Method for testing and calculating bending strength of flexible part

A technology of bending strength and calculation method, which is applied in the direction of applying stable bending force to test material strength, strength characteristics, measuring devices, etc., can solve problems such as broken, broken, cracked, etc., and achieve the effect of avoiding breaking and reducing reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

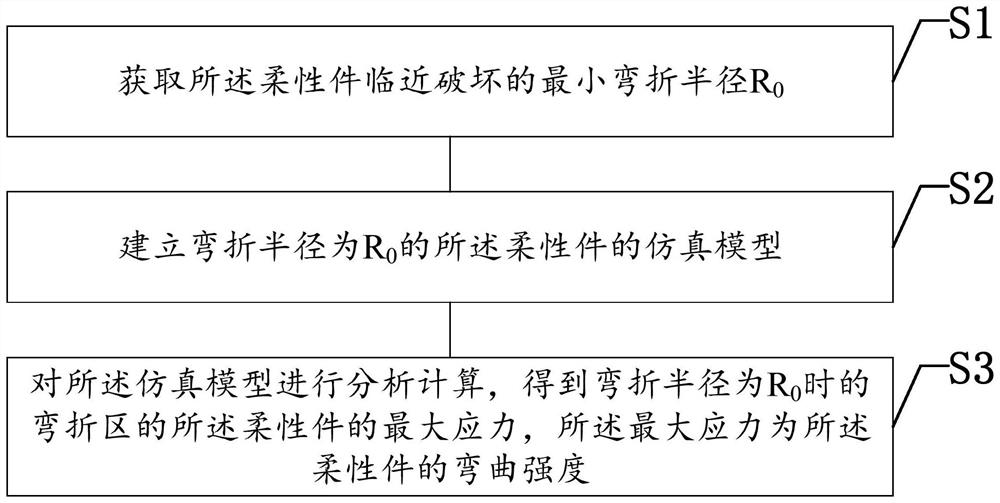

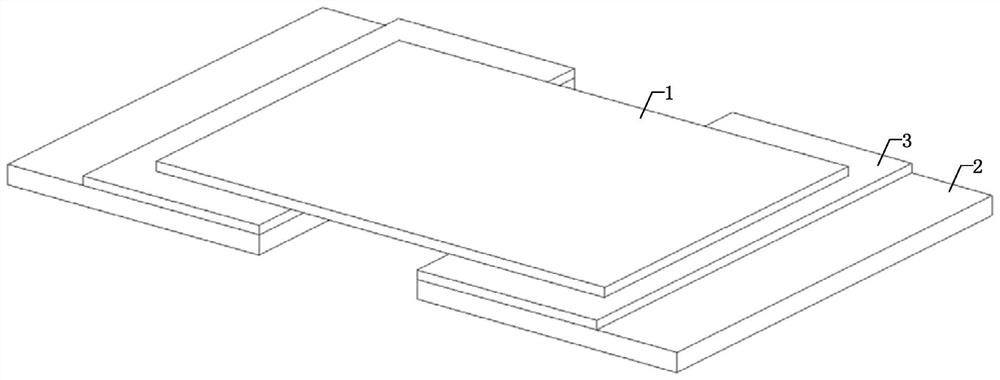

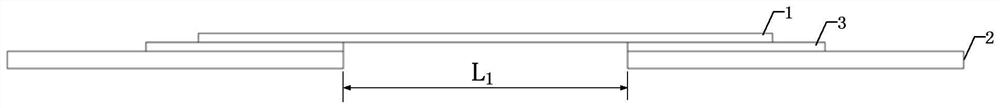

[0030] Such as figure 1 As shown, this embodiment provides a method for testing and calculating the bending strength of the flexible member 1, which includes the following steps: S1, obtaining the minimum bending radius R of the flexible member 1 that is close to failure 0 ;S2, establish the bending radius as R 0 The simulation model of the flexible part 1; S3, analyze and calculate the simulation model, and obtain that the bending radius is R 0 The maximum stress of the flexible part 1 in the bending area at time, the maximum stress is the bending strength of the flexible part 1 . In this embodiment, the flexible member 1 is ultra-thin glass.

[0031] Through the testing and calculation method of the bending strength of the flexible member 1 of this embodiment, the bending strength of the ultra-thin glass is obtained. When the ultra-thin glass of this embodiment is applied to a flexible display product, the flexible display product can be bent according to the bending stren...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com