A polarization maintaining fiber

A polarization-maintaining fiber and fiber core technology, which is applied in polarization fiber, cladding fiber, multi-layer core/cladding fiber, etc., can solve the problem that the environmental performance has a large impact, cannot meet the needs of fiber optic gyroscope development, and is difficult to take into account at the same time. FOG development requirements and other issues, to achieve the effect of reducing side lobes, avoiding reliability reduction, and high-performance crosstalk output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

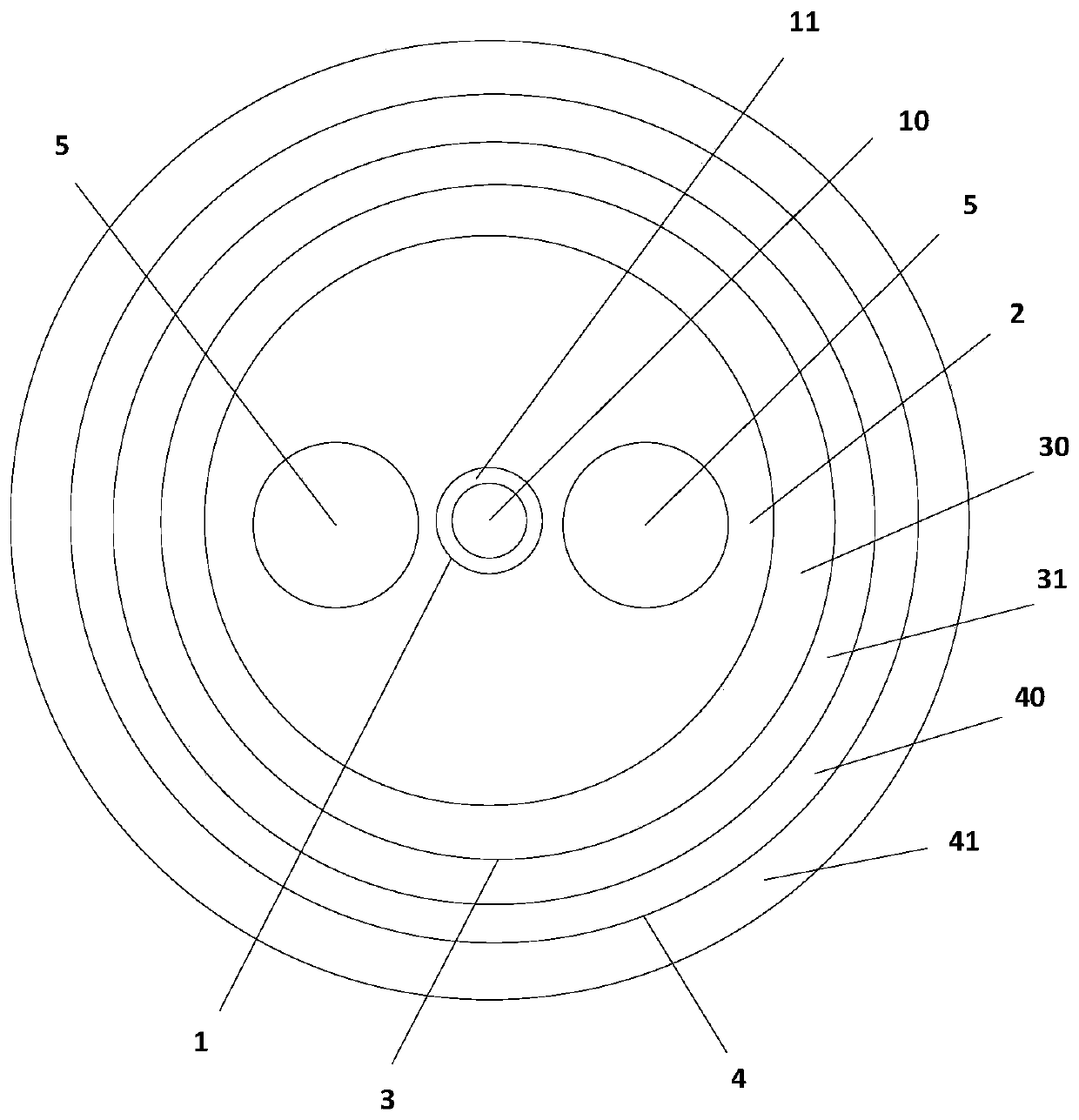

[0028] See figure 1 As shown, the embodiment of the present invention provides a polarization-maintaining fiber, which includes a core 1, a quartz cladding 2, an inner coating 3, and an outer coating 4 from the inside to the outside. The quartz cladding 2 is located in the core At the periphery of 1, two stress regions 5 are provided between the quartz cladding 2 and the core 1, and the two stress regions 5 are symmetrically distributed along the center of the core 1;

[0029] The core 1 includes a circular central core region 10 and at least one annular region 11 arranged concentrically with the central core region 10 from the inside to the outside, and the central core region 10 and the annular region 11 have different refractive indexes;

[0030] The inner coating 3 and the outer coating 4 both have a double-layer structure, and the modulus of each layer of the inner coating 3 and the outer coating 4 is different, and the modulus increases from the inner to the outer layer.

