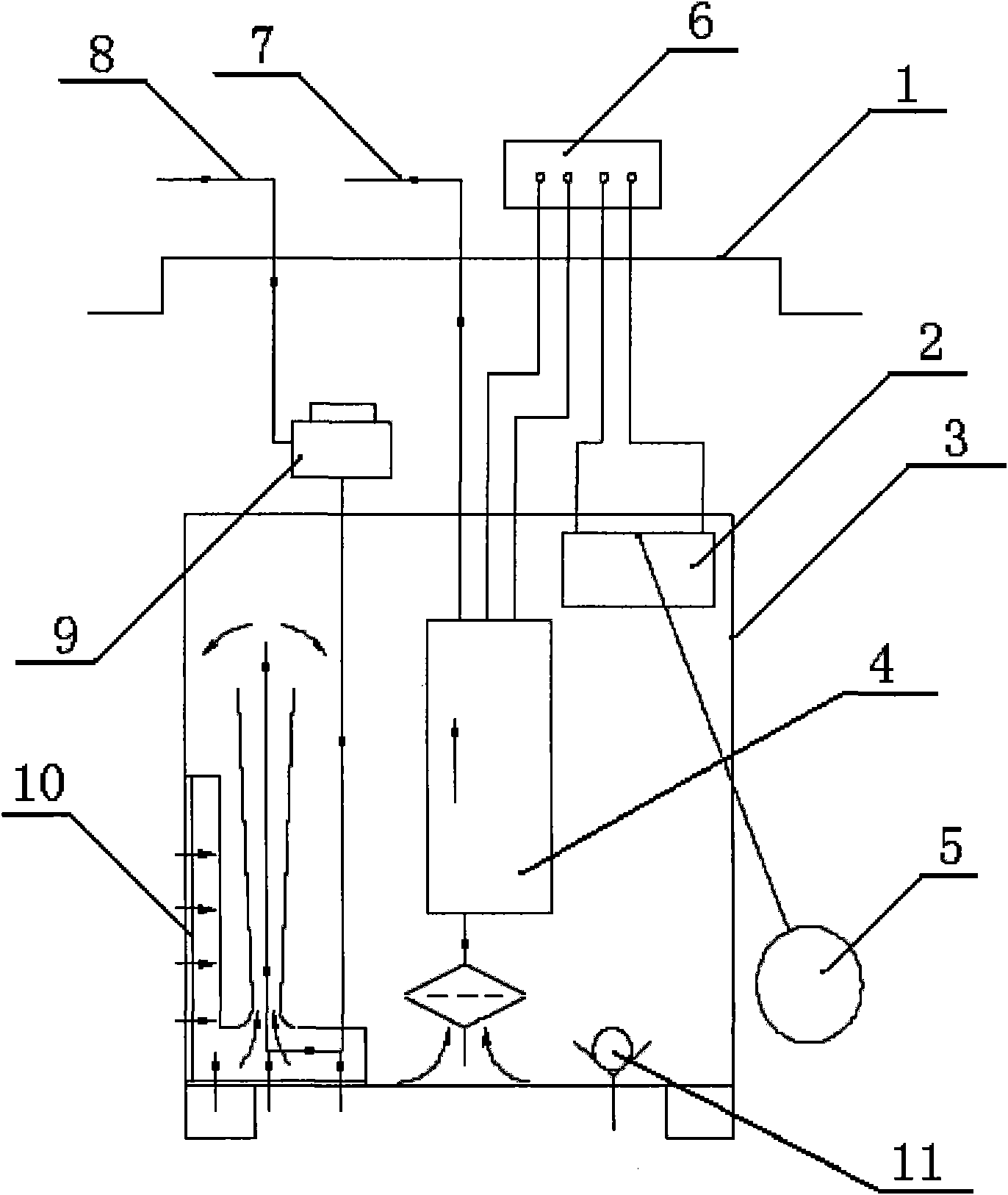

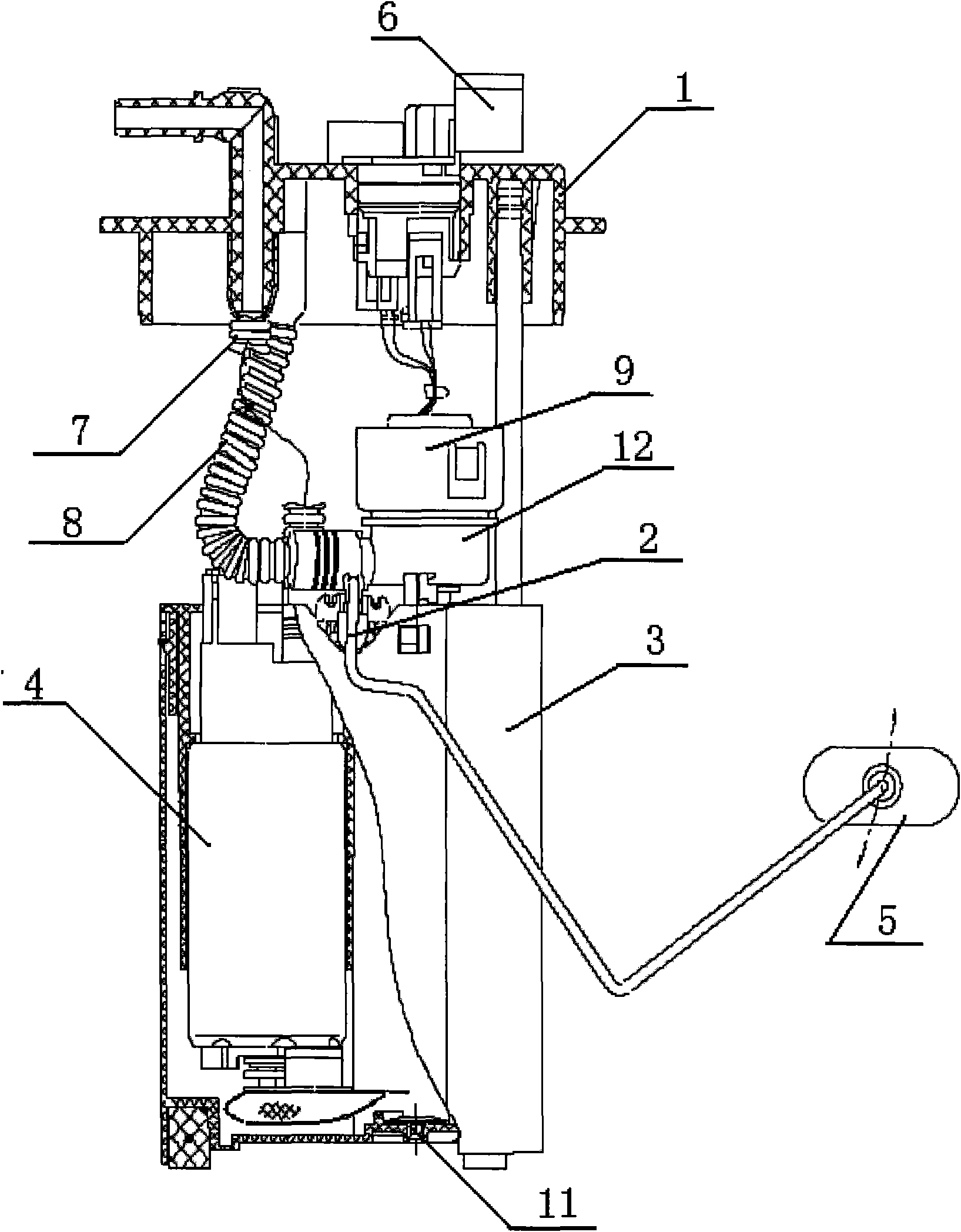

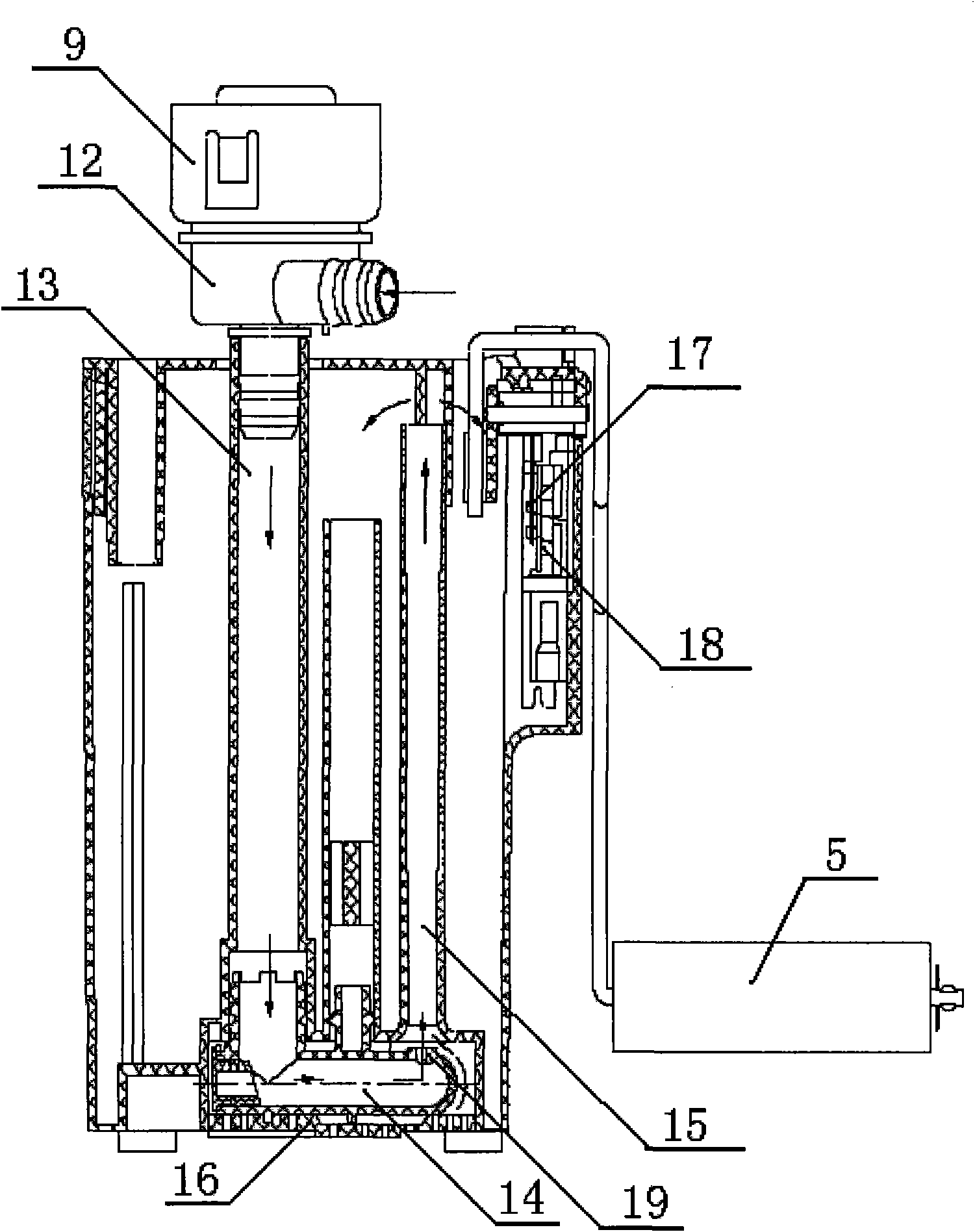

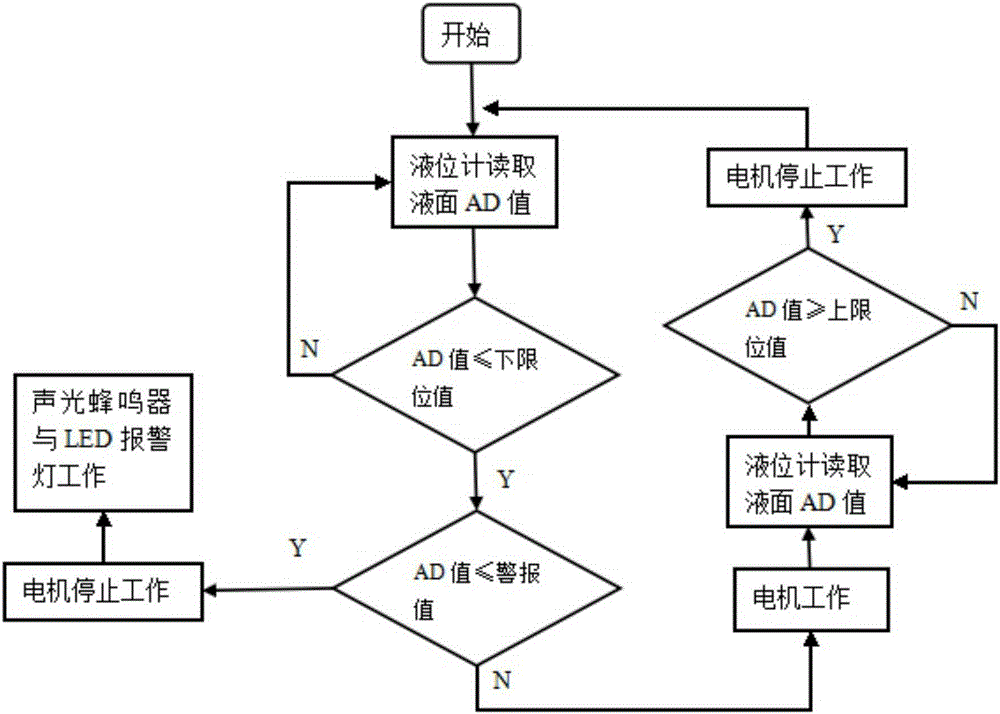

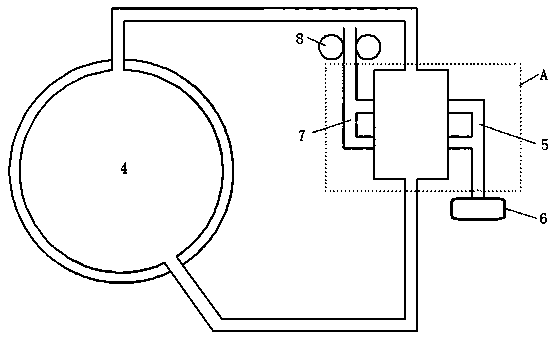

Intelligent fuel oil management system and operation method thereof

InactiveCN105183014AEnsure safetyThere will be no phenomenon such as idlingLevel controlTransmission systemsFuel oilFuel tank

The invention provides an intelligent fuel oil management system and an operation method thereof. The system comprises a cabinet; the cabinet obtains oil from an external oil box and provides the oil to an engine; the cabinet is internally provided with a transfer oil box, a power device, a controller and a meter; the controller comprises a single-chip microcomputer, a liquid level sensor, a relay control module and a duckbill switch; the liquid level sensor is connected with the single-chip microcomputer; the power device comprises a motor and a pump connected with the motor; the motor is controlled by the single-chip microcomputer; the meter is arranged on the motor and connected with the single-chip microcomputer; an oil management device is internally provided with oil pipes; and the oil pipes transmit oil between the oil management device and an external device. Oil can be transmitted between the system and the engine, and residual oil in the transfer oil box can be recovered, an emergency device can supply oil to the engine in emergency, and work safety of the system is ensured.

Owner:天津吉森机电设备工程有限公司

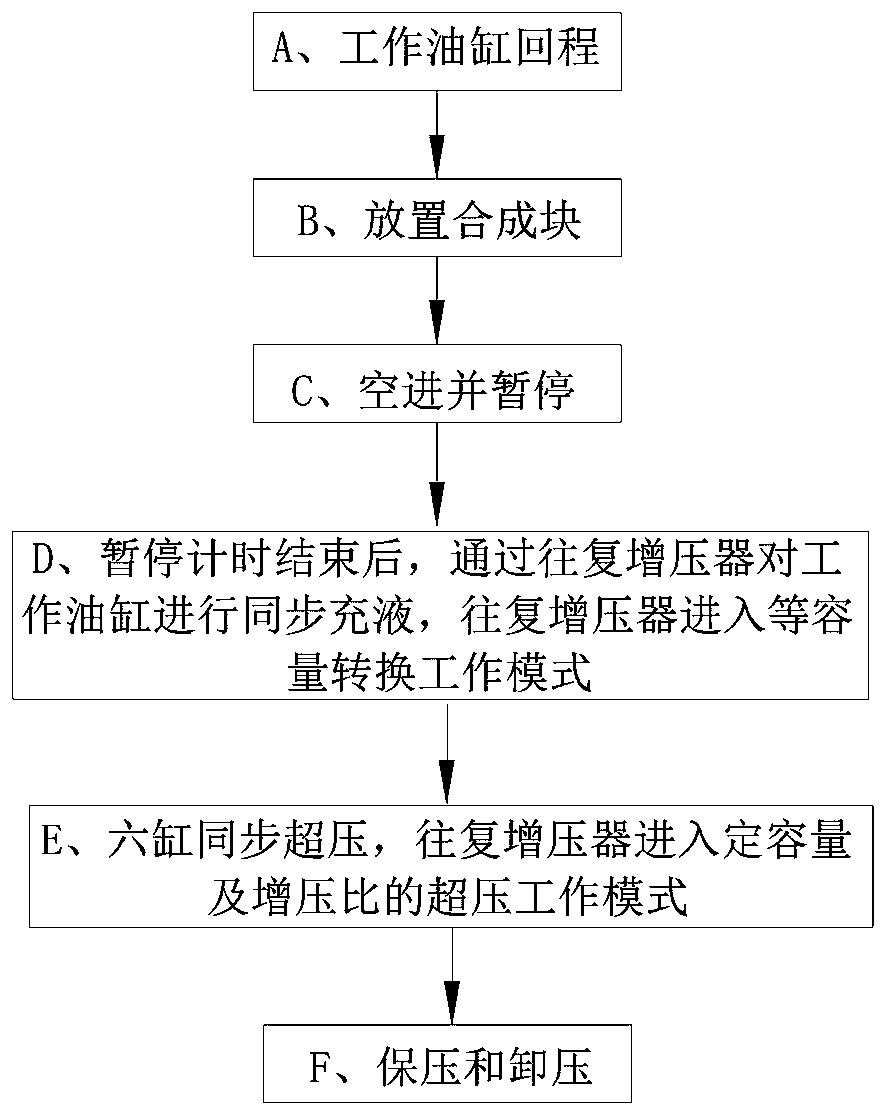

Synchronous control method for six-surface jacking press hydraulic oil cylinder

ActiveCN110873085ADoes not affect displacement changesEnsure synchronous displacement control accuracyUltra-high pressure processesServomotor componentsThermodynamicsSynchronous control

The invention discloses a synchronous control method for a six-surface jacking press hydraulic oil cylinder. The method comprises the following steps that firstly, return stroke of working oil cylinders, placement of a composite block, idling and pausing are carried out, then a reciprocating supercharger enters an equal-capacity conversion mode for synchronous liquid injecting the reciprocating supercharger enters a constant volume and pressurization ratio overpressure mode for synchronous overpressure, and finally pressure maintaining and pressure relief are carried out; in the liquid injecting process, high