Rotary compressor

A technology for rotary compressors and compression mechanisms, which is applied to rotary piston/oscillating piston pump components, mechanical equipment, machines/engines, etc. It can solve problems such as eccentric crankshaft and sliding plate wear, and prevent reliability reduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] As Embodiment 1 of the present invention, technical disclosure is made based on a rotary compressor, which is a typical representative model of rotary compressors.

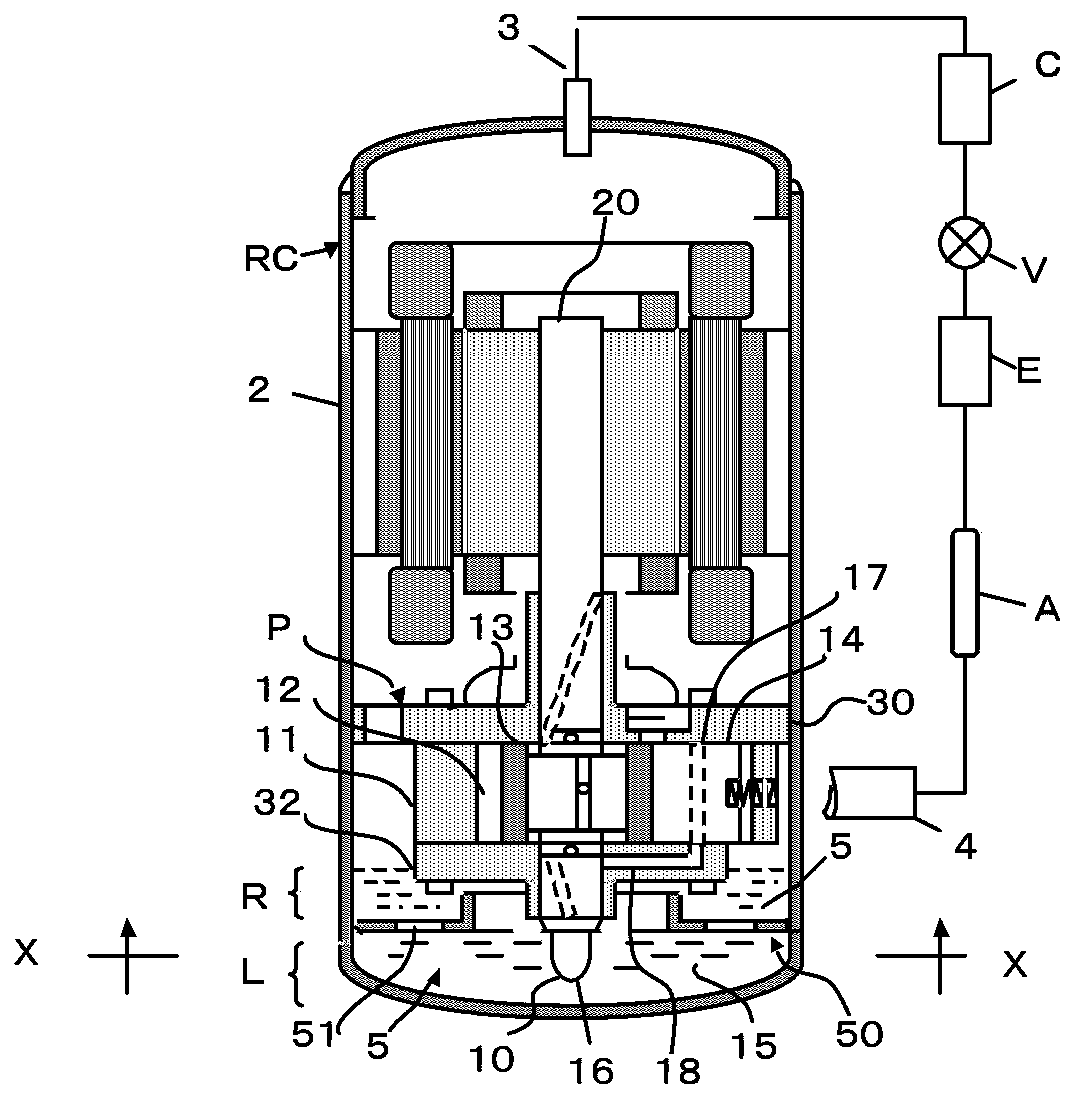

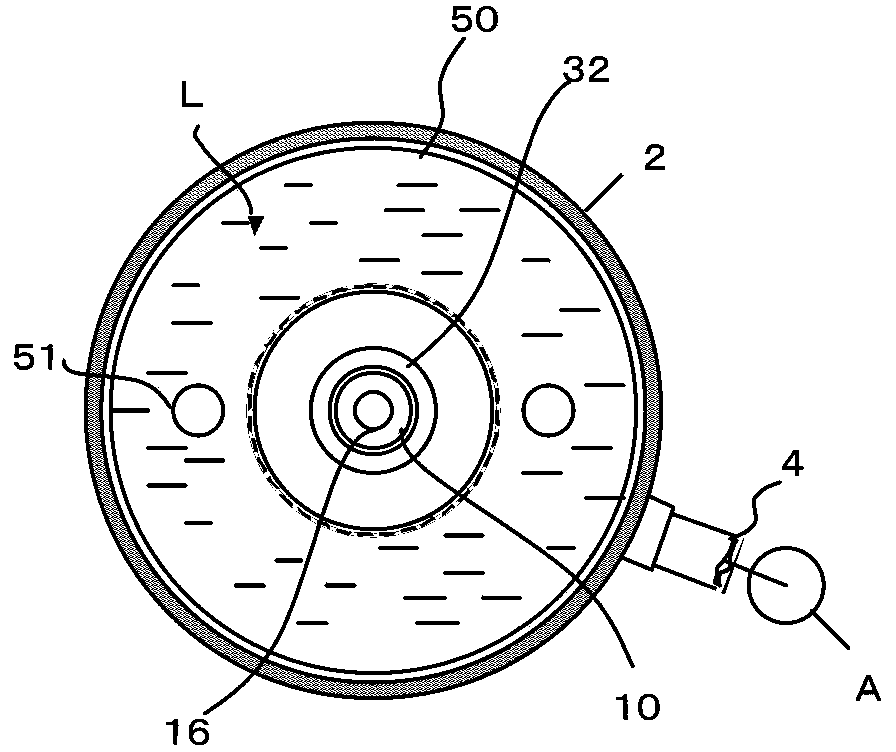

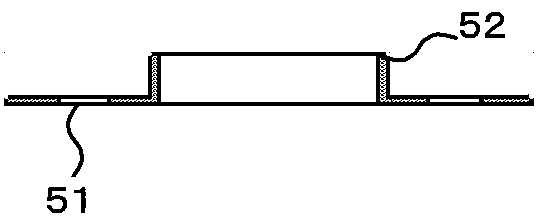

[0026] see figure 1 , represents the motor part arranged in the hermetic case 2 fixed in the rotary compressor RC and the compression mechanism P arranged under it. figure 2 yes figure 1 The X-X cross-section of , represents the partition plate 50 and the L layer viewed from the bottom of the casing 2 . Figure 3-Figure 4 is a detailed view of the partition plate 50 . Figure 5 It is a detailed diagram showing the compression mechanism P, the partition plate 50 , the relationship between the L layer and the R layer, and the oil supply circuit 18 to the slide plate 14 .

[0027] figure 1 The compression mechanism P includes a cylinder 11, a piston 13 that rotates eccentrically in the compression chamber 12 of the cylinder 11, a sliding plate 14 that reciprocates synchronously with the piston 13, an ecce...

Embodiment 2

[0053] In Example 1, refrigerant R290 and oil soluble in the refrigerant were used, but in Example 2, refrigerant R290, oil hardly soluble in the refrigerant, and insoluble oil that was hardly dissolved were used. In the description below, these are collectively referred to as non-dissolving oils. In addition, the specific gravity of these oils is close to that of Example 1.

[0054] R290 and non-dissolved oil form the L layer, and the condensed liquid refrigerant forms the R layer, and they form the separation layer. Therefore, the partition plate 50 having a specific gravity of 0.75 floats between these separation layers.

[0055] The oil that has finished lubricating the eccentric crankshaft 20, the main bearing and the auxiliary bearing, and the compression chamber 12 falls from the main bearing 30 to the upper end of the R layer, and due to the difference in specific gravity, the oil passes through the R layer from the upper end of the partition plate 50. The oil passag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com