[003...

Embodiment 2

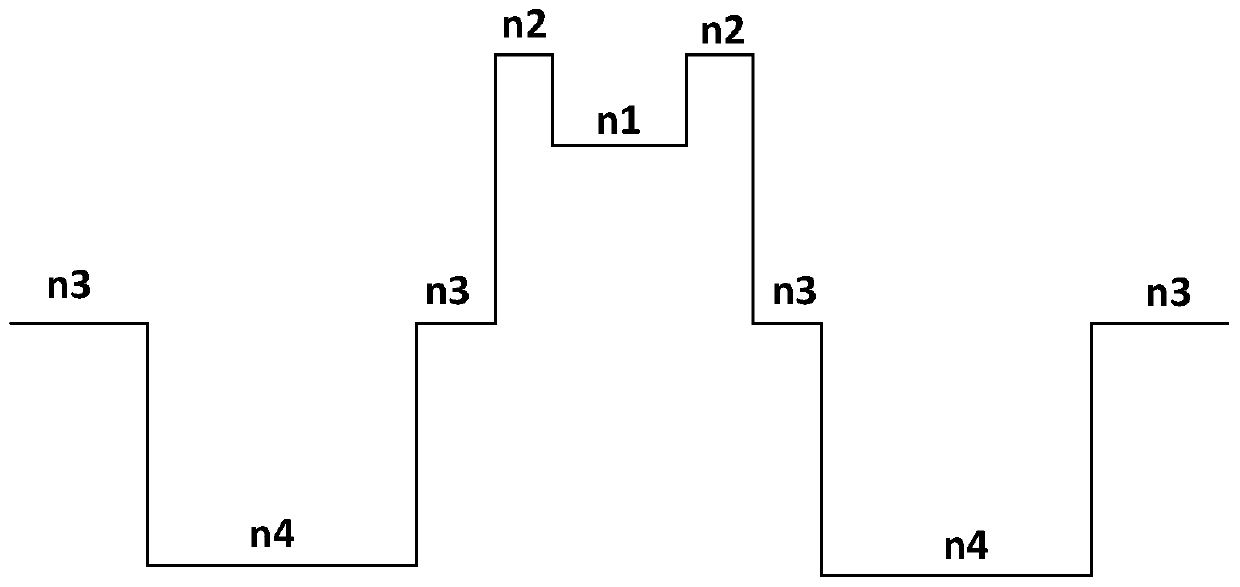

[0033] See figure 2 As shown, the difference between this embodiment and Embodiment 1 is that the refractive index of the central core region 10 is n1, the refractive index of the annular region 11 is n2, and the refractive index of the quartz cladding 2 is n3, so The refractive index of the stress region 5 is n4, and n4

[0034] The refractive index of the central core region 10 relative to the quartz cladding 2 is △n1, and the refractive index of the annular region 11 relative to the quartz cladding 2 is △n2, △n1<△n2, where the value of △n1 The range is 0.4% to 1.3%, and the value range of △n2 is 0.6% to 1.5%.

[0035] In the embodiment of the present invention, the refractive index n1 of the central core region 10 is smaller than the refractive index n2 of the annular region 11, that is, the core forms a U-shaped structure design, so that the mode characteristics of the optical signal transmitted by the polarization maintaining fiber tends to be more intermediate. R...

Embodiment 3

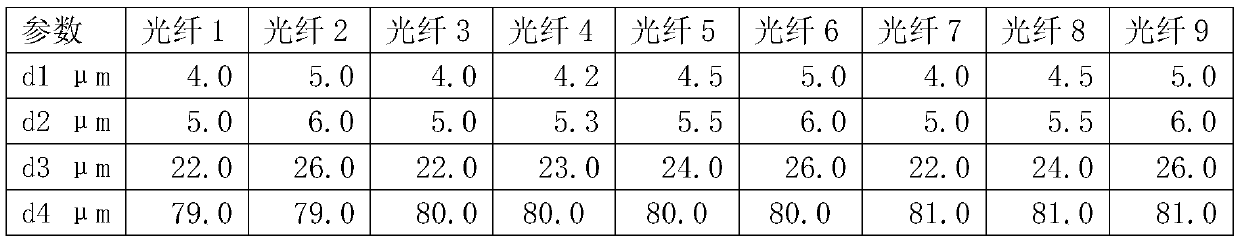

[0037] The difference between this embodiment and embodiment 1 is that the diameter of the central core region 10 is d1, the outer diameter of the annular region 11 is d2, the diameter of the stress region 5 is d3, and the diameter of the quartz cladding 2 The outer diameter is d4, and d1

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com