and low pressure outlet oil of the reciprocating supercharger is simultaneously and quantitatively injected into the working oil cylinders so that pistons of the oil cylinders can move quickly and accurately; and in the overpressure process, a piston of the reciprocating supercharger swings left and right, so that the reciprocating pressurized oil continuously is flown into the corresponding working oil cylinders for overpressure. According to the method, the synchronous displacement control precision of six-cylinder equal-volume oil supply is guaranteed, and the synchronous control precision can reaches 0.1 mm-0.2 mm, and meanwhile the reciprocating supercharger can also serve as an ultrahigh-pressure oil source so that the working oil cylinders can be loaded to the working pressure of 120 MPa; and in addition, the six-cylinder synchronous displacement can be accurately controlled in the liquid injecting and overpressure processes.

Owner:ZHENGZHOU RES INST FOR ABRASIVES & GRINDING CO LTD

Filtering system of far infrared electronic heating diesel filter

InactiveCN103047057ABurn fullyIncrease motivationInternal combustion piston enginesThermal treatment of fuelFlameoutFuel tank

The invention relates to a filtering system of a far infrared electronic heating diesel filter. The filtering system comprises a fuel tank, an engine and a power source, a heating diesel level sensor is arranged in the fuel tank and connected with heating diesel filters through heating diesel pipes, the heating diesel filters are connected with engine diesel pumps through the heating diesel pipes, a far infrared heating line is arranged in each heating diesel pipe, the outer surface of a diesel sucking pipe of the heating diesel level sensor and the outer surface of a filtering core inside each heating diesel filter are wound by far infrared heating lines, and two ends of each far infrared heating line are connected with the power source through a control unit. By adopting the structure and respectively heating the fuel tank, the diesel pipes and the diesel filters, problems of cold start and low-temperature traveling flameout of a diesel vehicle are solved, transport cost caused by use of high-grade diesel by the vehicle is lowered, engine power is increased, abrasion of internal components of the engine is lowered, the service life of the engine is prolonged, and sufficient burning of fuel plays a role in reducing tail gas emission.

