Patents

Literature

233results about How to "Avoid breakage damage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

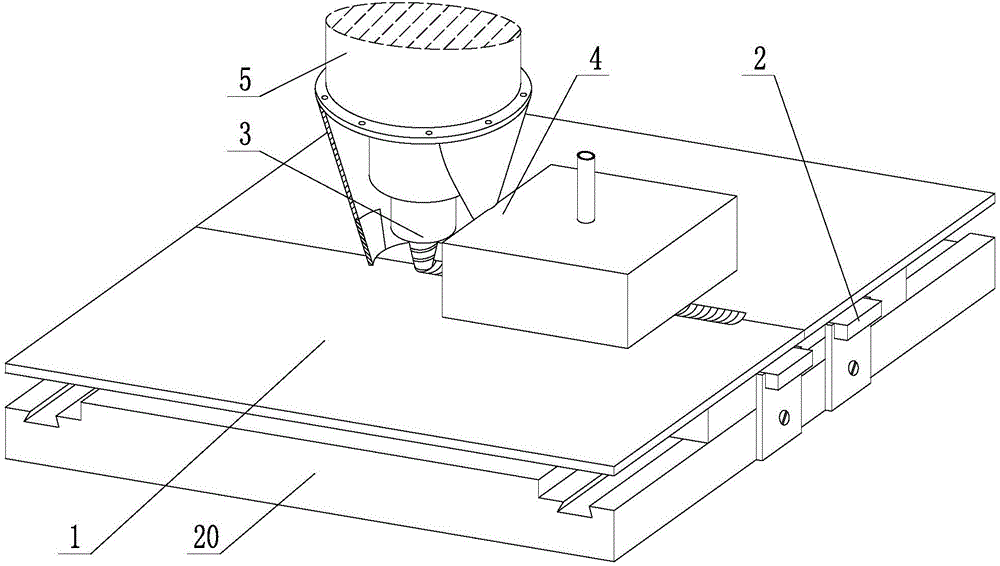

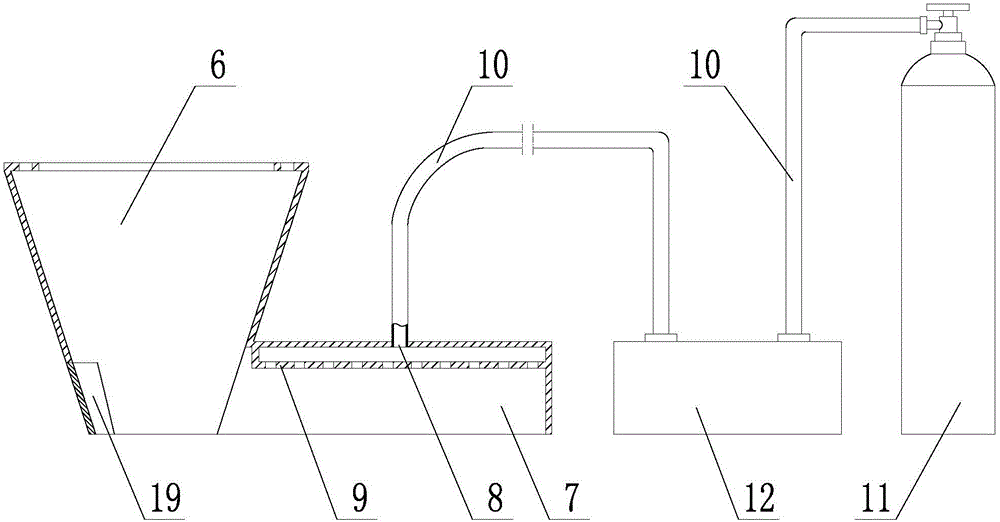

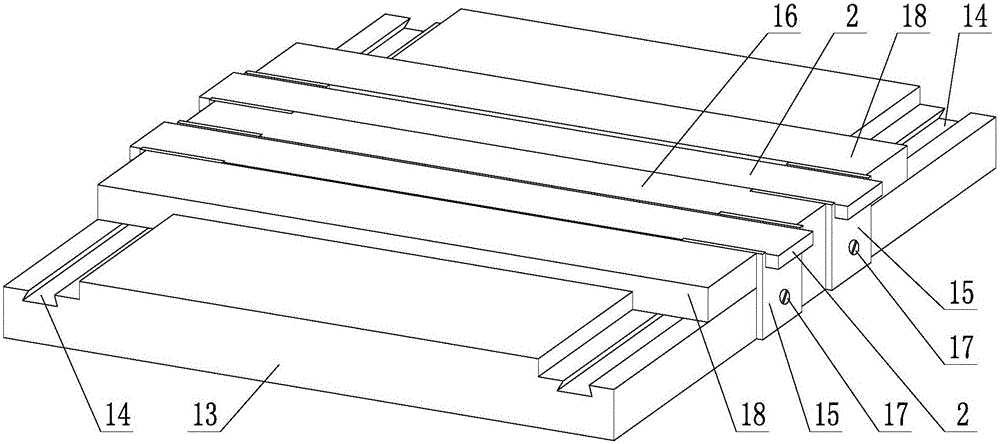

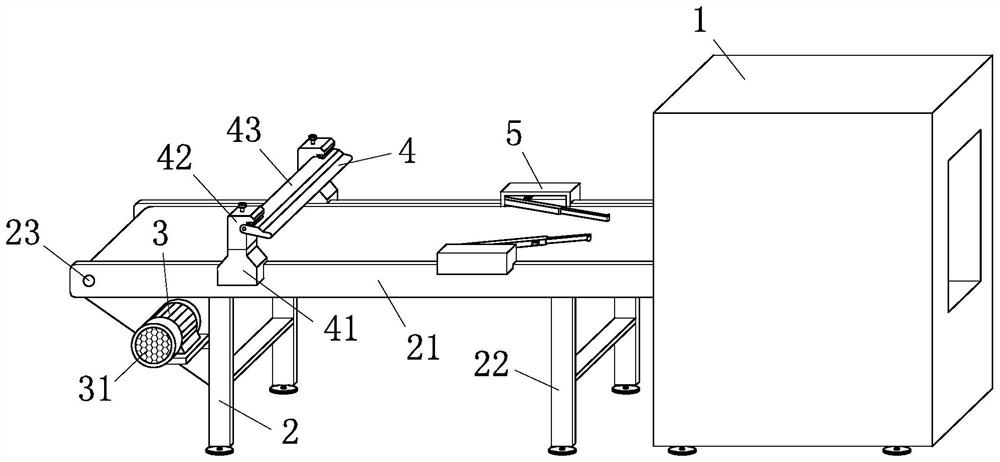

Friction stir welding process for combining back surface heating with frontal surface chilling

ActiveCN106271025AReduce temperature gradientImprove unevennessNon-electric welding apparatusCarbon Dioxide / HeliumShielding gas

The invention discloses a friction stir welding process for combining back surface heating with frontal surface chilling. The friction stir welding process comprises the following steps: a workpiece to be welded is fixedly clamped; heaters are arranged on two sides of a welding line area; a chilling shielding gas protective cover for moving along with a stirring head is arranged on the outer side of the stirring head; the heaters are started to heat the back surface of the workpiece to be welded, so that the temperature of the upper surface of the workpiece to be welded is not higher than 250 DEG C; the chilling shielding gas protective cover is filled with the chilling shielding gas, and the covering range includes the welding line area and the upper surface area of the workpiece to be welded rightly above the heaters; friction stir welding equipment is started, and the rotating stirring head is controlled to insert in the workpiece to be welded; the shaft shoulder end surface of the stirring head is continuously pressed down by a section of distance, and the stirring head is stopped until a set inserting depth is reached; the stirring head is controlled to continuously rotate by a period of time under the set inserting depth, so that the welding line area of the workpiece to be welded is fully preheated to reach an excellent plastic state; and the stirring head is controlled to finish the welding work of the welding line area at a set welding speed.

