Metal matrix inlaid elastic self-lubricating sliding bearing

A sliding bearing and embedded technology, which is applied in the direction of bearing components, shafts and bearings, mechanical equipment, etc., to avoid bearing crack damage, improve lubrication performance, and meet cooling requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

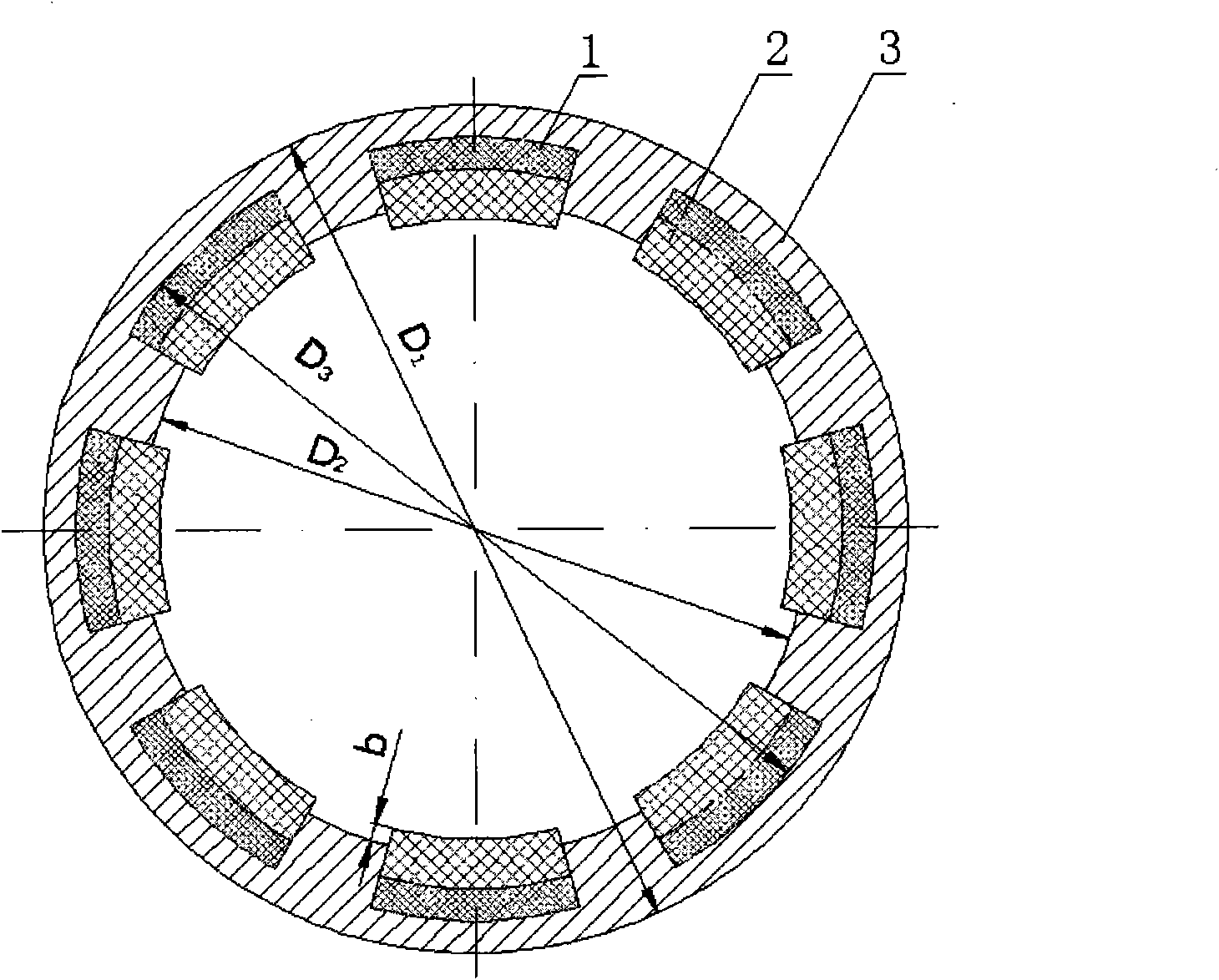

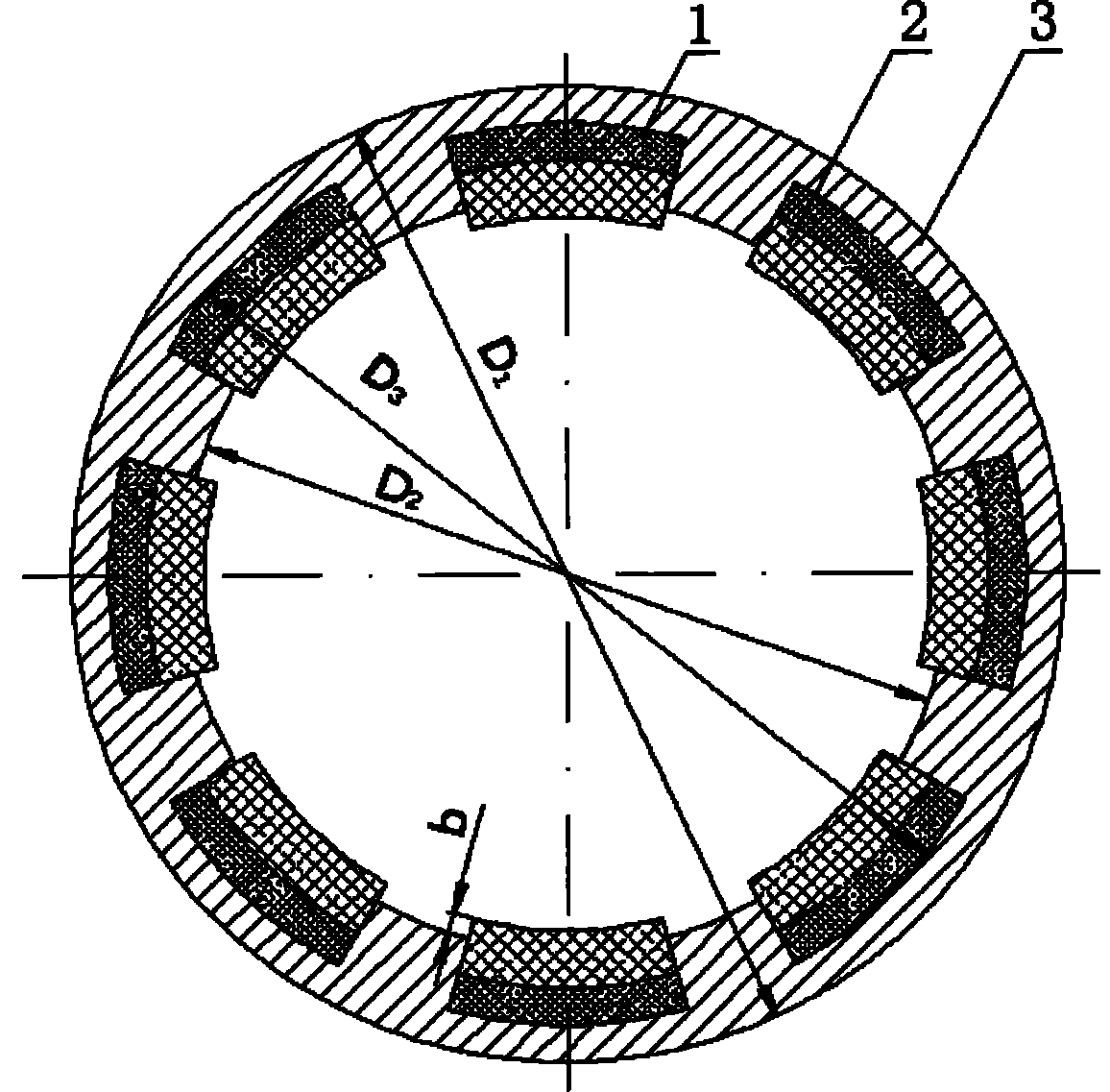

[0009] Embodiment: in conjunction with accompanying drawing, D 1 is the outer diameter of the metal substrate, D 2 is the inner diameter of the metal matrix, D 3 is the diameter of the metal substrate groove, b is the height of the bearing bar above the inner surface of the metal substrate, and the depth of the groove is a=(D 3 -D 2 ) / 2.

[0010] for D 1 = 100mm, D 2 =82mm,D 3 =92mm, b=1mm sealing ring, 8 grooves can be opened to form 8 bearing contact surfaces. The machining allowance should be considered for each surface, especially the bearing contact surface. The technology requires machining the blank. Then, assembly and final processing are carried out according to the above-mentioned specific assembly method to obtain a high-performance sliding bearing.

[0011] For bearings of different sizes and requirements, the length of the bearing and the number of grooves can be determined according to the actual situation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com