Owner:蚌埠国威滤清器有限公司 +1

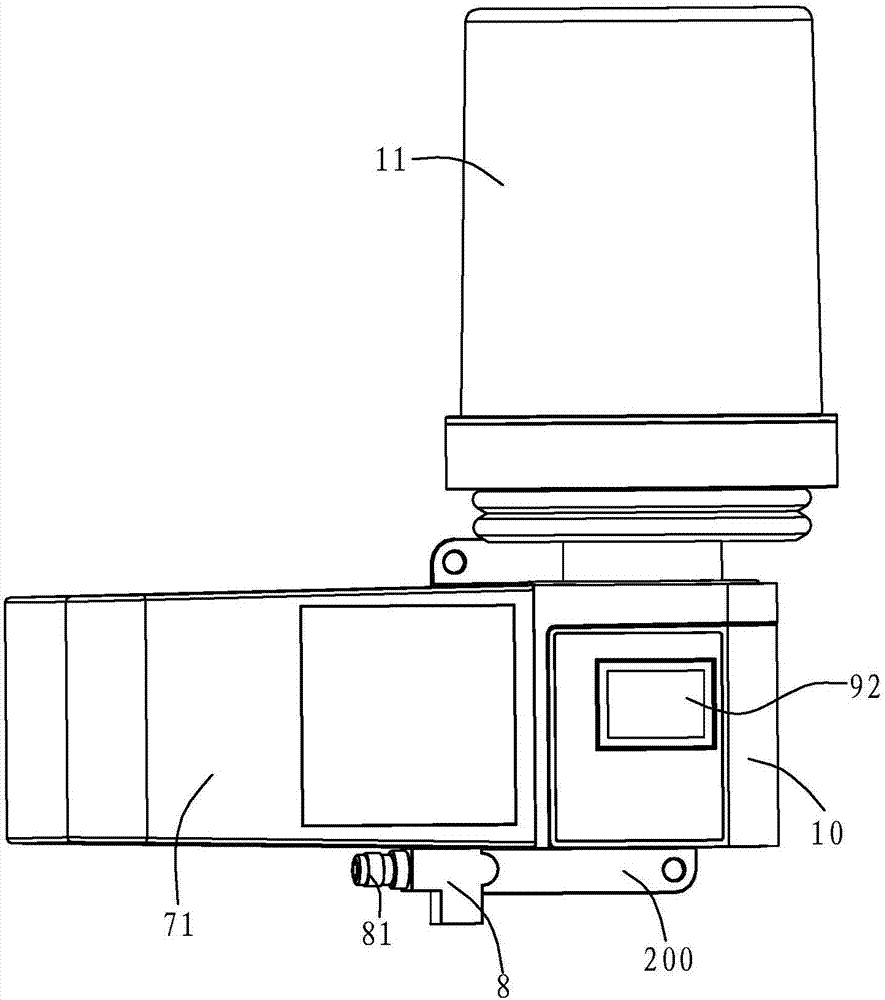

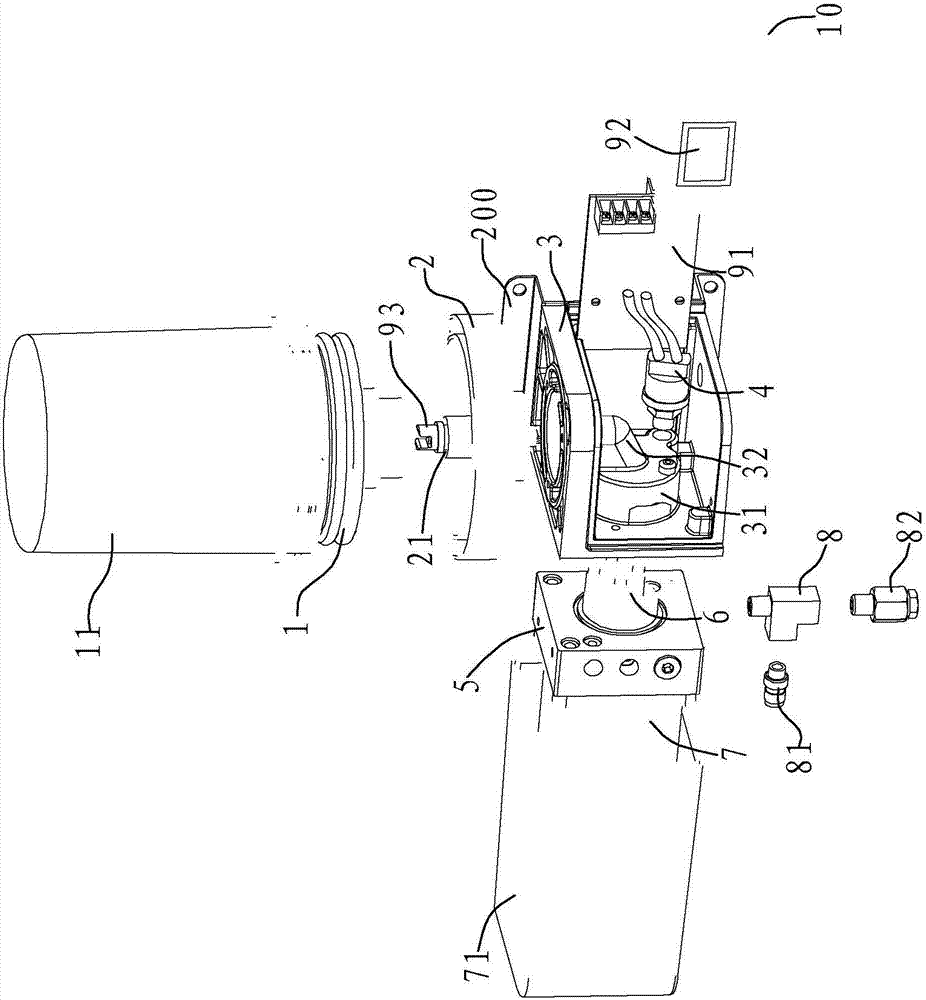

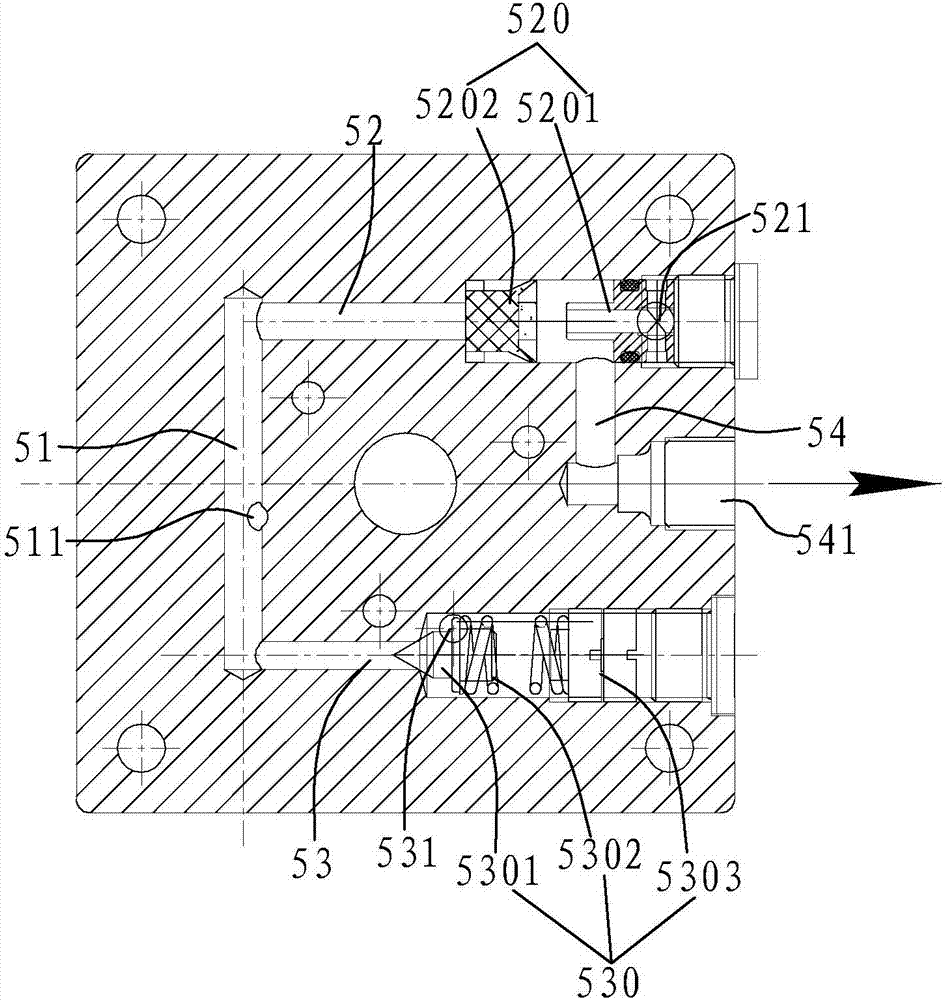

Automatic gear grease lubrication pump

PendingCN107152600AGuaranteed oil supplyAchieve continuous oil supplyLubricating pumpsSafety/regulatory devicesOil and greaseAutomatic control

The invention relates to an automatic gear grease lubrication pump which comprises a grease tank, a fixed seat, a pump seat, a flow channel block, a gear pump, a motor, a control device and the like. The grease tank can extend and retract. The fixed seat and the flow channel block are mounted on the pump seat. The grease tank and a cover cap are mounted on the fixed seat. The motor and an oil pump group are mounted on two sides of the flow channel block. A grease flow channel, a pressure relief flow channel, an overflow flow channel and an oil outlet flow channel are formed in the flow channel block. The pressure relief flow channel and the overflow flow channel communicate with the grease flow channel. The oil outlet flow channel communicates with the pressure relief flow channel. A pressure relief valve is arranged in the pressure relief flow channel. An overflow valve is arranged in the overflow flow channel. The control device is connected with the motor to control the motor to work. The automatic gear grease lubrication pump can realize full-automatic control, can quick relief pressure after oil supply, and ensure that a pressure relief type quantitative distributor can normally work.

Owner:许永久

A surveying and mapping drone that can automatically adjust its balance

ActiveCN109720552BReduce loadGuaranteed oil supplyAircraft stabilisation by gravity apparatusAircraftsElectrical batteryFuel tank

The invention relates to the technical field of unmanned aerial vehicle equipment for surveying and mapping. In order to solve the problem that the surveying and mapping work cannot be carried out normally due to the imbalance of the center of gravity due to the reduction of the oil volume of the fuel tank during the use of the existing surveying and mapping unmanned aerial vehicle , provides a surveying and mapping unmanned aerial vehicle that can automatically adjust the balance, including a body with a camera, the body includes a fuel system that provides power, and the fuel system includes a fuel tank; wherein: the body also includes a mount, and the camera is installed on the mount. At one end, the fuel tank is located at the other end of the mounting seat; the body is also provided with a mounting bar, on which the battery module is slidably connected, and a wire is connected between the battery module and the camera. On the end close to the fuel tank, the side of the battery module facing the helical section is provided with an iron patch; the installation crossbar is slidably connected with an iron slider through an elastic member, and the slider is inserted into the helical section after sliding away from the fuel tank.

