Display device and binding state detection method

A display device and binding technology, used in static indicators, instruments, nonlinear optics, etc., can solve the problems of incomplete separation of the drive circuit and the display panel, poor binding state, poor processing, etc., to ensure normal work and Reliability, improved efficiency, improved timeliness effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

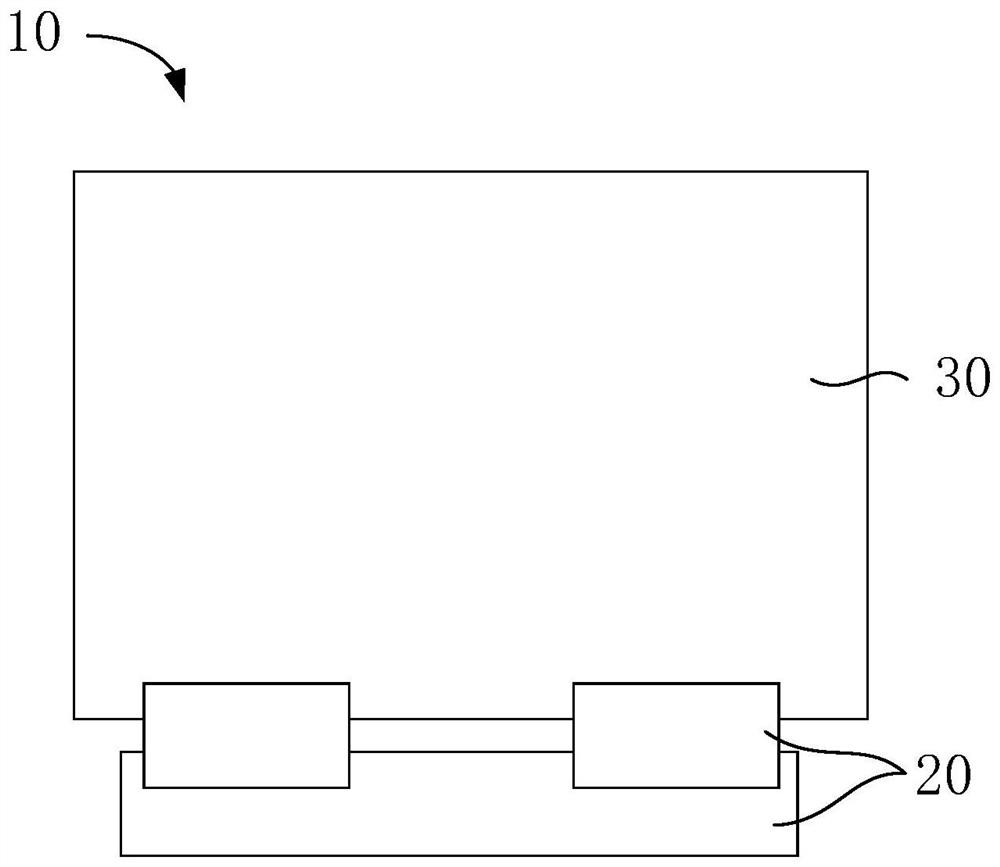

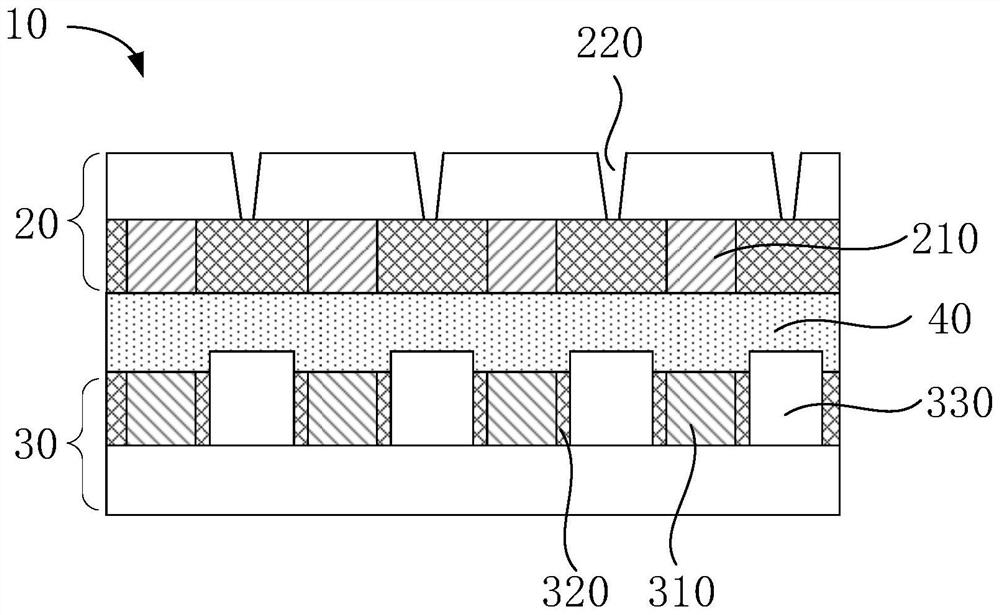

[0037] figure 1 is a schematic top view of a display device according to the first embodiment of the present application, figure 2 It is a schematic cross-sectional view of a display device according to the first embodiment of the present application, refer to figure 1 and figure 2It can be seen that, as the first embodiment of the present application, a display device 10 is disclosed, which includes a display panel 30 and a driving element 20 . The display panel 30 is bound and connected to the driving element 20 ; the driving element 20 includes a plurality of first binding terminals 210 , the display panel 30 includes a plurality of second binding terminals 310, the first binding terminals 210 are connected to the second binding terminals 310 through the anisotropic conductive