Owner:SHENYANG AEROSPACE UNIVERSITY

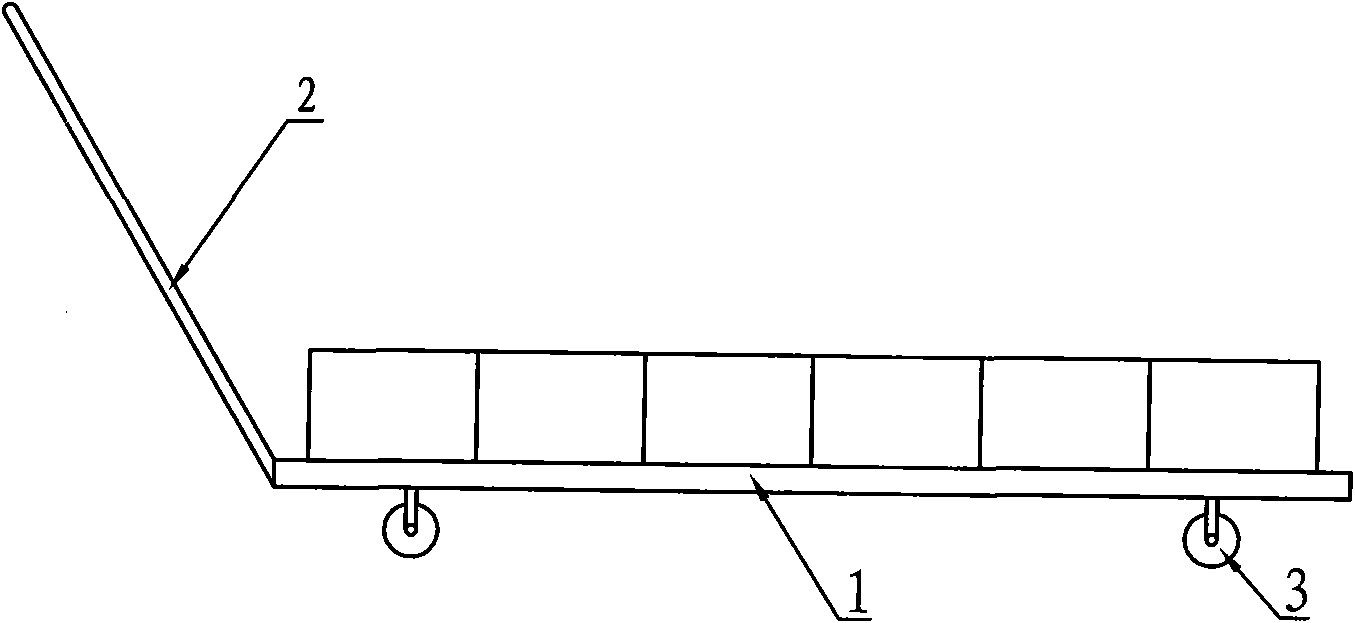

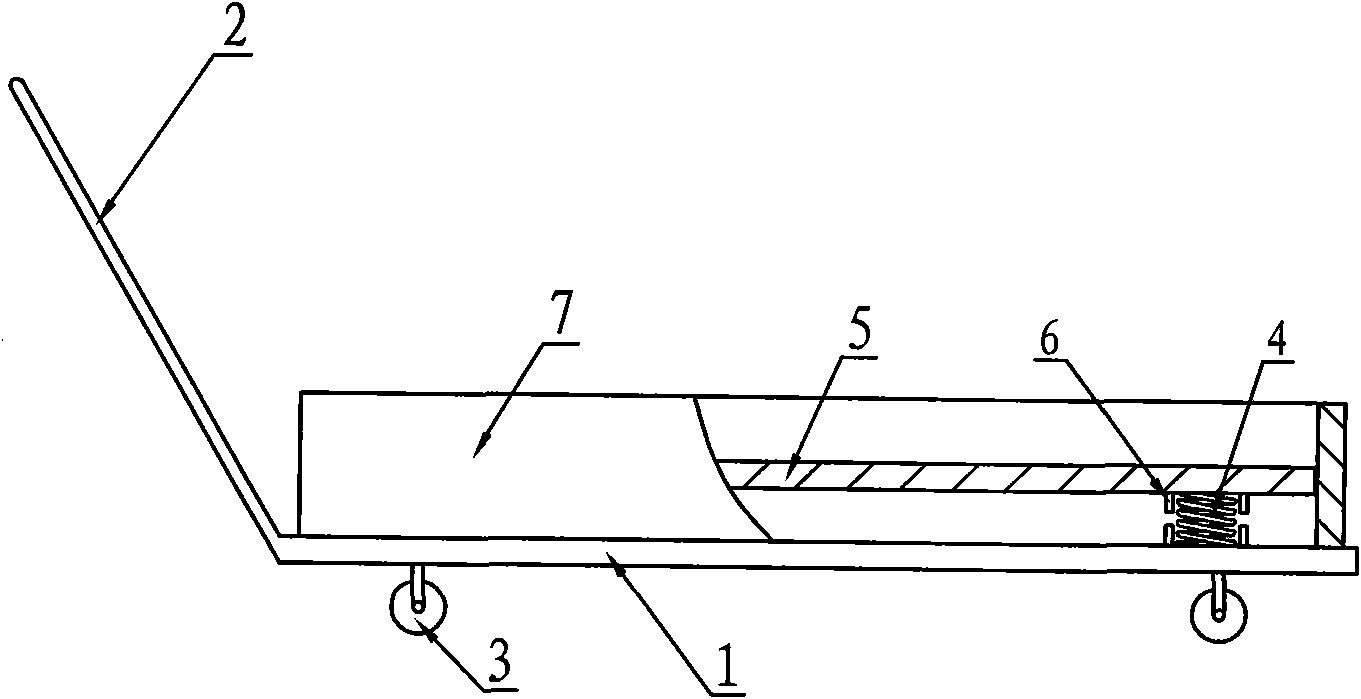

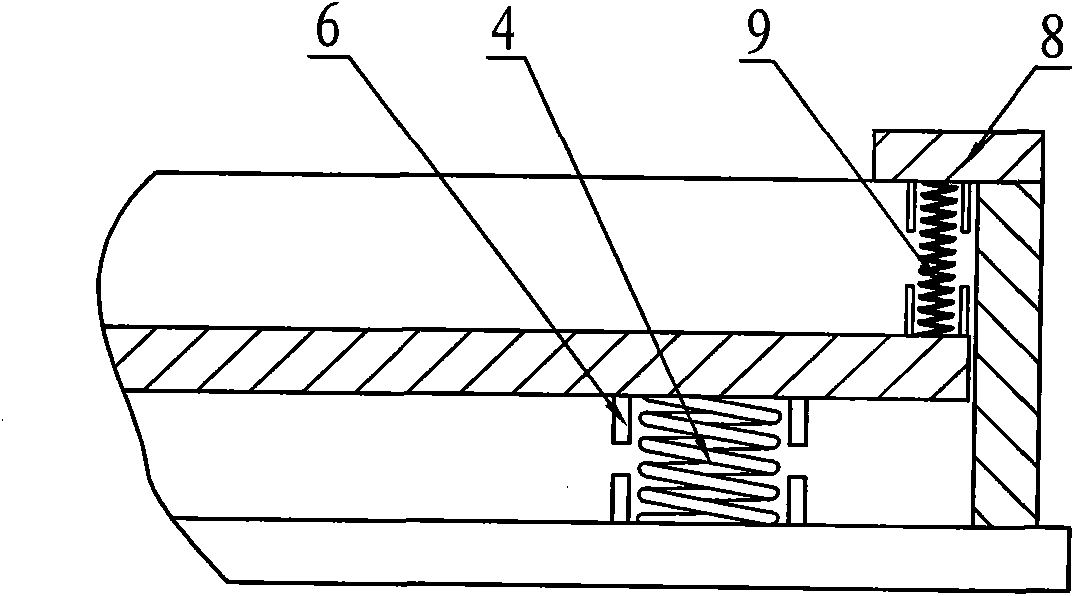

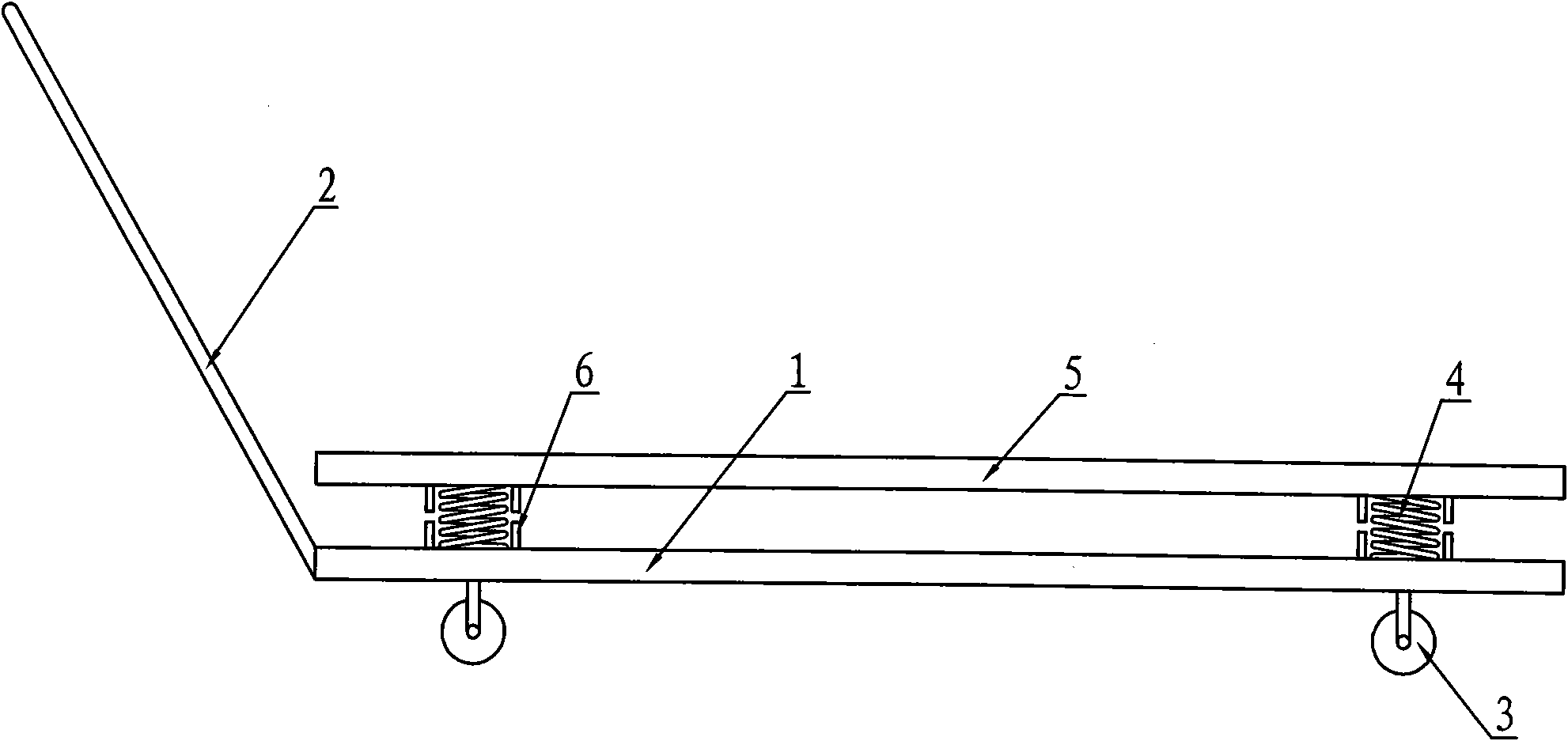

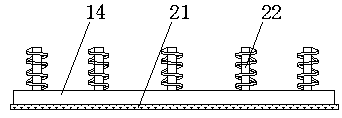

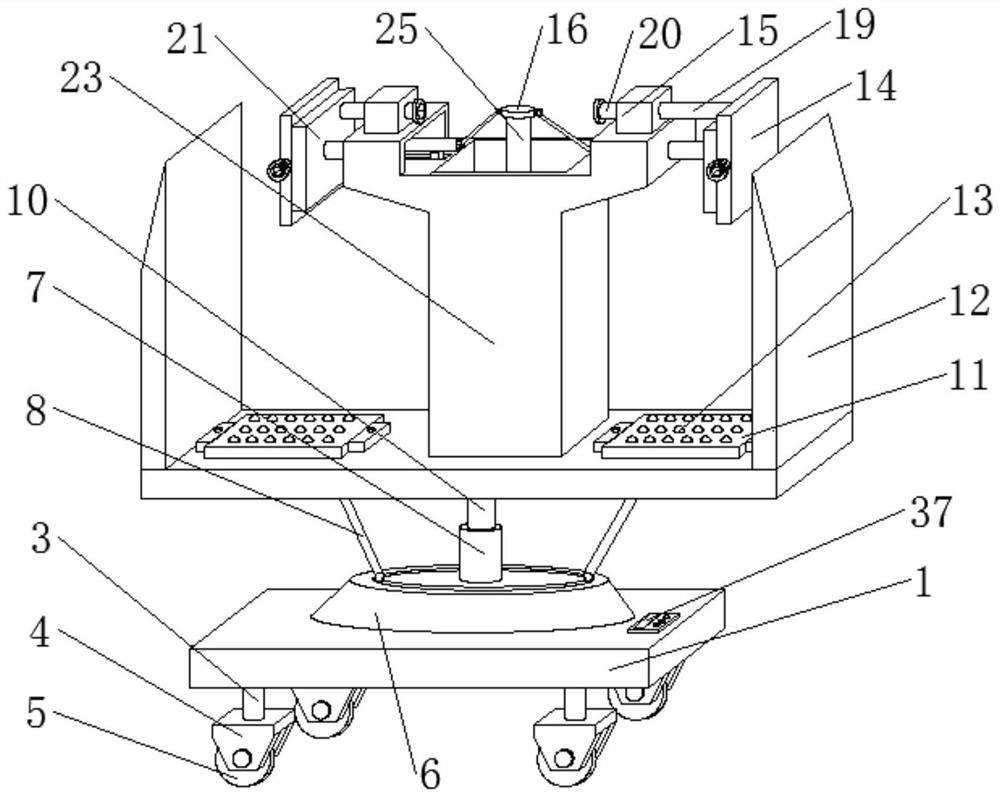

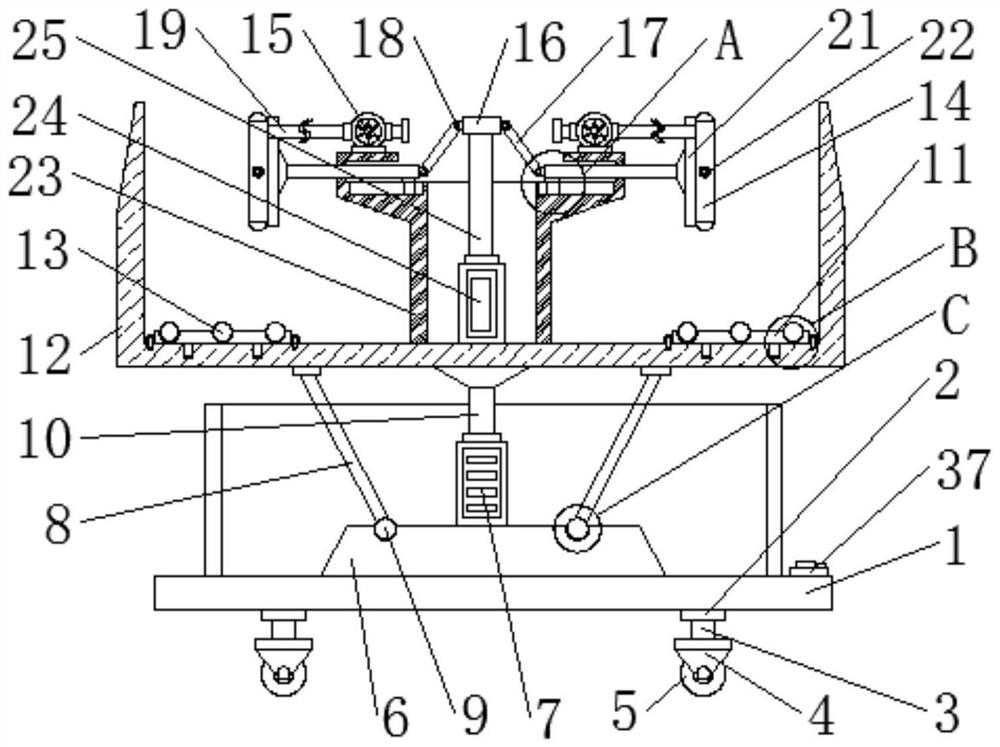

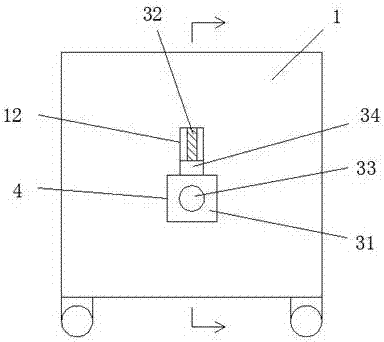

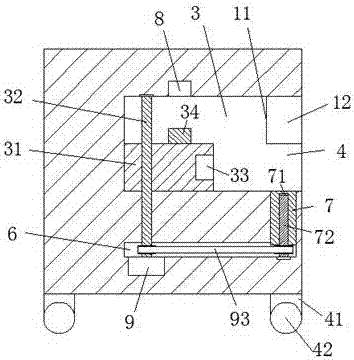

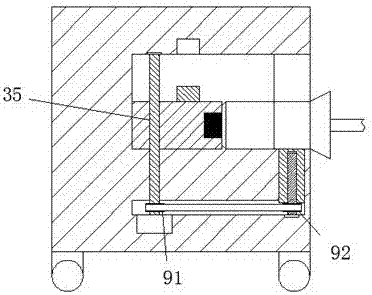

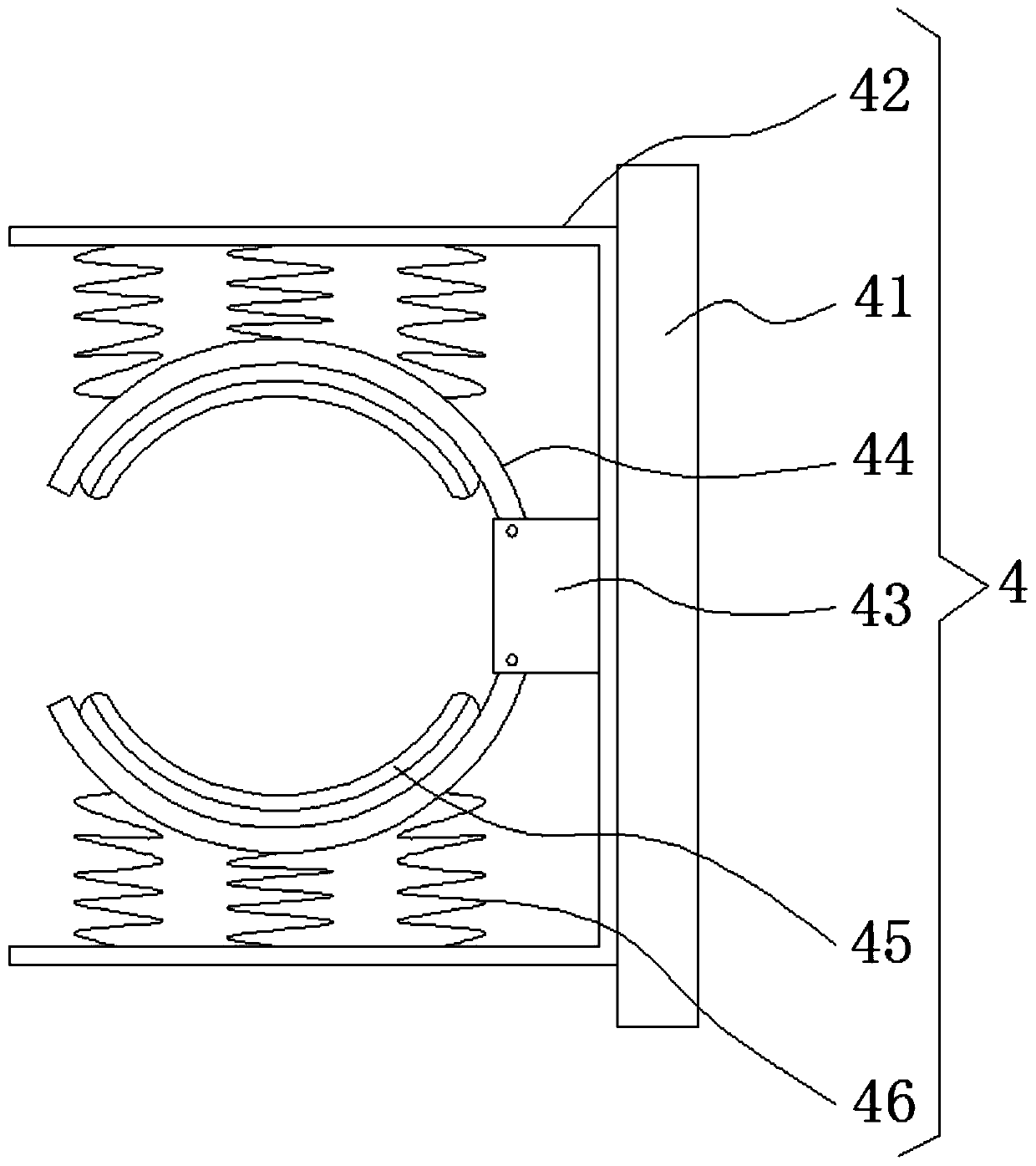

Damping and slide-prevention type tote handcart in silicon wafer working procedure

InactiveCN101830243AAvoid breakage damageAvoid damageHand carts with multiple axesElastomerPrevention types

The invention relates to a damping and slide-prevention type tote handcart in a silicon wafer working procedure, comprising a weight tray, a handle, a universal trundle, a damping device and a slide-prevention device, wherein the damping device comprises a damping elastic body and a loading plate; the damping elastic body is arranged between the loading plate and the weight tray; the upper end surface of the weight tray and the lower end surface of the loading plate are respectively provided with a limit socket sleeve correspondingly and the damping elastic body is positioned in the limit socket sleeve; the slide-prevention device is a limit frame fixed on the weight tray, and the limit frame is higher than the loading plate; and a buffer spring is arranged between the limit frame and the loading plate. The damping device reduces the shake and bumpiness generated in the process of pushing; the additional arranged limit frame can prevent a tote tank from sliding off from the loading plate; the additionally arranged buffer spring between the limit frame and the loading plate can further improve the buffer property of the loading plate, and greatly reduce the damage of solar energy crystal silicon wafers.

Owner:EGING PHOTOVOLTAIC TECHNOLOGY CO LTD

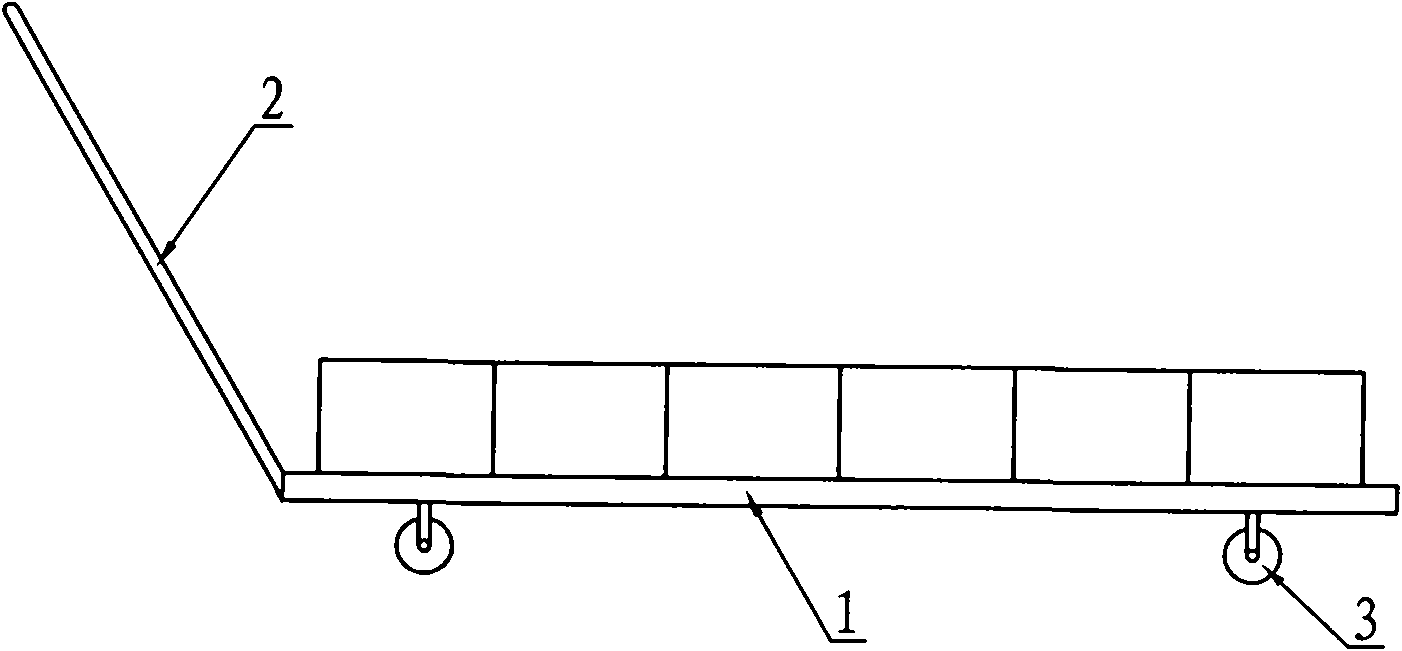

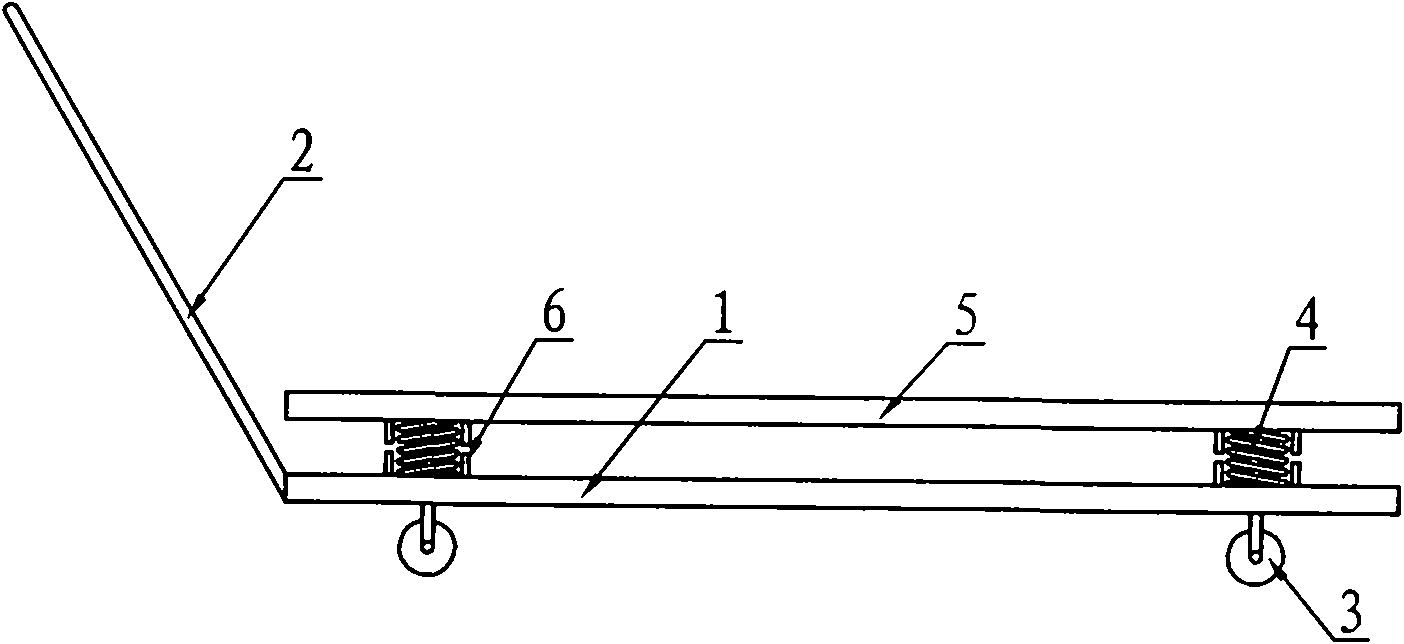

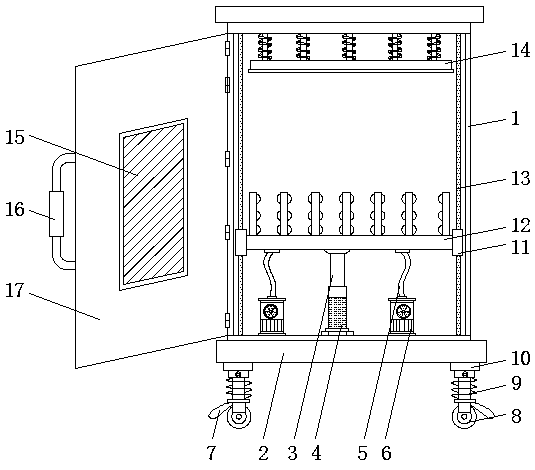

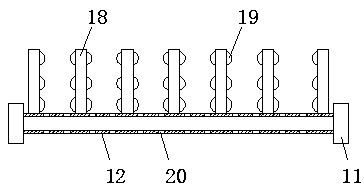

Damping silicon wafer process shifting trolley

InactiveCN101844572AAvoid breakage damageHand carts with multiple axesHand cart accessoriesElastomerSilicon chip

The invention relates to a damping silicon wafer process shifting trolley. The trolley comprises a bearing base plate, a handle, a swivel caster and a damping device, wherein the damping device contains damping elastomers and a load plate; the damping elastomer is arranged between the load plate and the bearing base plate, limit seat covers are correspondingly arranged on the upper end face of the bearing base plate and the lower end face of the load plate, and the damping elastomers are arranged in the limit seat covers. By installing the damping device, jolts in the pushing process can be reduced, thus further increasing the damping performance of the base plate and greatly reducing the damages of solar crystalline silicon wafers.

Owner:EGING PHOTOVOLTAIC TECHNOLOGY CO LTD

Transferring box for amorphous silicon membrane solar cell modules

InactiveCN107719882ARealize the height adjustment functionEasy to fixShock-sensitive articlesContainers to prevent mechanical damageHydraulic cylinderAmorphous silicon

The invention discloses a transferring box for amorphous silicon membrane solar cell modules. The transferring box comprises a box body, a hydraulic cylinder is arranged at the bottom of an inner cavity of the box body, a containing plate is connected to the top end of the hydraulic cylinder through a hydraulic rod, clamping plates distributed at equal intervals are arranged on the containing plate, and elastic protrusions are arranged on the inner walls of the clamping plates; and dust collectors are arranged at the positions, close to the two sides of the hydraulic cylinder, of the interiorof the box body, and the dust collectors are connected with the containing plate through dust collection pipes. The transferring box is simple in structure and convenient to use, a large number of solar cell modules can be clamped more firmly at a time, and the transferring efficiency is high; the elastic protrusions are arranged on the inner walls of the clamping plates, and therefore the solar cell modules can be clamped more firmly, and mutual collision, fracture and damage of the solar cell modules in the transporting process are avoided; and the hydraulic cylinder is arranged at the bottom of the inner cavity of the box body, the height adjusting function of the containing plate can be achieved, and the solar cell modules with different lengths can be transferred.

Owner:江阴艾能赛瑞能源科技有限公司

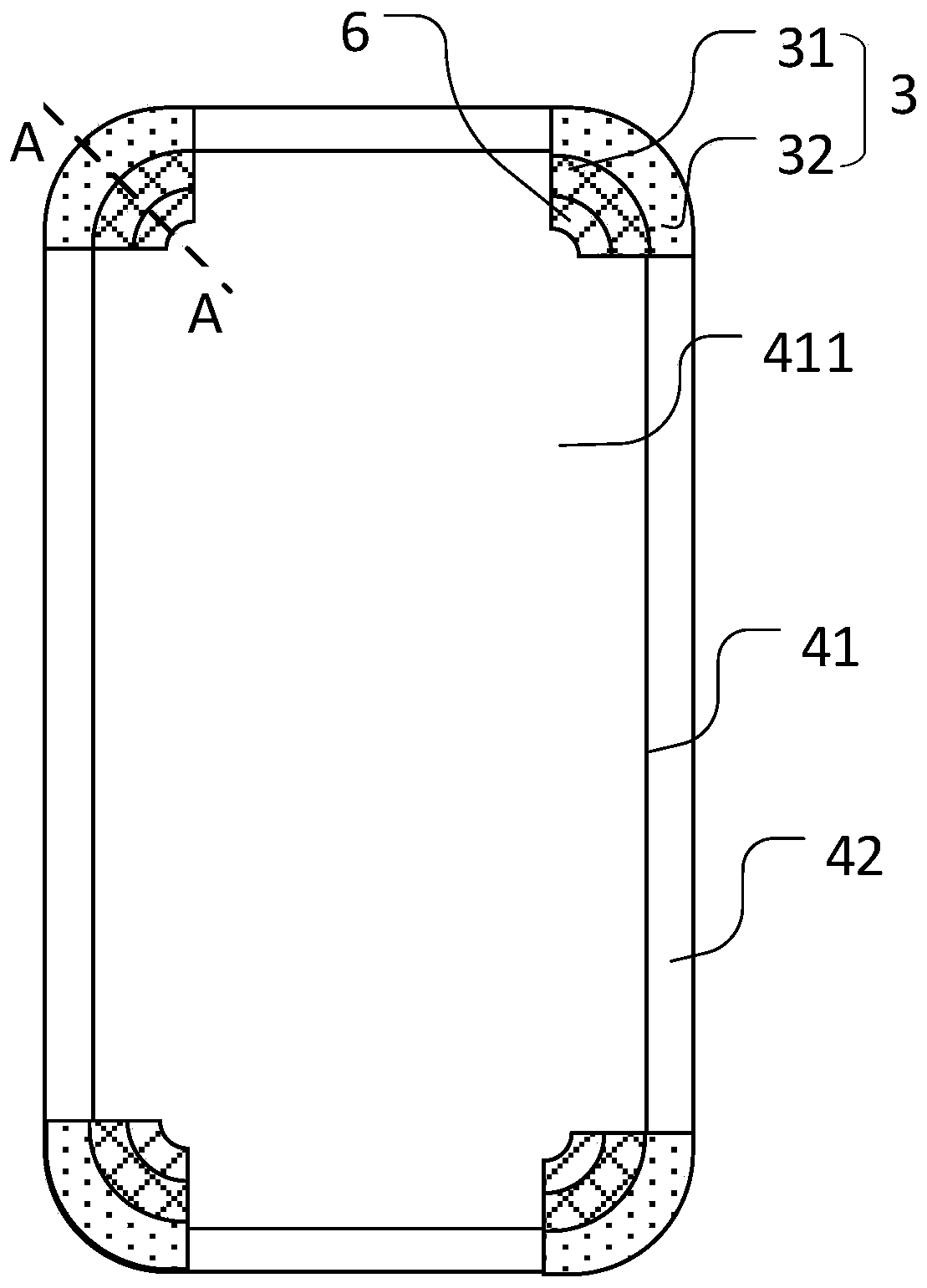

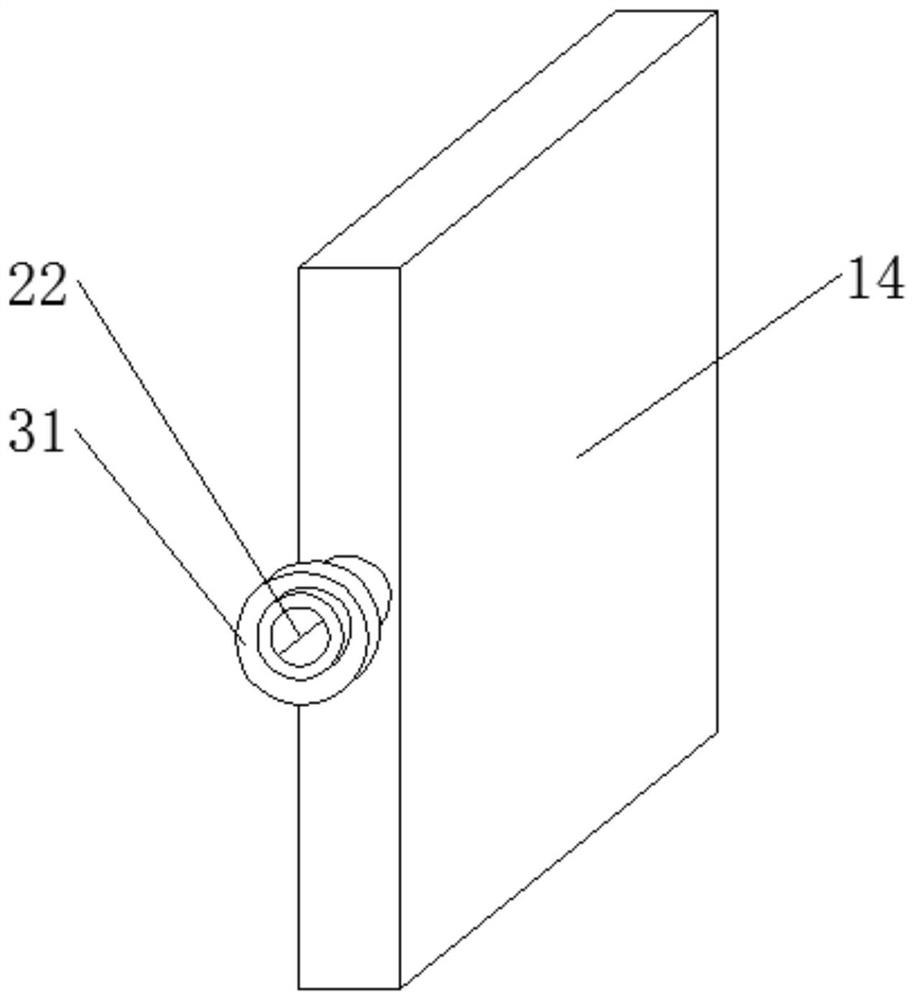

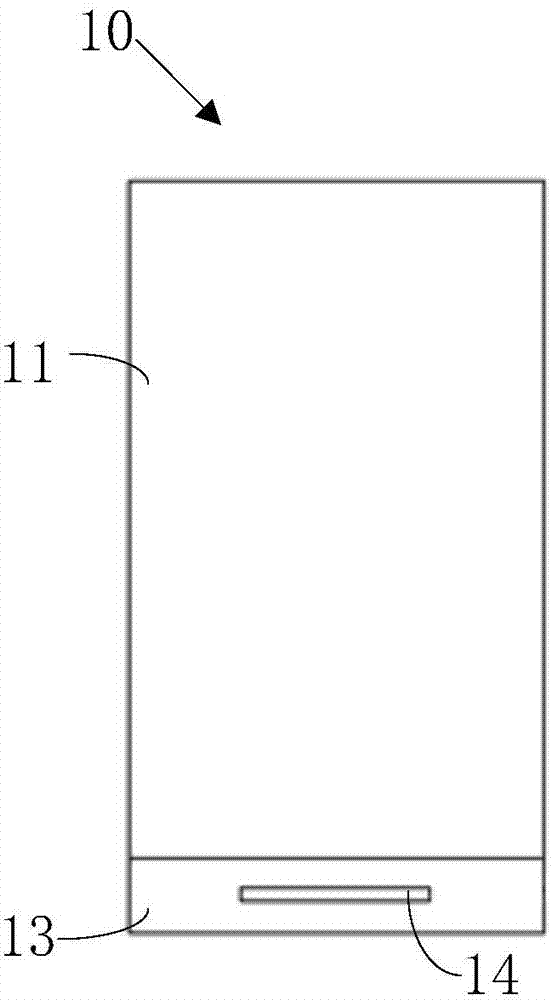

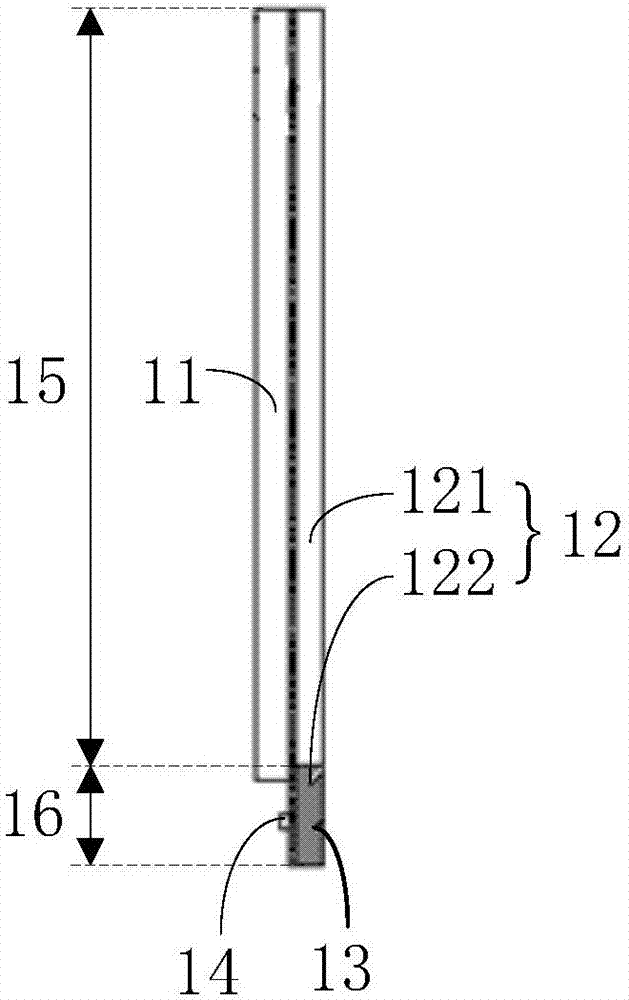

Display panel and display device

ActiveCN111584595AImprove bending performanceImprove tensile propertiesSolid-state devicesSemiconductor devicesDisplay deviceMaterials science

The invention relates to the technical field of the display. The invention provides a display panel and a display device, the display panel comprises an array substrate and a packaging layer packagedon one side of the array substrate, the display panel further comprises a stretching area, the stretching area is located at the corner position of the display panel, and the stretching area is provided with a hollow opening penetrating through the array substrate and the packaging layer. The periphery of the display panel can form a radian according to a certain bending radius, so that the comprehensive three-dimensional display of simultaneous display of the front and side surfaces is realized.