Owner:CHONGQING VOCATIONAL INST OF ENG

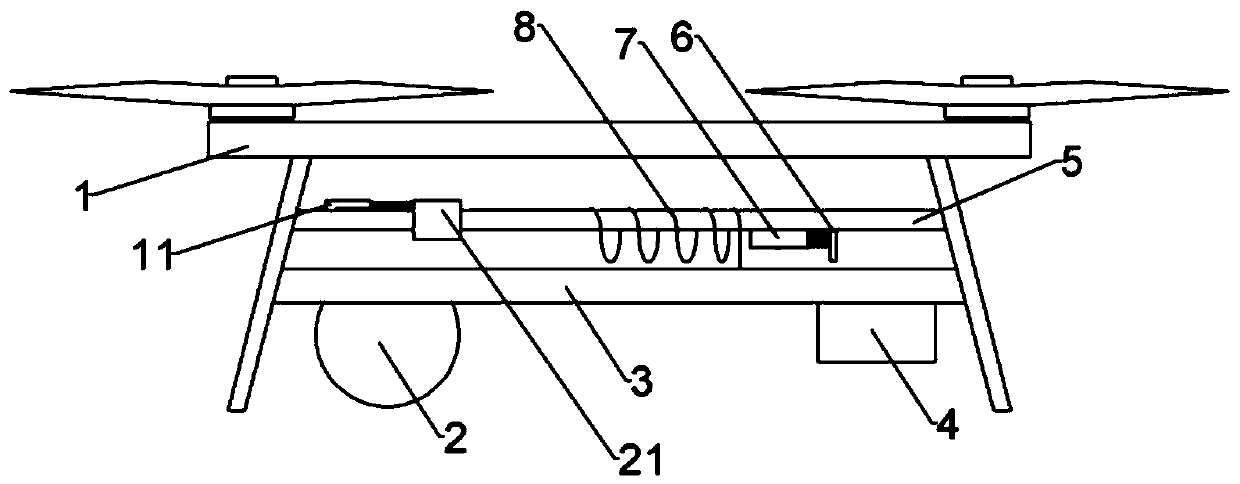

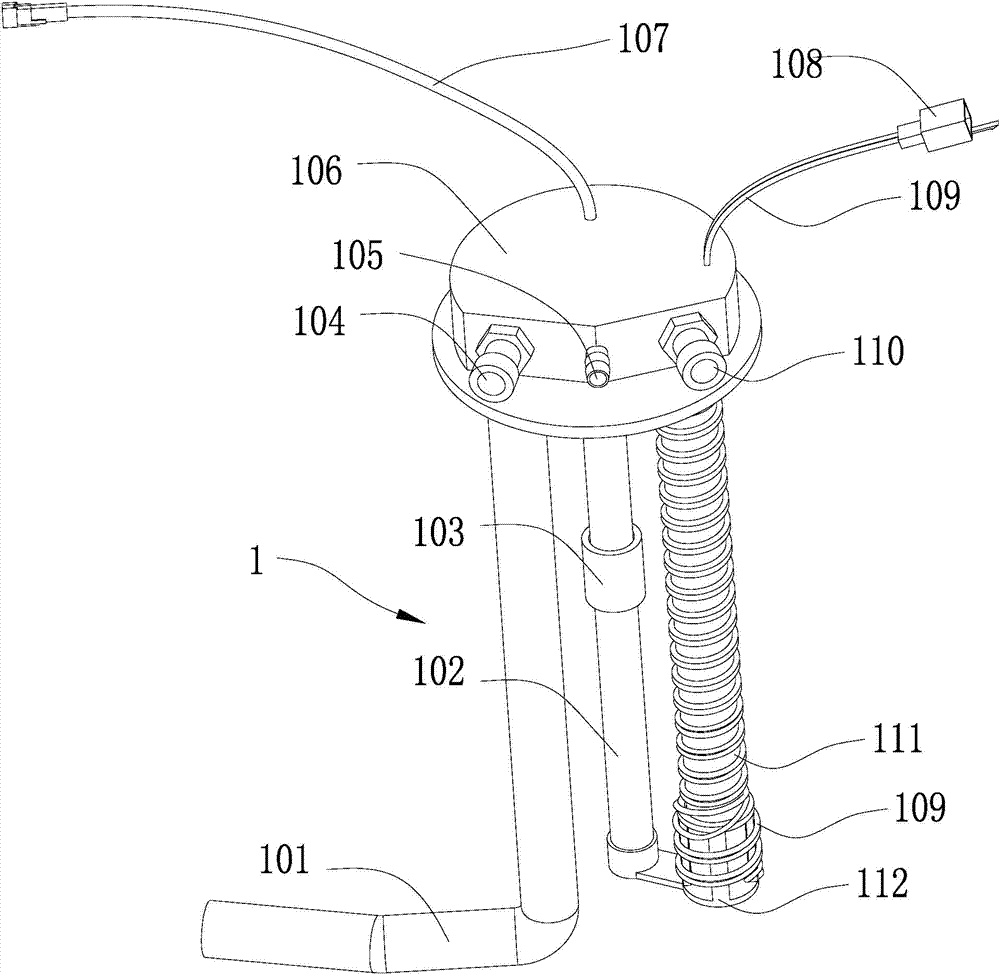

Gravity switching unit and aircraft engine inverted flight oil supply and ventilation device comprising same

PendingCN109252963AGuaranteed uptimeGuaranteed oil supplyTurbine/propulsion lubricationAviationFuel tank

The invention relates to a gravity switching unit and an aircraft engine inverted flight oil supply and ventilation device comprising the same. The oil supply and ventilation device comprises two gravity switching units and a lubricating oil box, wherein each gravity switching unit comprises a shell; a gravity switching barrel is in vertical sliding cooperation in the shell; the wall of the shellis provided with a first through hole I and a second through hole I; the wall of the gravity switching barrel is provided with a first through hole II and a second through hole II; the upper surface and the lower surface of the shell are respectively connected with a sealing plate; any one sealing plate is provided with a pipe connecting hole; the upper part and the lower part of the lubricating oil box are respectively connected with the pipe connecting holes of the gravity switching units; a through hole in communication with the shell of the gravity switching unit connected with the lower part of the lubricating oil box and a through hole that is misaligned to the shell of the gravity switching unit connected with the upper part of the lubricating oil box to be sealed are both connectedwith a booster pump through a lubricating oil conduit; another two through holes on two shells are both connected with a centrifugal ventilator through air conduits. According to the oil supply and ventilation device, the oil supply and the ventilation of the lubricating oil box can be simultaneously guaranteed.

Owner:重庆天骄航空动力有限公司

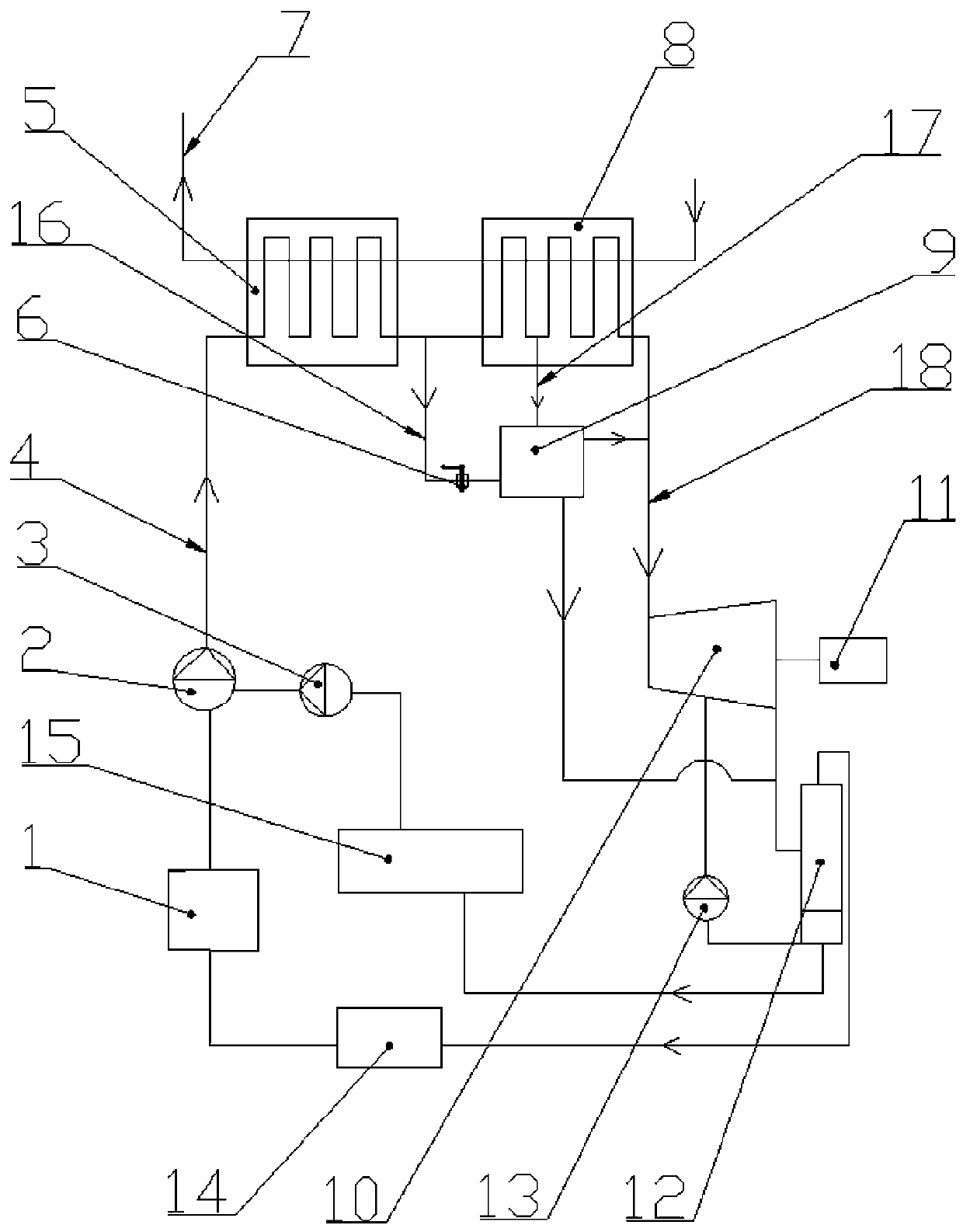

Power generation system for recycling waste heat of compressed gas

ActiveCN111396291AReliable operationAchieve recyclingPositive displacement pump componentsEngine componentsPhysicsElectric generator

The invention relates to a power generation system for recycling waste heat of compressed gas. The system comprises a compressed gas conveying pipe, a power generator, a screw expander, an evaporator,a preheater, a low-boiling-point organic working medium storage box and a working medium pump. The compressed gas conveying pipe passes through the evaporator and the preheater which are arranged insequence, the downstream end of the low-boiling-point organic working medium storage box is connected with an organic working medium conveying pipe through the working medium pump, the organic workingmedium conveying pipe is connected with a steam pipe after passing through the preheater and the evaporator in sequence, and the steam pipe is connected with the screw expander. A screw rotor of thescrew expander is connected with the power generator, an exhaust port of the screw expander is connected with an inlet of a separator through a pipe, and a working medium outlet of the separator is connected with a condenser through a pipe. The condenser is connected with the upstream end of the low-boiling-point organic working medium storage box through a pipe, one path of an oil outlet of the separator is connected with a lubricating oil inlet of the screw expander through a main oil pump, and the other path of the oil outlet of the separator is connected with the lubricating oil inlet of the working medium pump through a sub oil pump.