adhesive 40 in a one-to-one correspondence, the display panel 30 further includes a force-sensitive material layer 330, There are at least two force-sensitive material layers 330 , the force-sensi...

Embodiment 2

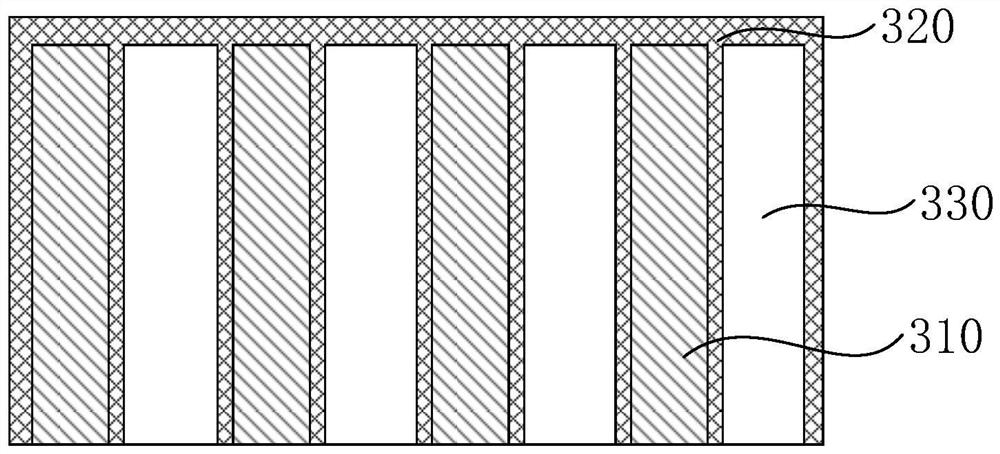

[0056] Figure 5 It is a schematic top view of the display panel in the second embodiment of the present application, refer to Figure 5 It can be seen that, different from the first embodiment, each force-sensitive material layer 330 is arranged in sections along the length direction of the first binding terminal 210 or the second binding terminal 310 .

[0057] In this embodiment, the force-sensitive material layer 330 and the second binding terminal 310 are alternately arranged at intervals as an example. Each force-sensitive material layer 330 is arranged in sections along the length direction of the second binding terminal 310 . It includes a plurality of force-sensitive material blocks 333, and the plurality of force-sensitive material blocks 333 are arranged at intervals, arranged along the length direction of the second binding terminals 310, and arranged between two adjacent second binding terminals 310, The force-sensitive material block 333 converts the force in di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com