Owner:BOE TECH GRP CO LTD

Method for manufacturing high-heat conduction ceramic circuit board

InactiveCN101699931AAvoid breakage damageGuaranteed YieldPrinted circuit secondary treatmentConductive material chemical/electrolytical removalSolder maskCeramic

The invention discloses a method for manufacturing a high-heat conduction ceramic circuit board, which comprises the steps of a, substrate pretreatment; b, pattern transfer; c, solder mask printing; d, character silk printing; e, electroless nickel immersion gold; and f, cutting and moulding. The invention aims to overcome the disadvantage in the prior art, and provides a method for manufacturing a high-heat conduction ceramic circuit board having simple process and good heat conducting and heat dissipating effects.

Owner:广东达进电子科技有限公司

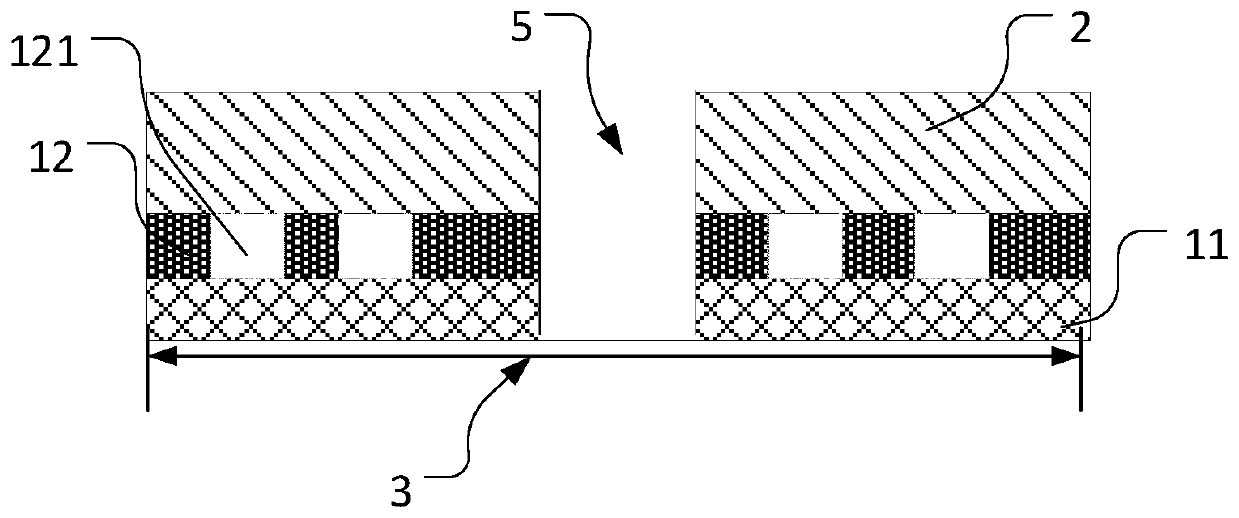

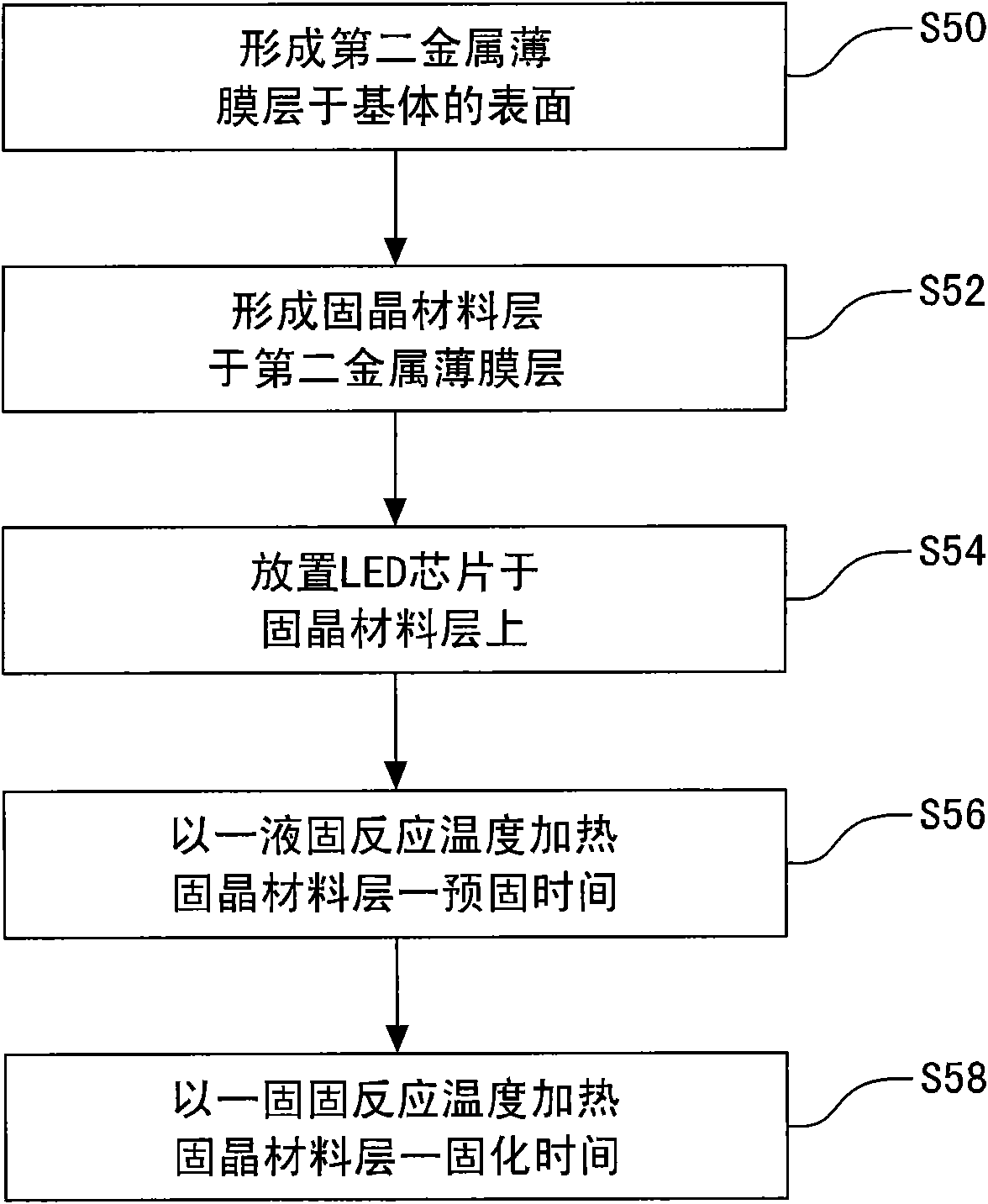

Light-emitting diode chip bonding method, bonded light-emitting diode and chip structure

ActiveCN102104090AImprove reliabilityHigh melting pointSolid-state devicesSemiconductor devicesSolid reactionReaction temperature

The invention discloses a light-emitting diode chip bonding method, a bonded light-emitting diode and a chip structure. The light-emitting diode chip bonding method is suitable for bonding a light-emitting diode chip on a substrate. The light-emitting diode chip is provided with a first metal film layer. The chip structure comprises a chip and a bonding material layer, wherein the bonding material layer is arranged on one side of the chip. The bonding method comprises the following steps of: forming a second metal film layer on the surface of the substrate; forming the bonding material layer on the second metal film layer; placing the light-emitting diode chip on the bonding material layer and making the first metal film layer contact the bonding material layer; heating the bonding material layer for a pre-curing time at a liquid-solid reaction temperature to form a first intermetallic layer and a second intermetallic layer; and heating the bonding material layer for a curing time at a solid-solid reaction temperature to perform a solid-solid reaction. The liquid-solid reaction temperature and the solid-solid reaction temperature are both lower than 110 DEG C; and the melting points of the first intermetallic layer and the second intermetallic layer after the solid-solid reaction are higher than 200 DEG C.

Owner:IND TECH RES INST

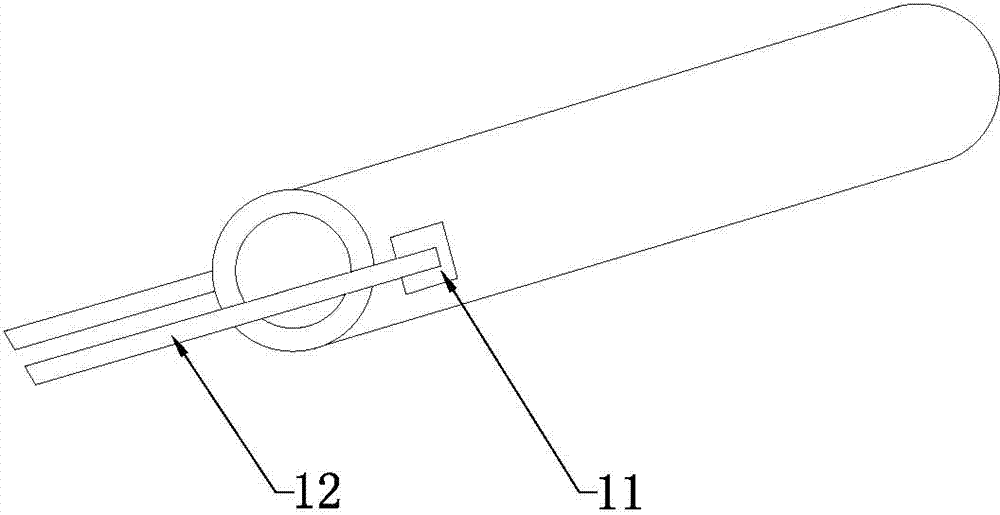

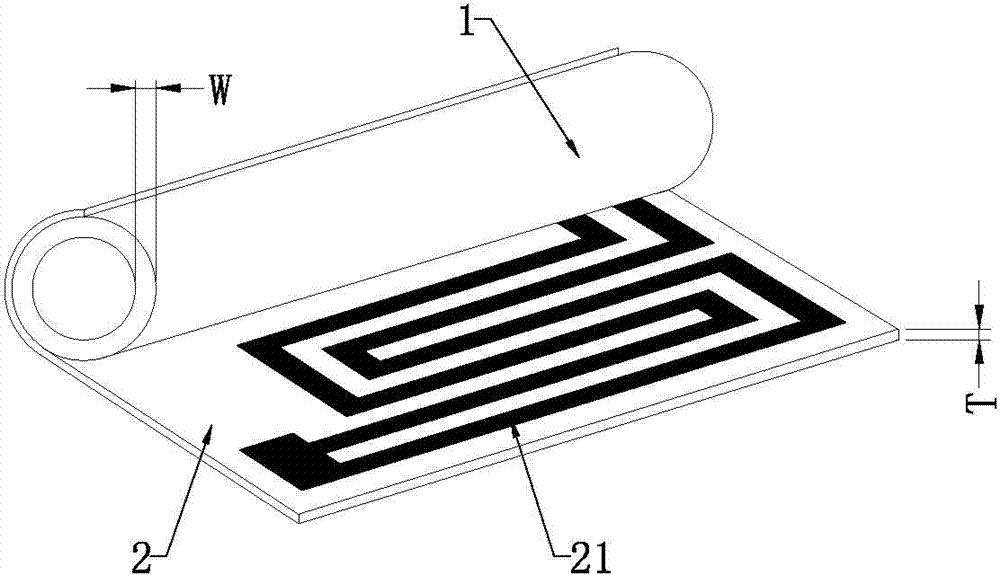

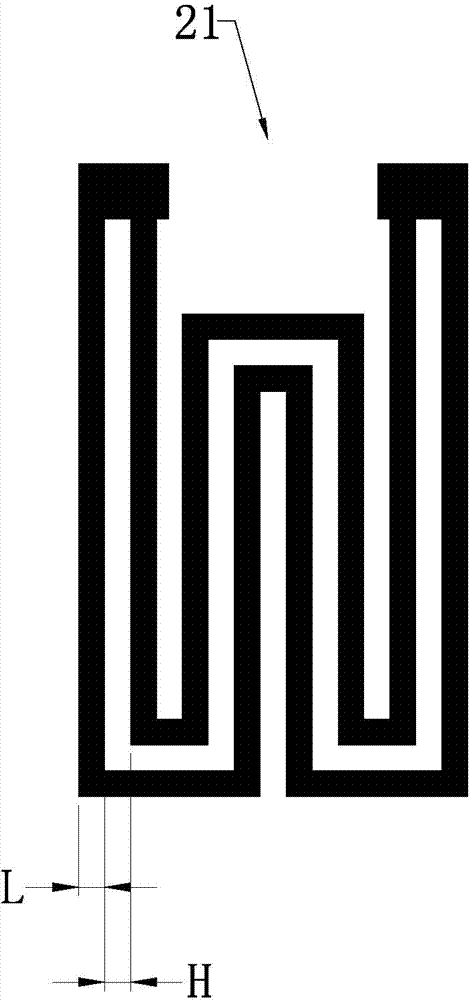

Large power ceramic heating unit

ActiveCN103546998AGuaranteed current carrying capacityUniform temperatureHeating element materialsCeramic substrateAlumina ceramic

The invention relates to the technical field of ceramic heating units, in particular to a large power ceramic heating unit. The large power ceramic heating unit comprises an aluminum oxide ceramic core and an aluminum oxide ceramic substrate, thick film heating circuits are printed on the inner side face of the aluminum oxide ceramic substrate, the thick film heating circuits are of a reciprocating inflection structure, the distance H is formed between two adjacent thick film heating circuits, the aluminum oxide substrate wraps the outer side face of the aluminum oxide ceramic core in a reeling shape, the width L of wires of the thick film heating circuits is 0.3-1.3mm, and the ratio H / L of the distance H formed by the thick film heating circuits and the width L of the wires of the thick is 0.5-1.5; the thickness T of the aluminum oxide substrate is 0.3-0.8 mm, and the ratio W / T of the thickness of the wall of the aluminum oxide ceramic core and the thickness T of the aluminum oxide substrate is 2-5. When the large power ceramic heating unit works, the power of the large power ceramic heating unit can be more than 3000W, the breakthrough that a small-sized heating unit carries out large-power heating is achieved, the temperature of the surface of the heating unit is kept uniform, generated bubbles are small and are not prone to being attached to the surface of the heating unit, and durability is extraordinary.