Owner:董荣华

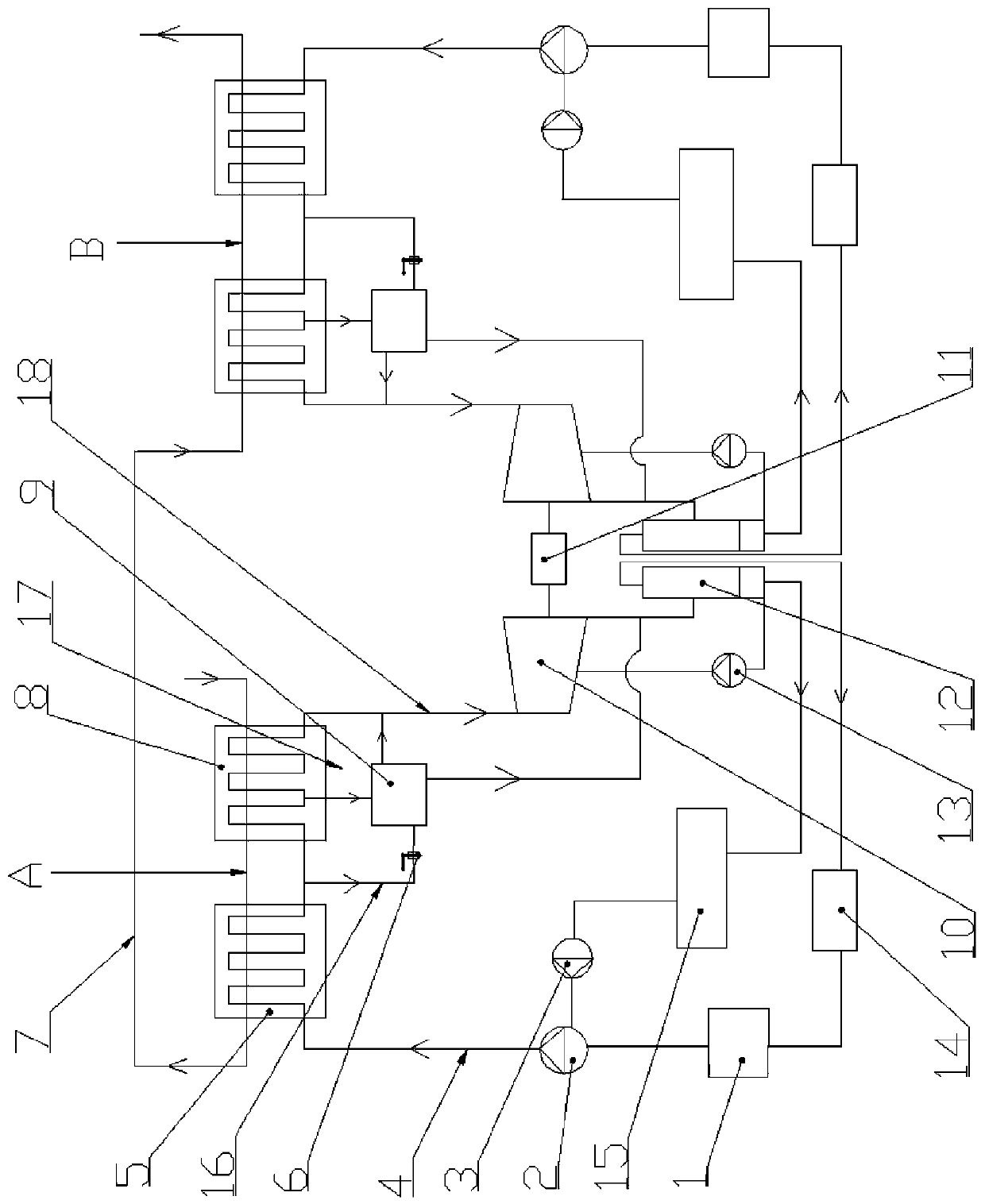

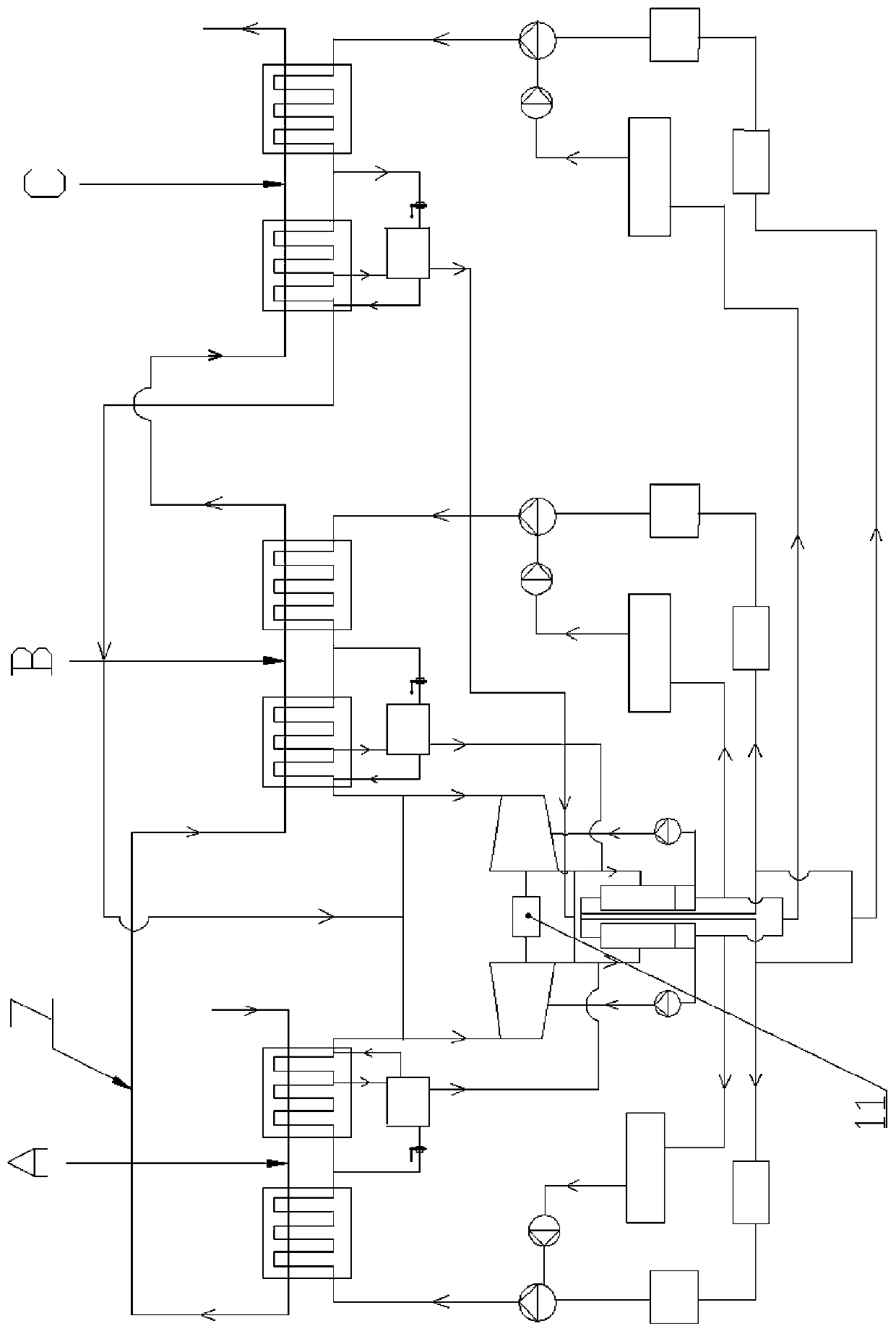

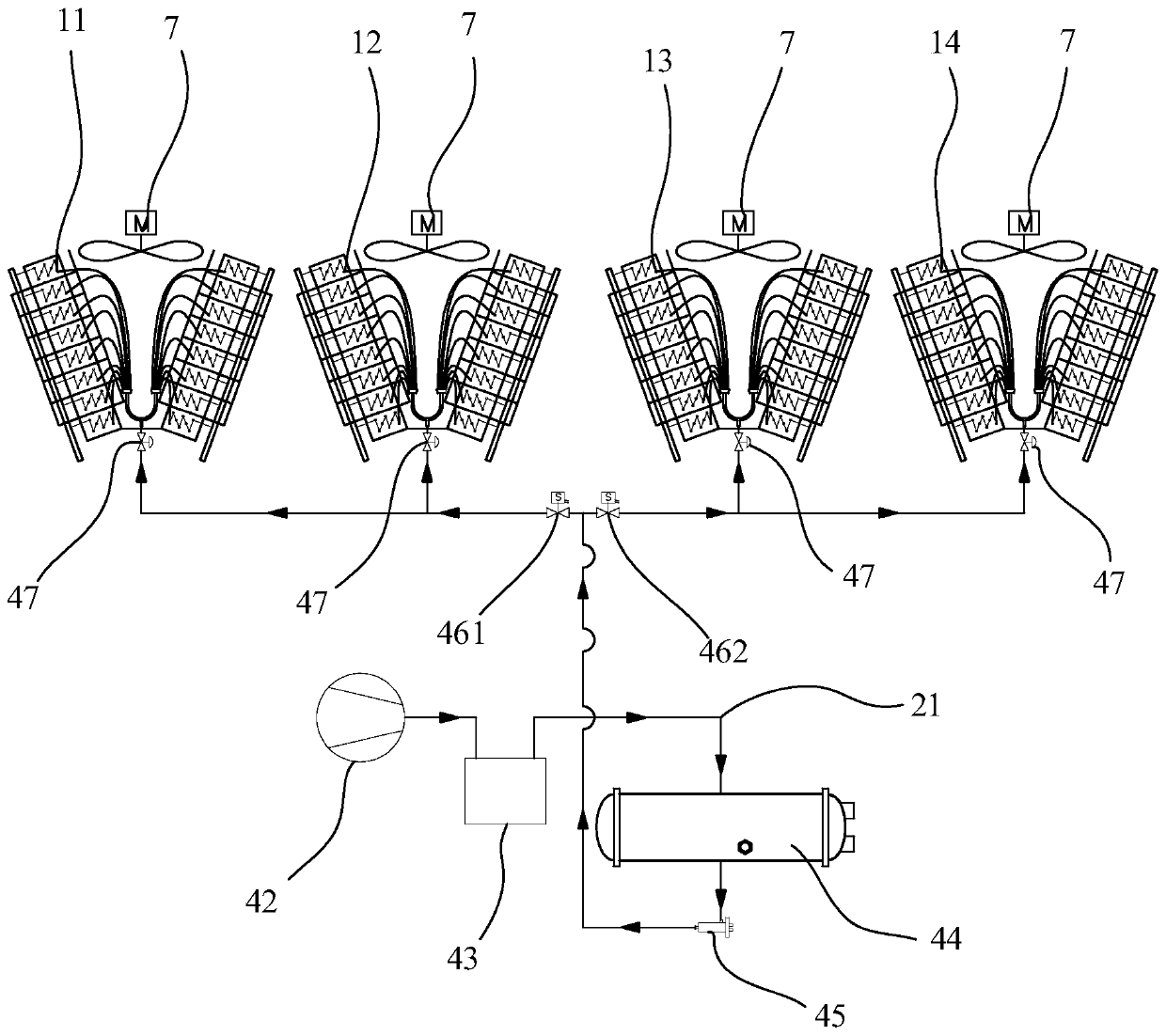

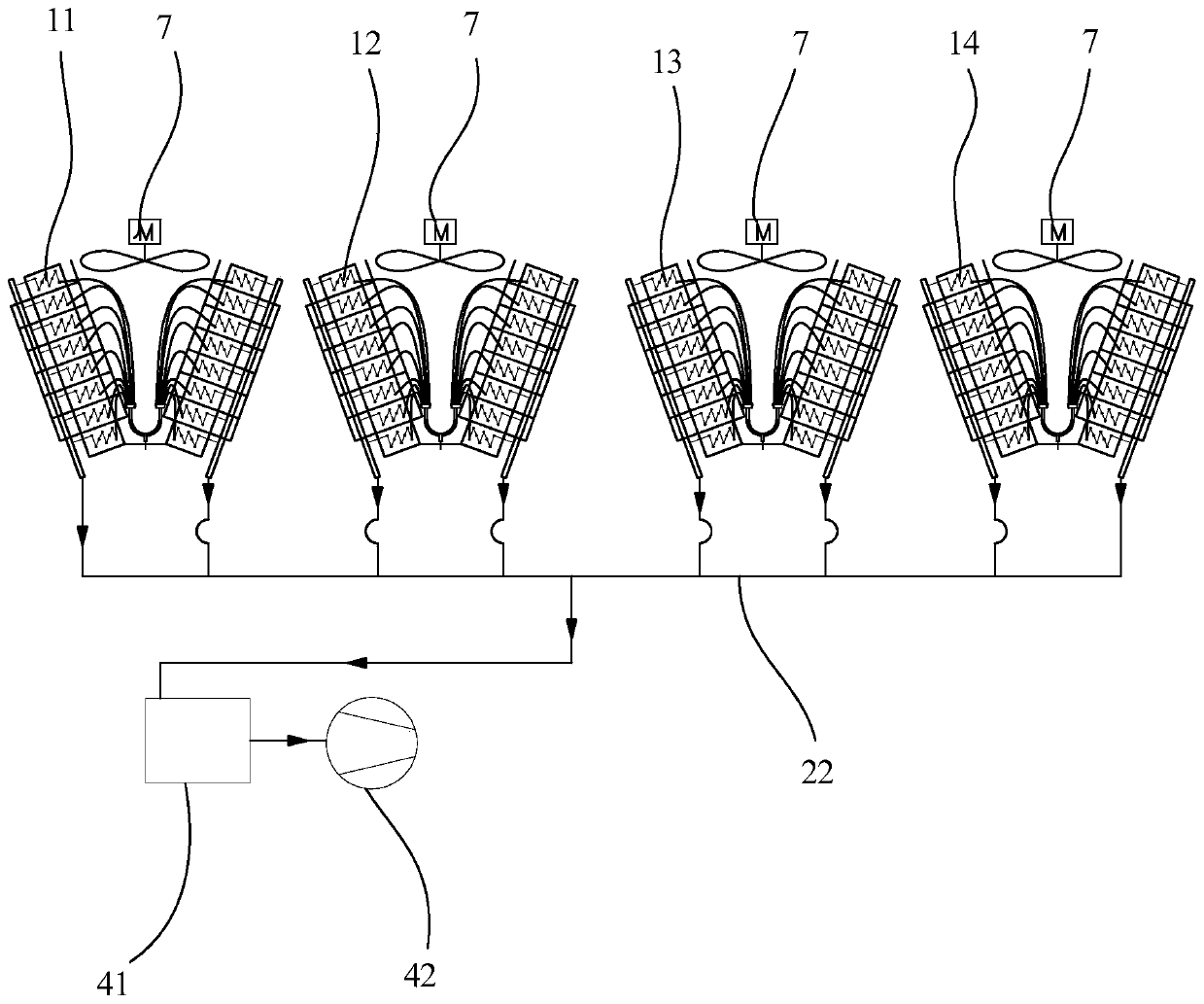

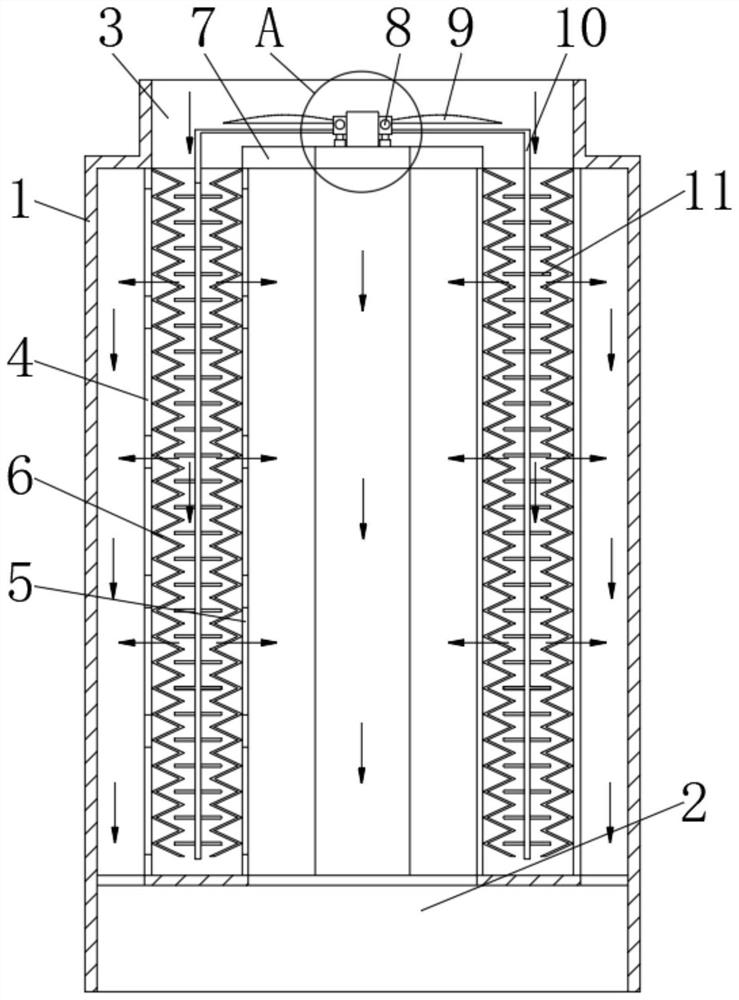

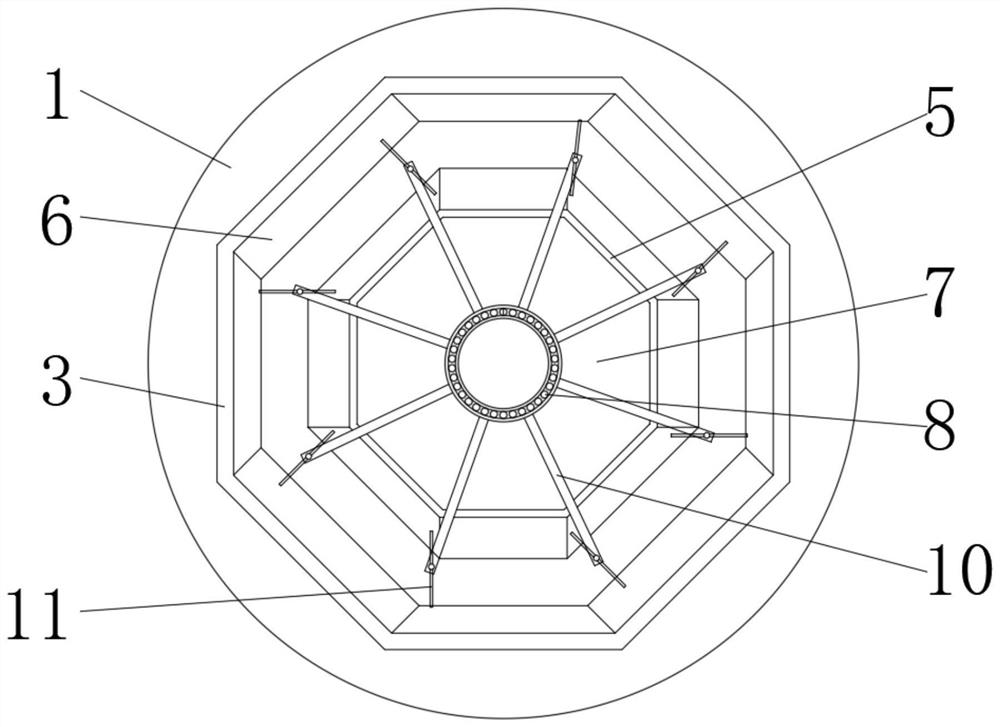

Distributed defrosting heat pump system

PendingCN110274412AGuaranteed suction and discharge pressureEasy to set upMechanical apparatusHeat pumpsEngineeringHigh pressure

The invention discloses a distributed defrosting heat pump system. The distributed defrosting heat pump system comprises at least two heat exchange sets, a heating pipeline, a defrosting pipeline, at least two defrosting valves and at least two main liquid way valves. Each heat exchange set comprises at least one fin heat exchanger. The heating pipeline cyclically communicates with the fine heat exchangers. The defrosting pipeline cyclically communicates with the fine heat exchangers. A defrosting gas pipeline is connected into the fin heat exchangers of the corresponding heat exchange sets through the defrosting valves. A heating high-pressure pipeline is connected into the fin heat exchangers of the corresponding heat exchange sets through the main liquid way valves. The heat exchange sets are adopted for distributed defrosting, one set of fin heat exchangers meeting the defrosting condition firstly can carry out defrosting firstly, a unit normally makes hot water and operates during defrosting, and it is guaranteed that the water outlet temperature of the unit does not fluctuate obviously; during defrosting, the compressor suction and exhaust pressure does not fluctuate obviously, and compressor oil supply and reliable operation are guaranteed; and the heating pipeline is simple and needs no one-way valve, and system operation is reliable.

