Distributed defrosting heat pump system

A heat pump system and distributed technology, applied in heat pump, refrigeration and liquefaction, lighting and heating equipment, etc., can solve the problems of many final rinsing times, large injection water consumption, long rinsing time, etc., to ensure oil supply and reliable operation. , The effect of simple setting and simple heating pipeline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention is further illustrated below by means of examples, but the present invention is not limited to the scope of the examples.

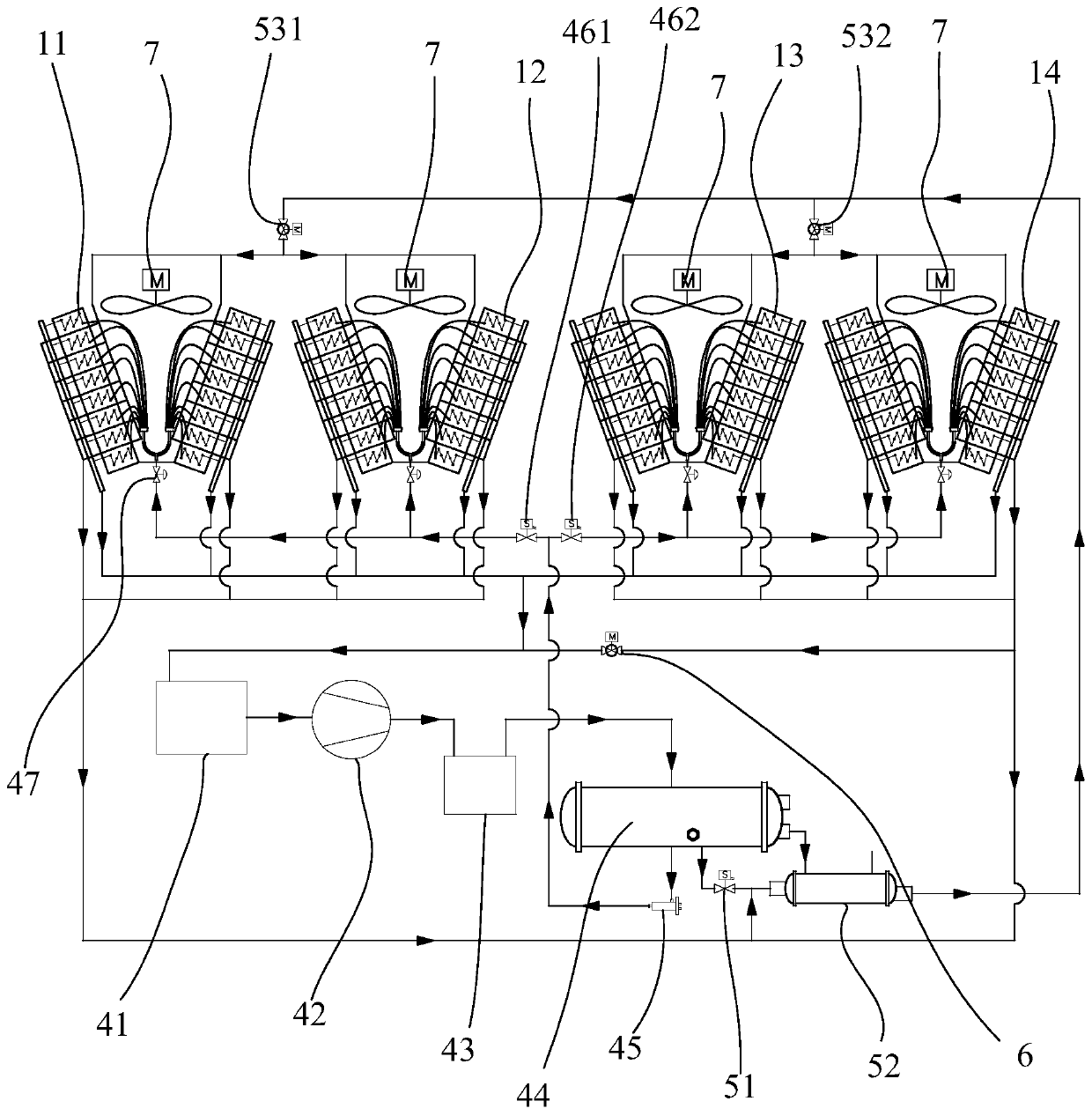

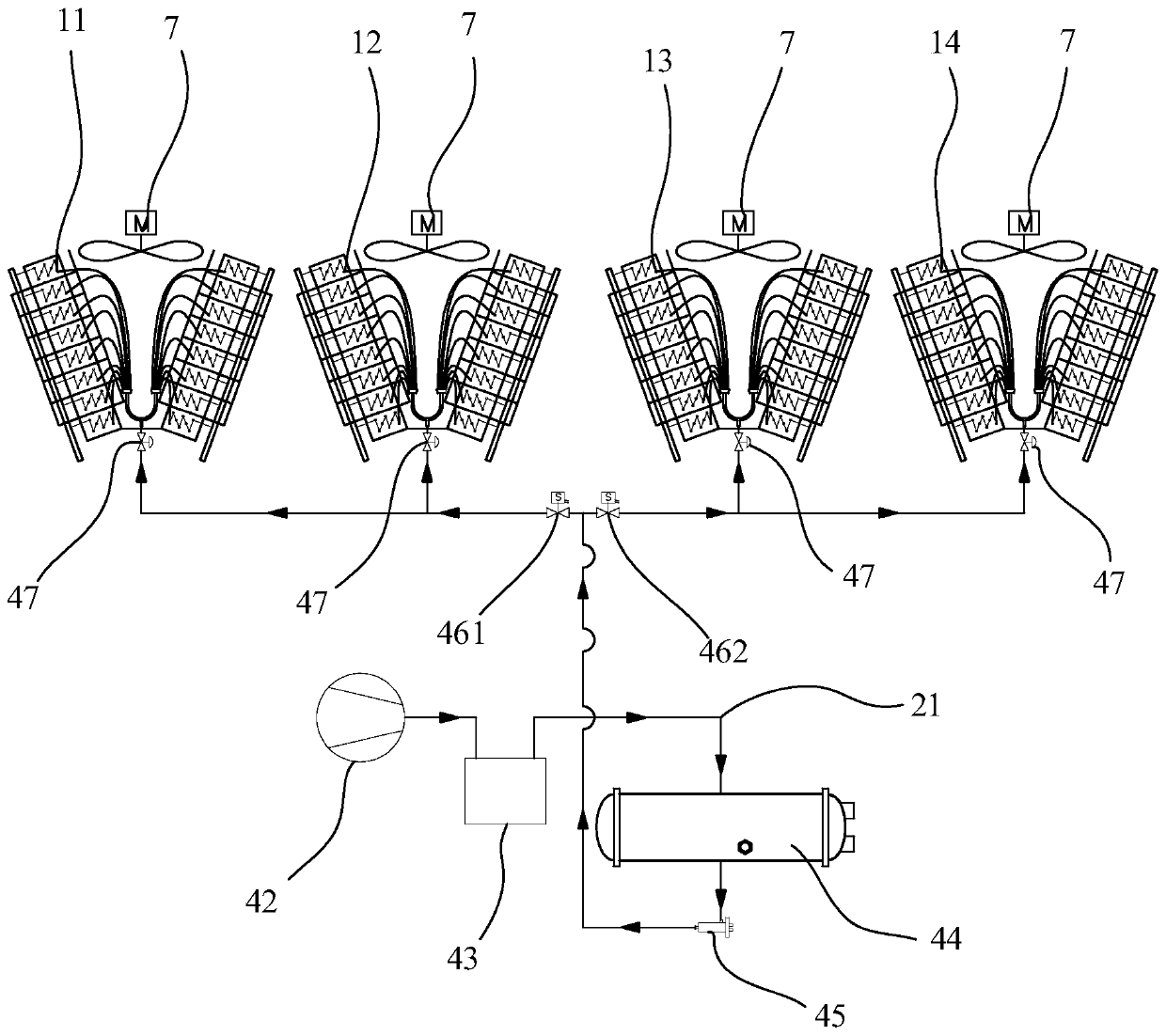

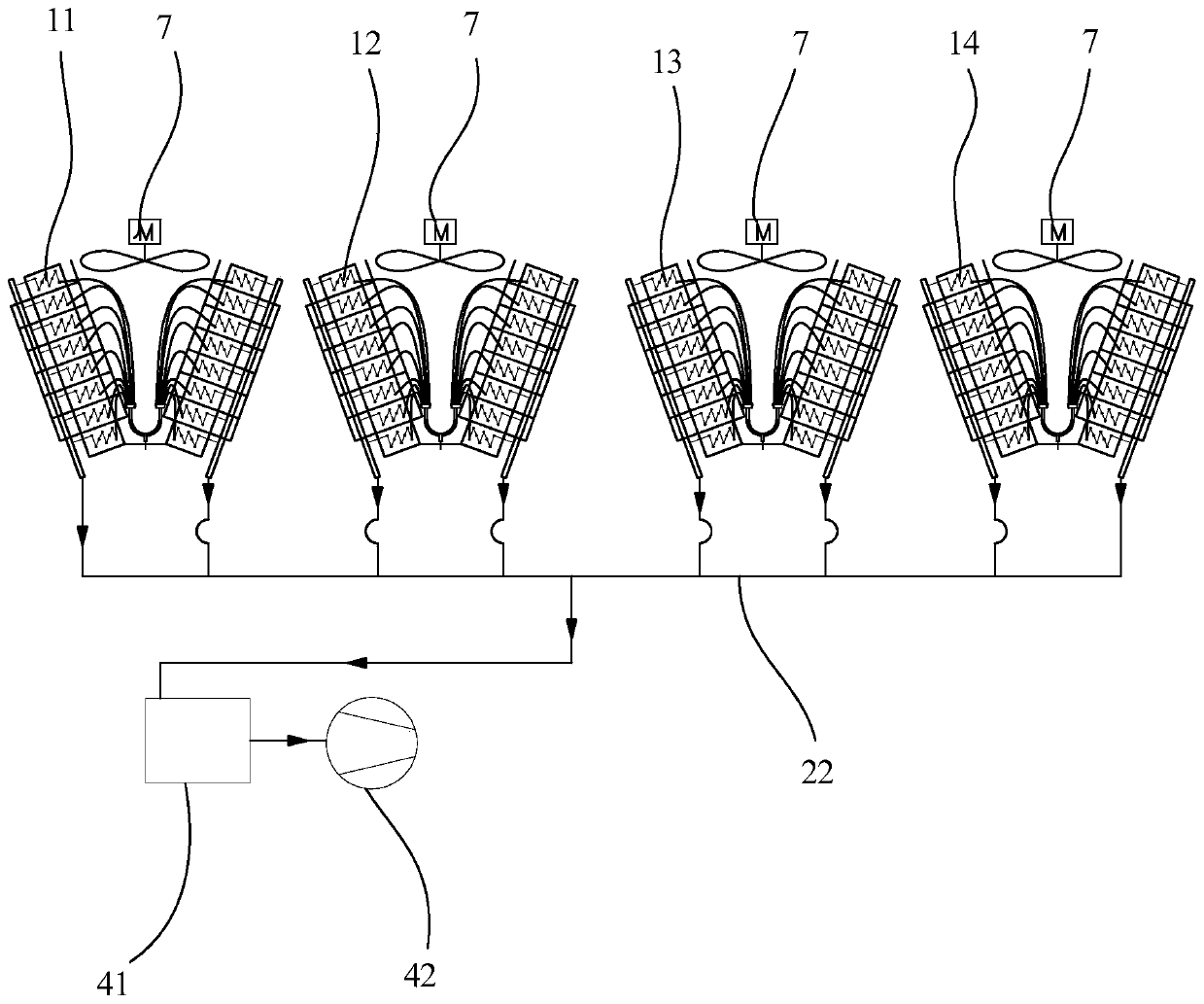

[0038] Such as Figure 1-Figure 5 As shown, this embodiment discloses a distributed defrosting heat pump system, including a fin heat exchanger 11 , a fin heat exchanger 12 , a fin heat exchanger 13 and a fin heat exchanger 14 . Wherein, the distributed defrosting heat pump system in this embodiment is divided into two heat exchange groups, and each heat exchange group includes two fin heat exchangers. The heat exchange group on the left side includes the fin heat exchanger 11 and the fin heat exchanger 12 ; the heat exchange group on the right side includes the fin heat exchanger 13 and the fin heat exchanger 14 .

[0039] Such as figure 2 and image 3 As shown, the distributed defrosting heat pump system of this embodiment includes a heating pipeline, the heating pipeline includes a heating low-pressure suction pipeline ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com