Owner:KEY MATERIAL

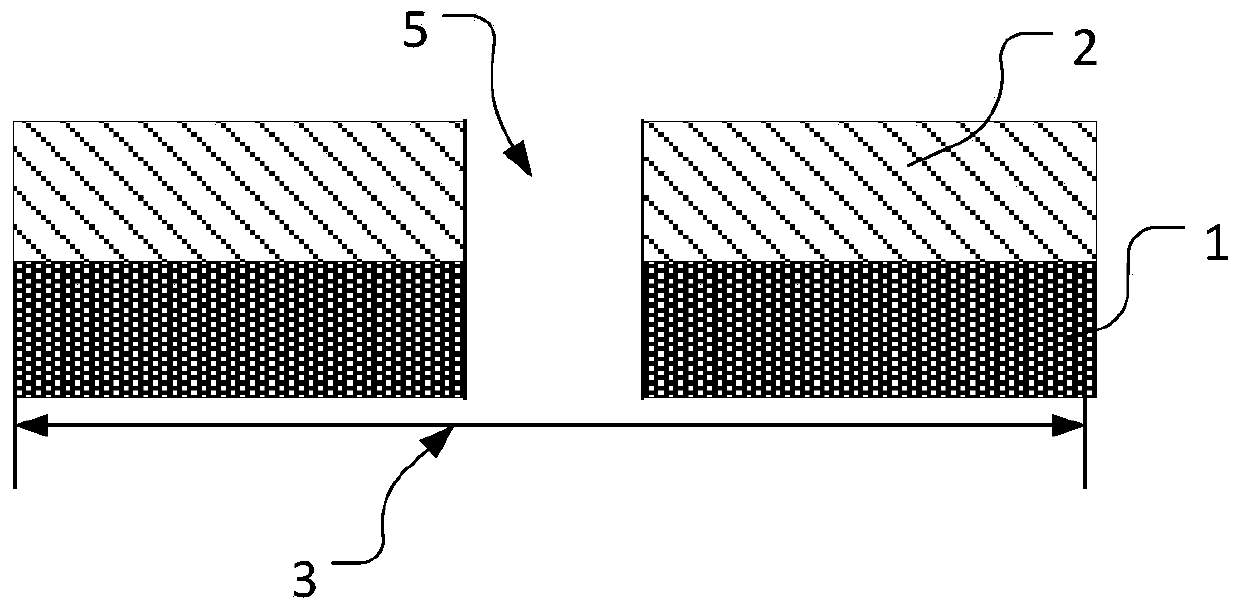

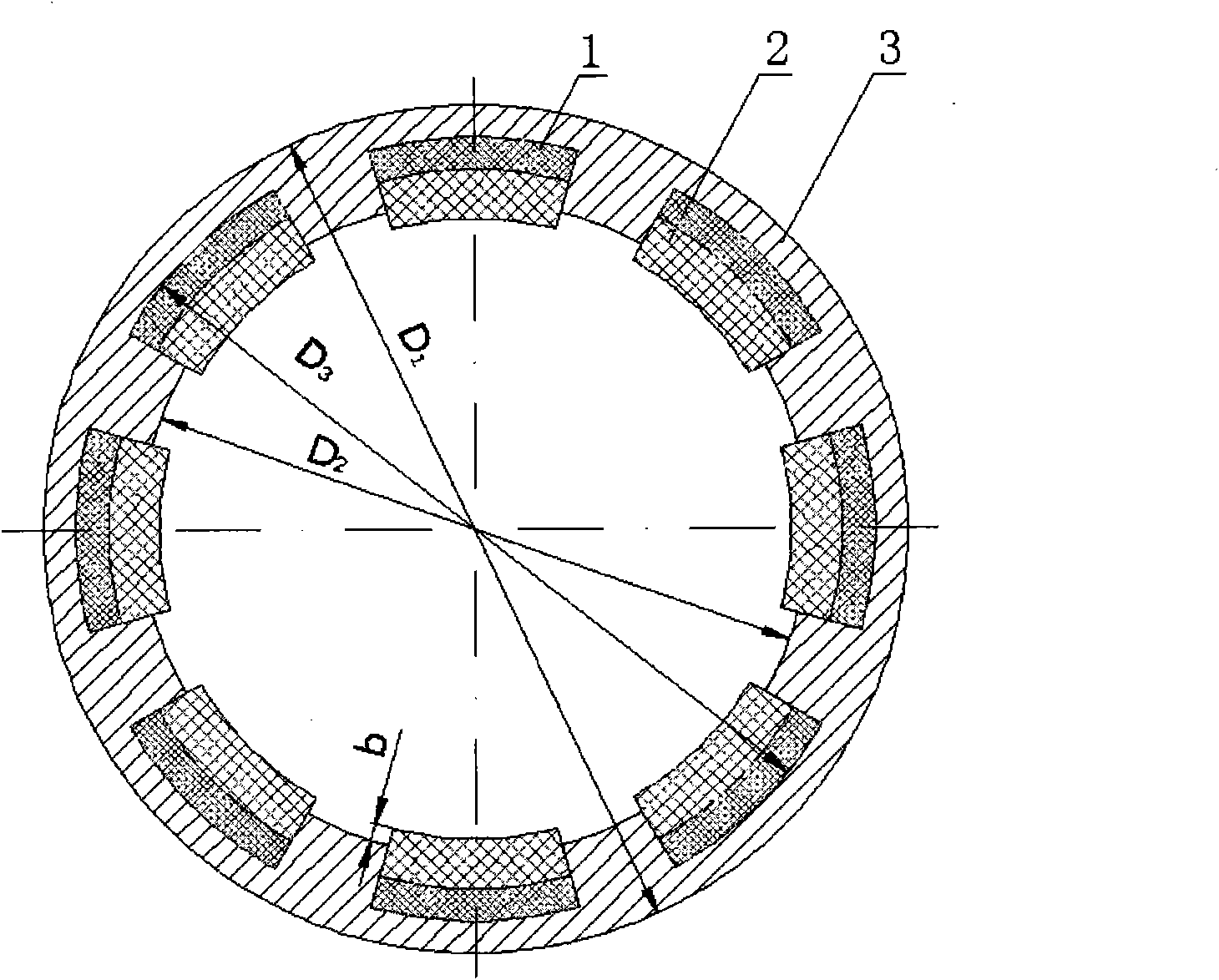

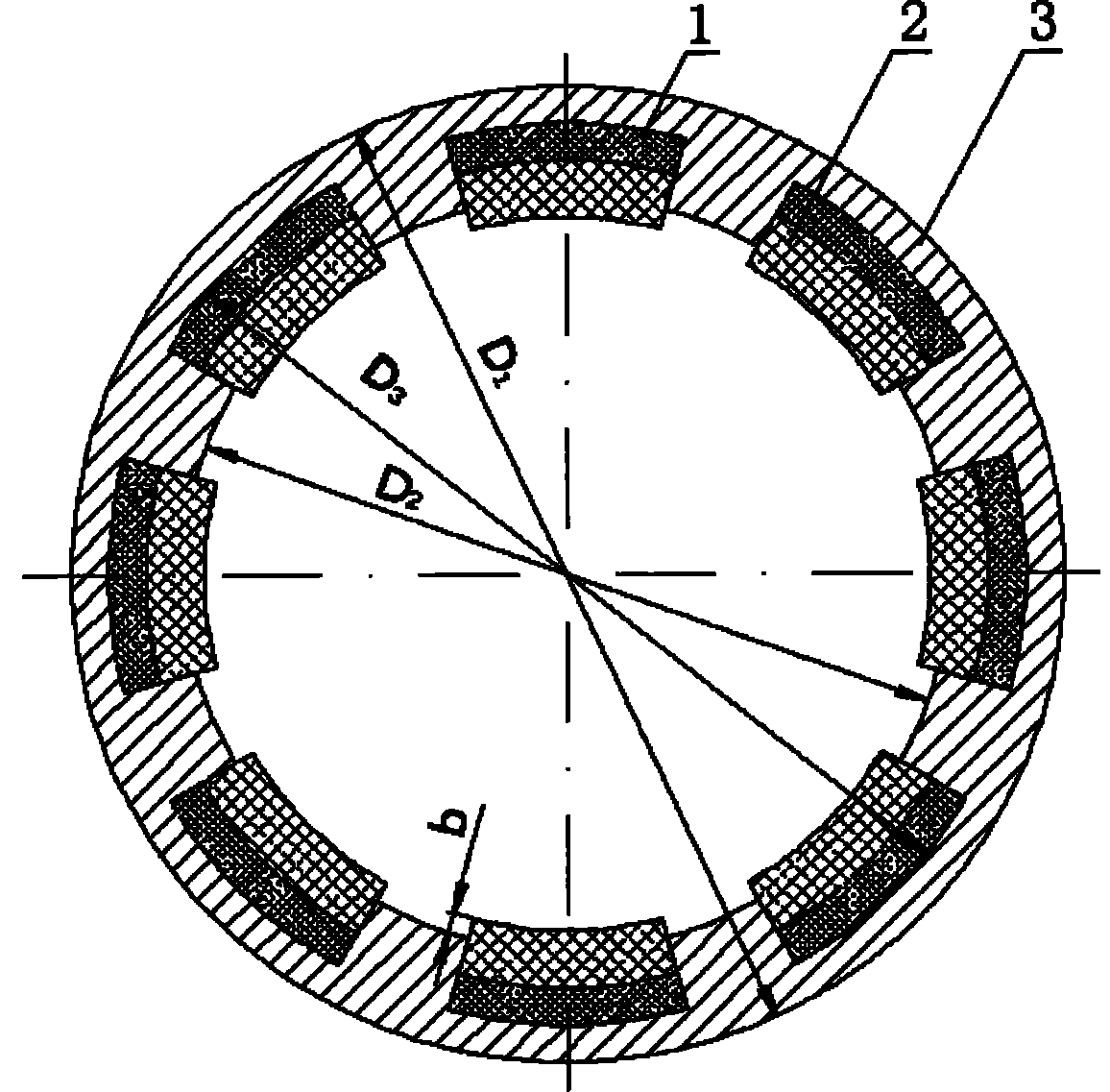

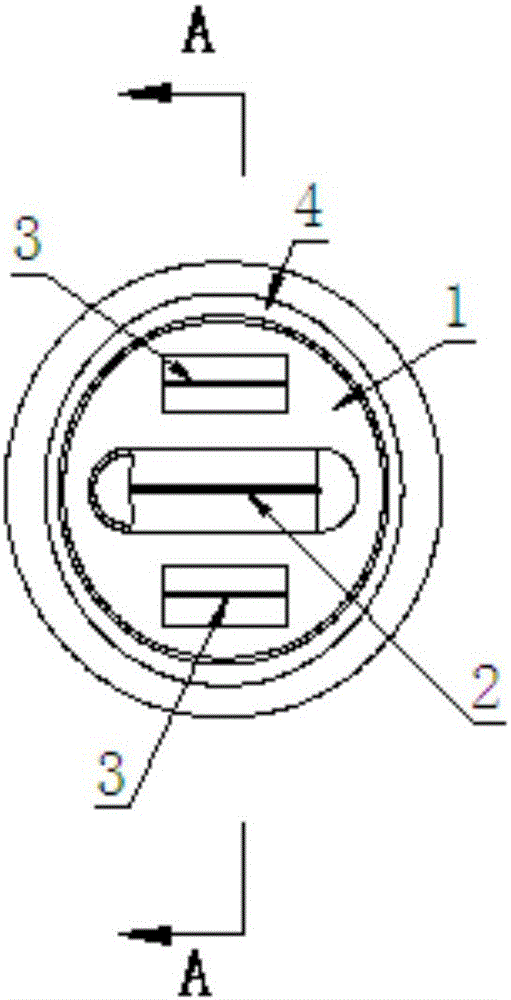

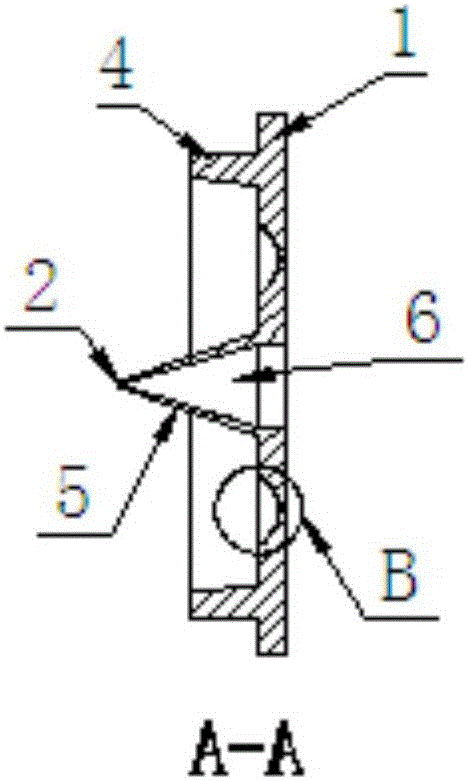

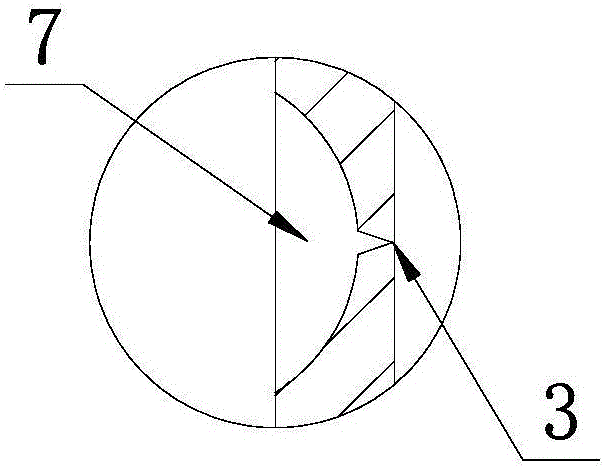

Metal matrix inlaid elastic self-lubricating sliding bearing

InactiveCN101858385AImprove wear resistanceImprove the lubrication effectBearing componentsPolymer metalWear resistant

The invention relates to the technical fields of polymer materials and sliding bearings, in particular to a metal matrix inlaid elastic self-lubricating sliding bearing which comprises a rubber cushion layer (1), a polymer bearing strip (2) and a metal matrix (3); and more than 6 axial grooves with the cross sections being a ring fan shape and similar to a ladder shape are arranged on the circumference of the inner surface of the upper edge of the metal matrix (3), the bottom of each groove is provided with the rubber cushion layer (1), and the polymer bearing strip (2) which is consistent with the groove shape at normal temperature is inlaid in, and the inner surface of the polymer bearing strip (2) on the inner cylindrical surface of the polymer metal matrix (3) forms the friction surface of the bearing. The metal matrix inlaid elastic self-lubricating sliding bearing simultaneously has the self-lubricating and the wear resistant performance of the polymer material and the elastic performance of rubber, not only can meet the flexible requirements of a shaft but also can effectively prolong the service life of the bearing, not only is applicable to the application fields of all common inlaid solid self-lubricating bearings, but also is applicable to occasions on which the shafts are quite long, the bending and deformation are easy, the vibration is easy to produce, the bearing is easy to wear and the like.

Owner:JIANGSU UNIV

Breathing valve, oil tank cover and oil tank

ActiveCN105805373AAvoid breakage damageEasy to useClosuresCheck valvesAtmospheric pressureBreathing process

The invention relates to a breathing valve, an oil tank cover and an oil tank. The breathing valve for the oil tank cover comprises a valve body. A one-way air inlet part and a one-way exhaust part are arranged on the valve body. When the pressure in the oil tank and outside pressure are balanced, the oil tank is closed, volatile gas in the oil tank cannot be exhausted out, and the environment is protected. When negative pressure is formed in the oil tank, outside air is led into the oil tank through the one-way air inlet part, and balance of the air pressure of the oil tank is ensured. When the pressure in the oil tank is increased, gas in the oil tank is exhausted to the outside through the one-way exhaust part, when the oil tank is inclined or inverted, it is ensured that oil in the oil tank cannot flow out through the breathing valve, and therefore the use safety of the oil tank is ensured.

Owner:CHONGQING BAIKE DINGYU TECH CO LTD

Hydraulic clamp with bidirectional clamping effect

PendingCN112536748ANo frequent replacementAvoid breakage damageWork holdersWork benchesElectric machineryExhaust pipe

The invention discloses a hydraulic clamp with a bidirectional clamping effect, and relates to the field of hydraulic clamps. The hydraulic clamp comprises a bottom plate, a support seat is fixed at the top of the bottom plate, and a motor is mounted in the middle of the top of the support seat. Through the arrangement of an air exhauster, air inlet pipes, air outlet hoses, buffering air bags, airvalves and exhaust pipes, after a user places a workpiece on a placement frame, the user starts the air exhauster through an operation table, the air exhauster works to enable the air inlet pipes toexhaust air, air enters the buffering air bags through the air outlet hoses to inflate the buffering air bags, after inflation is completed, the user can start an air cylinder to enable a piston rod to extend, then movable rods can be driven to move, clamping plates and the buffering air bags are also driven to move, the buffering air bags move to enable the clamping plates to clamp the workpiece,while when the air cylinder works to enable the piston rod to continue to retract and enable the movable rods to move to apply pressure to the workpiece, the buffering air bags are stressed to be compressed, and therefore, a buffering effect can be achieved on the movable rods and connecting rods.

Owner:广州皖安机电设备有限公司

Method for producing high thermal conductivity ceramic circuit board

InactiveCN101699932AAvoid breakage damageGuaranteed YieldConductive material chemical/electrolytical removalSolder maskThermal conductivity

The invention discloses a method for producing a high thermal conductivity ceramic circuit board, which comprises the following steps: a, pre-processing of a substrate; b, pattern transfer; c, manufacturing of conducting holes; d, printing of solder mask; e, silk screen printing of characters; f, chemical deposition of nickel, gold; and g, formation by cutting; the objective of the invention is to overcome the deficiencies in the prior art and provide a method for producing a high thermal conductivity ceramic circuit board with simple technology and good thermal conduction and radiating effects of the product.

Owner:广东达进电子科技有限公司

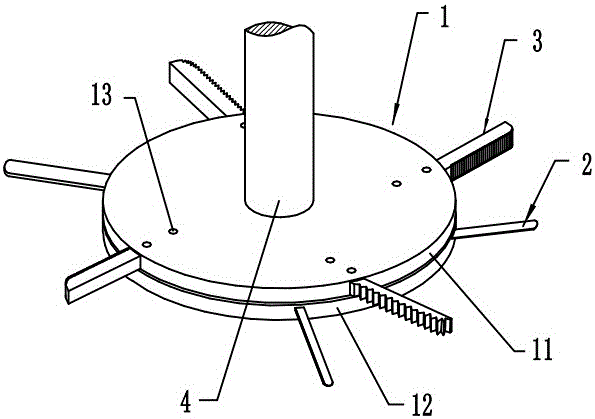

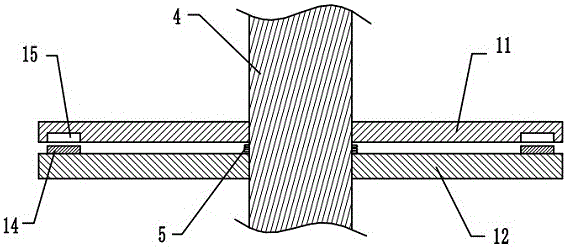

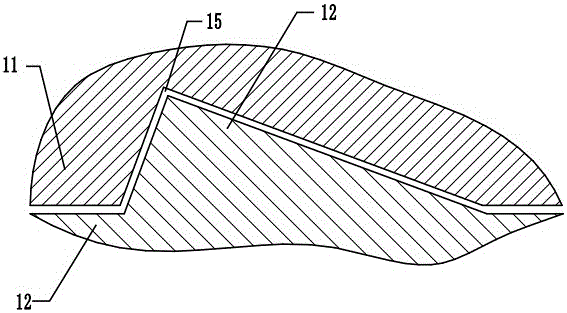

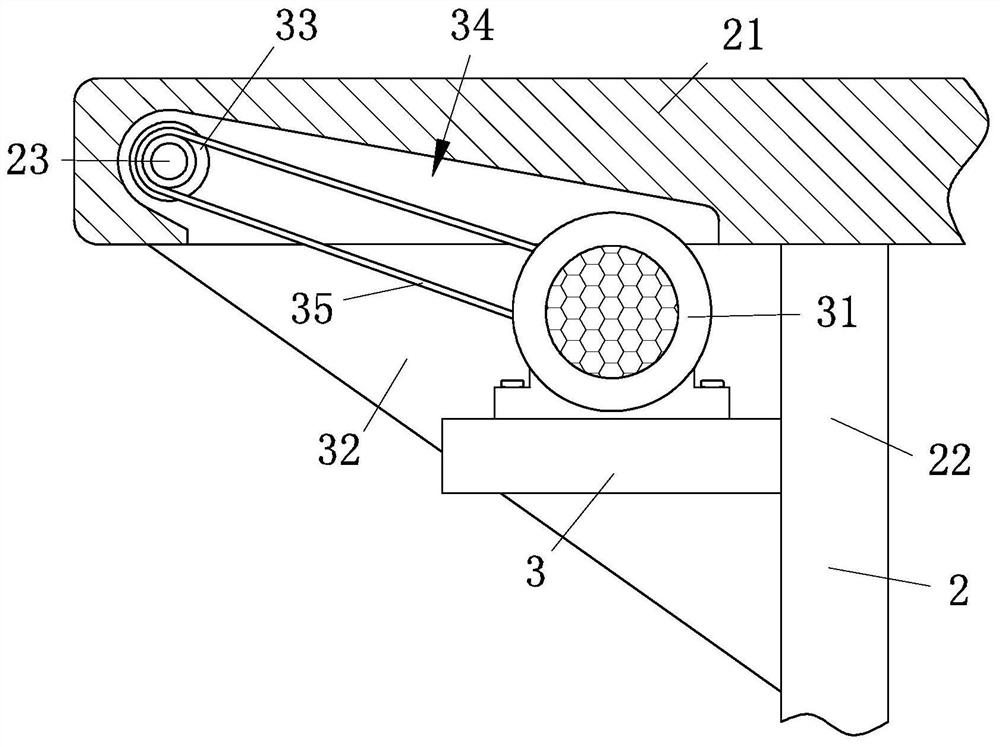

Bone and beef cutting tool capable of preventing cutters from being broken

ActiveCN106737968AAvoid breakage damageAvoid entanglementGrain treatmentsMetal working apparatusEngineeringMechanical engineering

The invention relates to the field of beef cutting tools, in particular to a bone and beef cutting tool capable of preventing cutters from being broken. The bone and beef cutting tool comprises a cutter disk and a rotating shaft. The cutter disk comprises a base disk body and a cover disk body which are buckled together. The base disk body is fixedly provided with wedge-shaped clamping blocks, and the cover disk body is provided with wedge-shaped clamping grooves matched with the wedge-shaped clamping blocks. The base disk body and the rotating shaft are connected in a free sleeving mode. The base disk body is evenly and fixedly connected with a plurality of beef cutters in the radial direction. Bone cutters are blunt cutters. The cover disk body is fixedly connected with the rotating shaft. The cover disk body is evenly and fixedly connected with the multiple bone cutters in the radial direction. A torsional spring is arranged in a cavity formed by buckling the base disk body and the cover disk body. The rotating shaft is freely sleeved with the torsional spring. One end of the torsional spring is connected with the base disk body, and the other end of the torsional spring is connected with the cover disk body. According to the bone and beef cutting tool, when the beef cutters encounter bone, the base disk body can temporally break away from the cover disk body, the phenomenon that the beef cutter can be broken and damaged when being used for forcedly cutting the bone is avoided, the beef cutters are protected, and the beef cutters can be prevented from being broken.

Owner:蚌埠企弧知识产权服务有限公司

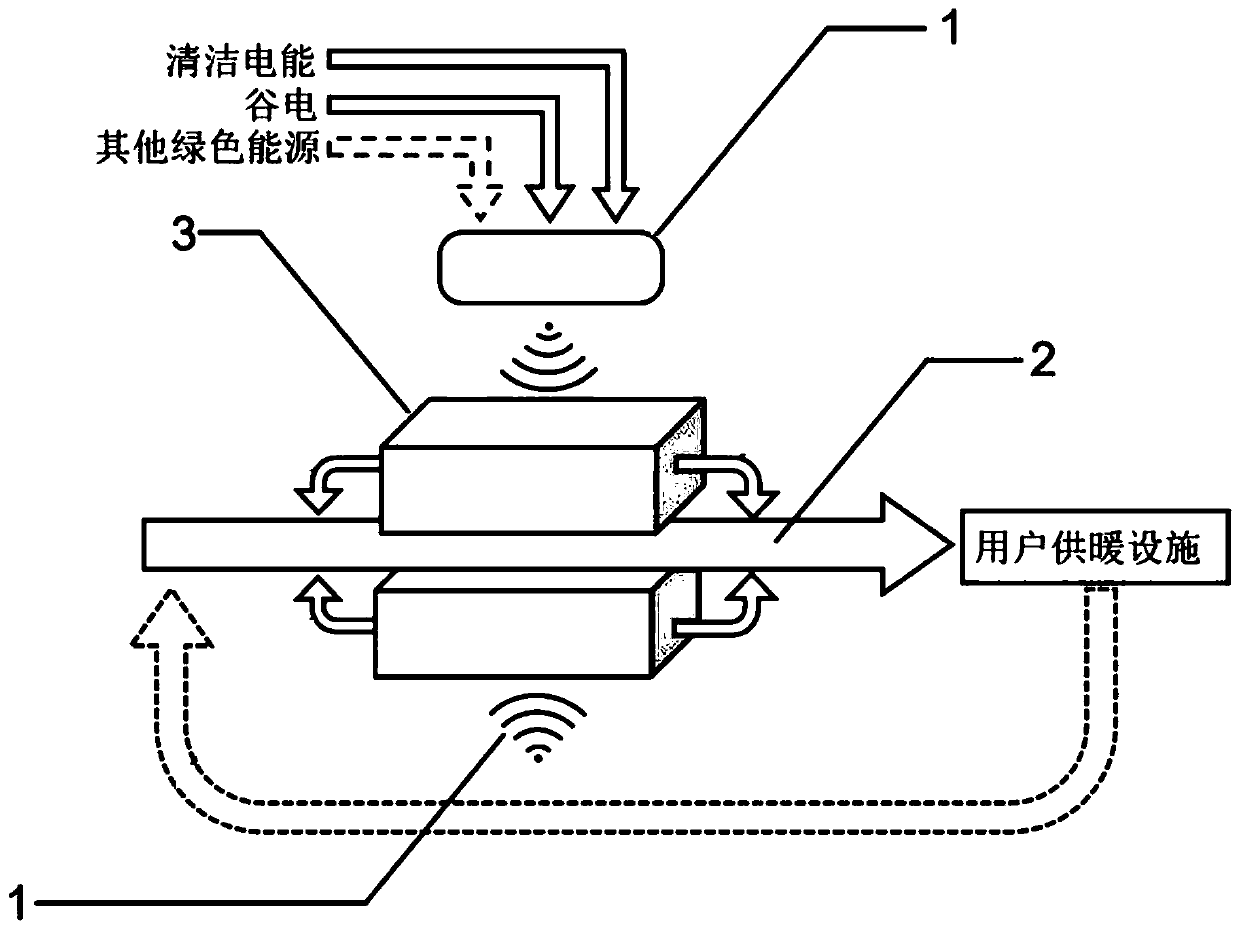

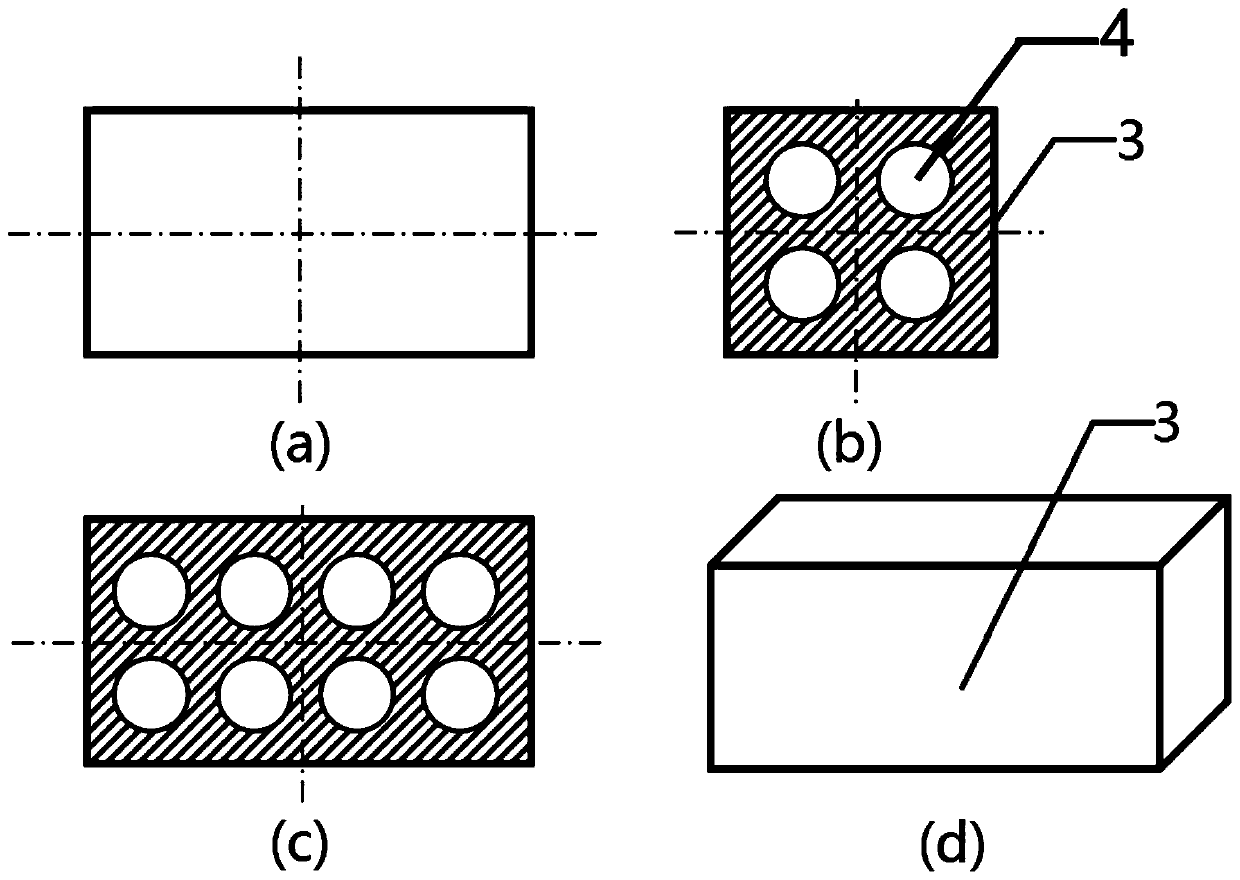

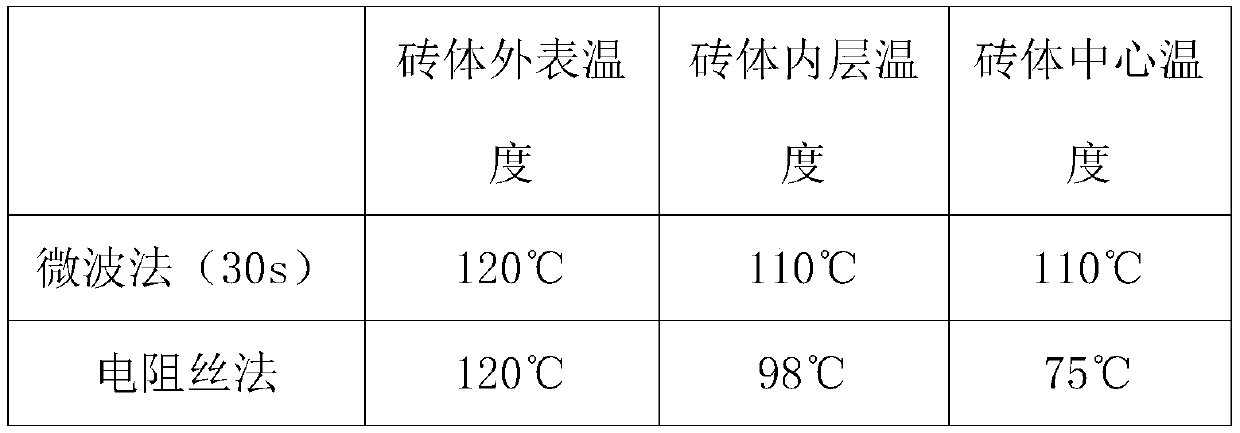

Composite material based on microwave heating, heat storage system and operation method thereof

InactiveCN110345542ASmall heating is convenientLow costCentral heating with accumulated heatHeat storage plantsElectricityMicrowave

The invention discloses a composite material based on microwave heating, a heat storage system and an operation method thereof. The composite material comprises a heat storage phase change material and a wave absorption material, wherein the mass ratio of the heat storage phase change material to the wave absorption material is 1 to (0.01-0.02); the heat storage phase change material and the waveabsorption material are heated, melted or mixed to prepare the composite material; and heat storage temperature of the composite material heated by microwave is 91-607 DEG C. According to the heat storage system, new energy or off-peak electricity is used for supplying power to a microwave system; the microwave environment is used for heating the composite material and storing heat; the heated heat is supplied to user sides through circulation heating water; the heat storage system is green and environmentally friendly, is low in cost and rapid in heat storage, and is taken as an extremely promising new mechanism.