Owner:SHANGHAI COMER MACHINERY

Engine oil filter for automobile assembly

InactiveCN111980778AIncrease the outflow areaIncrease speedPressure lubricationLubricant mounting/connectionFilter paperControl theory

The invention relates to the technical field of automobile equipment, and discloses an engine oil filter for automobile assembly. The engine oil filter comprises a filter body, wherein an oil discharge port is formed in the lower surface of the filter body. According to the engine oil filter for automobile assembly, two groups of filter paper are installed, so that injected engine oil is divided into two directions for filtering, the equipment filtering area is increased, the equipment instantaneous maximum filtering amount is increased, the engine rotation speed required by equipment to opena bypass valve is increased, and the service life of an engine is prolonged. Meanwhile, through an outer support and an inner support which are in a regular polygon shape, the filter paper can be installed on the outer support and on the inner support after being bent in the horizontal direction, and therefore it is ensured that a movable rod can rotate within the folded corners of the filter paper, and impurities adhering to the surface of the filter paper are carried away; and the horizontally bent filter paper can serve as the bypass valve to communicate with each cavity, so that a specialbypass valve is not needed, the outflow area is increased after filtering of the filter paper, and the amount of filtered engine oil is increased.

Owner:滁州市共赢汽车配件有限公司

Genset base with oil tank

ActiveCN103644428BDoes not affect normal useGuaranteed oil supplyMachines/enginesLiquid fuel feedersFuel tankFuel supply

The invention discloses a generator set base provided with a fuel tank. The generator set base comprises a fuel tank bottom plate, a fuel tank top cover plate and a pair of base beams, wherein the fuel tank bottom plate and the fuel tank top cover plate are sealed to form the fuel tank; the base beams are fixed at opposite end parts of the fuel tank respectively; a wave-proof plate is transversely arranged in the fuel tank and divides the fuel tank into an upper fuel tank layer and a lower fuel tank layer; and a plurality of oil leakage holes are formed in the wave-proof plate. Due to a gravity factor, when the fuel tank is placed horizontally, the lower fuel tank layer is always filled with fuel, when the fuel tank is inclined suddenly, the fuel in the lower fuel tank layer is inclined in the lower layer under the limitation action of the wave-proof plate, only small part of fuel flows to the upper fuel tank layer from the oil leakage holes due to the inclination action, and fuel supply for a generator set is guaranteed.

Owner:GUANGZHOU WANON ELECTRIC & MACHINE

Front PTO transmission system, transmission case and tractor

PendingCN114838092AFast inputFast outputHybrid vehiclesFluid actuated clutchesGear wheelControl theory

The invention relates to a front PTO transmission system, a transmission case and a tractor, the PTO transmission system comprises a power output shaft and an input gear, and the power output shaft can rotate around the axial direction of the power output shaft; the input gear coaxially and rotatably sleeves one end of the power output shaft, is combined with the power output shaft through the hydraulic clutch and rotates along with the power output shaft or is separated from the power output shaft. The power transmission device has the beneficial effects that power can be rapidly output, the transmission efficiency is high, the structure is compact, the integration degree is high, the occupied space is small, and the weight is light.

Owner:LOVOL HEAVY IND

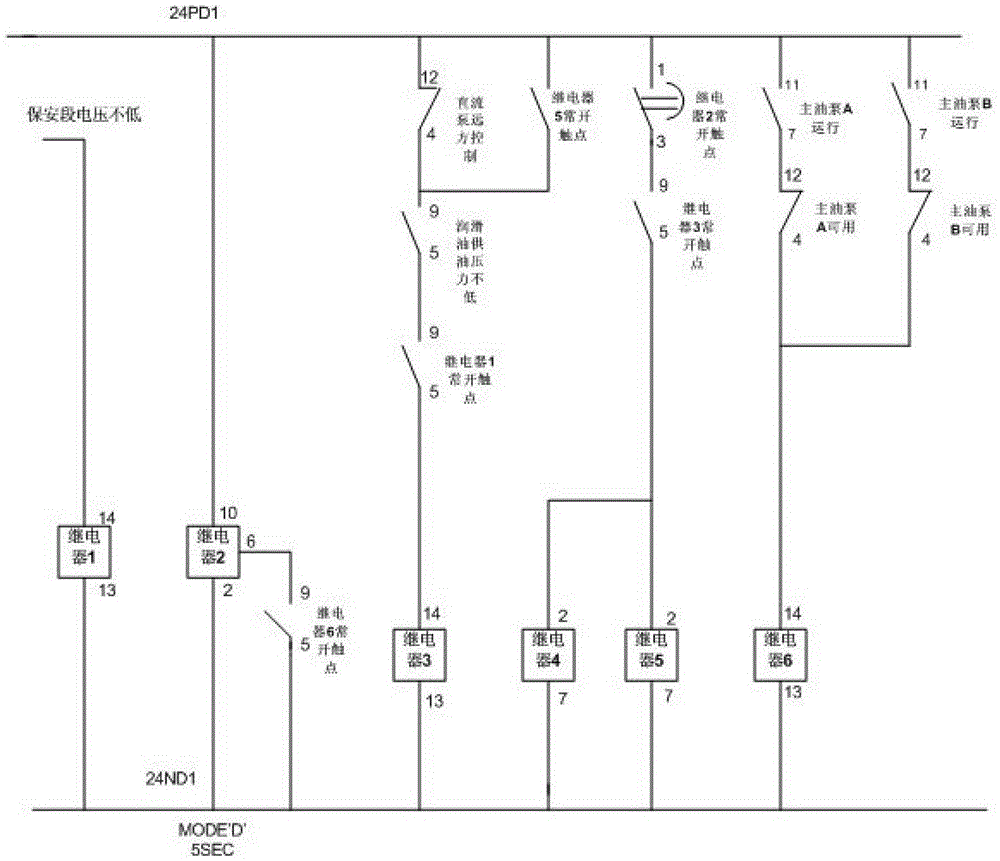

Method and device for improving oil supply reliability of lubricating oil system of generating set

InactiveCN103470378BNormal supplyImprove oil supply reliabilityGas turbine plantsJet propulsion plantsLow voltagePower switching

The invention relates to a method and a device for improving the oil-supplying reliability of a lubricating-oil system of a power generating set. The method is characterized in that in a control logic of a DCS (Distributed Control System) of the lubricating-oil system of the power generating set, when the low voltage of a safety section is related to tripping, additionally setting time delay of 2-5 seconds for an alternating-current lubricating-oil pump, so as to avoid the voltage-loss time of the alternating-current lubricating-oil pump for 1-2 seconds when a power switch of the safety section is switched, and ensuring no tripping of the alternating-current lubricating-oil pump when the power switch of the safety section is switched; setting a low-voltage instantaneous linked starting condition of the safety section in the hard-wiring condition of related starting of a direct-current lubricating-oil pump, setting a low-voltage instantaneous starting condition into failure of the alternating-current lubricating-oil pump in the linking logic of the direct-current lubricating-oil pump, and ensuring that oil pressure is provided by the direct-current lubricating-oil pump when in short-time voltage loss of a power switching bus of the safety section. The method and the device have the advantages that the oil-supplying reliability of the lubricating-oil system of the power generating set is improved from two aspects, the reliability is high and normal oil supplying of the lubricating-oil system at the low voltage of the safety section and under the condition that the alternating-current lubricating-oil pump fails is ensured.