Owner:XI AN JIAOTONG UNIV

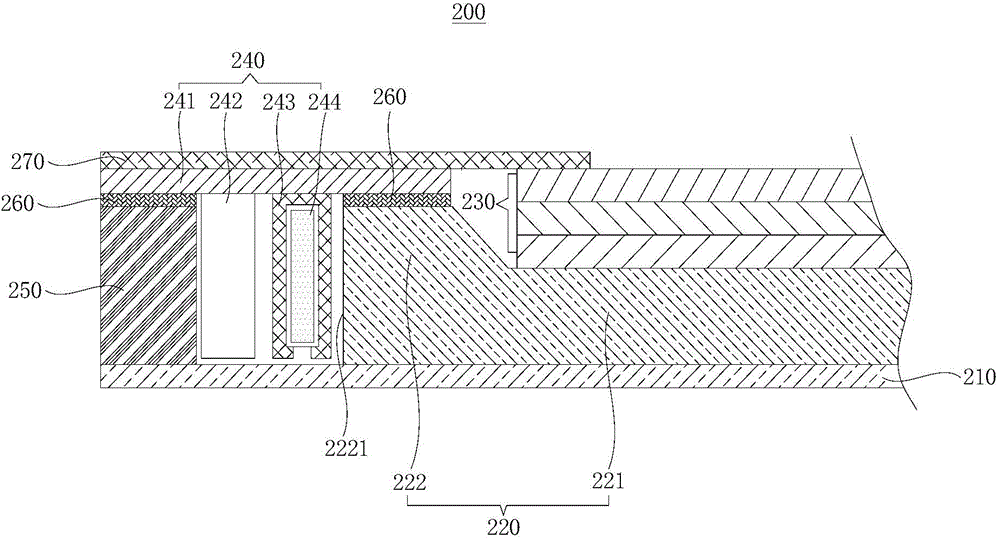

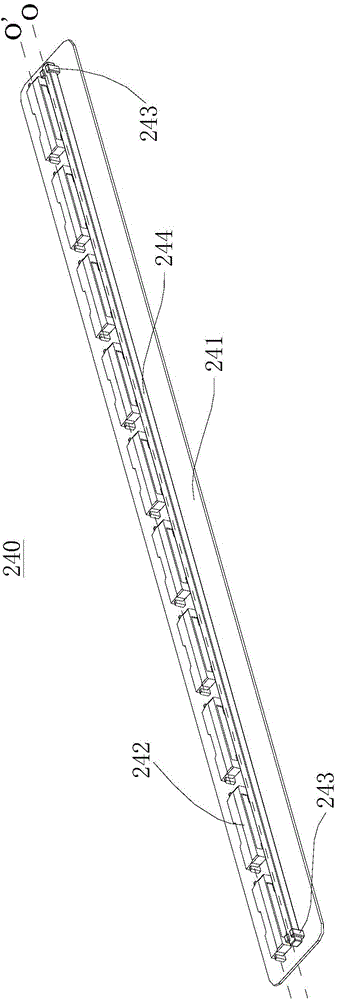

Light source assembly, backlight module and liquid crystal display device

InactiveCN104808387AAvoid breakage damageIncrease brightnessPlanar/plate-like light guidesNon-linear opticsLiquid-crystal displayLight guide

The invention discloses a light source assembly, which comprises a substrate (241), dot light sources (242), at least two brackets (243) and a quantum tube (244), wherein the dot light sources (242) are arranged on the substrate (241) at intervals; the brackets (243) are fixedly arranged on the substrate (241) and are arranged near the dot light source (242); the quantum tube (244) is fixedly arranged in the brackets (243). The invention also discloses a backlight module and a liquid crystal display device with the light source assembly. The light source assembly has the advantages that when the quantum tube is fixedly arranged near the dot power source by the brackets, as the brackets are made of a buffer material, the quantum tube can be buffered to certain content by the brackets under the condition of outside shock or vibration, the crushing and damage of the quantum tube are avoided, and the reliability of a product is improved; the brightness of light rays entering a light guide plate is improved by a prism structure and an attached prism membrane sheet at the side surface, backward to the dot light source, of the quantum tube.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

Display panel

InactiveCN107479236AAvoid breakage damageSolve technical problems that are prone to cracking and damageSolid-state devicesNon-linear opticsComputer science

The invention provides a display panel. The display panel comprises a first substrate, an array substrate and a luminous display layer; the array substrate comprises a base layer and a plastic base material layer which is arranged on the base layer and used for arranging a pixel unit and driving a chip; the array substrate comprises a display area corresponding to the first substrate and a driving area arranged at one side of the display area; the base layer of the array substrate of the display area is a glass substrate, and the base layer of the array substrate of the diving area is a reinforcement plate. According to the display panel, by means of the reinforcement plate, the array substrate of the area corresponding to a driving chip can be subjected to good support protection, and then the phenomenon that the glass substrate of the display panel is broken and damaged is prevented.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

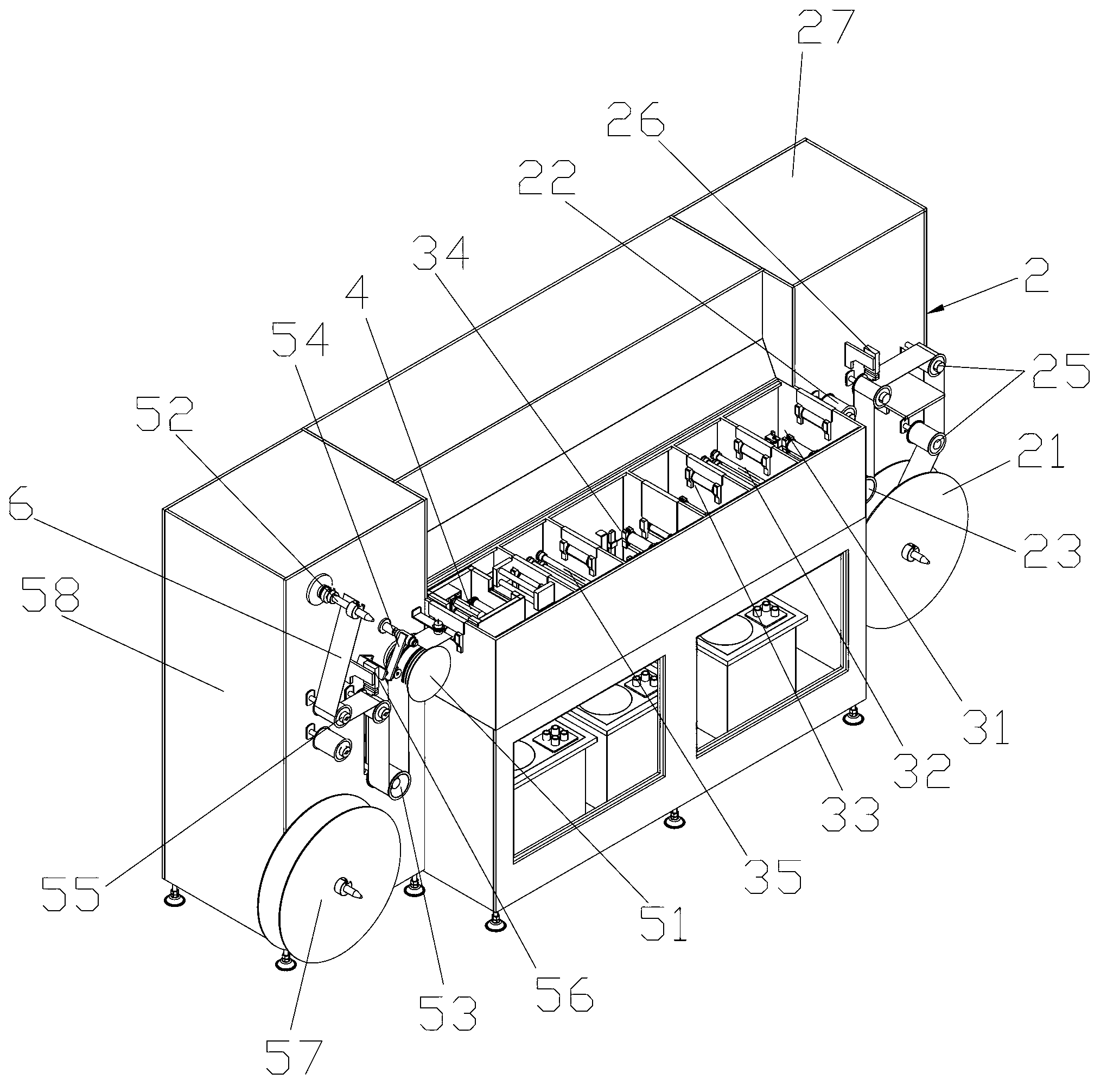

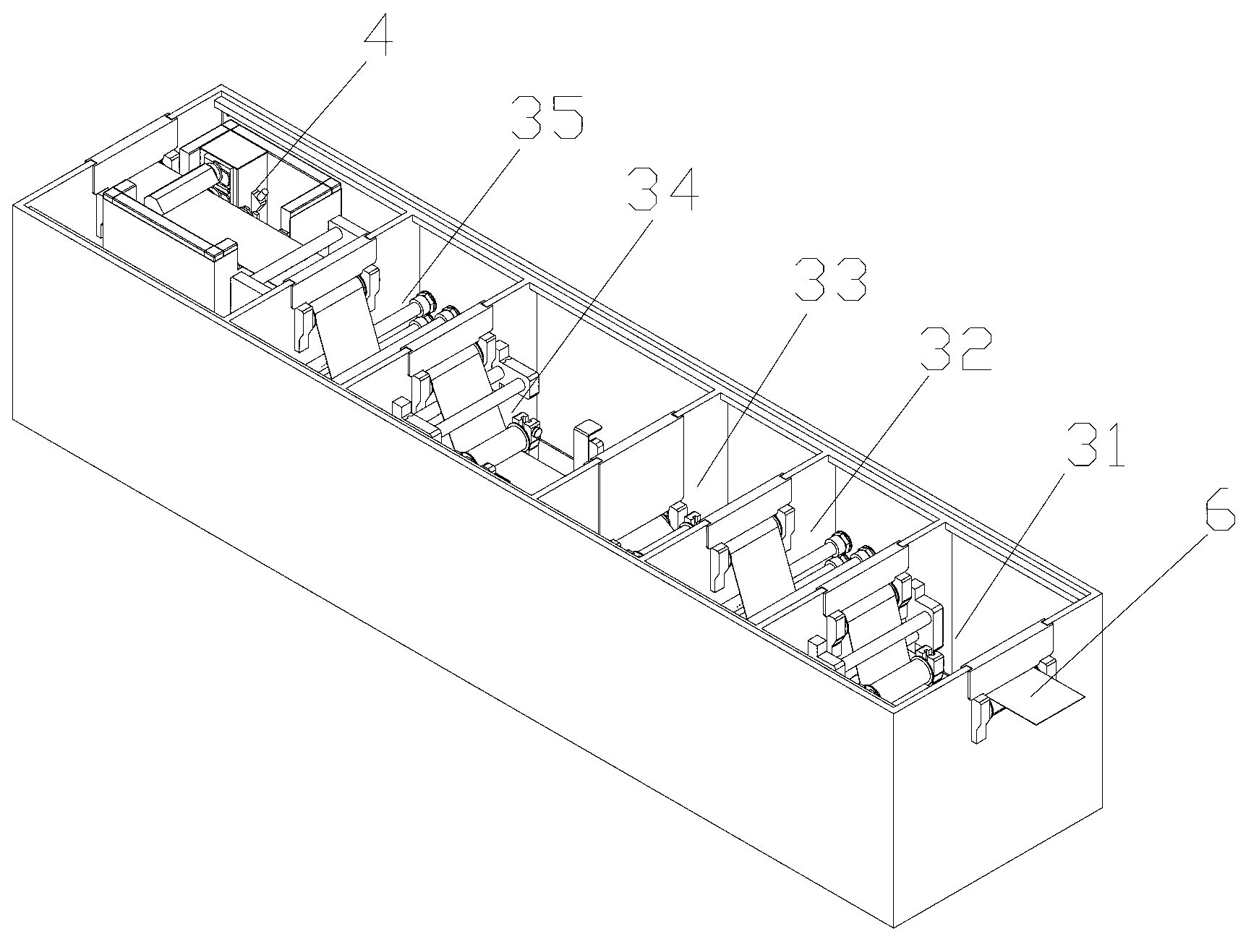

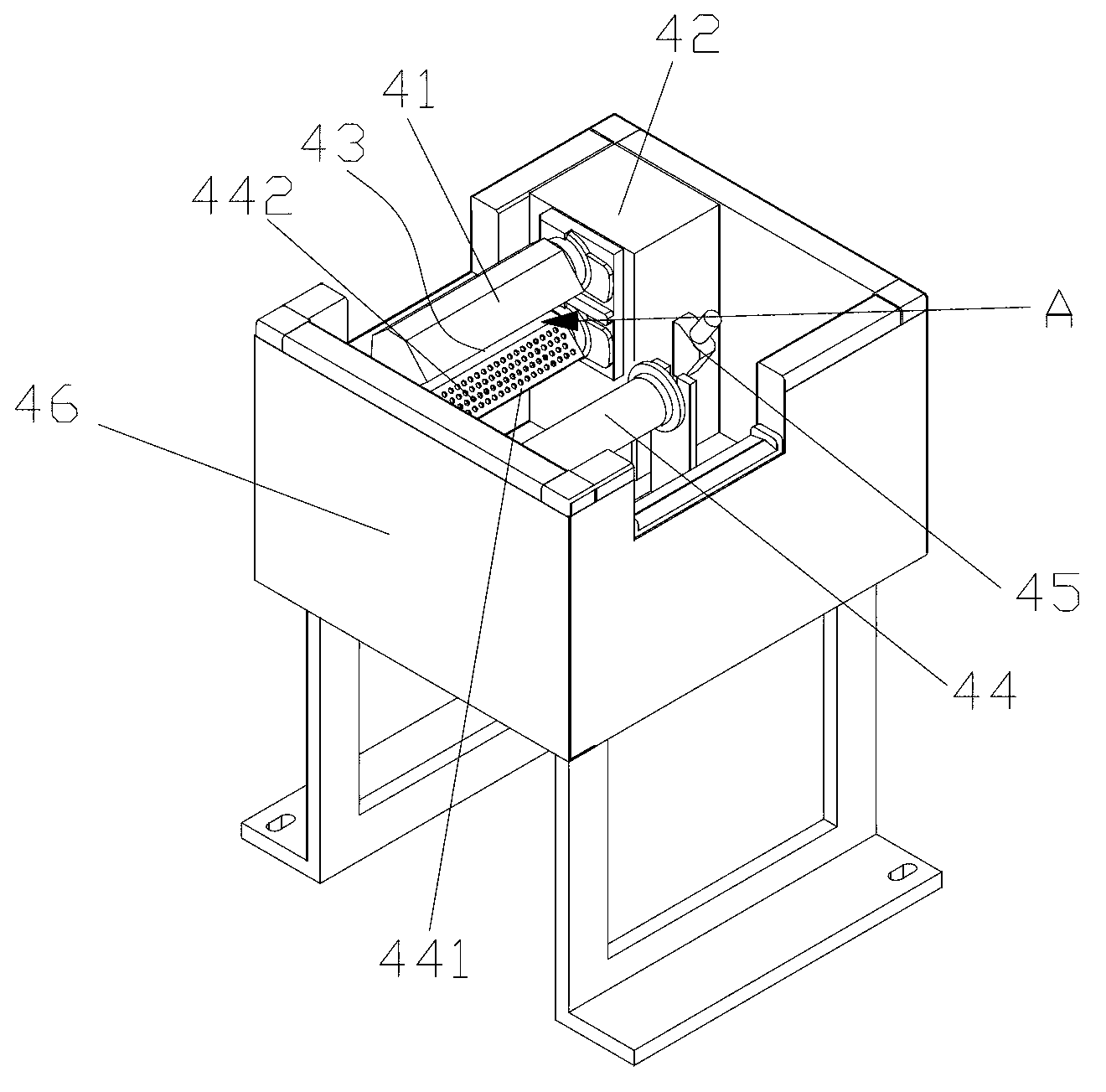

Flexible carrier sheet electroplating device

The invention discloses a flexible carrier sheet electroplating device, which is characterized by comprising a feeding component, an electroplating component, a drying component and a rolling component, wherein the feeding component is used for supporting a flexible carrier sheet and feeding the flexible carrier sheet; the electroplating component is used for electroplating the flexible carrier sheet; the drying component is used for drying the electroplated flexible carrier sheet; and the rolling component drives the flexible carrier sheet to pass through the electroplating component and the drying component sequentially, and rolls the dried flexible carrier sheet into rolls. According to the invention, the flexible carrier sheet electroplating device can finish deoxidation and other pretreatment processes, as well as other processes of the flexible carrier sheet, such as washing, drying and electroplating, with one device, so as to improve the production efficiency of the flexible carrier sheet.

Owner:SHANGHAI SINYANG SEMICON MATERIALS

Vacuum cleaner

InactiveCN107204547AImprove stability and securityImprove stabilityCoupling device engaging/disengagingCoupling device detailsElectric shockVacuum cleaner

The invention discloses a dust remover, which comprises a housing and an electrical connection terminal mated with the housing, a sliding chamber is arranged in the housing, and the right side of the sliding chamber is connected to the outside of the housing by a plug-in connection. A spacer fixedly connected with the housing is provided above the insertion hole, and a counterbore opened upward is provided in the spacer, the left side of the counterbore is connected to the sliding cavity, and the right side is connected to the sliding cavity. The outer part of the housing and the lower part are connected to the insertion hole, the top end of the left side of the sliding chamber is provided with a first electrical connection chamber, and the bottom end of the sliding chamber is provided with a downwardly expanding cover The overall structure of the present invention is simple, the production cost is low, the power supply is safe and reliable, and the operation is simple and convenient. The occurrence of power failure accidents of the dust collector is suitable for promotion and use.

Owner:袁兴芳

Method for producing locatable high heat conduction ceramic circuit board

InactiveCN101699935AAvoid breakage damageGuaranteed YieldConductive material chemical/electrolytical removalState of artCeramic

The invention discloses a method for producing a locatable high heat conduction ceramic circuit board, comprising the steps: a. pretreatment of base material; b. imaging transfer; c. preparation of a locating hole; d. printing weld preventing ink; e. silk-screen words; f. chemically precipitating Ni and Au; and g. cutting for molding. The invention aims at overcoming the defects of the prior art, and provides the method for producing the locatable high heat conduction ceramic circuit board with simple technique as well as good effects of heat conduction and heat dissipation of the product.

Owner:广东达进电子科技有限公司

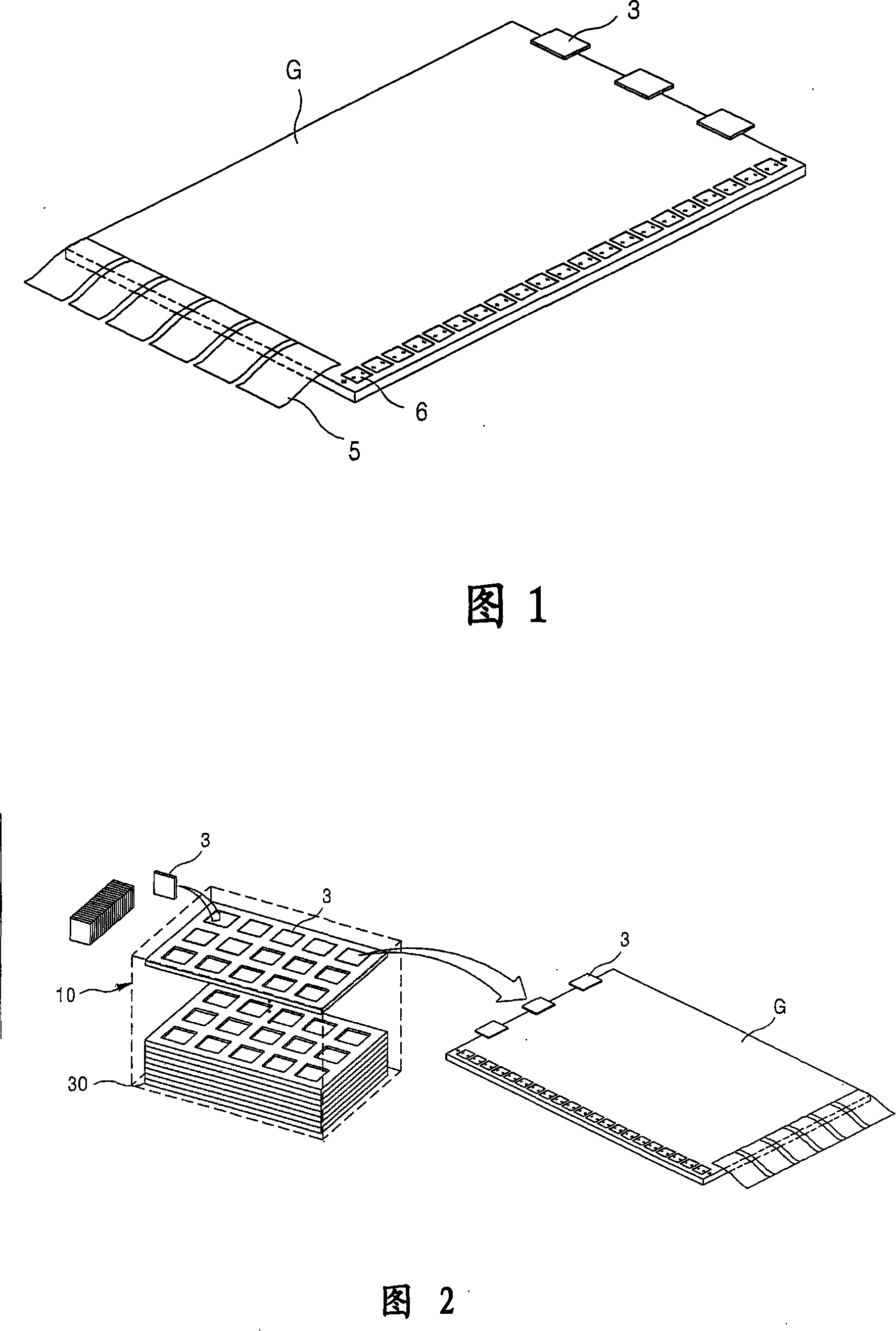

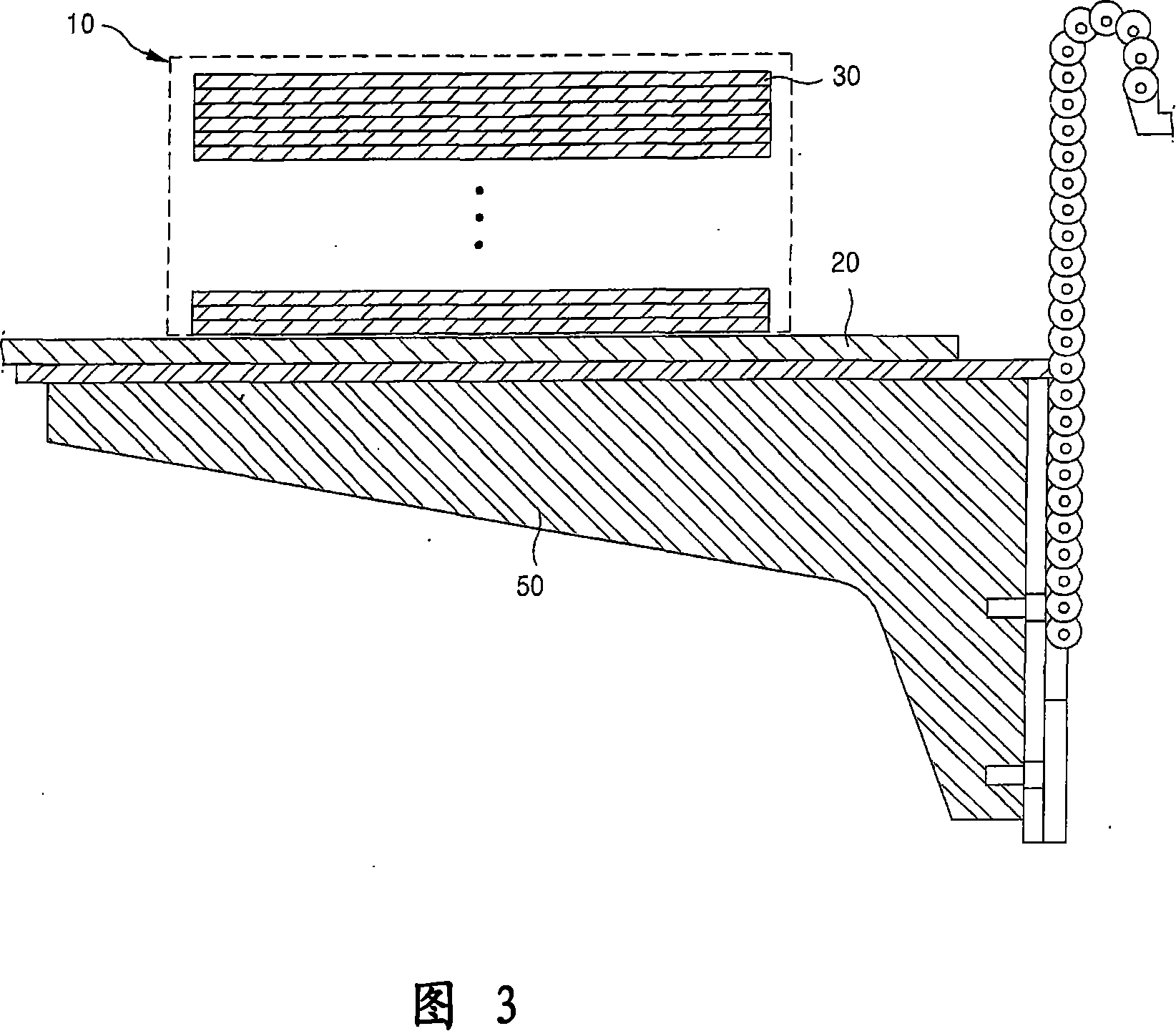

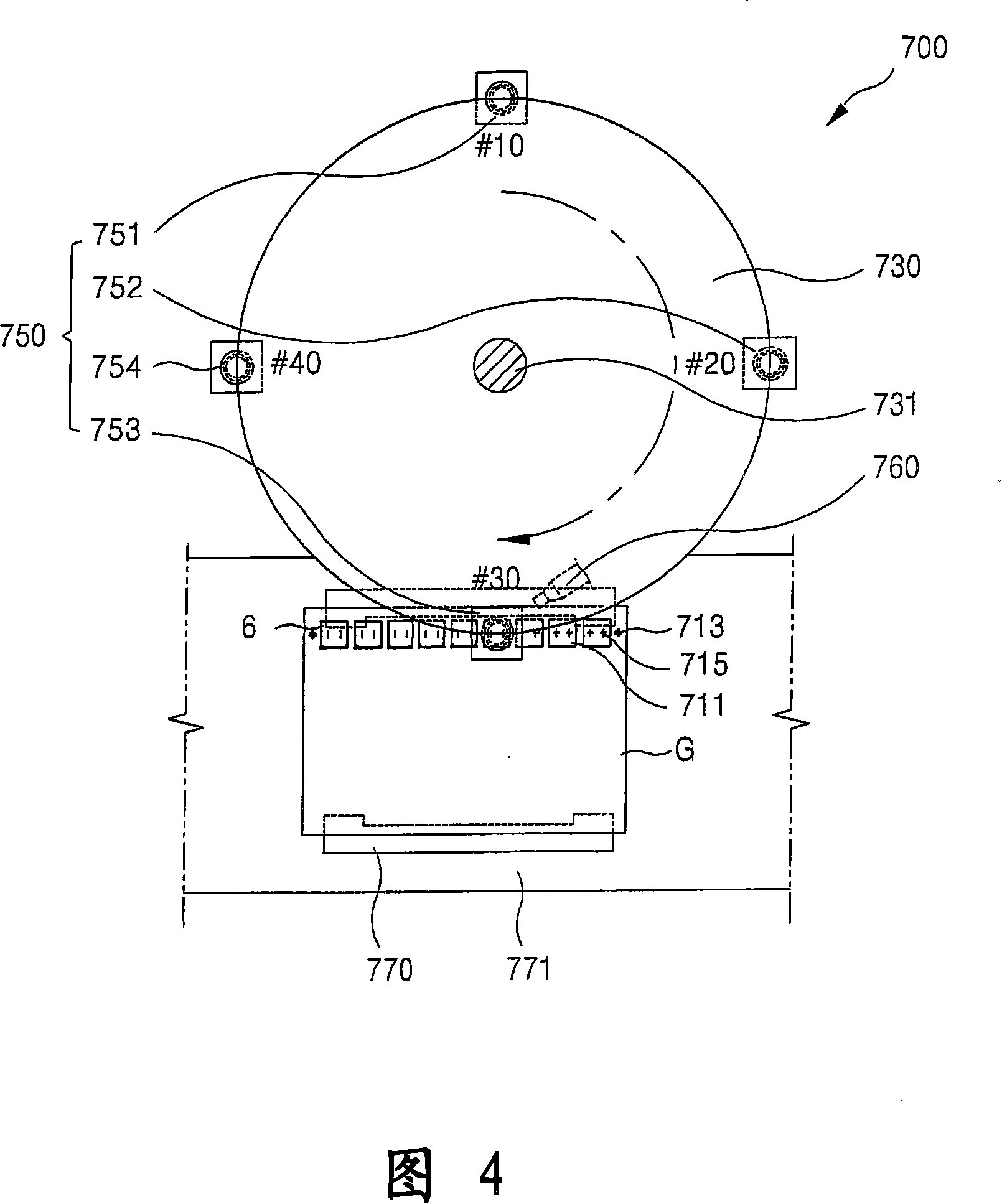

Apparatus, method and its case type shell for supplying, joining drive circuit board

InactiveCN101126875AAdjust planarityAvoid breakage damageStatic indicating devicesTube contructional detailsEngineeringPrinted circuit board

The invention discloses an apparatus for providing drive circuit board and cassette case thereof, bonding apparatus and bonding method of drive circuit board, and bonding system of drive circuit board comprising the bonding apparatus. Bonding apparatus of drive circuit board includes a compression unit for compressing the drive circuit board onto bonding surface attached with underlay of drive circuit board, wherein the compression unit includes a compression body provided for closing to bonding surface on top of the underlay and separating from the bonding surface; a bonding tool comprising a pressure surface, when the drive circuit is compressec onto the bonding surface, the pressure surface contacting with the drive circuit board; a plurality of height regulation components for regulating displacement of the pressure surface relative to the bonding surface to obtain planarity of pressure surface of the bonding tool; and rotation regulation parts provided on the height regulation components for regulating rotation of the height regulation component and provided on a area between the compression body and the bonding tool of the height regulation component.

Owner:SFA ENG CORP

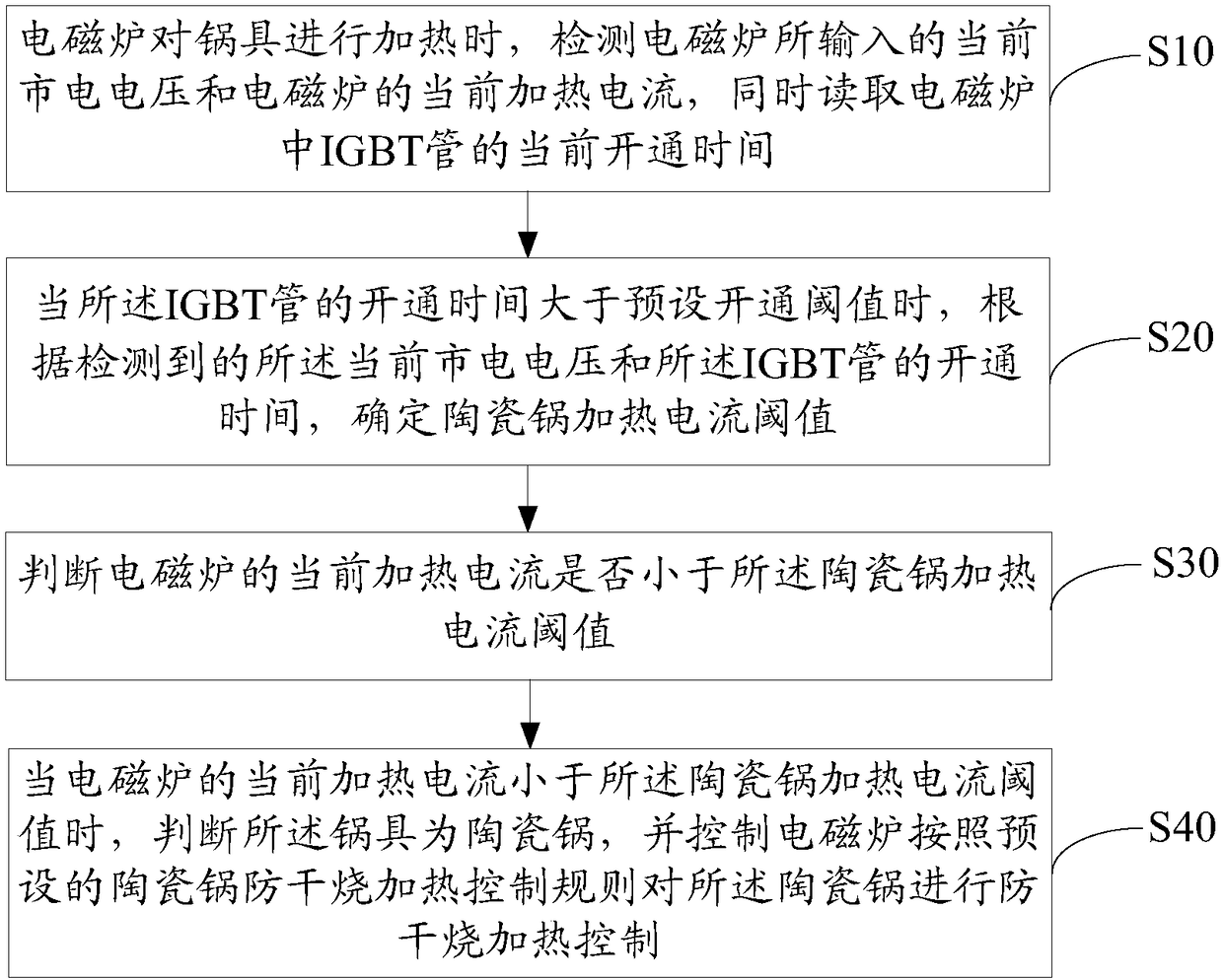

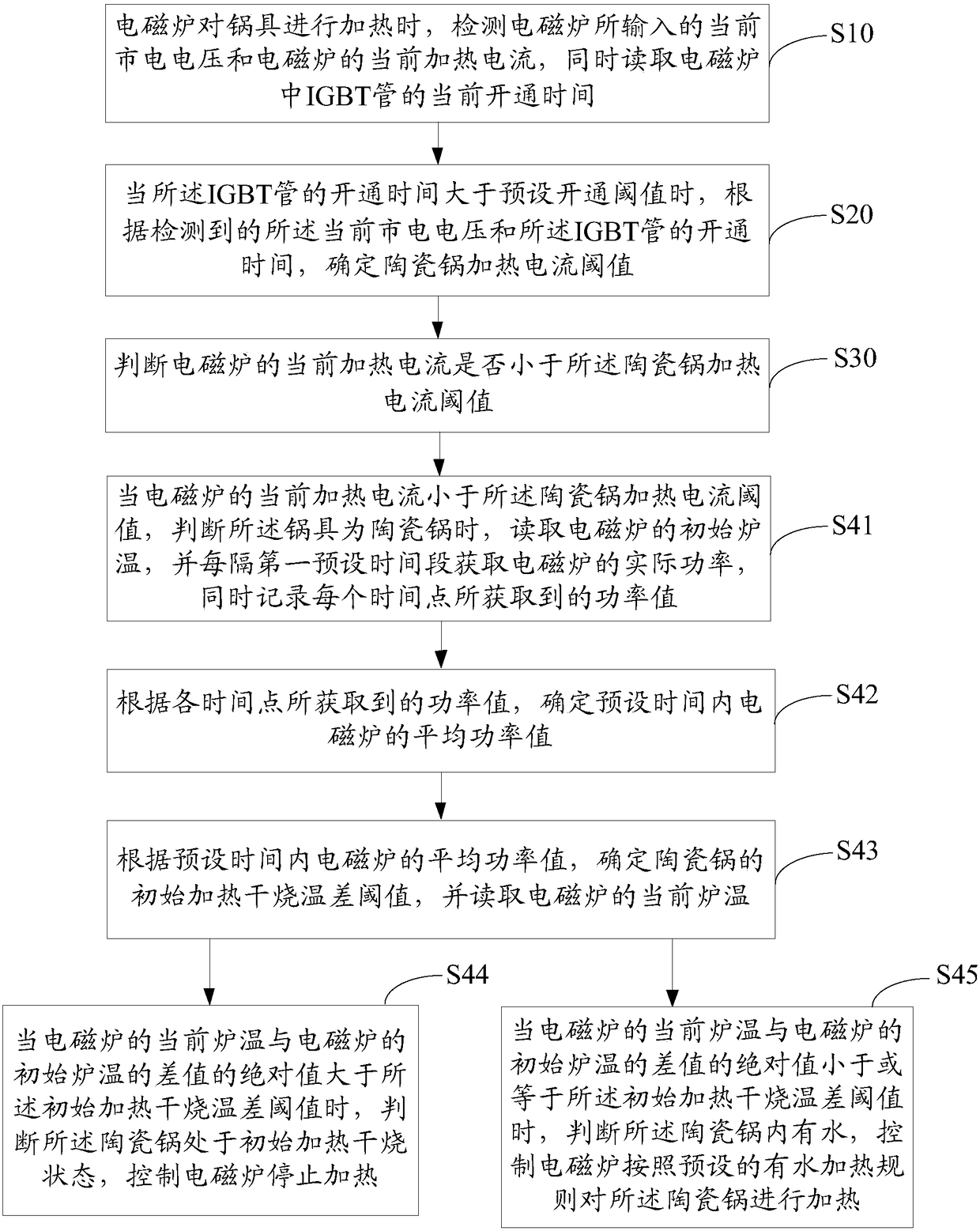

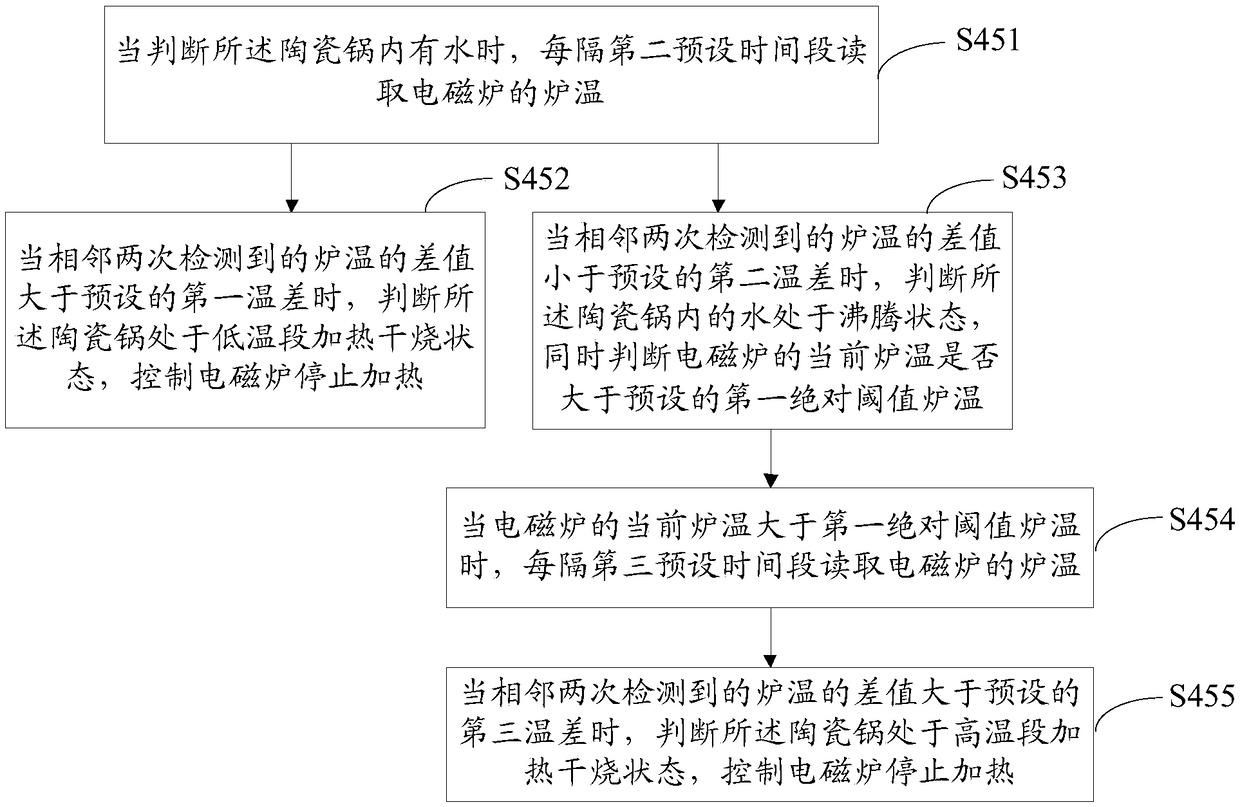

Induction cooker heating control method and device

ActiveCN108731043AAvoid breakage damageDomestic stoves or rangesLighting and heating apparatusCurrent electricCurrent threshold

The invention discloses an induction cooker heating control method and device. The induction cooker heating control method comprises the steps that when an induction cooker is used for heating cookware, the induction cooker input current electric supply voltage and the induction cooker current heating current are detected, and meanwhile, the current connecting time of an IGBT in the induction cooker is read; when the connecting time of the IGBT is greater than a preset connecting threshold value, a ceramic pot heating current threshold value is confirmed according to the current electric supply voltage and the connecting time of the IGBT; whether the induction cooker current heating current is smaller than the ceramic pot heating current threshold value or not is judged; and when the induction cooker current heating current is smaller than the ceramic pot heating current threshold value, it is judged that the cookware is a ceramic pot, and the induction cooker is controlled to performanti-burning heating control over the ceramic pot according to preset ceramic pot anti-burning heating control rules. By means of the induction cooker heating control method and device, the situationthat the ceramic pot cracks due to burning when heated on the induction cooker can be prevented.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