Owner:SHENZHEN GUANGQIAN ELECTRIC POWER

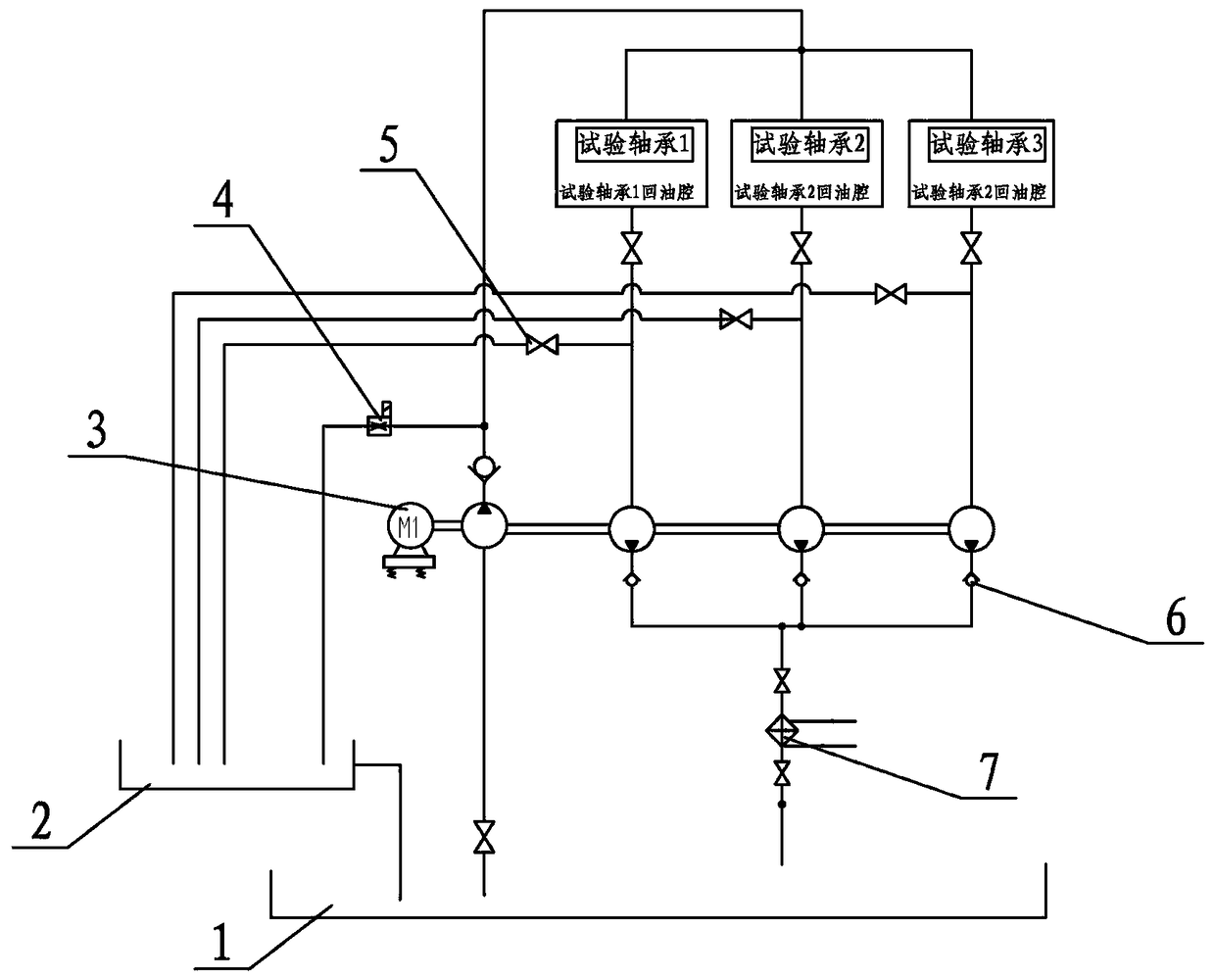

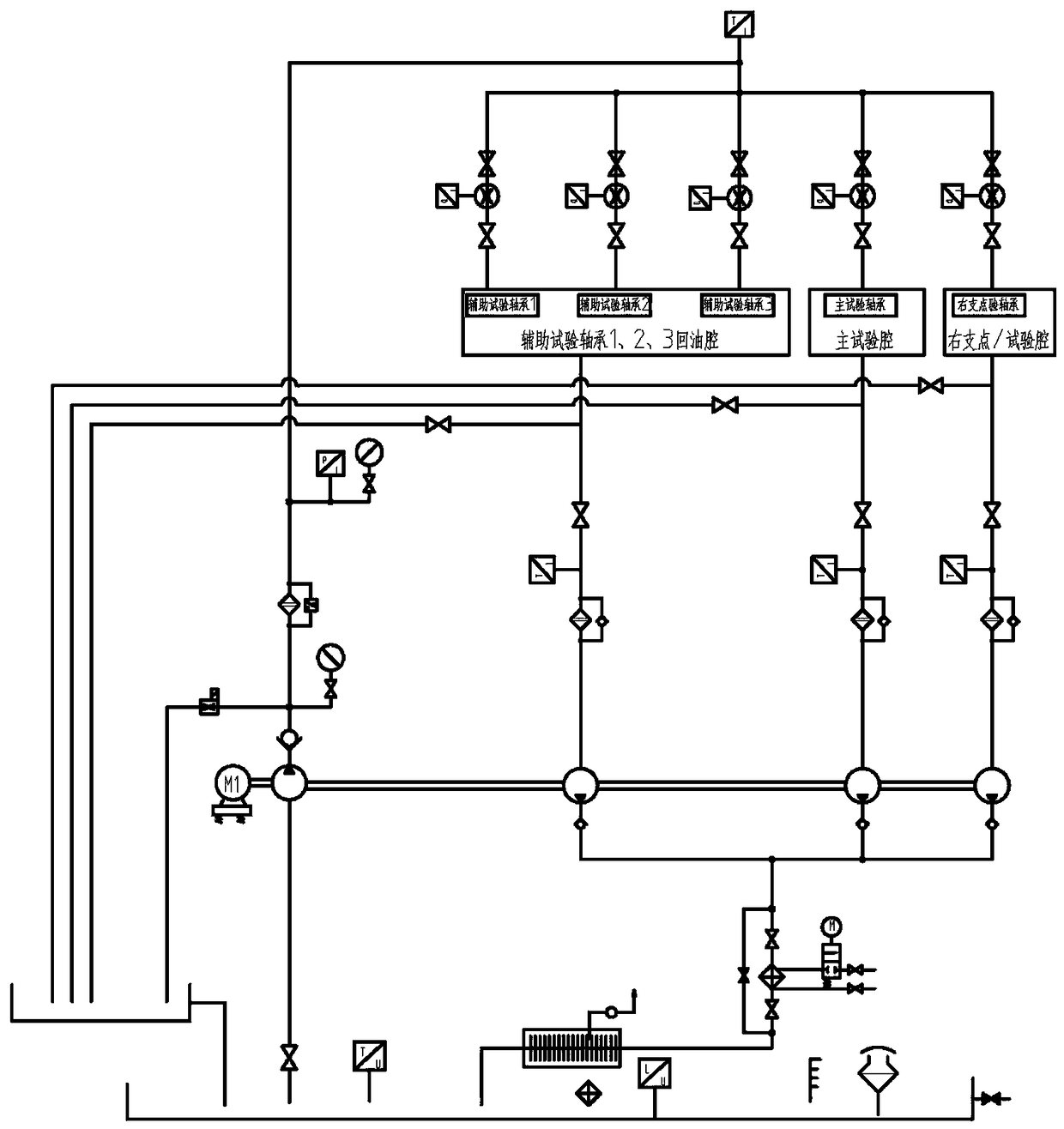

A multi-bearing lubrication system

Owner:HARBIN GUANGHAN POWER TRANSMISSION

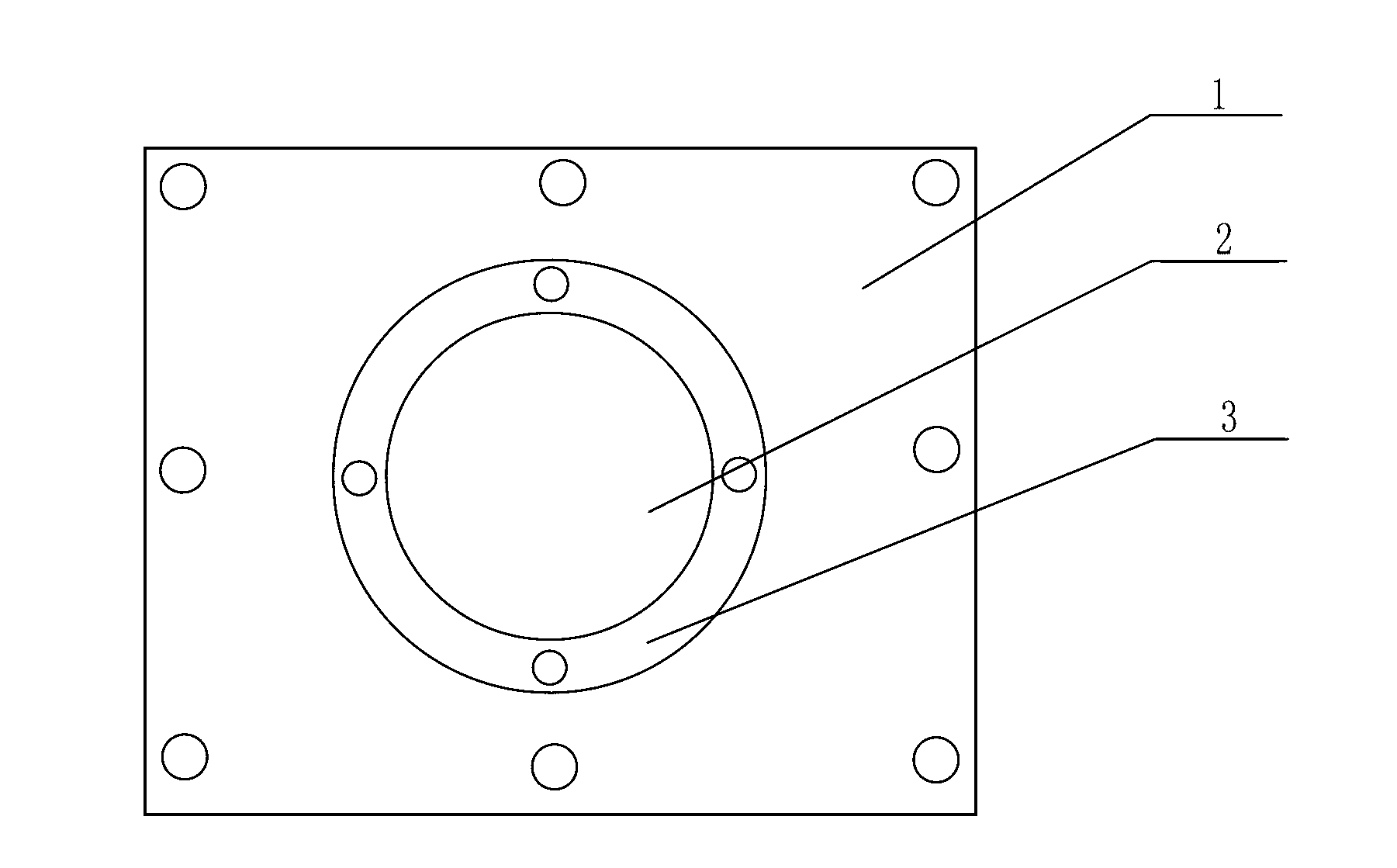

Oil observing window of reducer

InactiveCN103267115AGuaranteed oil supplyExtended service lifeGear lubrication/coolingMetallurgyReducer

The invention relates to an oil observing window, in particular to an oil observing window of a reducer. The oil observing window comprises a steel plate (1) with circular holes and a temperature resistant glass (2). The temperature resistant glass (2) is fixed on the steel plate (1) and corresponds to the circular holes of the steel plate (1). The temperature resistant glass (2) is circular, and an annular rubber gasket (3) is arranged on the front of the temperature resistant glass (2) and between the temperature resistant glass (2) and the steel plate (1). By means of the oil observing window, oil quantity in the reducer can be observed in real time, convenience is provided for patrolling of operators, oil supply for the reducer is guaranteed, the service life of the reducer is greatly prolonged, the structure is simple, design is reasonable, and the appearance is elegant.

Owner:SHANDONG HUALIAN MINING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com