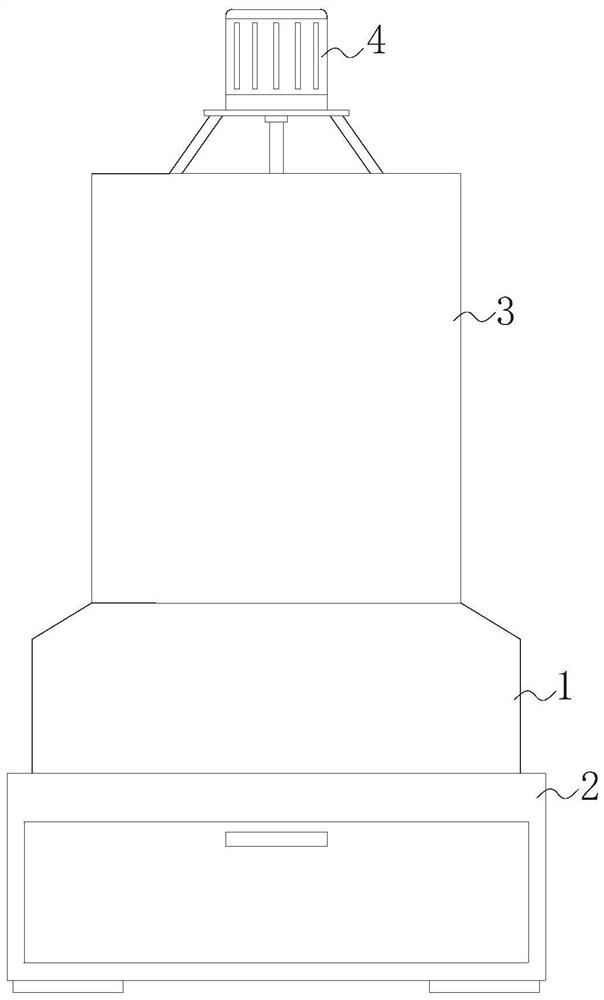

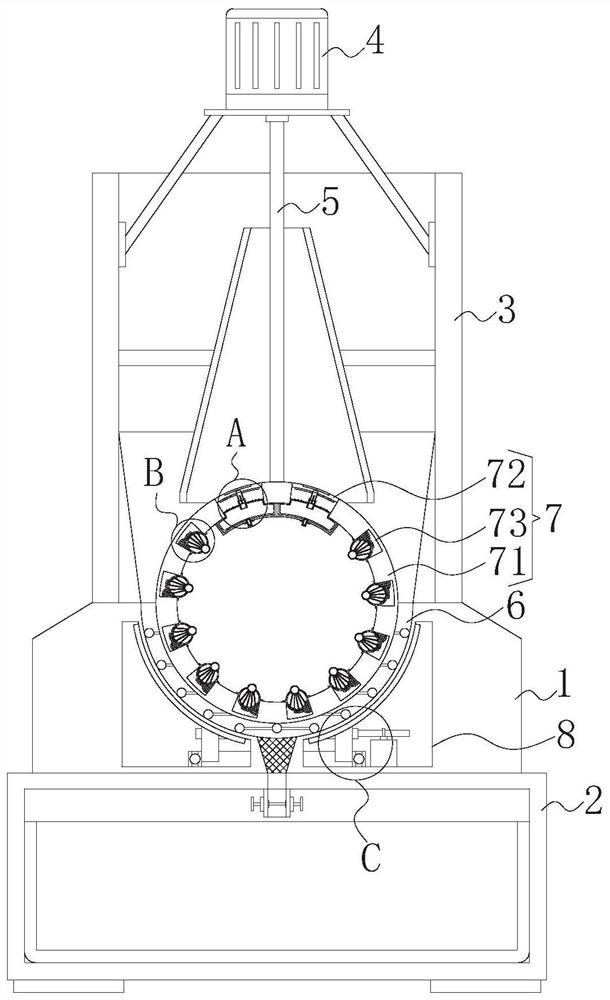

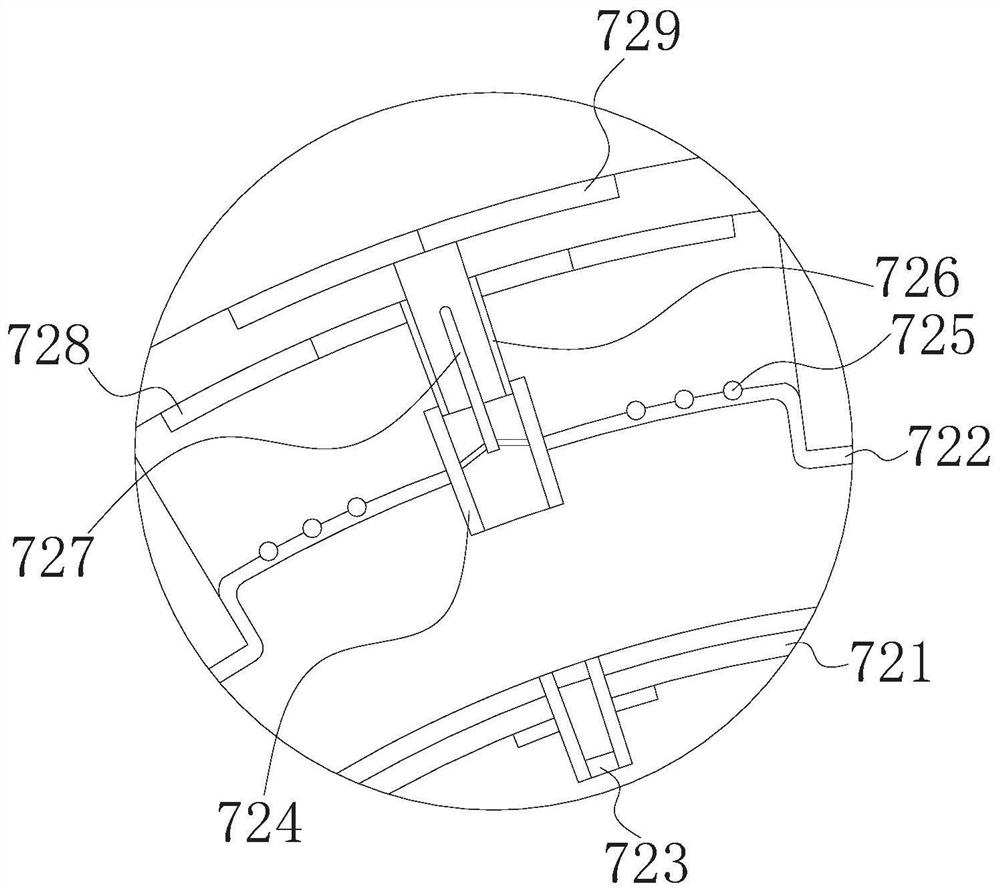

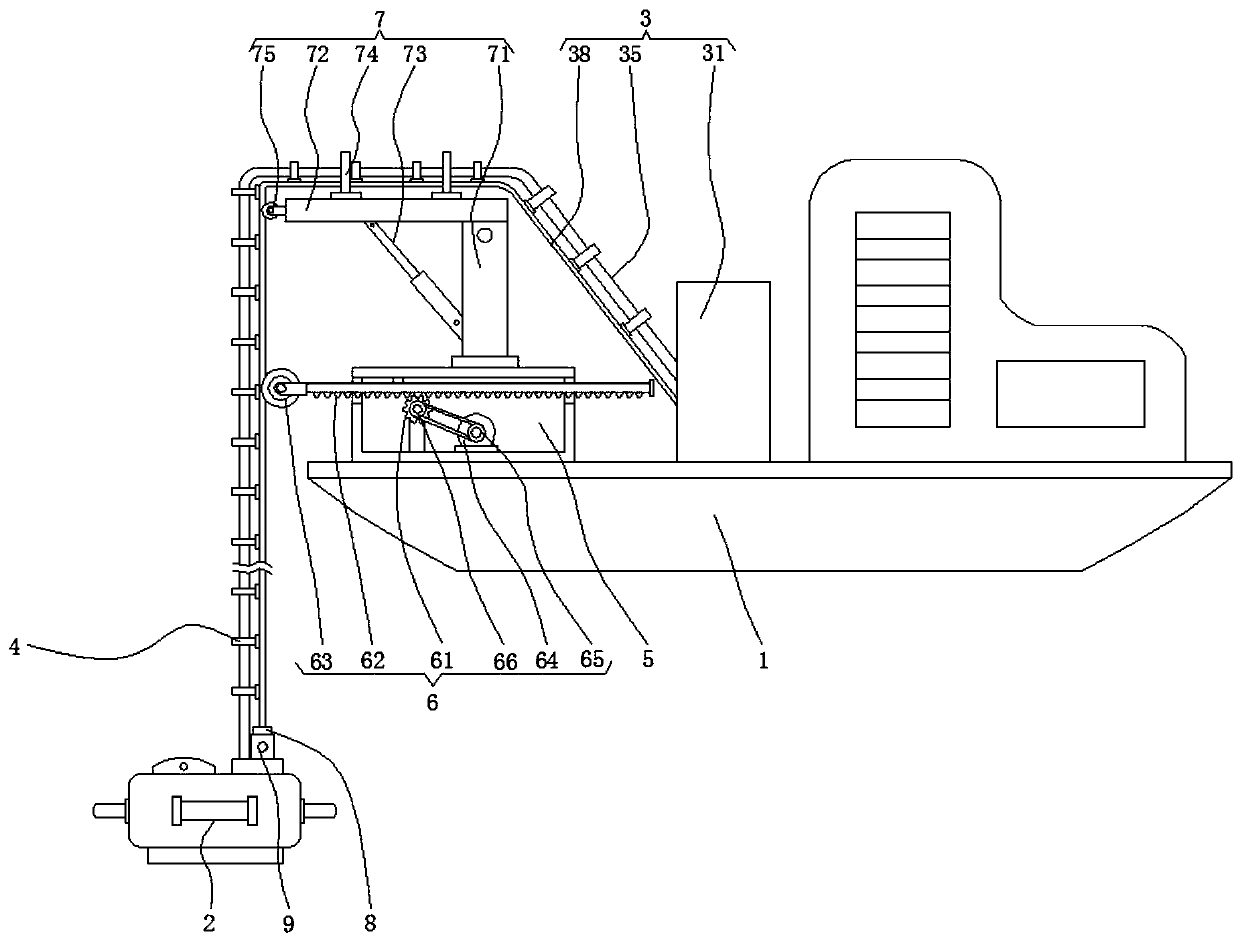

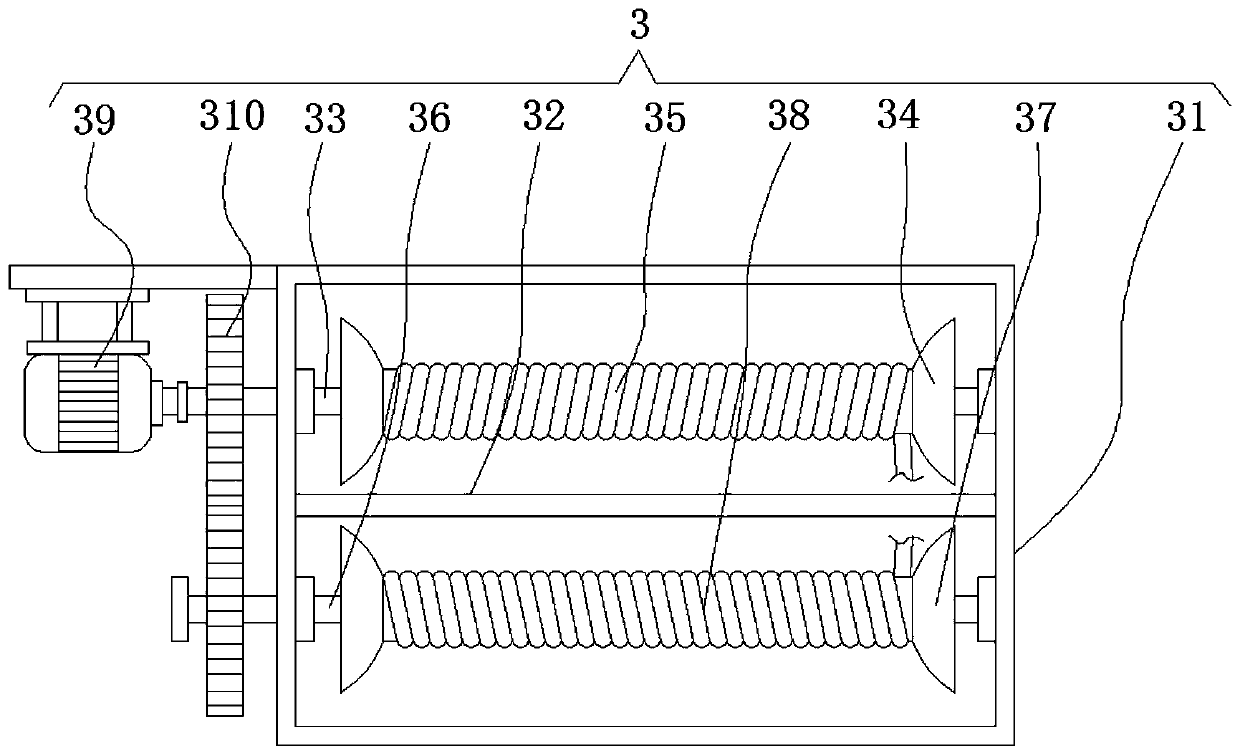

Preparation device of lithium ion battery anode silicon-carbon composite material

ActiveCN111744626APressure monitoringTo achieve the effect of reducing blood pressureNegative electrodesSecondary cellsCarbon compositesElectric machinery

The invention discloses a preparation device of a lithium ion battery anode silicon-carbon composite material, and relates to the technical field of battery manufacturing. The preparation device of the lithium ion battery anode silicon-carbon composite material includes a machine body, the bottom of the machine body is welded with a base, and the top of the machine body is welded with a cylinder.The top of the inner wall of the cylinder is fixedly provided with a driving motor. An output shaft of the driving motor is fixedly connected with the top end of a driving rod through a coupling. Thetop of the machine body is provided with a material groove. The bottom end of the driving rod is fixedly provided with a grinding ball protection mechanism. The preparation device of the lithium-ion battery anode silicon-carbon composite material is operating based on the cooperation of the grinding ball protection mechanism and an attached powder scraping mechanism. The device can effectively reduce the high temperature generated during the working process of a grinding ball. At the same time, the grinding ball protection mechanism eliminates a static charge on the surface of the grinding ball. The simultaneous operation of the attached powder scraping mechanism can form a continuous and intermittent barrier between powder and the grinding ball.

Owner:宁波启新精合新能源研究院有限公司

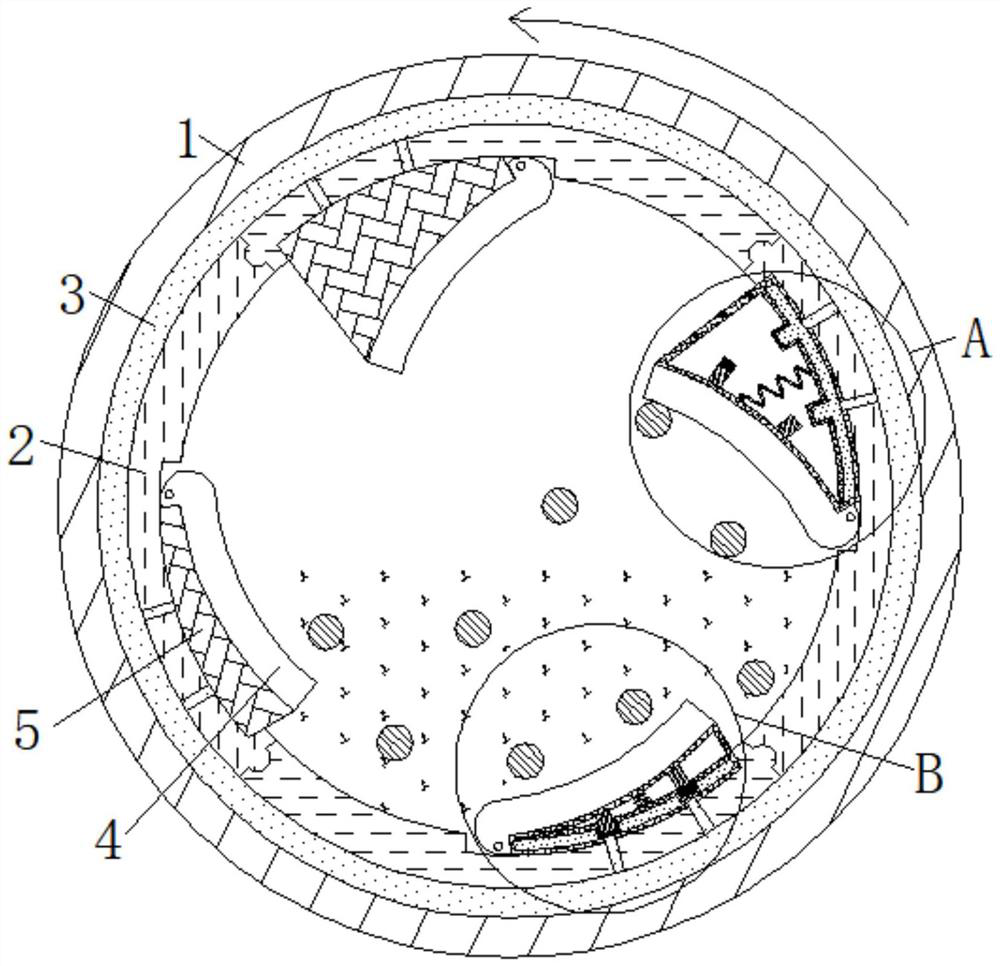

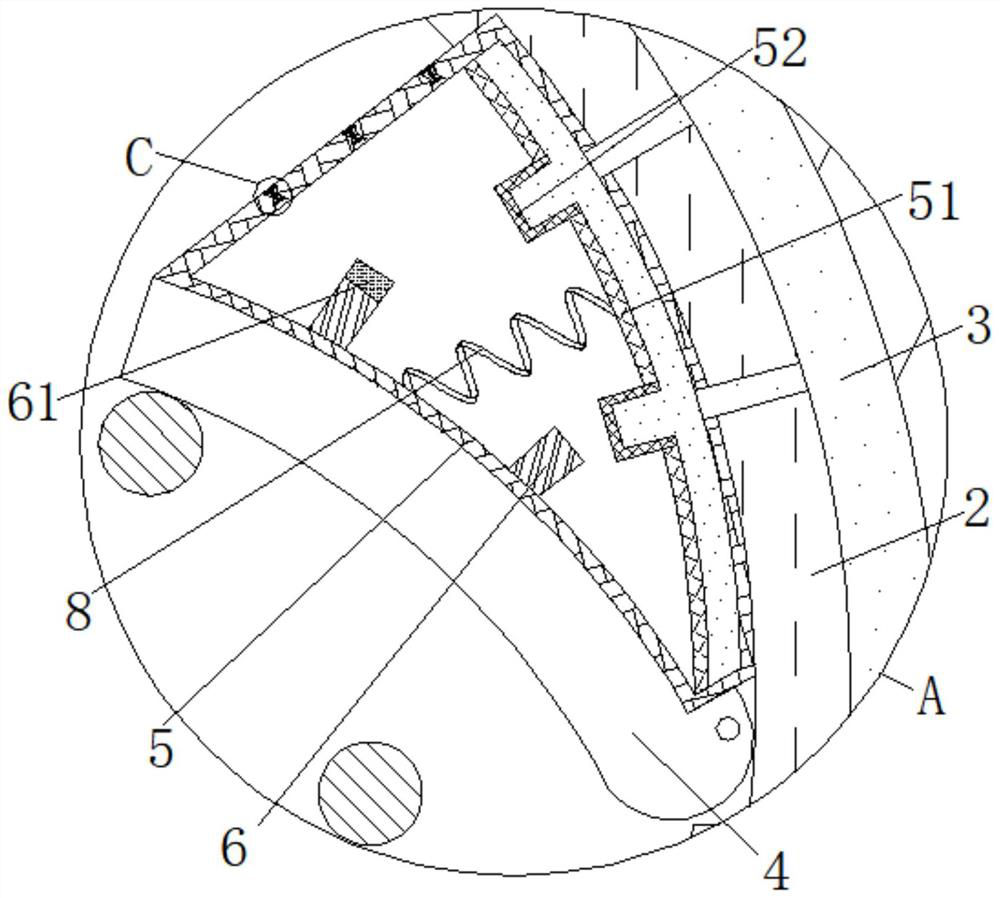

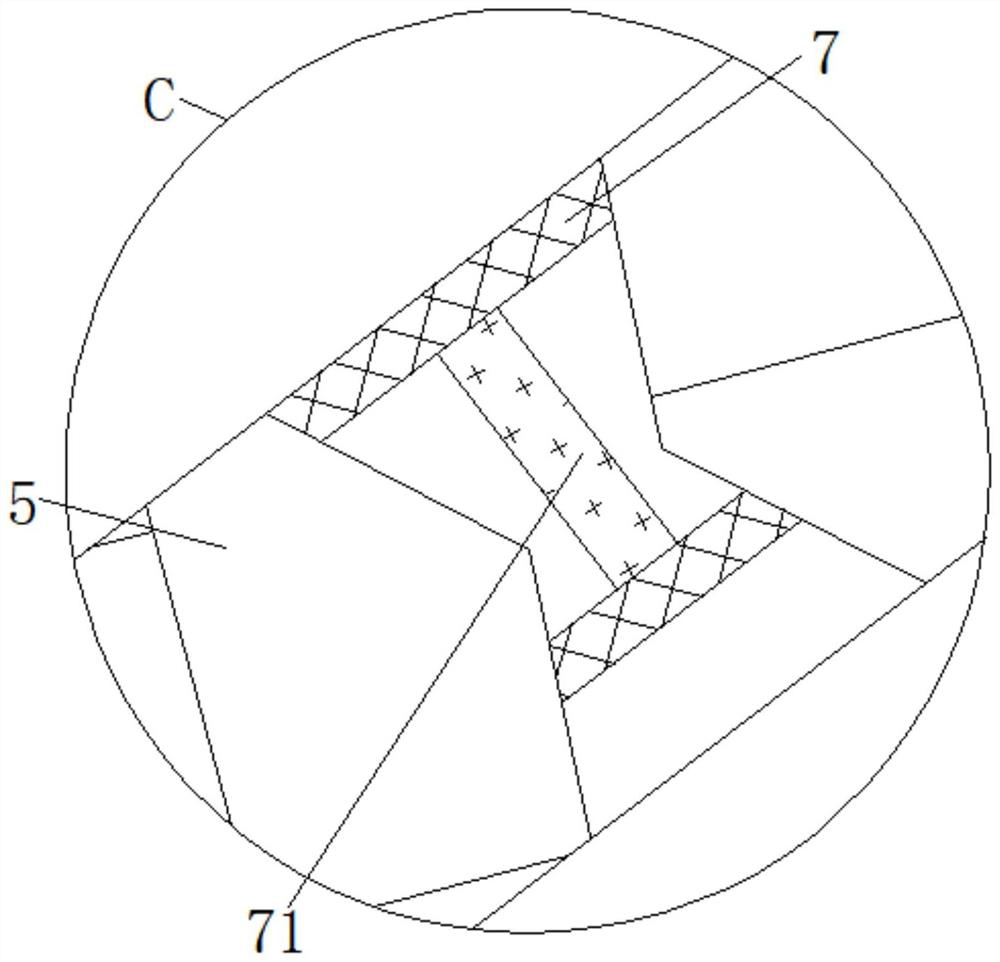

Ball mill for cement production

ActiveCN113649134AAvoid breakage damageGrind fullyCement productionGrain treatmentsWater storageStructural engineering

The invention relates to the technical field of grinding equipment, and discloses a ball mill for cement production. The ball mill comprises a cylinder; the two ends of the interior of the cylinder are fixedly connected with a lining assembly; the lining assembly is composed of four lining plates; the lining plates are arranged around the cylinder; the two lining plates are clamped with each other; a water storage cavity is arranged between the cylinder and the lining plates; and grooves are arranged in the lining plates, and movable plates are hinged to the inner walls, located at one ends of the grooves, of the lining plates. The movable plates and limiting bags are arranged in the lining plates, so that the movable plates rotate outwards due to gravity in the ascending stage, the movement path of a grinding ball is changed due to the external force of the movable plates during centrifugal operation, the throwing movement is formed, the grinding ball is effectively made to fully grind materials, and the grinding efficiency of the grinding ball is improved, and meanwhile, the lining plates and the movable plates are connected through the limiting bags, so that an effective supporting and protecting effect is provided for rotation of the movable plates, and the phenomenon that the grinding ball is clamped between the movable plates and the lining plates is avoided.

Owner:重庆市新嘉南建材有限责任公司

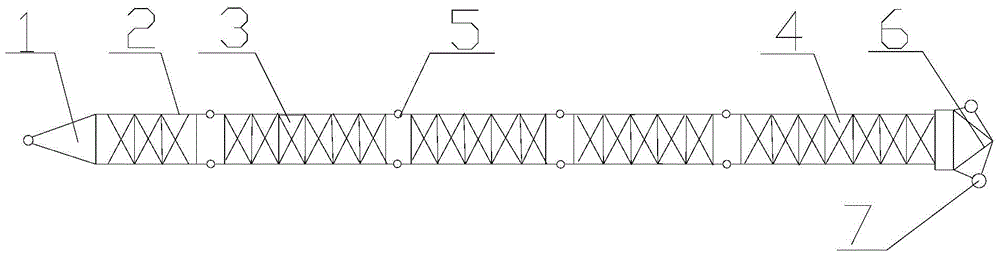

Reinforced boom frame structure of jib crane

The invention discloses a reinforced boom frame structure of a jib crane. A tripod is arranged at the bottom of a bottom knuckle boom, middle booms are arranged at the top of the bottom knuckle boom through connecting sheets, a plurality of middle booms are connected together by the connecting sheet, a top knuckle boom is arranged at the tail end of the last middle arm through the connecting sheet, and a support is formed at the front end of the top knuckle boom, and thus a frame body of the bottom knuckle boom, the middle booms and the top knuckle boom is formed; a square frame formed by outer rods is positioned at the outermost side, the about one-fourth position of the adjacent outer rod is connected and fixed by a reinforcing rod I, and one end of each reinforcing rod I is connected and fixed together with the farther end of the adjacent reinforcing rod I by a reinforcing rod II. According to the reinforced boom frame structure of the jib crane, when a heavy object is hoisted, the boom frame can be reinforced by the reinforcing rods I and the reinforcing rods II, so that breaking damage of the boom frame is avoided; and the reinforced boom frame structure of the jib crane is simple and novel in design, and is novel.

Owner:DALIAN BOHAI CRANE DEVICE

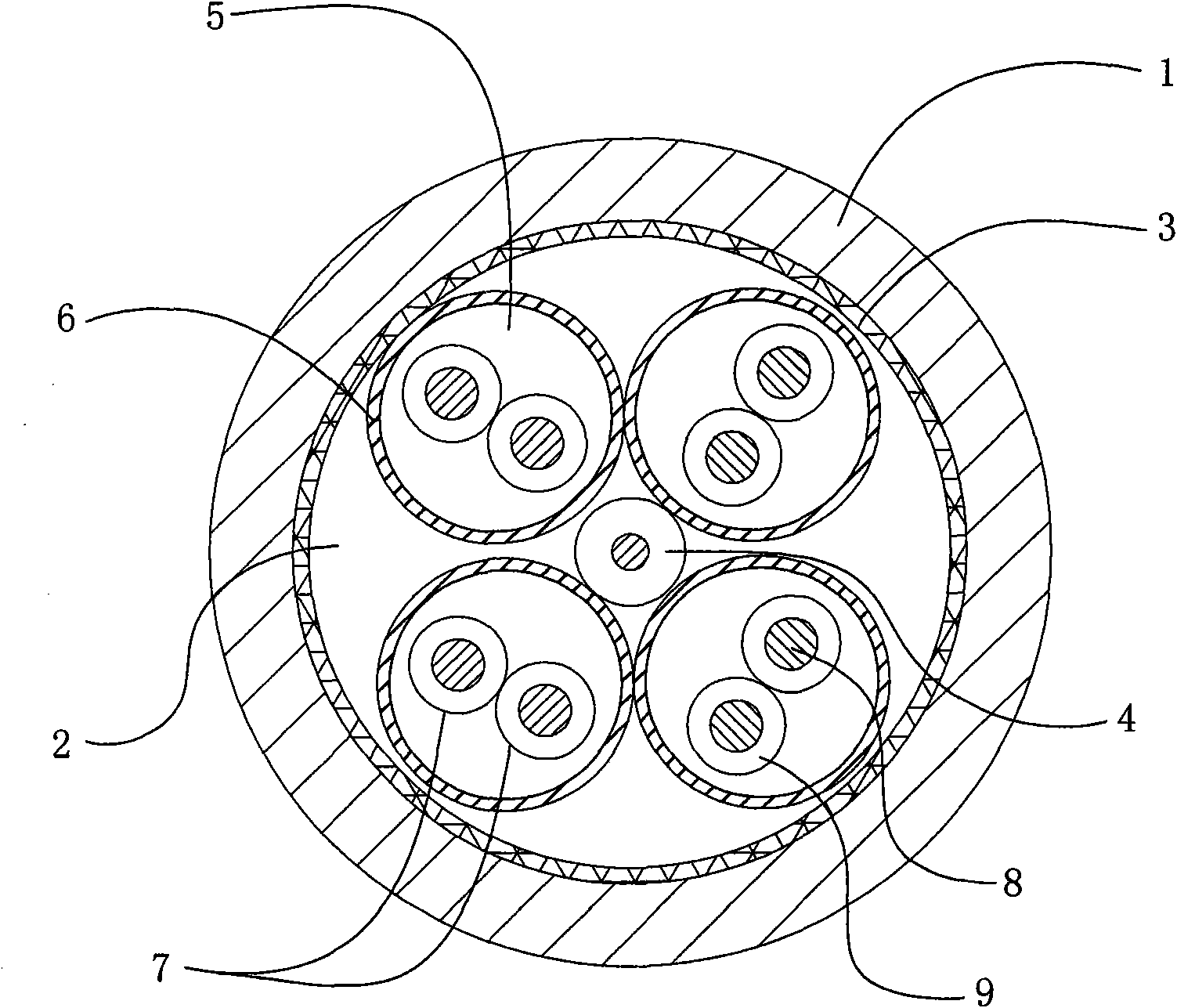

Hybrid optical fiber cable

InactiveCN102074305APlay a protective effectReduce non-interferenceCommunication cablesEngineeringCopper

The invention discloses a hybrid optical fiber cable. The hybrid optical fiber cable comprises a cable core and an outer coating layer, wherein the outer coating layer coats the cable core; the center of the cable core is provided with an optical fiber cable; a plurality of data cables surround around the optical fiber cable; each of the data cables comprises a data cable pair which is formed by intertwisting; a shielding layer formed by weaving aluminum-magnesium alloy wires and a thinned copper material is arranged between the outer coating layer and the cable core; and a data cable shielding layer made of an aluminum foil is coated outside the data cable pair of the data cable. The woven shielding layer of the hybrid optical fiber cable and the data cable shielding layer made of the aluminum foil can effectively prevent internal and external interference of the cable, so that the cable has higher shielding performance; thereof, the optical fiber cable and the data cable can keep respective outstanding performance when transmitting independently; moreover, the optical fiber cable and the data cable are arranged on the same cable, so that convenience is brought to construction, the cost is reduced, and an effect of protecting the optical fiber is also achieved.

Owner:宁波能士通信设备有限公司

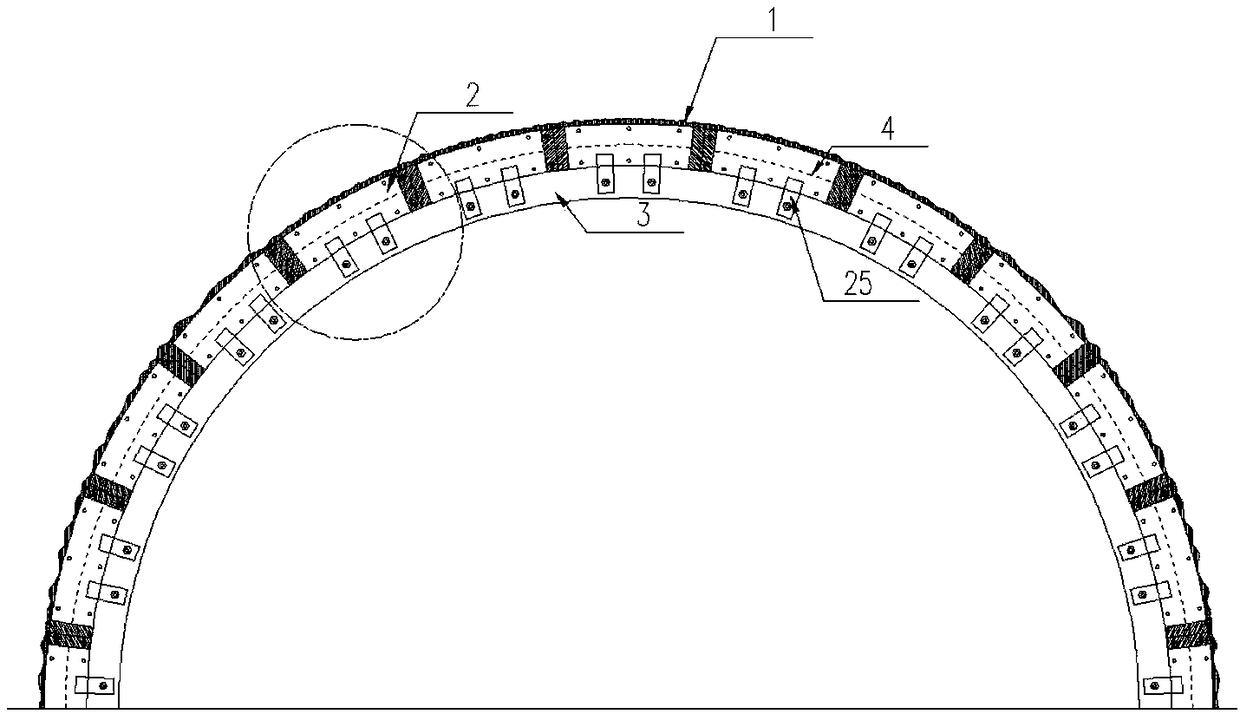

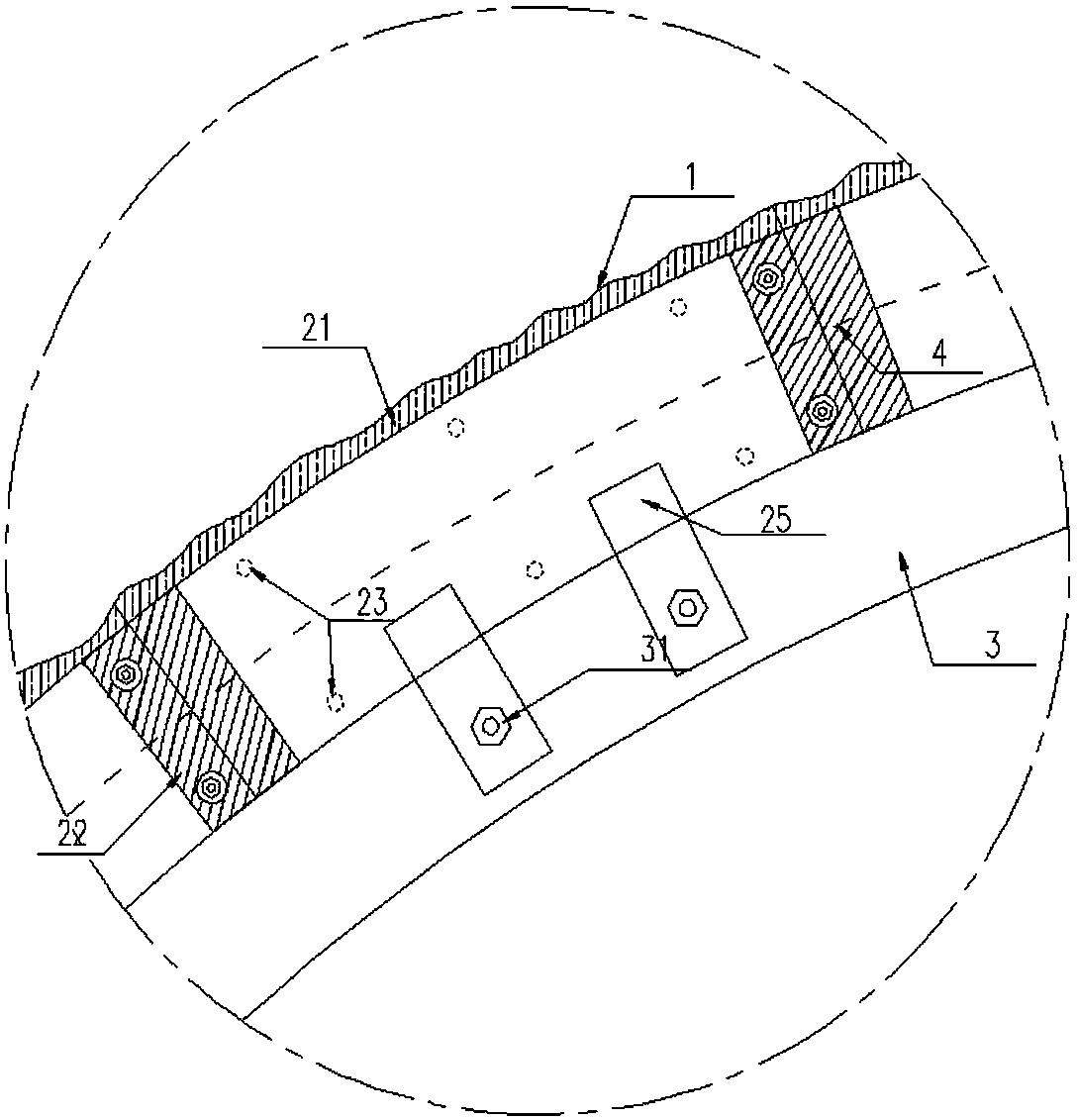

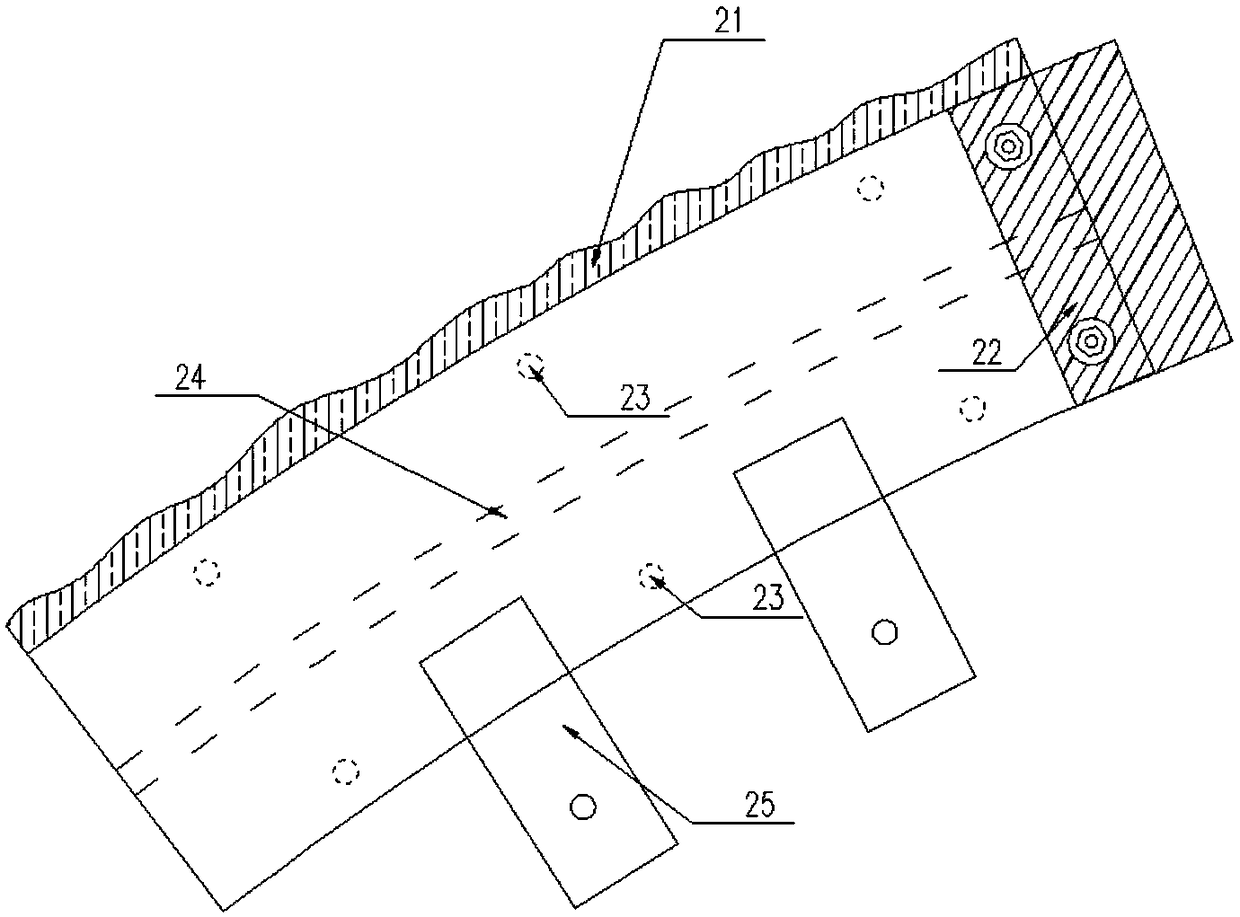

Tunnel secondary lining reinforced concrete section end formwork structure and mounting method

PendingCN108533292ARealize detachable connectionPrevent leakageUnderground chambersTunnel liningReinforced concreteEngineering

The invention discloses a tunnel secondary lining reinforced concrete section end formwork structure and further discloses a mounting method of tunnel secondary lining reinforced concrete section endformworks. The tunnel secondary lining reinforced concrete section end formwork structure comprises secondary lining longitudinal steel bars (52), arc-shaped end formworks (2), middle-buried water stopping belts (4) and middle-buried water stopping belt fixing devices (51). A middle-buried water stopping belt reserved clamping groove (24) and end formwork longitudinal steel bar reserved holes (23)are formed in each arc-shaped end formwork (2); each middle-buried water stopping belt fixing device (51) comprises hooks on the two sides and a U-shaped groove; one end of each secondary lining longitudinal steel bar (52) is arranged in the corresponding end formwork longitudinal steel bar reserved hole (23); the hooks are arranged on the secondary lining longitudinal steel bars (52) in a winding mode; and the outer sides of the middle-buried water stopping belts (4) are arranged in the middle-buried water stopping belt reserved clamping grooves (24), and the inner sides of the middle-buriedwater stopping belts (4) are arranged in the U-shaped grooves. According to the tunnel secondary lining reinforced concrete section end formwork structure, the middle-buried water stopping belts arefixed through the secondary lining longitudinal steel bars and the middle-buried water stopping belt fixing devices, and the mounting precision, the mounting smoothness and the exposed width of the water stopping belts are ensured.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

Mobile phone carton packaging machine with guiding and protecting functions

InactiveCN112793835AEasy to install and supportConvenient detachable installation connectionConveyorsPackagingCarton flowCarton

The invention relates to the technical field of mobile phone carton packaging guiding, in particular to a mobile phone carton packaging machine with guiding and protecting functions. The mobile phone carton packaging machine comprises a packaging machine body, a conveying mechanism, a driving mechanism, protecting mechanisms, guiding mechanisms and a limiting mechanism. The conveying mechanism is installed to be in butt joint with the packaging machine body conveniently, the conveying mechanism works under the action of the driving mechanism, cartons needing packaging are conveyed advantageously, the conveyed cartons are tidied and blocked advantageously through the protecting mechanisms installed at the two sides of the top of the conveying mechanism, and the condition that the stacked or stacked cartons flow downwards so that the cartons cannot be used for packaging work is prevented; the guiding mechanisms are installed at the two sides of the top of the conveying mechanism, so that the conveyed cartons can be straightened and placed conveniently, the cartons are installed at a certain position to flow downwards, and the packaging machine body can conduct packaging work conveniently; and meanwhile, through adjustment of the limiting mechanism, the length of the guiding mechanisms can be changed conveniently, and the cartons with different sizes can be conveniently straightened and guided.

Owner:李沁芯

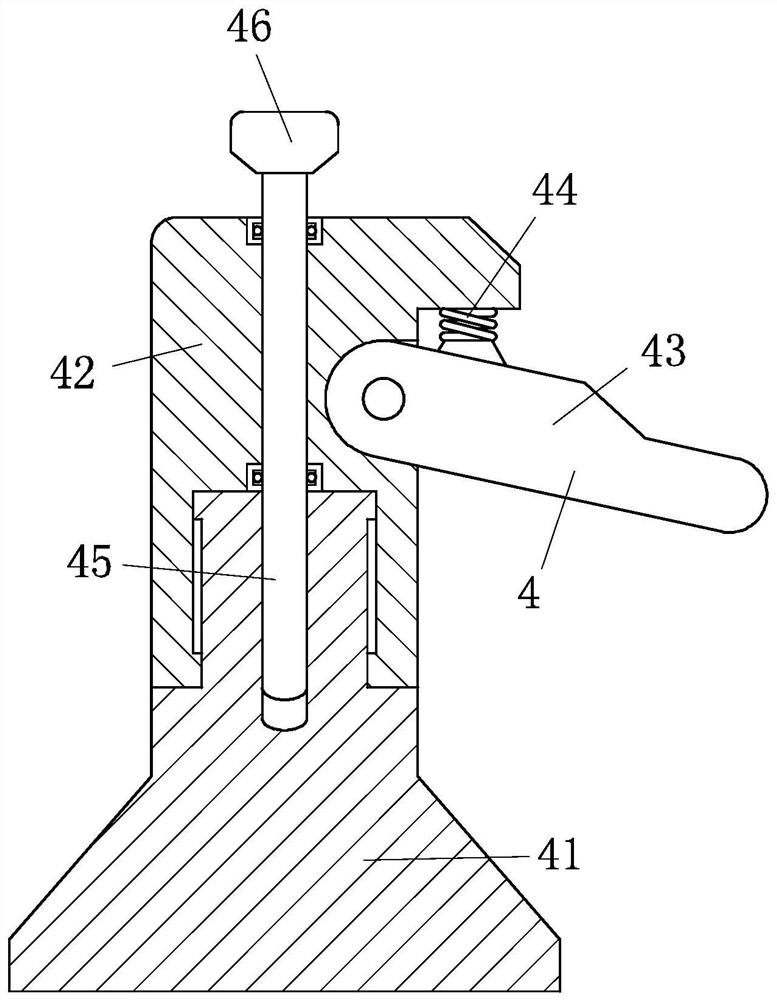

Underwater robot traction mechanism

PendingCN111114716AAvoid breakage damageEasy to operateVessel salvagingUnderwater equipmentMarine engineeringWire rope

The invention provides an underwater robot traction mechanism. The underwater robot traction mechanism comprises: a ship body and a robot body; a winding structure which is arranged at the top of theship body, wherein the winding structure comprises a movable frame, and a partition plate is fixedly connected between the two sides of the inner wall of the movable frame. The underwater robot traction mechanism is simple to operate and convenient to use and can effectively tract a robot, a steel wire rope replaces a cable to serve as a traction force carrier, it is effectively avoided that the cable is fractured and damaged in the traction process, the traction force direction can be changed, the cable has a certain lifting and pulling effect, and it is avoided when the underwater robot is wound, the robot cannot be pulled; by arranging of a clamping structure, the cable is clamped to ensure the traction, lifting and pulling of the steel wire rope, drive the cable to perform traction, lifting and pulling and avoid winding and knotting of the cable.

Owner:上海宇鹤自动化科技有限公司 +1

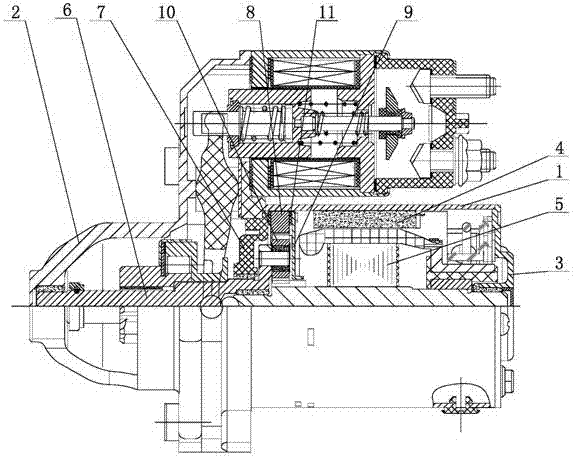

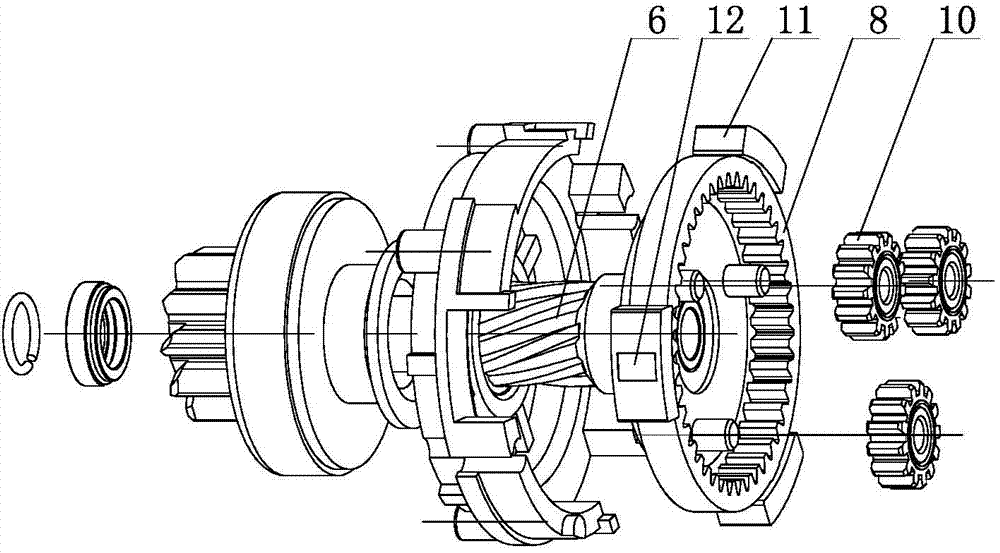

Shock-resistant cranking motor for automobile

InactiveCN103618405AImprove transmission efficiencyGuaranteed reliabilityMechanical energy handlingReduction driveEngineering

The invention discloses a shock-resistant cranking motor for an automobile. A gear base (7) is installed at the rear end of a reducer output shaft (6) in a sleeved mode. An internal gear (8) and a cover plate (9) are arranged on the back of the gear base (7). The internal gear (8) and a planetary gear (10) in the internal gear (8) are meshed. The periphery of the internal gear (8) is provided with a plurality of vibration reduction blocks (11) uniformly distributed along the circumference. The inner surfaces of the vibration reduction blocks (11) are closely attached to the outer circumferential face of the internal gear (8). The outer surfaces of the vibration reduction blocks (11) are attached to the inner wall of the case (1). The front end faces of the vibration reduction blocks (11) are attached to the gear base (7), and the rear end faces of the vibration reduction blocks (11) are attached to the cover plate (9). The shock-resistant cranking motor can effectively absorb the impact load of an engine, on one hand, failure of rotation stressing parts of a cranking motor is avoided, and the reliability of the cranking motor is ensured; on the other hand, the cranking motor works and operates stably, vibration is small, the work noise is lowered, and the use comfort of products is greatly improved.

Owner:重庆博耐特实业(集团)有限公司

Production method of bright-copper-face high-heat-conductivity ceramic circuit board capable of locating

InactiveCN101699936AAvoid breakage damageGuaranteed YieldConductive material chemical/electrolytical removalCeramicMetallic Nickel

The invention discloses a production method of a bright-copper-face high-heat-conductivity ceramic circuit board capable of locating, which comprises the following steps: (a) pretreating a base board; (b) transferring a pattern; (c) making a locating hole; (d) printing solder-resisting ink; (e) screen-printing the text; (f) chemically depositing nickel and gold; (g) and forming by cutting. The invention aims to overcome the defects in the prior art and provide a production method of the bright-copper-face high-heat-conductivity ceramic circuit board capable of locating. The invention has the advantages of simple technique and favorable effects of heat conduction and dissipation of the product.

Owner:广东达进电子科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com